Hayward AQR100 Owner's Manual

092735 RevB

AQR100

Chlorine Generator for Inground

Swimming Pools up to 30,000 gallons

Owner’s Manual

\

Contents

Introduction................................2

Installation..................................3

Pool Chemistry............................9

Operation..................................12

Troubleshooting.........................15

Mounting Hole Template............18

Warranty....................................18

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

AQR100

Hayward Pool Products

620 Division Street, Elizabeth NJ 07207

Phone (908)-355-7995

www.hayward.com

IMPORTANT SAFETY INSTRUCTIONS

When installing and using this electrical equipment, basic safety precautions should always be followed, including the following:

• READ AND FOLLOW ALL INSTRUCTIONS

• TO REDUCE THE RISK OF DROWNING FROM HAIR AND BODY ENTRAPMENT, INSTALL A SUITABLY

RATED SUCTION GUARD TO MATCH THE MAXIMUM FLOW RATE MARKED. ATTENTION : LES

PRISES DASPIRATION DOIVENT ETRE EQUIPEES DE GRILLES CONVENANT AU DEBIT MAXIMAL

INDIQUE.

• WARNING: To reduce the risk of injury, do not permit children to use this product unless they

are closely supervised at all times.

• Do not bury cord. Locate cord to minimize abuse from lawn mowers, hedge trimmers, and other

equipment.

• WARNING: To reduce the risk of electric shock, replace damaged cord immediately.

• CAUTION: To reduce the risk of electric shock, install at least 10 feet (3 meters) horizontally from

the inside walls of a pool or spa/hot tub. Do not use an extension cord. ATTENTION : MAINTENIR

UNE DISTANCE MINIMALE D’UN METRE, MESUREE DANS UN PLAN HORIZONTAL, ENTRE LE

BASSIN ET LES APPAREILS ET COMMANDES.

• For Canadian Units: At least two lugs marked “BONDING LUGS” are provided on the external

surface or on the inside of the supply terminal box or compartment. To reduce the risk, connect the local common bonding grid in the area of the hot tub or spa to these terminals with an

insulated or bare copper conductor not smaller than No. 6 AWG.

SAVE THESE INSTRUCTIONS

1

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Introduction

The AQR100 is an automatic chlorine generation system for pool sanitization. It is designed for

inground swimming pools up to 30,000 gallons only. The AQR100 is NOT to be used with

above ground pools or with inground pools greater than 30,000 gallons.

The AQR100 requires a low concentration of salt (sodium chloride) in the pool water. It automatically

sanitizes your pool by converting the salt into free chlorine which kills bacteria and algae in the water.

Chlorine will revert back to sodium chloride after killing bacteria. These reactions will continuously

recycle virtually eliminating the need to add sanitizing chemicals to your pool.

The AQR100 can handle the purification needs of most residential swimming pools up to 30,000

gallons (113,000 liters). This unique low cost chlorine generator uses a replaceable electrolytic Cell

that is designed to last for one pool season.

NOTE: The actual amount of chlorination required to properly sanitize a pool varies due to bather

load, rainfall, temperature, and the pool’s cleanliness.

NOTE: Before installing this product as part of a saline water purification system in a pool or spa

using natural stone for coping or for immediately adjacent patios/decking, a qualified stone installation specialist should be consulted regarding the appropriate type, installation, sealant (if any) and

maintenance of stone used around a saline pool with electronic chlorine generator in your particular

location and circumstances.

NOTE: The use of dry acid (sodium bisulfate) to adjust pool pH is discouraged especially in arid regions

where pool water is subject to excessive evaporation and is not commonly diluted with fresh water.

Dry acid can cause a buildup of by-products that can damage your chlorinator Cell.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

