Hayter Mowers RZT420H User Manual

Operator ’sManual

RZT420HRide-On

withRecycling/SideDischargeDeck

Code136E

SerialNo.280000001

ManualPartNo.111-2089RevB

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

Contents

Wheneveryouneedservice,genuineHayterparts,or

additionalinformation,contactanAuthorizedService

DealerorHayterCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

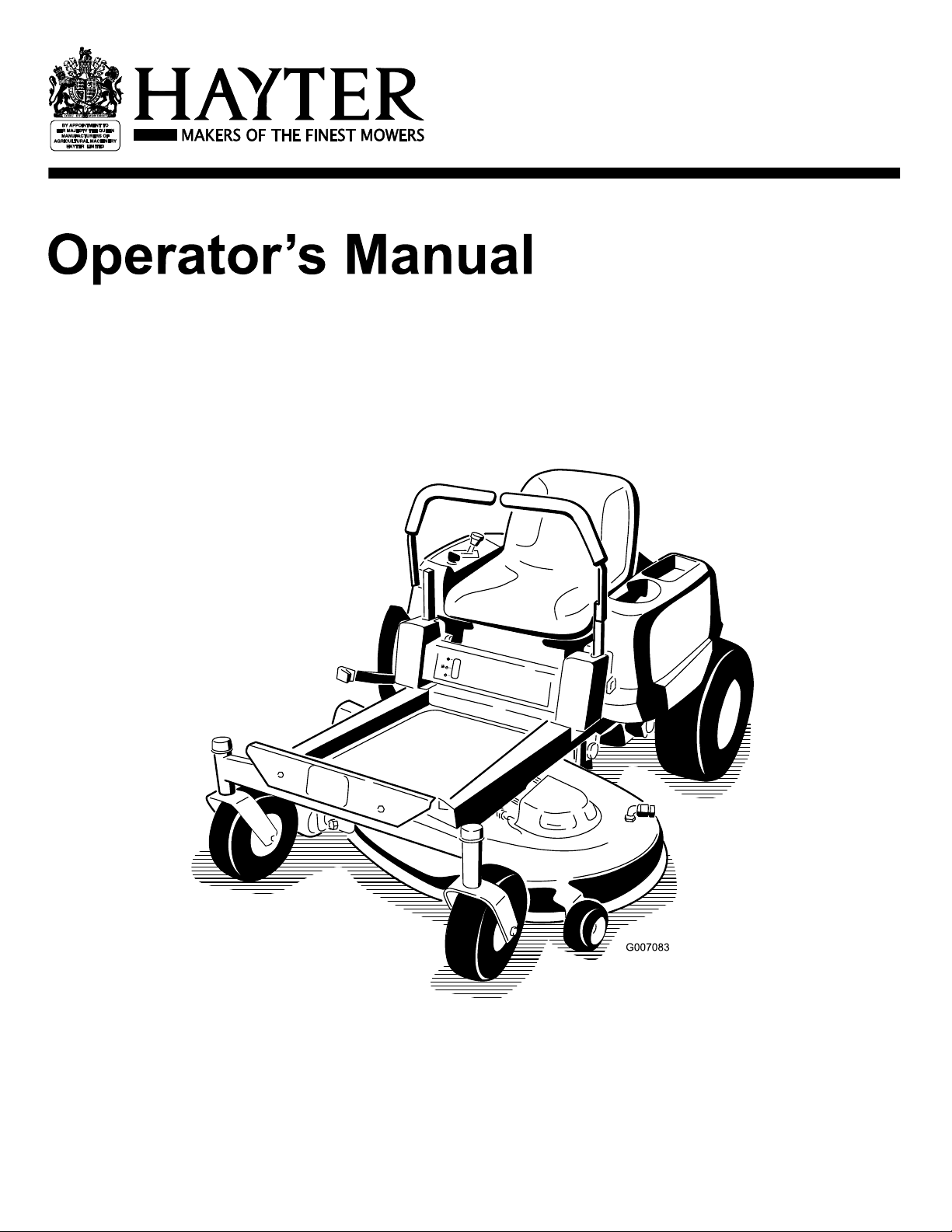

Figure1

Undertheseat

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

ModelNo.

SerialNo.

