Page 1

Hayward

OnCommand

Automation

Installation Manual

for models

ONCOM

ONCOM-ACT

ONCOM-RC

ONCOM-ACT-RC

www.haywardnet.com

Page 2

IMPORTANT SAFETY INSTRUCTIONS

!

!

!

When using this electrical equipment, basic safety precautions should always be

followed, including the following:

•

•

•

•

• A green colored terminal marked “Earth Ground” is located inside the wiring

• A wire connector is provided on this unit to connect a minimum 8 AWG (8.4

READ AND FOLLOW ALL INSTRUCTIONS

WARNING: Disconnect all AC power during installation.

WARNING: Water in excess of 100 degrees Fahrenheit may be

hazardous to your health.

WARNING: To reduce the risk of injury, do not permit children to

use this product unless they are closely supervised at all times.

compartment. To reduce the risk of electric shock, this terminal must be

connected to the grounding means provided in the electric supply service

panel with a continuous copper wire equivalent in size to the circuit conductors

supplying the equipment.

mm) solid copper conductor between this unit and any metal equipment,

metal enclosures of electrical equipment, metal water pipe, or conduit within

5 feet (1.5m) of the unit, to connect the equipment assembly or spa to a

circuit protected by a ground-fault circuit-interrupter.

• SAVE THESE INSTRUCTIONS

Page 3

Table of Contents

Introduction Before You Begin................................................................... 1

Installation Steps.................................................................... 1

1. Mounting OnCommand Control Center............................................... 2

Equipment Temperature Sensors............................................................ 2

Wireless Remote Control...................................................... 2

Base Station........................................................................... 3

Optional Valve Actuators....................................................... 3

2. Plumbing Plumbing Configuration.......................................................... 4

3. Electrical Grounding............................................................................... 5

Wiring Input Wiring............................................................................ 5

High Voltage Pool Equipment............................................. 6

Low Voltage Wiring................................................................ 8

4. Configuration Configuration Menu............................................................... 13

5. System Startup Before Startup........................................................................ 26

and Checkout Heater Checkout.................................................................... 26

Service Mode......................................................................... 27

6. Warranty OnCommand Limited Warranty........................................... 28

Page 4

Introduction

Before You Begin

What’s Included

The following components have been included in the OnCommand package:

(1) OnCommand Control Unit

(3) Temperature sensors with 15 ft. (5m) cable, hose clamp

(2) Goldline GVA-24 actuators (ONCOM-ACT, ONCOM-ACT-RC only)

(1) Goldline AQL2-BASE-RF/AQL2-SS-RF remote control (ONCOM-RC, ONCOM-ACT-RC only)

What’s NOT Included

Some of the additional items that you will need to complete the installation include:

Wire

4-conductor cable for use with optional external chlorination

Wire/conduit for input power connection and auxiliary output connections

Miscellaneous

Mounting hardware (screws, etc.) for mounting OnCommand

Valves (use standard Hayward, Pentair/Compool, or Jandy valves)

Accessory Products - Order Separately if not included

AQL2-POD Handheld Wireless Remote Control

AQL2-SS-RF Wireless Spa Side Remote Control (Included with ONCOM-RC, ONCOM-ACT-RC)

AQL2-BASE-RF Base Station required if using AQL2-SS-RF (included with ONCOM-RC, ONCOM-ACT-RC)

AQR Aqua Rite chlorination unit

AQL-DIM Light Dimmer Relay (refer to AQL-DIM manual to ensure dimmer wattage specifications match lighting wattage)

GVA-24 Valve Actuator

V&A-xx Valve & Actuator (xx=1P (1.5” positive seal), -2P (2” positive seal))

Installation Steps

Details on each installation step are presented on the following pages:

1. Mounting the equipment (page 2)

OnCommand main unit

Temperature sensors

Wireless Remote Controls (if applicable)

Base Station (if applicable)

Valve actuators (if applicable)

2. Plumbing (page 4)

General Pool Equipment

3. Electrical Wiring (page 5)

Grounding

OnCommand control power

High Voltage pool equipment

Low voltage wiring (temperature sensors, heater, etc.)

4. OnCommand configuration (page 13)

5. System Startup and checkout (page 26)

1

Page 5

1. Mounting the Equipment

!

OnCommand Control Unit

The OnCommand is contained in a raintight enclosure that is suitable for outdoor mounting. The control must be

mounted a minimum of 5 ft. (2 meters) horizontal distance from the pool/spa (or more, if local codes require). The

OnCommand is designed to mount on a flat surface with the knockouts facing downward.

When selecting a location, note that the standard cables supplied with the temperature sensors, and valve actuators

(if applicable) are all 15 ft. (5m) long.

Temperature Sensors

Three sensors are included with the OnCommand. A water sensor and an air sensor must be installed at all times

for proper operation. A solar sensor is required if the solar function is enabled.

Water Sensor

This sensor is used to measure the pool/spa temperature and is installed in the filtration plumbing after the filter but

before either the solar or conventionally fueled heaters—refer to the plumbing overview diagram.

1. Drill a 3/8” (10mm) diameter hole in the PVC piping and remove all chips and burrs.

2. Insert sensor until O-ring collar sits flush on the hole.

3. Position hose clamp over the sensor and gently tighten until O-ring makes an adequate seal. Do not over-

tighten.

4. For maximum temperature accuracy, cover the sensor and 3” (6cm) of pipe on either side with insulation and

white paint.

Air Sensor

Mount the air sensor outdoors.

IMPORTANT: Mount the air sensor out of direct sunlight.

Solar Sensor

For solar applications, mount the sensor near the solar collector array so that it is exposed to the same sunlight as

the collectors. Use additional cable (20 AWG), if necessary.

Wireless Remote Controls

A single Base Station must be installed on the OnCommand in order to use Goldline wireless remote controls.

There is no limit on the number of wireless remotes that can used. The maximum distance between wireless remote

controls and the base station on the OnCommand main control unit is 400 feet (120m) line of sight or 200 feet

(60m) through walls, etc. If in doubt about the distance, test operation before installing the remote. Wireless

remote controls require the user to run the “Teach Wireless” routine in the Settings Menu. Refer to the Operation

section for more information. Compatible wireless remote control models are listed below:

AQL2-SS-RF

The waterproof AQL2-SS-RF is a convenient limited function remote that can be left in or around the pool/spa for

easy access. The AQL2-SS-RF can control the Pool/Spa valves as well as offering ON/OFF control of the pool

filter pump operation, heater operation, lights, and two auxiliary outputs.

AQL2-POD

The AQL2-POD is a full function rechargeable handheld remote with display. It offers the same control options as

the local display/keypad. This waterproof portable remote is designed to be used in and around the pool/spa area.

2

Page 6

Base Station

OUT

(Common)

IN

(Common)

OUT

OUT

IN

Valve 3 Pump Spd

Settings Menu

only if filter pump is set to variable

and relay type is set to standard

Move to previous/next configuration menu

Valve3 Freez e

Disabled

Toggle between Enabled and Disabled (default) Valve3 Freeze

Move to previous/next configuration menu

for all functions except super chlorinate

Valve3 Config.

+ to view/change

Valve3 Function

Solar

Push to access Valve3 options

Rotates between k

Filter, Lights, Aux1 and Aux2

Move to previous/next configuration menu

Move to next menu item

Valve3 Interlock

Disabled

Move to next menu item

for all functions except solar and super chlorinate

The AQL2-BASE-RF base station must be installed if the AQL2-SS-RF or AQL2-POD will be used. To install

the base station, remove the knockout on the upper left side of the OnCommand main control unit, insert the base

station, and then tighten the nut from the inside. Also refer to the Base Station installation manual and the diagram

on page 12.

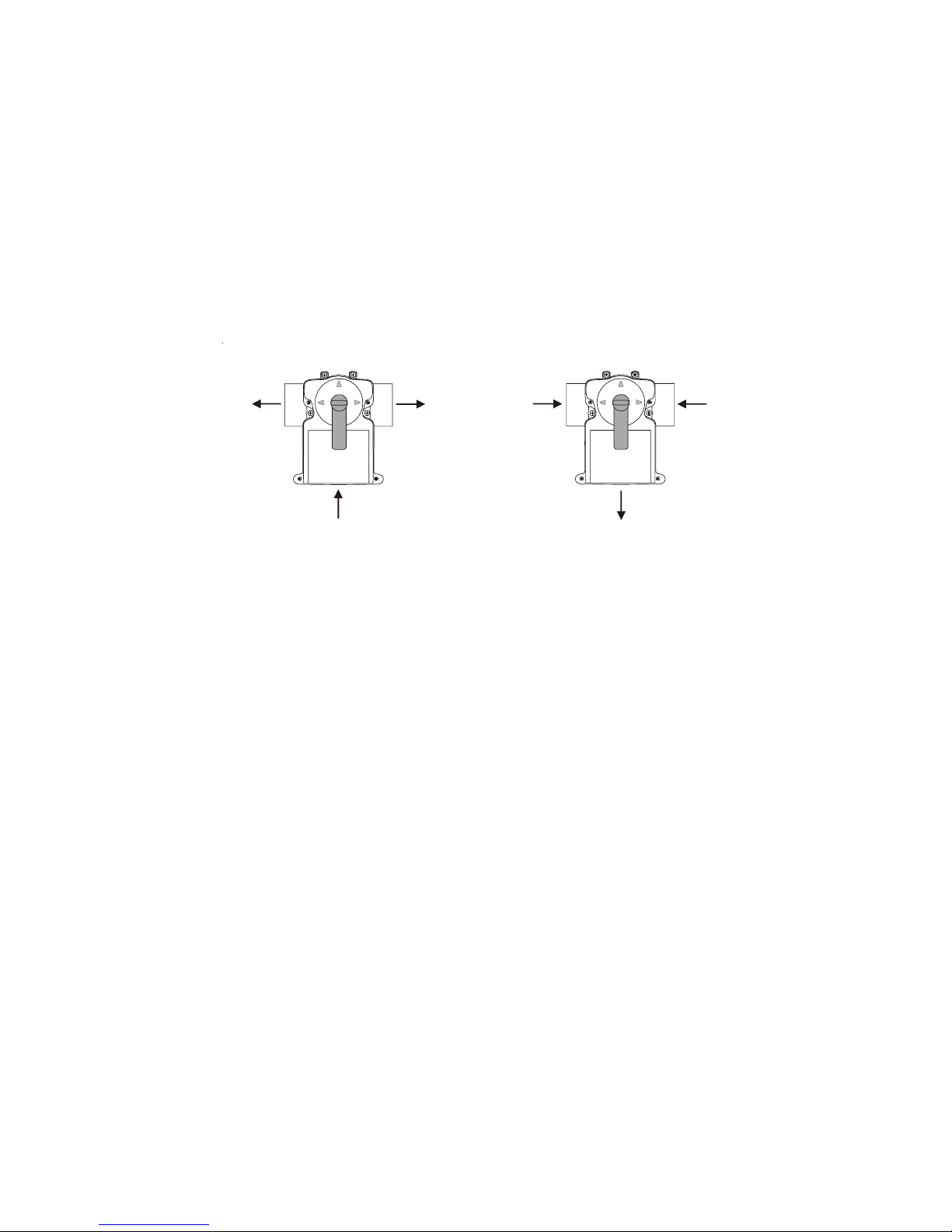

Optional Valve Actuators (included with ONCOM-ACT, ONCOM-ACT-RC)

For optional actuators used with the OnCommand—note that the internal cams in the actuator may also have to be

adjusted depending on the way the actuator is mounted on the valve and the desired valve action.