2

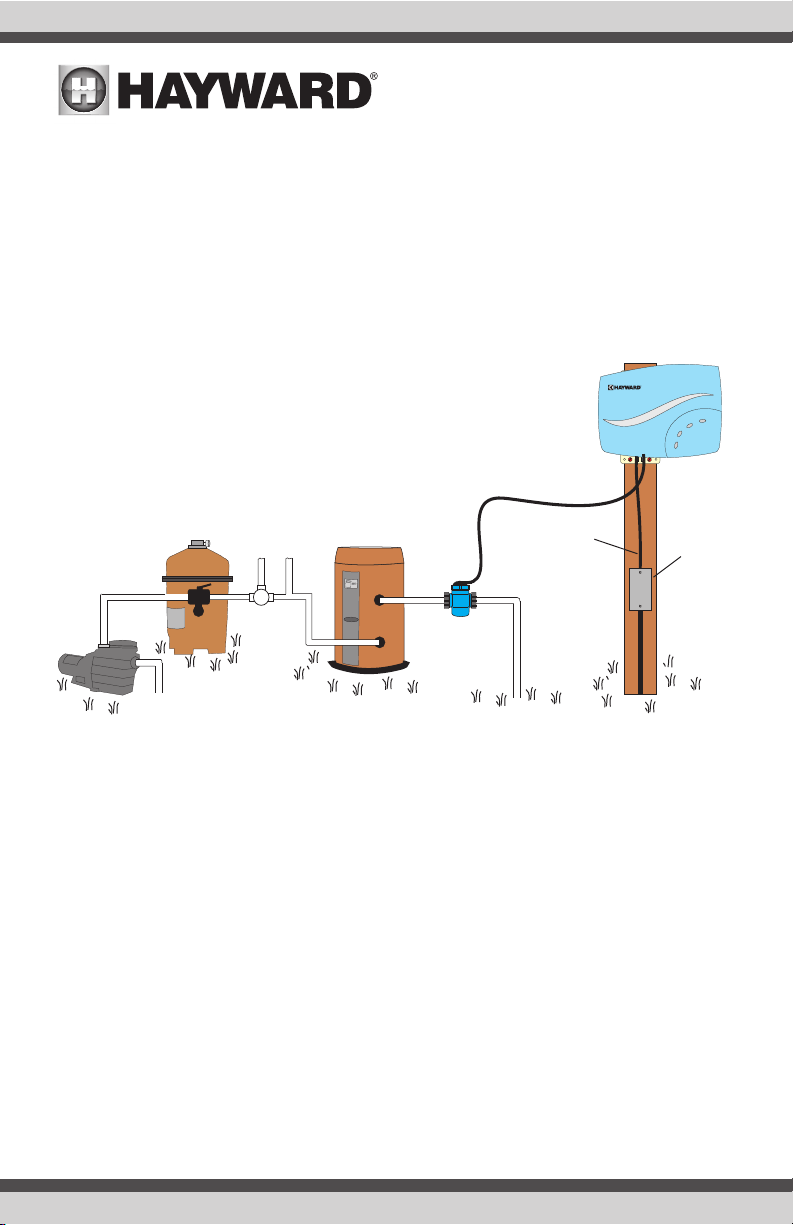

Installation

FROM

POOL

TO

POOL

Remove power to the pool filter pump before starting this installation. Installation must be performed

in accordance with Local and NEC codes. The AQR100 can be powered by either 120 VAC or 240

VAC from the same circuit as the pool pump. Its 6 ft. power cord must be connected to power within

a junction box. The Control Box must be mounted a minimum of 10 ft. horizontal distance (or more, if

local codes require) from the pool and within 15 ft. from where the Cell will be installed. Take care to

protect the Cell Cap connector pins while handling the AQR100 unit during installation. If the supply

cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

15' CELL CABLE

UL LISTED

JUNCTION

BOX

FILTER

PUMP

FILTER

SOLAR

HEATER

POWER

CORD

CELL

VESSEL

Preparing Pool Water

To prepare the pool water for AQR100 operation, the pool’s chemistry must be balanced and salt

must be added. This must be done BEFORE activating the AQR100. Some adjustments to your pool

chemistry may take several hours, so start the procedure well before you intend to operate the AQR100.

To properly prepare your pool water for use with the AQR100, refer to the “Pool Chemistry” section

on page 9 of this manual.

Adding Salt: Add salt several hours or, if possible, 1 day prior to operating the AQR100. Take care

not to exceed the recommended salt level. Measure salt 6-8 hours after adding to the pool.

NOTE: If the pool does not have new water, add 1 quart (1 liter) of metal remover and 1 quart (1 liter)

of non-copper based algaecide to the pool, per manufacturer’s instructions. This ensures a quick,

troublefree transfer to the AQR100 system.

3

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

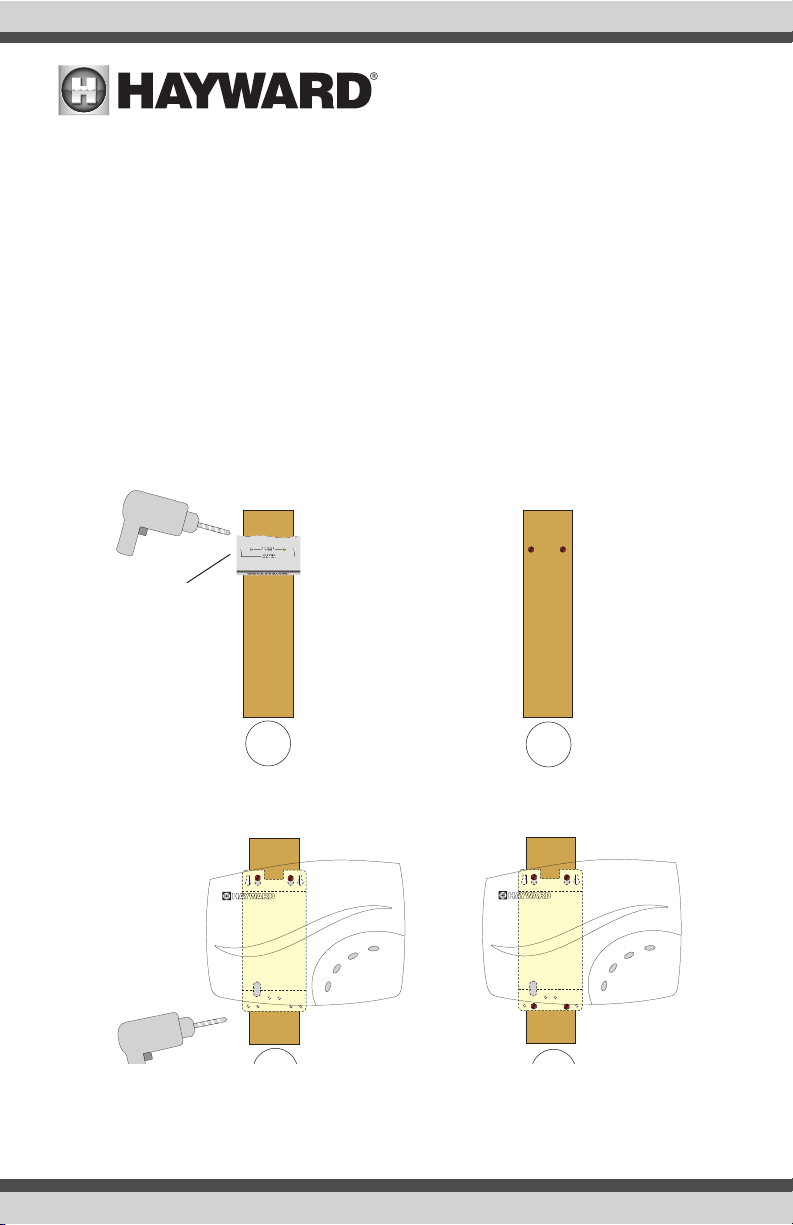

Mounting the AQR100 Control Box

Screw in top

fasteners leaving

1/8” space between

screw head and surface

Attach top mounting hole

guide to desired location and

drill mounting holes.

