Hayward H135ID, ABG135 Service & Installation Manual

POOL AND SPA/HOT TUB HEATERS

H135ID & ABG135 MODELS

SERVICE & INSTALLATION MANUAL

Unit must be installed outdoors only and below an

altitude of 2000 feet

FOR YOUR SAFETY

WARNING: If the information in these

instructions is not followed exactly, a fi re or

explosion may result causing property damage,

injury, or death.

- Do not store or use gasoline or other fl am-

mable vapors or liquids in the vicinity of this

or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fi re department.

- Installation and service must be performed by

a qualifi ed installer, service agency, or the

gas supplier.

FOR YOUR SAFETY

This product must be installed and serviced by authorized personnel, qualifi ed in pool/

spa heater installation. Improper installation and/or operation can create carbon monoxide gas

and fl ue gases that can cause serious injury, property damage, or death.

See www.hayward-pool.com/patent for U.S. and

Canadian patent information

1301503701 Rev B 0917

2

CONTENTS

Safety Information ..............................................3

Section I General information ...........................7

Introduction .................................................... 7

Warranty Summary .........................................7

Maintaining proper water chemistry ............... 7

Section II Installation .........................................9

Equipment inspection .................................... 9

Important notice ............................................. 9

Conformance with codes ............................... 9

Locating the heater ......................................... 9

Flooring ........................................................10

Clearances ...................................................10

Gas supply and piping ................................. 12

Water piping .................................................14

Installation above pool surface .................... 15

Chlorinator/chemical feeder ......................... 16

Pressure relief valve .................................... 16

Electrical specifi cations ................................ 16

Electrical connections .................................. 17

Remote control connection .......................... 17

Section III Check-out & Start-up .....................20

General ........................................................ 20

Gas line testing ............................................ 21

Gas pressure testing ...................................21

Water pressure switch ................................. 22

Two-speed pump ......................................... 23

Temperature adjustment .............................. 24

Temperature lock-out ................................... 25

Fahrenheit v. Celsius ................................... 25

Heating mode .............................................. 25

Retry (Failure of light) .................................. 26

Recycle (Loss of fl ame) ............................... 26

Keypad inputs .............................................. 26

Automatic reset time .................................... 27

Periodic inspection ......................................27

Winterization ................................................ 27

Draining the heat exchanger .......................28

Spring start-up ............................................. 28

Igniter ...........................................................31

Flame sensor ............................................... 32

Burner orifi ces ............................................. 32

Gas conversion ............................................ 32

Electrical wiring ............................................ 32

Ignition control system ................................. 32

Blower vacuum switch .................................. 33

High limit switches ....................................... 33

Exhaust gas temp limit .................................34

Thermistor ....................................................34

Water pressure switch ................................. 34

Transformer ................................................. 35

Blower ..........................................................35

By-pass service cartridge ............................ 35

Section V Troubleshooting ............................. 36

General ........................................................ 36

Automatic reset time .................................... 36

Supply wiring ............................................... 36

Internal wiring .............................................. 36

Fuse specifi cations ...................................... 36

Error codes ................................................... 37

Troubleshooting ........................................... 39

Warranty ....................................................... 43

Service Parts ................................................ 45

Section IV Technician Service ........................ 29

General ........................................................ 29

Maintenance ................................................ 29

Heat exchanger inspection and cleaning ..... 29

Combustion chamber ..................................30

Burner inspection and cleaning ................... 30

Burner removal and replacement ................ 30

Gas valve replacement ................................ 31

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

SAFETY INFORMATION

Basic safety precautions should always be followed, including the following: Failure to follow instructions

can cause severe injury and/or death.

This is the safety-alert symbol. When you see this symbol on your equipment or in this manual, look

for one of the following signal words and be alert to the potential for personal injury.

WARNING warns about hazards that could cause serious personal injury, death or major property

damage and if ignored presents a potential hazard.

CAUTION warns about hazards that will or can cause minor or moderate personal injury and/or

property damage and if ignored presents a potential hazard. It can also make consumers aware of

actions that are unpredictable and unsafe.

ATTENTION indicates special instructions that are important but not related to hazards.

READ AND FOLLOW ALL INSTRUCTIONS IN THIS OWNER’S

MANUAL AND ON EQUIPMENT.

IMPORTANT SAFETY INSTRUCTIONS

Before installing or servicing this electrical equipment, turn power supply OFF.

KEEP SAFETY LABELS IN GOOD CONDITION AND REPLACE IF MISSING OR DAMAGED.

3

WARNING – To reduce risk of injury, do not permit children to use or climb on the heater, pumps or

fi lters. Closely supervise children at all times. Components such as the fi ltration system, pumps, and

heaters must be positioned to prevent children from using them as a means of access to the pool.

CAUTION – This heater is intended for use on permanently installed swimming pools and may also

be used with spas. Do NOT use with storable pools. A permanently installed pool is constructed in or

on the ground or in a building such that it cannot be readily disassembled for storage. A storable pool is

constructed so that it is capable of being readily disassembled for storage and reassembled to its original integrity.

Though this product is designed for outdoor use, it is strongly recommended to protect the electrical

components from the weather. Select a well drained area, one that will not fl ood when it rains. It requires free

circulation of air for cooling. Do not install in a damp or non-ventilated location.

WARNING – It is required that licensed electricians do all electrical wiring. Risk of

Electric Shock. Hazardous voltage can shock, burn, cause death or serious property

damage. To reduce the risk of electric shock, do NOT use an extension cord to connect

unit to electric supply. Provide a properly located outlet. All electrical wiring MUST be

in conformance with applicable local and national codes and regulations. Before working on this unit, turn off power supply to the heater.

WARNING – To reduce the risk of electric shock replace damaged wiring immediately. Locate conduit

to prevent abuse from lawn mowers, hedge trimmers and other equipment.

WARNING – Failure to bond to pool structure will increase risk for electrocution and could result in

injury or death. To reduce the risk of electric shock, the electrician must comply with installation

instructions and must bond the heater accordingly. In addition, the licensed electrician must also conform to local electrical codes for bonding requirements.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

4

NOTES TO THE ELECTRICIAN:

Use a solid copper conductor, size 8 or larger. Run a continuous wire from external bonding lug to reinforcing rod or mesh. Connect a No. 8 AWG solid copper bonding wire to the grounding lug provided on the

heater and to all metal parts of swimming pool or spa, and to all electrical equipment, metal piping (except

gas piping), and conduit within 5 ft. (1.5 m) of inside walls of swimming pool or spa.

IMPORTANT -Reference NEC codes for all wiring standards including, but not limited to, grounding,

bonding and other general wiring procedures.

WARNING – Suction Entrapment Hazard.

Suction in suction outlets and/or suction outlet covers which are damaged, broken,

cracked, missing, or unsecured can cause severe injury and/or death due to the following

entrapment hazards:

Hair Entrapment- Hair can become entangled in suction outlets.

