Page 1

IS50C Rev C

PERFLEX

by

Owner’s Manual

™

MODEL: EC50AC

PERFLEX

This is the safety-alert symbol. When you see this symbol on your equipment or in this manual, look for one of the

following signal words and be alert to the potential for personal injury or death.

WARNING Warns about hazards that could cause serious personal injury or, death, and or major property damage

and if ignored presents a potential hazard.

CAUTION Warns about hazards that will or can cause minor or moderate personal injury and/or property damage

and if ignored presents a potential hazard. It can also make consumers aware of actions that are unpredictable and

unsafe.

The NOTICE label indicates special instructions that are important but not related to hazards.

®

Extended Cycle Filter

SAVE THIS INSTRUCTION MANUAL

Hayward Pool Products

One Hayward Industrial Drive, Clemmons, NC 27012

Phone: 336-712-9900

www.haywardnet.com

Page 2

READ, UNDERSTAND, AND FOLLOW ALL SAFETY AND OPERATION

INSTRUCTIONS.

SEVERE PERSONAL INJURY OR DEATH.

CAUTION To reduce risk of injury, do not permit children to use or climb on this product. Closely

supervise children at all times. The ANSI/APSP-4 Standard (above-ground and on-ground pools)

advises that components such as the filtration system, pumps, and heaters be positioned to prevent

their being used as a means of access to the pool by young children

WARNING COMPONENT SEPARATION HAZARD

Pool and spa water circulation systems operate under hazardous pressure during start up, normal

operation, and possibly after pump shut off. Pressure in system can cause explosive component

separation of the upper filter body if safety and operation instructions are not followed. Severe

personal injury or death can result.

This product should be installed and serviced only by a qualified pool professional.

FAILURE TO FOLLOW SAFETY AND OPERATION INSTRUCTIONS CAN RESULT IN

.

TO AVOID COMPONENT SEPARATION

•

Follow all safety and operation instructions.

•

Do not operate water circulation system if a system component is assembled improperly, damaged,

missing, or not a genuine Hayward component.

• Before performing maintenance on the water circulation system, verify all system and pump controls

are in OFF position and filter manual air relief valve is in the OPEN position.

• Always tighten nut until spring coils touch each other, never only hand tighten.

• Before starting the system pump, verify that all system valves are set in a position to allow water from

the filter to return back to the pool.

• Before starting the system pump, the manual air relief valve must be in the OPEN position.

• When starting pump, do not stand over or near filter.

• Return to filter to close manual air relief valve only when a steady stream of water (Not air or air and

water mix) is discharged from the manual air relief valve.

WARNING EXCESS PRESSURE HAZARD

Pressure testing of the pump and filter system in excess of the 45 PSI can cause explosive separation of

the components. Component separation can result in severe personal injury or death.

WARNING ELECTROCUTION HAZARD

High Voltage electricity is present in the pool and spa equipment. High voltage electricity can cause shock

and electrocution. Shock and electrocution can result in severe personal injury or death.

• All electrical wiring MUST be in conformance with applicable local codes, regulations and the National

Electrical Code (NEC).

• Before performing any service or maintenance on electrical equipment turn off all electrical power.

• Contact a licensed electrician or building inspector for information on local electrical codes for bonding

requirements.

• Verify water discharge from the filter manual air relief valve is directed away from electrical devices.

Do not locate pump controls over or near filter.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Page 2 of 12

PERFLEX

™ Filtration Series IS50C REV C

Page 3

WARNING – SUCTION ENTRAPMENT HAZARD.

Suction in suction outlets and/or suction outlet covers that are, damaged, broken, cracked, missing, or

unsecured can cause severe injury and/or death due to the following entrapment hazards:

Hair Entrapment- Hair can become entangled in suction outlet cover.

Limb Entrapment- A limb inserted into an opening of a suction outlet sump or suction outlet cover that

is damaged, broken, cracked, missing, or not securely attached can result in a mechanical bind or

swelling of the limb.

Body Suction Entrapment- A negative pressure applied to a large portion of the body or limbs can

result in an entrapment.

Evisceration/ Disembowelment Entrapment- A negative pressure applied directly to the intestines

through an unprotected suction outlet sump or suction outlet cover that is, damaged, broken, cracked,

missing, or unsecured can result in evisceration/ disembowelment entrapment.