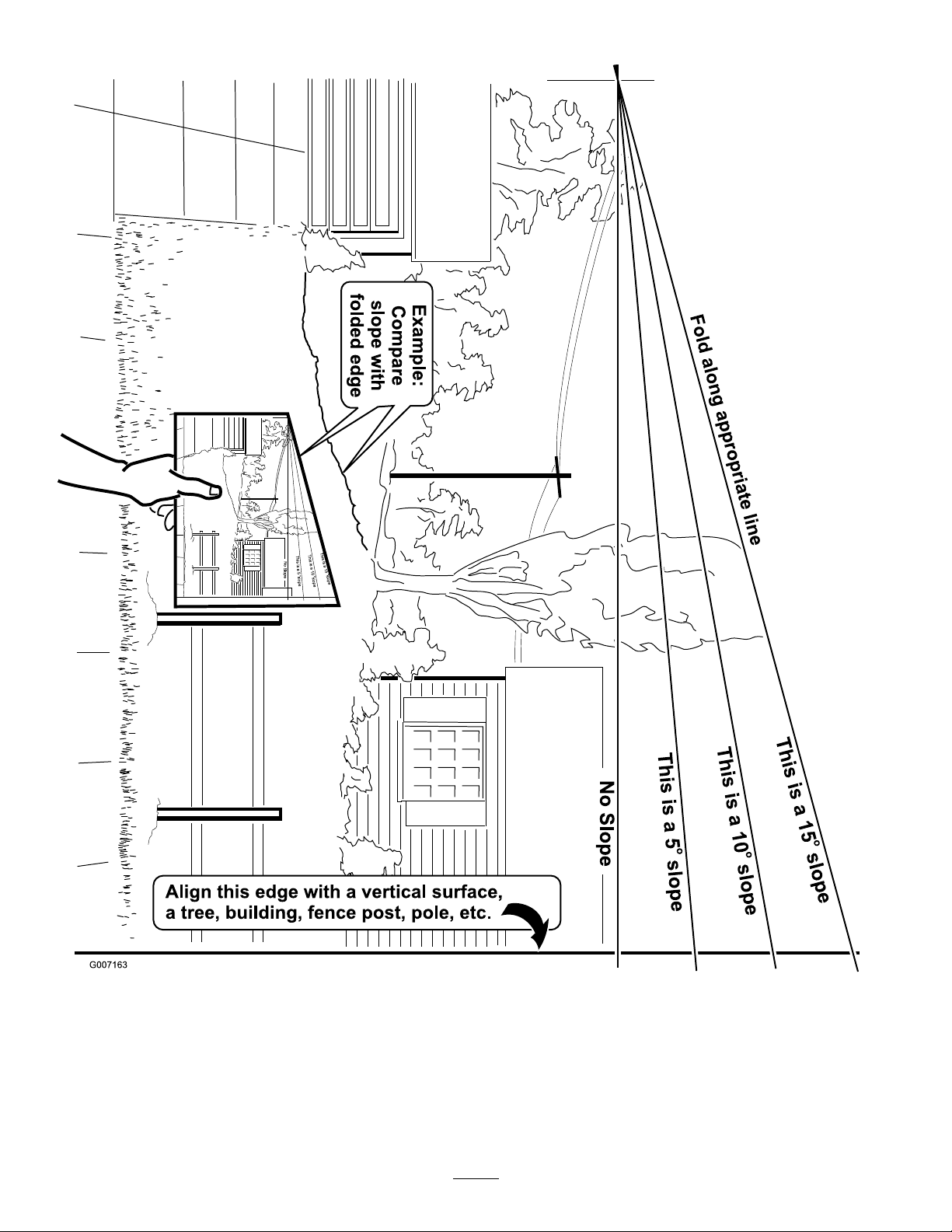

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol.

Introduction.................................................................2

Safety...........................................................................3

SafeOperationPracticesforRide-on(riding)