RETURN

SUCTION

IN

3

Page 7

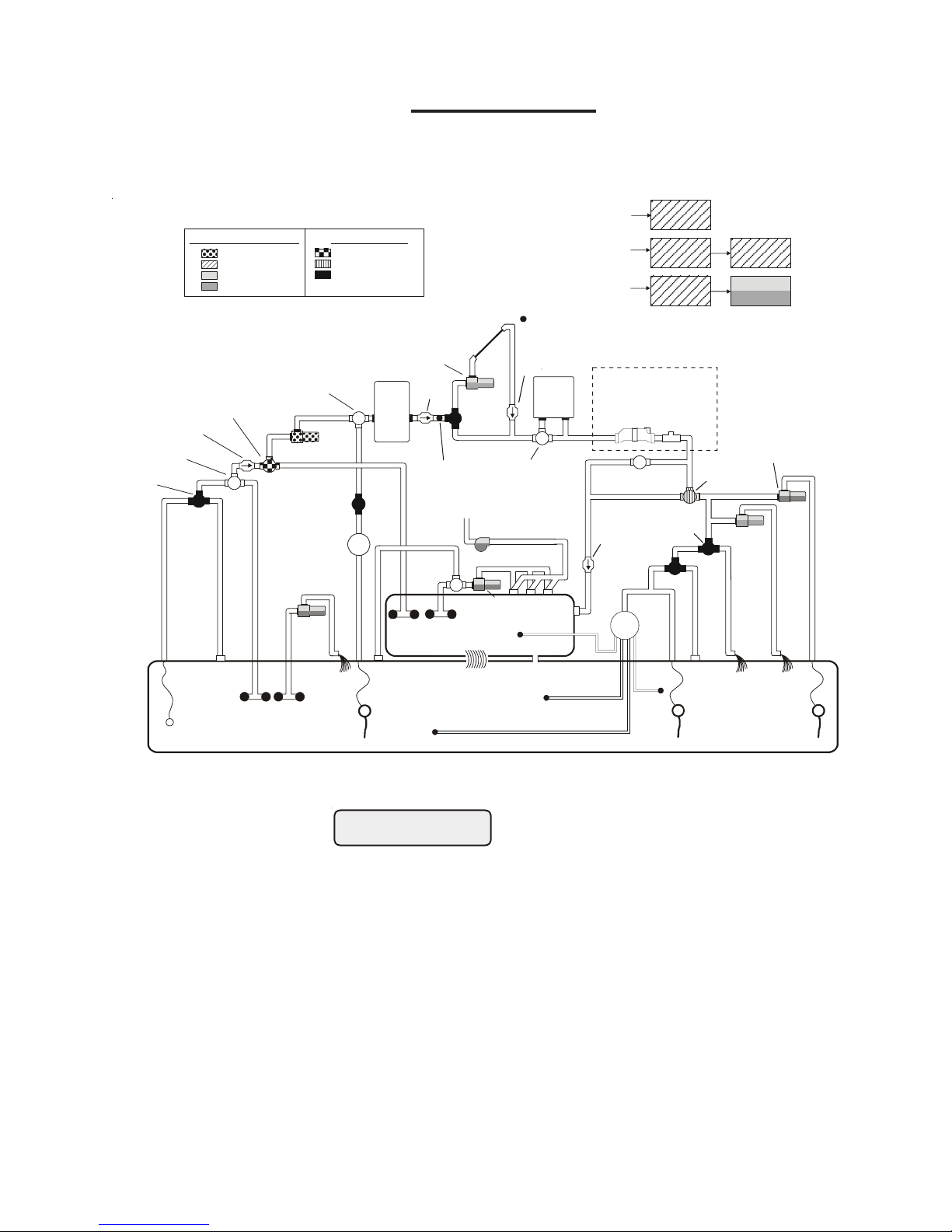

2. Plumbing

Pool/Spa Setup

Pool and Spa

FILTER

SOLAR BOOST

PUMP

SOLAR

VALV E

HEATER

HEATER

BYPASS

VALVE

(manual)

CELL

FLOW

SWITCH

CHECK

VALVE

PUMP

RETURN

VALV E

WATER

FEATURE

VALV E

SPA

SPA JET

PUMP

SPA

BLOWER

POOL/SPA SUCTION

VALV E

CHECK VALVE

POOL VACUUM

VALV E

MANUAL

VALV E

MANUAL

VALV E

MANUAL

VALV E

ENERGY

FILTER

TWO-WAY

VALV E

SKIM

POP-UP

SPILLOVER

POP-UP

OVERFLOW

POP-UP

RETURN

JET

IN-FLOOR

CLEANER

VALVE

WATER

FEATURE

PUMP

WATER

FEATURE

POP-UP

MAIN

DRAIN

ENERGY

SAVER

PRESSURE

CLEANER

NON-BOOST

PRESSURE

CLEANER

PRESSURE

CLEANER

SUCTION

CLEANER

SENSOR

FILTER

PUMP

Valve Outp ut s

Filter Pump

Lights

Aux 1

Aux 2

Pool/Spa Suction

Pool/Spa Return

Val ve 3

HIGH VOLTAGE

LIGHTS

LOW VOLTAGE

LIGHTS

FIBER OPTIC

LIGHT SOURCE

COLOR WHEEL

ISOLATED

WATE R

FEATURE

PUMP

TEMPERATURE

SENSOR

CHECK

VALV E

(prevents drai ning

of raised sp as)

V

of raised spas)

control is used

Pool/Spa system configuration

These systems use a single filter pump and filter. Pool or spa operation is controlled by two 3-way valves (suction

and return). Refer to the diagram below.

High Voltage Relays

Some important notes regarding the OnCommand control of Standard Pool/Spa systems (refer to the Operation

section for more information):

In Pool/Spa Config., select:

1. The OnCommand can be programmed to accommodate spa spillover, if desired.

2. A conventional heater (gas or heat pump) and solar can be used to heat both the pool and the spa.

3. If the chlorinator cell is plumbed prior to the pool/spa return valve, then both the pool and the spa can be

chlorinated (only when optional external chlorination is used).

4. The water sensor should be installed prior to any heater or solar and will display either the pool or the spa

temperature, depending on the current operation of the pool. The temperature will only be displayed when

the filter pump is running.

5. If any water feature or pressure side cleaner boost pumps are used, be sure to enable the “interlock”

feature (see “Configuration Menu” for details) to ensure that the pumps operate only when the filter pump

is on and the system is in the “pool only” operating mode.

6. The plumbing diagram above is intended to be used as a general guideline and is not a complete plumbing

schematic for the pool.

7. The air sensor must be installed if the freeze protection feature is enabled for the filter, valves or aux outputs

or if the chlorinator is enabled.

POOL/SPA

POOL

TEMPERATURE

4

SOLAR

if optional Aqua Rite or

Swimpure ext ernal chlorination

CHECK

ALVE

(prevents drai ning

TRANSFORMER

POOL/SPA

POOL SWEEP

BOOST PUMP

WATE R

FEATURE

Page 8

3. Electrical Wiring

Aux1 Pump Spd

Settings Menu

only if filter pump is set to variable

and relay type is set to standard

Move to previous/next configuration menu

Aux1 Config.

+ to view/change

Aux1 Function

Manual On/Off

Aux1 Relay

Standard

Push to access Aux options

Toggle between Standard (default) and Dimmer

Move to previous/next configuration menu

Aux1 Interlock

Disable

Aux1 Freeze

Disable

Toggle between Enabled and Disabled Aux1 Freeze(default)

Move to next menu item

Move to previous/next configuration menu

for manual on/off, countdown

timer and timeclock functions

Move to next menu item

Rotates between

for all functions except dimmer relay, solar

super chlorinate, and low speed

f

super chlorinate, and low speed

or all functions except dimmer relay,

Aux1 Group

Filter: Unaffected

Aux1 Group

Timer: None(Manual)

Options available depend on the function that is selected

Rotates between Manual On/Off (default),Countdown Timer and Timeclock

Move to previous/next menu item or next configuration menu

Move to next menu item

for group function only

for group function only

!