Mechanical Entrapment- There is potential for jewelry, swimsuit, hair decorations, finger, toe or

knuckle to be caught in an opening of a suction outlet cover resulting in mechanical entrapment.

TO REDUCE THE RISK OF ENTRAPMENT HAZARDS:

• A minimum of two functioning suction outlets per pump must be installed. Suction outlets in the

same plane (i.e. floor or wall), must be installed a minimum of three feet (3’) [1 meter] apart, as

measured from near point to near point.

• Dual suction outlets shall be placed in such locations and distances to avoid “dual blockage” by a

user.

• Dual suction outlets shall not be located on seating areas or on the backrest for such seating areas.

• The pool or spa circulation system shall be designed to comply with ANSI/APSP-7 2006.

• Suction outlet covers shall conform to ANSI/ASME A112.19.8

• Never use Pool or Spa if any suction outlet component (cover/grate) is damaged, broken, cracked,

missing, or not securely attached.

• Immediately replace damaged, broken, cracked, missing, or not securely attached suction outlet

components.

• The CPSP as well as the ICC

specifies the installation of a safety vacuum release system conforming to ASME A112.19.17, or an

approved gravity drain system.

• Failure to remove pressure test plugs and/or plugs used in winterization of the pool/spa from the

suction outlets can result in an increased potential for suction entrapment.

International Residential Code

Part IX, Appendix G, Section AG106

• Failure to keep suction outlet components clear of debris, such as leaves, dirt, hair, paper and other

material can result in an increased potential for suction entrapment.

Suction outlet covers and grates have a finite life. They should be inspected frequently and

replaced within specified life.

KEEP SAFETY LABELS IN GOOD CONDITION AND REPLACE IF MISSING OR DAMAGED.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Page 3 of 12

PERFLEX

™ Filtration Series IS50C REV C

Page 4

The Hayward-Perflex is a high performance swimming pool filter with a filtration rating of 3,000 gallons (11 KL) per hour.

Manufactured from durable, corrosion-proof materials, it is designed for continuous operation, for installation above or below, the

pool water line. It may be used on fresh or salt water swimming pools.

The Perflex filter uses diatomite filter powder (commonly called D.E.). D.E. is the most efficient dirt remover known. It is normally fed

into the system through the skimmer when the filter is initially started; then drained from the filter when it can no longer efficiently

remove dirt from the water. Through the Perflex's exclusive "BUMP" action, the D.E. is periodically regenerated and the filter cycle

extended without changing the powder. When the filter powder is totally used, the "BUMP" action makes it possible to drain the used

diatomite without backwashing or dismantling the filter. The EC-50AC is equipped with a special, polished stainless steel clamp,

designed for easy access to the internals of the filter.

