Hayward ENP4MS, ENP1MS, ENP2MS, ENP3MS, ENP5MS Installation Instructions Manual

...

ENERGYLINE PRO

SWIMMING POOL HEAT PUMP UNIT

Installation & Instruction Manual

CONTENTS

1. Preface 1

2. Specifications 2

2.1 Technical data for the swimming pool heat pump unit 2

2.2 Operating range 3

2.3 Dimensions 4

3. Installation and connection 5

3.1 Functional diagram 5

3.2 Heat pump unit 6

3.3 Hydraulic connection 6

3.4 Electrical connection 7

3.5 Initial start-up 8

3.6 Water flow setting 10

4. User interface 11

4.1 Overview 11

4.2 Clock function/settings 13

4.3 Tuner function/settings 13

4.4 Operation mode selection: heating or

cooling 14

4.5 Setting and visualisation for the set point 15

4.6 Locking and unlocking the touch screen 15

5. Maintenance and Winterising 16

5.1 Maintenance 16

5.2 Winterising 16

6. Appendix 17

6.1 Electrical Diagrams 17

6.2 Heating priority wiring 22

6.3 Exploded view and spare parts 24

6.4 Troubleshooting guide 34

6.5 Warranty 35

Please read attentively and save for future consultation.

This document must be given to the pool owner and should be kept in a safe place.

1. PREFACE

We thank you for purchasing this Hayward swimming pool heat pump unit.

This product was designed according to strict manufacturing standards to

satisfy the required quality levels. This manual includes all of the necessary

information concerning installation, debugging and maintenance. Please

attentively read this manual before opening the unit or before carrying out

any maintenance operations on it. The manufacturer of this product will not,

under any circumstances, be held responsible in the case of injury to the

user or damage to the unit resulting from improper installation, debugging

or unnecessary maintenance. It is essential to follow all of the instructions

specified in the manual at all times. The unit must be installed by a qualified

professional.

• Repairs must be made by a qualified professional.

• All electrical connections must be made by a qualified electrician according

to standards in the country of installation see § 3.4.

• Maintenance and the different operations must be carried out at the

recommended times and frequencies as specified in this manual.

• Only use genuine spare parts.

• Failure to comply with these recommendations will invalidate the warranty.

• This swimming pool heat pump unit heats swimming pool water and

maintains a constant temperature; it should not be used for any other

purpose.

After having read this manual, keep it for future usage.

Warnings concerning children/people with reduced physical capacity:

This appliance is not intended to be used by persons (especially children)

with reduced physical, sensory or mental capabilities or by persons who lack

experience or knowledge, unless they are under supervision or have received

instructions concerning the use of the appliance by a person responsible for

their safety.

This product contains greenhouse effect fluorinated gases covered by the

Kyoto protocol.

Type of refrigerant: R410A

GAP Value

(1)

: 1975

Periodic inspections for refrigerant leakage can be required as a function

of European or local legislation. Please contact your local distributor for

additional information.

(1) Potential for global warming

1

2. SPECIFICATIONS

2.1 Technical data for the swimming pool heat pump unit

ENP1MS ENP2MS ENP3MS ENP4MS ENP5MS ENP4TS ENP5TS

PRO

ENERGYLINE

15

12.5

15

12,6

11

8

5,9

kW

51225

42690

51225

42690

37570

27000

20140

BTU/h

3 / 50Hz

380 V

3 / 50Hz

380 V

1 / 50Hz

230 V

1 / 50Hz

230 V

1 / 50Hz

230 V

1 / 50Hz

230 V

1 / 50Hz

230 V

V

Ph/Hz

875

980

1140/470/

1240/500/

875

980

1140/470/

1240/500/

875

980

1140/470/

1240/500/

875

980

1140/470/

1240/500/

875

980

1140/470/

1240/500/

660

760

1025/455/

1130/470/

660

760

1025/455/

1130/470/

/h 2,5 3,4 5 5,2 6 5,1 6,2

3

dB(A) 51 54 56 56 56 56 56

kPa 2 6 12 9 12 12 12

mm

kg 57/71 61/75 80/98 106/124 106/124 106/124 106/124

Models

Heating capacity*

Absorbed electrical power kW 1,28 1,74 2,4 2,5 3,4 2,85 3,3

Running current* A 5,75 7,8 11,3 12,6 14,9 5,7 6,1

Power supply

aM type fuse calibre A 10 aM 12 aM 16 aM 20 aM 25 aM 10aM 10aM

Curve D circuit breaker A 10 D 12 D 16 D 20 D 25 D 10D 10D

Compressor quantity 1 1 1 1 1 1 1

Type of compressor Rotary Rotary Rotary Scroll Scroll Scroll Scroll

Fan quantity 1 1 1 1 1 1 1

Fan power W 120 120 150 150 150 150 150

Fan rotation speed RPM 850 850 850 850 850 850 850

Ventilation Horizontal Horizontal Horizontal Horizontal Horizontal Horizontal Horizontal

Sound pressure level

(at 1 metre)

Hydraulic connection mm 50 50 50 50 50 50 50

Nominal water flow* m

Water pressure drop

(max)

Unit net dimensions (L/l/h) mm

Unit shipping dimensions

(L/l/h)

Net weight / shipping

weight

* Value at +/- 5% under the following conditions: Exterior temperature = 15°C (59°F) / HR = 71% / Water inflow temperature = 26°C (78.8°F) / ∆T water 2°C (3.6°F).