• Ensure that Power is disconnected prior to wiring the OnCommand

• Follow all local and NEC (CEC if applicable) codes

• Use copper conductors only

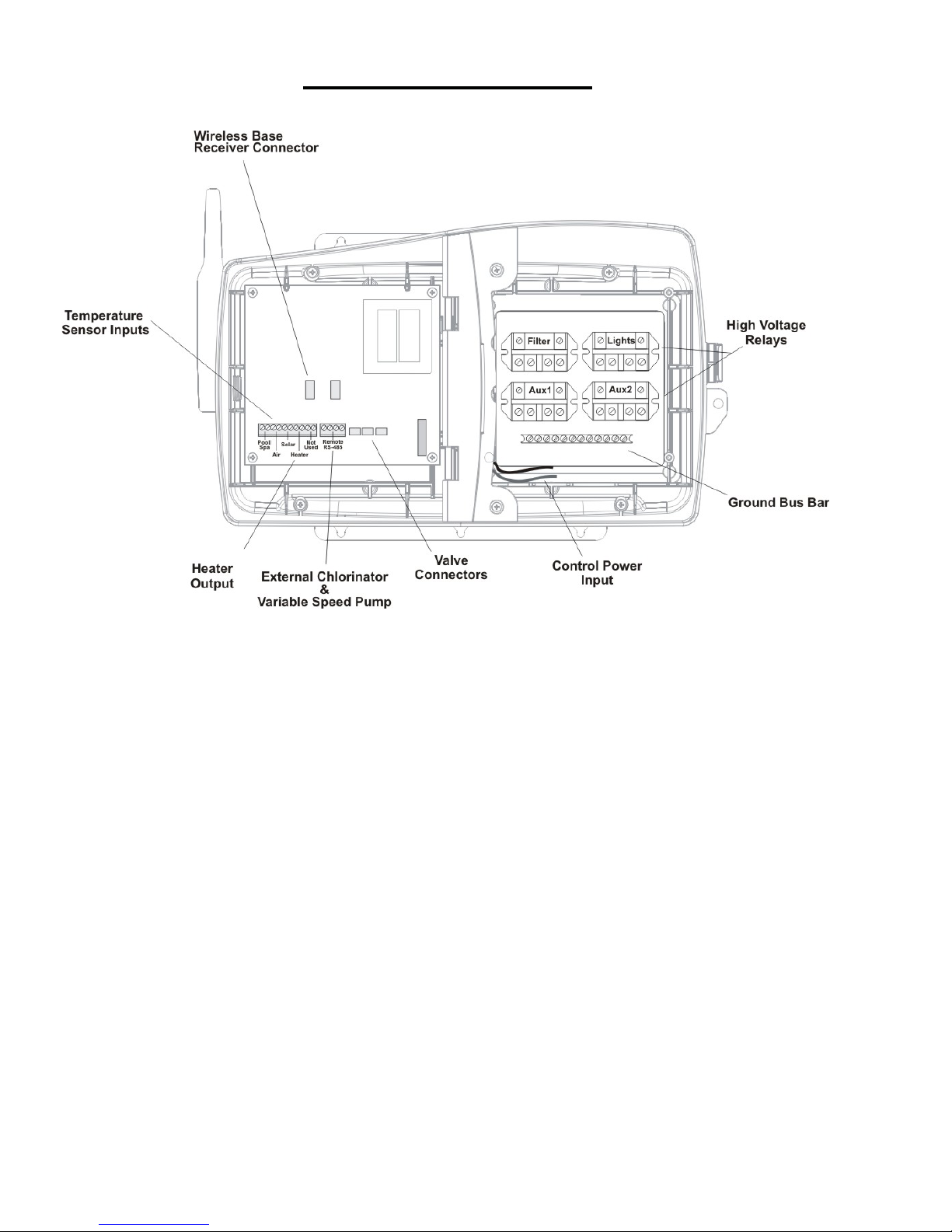

The OnCommand requires both high and low voltage connections. To gain access to the wiring compartments,

open the door and remove the left and right panel covers. A divider separates the OnCommand into low voltage

and high voltage compartments. All low voltage connections will be made to the printed circuit board (PCB) on the

left side of the divider. These connections include actuators, sensors, heaters, etc. All high voltage connections

such as PCB input power, pumps, lights, etc. are made on the right side of the divider.

Grounding

A ground bus bar is located in the high voltage compartment of the OnCommand. Connect a ground wire from the

primary electrical panel to this ground bus bar. Also use this ground bar to ground each piece of high voltage (120

or 240VAC) equipment that is connected to the OnCommand control relays.

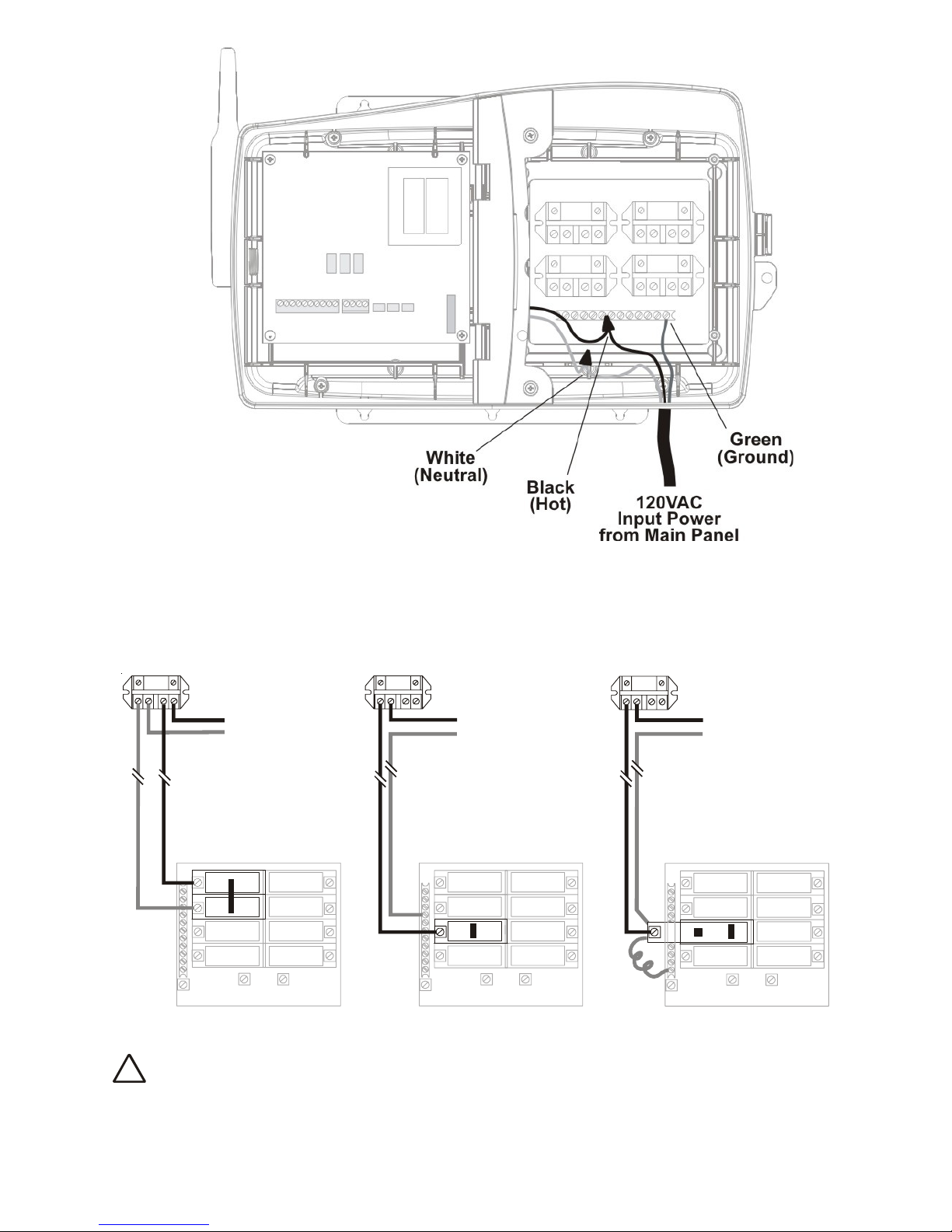

High Voltage Wiring

Input Wiring

The OnCommand requires 120VAC, .6A input power to operate the control logic circuits under maximum load.

This power should come from a circuit breaker rated at 125% of the intended load or the next higher size available.

Leads are supplied for input wiring as shown on the diagram on the following page.

5

Page 9

High Voltage (120/240V) Pool Equipment

!

240 VAC

Load

120 VAC

Load

Wiring relays for 240 VAC

Pool Equipment

Wiring relays for 120 VAC

Pool Equipment

Load

Pool Equipment

All OnCommand relays are double pole (they make/break both “legs” of 240V circuits) and are rated at 3HP/25A

at 240V (1½HP/25A at 120V). Refer to the diagram below for typical relay wiring.

120 VAC

WARNING: Do not use the OnCommand to control an automatic pool cover. Swim-

mers may become entrapped underneath the cover.

Wiring GFCB for 120 VAC

621

Page 10

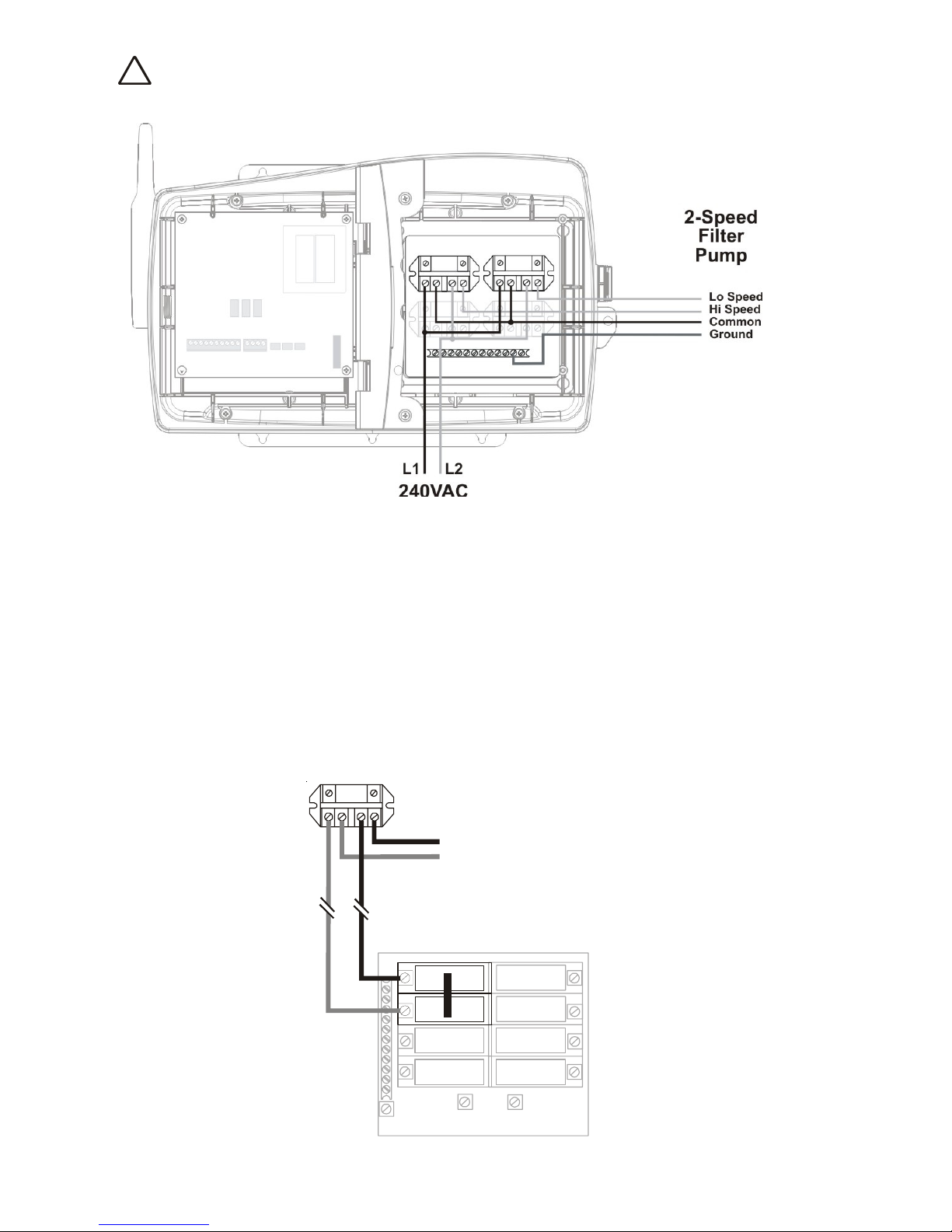

Two speed filter pump: Requires 2 relays (FILTER plus one of the AUX relays) for proper operation of both

!