Hang Control Box

on fasteners and drill

bottom holes.

Screw in bottom

fasteners securely.

1

2

The AQR100 is contained in a raintight enclosure that is suitable for outdoor mounting. The Control

Box must be mounted a minimum of 10 ft. (4 meters) horizontal distance (or more, if local codes

require) from the pool and within 15 ft. from where the Cell is installed.

The Control Box is designed to mount vertically on a flat surface with the cables facing downward.

Because the enclosure also acts as a heat sink (disperses heat from inside the box), it is important

not to block the four sides of the Control Box. Do not mount the Control Box inside a panel or tightly

enclosed area.

Before securing the Control Box to the intended location, make sure that the Cell cable will reach the

location where the Cell Vessel will be installed. For mounting information, refer to the diagram below.

Select appropriate fasteners for your mounting surface that are suitable for a 20lb load. The mounting

template shown in Step 1 can be found on page 18.

Located in

back of Manual

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

4

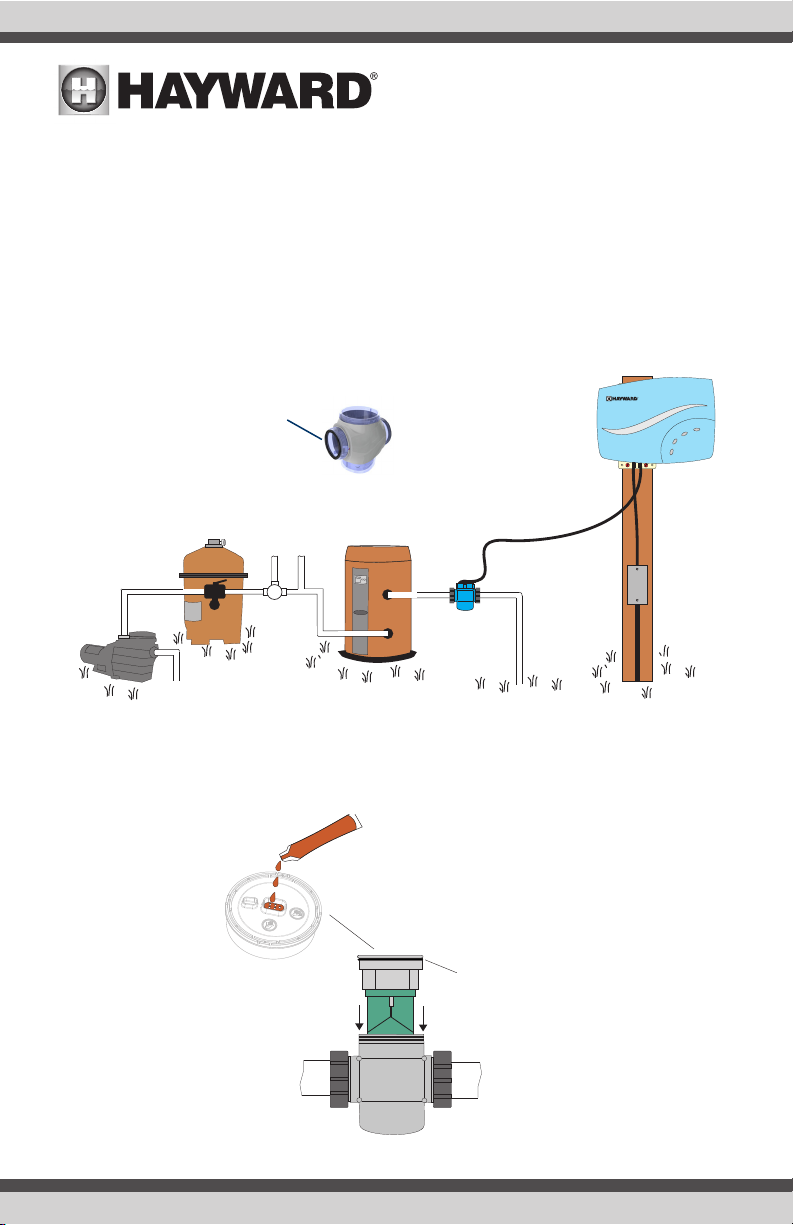

Plumbing

O-Ring

Grease

The Cell Vessel is designed to install in 2” (51mm) PVC pool plumbing. For pools using 1½” (38 mm)

polypipe, you must use a 2” adapter. The Cell Vessel must be installed on approximately 10” run of

straight pipe at the end of the return piping just before the water returns to the pool. All pool equipment should be upstream from the Cell Vessel as shown in the diagram below. It must be located

within 15 feet of where the Control Box is mounted. Also, position the Vessel in a manner where the

Cell can be easily inserted and removed.

With power removed to the pump and water drained from the pool plumbing, cut the plumbing in the

desired location and glue the unions to the pipe. Install the included rubber gaskets on the Cell Vessel

then install the Cell Vessel into the plumbing by handtightening the unions.

Install gaskets on Cell

Vessel before installation

When choosing an

installation location, allow

enough cord to easily

insert/remove the cell

FROM

POOL

TO

POOL

Remove the foam protector from the Cell. Verify that the O-Ring is attached before inserting the Cell

into the Cell Vessel. Fully cover Cell pins with supplied grease as shown.