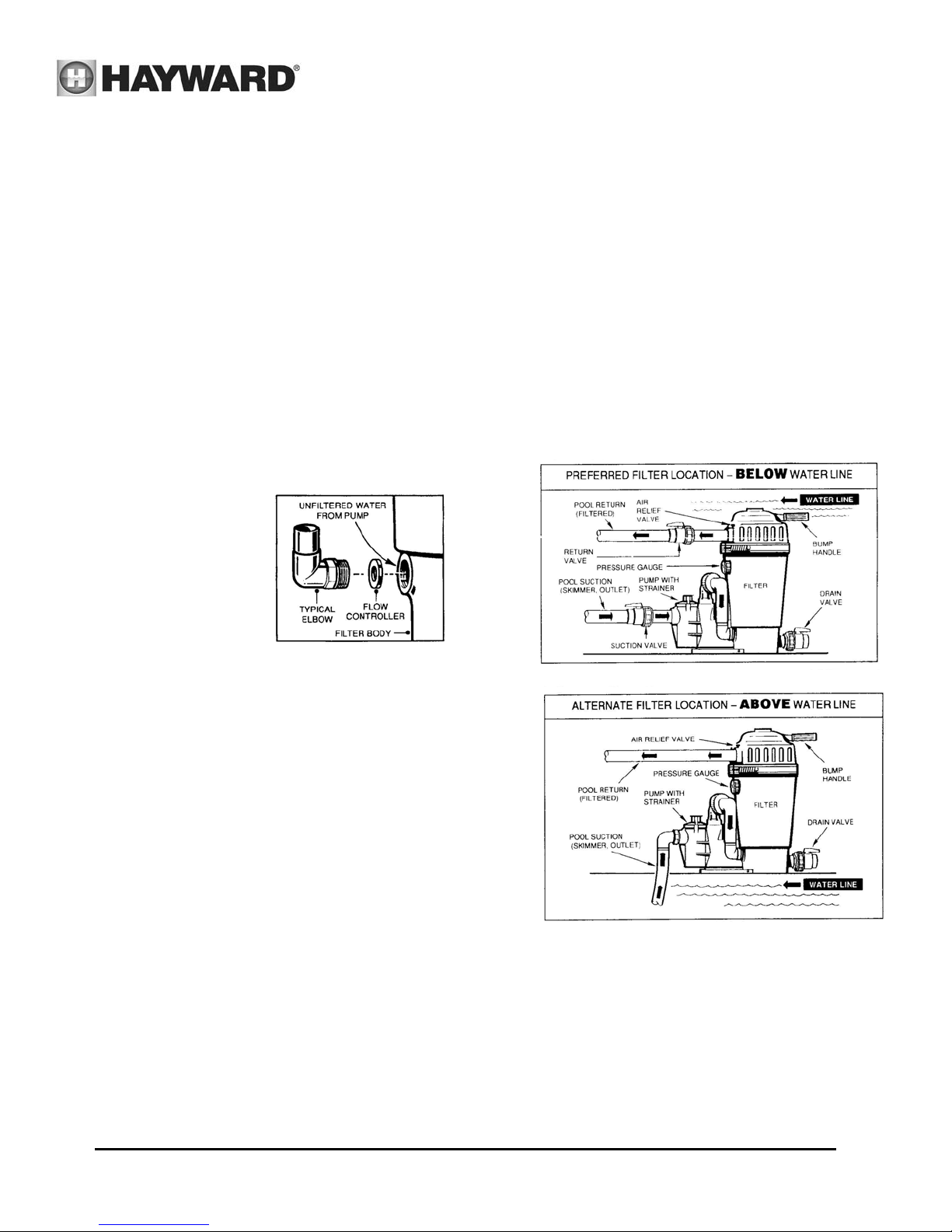

PUMP SELECTION

To power your Perflex filter, select a continuous duty

pump designed for swimming pool service. The filter may

be used with a variety of Hayward bases and plumbing

connections, or may be mounted on other suitable

surfaces.

It is important to determine whether the pump will be

located above or below the normal pool water line. If the

pump is going above the water line, a self-priming

centrifugal pump must be used. Self-priming pumps can

lift water from a lower level

and prime automatically.

There is another type of

pump simply called the

centrifugal. Unlike selfpriming centrifugals which

can lift water from a lower

level, a centrifugal must be

located below the water

line for dependable

priming.

Select a pump with an output rating of between 30 and

65 GPM (114-246 LPM). Since 50 GPM (189 LPM) is the

desired maximum filter flow, a flow controller (part

number ECX1055) is furnished with each unit for use

with pumps rated between 40 and 65 GPM (150-246

LPM). Install the flow controller in the filter body as

illustrated with an elbow adapter, union connector, or

adapter. The adapter both secures the controller in its

proper position, and completes the hydraulic balance

of the system.

PLUMBING & INSTALLATION

1. To facilitate servicing of the filter system and to allow

for indoor storage during the winter months, installing

union connections at the suction and outlet ports is

recommended.

2. Use 1-1/4" or 1-1/2" I.D. flexible plastic pipe, or hose,

joined with insert fittings and stainless steel clamps.

3. All plumbing connections on the system are 1-1/2"

FILTER LOCATION

1. Though the filter is designed for outdoor use, it is

advisable to protect electrical components from the

weather. Select a well-drained area, one that will not

flood when it rains. Locate the filter as close to the pool

as practical, keeping the number of fittings to a

minimum.

2. Set the filter on a level mounting platform or base. Keep

the filter bump handle, drain outlet, and pressure gauge

accessible for convenient operation.

3. Position the system so that the filter tank can drain by

gravity.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Page 4 of 12

PERFLEX

N.P.T. When making connections, use plastic male-end

adapters. Apply three turns of Teflon tape or plastic

pipe sealant compatible with ABS to the male threads.