Lights Pump Spd

Settings Menu

only if filter pump is set to variable

and relay type is set to standard

Move to previous/next configuration menu

Lights Config.

+ to view/change

Lights Function

Manual On/Off

Lights Relay

Standard

Push to access Lights options

Rotates between

Low Speed- Filter, Timeclock, Solar, and Super Chlorinate

Toggle between Standard (default) and Dimmer

Move to previous/next configuration menu

Move to next menu item

Lights Interlock

Disable

Lights Freeze

Disable

Toggle between Enabled and Disabled (default) Lights Freeze

Move to next menu item

Move to next menu item or previous/next configuration menu

f

super chlorinate, low speed, and group

or all functions except dimmer relay, solar

f

super chlorinate, low speed, and group

or all functions except dimmer relay,

for manual on/off, countdown

timer and timeclock functions

Lights Group

Filter: Unaffected

Lights Group

Timer: None(Manual)

Options available depend on the function that is selected

Rotates between Manual On/Off (default),Countdown Timer and Timeclock

Move to previous/next menu item or next configuration menu

Move to next menu item

for group function only

for group function only

power to VSC

speeds.

IMPORTANT: Be sure to follow the wiring diagram below AND to configure the control

logic according to the Operation Instructions.

Lights: A ground fault circuit breaker must be used to supply power for high voltage pool/spa lighting. Low

voltage lights will require an external transformer. For lighting systems that have both a light source and color

wheel, connect the light source to the “Lights” relay and then connect the color wheel to one of the AUX outputs.

Hayward Variable Speed Filter Pump: Proper installation of the Hayward TriStar Variable Speed Control

(VSC) includes high voltage input wiring, communication wiring, and menu configuration/settings. Refer to the

following diagram for proper input wiring to the VSC. Wiring from a 240V breaker must connect through the

OnCommand’s Filter relay. The Filter relay is used to supply input power to the VSC pump control. The relay will

be on when the filter pump output is on. When the filter pump output is off, the relay will be off. Note that when

the filter pump relay is off (power off to the VSC), the OnCommand will not display errors or diagnostics for the

pump. The filter pump relay must be on for diagnostic function.

240 VAC input

7

Page 11

Low Voltage Wiring

Heater

Kill Switch

Thermostat

Valve Actuators

The OnCommand can control up to three automatic valve actuators. Two of the valve outputs are dedicated to the

pool/spa suction (Valve2) and return (Valve1) valves. Valve3 is for general purpose use (solar, water feature, infloor cleaner, etc.).

For installations with solar heating, Goldline offers the AQ-SOL-KIT-xx solar kit that contains a valve, actuator,

and extra temperature sensor. The “xx” indicates the valve type from the choices below:

-1P 1.5” Positive Seal

-2P 2” Positive Seal

The OnCommand is compatible with standard valve actuators manufactured by Hayward, Pentair/Compool, and

Jandy. See diagram on page 5 for the location of valve connectors.

Heater Control

The OnCommand provides a set of low voltage dry contacts that can be connected to most gas heaters or heat

pumps with 24V control circuits. Refer to the diagram on the following page for a generic connection. The

manuals supplied with most heaters also include specific wiring instructions for connecting the heater to an external

control (usually identified as “2-wire” remote control). For millivolt or line voltage heaters, contact Goldline Tech

support, 908-355-7995. Refer to the diagrams and the information on the following pages for more details on the

connection to several popular heaters.

Generic Heaters

1. Wire heater to 120/240V power source per the instructions in the heater manual. The OnCommand does

NOT control the power going to the heater.

2. Wire the OnCommand dry contact heater output per the diagram below. Many internal parts of the heater can

get very hot--see the heater manufacturer’s recommendations on the minimum temperature rating for wires. If

no guidance is given, use 105°C rated wire.

3. Set any ON/OFF switch on the heater to ON.

4. Set the thermostat(s) on the heater to the maximum (hottest) setting.

Ignition/Valve

8

Page 12

Laars Heaters

Heater Config.

+ to view/change

Heater

Disable

Heater Cooldown

Disabled

Heater Extend

Disabled

Push to access heater options

Toggle between Enabled and Disabled (default) Heater

Toggle between Enabled and Disabled (default) Heater Cooldown

Toggle between Enabled and Disabled (default) Heater Extend

Move to previous/next configuration menu

Move to next menu item or previous/next configuration menu

Move to next menu item

Move to previous/next configuration menu

if “Heater1” is enabled

if “Heater1” is enabled

Allow Low Speed

Disabled

Move to

if “Heater1” is enabled and

1-speed filter pump is not selected

to limit switches

remove jumper

white

white

Terminal block located at

electrical junction box

Dipswitch located on heater

circuit board

PK

W

R

BK

R

ONºC

OFF

ºF

1. Turn power off to heater.

2. Remove factory jumper from terminal block.

3. Wire OnCommand to the heater as shown.

4. Ensure toggle switch is in the ON position.

5. Set heater thermostats to maximum position.

Fusible Link

Hayward Heaters

Refer to the instructions in the heater manual for “2-wire Remote Thermostat” operation under “Remote Control

Connections” and the diagram below:

1. Turn off power to heater.

2. Wire OnCommand to terminals 1 & 2 (see diagram).

3. Leave jumper attached to terminals 4 & 5.

4. Move “BYPASS” dipswitch on heater circuit board to “ON” position (up).

5. Turn heater power back on.

6. Switch heater to either “Pool” or “Spa” (it doesn’t make any difference which is selected, the OnCommand will

take control).

7. Heater display should be “bO” (for “bypass On).

8. Heater will fire whenever OnCommand requests (when OnCommand “Heater” LED is illuminated).

Do not remove jumper

9

Page 13

Pentair/Purex/MiniMax

!

MINIMAX

Ext.

Switch

Remove

Factor y Jumper

P7

Light Blue

Black

Orange Stripe

Orange

StripeBlack

RAYPAK RP2100

Switch to heater relay.

1. Turn power off to heater.

2. Remove factory installed jumper from the “Ext Switch” connector.

3. Wire the OnCommand to the “Ext Switch” connector as shown below.

4. The wires to the OnCommand must be separated from any line voltage wires. Failure to follow these

instructions may cause erratic operation of the heater.

5. Set the Power (Thermostat Select) switch to either “Pool” or “Spa”.

6. Set the “Pool” and “Spa” thermostats to their maximum settings.

Raypak RP2100 Pool/Spa Heater

1. Turn power off to heater.

2. Push the mode button to “spa” mode.

3. Set the temperature to the maximum.

4. Push the mode button to “OFF”.

5. Lastly, plug the prewired connector in the P7 position on the board.

IMPORTANT: The heater will display “OFF” when it is being remotely controlled by the

OnCommand. Some homeowners see the “OFF” display and, thinking this is a mistake, change the

mode to “POOL” or “SPA” which then disables the remote control by the OnCommand. To prevent

this: Remove the heater touch pad connector (P5) which will disable the touchpad.

Drawing is for digital heater. If heater is a

millivolt (analog) run red wires from Fireman’s

10

Page 14

STA-RITE Heater

Pool/Spa Config.

+ to view/change

Pool/Spa Setup

Pool and Spa

Spa Spillover

Enabled

Filter Operation

Spa Spillover

Push to access Pool/Spa options

Rotates between Pool Only (default), Spa Only and

Pool and Spa

(default)

(default)

Move to previous/next configuration menu

Move to next menu item

Move to previous/next configuration menu

if “Pool and Spa” is selected and

if “Spa Spillover” is enabled

Spa - CountDn

00:30

Move to next menu item

if “Pool and Spa” is selected

if “Pool and Spa” is selected

V1=Aux1, V2=Aux2

Disabled

(default)

if “Pool Only” or “Spa Only” is selected

Filter Off Valve

Change: Enabled

Toggle between Enabled and Disabled (default)

if “Pool and Spa” is selected

STA-RITE

Terminal

Board

Operating

‘Control

Firema n’s

Switch

4

4

2

233

1

1

Y

Y

VSC

“1” to “1”, “2” to “2”, e tc.

1. Turn power off to heater.

2. Remove upper jacket and open the control box.

3. Remove the jumper for the “fireman’s switch.

4. Wire to the OnCommand using wire rated for 105°C minimum.

Hayward Variable Speed Filter Pump: Refer to the diagram below for proper low voltage communication

wiring between the OnCommand and the Hayward Tristar Variable Speed Control (VSC).

Connect screw terminals

Use four conductor cable (typically phone cable) for communications connection between the VSC and the

OnCommand. The maximum wiring distance is 500 feet (160 meters). Note that the terminals on both the VSC

interface board and the OnCommand main board are numbered. The terminal connections should be matched

between both terminal blocks (connect 1 to 1, 2 to 2, etc.). The communications cable should be routed through

the knockout hole on the left side of the VSC enclosure, and a watertight fitting should be used to keep water and

debris out of the opening. The communications cable should also be routed away from the OnCommand and VSC

power connections if possible.