5

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

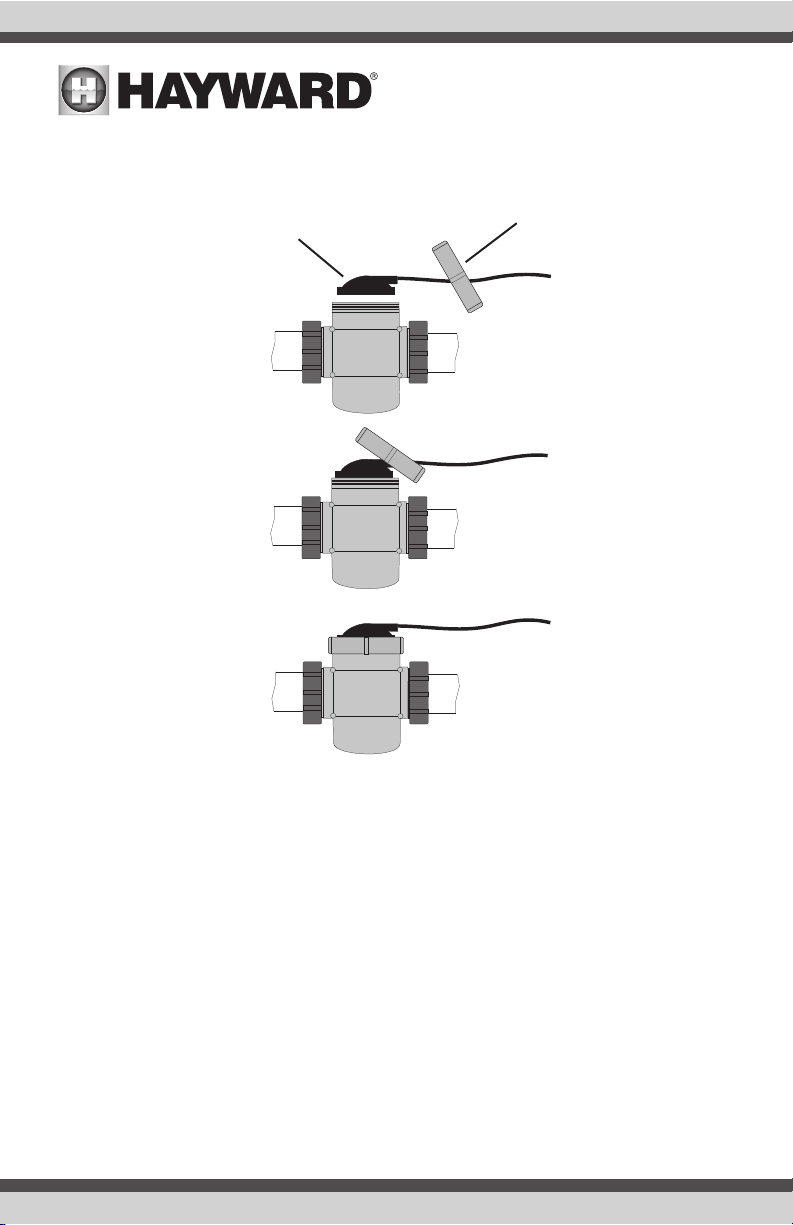

Connect and Fasten Cell Cap

Slip the Cell Cap through the Retaining Nut as shown below. Plug the Cell Cap into the Cell and

secure with the Retaining Nut.

Cell Cap

Retaining Nut

Wiring

Power must be shut off at the circuit breaker before performing any wiring. Be sure to follow Local

and NEC electrical codes. To provide safe operation, the AQR100 should be installed by a qualified

service professional and must be properly grounded and bonded.

The AQR100 can be powered by either 120 VAC or 240 VAC and must be wired in a manner that

the AQR100 turns on and off with the pool pump. If the pump is connected to a timeclock or switch,

wire the AQR100 in parallel.

Locate the 6 ft. long five conductor cable coming from the Control Box. These five colored wires are

used to select voltage and apply power to the AQR100. Refer to the wiring label on the AQR100 as

well as the diagrams on the following page to determine correct wiring connections for either 120

VAC or 240 VAC. Cut the cable and conductors to length and ensure that all connections are made

within a UL Listed junction box. Attach the junction box cover when wiring is complete.

