Page 1

PUMP SELECTION

To power your Perflex filter, select a continuous duty pump

designed for swimming pool service. The pump mounting

bracket and hardware furnished with the filter will readily accept

most units.

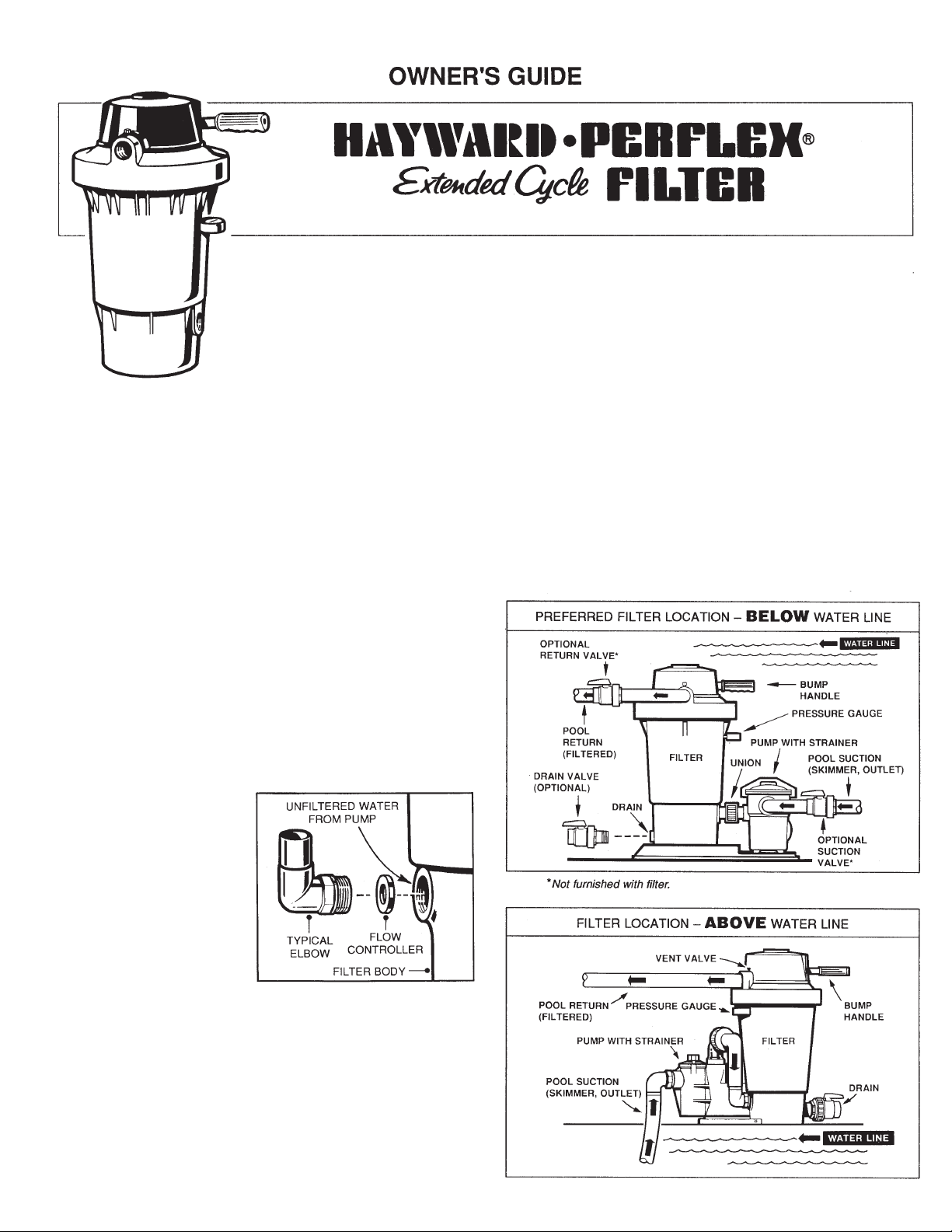

It is important to determine whether the pump will be located

above

or

below

the normal pool water line. If the pump is going

above the water line, a self-priming centrifugal pump must be

used. Self-priming pumps can lift water from a lower level and

prime automatically. There is another type of pump simply

called the

centrifugal

. Unlike self-priming centrifugals which

can lift water from a lower level, a centrifugal must be located

below

the water line for dependable priming.