GRN

EL

BLK

RED

RED

BLK

GRN

EL

11

Page 15

VSC Pump Address Setting

AIR

SENSOR

SOLAR

SENSOR

POOL/SPA

SENSOR

optional

The VSC address must be set to 001 when using the VSC with the OnCommand. Refer to the TriStar Pump

Owner’s Manual (IS3220VSC) and Hayward document IS3220VSCAQLL for specific instructions on setting

the pump address.

Temperature Sensors

The OnCommand utilizes 10K ohm thermistor type sensors. Three sensors (water temperature, air temperature

and solar temperature) are included. If the OnCommand is being used to control a solar heating system, the solar

sensor is required. The sensors are provided with a 15 ft. cable. If a longer cable is required, contact the Goldline

Technical Support department for information on suitable cable types and splices. See page 2 and the diagram

below for installation information.

Base Station

Plug in the pigtail connector from the wireless base station into the “wireless” connector on the main PCB in the

OnCommand control unit.

12

Page 16

Goldline Aqua Rite or Hayward Swimpure Chlorinator

4

3

2

1

GRN

BLK

YEL

RED

ONCOMMAND

Swimpure

green

yellow

black

red

ONCOMMAND

A

or

Swimpure

A

or

Swimpure

Additional

A

(if required)

Jumper Removed

For Secondary(s)

Jumper Installed

For Primary

YELLOW

BLACK

RED

Pool/Spa Unaffected, Pool only, Spa only, or Spillover

Pool Filter Unaffected, Off, On, High speed, or Low speed

or

Function Control Parameter

Lights Unaffected, Off, or On

Lights Unaffected, Off, On, 100%, 80%, 60%, 40%, or 20%

Aux1&2 Unaffected, Off, On

Aux1&2 Unaffected, Off, On, 100%, 80%, 60%, 40%, or 20%

Valve3 Unaffected, Off, or On

Spa Htr1 Set Unaffected, Off, 65º-104ºF

Pool Htr1 Set Unaffected, Off, 65º-104ºF

Spa Solar Set Unaffected, Off, 65º-104ºF

Pool Solar Set Unaffected, Off, 65º-104ºF

SuperChlr Unaffected, Off, On

Spa High Unaffected, 20% to Highest speed

Spa Low Unaffected, Lowest speed to 50%

Pool High Unaffected, 20% to Highest speed

Pool Low Unaffected, Lowest speed to 50%

(sta ndard rela y)

(dimmer relay)

(s

(dimmer relay)

tandar d relay)

The OnCommand can control one or more Goldline Aqua Rite or Hayward Swimpure chlorinators when additional sanitizing capacity is required. A 4 wire connection is used to communicate to the Aqua Rite/Swimpure and

can be wired up to 500' apart. Any outdoor rated 4 conductor cable can be used. Refer to the wiring diagrams

below for proper wiring connection to the Aqua Rite/Swimpure. NOTE: There must be only 1 "primary" unit. All

other Aqua Rite/Swimpure units must be configured as "secondary".

GREEN

4

3

2

1

(Factory Default)

qua Rite/Swimpure(s)

qua Rite

(Primary)

NOTE: Primary/Secondary jumper is located underneath small circui t board.

4. Configuration Setup

After plumbing and wiring are complete, the OnCommand MUST BE CONFIGURED before attempting to

operate. Configuration information is entered at the keypad and “tells” the OnCommand what equipment is

connected and how each should be controlled.

Group Function

The OnCommand offers the ability to assign one Group function to a particular button. Instead of the button

controlling one particular function, the button can be programmed to initiate a sequence of commands that are

programmed in the Configuration Menu. For example, instead of the Lights button turning on and off the pool light

only, the button can be programmed to turn on the pool light, turn on the bug light, turn off the pool cleaner, and turn

on the music all at the same time. This convenient feature can be assigned to either one of the Aux buttons, the

Lights button or the Valve 3 automated function.

Before assigning and configuring all the desired functions and their control parameters within the group, the group

itself must be configured. The options for controlling groups are Manual On/Off, Countdown Timer, and Timeclock.

The group will turn on and off based on this selection.

When setting up a Group function in the Configuration Menu, the first menu allows you to select the control

parameter (how the group is activated and de-activated) and the second menu allows you to select which functions

are to be controlled in the group.

13

(Secondary)

qua Rite

4

GRN

3

YEL

2

1

RED

Aqua Rite/

BLK

Page 17

A table of functions and their corresponding control parameters are listed below.

Pool/Spa Unaffected, Pool only, Spa only, or Spillover

Pool Filter Unaffected, Off, On, High speed, or Low speed

or

Function Control Parameter

Lights Unaffected, Off, or On

Lights Unaffected, Off, On, 100%, 80%, 60%, 40%, or 20%

Aux1&2 Unaffected, Off, On

Aux1&2 Unaffected, Off, On, 100%, 80%, 60%, 40%, or 20%

Valve3 Unaffected, Off, or On

Spa Htr1 Set Unaffected, Off, 65º-104ºF

Pool Htr1 Set Unaffected, Off, 65º-104ºF

Spa Solar Set Unaffected, Off, 65º-104ºF

Pool Solar Set Unaffected, Off, 65º-104ºF

SuperChlr Unaffected, Off, On

Spa High Unaffected, 20% to Highest speed

Spa Low Unaffected, Lowest speed to 50%

Pool High Unaffected, 20% to Highest speed

Pool Low Unaffected, Lowest speed to 50%

(sta ndard rela y)

(dimmer relay)

(s

(dimmer relay)

tandar d relay)

Note that all functions in the table may not be offered. The available functions are dependent on how the OnCommand

is configured. Also, under some circumstances, functions will be displayed but can’t be changed. Note that the

function whose menu you are in, will not be displayed as an option and will automatically turn on when the group is

activated. For example, if programming a Group function under the Lights menu, the Lights function will not be

offered as an option and the Lights function will automatically turn on with the group.

The available control parameters vary with each function. All functions offer “Unaffected”, which should be

selected if you do not wish to control that particular function within the group. All other parameters will depend on

the particular function selected.

Heater Setpoints in Groups

The OnCommand can be programmed to use alternate heater setpoints (conventional and/or solar) while running

a group command. This allows the heater to be set to a higher or lower temperature than normal, while the group

is activated. When the group stops, the setpoint will return to its normal setting.

Changing the setpoint while the group is running will make the group release the alternate setpoint control and

revert back to the normal heater setting. Any changes that are made at that point will affect the normal heater

setting. The next time the group is activated, the temperature will return to the group setpoint that was originally

programmed in the Configuration Menu. To change the setpoint while the group is running, go to the Settings menu

and press the +/- button while “Group Control” is displayed. The setpoint will change and be retained as the new

normal heater setpoint.

Super Chlorinate (requires external chlorinator)

If a Hayward Swimpure or Goldline Aqua Rite chlorinator is used, the OnCommand can be programmed to Super

Chlorinate the pool or spa while running a group command. When the group starts, the Super Chlorinate cycle will

begin. Super Chlorinate will continue until the preset time expires (see Timers Menu/Super Chlorinate Hours) or

until the group turns off. Changing the Super Chlorinate state using the Settings Menu, the Aqua Pod Super

Chlorinate button, or a Super Chlorinate assigned Aux/Lights/Valve button will temporarily cancel the group’s

control of Super Chlorinate until the next time the group is activated.

14

Page 18

Variable Speed in Groups

Configuration

Menu-Unlocked

Configuration

Menu-Locked

Press repeatedly until “Configuration Menu” is displayed

Move to configuration menu items

Move to next menu item

Ext. Chlorinator

Enabled

Display

Salt

Chlor. Config.

+ to view/change

Move to previous/next configuration menu

Move to next configuration menu

Push to access Chlorinator option

AIR

SENSOR

SOLAR

SENSOR

POOL/SPA

SENSOR

optional

The OnCommand can be programmed to use alternate pump speeds while running a group command. This allows

the pump to be set to a higher or lower speed than normal, while the group is activated. When the group stops, the

speed will return to its normal setting.

Changing the speed setting while the group is running will make the group release the alternate speed setting and

revert back to the normal speed setting. Any changes that are made at that point will affect the normal speed

setting. The next time the group is activated, the speed will return to the group speed setting that was originally

programmed in the Configuration Menu. To change the speed setting while the group is running, go to the Settings

menu and press the +/- button while “Group Control” is displayed. The speed setting will change to the normal

speed setting.

Accessing the Configuration Menus

Configuring the OnCommand requires that you navigate through the Configuration Menu and input various information. For more detailed information about using the OnCommand menu system, refer to the Operation Manual.

To access the Configuration Menu

Press BOTH buttons SIMULTANEOUSLY for 5 seconds to unlock

NOTE: The configuration menu automatically “locks” after 2 minutes of no buttons being pressed to

prevent unauthorized people from changing the control logic inadvertently and possibly damaging

the pool equipment or causing a “call back” to fix the configuration.

Configuration Menu Items

Each item needs to be programmed and may contain additional sub-menu items. Refer to the following pages for

information on programming.

Toggle between External Chlorinator Enabled and Disabled (default)

Toggle between Display Salt (default) and Minerals

Chlorinator

If the optional external chlorinator is enabled (requires the use of a Goldline Aqua Rite or Hayward

Swimpure chlorinator), the OnCommand will automatically chlorinate both the pool and spa according

to the desired output setting (see Settings Menu in the Operation manual). If disabled (default), all

displays relating to the chlorinator will be suppressed.

When the chlorinator is enabled, the OnCommand will automatically detect and control any Aqua

Rite/Swimpure(s) that is installed in the system.

Display

Allows for the display of salt (default) or mineral values.

15

Page 19

Pool/Spa Config.

+ to view/change

Pool/Spa Setup

Pool and Spa

Spa Spillover

Enabled

Filter Operation

Spa Spillover

Push to access Pool/Spa options

Rotates between Pool Only (default), Spa Only and

Pool and Spa

(default)

(default)

Move to previous/next configuration menu

Move to next menu item

Move to previous/next configuration menu

if “Pool and Spa” is selected and

if “Spa Spillover” is enabled

Spa - CountDn

00:30

Adjust time setting (Manual On/Off, 0:05, 0:10, 0:15..., (default is 4:00))

Move to next menu item

if “Pool and Spa” is selected

if “Pool and Spa” is selected

V1=Aux1, V2=Aux2

Disabled

(default)

if “Pool Only” or “Spa Only” is selected

Filter Off Valve

Change: Enabled

Toggle between Enabled and Disabled (default)

if “Pool and Spa” is selected

Toggle between Enabled and Disabled Spa Spillover

Move to next menu item or previous/next configuration menu

Toggle between Pool Only and Spa Spillover options

Toggle between Enabled and Disabled

Move to previous/next configuration menu

Move to previous/next configuration menu

Pool/Spa Setup

If “Pool Only” or “Spa Only” are selected, then the pool/spa valves are not needed and pushing the

POOL/SPA button on the display/keypad will have no effect. If “Pool and Spa” is selected, then the

pool/spa suction and return valve actuators should be connected to the OnCommand. Pressing the

POOL/SPA button on the display/keypad will alternate between pool and spa operation.