6

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

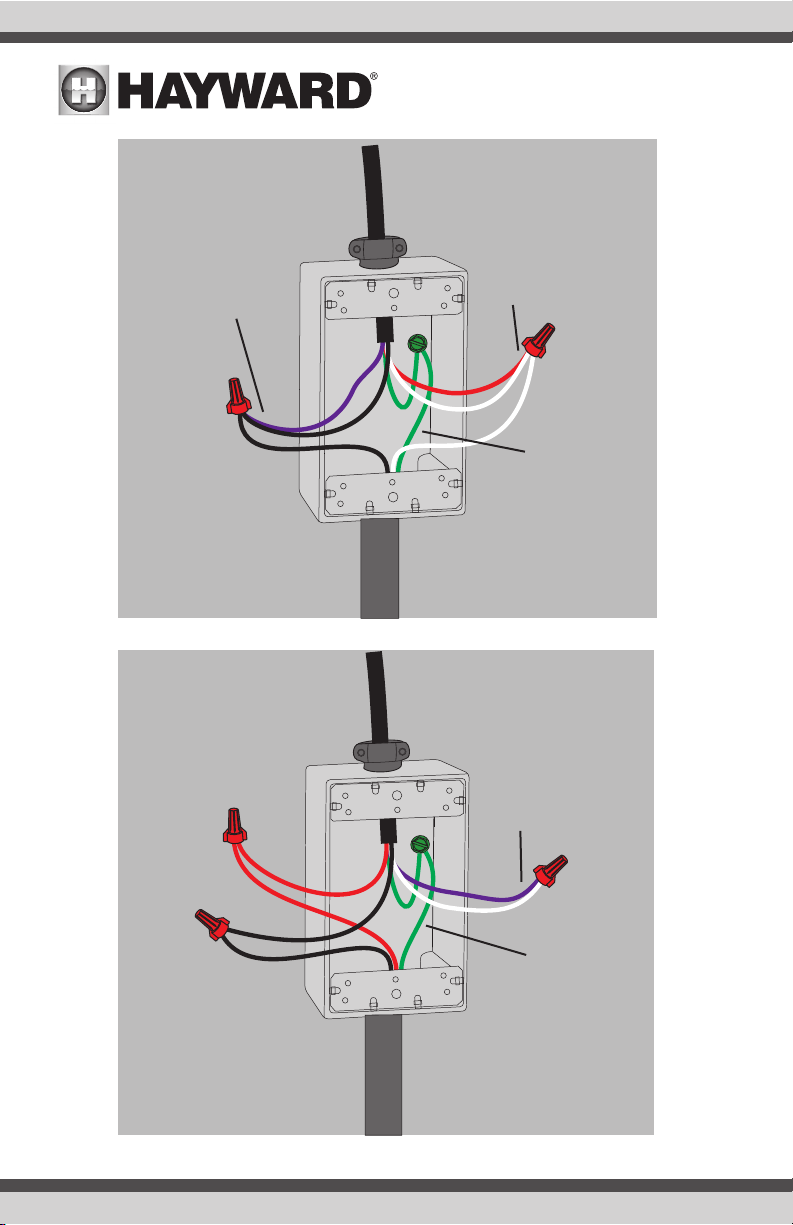

120 VAC

Power Cord from AQR100

black

&

violet

240 VAC

L2

L1

red

&

white

Neutral

Ground

UL Listed

Junction Box

Power Cord from AQR100

white

&

violet

red

black

L1

UL Listed

Junction Box

7

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Ground

Bonding

Pool bonding or “equipotential bonding” ensures that all pool components around the pool are at the

same electrical potential. If bonding is required at your location (see Local and NEC codes), bonding

lugs are is provided at the bottom of the AQR100 enclosure. Run an 8 AWG solid copper wire (6 AWG

Canada) from the bonding lug to your pool’s existing bonding loop.

To Pool Bonding loop

IMPORTANT: Before going any further, the pool water must be balanced and salt must be added to

your pool. If this has not already been done, refer to the “Pool Chemistry” section on page 9 of this

manual for information on how to prepare your pool water for AQR100 operation.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