RotaryLawnmowerMachines...........................3

SafeOperatingPractices.......................................3

ZTurnRidingMowerSafety.................................5

SoundPressure.....................................................5

SoundPower........................................................5

Vibration..............................................................5

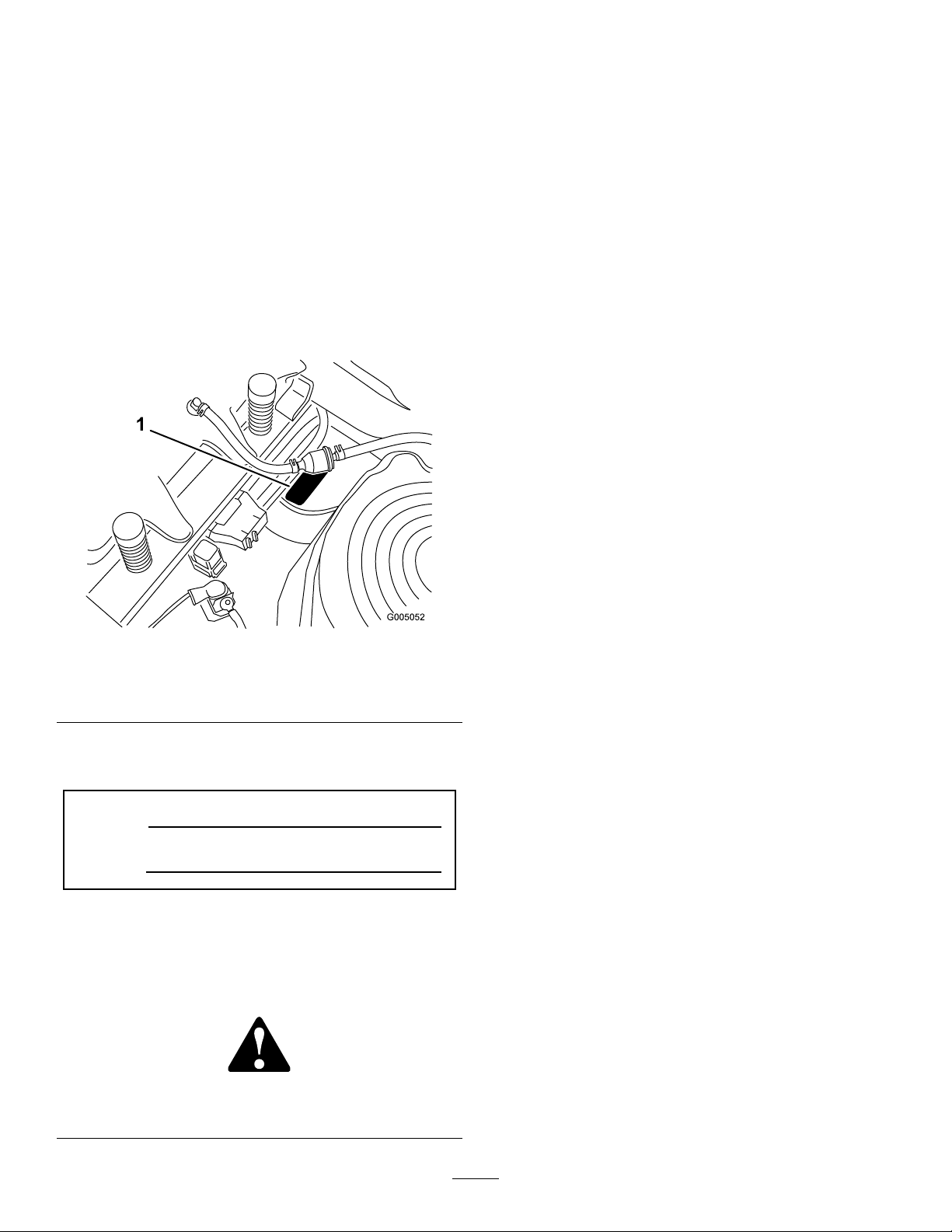

SlopeChart..........................................................6

SafetyandInstructionalDecals.............................7

Setup..........................................................................10