Spa CountDn

This menu will appear only if Pool/Spa Setup is set to “Pool and Spa”. This setting is the time, after

you manually switch the Pool/Spa valves to “Spa Only”, until the OnCommand automatically returns

the valves to their previous positions. It is programmed in increments of 5 minutes, from “Manual On/

Off” (0 minutes) to “21:00” (21 hours). The filter is forced on during this time period.

Spa Spillover

When spa spillover is “Enabled” and “Pool and Spa”, the homeowner will be able to rotate through

“Pool Only” (both suction and return valves switched to pool), “Spa Only” (both suction and return

valves switched to spa) and “Spillover” (suction valve switched to pool and return valve switched to

spa) by successive presses of the “Pool/Spa button.

Filter Operation

If “Spa Spillover” is selected, the OnCommand will automatically switch the pool/spa suction and

return valves to “spillover” at the start of the programmed pool filtering time period or when the super-

chlorinate function is turned on. The valves will remain in this position for the remainder of the superchlorinate period. This option is usually preferable because both the pool and spa water will be

filtered and sanitized.

If “Pool Only” is selected, then the OnCommand will switch the pool/spa valves to the “pool only”

position at the start of the programmed pool filtering time period or when the super-chlorinate function

is turned on. This may be desirable on some systems with in-floor cleaners because it allows the

cleaner to operate all the time the pool is being filtered and/or the super chlorinate is running.

V1=Aux1, V2=Aux2

This menu appears only if the Pool/Spa Setup is “Pool Only” or “Spa Only”. When enabled, Valve 1

(return) will follow the Aux1 output and Valve 2 (suction) will follow the Aux2 output. When disabled

(default), the return and suction pool/spa valves function normally.

Filter Off Valve Change

This menu appears only if Pool/Spa setup is set to “Pool and Spa - Std”. When enabled (default), the

filter pump will shut off for 35 seconds whenever the Pool/Spa valves are turning. The pump will NOT

shut off when a heater is in Heater Cooldown mode.

16

Page 20

!

Filter Config.

+ to view/change

Filter Pump

1 Speed

Freeze Protect

Enabled

Lowest Speed

10%

Highest Speed

100%

Push to access pump options

Rotates between 1-speed (default), 2-speed and variable speed options

Toggle between Enabled (default) and Disabled Freeze Protection

Adjust the lowest speed desired for variable speed operation

Adjust the highest speed desired for variable speed operation

Move to next menu item

Move to previous/next configuration menu

Move to next menu item or previous/next configuration menu

Move to next menu item

Move to next menu item

if “Variable Speed” is selected

if “Variable Speed” is selected

Freeze Temp

38ºF

Freeze Protect

High Speed

Adjust the desired freeze protection temperature (33ºF - 42ºF)

Toggle between high speed (default) and low speed

Move to previous/next configuration menu

Move to next menu item

if “Freeze Protect” is enabled

if “Freeze Protect” is enabled

and “1-speed Filter” is not selected

MINIMAX

Ext.

Switch

Remove

Factor y Jumper

P7

Light Blue

Black

Orange Stripe

Orange

StripeBlack

RAYPAK RP2100

Switch to heater relay.

Filter Pump

For 2-speed pumps: When a 2-speed pump is configured, one of the AUX relays must also be

configured to control the low speed motor winding on the pump. Refer to the appropriate sections in

the Installation manual for specific information regarding the control logic for 2-speed and variable

speed pump operation.

For the Hayward Tristar variable speed pump: The Filter relay is used to supply input power to the

VSC pump control. The relay will be on when the filter pump output is on. When the filter pump

output is off, the relay will be off. On , off and speed is controlled by commands sent to the pump.

Lowest Speed

This is the lowest speed that the variable speed pump is allowed to run at. It is used as the lower limit

in the Low Speed Settings Menu. Set lowest speed from 10% (default) to 50%.

Highest Speed

This is the highest speed that the variable speed pump is allowed to run at. It is used as the upper limit

in the High Speed Settings Menu. Also, this is the speed that the pump will run at during the first 3

minutes of operation anytime the pump has been off for more than 30 seconds. Set highest speed from

20% to 100% (default).

Freeze Protection

Freeze protection is used to protect the pool and plumbed equipment against freeze damage. If freeze

protection is enabled and the AIR temperature sensor falls below the freeze threshold (see below), the

OnCommand will turn on the filter pump to circulate the water. If “Pool and Spa” is selected in the Pool/

Spa sub-menu, the valves will also alternate between the pool and spa every 30 minutes and the filter

pump will turn off while the valves are turning. The chlorinator will not operate if freeze protection is

the only reason the pump is running.

Freeze Protection Speed

This menu only appears if freeze protection is enabled and the pump is configured for 2-speed or

variable speed pump operation. This is the speed that the pump will run at during freeze protection

operation. Select high (default) or low speed operation.

Freeze Protection Temperature

Select the temperature to be used for freeze protection. Temperature is adjustable from 33ºF - 42ºF

(1ºC - 6ºC). 38ºF (3ºC) is default. This threshold will be used for all outputs that have freeze protection

enabled.

17

Page 21

Heater Config.

+ to view/change

Heater

Disable

Heater Cooldown

Disabled

Heater Extend

Disabled

Push to access heater options

Toggle between Enabled and Disabled (default) Heater

Toggle between Enabled and Disabled (default) Heater Cooldown

Toggle between Enabled and Disabled (default) Heater Extend

Move to previous/next configuration menu

Move to next menu item or previous/next configuration menu

Move to next menu item

Move to previous/next configuration menu

if “Heater1” is enabled

if “Heater1” is enabled

Allow Low Speed

Disabled

Toggle between Enabled and Disabled (default)

Move to

if “Heater1” is enabled and

1-speed filter pump is not selected

next menu item or previous/next configuration menu

Heater

If the heater is “Enabled”, the heater relay will turn on when the water temperature is less than the

desired temperature setting and the filter pump is running. The desired temperature is in the “Settings

Menu”. If applicable, the homeowner will be prompted to enter separate “pool” and “spa” settings.

Depending on the position of the pool/spa suction valve, the proper temperature setting will be used.

Heater Cooldown

This feature ensures that the heater cools down before water circulation is stopped. When enabled,

the OnCommand will continue to run the filter pump for 5 minutes after the heater turns off. During

this period the filter pump LED will flash and also a “Heater Cooldown, X:XX remaining” message will

scroll on the display.

When the filter pump is running and the heater is on: Pressing the “Filter” button once will cause the

heater to turn off, but the filter pump will continue to run for heater cooldown (filter LED flashing and

message on display). Pushing the filter button a second time will override the heater cooldown

operation and turn the filter pump off.

Heater Extend

If “Enabled”, the filter extend logic keeps the filter pump running beyond the normal turn-off time until

the pool (or spa) is heated up to the desired temperature setting (see Settings Menu). Heater extend

will NOT cause the filter pump to turn on, it will only delay the turn off time when the heater is

operating.

Allow Low Speed

This menu only appears if the filter is configured for 2-speed or variable speed operation. During

default operation, high speed mode is used whenever the heater is on. If Allow Low Speed is enabled,

low speed will be allowed even if the heater is on.

18

Page 22

Solar Config.

+ to view/change

Solar

Disabled

Solar-Extend

Disabled

Solar Priority

Disabled

Push to access solar options

Toggle between Enabled and Disabled (default) Solar

Toggle between Enabled and Disabled (default) Solar Extend

Move to previous/next configuration menu

Move to next menu item or previous/next configuration menu

Move to next menu item

Move to next menu item

if “Solar” is enabled

if “Solar” is enabled

Allow Low Speed

Disabled

Move to

if “Solar” is enabled and

“1-speed Filter” is not selected

Heater

Kill Switch

Thermostat

Toggle between Enabled and Disabled (default) Solar Priority

Toggle between Enabled and Disabled (default)

next menu item or previous/next configuration menu

Solar

If the solar control logic is “Enabled”, several additional steps must be taken to ensure proper operation

of the solar system. If the solar is operated by a valve, then the Valve3 output must be setup for solar

logic. If the solar is operated by a pump, then one of the AUX relays must be set up for solar logic.

Also, the “solar” temperature sensor must be installed. This sensor is typically mounted near the

collector array and is used to sense whether sufficient solar heat is available.

If solar is “Enabled”, the valve or solar pump relay will turn on when the water temperature is less than

the desired temperature setting AND the solar sensor is hotter than the water. The desired temperature

is in the “Settings Menu”. If applicable, the homeowner will be prompted to enter separate pool and

spa desired temperature settings. Depending on the position of the pool/spa suction valve, the

proper temperature setting will be used.

Solar Extend

If “Enabled”, the filter extend logic keeps the filter pump running beyond the normal turn-off time if

solar heat is still available. When solar heat is no longer available, both the solar valve/pump and filter

pump will turn off simultaneously. Solar extend will NOT cause the filter pump to turn on, it will only

delay the turn off time when solar is operating.

Solar Priority

If both “Solar Control” and “Heater Control” are enabled, the Solar Priority feature will keep the

conventional heater off whenever solar heat is available. This provides the most cost effective way of

heating the pool. When solar heat is not available, the conventional heater will operate normally.

Allow Low Speed

This menu only appears if the pool filter is configured for 2-speed or variable speed operation. During

default operation, high speed mode is used whenever the solar heater is on. If Allow Low Speed is

enabled, low speed pump operation will be allowed during solar heating except for the first 3 minutes

after solar heat turns on.

19

Page 23

Lights Pump Spd

Settings Menu

only if filter pump is set to variable

and relay type is set to standard

Move to previous/next configuration menu

Lights Config.