8

Pool Chemistry

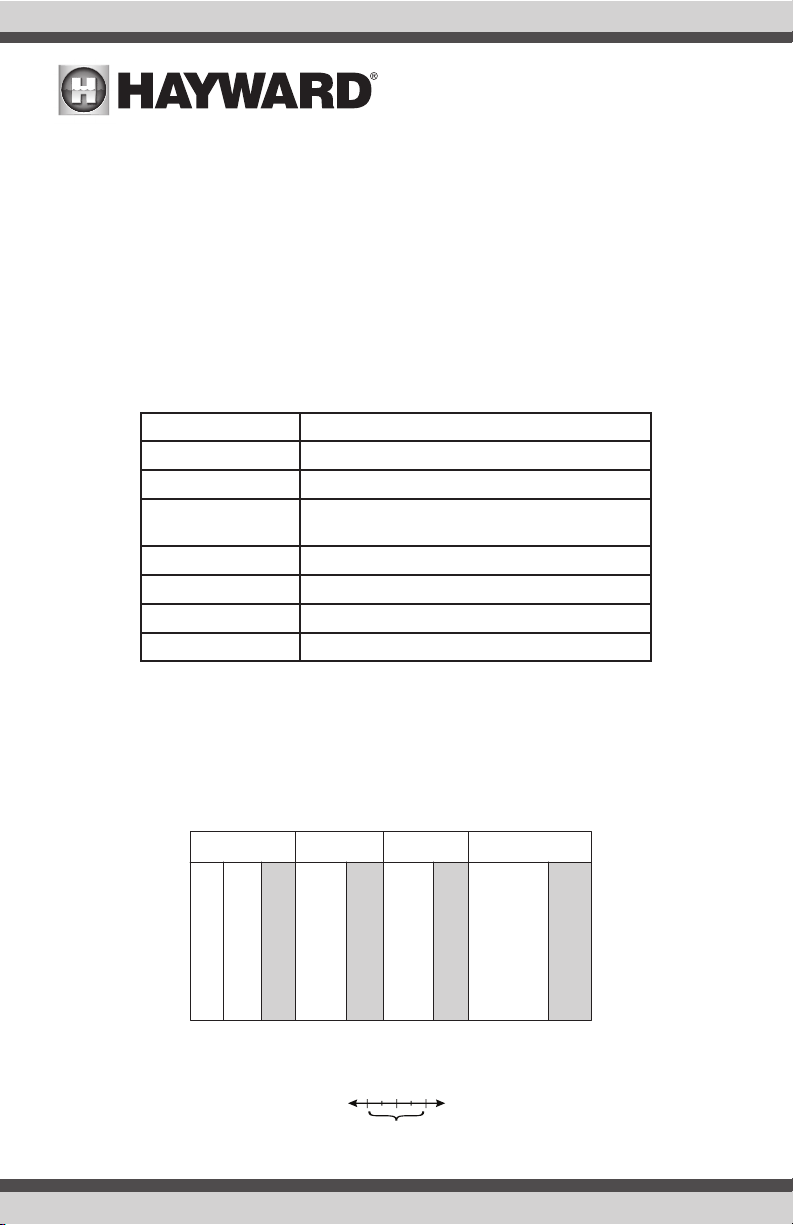

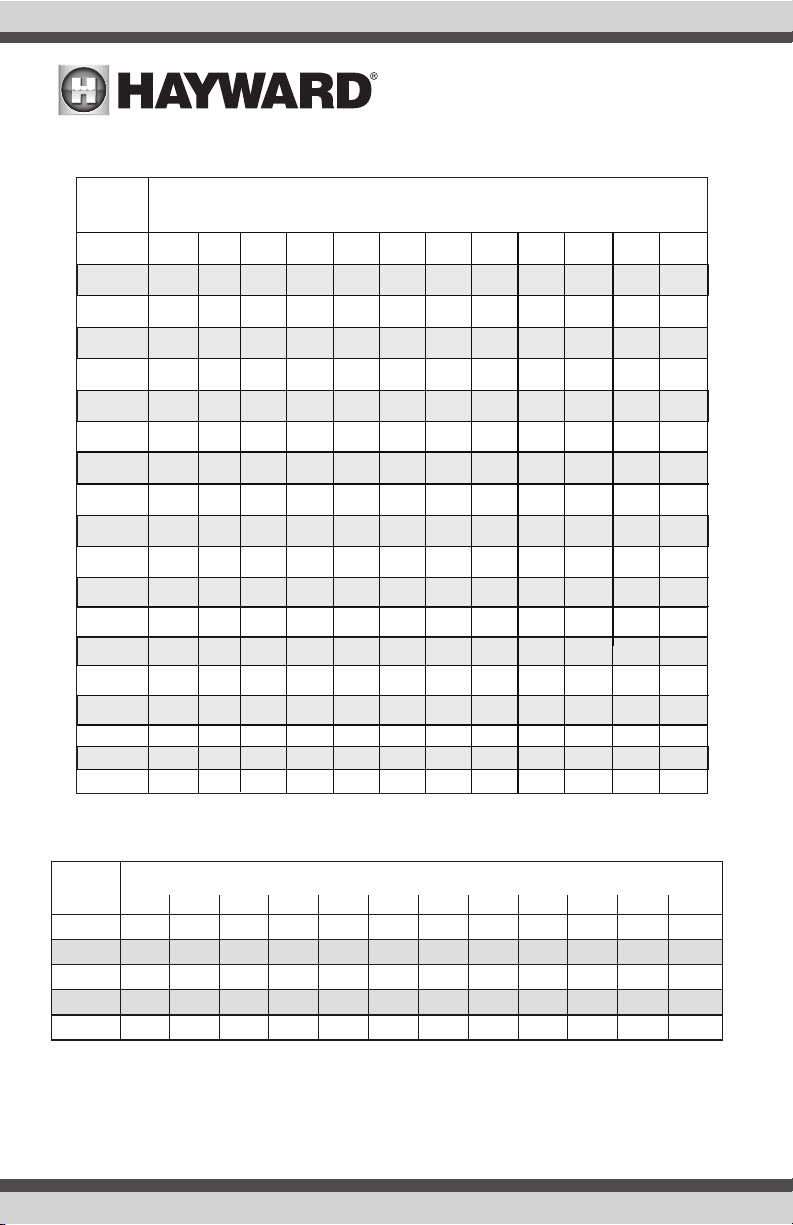

The table below summarizes the levels that are recommended by The Association of Pool and Spa

Professionals (APSP). It is important to maintain these levels in order to prevent corrosion or scaling

and to ensure maximum performance from your AQR100 chlorine generator. Your authorized AQR100

dealer or most pool stores can provide you with the chemicals and procedures to adjust the water

chemistry as well.

Note that pool water emanating from wells and municipal water supplies, along with the introduction

of environmental contaminants, can contain chemistries that are deleterious to the life expectancy

of the Cell.

CHEMICAL IDEAL LEVELS

Salt 1500 to 4500 ppm (3200 ideal)

Free Chlorine 1.0 to 3.0 ppm

pH 7.2 to 7.8

Cyanuric Acid

(Stabilizer)

Total Alkalinity 80 to 120 ppm

Calcium Hardness 200 to 400 ppm

Metals 0 ppm

Saturation Index -.2 to .2 (0 best)

Saturation index

The saturation index (Si) relates to the calcium and alkalinity in the water and is an indicator of the

pool water “balance”. Your water is properly balanced if the Si is 0 ± 0.2. If the Si is below -0.2,

the water is corrosive and plaster pool walls will be dissolved into the water. If the Si is above +0.2,

scaling and staining will occur. Use the chart below to determine the saturation index.

Outdoor Pools 30-50 ppm

Indoor Pools - 0 ppm

Si = pH + Ti + Ci + Ai - TDS

°C °F Ti Ci Ai TDS

12

53

16

60

19

66

24

76

29

84

34

94

39

102

Use: Measure the pH of the pool water, the temperature, water hardness, total alkalinity,

and total dissolved solids. Use the table above to determine Ti, Ci, Ai, and TDS in the

formula shown above. If the Si is equal to 0.2 or more, stains may appear. If the Si is

equal to -0.2 or less, corrosion or deterioration may occur.