According to the NF 414 standard.

2

2. SPECIFICATIONS (continued)

2.2 Operating range

Use the swimming pool heat pump unit within the following ranges of

temperature and humidity to ensure safe and efficient operation.

Heating mode Cooling mode

Outside temperature -7°C ~ +35°C +7°C ~ +43°C

Water temperature +12°C ~ +35°C +8°C ~ +35°C

Relative humidity < 80% < 80%

Setting range from the set

point

If the temperature or humidity does not correspond to these conditions,

the security measures could be activated and the swimming pool heat

pump unit may no longer work.

The maximum heating temperature is set at 32°C to prevent damage to

the liners. Hayward cannot be held responsible if used at a temperature

above +32°C.

+15°C ~ +32°C +8°C ~ +32°C

3

2. SPECIFICATIONS (continued)

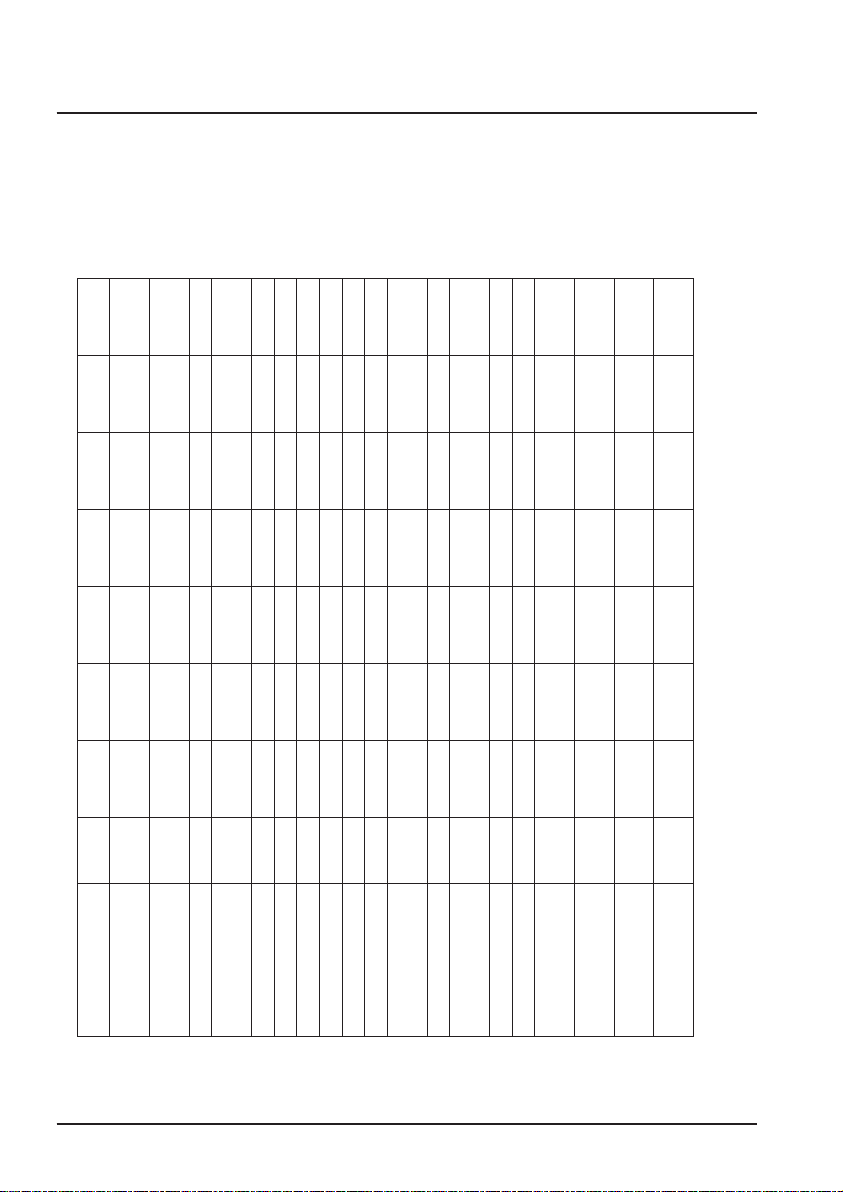

2.3 Dimensions

Models: ENP1MS/ENP2MS Unit: mm

Water inlet

50

66 0

Water outlet

Drainage

Frontal view

45 5

43 0

630

1025

Overhead view

Models: ENP3MS/ENP4MS/ENP5MS Unit: mm

ENP4TS/ENP5TS

12 0

50

27 0

25

82

Water inlet

50

87 5

Water outlet

Drainage

47 0

43 0

740

1140

12 0

50

40 0

25

82

4

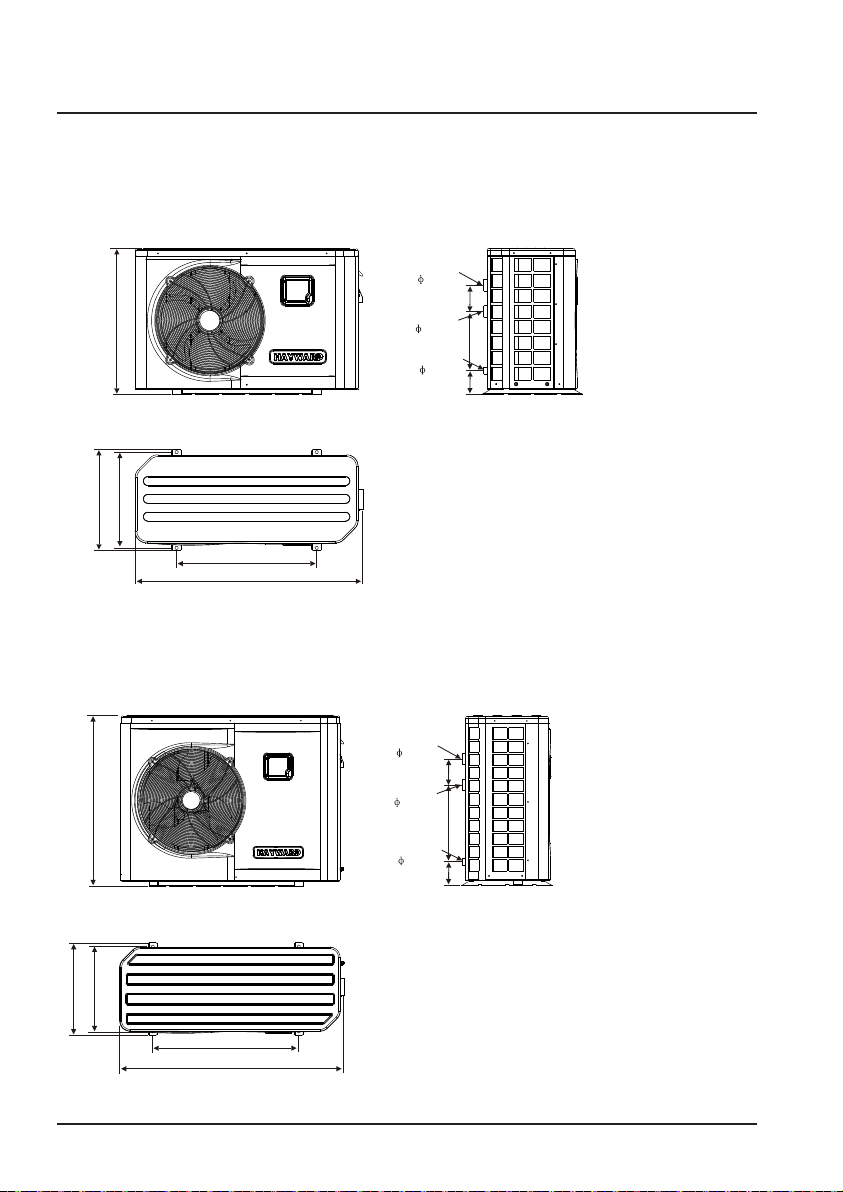

3. INSTALLATION AND CONNECTION

3.1 Functional Diagram

Water Inlet

valve

Water outlet

valve

By-pass

valve

Chlorinator cell

(or other treatment)

Filter

Water outlet

Pump

filtration

Pool

Note: The swimming pool heat pump unit is sold without any treatment or

filtration equipment. The components presented in the diagram are

spare parts to be supplied by the installer.