Limb Entrapment- A limb inserted into an opening of a suction outlet or suction outlet

cover that is damaged, broken, cracked, missing, or not securely attached can result in a

mechanical bind or swelling of the limb.

Body Suction Entrapment- A differential pressure applied to a large portion of the body or limbs can

result in an entrapment.

Evisceration/ Disembowelment - A vacuum applied directly to the intestines through an unprotected

suction outlet sump or suction outlet cover which is damaged, broken, cracked, missing, or unsecured

can result in evisceration (disembowelment).

Mechanical Entrapment- There is potential for jewelry, swimsuit, hair decorations, fi nger, toe or knuck-

le to be caught in an opening of a suction outlet or suction outlet cover resulting in mechanical entrapment.

WARNING - To reduce the risk of entrapment hazards:

• When suction outlets are less than a 18” x 23” equivalent, a minimum of two

functioning suction outlets per pump must be installed. Suction outlets in the

same plane (i.e. fl oor or wall), must be installed a minimum of three feet (3’) [1

meter] apart, as measured from near point to near point.

• Dual suction outlets shall be placed in such locations and distances to avoid

“dual blockage” by a user.

• Dual suction fi ttings shall not be located on seating areas or on the backrest for

such seating areas.

• The maximum system fl ow rate shall not exceed the fl ow rating of any listed (per current revision of

ASME/ANSI A112.19.8) suction outlet cover installed.

• Never use the Pool or Spa if any suction outlet component is damaged, broken, cracked, missing, or not

securely attached.

• Replace damaged, broken, cracked, missing, or not securely attached suction outlet components immediately.

• Install two or more suction outlets per pump in accordance with latest APSP (formally NSPI) Standards

and CPSC guidelines. Follow all applicable National, State, and Local codes.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

5

WARNING – Failure to remove pressure test plugs and/or plugs used in winterization of the pool/spa

from the suction outlets can result in an increase potential for suction entrapment as described above.

WARNING – Failure to keep suction outlet components clear of debris, such as leaves, dirt, hair, paper

and other material can result in an increase potential for suction entrapment as described above.

WARNING – Suction outlet components have a fi nite life, the cover/grate should be inspected fre-

quently and replaced at least every ten years or if found to be damaged, broken, cracked, missing, or

not securely attached.

WARNING – All suction and discharge valves MUST be OPEN when starting the circulation system.

Failure to do so could result in severe personal injury and/or property damage. All drains and suction

outlets MUST have properly installed covers, securely attached using the screws supplied with the

covers. If screws are lost, order replacement parts from your supplier.

WARNING – Hazardous Pressure. Pool and spa water circulation systems

operate under hazardous pressure during start up, normal operation, and after

pump shut off. Stand clear of circulation system equipment during start up. Failure to follow safety and operation instructions could result in violent separation of

the pump housing and cover due to pressure in the system, which could cause

property damage, severe personal injury, or death. Before servicing pool and spa

water circulation system, all system and pump controls must be in off position and

fi lter manual air relief valve must be in open position. Before starting system

pump, all system valves must be set in a position to allow system water to return

back to the pool. Do not change fi lter control valve position while system pump is

running. Before starting system pump, fully open fi lter manual air relief valve. Do

not close fi lter manual air relief valve until a steady stream of water (not air or air

and water) is discharged.

WARNING – Separation Hazard. Failure to follow safety and operation instructions could result in violent separation of pump components. Strainer cover

must be properly secured to pump housing with strainer cover lock ring. Before

servicing pool and spa circulation system, manual air relief valve must be in open

position. Do not operate pool and spa circulation system if a system component is

not assembled properly, damaged, or missing. Do not operate pool and spa circulation system unless fi lter air relief valve body is in locked position in fi lter upper

body.

WARNING – Never operate or test the circulation system at more than 40 PSI.

WARNING – Fire and burn hazard. Motors operate at high temperatures and if they are not properly

isolated from any fl ammable structures or foreign debris they can cause fi res, which may cause severe

personal injury or death. It is also necessary to allow the motor to cool for at least 20 minutes prior to

maintenance to minimize the risk of burns.

WARNING – Failure to install according to defi ned instructions may result in severe personal injury or

death.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

6

WARNING – The following “Safety Rules for Hot Tubs” recommended by the U.S. Consumer

Product Safety Commission should be observed when using the spa.

1. Spa or hot tub water temperatures should never exceed 104°F [40°C]. A temperature of 100°F [38°C]

is considered safe for a healthy adult. Special caution is suggested for young children. Prolonged immersion in hot water can induce hyperthermia.

2. Drinking of alcoholic beverages before or during spa or hot tub use can cause drowsiness, which could

lead to unconsciousness and subsequently result in drowning.

3. Pregnant women beware! Soaking in water above 100°F [38°C] can cause fetal damage during the

fi rst three months of pregnancy (resulting in the birth of a brain-damaged or deformed child). Pregnant

women should adhere to the 100°F [38°C] maximum rule.

4. Before entering the spa or hot tub, users should check the water temperature with an accurate ther-

mometer; spa or hot tub thermostats may err in regulating water temperatures by as much as 4°F

(2.2°C).

5. Persons taking medications, which induce drowsiness, such as tranquilizers, antihistamines or antico-

agulants, should not use spas or hot tubs.

6. If the pool/spa is used for therapy, it should be done with the advice of a physician. Always stir pool/

spa water before entering the pool/spa to mix in any hot surface layer of water that might exceed

healthful temperature limits and cause injury. Do not tamper with controls, because scalding can result

if safety controls are not in proper working order.

7. Persons with a medical history of heart disease, circulatory problems, diabetes or blood pressure prob-

lems should obtain a physicians advice before using spas or hot tubs.

8. Hyperthermia occurs when the internal temperature of the body reaches a level several degrees above

normal body temperature of 98.6°F [37°C]. The symptoms of Hyperthermia include: drowsiness, lethargy, dizziness, fainting, and an increase in the internal temperature of the body.

The effects of Hyperthermia include:

1.

Unawareness of impending danger.

2. Failure to perceive heat.

3. Failure to recognize the need to leave the spa.

4. Physical inability to exit the spa.

5. Fetal damage in pregnant women.

6. Unconsciousness resulting in danger of drowning.

DEFINITIONS:

Suction Outlet – The term Suction Outlet is a fi tting, fi tting assembly, cover/grate and related

components that provide a means for water to exit the pool and into the pump

circulating system.

Inches of Mercury (in Hg) - A unit for measuring pressure below atmospheric (“suction” or “vacuum”) (1.0

inch Hg = .491 PSI)

Main Drain – See Suction Outlet

PSI – An abbreviation for pounds per square inch.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

SECTION I. GENERAL INFORMATION

7

INTRODUCTION:

This manual contains instructions for installation, operation, maintenance, troubleshooting, and parts lists

for the safe use of the swimming pool/spa/hot tub heaters. Hayward strongly recommends that the installer

read the manual before installing the swimming pool/spa/hot tub heater. If after reviewing the manual any

questions remain unanswered, contact the factory or local representative. Following heater installation, the

installer should leave all manuals with the consumer for future reference.