Screw the fitting into the thread hand tight; then, using

a wrench, tighten one more full turn. Additional

tightening is unnecessary-and-could result in damage

to components.

4. Refer to the diagrams for suggested valving. Ball-type

valves are recommended where needed.

™ Filtration Series IS50C REV C

Page 5

5. Tighten pump base mounting bolts, if loose.

6. Securely

and pump.

7. Connect the pool suction plumbing between the

skimmer, pool outlet, and the pump.

8. Connect the pool return (inlet) plumbing

9. If the pressure gauge is not installed, apply Teflon

tape to the gauge threads, and

gauge into the threaded hole in the side of the filter

body.

10. A filter drain plug, with gasket, is furnished with

each filter and is all that is needed for complete

filter draining. If desired however, drain piping may

be extended from the filter by using the optional

Drain Valve Kit (Model SP0723) and an appropriate

length of 1-1/2" pipe. Piping must slope away from

the filter so the tank can drain by gravity.

11. All electrical connections should be made in

accordance with applicable electrical codes.

12. Check for joint leaks before operating system.

13. Refer to pump instruction booklet for pump

information.

BEFORE STARTING THE FILTER

1. Obtain a supply of operating chemicals, D.E., and a

pool test kit. Use only the swimming pool grades of

D.E., such as:

CELATOM Eagle-Picher Industries, Inc.

AQUA-CEL Johns-Manville Products

DICALITE 4200 Grefco Inc.

WITCO Witco Corporation

2. Superchlorinate the pool water by adding

unstabilized granular or liquid chlorine. Stabilized

forms of chlorine are recommended for normal daily

use after the initial clean up of the water. Follow

chemical manufacturer's recommendations for

superchlorination and daily use.

hand tighten

Corporation

the union nut between the filter

carefully

screw the

INITIAL SET-UP

1. Always turn off pump and relieve tank pressure by

opening Air Relief Valve before loosening Center

Clamp or servicing filter.

WARNING-SEPARATION HAZARD

Tighten nut until spring coils touch each other.

2. To re-assemble Clamp on filter, make sure Clamp is

located and centered properly over the filter flange. If

Clamp is tight, tap Clamp with rubber mallet or block of

wood to help seat it.

The end of the T-bolt must extend through the

trunnion, slide a (1) Washer ECX500J4 over the end of

the T-Bolt followed by the (2) Spring ECX500JS, then

the (3) Washer ECX500J3. (4) Thread the Nut ECX360JN

onto the end of the T-Bold.

Tighten the nut with a using a wrench and 9/16”

socket until the spring coils all touch and then an

additional 2 turns.

3. To re-start system, open all in-line valves. Open Air

Relief Valve before starting pump. Stand clear of filter

and prime and start the pump per the manufacturer's

instructions. When a steady stream of water emerges

from the Air relief Valve, close Air Relief Valve.

STARTING THE FILTER

Close the filter drain and the vent valve.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Page 5 of 12

PERFLEX

CAUTION All suction and

discharge valves must be open

when starting the pump. Failure to

do so could cause severe personal

injury and/or property damage.

Prime and start the pump following the manufacturer's

instructions. Air trapped in the system will automatically

vent to the pool. When there is a steady flow of water

returning to the pool, the filter is ready for precoating.

DO NOT

without the precoat charge.

operate the filter for more than one minute

™ Filtration Series IS50C REV C

Page 6

PRECOATING

Scoop 5 lbs. (2.3 kgs.) of diatomite into the system

through the skimmer as fast as the plumbing will take it.

Note and record the pressure gauge reading after the

diatomite has been added. This is the

"precoat

pressure."

FILTERING

Filtration starts as soon as the filter has been precoated.

As the filter removes dirt from the pool water, the

accumulated dirt causes a resistance to flow. As a

result, the gauge pressure will rise and the flow will

decrease. When the pressure rises 7-10 psi (.49-.70 Bar)

above the precoat pressure, regenerate the filter.

REGENERATION (Extending the Cycle)

Stop the pump. Move the bump handle down slowly,

then up briskly. Repeat 3 times. Restart the pump and

filtration will resume at near the original flow and

pressure.

After each regeneration, and until the filter is cleaned,

there may be a slight increase in the starting pressure.

This is the result of dirt accumulating within the filter and

is completely normal.