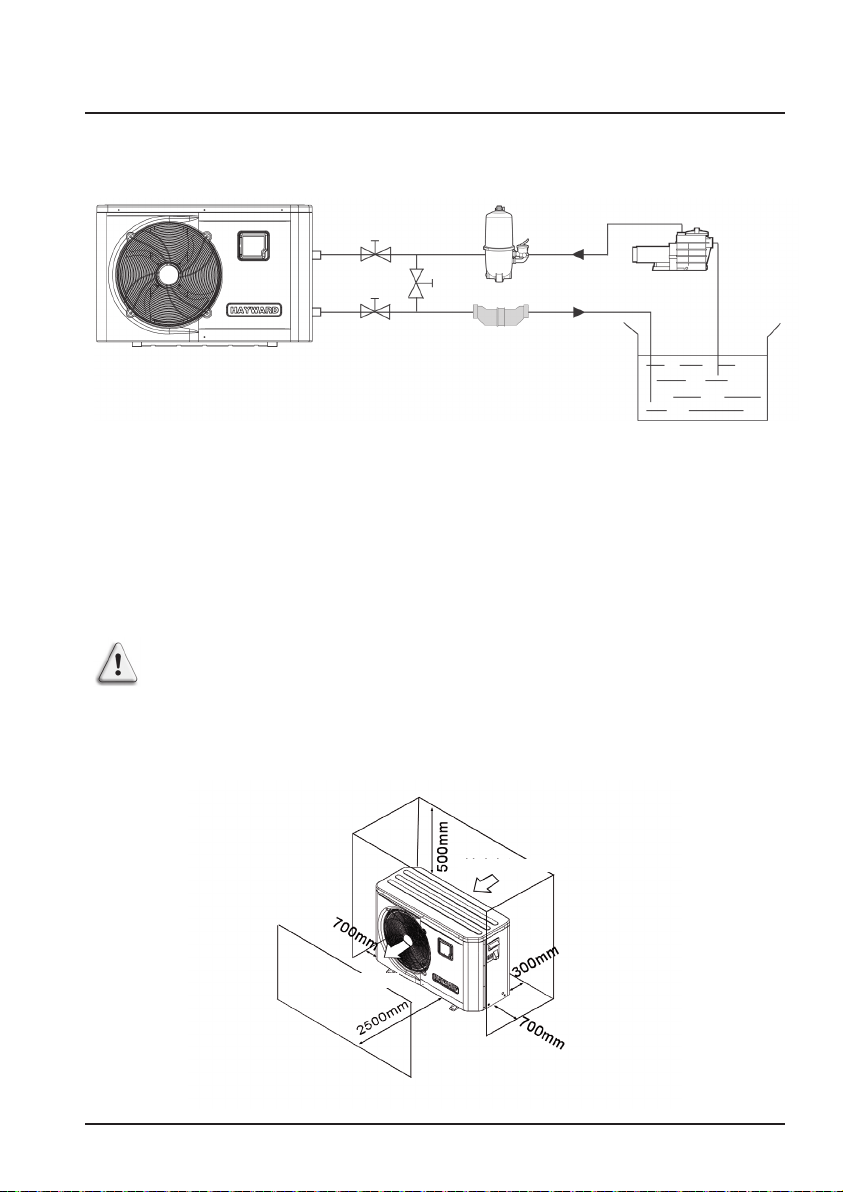

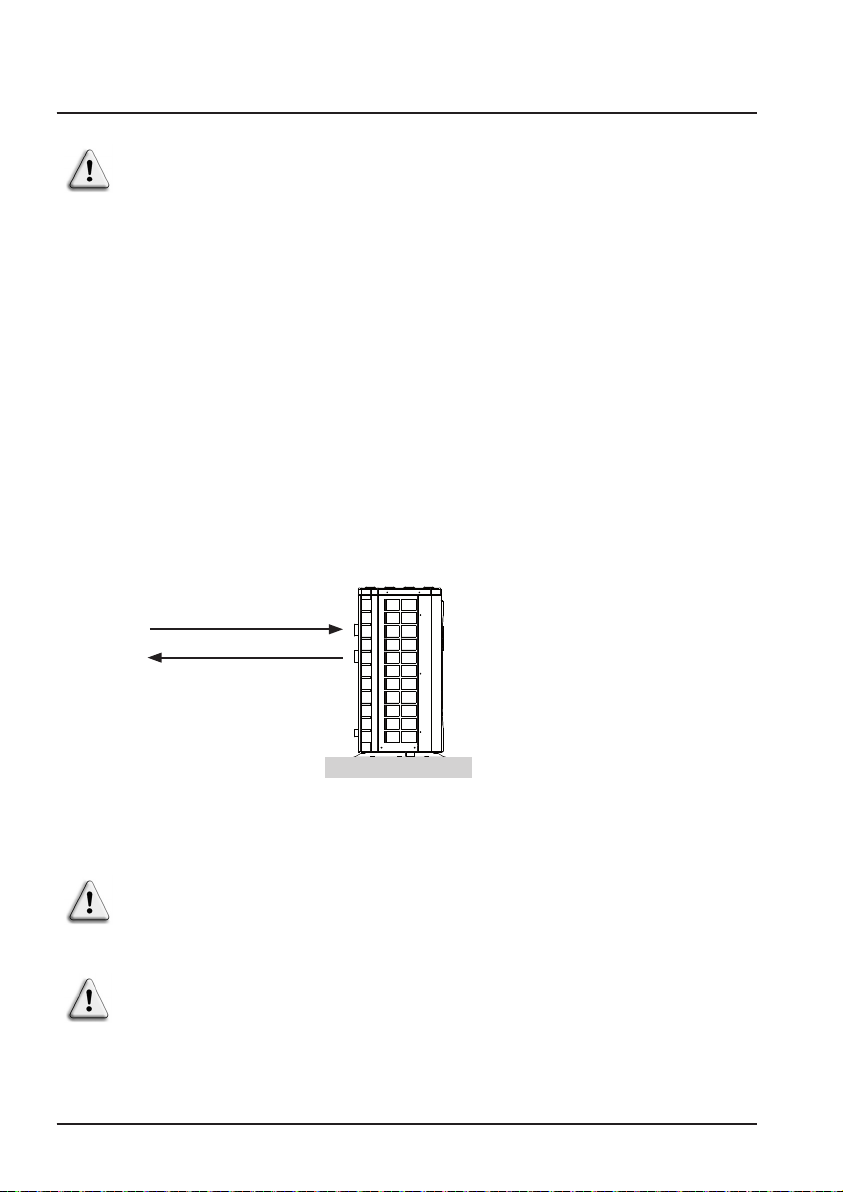

3.2 Heat pump

Place the heat pump outdoors and away from any enclosed technical

space.

Placed under a shelter, the minimum required distances mentioned

below must be respected in order to avoid any risk of air recirculation

and a deficiency in the unit's overall performance.

Air evacuation

Air intake

5

3. INSTALLATION AND CONNECTION (continued)

It is advised to install the unit on a dissociated cement block or a

mounting bracket designed for this use and to set up the unit on the

supplied rubber bushing (fastenings and washers not supplied).

The maximum installation distance between the unit and the swimming

pool is 15 metres.

The total length of the piping to and from the unit is 30 metres.

Insulate both the above ground and buried hydraulic piping.

3.3 Hydraulic connection

The unit is supplied with two 50 mm Ø union connections. Connect the water

inlet to the heat pump coming from the filtration group then connect the water

outlet to the heat pump at the water conduit going to the pool (see diagram

below).

of the filter Ø 50 ENTRY H2O

to the pool Ø 50 EXIT H2O

Install a by-pass valve between the heat pump entrance and exit.

If an automatic distributor or an electrolyser is used, it should be

installed imperatively after the heat pump with the goal of protecting the

titanium condenser against an elevated concentration of chemicals.

Be sure to install the by-pass valve and the supplied union connections

at the water inlet and outlet level in order to simplify purging during

the winter period and to facilitate access when disassembling for

maintenance.