Select a pump with an output rating of between 30 and 65

GPM (114-246 LPM). Since 40 GPM (150 LPM) is the desired

maximum filter flow, a flow controller (part number ECX1055) is

furnished with each unit for use with pumps rated between

40 and 65 GPM (150-246 LPM). Install the flow

controller in the filter body as illustrated with an elbow adapter,

union connector, or adapter. The adapter both secures the

controller in its proper

position, and completes

the hydraulic balance of

the system.

FILTER LOCATION

Since plumbing fittings

offer a resistance to

water flow, locate the

filter as close to the

swimming pool as

practical. Keep the

number of fittings to a minimum. Select a well-drained area,

one that will not flood when it rains.

Set the filter on a

level

platform or base. Keep the filter

“BUMP” handle, drain outlet, and pressure gauge

accessible for convenient operation. There is an alternate

“BUMP” handle location on the other side of the filter out

let.

Instructions for changing the handle position are covered

later.

Position the filter so the tank can drain by gravity.

PLUMBING

Use 1-1/4” or 1-1/2” I.D. flexible plastic pipe, or hose, joined

with insert fittings and stainless steel clamps. If a rigid pipe

is used, be sure to provide unions for easy servicing.

Ball-style control valves are recommended.

All plumbing connections on the EC40 filter are 1-1/2” N.P.T.

When making connections to the filter, use plastic male-end

adapters. Apply three turns of Teflon tape or plastic pipe

sealant to the male threads.

IS40AB-98

1.

2.

3.

1.

2.

3.

MODEL EC40 SERIES

The Perflex Model EC40 is a high performance swimming pool filter with a filtration rating of 2,400 gallons

(9.1 KL) per hour. Manufactured from durable, corrosion-proof materials, it is designed for continuous

operation, for installation above or below the pool water line, for fresh or salt water swimming pools. The

EC40 filter uses diatomite filter powder (commonly called D.E.). D.E. is the most efficient dirt remover known.

It is normally fed into the system through the skimmer when the filter is initially started; then drained from the

filter when its dirt holding capacity has been reached. Through Perflex’s exclusive “BUMP” action, the D.E.

is periodically regenerated and the filter cycle extended without changing the powder. When the filter

powder is totally used, the “BUMP” action makes it possible to drain the used diatomite without backwashing

or dismantling the filter.

Page 2

SPECIFICATIONS

MODEL

NO.

EFFECTIVE

FILTRATION

AREA

DESIGN FLOW RATE

RESIDENTIAL PUBLIC

PRESSURE LOSS AT

DESIGN FLOW RATE

RESIDENTIAL PUBLIC

MAXIMUM

WORKING

PRESSURE

REQUIRED CLEARANCE

SIDE ABOVE

EC40 19 ft.21.8 m

2

38

GPM

144

LPM

38

GPM

144

LPM

3

PSI

0.2

BAR

3

PSI

0.2

BAR

50

PSI

3.45

BAR

12 inch 30 cm 18 inch

46 cm

NOTE: ANSI/NSPI-4 Article V, standard for above-ground and

on-ground pools, advises that components such as the

filtration system, pumps and heater be positioned so as to

prevent their being used as a means of access to the pool by

young children.