+ to view/change

Lights Function

Manual On/Off

Lights Relay

Standard

Push to access Lights options

Rotates between

Manual On/Off (default), Countdown Timer,

Low Speed- Filter, Timeclock, Solar, and Super Chlorinate

Toggle between Standard (default) and Dimmer

Move to previous/next configuration menu

Move to next menu item

Lights Interlock

Disable

Lights Freeze

Disable

Toggle between Enabled and Disabled (default) Lights Freeze

Move to next menu item

Move to next menu item or previous/next configuration menu

f

super chlorinate, low speed, and group

or all functions except dimmer relay, solar

f

super chlorinate, low speed, and group

or all functions except dimmer relay,

for manual on/off, countdown

timer and timeclock functions

Lights Group

Filter: Unaffected

Lights Group

Timer: None(Manual)

Options available depend on the function that is selected

Rotates between Manual On/Off (default),Countdown Timer and Timeclock

Move to previous/next menu item or next configuration menu

Move to next menu item

for group function only

for group function only

Move to next menu item or previous/next configuration menu

Toggle between Enabled and Disabled (default) Lights Interlock

Select between Settings Menu (default) and the desired pump speed

Lights Function

Although designated as the “Lights” output, the function of the lights relay is similar to the aux1 and

aux2 relays. If pool lights are wired to the lights relay, some options including Solar function, Low

Speed of a 2-Speed Filter Pump, Lights Interlock and Lights Freeze Protection will not be necessary

and should be disabled. If no pool lights are used, the lights relay can be used to control other pool

devices that may require these options. The function of each option is shown below.

Manual On/Off (default)—the lights relay will alternate between turning on and off when the LIGHTS

button is pressed. There is no automatic control logic.

Countdown Timer—the lights relay will turn on when the LIGHTS button is pressed. The lights relay

will turn off automatically after a programmed time (see Timers Menu in Operation Manual). The

LIGHTS button can also be used to turn the output off.

Low Speed of a 2-speed Filter Pump – the OnCommand will turn on the lights relay whenever the low

speed operation of the filter pump is required. It is very important that the “2-speed” filter pump

option be selected under the “Filter Config.” Menu for proper operation.

Timeclock – the lights relay will turn-on and turn-off at the times set for the lights timeclock in the

Timers Menu (see Timers Menu in Operation Manual). The LIGHTS button can also be used to turn

the output on and off.

Solar – the lights relay can operate a solar booster pump which will turn on when the filter pump is

running and solar heat is available and the water is less than the desired temperature setting. It is

important to note that “Solar Control” must be enabled in the “Solar Config.” menu for proper operation

to occur.

Group – the lights relay operates when the Group function is initiated and shuts off when the Group

function is terminated. See Lights Group section for operation information for the Group function.

Super Chlorinate – if “Chlorinator” is enabled, this option allows the user to start a Super Chlorinate

cycle when the Lights button is pressed, rather than using the Settings Menu. Note that only one

button can be assigned to this function.

20

Page 24

!

Lights Relay

240 VAC

Load

120 VAC

Load

Wiring relays for 240 VAC

Pool Equipment

Wiring relays for 120 VAC

Pool Equipment

Load

Pool Equipment

This feature allows the user to select either “Standard” (default) or “Dimmer” type relay for the Lights

output. The optional AQL-DIM dimmer kit must be installed if “Dimmer” is desired. When “Dimmer”

is selected, and the Lights output is manually turned on, the “+” and “-” buttons adjust the level from

20% to 100% (default). The level is saved for the next time the lights are turned from off to on.

Lights Interlock

If enabled, this feature will override the function (Manual On/Off, Countdown Timer, Timeclock)

selected above and turn the lights relay off when: filter pump is off, first 3 minutes of filter pump

operation (allows the pump to prime and get water flowing), when the pool/spa suction return valves

are in any position other than “pool only”, or for the first 3 minutes after solar turns on (allows air in

the solar panels to be purged). Interlock is not available for solar, low speed filter pump, super

chlorinate, dimmer or group.

Lights Group

The Lights Group function allows the user to perform multiple tasks with a single push of the “Lights”

button. When setting up a Group function, refer to page 13 for specific programming information.

There are two Group menus; the first menu determines how the group command will be initiated

(Manual On/Off, Countdown Timer, or Timeclock) and the second menu selects the desired functions

and their respective control parameters.

Lights Freeze Protection

This function helps protect equipment that is wired to the lights relay against freeze damage. If Freeze

Protection is enabled and the AIR temperature sensor falls below the selected freeze temperature

threshold, the OnCommand will energize the lights relay. IMPORTANT: this only enables operation

of the lights relay during freeze--see the “Filter Pump Config.” menu to enable freeze protection for the

main circulation system.

Lights Pump Speed

This is the speed of the pump when the Lights output is on. The choices are the Settings Menu speed

and a speed that is unique to the Lights output only. The default selection is “Settings Menu”. This

is the speed of the pump that has been selected in the Settings Menu for normal filter operation. If an

alternate speed is desired when the Lights output is on, push “+” or “-” and select from “Lowest” to

“Highest” in 5% increments.

Page 25

NOTE: The configuration parameters for the Aux2 output are the same as shown below for Aux1.

Aux1 Pump Spd

Settings Menu

only if filter pump is set to variable

and relay type is set to standard

Move to previous/next configuration menu

Aux1 Config.

+ to view/change

Aux1 Function

Manual On/Off

Aux1 Relay

Standard

Push to access Aux options

Toggle between Standard (default) and Dimmer

Move to previous/next configuration menu

Aux1 Interlock

Disable

Aux1 Freeze

Disable

Toggle between Enabled and Disabled Aux1 Freeze(default)

Move to next menu item

Move to previous/next configuration menu

for manual on/off, countdown

timer and timeclock functions

Move to next menu item

Rotates between

for all functions except dimmer relay, solar

super chlorinate, and low speed

f

super chlorinate, and low speed

or all functions except dimmer relay,

Aux1 Group

Filter: Unaffected

Aux1 Group

Timer: None(Manual)

Options available depend on the function that is selected

Rotates between Manual On/Off (default),Countdown Timer and Timeclock

Move to previous/next menu item or next configuration menu

Move to next menu item

for group function only

for group function only

!

Low Speed- Filter, Timeclock, Solar, and Super Chlorinate

Manual On/Off (default), Countdown Timer,

Move to next menu item or previous/next configuration menu

Toggle between Enabled and Disabled (default) Aux1 Interlock

Select between Settings Menu (default) and the desired pump speed

WARNING: Do not use the OnCommand to control an automatic pool cover. Swim-

mers may become entrapped underneath the cover.

Aux1 Function

Manual On/Off (default)—the aux relay will alternate between turning on and off when the aux button

is pressed. There is no automatic control logic.

Countdown Timer – the aux relay will turn on when the AUX button is pressed and then will turn off

automatically after a programmed time (see Timers Menu, Operation Manual). The AUX button can

also be used to turn the output off.

Low Speed of a 2-speed Filter Pump – the OnCommand will operate the aux relay whenever the low

speed operation of the filter pump is required. It is very important that the “2-speed” filter pump

option be selected under the “Filter Config.” Menu for proper operation.

Timeclock – the aux relay will turn-on and turn-off at the times set for the aux1 timeclock in the Timers

Menu. The AUX button can also be used to turn the output on and off.

Solar – the aux relay operates a solar booster pump which will turn on when the filter pump is running

and solar heat is available and the water is less than the desired temperature setting. It is important to

note that “Solar Control” must be enabled in the “Solar Config.” menu for proper operation to occur.

Group – the aux relay operates when the Group function is initiated and shuts off when the Group

function is terminated. See Aux1 Group section for operation information for the Group function.

Super Chlorinate – if “Chlorinator” is enabled, this option allows the user to start a Super Chlorinate

cycle when the Aux button is pressed, rather than using the Settings Menu. Note that only one

button can be assigned to this function.

22

Page 26

Pool/Spa Setup

Pool and Spa

Aux1 Relay

FILTER

SOLAR BOOST

PUMP

SOLAR

VALV E

HEATER

HEATER

BYPASS

VALVE

(manual)

CELL

FLOW

SWITCH

CHECK

VALVE

PUMP

RETURN

VALV E

WATER

FEATURE

VALV E

SPA

SPA JET

PUMP

SPA

BLOWER

POOL/SPA SUCTION

VALV E

CHECK VALVE

POOL VACUUM

VALV E

MANUAL

VALV E

MANUAL

VALV E

MANUAL

VALV E

ENERGY

FILTER

TWO-WAY

VALV E

SKIM

POP-UP

SPILLOVER

POP-UP

OVERFLOW

POP-UP

RETURN

JET

IN-FLOOR

CLEANER

VALVE

WATER

FEATURE

PUMP

WATER

FEATURE

POP-UP

MAIN

DRAIN

ENERGY

SAVER

PRESSURE

CLEANER

NON-BOOST

PRESSURE

CLEANER

PRESSURE

CLEANER

SUCTION

CLEANER

SENSOR

FILTER

PUMP

Valve Outp ut s

Filter Pump

Lights

Aux 1

Aux 2

Pool/Spa Suction

Pool/Spa Return

Val ve 3

HIGH VOLTAGE

LIGHTS

LOW VOLTAGE

LIGHTS

FIBER OPTIC

LIGHT SOURCE

COLOR WHEEL

ISOLATED

WATE R

FEATURE

PUMP

TEMPERATURE

SENSOR

CHECK

VALV E

(prevents drai ning

of raised sp as)

V

of raised spas)

control is used

This feature allows the user to select either “Standard” (default) or “Dimmer” type relay for the Aux1

output. The optional AQL-DIM dimmer kit must be installed if “Dimmer” is desired. When “Dimmer”

is selected, and the Aux1 output is manually turned on, the “+” and “-” buttons adjust the level from

20% to 100% (default). The level is saved for the next time the aux1 output is turned from off to on.

Aux1 Interlock

If “Enabled”, this feature will override the function (Manual On/Off, Countdown Timer, Timeclock),

selected above and turn the aux1 off when: filter pump is off, first 3 minutes of filter pump operation

(allows the pump to prime and get water flowing), when the pool/spa suction return valves are in any

position other than “pool only”, or for the first 3 minutes after solar turns on (allows air in the solar

panels to be purged). Interlock is not available for solar, low speed filter pump, super chlorinate,

dimmer or group.

Aux1 Group

The Aux1 Group function allows the user to perform multiple tasks with a single push of the “Aux1”

button. When setting up a Group function, refer to page 13 for specific programming information.

There are two Group menus; the first menu determines how the group command will be initiated

(Manual On/Off, Countdown Timer, or Timeclock) and the second menu selects the desired functions

and their respective control parameters.