6

3. INSTALLATION AND CONNECTION (continued)

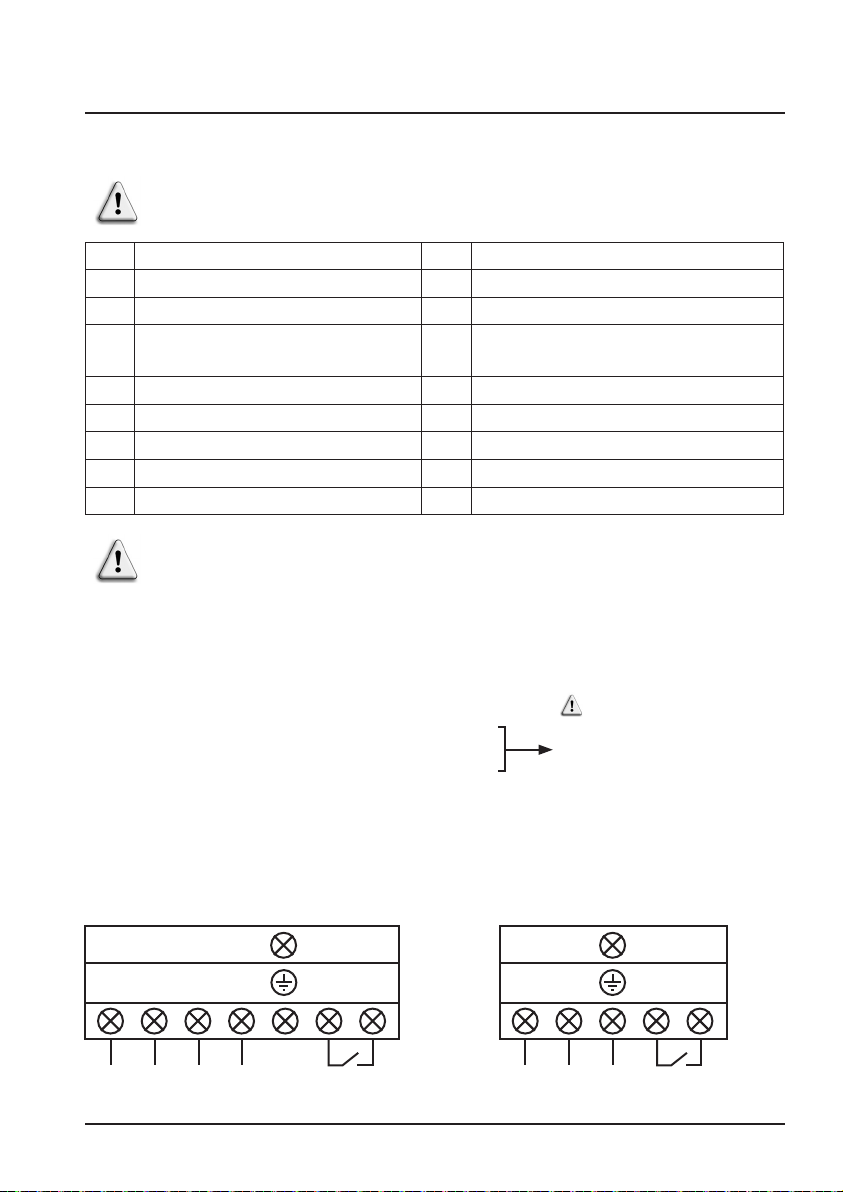

3.4 Electrical connection

Electrical installation and wiring for this equipment must be in

conformity with local installation standards.

F NF C15-100 GB BS7671:1992

D DIN VDE 0100-702 EW EVHS-HD 384-7-702

A ÖVE 8001-4-702 H MSZ 2364-702/1994/MSZ 10-553 1/1990

E UNE 20460-7-702 1993,

RECBT ITC-BT-31 2002

IRL Wiring Rules + IS HD 384-7-702 PL PN-IEC 60364-7-702:1999

I CEI 64-8/7 CZ CSN 33 2000 7-702

LUX 384-7.702 S2 SK STN 33 2000-7-702

NL NEN 1010-7-702 SLO SIST HD 384-7-702.S2

P RSIUEE TR TS IEC 60364-7-702

Verify that the available electrical power supply and the network

frequency correspond to the required operating current taking into

account the appliance's specific location, and the current required to

supply any other appliance connected to the same circuit.

ENP1MS 230 V~ +/- 10% 50 HZ 1 Phase

ENP2MS 230 V~ +/- 10% 50 HZ 1 Phase

ENP3MS 230 V~ +/- 10% 50 HZ 1 Phase

ENP4MS 230 V~ +/- 10% 50 HZ 1 Phase

ENP5MS 230 V~ +/- 10% 50 HZ 1 Phase

ENP4TS 380 V~ +/- 10 % 50 HZ 3 Phases

ENP5TS 380 V~ +/- 10 % 50 HZ 3 Phases

M MSA HD 384-7-702.S2

Check that the phases

balance does not exceed 2%

See the corresponding wiring diagram in the appendix.

The connection box is located on the right side of the unit. Three

connections are designed for the power supply and two are for

controlling the filter pump (Enslavement).

= = = =

R S T N

Power supply

380V~ / 50Hz

==

1 2

Dry contact 7 A max Dry contact 7 A max

= = = =

L N 1 2

Power supply

230V~ / 50Hz

7

3. INSTALLATION AND CONNECTION (continued)

The electrical power supply must have, when appropriate, a fuse

protection device like a feed motor (aM) or D curve circuit breaker as

well as a differential circuit breaker 30mA (see following table).

Models

Power supply V/Ph/Hz

aM type fuse

calibre

Curve D circuit

breaker

Cable section mm

Use an RO 2V/R 2V or equivalent power cord.

The cables sections are given for a maximum length of 25 m. They

must however be checked and adjusted according to the installation

conditions.

Always shut down the main power supply before opening the electrical

control box.

ENP1MS ENP2MS ENP3MS ENP4MS ENP5MS ENP4TS ENP5TS

230 V~

1/50 Hz

A 10 aM 12 aM 16 aM 20 aM 25 aM 10 aM 10 aM

A 10 D 12 D 16 D 20 D 25 D 10 D 10 D

3G2,5

2

3 x 2,5

230 V~

1/50 Hz

3G2,5

3 x 2,5

230 V~

1/50 Hz

3G2,5

3 x 2,5

230 V~

1/50 Hz

3G4

3 x 4

230 V~

1/50 Hz

3G6

3 x 6

380 V~

3/50 Hz

5G2,5

5 x 2,5

380 V~

3/50 Hz

5G2,5

5 x 2,5

3.5 Initial start-up

Start-up procedure - After installation is complete, follow these steps:

1) Rotate the fan by hand to verify that it can turn freely, and that the turbine

is correctly affixed to the motor shaft.

2) Ensure that the unit is connected correctly to the main power supply (see

the wiring diagram in the appendix).

3) Activate the filtration pump.

4) Verify that all water valves are open and that the water flows toward the

unit before switching on the heating or cooling mode.