LIMITED WARRANTY SUMMARY:

Hayward warrants the pool/spa/hot tub heater to be free from defects in materials and workmanship, and

will within one year from date of installation for all users, for the original purchaser, repair or, at our option,

replace without charge any defective part. Hayward further warrant that if the heat exchanger or exchanger

headers (water-containing section) leak within one year from date of such installation for all users, due to

defects in materials and workmanship, Hayward will provide a replacement part. Cost of freight, installation,

fuel, and service labor (after one year) is at user’s expense. For full details of warranty agreement, see warranty certifi cate included in this manual.

ATTENTION: If the pool/spa/hot tub heater is damaged or destroyed by improper maintenance, exces-

sive water hardness, incorrect water chemistry, or freezing it is not covered under the manufacturer’s

warranty.

MAINTAINING PROPER WATER CHEMISTRY:

WARNING: Failure to maintain proper water chemistry may cause premature

heat exchanger damage or failure.

The heat exchanger in your Hayward pool heater is made from the highest quality of copper and nickel

(Cupronickel) materials. The premium materials and the exacting processes used in the manufacture of the

heat exchanger is state of the art in pool heater design and manufacture. Yet, it remains vital that the heat exchanger be protected from damaging or corrosive chemicals, insuffi cient water fl ow or improperly balanced

water chemistry. Heat exchanger damage or failure resulting from improper fl ow, improperly balanced pool

water or the improper addition of sanitizer into the water is NOT covered under the terms of your warranty.

The following factors are critical to heat exchanger protection. Follow these guidelines to help prevent

pre-mature damage or failure to your heater and heat exchanger.

1. WATER FLOW THROUGH HEATER

Water must be fl owing through the heater at the minimum rated fl ow rate during operation. Check that

the pump is operating and the system is fi lled with water and purged of all air prior to starting the heater.

The minimum rated fl ow rate is listed on page 15. Some installations may require an adjustment to the water

pressure switch for proper low-fl ow protection. Test your system and if necessary, adjust the water pressure

switch as described on page 22.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

8

Recommended

Level

Effect of Low Levels Effect of High Levels

Chlorine

1 - 3 ppm

Bromine

2 - 4 ppm

pH

7.4 - 7.6

corrosive to heat exchanger,

swimmer irritation

cloudy water, scaling of heat exchanger,

reduced sanitizer effectiveness

Total Alkalinity

80 - 120 ppm

corrosive to heat exchanger,

large fluctuations in pH

scaling of heat exchanger

Calcium Hardness

200 - 400 ppm corrosive to heat exchanger scaling of heat exchanger

Salt

2700 - 5000 ppm poor salt chlorinator performance corrosive to heat exchanger

hazy water, algea growth,

bacteria causing infections

swimmer irritation, bleaching of clothes/hair,

corrosive to heat exchanger

2. POOL/SPA WATER CHEMISTRY

The chemistry balance and mineral content of swimming pool water changes daily due to the addition of

pool and sanitizing chemicals, bather loads, rain, runoff and the amount of sun - to name a few. Improper chemistry balance and mineral content can cause scaling and deposits to form on pool walls, in the fi ltration system,

in the heat exchanger tubes and additionally can promote corrosive action to all metals in the water path. Changing spa water regularly and maintaining the correct chemical balance in your pool/spa will keep the pool/spa

safe and sanitary, and will help protect the heat exchanger. Use a 4-way pool/spa water test kit to check your

water frequently (at least weekly). Use the following guidelines to help protect your heater’s heat exchanger:

3. SKIMMER CHLORINATION

Placing chlorine or bromine tablets directly into the skimmer may result in high chemical concentrations

fl owing through the heater. DO NOT place chlorine or bromine tablets in the skimmer.

4. CHLORINATOR INSTALLATION

Chlorinators must be installed downstream of the heater, and a check valve must be installed between the

heater and chlorinator to prevent high chemical concentrations from back fl owing into the heater. Make sure your

piping arrangement meets the chlorinator installation requirements shown on page 16.

5. BYPASS

Until water chemistry is properly balanced, and if your piping has a bypass valve installed for the heater,

open the bypass so that corrosive and potentially damaging water will not fl ow through the heater and there-

fore the heat exchanger. Close the bypass valve once the water is properly balanced. Failure to close the

bypass valve when attempting to operate the heater will result in extensive damage to the heat exchanger.

Ensure water fl ow through the heater is restored before operating the heater. A bypass feature is also advanta-

geous for service needs and for the ability to remove the heater from the water path when not heating. Refer

to page 15 for further information.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

SECTION II. INSTALLATION

9

EQUIPMENT INSPECTION:

On receipt of the heater, inspect the heater carton(s) for damage. If any carton(s) is damaged, note it when

signing for it. Remove the heater from the carton(s) inspect it and advise the carrier of any damages at once.

IMPORTANT NOTICE:

The installation instructions are intended for the use of a qualifi ed technician, specifi cally trained and

experienced in the installation of this type of heating equipment. Some states or provinces require that installation be licensed. If this is the case in the state or province where heater is located, the contractor must be

properly licensed.

WARNING: Failure to comply with the appliance and vent package installation instructions and service

instructions in this manual may result in equipment damage, fi re, asphyxiation, or carbon monoxide

poisoning. Exposure to products of incomplete combustion (carbon monoxide) can cause cancer and

birth defects or other reproductive harm.

CONFORMANCE WITH CODES:

The heater shall be installed in accordance with all local and state codes. The heater installation must conform to the latest edition of the National Fuel Gas Code (ANSI Z223.1/NFPA 54) and with the requirements of

the authority having jurisdiction. Design certifi cation of the heater is in compliance with ANSI Z21.56/CSA 4.7.

For Canadian installations, the heater is to be installed in accordance with the standards CAN/CGA B149.1

and B149.2 – Installation Codes for Gas Burning Appliances and Equipment and/or local codes and, if applicable, CSA C22.1 – Canadian Electrical Code, Part I.

LOCATING THE HEATER:

Locate the pool/spa/hot tub heater in an area where leakage of the heat exchanger or connections will not

result in damage to the area adjacent to the heater or to the structure. When such locations cannot be avoided,

it is recommended that a suitable drain pan, with drain outlet, be installed under the heater. The pan must not

restrict airfl ow.

This heater must be installed at least (5) feet from the inside wall of a pool (in-ground or above-ground)/

spa/hot tub unless separated from the pool/spa/hot tub by a solid barrier.