CLEANING

Cleaning is recommended when the gauge pressure

rises more than 10 psi (.70 Bar) in less than a 24 hour

period or when cloudy water returns to the pool for more

than 30 seconds after regeneration. To clean, first stop

the pump; then move the bump handle down slowly,

then up briskly. Repeat 8 times. Open the vent valve

(under bump cover), open the filter drain (Note: if the

filter is installed below the pool water line, close the

suction and return valves) and allow water and-dirt-toempty completely.

After the filter has drained, and with the drain still open,

run the pump for a few seconds to flush out any dirt

remaining in the bottom of the filter. (Note: If the filter is

installed below the pool water line, opening the

valve for a few seconds with the pump off will

adequately flush the unit.)

Close the filter drain and the vent valve. Open the

suction and return valves (when used). Start the pump

and let the filter fill with water and repeat the CLEANING

procedure. This completes the cleaning phase. The filter

is now ready for recharging. Proceed as in STARTING THE

FILTER and PRECOATING.

suction

VACUUMING

Vacuuming can be performed directly into the filter

whenever needed. For fastest results, regenerate the

filter before and after each vacuuming operation.

TO CHANGE BUMP HANDLE POSITION

1. Remove the bump handle grip. Push in tab at

base of handle. Carefully pry the bump cover

from the retaining groove and slide the cover off

the handle.

2. Using a drift (or 10 penny nail), tap the pivot pin

out of the filter head anchor point, freeing the

end of the handle.

3. Rotate the bump handle to the alternate position

and align the handle and the head anchor holes.

Tap the pivot pin in place.

4. Reinstall the bump cover and grip.

GAUGE/INSPECTION PORT ADAPTER

The gauge/inspection port adapter provides an easy way

to look into the filter, at the top area of the tube nest

assembly. It gives a quick inspection capability to check

tube nest conditions (algae, calcium or D.E. build-up, ect.)

without requiring the removal of the filter head. It also

allows you to wash off trapped debris and excess D.E.

from between the Flex-Tubes; and from under the tube

sheet, by spraying with a garden hose, or utilizing

Hayward’s Jet-Action Cleaning Wand (EC2024) that

attaches to the end of a garden hose.

To remove adapter- shut off the pump and valves. Open

the air relief. Drain the water in the filter to a level below

the adapter port. Unscrew the adapter, with the pressure

gauge, counterclockwise.

To Reinstall the adapter - thread the adapter, with the

adapter o-ring in place, securely into the filter housing.

PREVENTIVE MAINTENANCE

While Perflex filters are basically resistant to the

difficulties often encountered as a result of chemical

build-up in swimming pools, it is important to keep in

mind that the mineral content in a pool increases every

day as a result of the chemicals and the normal water

evaporation process. If the concentration of minerals is

allowed to get too high, the minerals will form deposits on

the Flex-Tubes inside the filter, and will eventually result

in shortened filter cycles.

The filter elements can be cleaned by washing with a

garden hose. For best results, carefully brush the surface

to remove fine particles. Do Not Pressure wash as it can

damage the filter elements.

You may find some debris on the filter elements , which

may not be removed with hosing.

After cleaning, thoroughly flush all affected parts with

cold water.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Page 6 of 12

PERFLEX

™ Filtration Series IS50C REV C

Page 7

REF.

NO.

1 ECX5000D Bump Mechanism Cover 1

2 ECX1322A Vent Val ve with O-r ing 1

3 ECX5000BP Filter Head with Vent Valv e 1

4 ECX5 000C Clamp Assem bly with Spring 1

5 ECX100Z9 Pivot Pin (long) 1

6 ECX4236 Shoulder Screw 1

7 ECX1040 Bump Handle 1

8 ECX1037B Bump Handle Grip 1

9 ECX360JN

10 ECX4249 Locknut 1

11 ECX5000F Bump Shaft, 1/2" 1

12 SPX1500NYA Tube S heet Bolt S et 12

13 ECX100 4A Tube Sheet Top 1

14 ECX5000G Diaphragm Gasket 1

15 ECX100 4 Tube S heet B ottom 1

16 Tube Sheet Nut (Included in b olt set) 12

17 O-Ring 2

18 Retainer 2

19 Thrust Washer 2

20 ECX1032 Flex-Tube Assembly 72

21 ECX5000AP Filter Body w/Flow Diffuser 1

22 ECX270 91 Pressure Gauge, back mou nt 1

23 ECX128 66 Gauge/Inspecti on Port Ada pter 1

24 ECX1287 O-ring for Gauge Adapter 1

25 ECX5029 Decal -Operation 1

26 SPX1055 Flow Controller 1

27 ECX4077B1 Check Valve 1

28 ECX1256 Flow Diffuser with Check Valve 1

29 SP1022C Drain Plug with Gasket 1

30a

30b

30c

PART NO. DESCRIPTION

Nickel Plated Sleeve Nut, 5/16 ”