5) Verify that the drainage hose is correctly affixed and that it causes no

obstructions.

6) Activate the unit power supply, then press the On/Off button on the

control panel.

8

3. INSTALLATION AND CONNECTION (continued)

7) Ensure that no ALARM code is displayed when the unit is ON (see

troubleshooting guide).

8) Set the water flow using the by-pass valve (see § 3.6 and 2.1), as

provided for by each model, to obtain an Entry/Exit temperature of 2°C.

9) After running for several minutes, verify that the air exiting the unit is cool

(between 5 and 10°).

10) With the unit operating, turn off the filter pump. The unit should

automatically turn off and display error code E03.

11) Allow the unit and the pool pump to run 24 hours per day until the

desired water temperature has been reached. When the set water inlet

temperature is reached, the unit will turn off. It will automatically restart (as

long as the pool pump is running) if the pool temperature is at least 0.5°C

below the set temperature.

Water flow switch - The unit is equipped with a flow switch that turns on the

heat pump when the pool filtration pump is running, and deactivates it when

the filtration pump is out of order. If the water is low, the E03 alarm code will

appear on the regulator (See § 6.4).

Time delay - The unit is equipped with a time delay of 3 minutes in order

to protect the control circuit components, to eliminate restart cycling and

contactor chatter. Thanks to this time delay, the unit automatically restarts

approximately 3 minutes after each control circuit interruption. Even a brief

power interruption will activate the restart time delay.

Phase switch - The Triphasic units include a phase switch to ensure that the

compressor is rotating in the correct direction. If the unit does not start, check

L1 L2 L3

the condition of the phase switch located in the electrical box.

4 Yellow/orange ON = Relay ON = Order and Phase number OK

4 Green = Power on

9

3. INSTALLATION AND CONNECTION (continued)

3.6 Water flow setting

With the water entry and exit valves being open, adjust the by-pass valve in

order to obtain a difference of 2°C between the inflow and outflow temperature

(see principle diagram § 3.1). You can verify the switch by seeing the entry/

exit temperatures directly on the control panel.

Water inlet temperature

Water outlet

temperature

Note: Opening the by-pass valve creates a weaker flow, which leads to an

increasein∆T.

Closing the by-pass valve creates a stronger flow, which leads to a

decreasein∆T.