The heater must be installed such that the location of the exhaust gas vent outlet relative to adjacent

public walkways, adjacent buildings, openable windows, and building openings complies with the National

Fuel Gas Code (ANSI Z223.1/NFPA 54) and/or CAN/CGA B149 installation codes. Outdoor installation and

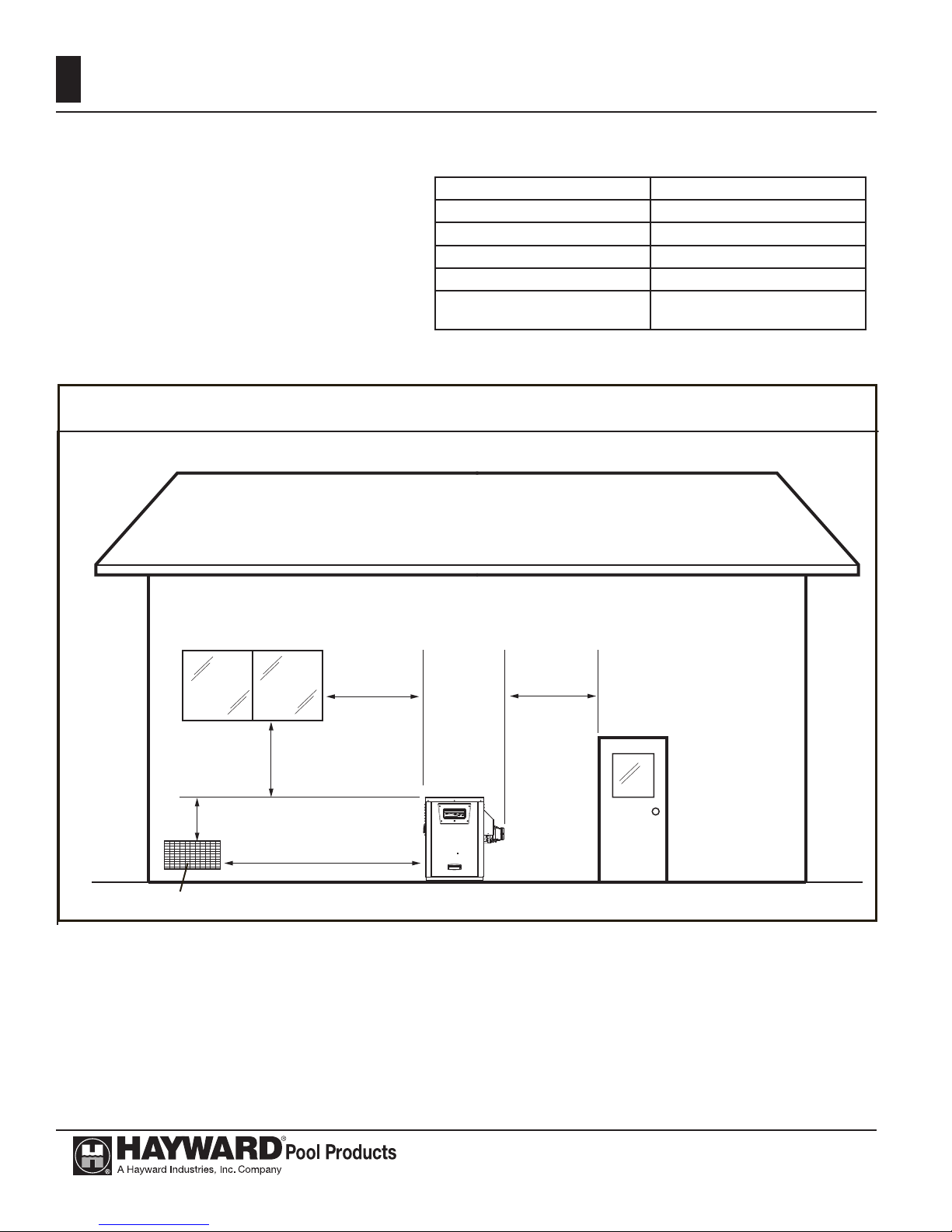

service clearances:

The heater must be installed outdoors such that the installation and service clearances from combustible

materials shown in Table 2 are maintained. This heater may be installed on combustible fl oors.

1.

The heater is self-venting when installed outdoors and does not require additional vent piping.

2. Do not install in a location where growing shrubs may in time obstruct a heater’s combustion air and

venting areas.

3. Do not install this appliance under an overhang less than (3) feet from the top of the appliance. The

area under the overhang must be open on (3) sides.

4. Do not install the heater where water spray from ground sprinkler can contact the heater. The water

could splash on the controls causing electrical damage.

5. Do not install under a deck.

6. Do not install within 24” of any outdoor HVAC equipment.

7. Do not install where water may run-off a roof into the heater. A gutter may be needed to protect the

heater.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

10

8. If the heater is to be installed in front of

an exterior wall with vinyl siding, increase the clearance from the back of the

unit shown in Table 2 to 12 inches.

9. For minimum exhaust vent clearances

for all building openings, including but

not limited to vented eaves, doors, windows, or gravity inlets, see Figure 01. In

Canada, the heater must be installed with

the top of the vent at least 10 feet (3m)

below, or to either side of, any opening

into a building.

Figure 01: Minimum Clearances

Table 2

Outdoor Installation Clearances

Heater Panel Required Clearance

Top Unobstructed

Front 18 inches

Back 6 inches

Water Connection Side 12 inches

Side Opposite Water Connec-

tion

6 inches

4 ft

Minimum

4 ft

Minimum

3 ft

Minimum

10 ft

Minimum

4 ft

Minimum

Forced Air Inlet

FLOORING:

This heater may be installed on either non-combustible or combustible fl ooring. Ultralite™ or equiva-

lent concrete-over-foam HVAC pads are acceptable.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