1SettingUptheMotionControlLevers..............10

2InstallingtheSeatCable...................................12

3ConnectingtheBattery....................................12

4CompletingtheSetup......................................13

ProductOverview......................................................14

Controls.............................................................15

Operation...................................................................16

ThinkSafetyFirst...............................................16

RecommendedFuel............................................16

CheckingtheEngineOilLevel............................18

StartingtheEngine.............................................18

OperatingtheBlades..........................................19

StoppingtheEngine...........................................19

TheSafetyInterlockSystem................................19

DrivingForwardorBackward.............................20

StoppingtheMachine.........................................20

AdjustingtheHeightofCut................................21

PositioningtheSeat............................................21

AdjustingtheMotionControlLevers..................21

PushingtheMachinebyHand.............................22

SideDischarge....................................................22

RemovingandInstallingtheDischarge

Cover.............................................................23

OperatingTips...................................................24

Maintenance...............................................................25

RecommendedMaintenanceSchedule(s)................25

PremaintenanceProcedures....................................26

RaisingtheSeat..................................................26

AccessingtheEngine..........................................26

AccessingtheBattery.........................................26

Lubrication.............................................................27

GreasingtheBearings.........................................27

EngineMaintenance...............................................28

©2008—HayterLimited,

AllRightsReserved

2

ServicingtheAirCleaner....................................28

ServicingtheEngineOil.....................................29

ServicingtheSparkPlug.....................................31

CleaningtheBlowerHousing..............................31

FuelSystemMaintenance.......................................32

ReplacingtheFuelFilter.....................................32

ElectricalSystemMaintenance................................33

ChargingtheBattery...........................................33

ServicingtheFuses.............................................34

DriveSystemMaintenance.....................................35

CheckingtheTyrePressure.................................35

CutterDeckMaintenance.......................................36

ServicingtheCuttingBlades...............................36

LevelingtheCutterDeckfrom

Side-to-Side....................................................37

AdjustingtheFront-to-RearBladeSlope.............38

RemovingtheCutterDeck.................................39

CutterDeckBeltMaintenance............................40

InstallingtheCutterDeck...................................40

ReplacingtheGrassDeector.............................41

Cleaning.................................................................42

WashingtheUndersideoftheCutter

Deck..............................................................42

Storage.......................................................................43

CleaningandStorage..........................................43

Troubleshooting.........................................................44

Schematics.................................................................46

Safety

SafeOperationPractices

forRide-on(riding)Rotary

LawnmowerMachines

ThismachinemeetsorexceedsEuropeanStandardsin

effectatthetimeofproduction.However,improper

useormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

CAUTION,WARNING,orDANGER-“personal

safetyinstruction.”Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheENstandard

EN836:1997.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Training

•Readtheinstructionscarefully.Befamiliarwiththe

controlsandtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethelawnmower.Localregulations

canrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby.

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessional

andpracticalinstruction.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

3

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

–stayalertforhumpsandhollowsandother

hiddenhazards;

•Usecarewhenpullingloads.

Preparation

•Whilemowing,alwayswearsubstantialfootwearand

longtrousers.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning-Fuelishighlyammable.

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladeboltsandcutterassemblyarenotworn

ordamaged.Replacewornordamagedbladesand

boltsinsetstopreservebalance.

•Onmulti-bladedmachines,takecareasrotatingone

bladecancauseotherbladestorotate.

–Useonlyapproveddrawbarhitchpoints.

–Limitloadstothoseyoucansafelycontrol.

–Donotturnsharply.Usecarewhenreversing.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguardsor

withoutsafetyprotectivedevicesinplace.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengineat

excessivespeedcanincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator’sposition:

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachments,stoptheengine,

anddisconnectthesparkplugwire(s)orremovethe

ignitionkey

–beforeclearingblockagesoruncloggingchute;

–beforechecking,cleaningorworkingonthe

lawnmower;

Operation

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutchesandshiftintoneutral.

•Donotuseonslopesofmorethan15degrees.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–uselowspeedsonslopesandduringtightturns;

–afterstrikingaforeignobject.Inspectthe

lawnmowerfordamageandmakerepairsbefore

restartingandoperatingtheequipment;

–ifthemachinestartstovibrateabnormally(check

immediately).

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment

–beforerefuelling;

–beforeremovingthegrasscatcher;

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’s

position.

•Reducethethrottlesettingduringenginerun-out

and,iftheengineisprovidedwithashut-offvalve,

turnthefueloffattheconclusionofmowing.

4

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumescanreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,silencer,

batterycompartmentandfuelstorageareafreeof

grass,leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,thisshouldbe

doneoutdoors.

•Whenmachineistobeparked,storedorleft

unattended,lowerthecuttingmeans.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanks,orwater.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.frommowingarea.Tallgrasscanhideobstacles.

•Watchforditches,holes,rocksdips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheelsmay

causedrivewheelstoslipandcauselossofbraking

andsteering.

ZTurnRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecicto

Hayterproductsorothersafetyinformationthatisnot

includedintheCENstandard.

•Engineexhaustcontainscarbonmonoxide,whichis

anodorless,deadlypoisonthatcankillyou.Donot

runengineindoorsorinanenclosedarea.

•Keephands,feet,hairandlooseclothingawayfrom

attachmentdischargearea,undersideofcutterdeck

andanymovingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjust,orservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyesandclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks,

andamesawayfrombattery.

•UseonlygenuineHayterreplacementpartstoensure

thatoriginalstandardsaremaintained.

•UseonlyHayter-approvedattachments.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftyreslosetraction,disengagethebladesand

proceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprovestability.

•Useextremecarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

SoundPressure

Thisunithasamaximumsoundpressurelevelatthe

operator’searof89dBA,basedonmeasurementsof

identicalmachinesperEN836andISO11201.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof100

dBA,basedonmeasurementsofidenticalmachinesper

ISO11094.