10

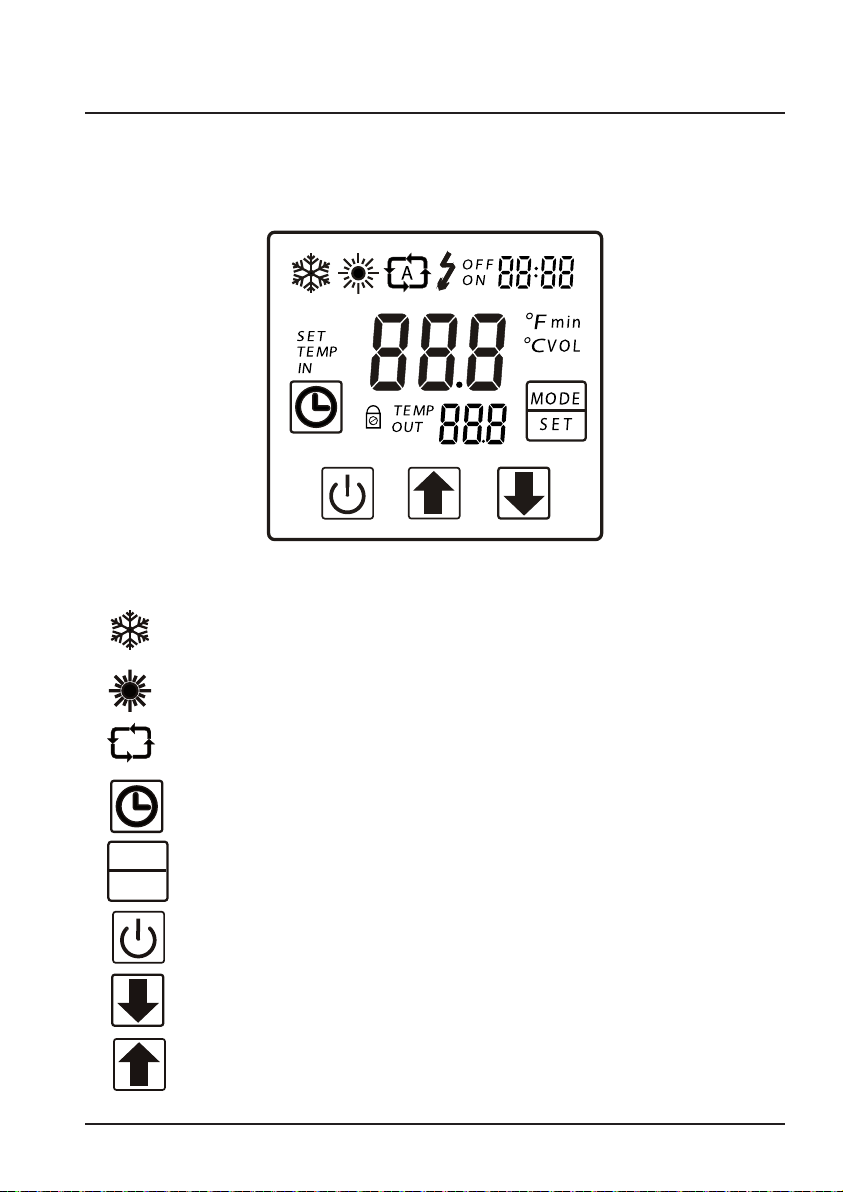

4. USER INTERFACE

4.1 General presentation

The heat pump is equipped with a digital control panel with a touch screen,

electronically connected and pre-set at the factory in heating mode.

Key

Symbol Cooling Mode

A

MO DE

S E T

Symbol Heating Mode

Automatic mode

Clock and timer settings

Selection and settings button

On/Off button and return

Scroll down

Scroll up

11

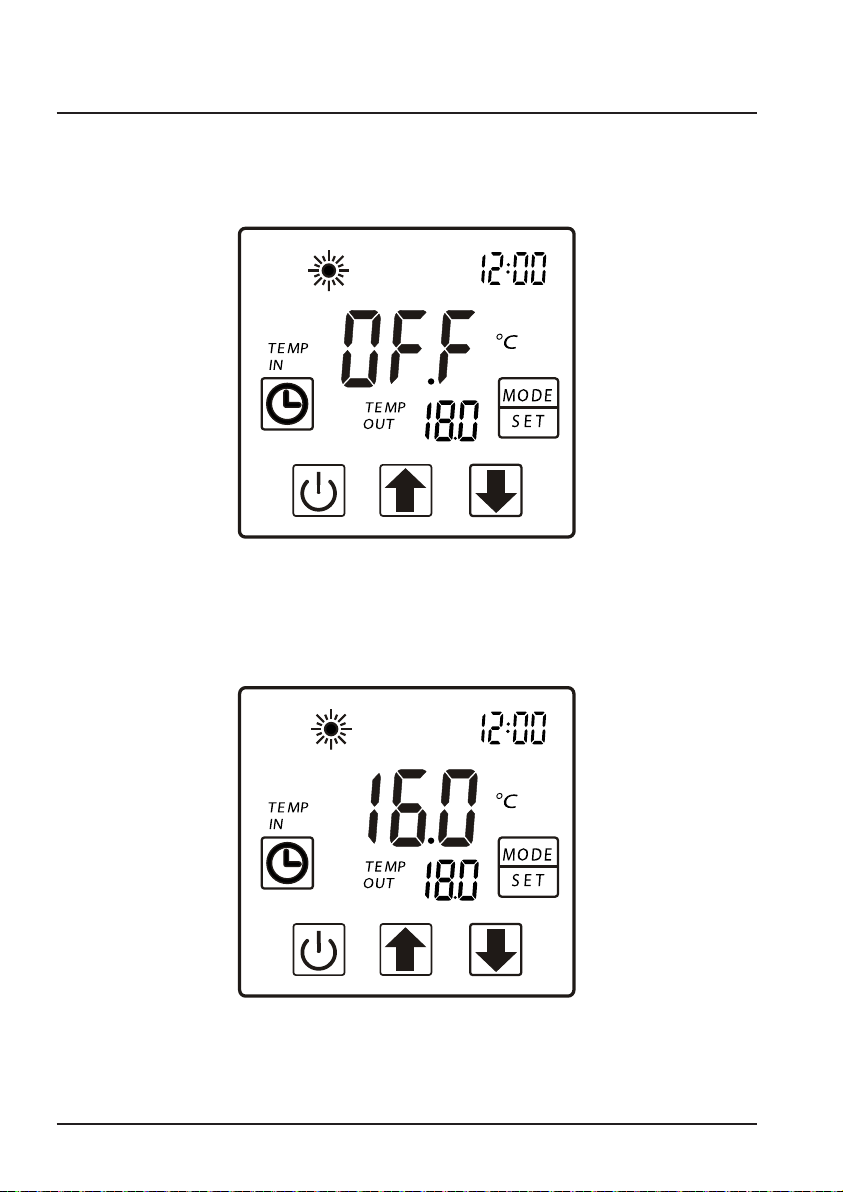

4. USER INTERFACE (continued)

OFF Mode

When the heating pump is in sleep mode (OFF Mode) “OFF” is displayed on

the command screen.

ON Mode

When the heating pump is running or regulating (ON Mode), the inlet and

outlet water temperatures are displayed on the command screen.

12

Loading...

Loading...