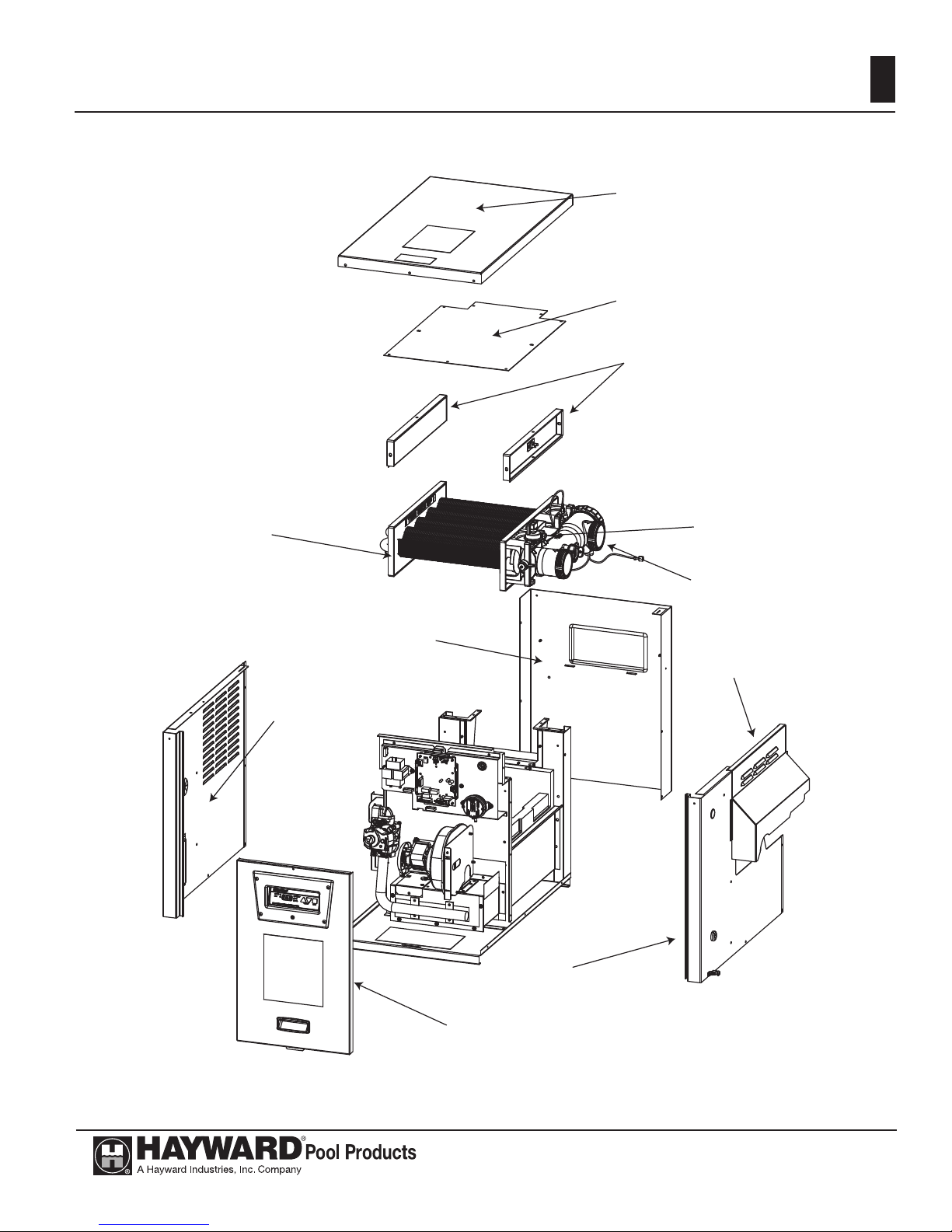

Figure 02: Sub-Assemblies

Top Jacket

Flue Transition

Top Cap

Flue Collector

Side Panels

Heat Exchanger

Assembly

Pressure Switch

Port

Temperature

Limit Switches

Left Side

Jacket

Right Side

Jacket

Front Access

Panel

Heat Exchanger

Cover

Rear

Jacket

11

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

12

HOW TO OPEN FRONT ACCESS PANEL

ATTENTION: Care must be taken to not damage ribbon cable connecting display board to ignition

board when removing Front Access Panel.

1. Remove (1) screw above control, securing top jacket to front access panel.

2. Lift Access Panel up by the handle at the bottom.

3. Swing bottom of panel out.

4. Slide top of panel down, and then out. Be sure not to place too much tension on the ribbon

cable as the front panel is removed from the unit

5. Disconnect ribbon cable from ignition board.

GAS SUPPLY AND PIPING:

To properly size the gas piping for the heater, refer to Tables 3 or 4, depending on natural or propane gas,

and single-stage or 2-stage regulation. Follow local gas codes for proper gas line material selection (copper,

iron, plastic, etc.). It is VERY IMPORTANT when installing a propane heater on a 2-stage regulation system

to follow the gas line sizing data in Table 4 without exception.

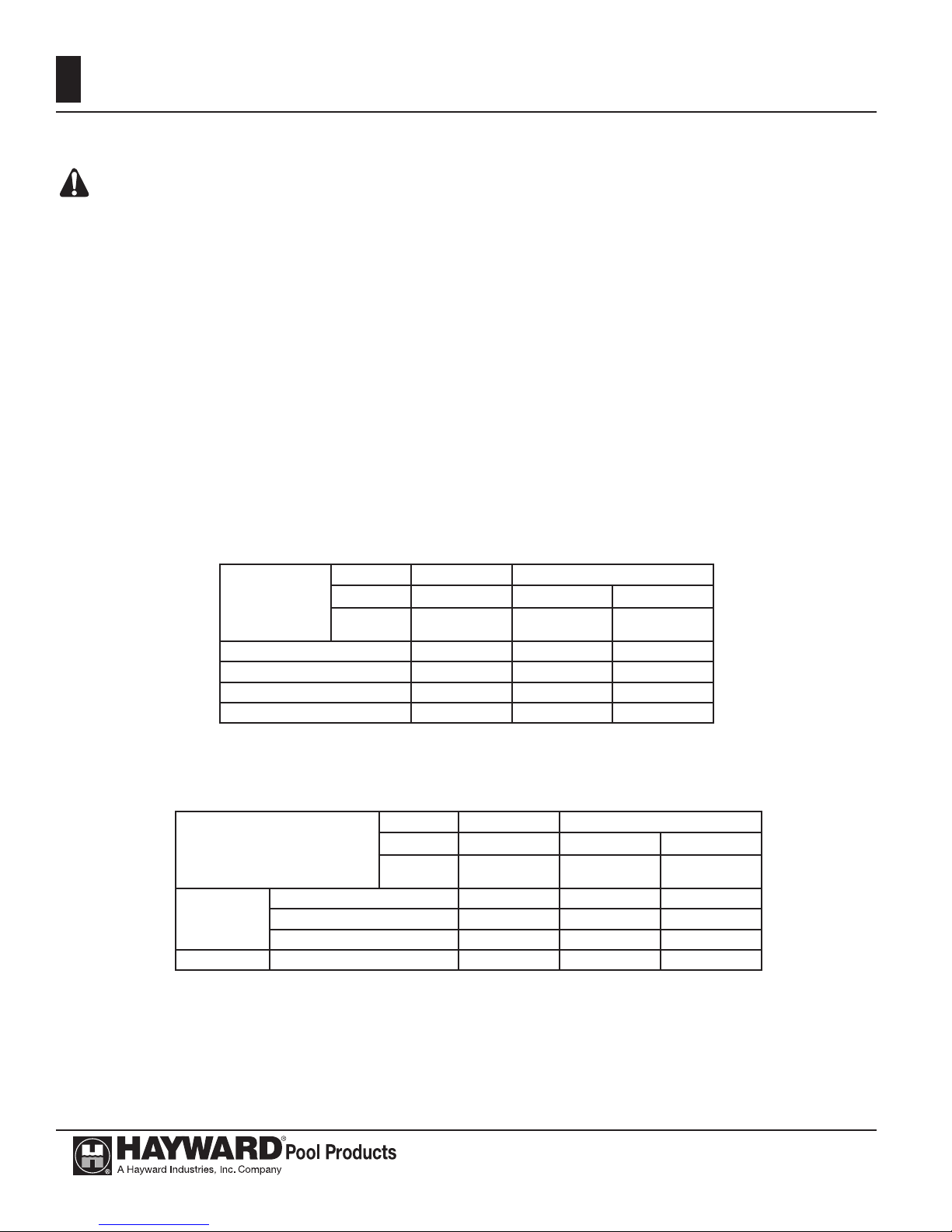

Table 3

Low-Pressure, Single-Stage Regulaion

Distance from

Gas Meter or Tank

Regulator Outlet to

Heater Gas Valve

Inlet

0 to 50 ft 3/4” 3/4” 3/4”