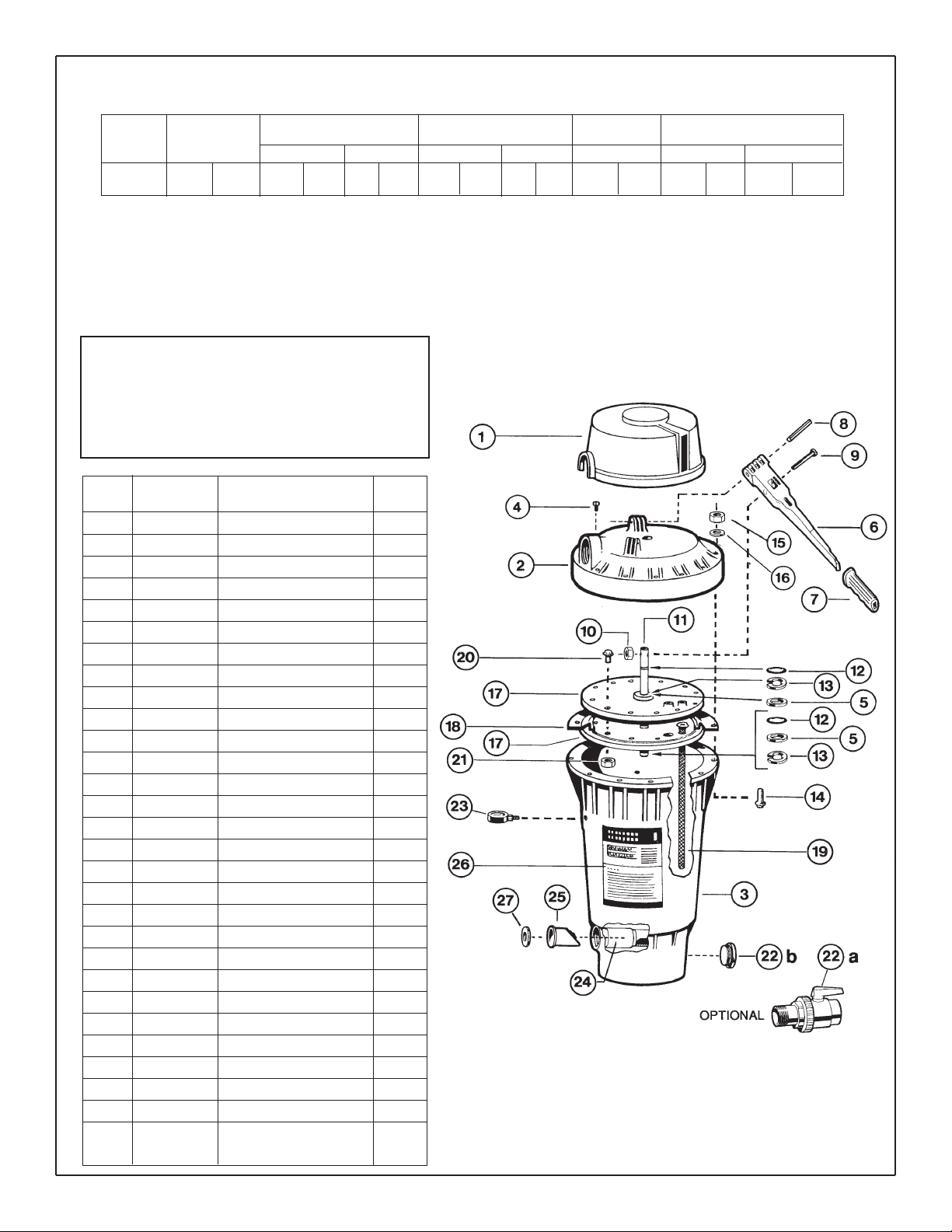

PARTS

MODEL EC40 SERIES FILTER

REF.

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22a

22b

23

24

25

26

27

---

NO.

REQ’D.

1

1

1

1

2

1

1

1

1

1

1

2

2

12

12

12

2

1

72

12

12

1

1

1

1

1

1

1

1

PART NO.

EC1006

EC1033B

ECX10344

ECX1321A

ECX1011

ECX1040

ECX1037B

ECX100Z9

ECX4236

ECX4249

ECX1009

ECX9611246

ECX1014

ECX10271

ECX176855

ECX1077

ECX1004

ECX1003

ECX1031

SPX1500N1

SPX1500Y1

SP0723

SPX1022C

EC2708

ECX1005

ECX4077B

ECX1028

ECX1055

ECX1035

DESCRIPTION

Bump Mechanism Cover

Filter Head w/Vent Valve

Filter Body w/Flow Diffuser

Vent Valve w/O-Ring

Thrust Washer

Bump Handle Assembly

Bump Handle Grip

Pivot Pin

Shoulder Screw

Locknut

Bump Shaft

O-Ring

Retainer

Filter Head Screw

Filter Head Nut

Washer

Tube Sheet (Top or Bottom)

Diaphragm Gasket

Flex-Tube™ Assembly

Tube Sheet Screw

Tube Sheet Nut

1-1/2” Ball-Type Drain Valve

Plug w/Gasket

Pressure Gauge

Flow Diffuser

Check Valve

Decal — Operation

Flow Controller

Flex-Tube Nest (Incls. 5, 9,

10, 11, 14 thru 15)

Page 3

Screw the fitting into the thread hand tight; then, using a

wrench, tighten one more full turn. Additional tightening is

unnecessary and could result in broken or damaged fittings.