Must be used with clamp spring

assembly

ECX1014A

ECX500J4 Spring washer (Small hole) 1

ECX500JS Spring 1

ECX500J3 Spring Washer (Lar ge hole)

SP0723 Ball-Type Drain Valve with Nipple 1

Bump Shaft Kit

(Includes 17,18, & 19)

NO.

REQ'D.

1

1

1

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Page 7 of 12

PERFLEX

™ Filtration Series IS50C REV C

Page 8

y

WINTERIZING

In areas where sub-freezing temperatures can be

expected, the filter should be drained and removed from

its operating location and stored indoors. Prior to

removal, cycle the filter as described under CLEANING.

SERVICE & REPAIRS

Consult your local authorized

service center. No returns may be made directly to the

factory without the expressed written authorization of

Hayward Pool Products, Inc.

Hayward-Perflex

dealer or

ALGAE CONTROL

Algae is a form of plant life which can vary in size from a

few thousandths of an inch to the size of a small tree. Of

the many forms of algae, those most frequently found in

swimming pool water are microscopic in size and green

in color.

Algae readily grows in sunlight and can, under favorable

conditions, quickly overgrow a swimming pool turning it

completely green in just a few hours. On the other hand,

swimming pool water can be kept unfavorable to algae

growth simply by maintaining a chlorine level of at least

0.5 ppm in the water at all times. The chlorine level

SUGGESTED POOL CHEMISTRY LEVELS

should be checked at least once a day using a suitable

test kit.

If an algae condition develops and the pool water

"blooms" green, superchlorination of the pool will be

necessary to clear it. Add unstabilized granular chlorine,

or liquid chlorine.

Follow chemical manufacturer's recommendation for

superchlorination. The algae will quickly become inactive

and can then be removed by the filter. Live algae, on the

other hand, multiplies so fast that the filter cannot keep

up with its growth rate. In an active algae situation, it

may be necessary to regenerate the Perflex filter as

frequently as every 2 to 3 hours.

When correctly used, commercial algaecides are effective

against algae, though algaecides should be used in

conjunction with, and not as a substitute for, regular

chlorination or superchlorination.

Maintaining a chlorine level of at least 0.5 ppm in the pool

water at all times is the most effective way to prevent

algae growth in swimming pools.

pH 7.2 to 7.6

TOTAL ALKALINITY 100 to 130 ppm

CHLORINE (UNSTABILIZED)

CHLORINE (STABILIZED) 1.0 to 3.0 ppm

CHLORINE STABILIZER

(C

anuric Acid)

0.3 to 1.0 ppm

40 to 70 ppm

PRODUCT REGISTRATION

(Retain for Your Records)

DATE OF INSTALLATION_________________

PURCHASED FROM _____________________

MODEL _______________

SERIAL NUMBER ______________________

▲Retain this Warranty Certificate in a safe and convenient location for your records.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Page 8 of 12

PERFLEX

™ Filtration Series IS50C REV C

Page 9

PROBLEM PROBABLE CAUSE REMEDY

Running at high

pressures.

Drop off of return flow.

Short cycles.

Short cycles --

even after proper

bumping, draining,

and recharging

1. D.E. coated with normal accumulation of pool dirt, algae,

etc.

2. Overcharge of D.E.

3. Restriction in return line caused by small eyeball fitting.

4. Partially closed valve on return line.

1. D.E. coated with normal accumulation of pool dirt,

algae, etc.