50 to 100 ft 1” 3/4” 1-1/8”

100 to 200 ft 1-1/4” 1” 1-1/8”

200 to 300 ft 1-1/4” 1” 1-1/8”

*Based upon an inlet pressure of 0.5 psig or less at a pressure drop of 0.5 in-wc.

**Based upon an inlet pressure of 11 in-wc at a pressure drop of 0.5 in-wc.

Gas Type Natural Gas* Propane**

btu/hr input 135,000 135,000 135,000

Line Material

Gas Pipe Sizing

Iron or Plastic

Pipe

Iron Pipe Plastic Pipe

Distance from Gas Meter or Tank

Regulator Outlet to Heater Gas Valve

Inlet

First Stage

Second Stage 0 to 10 ft 1/2” ** 1/2” **** 5/8” ****

*Based upon an inlet gas pressure of 2 psig at a pressure drop of 1 psi.

**Based upon an inlet gas pressure of 10 in-wc at a pressure drop of 0.5 in-wc.

***Based upon an inlet gas pressure of 10 psig at a pressure drop of 1 psi.

****Based upon an inlet gas pressure of 11 in-wc at a pressure drop of 0.5 in-wc.

Table 4

High-Pressure, 2-Stage Regulaion

0 to 50 ft 1/2” * 1/2” *** 1/2” ***

50 to 100 ft 1/2” * 1/2” *** 1/2” ***

100 to 150 ft 1/2” * 1/2” *** 1/2” ***

Gas Pipe Sizing

Gas Type Natural Gas Propane

btu/hr input 135,000 135,000 135,000

Line Material

Iron or Plastic

Pipe

Iron Pipe Plastic Pipe

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

13

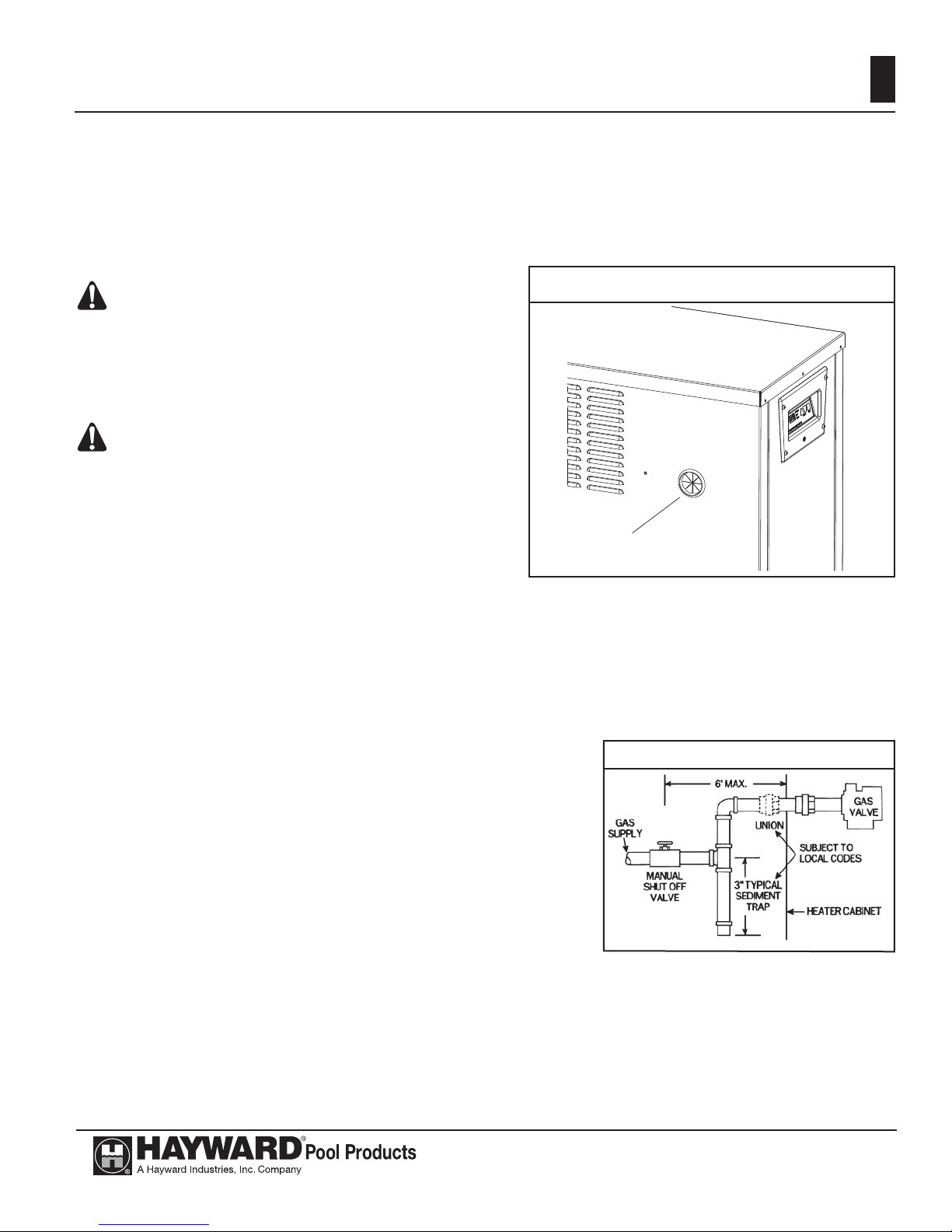

Gas Connection

GAS SUPPLY INSTALLATION:

The gas connection is located on the left-hand side of the heater cabinet. Insert the pipe to the gas valve

through the grommet in the cabinet side (see Figure 043.) A union should be installed outside the heater cabinet for easy removal of the gas manifold assembly during service.

A CSA certifi ed main gas shutoff valve must be installed outside the cabinet and within 6 feet of the

heater. This valve must have an I.D. large enough to supply the proper amount of gas volume to the heater.

See Figure 034.

Figure 03: Gas Connection Location

ATTENTION: Apply joint compound (pipe dope)

sparingly and only to the male threads of pipe joints.