Refer to the diagrams for suggested valving.

Connect the pool suction plumbing between the skimmer,

pool outlet, etc., and the pump.

Install the pool return plumbing.

A drain plug, with gasket, is furnished with each filter and is

all that is needed for complete filter draining. If desired

however, drain piping may be extended from the filter by

using an appropriate length of 1 1/2” pipe. Piping must

slope away from the filter so the tank can drain by gravity.

DO NOT

use roll-flat type hose for drain piping.

BEFORE STARTING THE FILTER

Obtain a supply of operating chemicals, D.E., and a pool

test kit. Use only the swimming pool grades of D.E., such

as:

CELATOM . . . . . . . . . . . Eagle Pitcher Industries, Inc.

AQUA-CEL . . . . . . . . . . . Johns-Manville Products Corporation

DICALITE 4200 . . . . . . . Grefco, Inc.

WITCO . . . . . . . . . . . . . . Witco Corporation

Superchlorinate the pool water by adding unstabilized

granular or liquid chlorine. Stabilized forms of chlorine

are recommended for normal daily use after the initial

clean up of the water. Follow chemical manufacturer’s

recommendations for superchlorination and daily use.

STARTING THE FILTER

Close the filter drain and the vent valve. Caution: All suction

and discharge valves must be open when starting the

pump. Failure to do so could cause severe personal injury

and/or property damage.

Prime and start the pump following the manufacturer’s

instructions. Air trapped in the system will automatically vent to

the pool. When there is a steady flow of water returning to the

pool, the filter is ready for precoating.

DO NOT

operate the

filter for more than one minute without the precoat charge.

PRECOATING

Scoop 4 lbs. (1.8 kgs.) of diatomite into the system through the

skimmer as fast as the plumbing will take it. Note and record

the pressure gauge reading after the diatomite has been

added. This is the

“precoat pressure.”

FILTERING

Filtration starts as soon as the filter has been precoated. As

the filter removes dirt from the pool water, the accumulated dirt

causes a resistance to flow. As a result, the gauge pressure

will rise and flow will decrease. When the pressure rises 7-10

psi (.49-.70 Bar) above the precoat pressure, regenerate the

filter.

REGENERATION (Extending the Cycle)

Stop the pump. Move the bump handle down slowly, then up

briskly. Repeat 3 times. Restart the pump and filtration will

resume at near the original flow and pressure.

After each regeneration, and until the filter is cleaned, there

may be a slight increase in the starting pressure. This is the

result of dirt accumulating within the filter and is completely

normal.

CLEANING

Cleaning is recommended when the gauge pressure rises

more than 10 psi (.70 Bar) in less than a 24 hour period or

when cloudy water returns to the pool for more than 30

seconds after regeneration. To clean, first stop the pump, then

move the bump handle down slowly, then up briskly. Repeat 8

times. Open the filter drain and open the vent valve (Note: if

the filter is installed below the pool water line, close the suction

and return valves) and allow water and dirt to empty

completely.

After the filter has drained, and with the drain still open, run the

pump for a few seconds to flush out any dirt remaining in the

bottom of the filter. (Note: If the filter is installed below the pool

water line, opening the

suction

valve for a few seconds with the

pump off will adequately flush the unit.)

Close the filter drain and the vent valve. Open the suction and

return valves (when used). Start the pump and let the filter fill

with water and repeat the CLEANING procedure. This

completes the cleaning phase. The filter is now ready for

recharging. Proceed as in STARTING THE FILTER and

PRECOATING.

VACUUMING

Vacuuming can be performed directly into the filter whenever

needed. For fastest results, regenerate the filter before and

after each vacuuming operation.

