Page 1

IS2001540LS-99

OWNER’S GUIDE

Your Micro Star-Clear cartridge filter has an output rating of 1400 gallons (5299 L) per hour.

The filter and pump are combined on a molded mounting base and are manufactured from

durable, corrosion-proof materials. The system is designed for installation below the pool

water line.

The Micro Star-Clear filter system utilizes a reusable single element, reinforced polyester

filter cartridge to provide a high degree of water clarity with absolute minimum care.

Removal of the cartridge for routine cleaning is fast and easy to do.

The SP1540 series Power-Flo LX pump is a non-corrosive centrifugal pump with pressure,

flow and operation designed for swimming pool service and may be operated on an intermittent or continuous basis.

SYSTEM LOCATION

Though the system is designed for outdoor use, it is

advisable to protect electrical components from the

weather. Select a well-drained area, one that will not

flood when it rains.

Position the system below the swimming pool water

line and as close to the pool as possible. Set the

mounting platform level. Allow a minimum clearance

for cartridge removal. Be sure the pipe connections,

drain, etc., are accessible for convenient operation

and cartridge removal.

TO ASSEMBLE THE SYSTEM

Place pump and motor on mounting base. Align holes

in motor base with holes in mounting base and secure

with two screws and washers provided.

Securely thread sweep elbow, with 3-4 wraps of

Teflon pipe tape, into outlet of pump. Position so that

large thread end points back toward the motor, at an

angle, toward corner of base.

Thread the ball end of union, with union nut, into

filter connection marked “IN.” Use Teflon tape (3-4

wraps on thread) and screw in as far as possible hand

tight, then one additional turn with a wrench.

Adjust ball and socket and join by hand tightening

union nut. Do not overtighten.

All plumbing connections on the system are 1-1/2”

N.P.T. When making connections, use plastic maleend adapters and flexible hose. Apply three turns of

Teflon tape or plastic pipe sealant to the male

threads. Screw the fitting into the thread hand tight;

then using a wrench, tighten one more full turn.

Additional tightening is unnecessary and could

result in damage to components.

NOTE: For extra convenience, you may wish to install

valves on the inlet and discharge of the system to

prevent back flow of water when removing cartridge.

See dealer for further information.

Connect the pool suction plumbing between the

skimmer pool outlet, and the pump. Connect the pool

return (inlet) plumbing.

A drain plug is furnished with each filter and is all

that is needed for complete filter draining. Amanual

air vent valve is furnished to aid in bleeding off

unwanted air when starting the filter.

All electrical connections must be made in

accordance with local codes.

Check for joint leaks before operating the system.

Refer to pump instruction booklet for pump

information.

BEFORE STARTING THE FILTER

Superchlorinate the pool water by adding unstabilized

granular or liquid chlorine. Stabilized forms of chlorine

are recommended for normal daily use after the initial

clean up of the water. Follow chemical manufacturer ’s

recommendations for superchlorination and daily use.

STARTING THE FILTER

Open manual air vent valve a few turns. CAUTION: All

suction and discharge valves must be open when

starting the system. Failure to do so could cause

severe personal injury and/or property damage.

Prime and start the pump following the manufacturer’s

instructions. Air trapped in the system will automatically

vent to the pool and out vent valve. Close vent valve as

soon as air is vented.

1.