Hardness

Calcium

75

0.3

100

0.4

125

150

0.5

200

0.6

250

300

0.7

400

0.8

600

800

0.9

Corrosion Stain

Total

alkalinity

75

1.5

100

1.6

125

1.7

150

1.8

200

1.9

250

2.0

300

2.1

400

2.2

600

2.4

800

2.5

-0.2 0.2

Ok

1.9

2.0

2.1

2.2

2.3

2.4

2.5

2.6

2.8

2.9

Total Dissolved

Solids

0-1000

1001-2000

2001-3000

3001-4000

4001-5000

12.10

12.29

12.35

12.41

12.44

9

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Salt Level

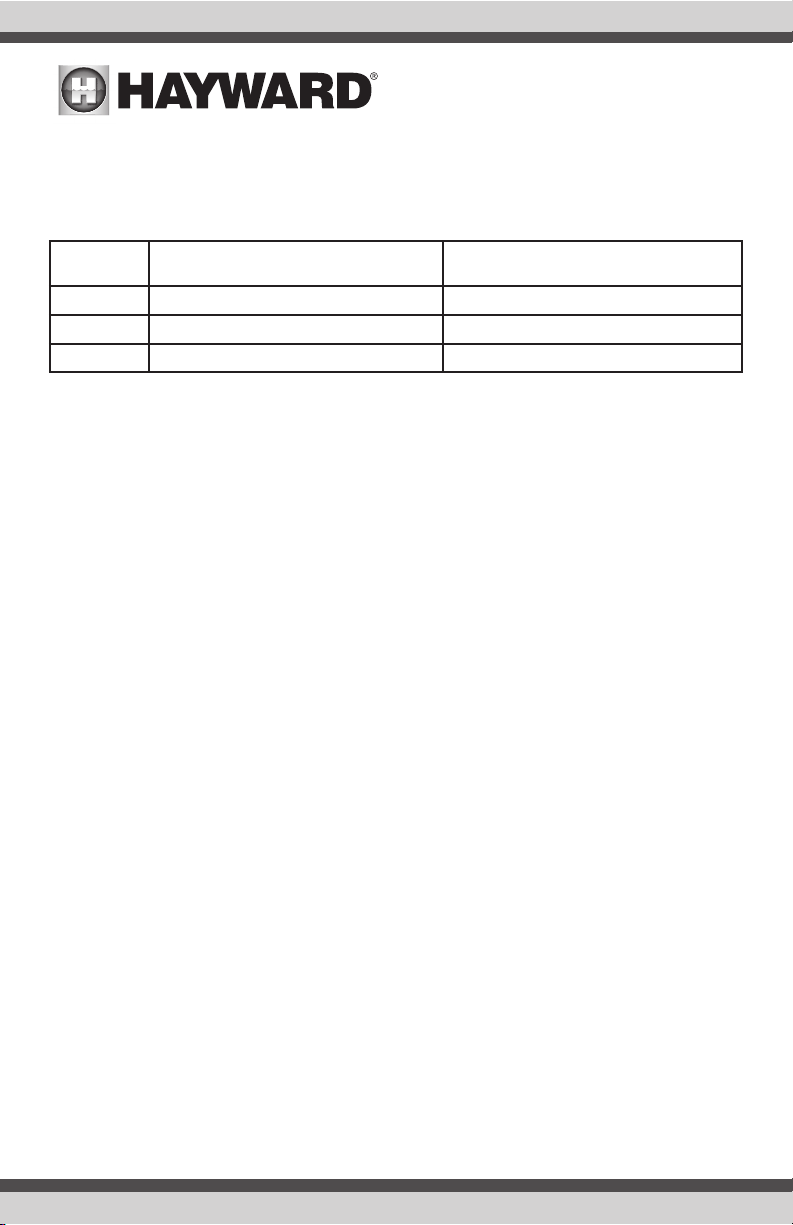

Determining the optimal salt concentration for your pool should be based on your desired pump run

time and the size of your pool. Use the chart on page 11 to determine how much salt in pounds or

(Kgs) need to be added to reach the recommended levels. Use the equations below (measurements

are in feet/gallons and meters/liters) if pool size is unknown.

Gallons

(pool size in feet)

Rectangular Length x Width x Average Depth x 7.5 Length x Width x Average Depth x 1000

Round Diameter x Diameter x Average Depth x 5.9 Diameter x Diameter x Average Depth x 785

Oval Length x Width x Average Depth x 6.7 Length x Width x Average Depth x 893

The AQR100 is designed to operate with a salt level between 1500-4500 ppm (parts per million),

with 3200 ppm being ideal. This broad operating range offers the flexibility to use a salt level that

best suits your pool application. Note that lower salt levels will reduce the efficiency of the AQR100

and result in lower chlorine production. This lower chlorine production may require longer run times

to effectively sanitize the pool. If the pool is too large or the salt level too low, you may not produce

enough chlorine to meet your pool’s demand. In general,

• For pools up to 15,000 gallons, lower salt levels (1500 - 2700 ppm) may be used. Higher levels

can also be used and will require less operating time.

• For pools larger than 15,000 gallons and up to 30,0000 gallons, salt concentration should be

higher than 2800 ppm. Note that a high salt level can begin to give a salty taste to your pool

and can even cause the AQR100 to shut down. Generally, salt will begin to be tasted at a level

of about 3500-4000+ ppm.

The salt in your pool is constantly recycled and the loss of salt throughout the swimming season should

be small. This loss is due primarily to the addition of water because of splashing, backwashing, or

draining (because of rain). Salt is not lost due to evaporation.

Liters

(pool size in meters)

Type of Salt to Use

It is important to use only sodium chloride (NaCl) salt that is greater than 99% pure. This is common

food quality or water softener salt and is usually available in 40-80 lb. bags labeled “Coarse Solar

Salt” or “Pool Salt”. It is also acceptable to use water conditioning salt pellets, however, it will take

longer for them to dissolve. Do not use rock salt, salt with yellow prussiate of soda, salt with anticaking additives, or iodized salt.

How to Add or Remove Salt

For new plaster pools, wait 10-30 days (check with you local pool professional) before adding salt to

allow the plaster to cure. Turn the circulating pump on and add salt directly into the pool. Brush the

salt around to speed up the dissolving process--do not allow salt to pile up on the bottom of the pool.

Run the filter pump for 24 hours with the suction coming from the main drain (use pool vac if there

is no main drain) to allow the salt to evenly disperse throughout the pool.

The only way to lower the salt concentration is to partially drain the pool and refill with fresh water.