TO CHANGE BUMP HANDLE POSITION

Remove the bump handle grip. Carefully pry the bump

cover from the head retaining groove and slide the cover off

the handle.

Using a drift (or 10 penny nail), tap the pivot pin out of the

filter head anchor point, freeing the end of the handle.

Rotate the bump handle to the alternate position and align

the handle and the head anchor holes. Tap the pivot pin in

place.

Reinstall the bump cover and grip.

PREVENTIVE MAINTENANCE

While Perflex filters are basically resistant to the difficulties

often encountered as a result of chemical build-up in swimming

pools, it is important to keep in mind that the mineral content in

a pool increases every day as a result of the chemicals added

and the normal water evaporation process. If the concentration

of minerals is allowed to get too high, the minerals will form

deposits on the Flex-Tubes inside the filter, and will eventually

result in shortened filter cycles. To guard against this, a yearly

chemical cleaning (soaking) of the Flex-Tube assembly is

suggested. Use commercially available 20% muriatic acid

added to water in 1 to 1 ratio; or use other commercial filter

element cleaner mixed according to the package instructions.

Use a plastic container and take extreme caution when

handling cleaning agents as they can be harmful to the eyes,

skin and clothing. After cleaning, thoroughly flush all affected

parts with cold water.

4.

5.

6.

7.

1.

2.

1.

2.

3.

4.

Page 4

WINTERIZING

In areas where sub-freezing temperatures can be expected,

the filter should be drained and removed from its operating

location and stored indoors. Prior to removal, cycle the filter as

described under CLEANING.

ALGAE CONTROL

Algae is a form of plant life which can vary in size from a few

thousandths of an inch to the size of a small tree. Of the many

forms of algae, those most frequently found in swimming pool

water are microscopic in size and green in color.

Algae readily grows in sunlight and can, under favorable

conditions, quickly overgrow a swimming pool turning it

completely green in just a few hours. On the other hand,

swimming pool water can be kept unfavorable to algae growth

simply by maintaining a chlorine level of at least 0.5 ppm in the

water at all times. The chlorine level should be checked at

least once a day using a suitable test kit.

If an algae condition develops and the pool water “blooms”

green, superchlorination of the pool will be necessary to clear

it. Add unstabilized granular chlorine, or liquid chlorine. Follow

SERVICE & REPAIRS

Consult your local authorized

Hayward-Perflex

dealer or

service center. No returns may be made directly to the factory

without the expressed written authorization of Hayward Pool

Products, Inc.

chemical manufacturer’s recommendation for superchlorination.

The algae will quickly become inactive and can then be

removed by the filter. Live algae, on the other hand, multiplies

so fast that the filter cannot keep up with its growth rate. In an

active algae situation, it may be necessary to regenerate the

Perflex filter as frequently as every 2 to 3 hours.

When correctly used, commercial algaecides are effective

against algae, though algaecides should be used in

conjunction with, and not as a substitute for, regular

chlorination or superchlorination.

Maintaining a chlorine level of at least 0.5 ppm in the pool water

at all times is the most effective way to prevent algae growth in

swimming pools.

POOL CHEMISTRY GUIDELINES

ACTION REQUIRED TO CORRECT POOL CHEMISTRY

TO RAISE

TO LOWER

SUGGESTED POOL CHEMISTRY LEVELS

pH

TOTAL ALKALINITY

CHLORINE (UNSTABILIZED)

CHLORINE (STABILIZED)

CHLORINE STABILIZER

(Cyanuric Acid)

7.2 to 7.6

100 to 130 ppm

0.3 to 1.0 ppm

1.0 to 3.0 ppm

40 to 70 ppm

Add Soda Ash

Add Sodium Bicarbonate

Add Chlorine Chemical

Add Chlorine Chemical

Add Stabilizer

Add Muriatic Acid or Sodium Bisulphate

Add Muriatic Acid

No action - chlorine will naturally dissipate

No action - chlorine will naturally dissipate

Dilution - partially drain & refill pool with water

that has not been treated with Cyanuric Acid.

©1998 Hayward Printed in U.S.A.

Rev. 11/98

Loading...

Loading...