2.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

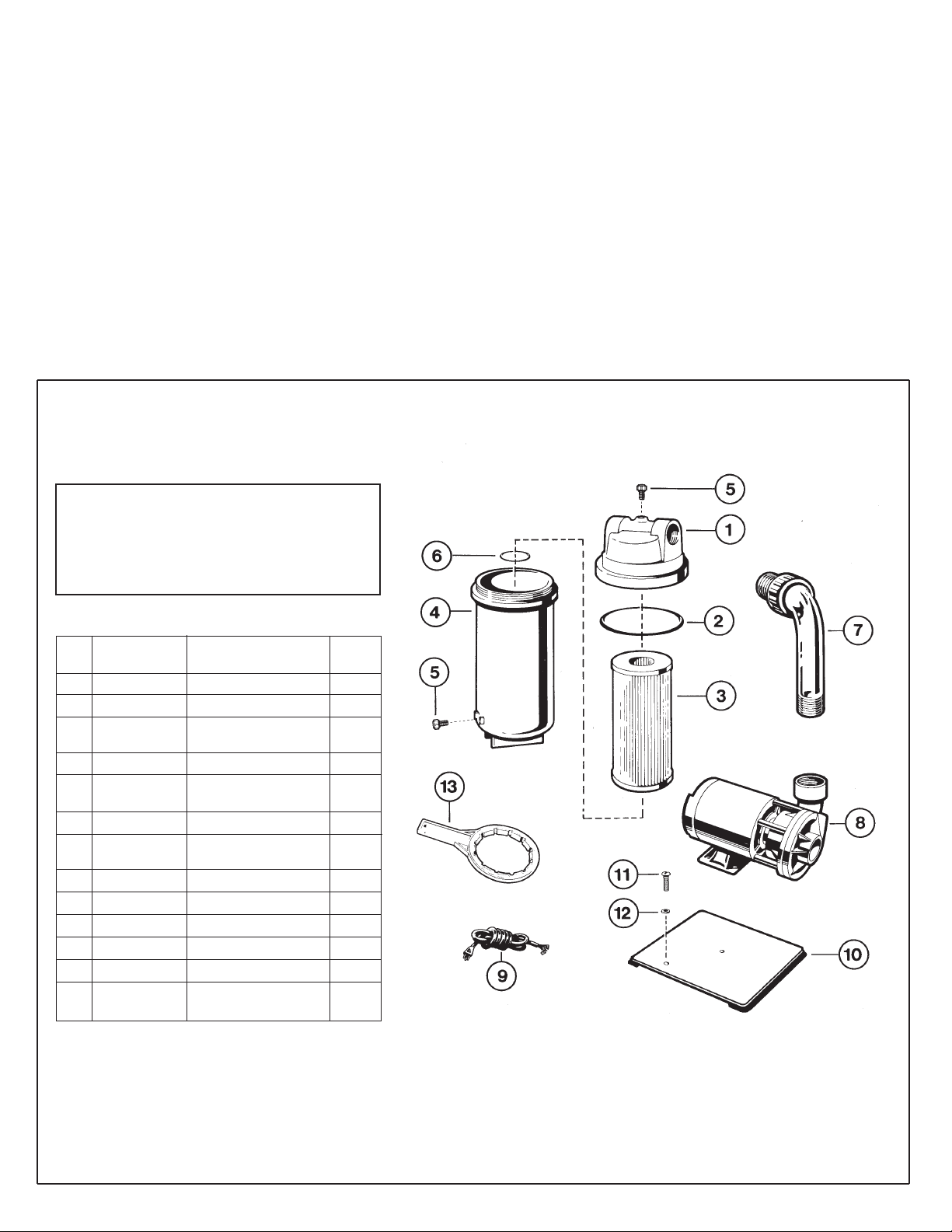

MODEL C2001540LS SERIES

Page 2

FILTERING

Filtration starts as soon as flow is steady through the

filter. As the filter cartridge removes dirt from the pool

water, the accumulated dirt causes a resistance to flow.

As a result, pressure will rise and the flow will decrease.

When flow decreases below desired rate, clean or replace

the filter cartridge.

CLEAN/REPLACE CARTRIDGE

Removing Cartridge Element

Shut off the pump.

Block off suction and discharge lines (close valves if

used) to prevent back flow of water from pool.

Open top air relief valve and remove drain valve to

allow water to drain from filter.

Unscrew union nut, freeing filter from rigid union

connection.

Hold filter head firmly and unscrew filter housing to

remove. If difficult to unscrew, apply a lever between

the two tab extensions on the bottom of the filter

housing and apply a slight pressure to assist in

freeing the thread seal. Or, apply optional S200KT

wrench (if supplied) to bottom side tabs.

Remove cartridge element and clean. Or, replace

with clean, spare cartridge. (See Cleaning Cartridge)

1.

2.

3.

4.

5.

6.

PARTS

Model C2001540LS

1

2

3

4

5

6

7

8

9

10

11

12

13

1

1

1

1

2

1

1

1

1

1

2

2

---

CX120AA

CX120D

CX200RE

CX120B

ECX1321A

SPX1485C

SPX14858PAK

SP1540CLS

SPX1500WA

ECX12891

ECX1108

ECX1109

S200KT

Filter Head

O-Ring

Cartridge Element -

20 sq. ft.

Filter Body Housing

Air Relief Valve

with O-Ring

Gasket

Threaded Elbow

Union Assembly

Power-Flo LX Pump

6 Ft. Cord Set

Mounting Base

Mounting Screw

Washer

Wrench Tool for Body

(optional)

PART NO.

DESCRIPTION

REF.

NO

NO.

REQ’D.