2. Pump strainer basket clogged.

3. Skimmer basket clogged.

4. Pump impeller vanes clogged.

5. Air leak on suction side of pump.

6. Electric motor running less than maximum R.P.M. (under

speed)

1. D.E. loaded to capacity with pool dirt, algae, etc.

2. Bumping incorrectly.

3. Bump handle bent.

4. Pump output exceeds design flow rate of filter.

5. Presence of algae.

Contaminated (clogged) Flex-Tube braids caused by:

a. Natural accumulation of chemical deposits

(accelerated if chemicals are fed thru skimmer).

b. Running D.E. charge too long with excessive amount

of live algae present in pool.

c. Operating filter without D.E.

d. Operating too long without D.E. after starting pump.

D.E. must be added as soon as filter is full of water and

pump is putting out a steady stream.

IMPORTANT —

without adding D.E. will cause this type of clogging.

Testing a new pool plumbing system

1. Bump.

2. Bump-Drain-Recharge.

3. Change to larger size fitting.

4. Open valve.

1. Bump.

2. Clean.

3. Clean.

4. Cleaning with a stiff wire thru the pump

strainer opening will usually work.

Alternate would be to disassemble-and

clean.

5. Check cover gasket, hand knobs, hose,

clamps, etc. Replace or tighten as

necessary.

6. Consult pump and motor trouble shooting

guide.

NOTE:

1. Undersized or improper wiring.

2. Power cut-backs or a combination of

1. Bump-Drain-Recharge.

2. Slow down stroke - brisk upstroke.

3. Check and straighten or replace.

4. Check GPM/LPM output. Regulate pump

5. Super-chlorinate; Bump-Drain-Recharge

Clean Tube Nest

Most motor problems are due to:

both.

Repeat 6 times.

GPM/LPM output to max. filter GPM/LPM

rating.

as needed.

a) Cleaning: Remove tube nest and hose

down with forceful stream of clean

water. Brush to remove fine particles.

b) Detergent Cleaning: Remove tube nest

and hose down with forceful stream of

clean water. Soak tube nest in strong

solution of laundry detergent (such as

Cheer)

again.

and warm water. Hose down

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Page 9 of 12

PERFLEX

™ Filtration Series IS50C REV C

Page 10

PROBLEM

D.E. leaking to

pool via the

return lines.

Hard bumping.

D.E. leaking back to

pool via skimmer or

main drain.

Very short cycles

when vacuuming.

PROBABLE CAUSE REMEDY

1. Opening or tear in one or more Flex-Tubes.

2. Rip or hole in diaphragm gasket.

3. Worn or loose fitting diaphragm gasket (chemicals fed

thru suction lines may shorten life of this part).

4. Loose bolts on tube nest plates.

1. Caking of D.E. under tube sheet. Sometimes caused by

accumulation of sun tan oils, hair or floating particles

that bind together in a clay-like form.

2. Overloaded with D.E. Sometimes happens when last

charge of dirty D.E. was not properly drained.

3. Filter runs too long between bumping.

Filter check valve worn or stuck open. Clean and/or replace.

Normal if pool contains:

1. Very dirty water.

1. Replace Flex-Tube.

2. Replace gasket.

3. Replace gasket.

4. Tighten bolts.

1. Bump-Drain-Recharge more often and

reduce the use of oils.

2. Bump-Drain-Recharge with proper

amount of D.E.

3. Bump more frequently.

1. Bump-Drain-Recharge more often.

2. Presence of live, vigorously growing algae.

3. Presence of alum or floccing agents, which will clog filter.

2. Add enough chlorine to control this growth

— then vacuum.

3. Vacuum so as to by-pass filter.

Avoid using floccing agents.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Page 10 of 12

PERFLEX

™ Filtration Series IS50C REV C

Page 11

HAYWARD®LIMITED WARRANTY

This equipment was inspected before shipment from our plant. To original purchasers of this equipment, Hayward

Pool Products, Inc., 620 Division Street, Elizabeth, New Jersey, warrants its products free from defects in materials

and workmanship for a period of ONE (1) year from the date of purchase.

Parts which fail or become defective during the warranty period, except as a result of freezing, negligence, improper

installation, use, or care, shall be repaired or replaced, at our option, without charge, within 90 days of the receipt

of defective product, barring unforeseen delays.

To obtain warranty replacements or repair, defective components or parts should be returned, transportation paid,

to the place of purchase, or to the nearest authorized Hayward service center. For further Hayward dealer or service

center information, contact Hayward customer service department. No returns may be made directly to the factory

without the express written authorization of Hayward Pool Products, Inc.