Do not apply joint compound to the fi rst two threads.

Use joint compounds resistant to the action of liquefi ed petroleum gas. Do not overtighten the gas inlet

pipe or damage may result.

ATTENTION : Do not use fl exible appliance con-

nectors on any gas connections unless the connector

is CSA approved for outdoor installation, is marked

with BTUH capacity (which must be equal to or

greater than the heater rated input) and the type of gas

(natural or LP).

Reduction of gas supply pipe or tubing to the inlet of the heater gas valve must be made at the valve only

and must match the valve inlet size (3/4” NPT).

If more than one appliance is installed on the gas line, consult the local gas company for the proper gas

line size.

Questions on the installation of the proper gas line size can be directed to Hayward Technical Service.

NATURAL GAS:

Figure 04: Gas Piping

The gas meter must have the capacity to supply enough gas to the

pool heater and any other gas appliances if they are on the same pipeline (Example: 225 meter = 225,000 BTUH). If doubt exists as to the

meter size, consult the local gas utility for assista

nce. Natural gas must

be “pipeline quality” supplied from a natural gas utility company.

Hayward will not be responsible for heaters that soot up due to improper meter and gas line sizing resulting in improper gas volume, or

heaters that are damaged in any way if connected to a natural gas well.

PROPANE GAS:

All propane gas tanks must be located outdoors and away from pool/spa structure and in accordance with

the standard for storage and handling of propane gas, ANSI/NFPA 58 (latest edition) and applicable local

codes. If the propane gas tank is installed underground, the discharge of the regulator vent must be above the

highest probable water level.

Propane tanks must have suffi cient capacity to provide adequate vaporization for the full capacity of the

equipment at the lowest expected temperatures. Consult a propane company expert for correct sizing.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

14

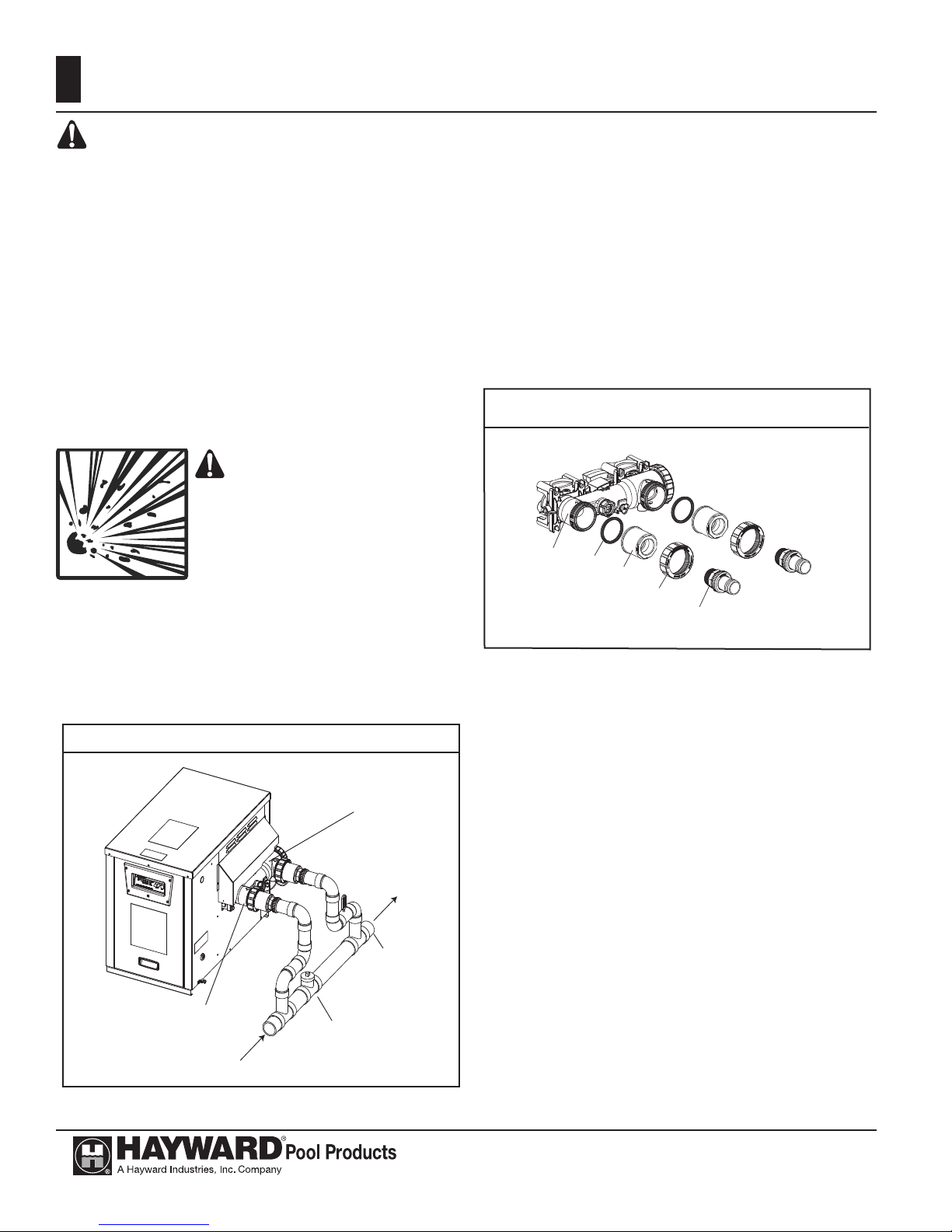

Gaskets

Pipe Nipples

Union Nuts

Heater

Header

1.5” Hose Fittings

ATTENTION: Whenever a high-pressure double regulation system is utilized for propane gas, consult

a propane expert for accurate pipe and pressure sizing. Make sure that 1st and 2nd stage regulators are

large enough to handle the BTUH input listed for the heater(s) being used.

Hayward will not be responsible for heaters that soot up due to

improper gas line or propane tank siz-

ing resulting in improper gas volume.

WATER PIPING:

The heater is designed for use with pool and spa/hot tub water only, as furnished by municipal water dis-

tribution systems. The warranty does not cover heater use with mineral water, seawater (PPM>5000), or other

non-potable waters.

Do not install any restriction in the water pipe between the heater outlet and the pool/spa with the

exception of:

1. three-way switching valve

2. in-line chlorinator

3. chlorinator check valve

WA R N ING: EXPLOSION

HAZARD Blockage of water

fl ow from heater return to pool

may result in fi re or explosion

causing property damage, personal

injury, or loss of life.

Figure 05: Water Connection Assembly

The heater is shipped with CPVC fl anged pipe

nipples that are pre-assembled with the required reducer

to be used with the supplied 1.5” fl exible hose fi ttings.

Assemble all water connection components as shown in Figure 05. Assemble these parts to the heater prior to

plumbing. Tighten all nuts securely, ensuring a seal with the rubber gaskets, before connecting fl exible hose.