NOTE; ANSI/NSPI-4 Article V, standard for above-ground and on-ground pools,

advises that components such as the filtration system, pumps and heater be

positioned so as to prevent their being used as a means of access to the pool

by young children.

Page 3

Reinstalling Cartridge Element

Clean any collected debris from the bottom of the

filter housing.

Reinstall cartridge in filter housing. Be sure O-ring is

in place on threads.

Clean O-ring. For ease of future disassembly, apply a

very light film of a dilute solution of non-granulated

liquid-type soap to O-ring and threads.

Screw filter housing with O-ring into filter head. Do

not overtighten. Tighten drain valve and top air relief

valve.

Secure to system with union nut.

Proceed as in Starting the Filter.

Cleaning Cartridge

The cartridge filter element can be cleaned by pressure

washing inside and out with a garden hose. Rotate

cartridge, hosing from top down. (The cartridge is easier

to clean when dry). After hosing the cartridge, for best

results, allow cartridge to dry and carefully brush

pleated surface areas to remove fine particles.

Algae, suntan oil and body oils can form a coating on the

cartridge pleats which may not be thoroughly removed by

hosing. To remove such materials, soak the cartridge in a

solution of filter element cleaner (various brands available

at pool dealer). Follow manufacturer ’s directions for use

and allow an hour for soaking. Hose thoroughly before

reinstalling in filter.

If calcium or mineral deposits are excessive, the cartridge

may be restored to “like new” condition by soaking in

muriatic acid. Use commercially available 20% muriatic

acid added to water in 1 to 1 ratio. Use a plastic container

and take extreme care when handling cleaning agents as

they can be harmful to eyes, skin and clothing. After

cleaning, flush with water.

VACUUMING

Vacuuming can be performed directly into the filter

whenever needed. Clean cartridge after vacuuming, if

required.

WINTERIZING

In areas where sub-freezing temperatures can be

expected, the filter should be drained and/or removed

from its operating location and stored indoors. Remove

and clean cartridge. Reinstall cartridge in filter tank.

Tighten cover only a few turns when storing.

SERVICE & REPAIRS

Consult your local and authorized Hayward dealer or

service center. No returns may be made directly to the

factory without the expressed written authorization of

Hayward Pool Products, Inc.

1.

2.

3.

4.

5.

6.

ALGAE CONTROL

Algae is a form of plant life which can vary in size from a

few thousandths of an inch to the size of a small tree. Of

the many forms of algae, those most frequently found in

swimming pool water are microscopic in size and green in

color .

Algae readily grows in sunlight and can, under favorable

conditions, quickly overgrow a swimming pool turning it

completely green in just a few hours. On the other hand,

swimming pool water can be kept unfavorable to algae

growth simply by maintaining a chlorine level of at least

1.0 ppm in the water at all times. The chlorine level

should be checked at least once a day using a suitable test

kit.

If an algae condition develops and the pool water

“blooms” green, superchlorination of the pool will be

necessary to clear it. Add unstabilized granular chlorine,

or liquid chlorine. Follow chemical manufacturer’s

recommendation for superchlorination. The algae will

quickly become inactive and can then be removed by the

filter. Live algae, on the other hand, multiplies so fast,

that the filter cannot keep up with its growth rate.

When correctly used, commercial algaecides are effective

against algae, though algaecides should be used in

conjunction with, and not as a substitute for, regular

chlorination or superchlorination.

Maintaining a chlorine level of at least 1.0 ppm in the

pool water at all times is the most effective way to

prevent algae growth in swimming pools.

POOL CHEMISTRY GUIDELINES

ACTION REQUIRED TO CORRECT POOL CHEMISTRY

TO RAISE

TO LOWER

SUGGESTED POOL CHEMISTRY LEVELS

pH

TOTAL ALKALINITY

CHLORINE (UNSTABILIZED)

CHLORINE (STABILIZED)

CHLORINE STABILIZER

(Cyanuric Acid)

7.2 to 7.6

100 to 130 ppm

0.3 to 1.0 ppm

1.0 to 3.0 ppm

40 to 70 ppm

Add Soda Ash

Add Sodium Bicarbonate

Add Chlorine Chemical

Add Chlorine Chemical

Add Stabilizer

Add Muriatic Acid or Sodium Bisulphate

Add Muriatic Acid

No action - chlorine will naturally dissipate

No action - chlorine will naturally dissipate

Dilution - partially drain & refill pool with water

that has not been treated with Cyanuric Acid.

Page 4

© 1999 Hayward Printed in U.S.A.

Rev. 4/99 A

Loading...

Loading...