To original purchasers of this equipment, Hayward Pool Products, Inc. warrants its vacuum release systems to be

free from defects in materials and workmanship for a period of ONE (1) year from the date of purchase.

Filters which become defective during the warranty period, except as a result of freezing, negligence, improper

installation, use or care, shall be repaired or replaced, at our option, without charge.

All other conditions and terms of the standard warranty apply.

Hayward shall not be responsible for cartage, removal and/or reinstallation labor or any other such costs incurred in

obtaining warranty replacements.

The Hayward Pool Products warranty does not apply to components manufactured by others. For such products, the

warranty established by the respective manufacturer will apply.

Some states do not allow a limitation on how long an implied warranty lasts, or the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state.

Hayward Pool Products, Inc.

620 Division Street

Elizabeth, NJ 07207 *Supersedes all previous publications.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Page 11 of 12

PERFLEX

™ Filtration Series IS50C REV C

Page 12

Get the Scoop on Achieving Optimum D.E. Filter

Performance with Hayward's D.E. Pre-Measure

Scoop!

With Hayward's D.E. Pre-Measure Scoop, you can now accurately measure and add the correct

amount of diatomaceous earth powder to your pool filter ensuring optimum performance and crystal

clear, sparkling water. Hayward's D.E. Pre-Measure Scoop is the only scoop that provides an exact

measure of 1 lb. or 1/2 lb. of D.E. Needless guesswork is eliminated. Adding D.E. is accurate, easy,

and fast–all with no mess. The D.E. Pre-Measure Scoop doubles as a broadcaster for distributing

granular chlorine to your pool. It can also be used for scooping out those hard-to-remove final

gallons of water from your spa. Plus, there are hundreds of other uses. Hayward's D.E. Pre-Measure

Scoop is available at your pool dealer. Just look for the bright orange display.

Watch it on Video!

Now that you’ve got the filter that provides the cleanest, clearest pool water...Get the video that keeps maintenance at a

minimum and pool enjoyment at a maximum! That's right. Hayward Pool Products has an easy, stress-free way for you to

learn about how to operate and maintain your Perflex filter–by video. The new twelve minute Perflex video includes easy-tofollow

how-to's,

fitter, cleaning your Perflex, plus vacuuming, preventative maintenance, and winterizing. Perflex – the video. It keeps

maintenance at a minimum and pool equipment at a maximum!

Just order “Operation and Maintenance” Video Part Number EC-OM-Video-90 and include your check or money order for

$9.95* (+ $2.50 for shipping and handling) and mail to: Hayward Pool Products Inc.

Attn: Marketing Communications

DETACH HERE: Fill out bottom portion completely and mail within 10 days of purchase/installation or register online.

------------------------------------------------------------------------------------------------------------

PERFLEX™ Warranty Card Registration

Please Print Clearly:

First Name___________________________ Last Name:___________________________________

Street Address______________________________________________________________________

City____________________________________ State_______________ Zip___________________

Phone Number:_______________________________ Purchase Date:________________________

E-mail

Address________________________________________________________________________

Serial Number

(10-17 digit number)

Model

Number:______________________________________________________________________

on achieving and maintaining proper pool water chemistry, initial start-up and operation of your Perflex

620 Division Street

Elizabeth, NJ 07207

Register online at www.haywardnet.com

Years Pool has been in service

1 year or less 2-3 4-5 6-10 11-15 >16

Purchased from________________________________

Builder Retailer Pool Service Internet/Catalog

Company Name_______________________________

Address ______________________________________

City __________________ State______ Zip _________

Phone _______________________________________

Type of Pool:

Concrete/Gunite Vinyl Fiberglass Other_____

Pool Capacity ___________(U.S. Gallons)

Please include me on all e-mail communications regarding Hayward Equipment or promotions.

Mail to: Hayward Pool Products, 620 Division Street, Elizabeth, NJ 07207

Attn: Warranty Dept

or REGISTER YOUR WARRANTY ON-LINE AT WWW.HAYWARDNET.COM.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Hayward is a registered trademark and PERFLEX is a trademark of Hayward Industries, Inc.

© Hayward Pool Products. 2010 All rights reserved

Page 12 of 12

PERFLEX

New Installation Replacement

Installation for:

In ground Above Ground Spa

™ Filtration Series IS50C REV C

Loading...

Loading...