The CPVC fl anged pipe nipples and reducers must be installed on the heater inlet and outlet without modi-

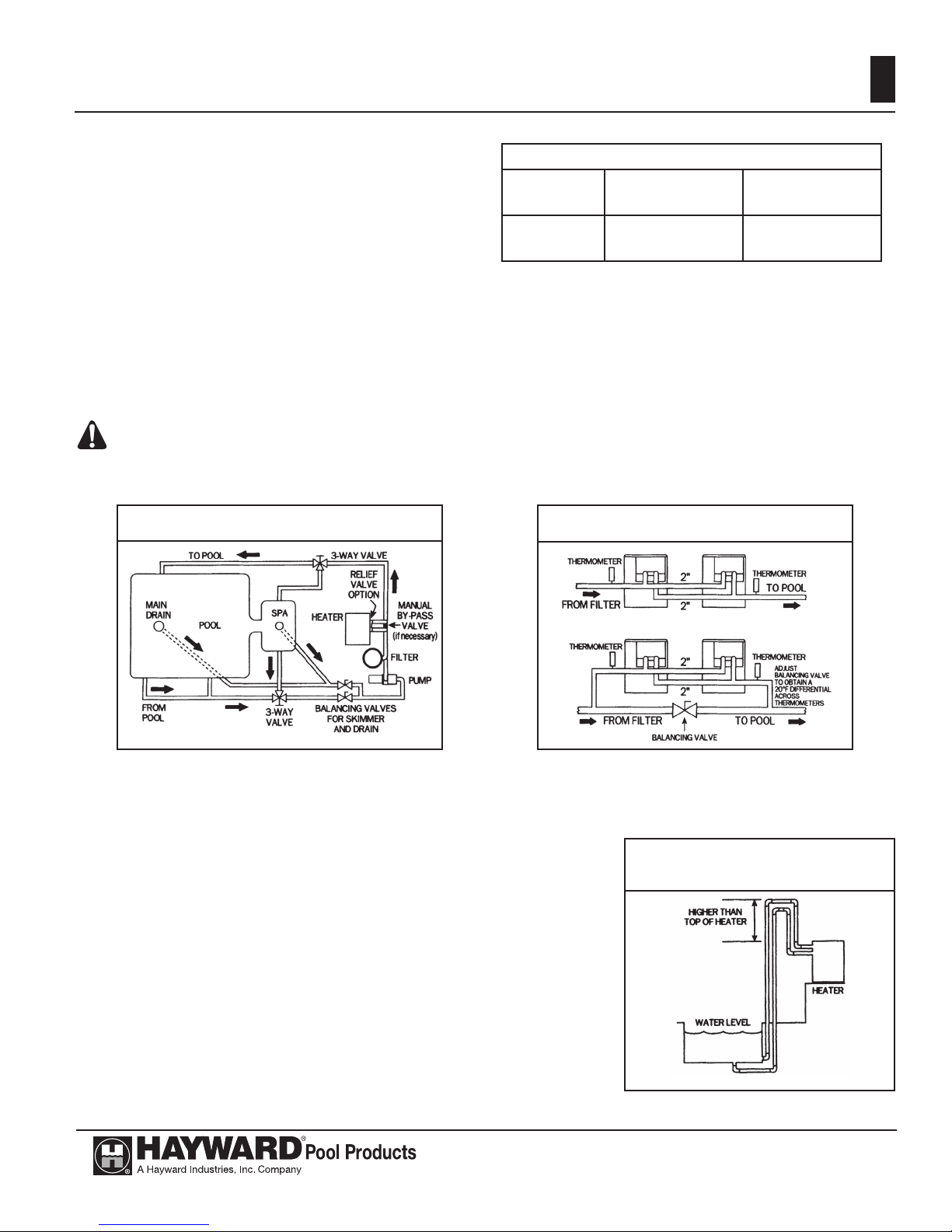

Figure 06: Manual Bypass valve

fi cation. Pipe, fi ttings, valves, and any other element

of the fi lter system may be made of plastic materials, if

acceptable to the authority having jurisdiction.

Heater Outlet

Installation of this pool/spa/hot tub heater with

rigid PVC pipe plumbed directly to the inlet and outlet

connections of the heater requires purchase of Hayward

accessory Union Kit SPX3200UNKIT. The kit contains

Flow Meter

the appropriate gaskets, pipe nipples and union nuts to

allow 2” or 2 ½” PVC pipe to be plumbed to the unit.

Use PVC primer and glue to connect water piping to the

connectors supplied in the kit.

Return to

Pool / Spa

Heat sinks, heat tapes, fi remen switches, and check

valves are not required on the heater. However, if there

Heater Inlet

Bypass Valve

is any chance of “back-siphoning” of hot water when

the pump stops running, it is suggested that a check

valve be used on the heater inlet pipe.

The built-in bypass inside the header will maintain

proper fl ow through the heat exchanger if the fl ow rate

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

is within the range for the heater. See Table 5. The

minimum fl ow rate is to be calculated or measured with

the in-fl oor cleaning system in use, if the pool is so

equipped, as well as any other jets or other demands on

Table 5: Allowable Water Flow Rate Range

Model

Minimum Flow

Rate (GPM)

Maximum Flow

Rate (GPM)

the water fl ow.

If the normal pump and fi lter system fl ow rate

exceeds 125 gpm then a manual bypass valve must be

installed as show

n in Figure 06. Damage caused by fl ow

H13510

ABG135

20 125

rates outside this range will void the manufacturer’s warranty.

The installation is as follows:

1.

Install a fl ow meter on the outlet line of the heater.

2. Adjust the manual bypass valve until the fl ow rate is within the fl ow rate range specifi ed for the heater.

3. Once the valve is set, note the position and remove the valve handle to prevent further adjustment.

ATTENTION: Improperly adjusted manual bypass valves will result in damage to the heater if the fl ow

rates are not maintained as specifi ed in Table 5 under all operating conditions. The heat exchanger will

fail and this damage will not be covered under the Hayward warranty.

15

Figure 07: Typical plumbing to pool

Figure 08: Multiple heater system

Figure 0707 illustrates a typical pool piping diagram and layout for the pool equipment.

Figure 0808 illu

strates a multiple heater installation for very large pools with and without a manual

bypass valve.

INSTALLATION ABOVE/BELOW WATER SURFACE:

If the heater is installed less than three (3) feet above the surface of

Figure 09: Heater installation

above pool/spa

the pool/spa water, install eyeball fi ttings or directional fl ow fi ttings on

the end of the return water line to the pool/spa to create adequate back

pressure at the heater to operate the pressure safety switch when the

fi lter pump is running.

If the heater is installed more than three (3) feet above the surface

of the pool/spa water, install a loop as shown in Figure 0909 to prevent

drainage of water in the heater during a fi lter change.

For installation below the pool/spa surface, refer to Section III.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

Loading...

Loading...