Always check stabilizer (cyanuric acid), when checking salt. These levels will most likely decline

together. Use the chart on the following page to determine how much stabilizer must be added to

raise the level to 40 ppm.

10

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Current salt

level

ppm

0

200

400

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

3200

3400

3600+

8,000

(30,000)

213

(97)

200

(91)

187

(85)

173

(79)

160

(73)

147

(67)

133

(61)

120

(55)

107

(48)

93

(42)

80

(36)

67

(30)

53

(24)

40

(18)

27

(12)

13

(6)

Ideal

Dilute

POUNDS and (Kg) of SALT NEEDED FOR 3200PPM

Gallons and (Liters) of Pool Water

10,000

12,000 14,000 16,000 18,000 20,000 22,000 24,000 26,000

(37,500)

(45000) (52,500) (60,000) (67,500) (75,000) (82,500) (90,000) (98,400)

267

320

373

427

(121)

(145)

250

300

(114)

(136)

233

280

(106)

(127)

217

260

(98)

(118)

200

240

(91)

(109)

183

220

(83)

(100)

167

200

(76)

(91)

150

180

(68)

(82)

133

160

(61)

(73)

117

140

(53)

(64)

100

120

(45)

(55)

83

100

(38)

(45)

80

67

(30)

(36)

60

50

(23)

(27)

33

40

(15)

(18)

17

20

(8)

(9)

Ideal

Ideal Ideal Ideal Ideal Ideal Ideal Ideal Ideal

(170)

350

(159)

327

(148)

303

(138)

280

(127)

257

(117)

233

(106)

210

(95)

187

(85)

163

(74)

140

(64)

117

(53)

93

(42)

70

(32)

47

(21)

23

(11)

(194)

400

(182)

373

(170)

347

(158)

320

(145)

293

(133)

267

(121)

240

(109)

213

(97)

187

(85)

160

(73)

133

(61)

107

(48)

80

(36)

53

(24)

27

(12)

OKOKOKOKOK OK OK OK OK OK

Dilute

Dilute Dilute Dilute Dilute Dilute Dilute Dilute Dilute

480

(218)

450

(205)

420

(191)

390

(177)

360

(164)

330

(150)

300

(136)

270

(123)

240

(109)

210

(95)

180

(82)

150

(68)

120

(55)

90

(41)

60

(27)

30

(14)

533

(242)

500

(227)

467

(212)

433

(197)

400

(182)

367

(167)

333

(152)

300

(136)

267

(121)

233

(106)

200

(91)

167

(76)

133

(61)

100

(45)

67

(30)

33

(15)

587

(267)

550

(250)

513

(233)

477

(217)

440

(200)

403

(183)

367

(167)

330

(150)

293

(133)

257

(117)

220

(100)

183

(83)

147

(67)

110

(50)

73

(33)

37

(17)

640

(291)

600

(273)

560

(255)

520

(236)

480

(218)

440

(200)

400

(182)

360

(164)

320

(145)

280

(127)

240

(109)

200

(91)

160

(73)

120

(55)

80

(36)

40

(18)

693

(315)

650

(296)

607

(277)

563

(256)

520

(236)

477

(217)

433

(197)

390

(178)

347

(157)

303

(137)

260

(118)

217

(99)

173

(79)

130

(60)

87

(39)

43

(19)

28,000 30,000

(106,000)

(113,500)

746

(339)

(363)

700

(342)

(319)

654

(299)

(326)

606

(276)

(296)

560

600

(254)

(272)

514

(234)

(251)

466

499

(212)

(227)

420

450

(192)

(206)

374

401

(169)

(181)

326

349

(147)

(157)

280

(127)

(136)

251

234

(107)

(114)

186

199

(85)

140

150

(65)

94

(42)

46

(20)

Ideal Ideal

OK OK

Dilute Dilute

799

750

701

609

551

300

(91)

(70)

101

(45)

49

(21)

Current

Stabilizer

level

(ppm)

0 ppm

10 ppm

20 ppm

30 ppm

40 ppm

11

POUNDS and (Kg) OF STABILIZER (CYANURIC ACID) NEEDED FOR 40 PPM

Gallons and (Liters) of Pool Water

8,000

(30000)

2.7

(1.2)

2.0

(.9)

1.3

(.59)

0.7

(.31)

10,000

(37500)

3.4

(1.5)

2.5

(1.1)

1.7

(.77)

0.8

(.36)

14,000

12,000

(52500)

(45000)

4.0

4.7

(1.8)

(2.2)

3.0

3.5

(1.6)

(1.4)

2.3

2.0

(1.1)

(.90)

1.0

1.2

(.45)

(.54)

0.00.0 0.00.0 0.0

16,000

(60000)

5.4

(2.5)

4.0

(1.8)

2.7

(1.3)

1.4

(.64)

18,000

(67500)

6.0

(2.7)

4.5

(2.0)

3.0

(1.3)

1.5

(.68)

0.0

20,000

(75000)

6.7

(3.0)

5.0

(2.3)

3.3

(1.5)

1.7

(.77)

0.0

22,000

(82500)

7.4

(3.4)

5.5

(2.5)

3.7

(1.6)

1.8

(.82)

0.0

24,000

(90000)

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

8.0

(3.6)

6.0

(2.7)

4.0

(1.8)

2.0

(.91)

0.0

20,000

(97500)

8.7

(4.0)

6.5

(3.0)

4.3

(2.0)

2.2

(.97)

0.0

28,000

(105000)

9.4

(4.3)

7.0

(3.2)

4.6

(2.1)

2.4

(1.1)

0.0

30,000

(112500)

10.0

(4.5)

7.5

(3.4)

4.9

(2.2)

2.6

(1.2)

0.0

Loading...

Loading...