Aux1 Freeze Protection

This function protects the pool, plumbing, and equipment against freeze damage. If Freeze Protection

is enabled and the AIR temperature sensor falls below the selected freeze temperature threshold, the

OnCommand will turn on the aux relay to circulate the water. IMPORTANT: this only enables

operation of the AUX output during freeze--see the “Filter Pump Config.” menu to enable freeze

protection for the main circulation system.

Aux1 Pump Speed

This is the speed of the pump when the Aux1 output is on. The choices are the Settings Menu speed

and a speed that is unique to the Aux1 output only. The default selection is “Settings Menu”. This

is the speed of the pump that has been selected in the Settings Menu for normal filter operation. If an

alternate speed is desired when the Aux1 output is on, push “+” or “-” and select from “Lowest” to

“Highest” in 5% increments.

23

Page 27

Valve 3 Pump Spd

Settings Menu

only if filter pump is set to variable

and relay type is set to standard

Move to previous/next configuration menu

Valve3 Freez e

Disabled

Toggle between Enabled and Disabled (default) Valve3 Freeze

Move to previous/next configuration menu

for all functions except super chlorinate

Valve3 Config.

+ to view/change

Valve3 Function

Solar

Push to access Valve3 options

Rotates between k

Timecloc (default), Solar, In-floor Cleaner,

Filter, Lights, Aux1 and Aux2

Move to previous/next configuration menu

Move to next menu item

Valve3 Interlock

Disabled

Move to next menu item

for all functions except solar and super chlorinate

Toggle between Enabled and Disabled (default) Valve3 Interlock

Select between Settings Menu (default) and the desired pump speed

Valve3 Function

Timeclock (default) – the valve turns on/off at the times set for the valve3 timeclock in the Timers

Menu (see Operations Manual).

Solar – the valve operates when the filter pump is running and solar heat is available and the water is

less than the desired temperature setting. Solar heating must be enabled in the “Solar Config. menu

for proper operation to occur.

In-Floor Cleaner – the valve switches the water returning to the pool between the in-floor cleaner and

the normal return jets which facilitate efficient surface skimming. The valve will operate the in-floor

cleaner for the first half of each clock hour and then switch to the jets/skimming for the last half of the

hour.

Group – the valve operates when the Group function is initiated and shuts off when the Group

function is terminated. See Valve3 Group section for operation information for the Group function.

Valve3=Filter – the valve operates whenever the Filter relay is on.

Valve3=Lights – the valve operates whenever the Lights relay is on.

Valve3=Aux1 – the valve operates whenever the Aux1 relay is on.

Valve3=Aux2 – the valve operates whenever the Aux2 relay is on.

Valve3 Interlock

If “Enabled”, this feature will override the function (timeclock or in-floor cleaner) selected above and

turn the valve off when: the filter pump is off, first 3 minutes of filter pump operation (allows the pump

to prime and get water flowing), or for the first 3 minutes after solar turns on (allows air in the solar

panels to be purged). Interlock is not available for solar or super chlorinate.

Valve3 Group

The valve3 Group function allows the user to perform multiple tasks when the automated valve3

function is initiated. When setting up a Group function, refer to page 13 for specific programming

information. There are two Group menus; the first menu determines how the group command will be

initiated (Manual On/Off, Countdown Timer, or Timeclock) and the second menu selects the desired

functions and their respective control parameters.

Valve3 Freeze Protection

This function protects the pool and plumbed equipment against freeze damage. If Freeze Protection

is enabled and the AIR temperature falls sensor falls below the selected freeze temperature threshold,

the OnCommand will turn on the valve to allow circulation of the water. IMPORTANT: this only

enables operation of the valve3 output during freeze--see the “Filter Pump Config.” menu to enable

freeze protection for the main circulation system.

24

Page 28

!

Valve3 Pump Speed

Remote Menus

Enabled

Toggle between Enabled (default) and Disabled Remote Menus

Move to previous/next configuration menu

All Timeclocks

7-day

Move to previous/next configuration menu

Time Format

12 hour AM/PM

Units

ºF and PPM

Move to previous/next configuration menu

Move to previous/next configuration menu

Toggle between ºF and PPM (default) and ºC and g/L (Metric) options

Reset Config. to

Default Press +

Are you sure?

+ to proceed

Config. reset

Confirmed

Reset all configuration parameters

Move to previous/next configuration

Move to previous/next menu (config. not reset)

Move to previous/next configuration menu

This is the speed of the pump when the Valve3 output is on. The choices are the Settings Menu speed

and a speed that is unique to the Valve3 output only. The default selection is “Settings Menu”. This

is the speed of the pump that has been selected in the Settings Menu for normal filter operation. If an

alternate speed is desired when the Valve3 output is on, push “+” or “-” and select from “Lowest” to

“Highest” in 5% increments.

This feature will prevent unauthorized access to the Settings, Timers, and Configuration menus from

any of the OnCommand’s remote display/keypads. When disabled, the remote display/keypads will

only show the default menu and allow on/off control via the pushbuttons. Note that the function of

the OnCommand’s built-in display/keypad is unchanged by this selection. Once disabled, the only

way to enable “Remote Menus” is to use the local display/keypad.

Toggle between 7-day (default) and Weekend/Weekday time options

This selection affects ALL of the timeclock logic in the OnCommand. If “7-day” is selected, each

timeclock will have one set of turn-on/turn-off settings that operate every day of the week. If “Weekend/

Weekdays” option is selected then the user can enter one set of turn-on/turn-off times for the weekend

(fixed as Saturday/Sunday) and another set of turn-on/turn-off times for weekdays (Monday through

Friday).

Toggle between 12 hour AM/PM (default) and 24 hour time format options

Initiate reset of all configuration parameters

menu (config. not reset)

Use this function to erase all previous system configuration and reset all configuration parameters

back to the factory default values. This function is NOT reversible--be careful.

25

Page 29

5. System Startup and Checkout

Before Startup

Before starting the OnCommand for the first time, be sure that the following items have been completed:

1. Properly rated circuit breakers are installed in the OnCommand subpanel.

2. All wiring is performed according to NEC and local codes.

3. The OnCommand is properly grounded and bonded.

4. The OnCommand is properly configured to control all desired functions.

Program Automatic Operation

Refer to the programming flow chart on the back cover of this manual for a listing of the available menus and the

items included in each menu.

Settings Menu

Heater and/or solar thermostat settings

Chlorinator settings (if applicable)

Day and Time

Timers Menu

Timeclock and/or Countdown timer settings

Heater Checkout

Follow these instructions to verify that the OnCommand is properly controlling the heater.

1. Check that the OnCommand is calling for the heater to turn on as indicated by the “Heater” LED being illuminated. If the “Heater” LED is illuminated, go directly to step 2; if not, then check the following:

• The heater is enabled (Configuration Menu/Heater Config.).

• The heater temperature setting is at least 2ºF greater than the water temperature (Settings Menu / Pool

Heater & Spa Heater).

• The filter pump is running.

• If the pool has solar heat and the solar priority feature is enabled (Configuration Menu/Solar Config) then

solar must be off in order for the heater to fire. The easiest way to force solar off is to go to the Settings

Menu / Pool Solar & Spa Solar and temporarily lower the temperature settings below the current water

temperature.

2. Check that the heater is running. If not, then check:

• Power is supplied to the heater.

• The OnCommand control output is properly connected to the heater control (see ”Heater Control” wiring,

page 8).

• Some heaters also have internal switches or jumpers that have to be set correctly for remote control

operation—refer to the heater manual and also “Heater Control” (page 8).

• Heater is turned on (“Kill Switch” is in the “ON” position).

• If a heater bypass valve is installed, check that water is flowing through the heater.

• The heater temperature setting is set as high as possible (usually 104ºF/40ºC). Also note that some heat

pumps actually have be set to the lowest possible temperature.

3. Once the heater is running, you can verify the “heater cooldown” feature (optional - see Configuration Menu/

Heater Config.) is operating properly:

• Press the “Filter” button once (for 2 speed pumps, this may require 2 pushes of the “Filter” button).

• The heater should turn off (“Heater” LED off) and the “Filter” LED will flash to indicated heater cooldown

is active.

26

Page 30

• The display will periodically indicate that the filter pump is on for heater cooldown and show the minutes

remaining.

• The pump will automatically turn off at the end of the 5 minute heater cooldown period.

For more detailed instructions on control and operation of the OnCommand system, refer to the Operation Manual.

Service Mode

Service mode disables all automatic control operation and is intended to be used when servicing the pool system.

To enter service mode, push the SERVICE button once on the main unit keypad. This will initially turn all outputs

off and then allow you to turn outputs on/off manually at the main display (only). In service mode, the buttons on

the optional spa side remote will turn outputs off, but will not turn any output on. Heater control outputs and solar

control outputs are prevented from turning on if the water temperature exceeds 104ºF (40ºC).

Pushing the SERVICE button again will enter a timed service mode. Service operation as described above will

continue for 3 hours, then automatically return to normal operation.

Push the SERVICE button once more to exit out of Service mode.

27

Page 31

LIMITED WARRANTY (effective 04/01/09) Hayward/Goldline warrants its Pro Logic and E-Command

pool automation products as well as its Aqua Rite, Aqua Rite Pro, Aqua Plus and SwimPure chlorination products

to be free of defects in materials and workmanship, under normal use and service, for a period of three (3) years.

Hayward/Goldline also warrants its Aqua Trol chlorination products to be free of defects in materials and workmanship, under normal use and service for a period of one (1) year. These warranties are applicable from the initial

date of installation on private residential swimming pools in the US and Canada.

Hayward/Goldline warrants all the above-identified pool automation and chlorination products installed on commercial swimming pools and on swimming pools outside of the US and Canada for a period of one (1) year.

Likewise, Hayward/Goldline warrants all accessories and replacement parts for the above-identified pool automation and chlorination products for a period of one (1) year. Each of these warranties is not transferable and

applies only to the original owner.

Proof of purchase is required for warranty service. If written proof of purchase is not provided, the manufacturing

date code will be the sole determinant of the date of installation of the product. To obtain warranty service or

repair, please contact the place of purchase or the nearest Hayward/Goldline authorized warranty service center.

For more information on authorized service centers please contact the Hayward/Goldline Technical Service Support Center (61 Whitecap Road, North Kingstown RI, 02852) or visit the Goldline web site at