Vibration

SlopeOperation

•Donotmowslopesgreaterthan15degrees.

•Donotmowneardrop-offs,ditches,steepbanks,

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death,

ordrowning.

Thisunitdoesnotexceedahand/armvibrationlevelof

4.5m/s2,basedonmeasurementsofidenticalmachines

perEN836andEN1033.

Thisunitdoesnotexceedawholebodyvibrationlevel

of0.70m/s2,basedonmeasurementsofidentical

machinesperEN836andEN1032.

5

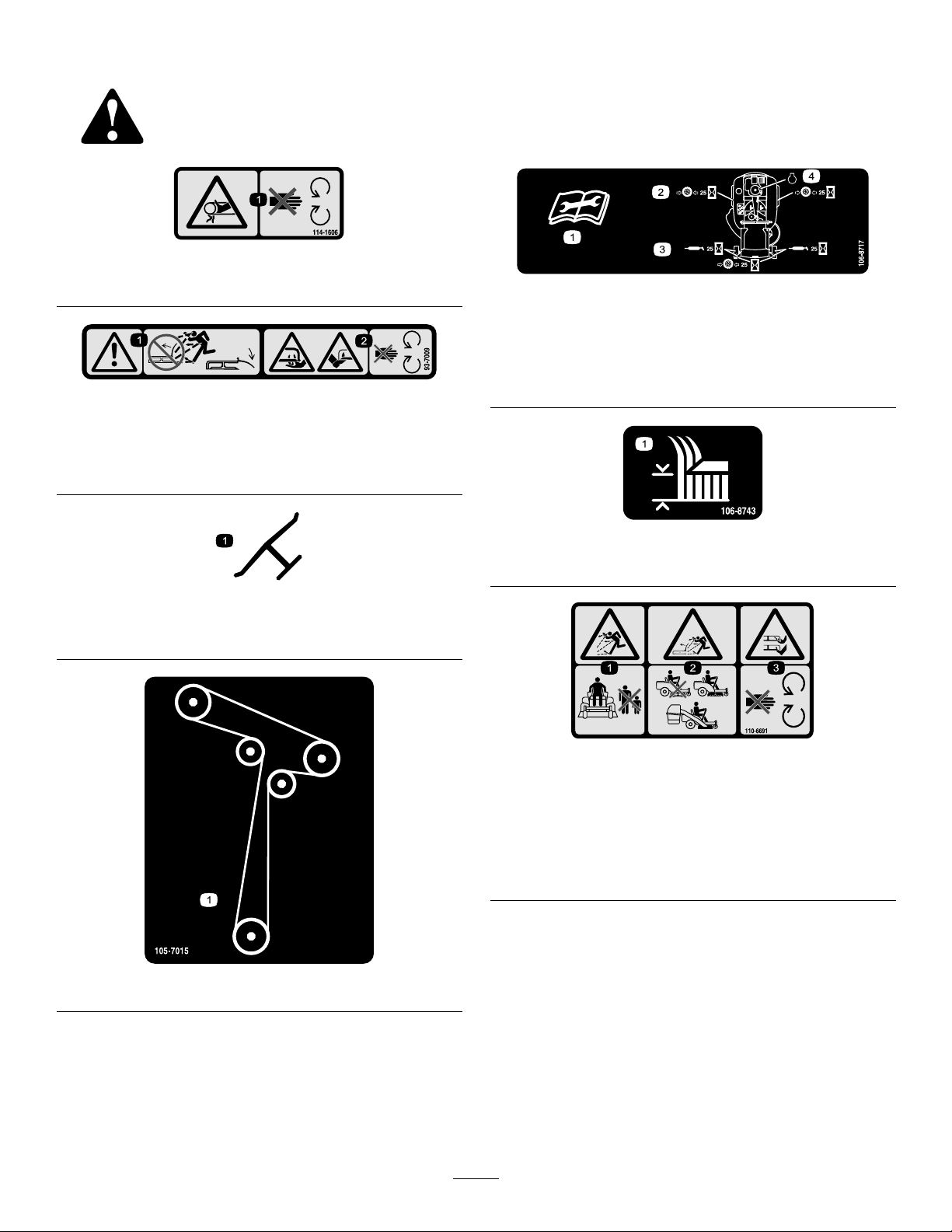

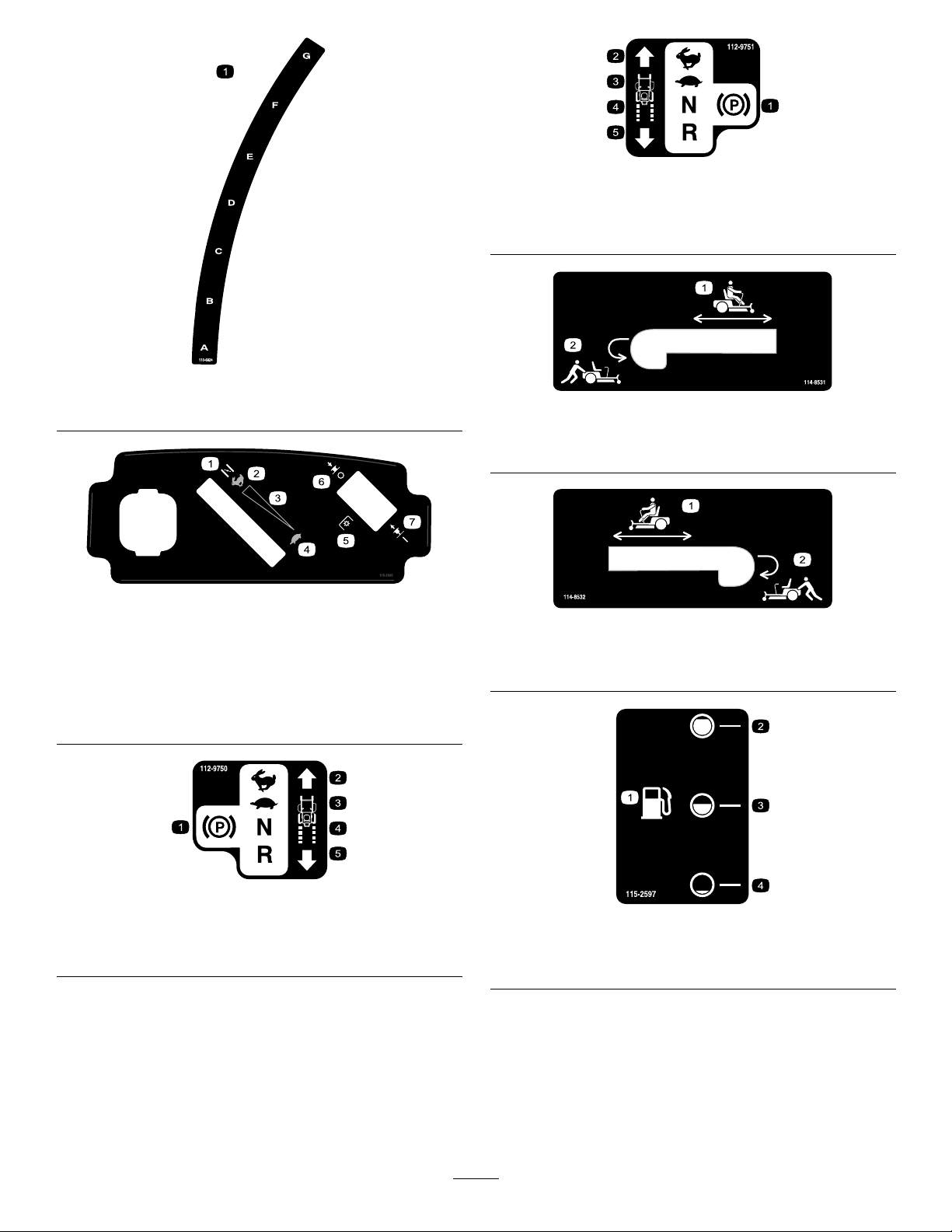

SlopeChart6SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

93-7009

1.Warning—don’toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktyrepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

106-8743

1.Heightofcut

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

105-7015

110-6691

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatethewithout

deector,dischargecoverorgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

7

110-6824

1.Height-of-cut

115-2500

1.Choke5.Powertake-off(PTO),

2.Fast

3.Continuousvariable

setting

4.Slow

Bladecontrolswitchon

somemodels

6.Bladecontrolswitch—Off

7.Bladecontrolswitch—On

112-9751

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

114-8531

1.Bypassleverpositionfor

operatingthemachine

114-8532

1.Bypassleverpositionfor

operatingthemachine

2.Bypassleverpositionfor

pushingthemachine

2.Bypassleverpositionfor

pushingthemachine

112-9750

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

1.Fuelgauge

2.Full4.Empty

8

115-2597

3.Half

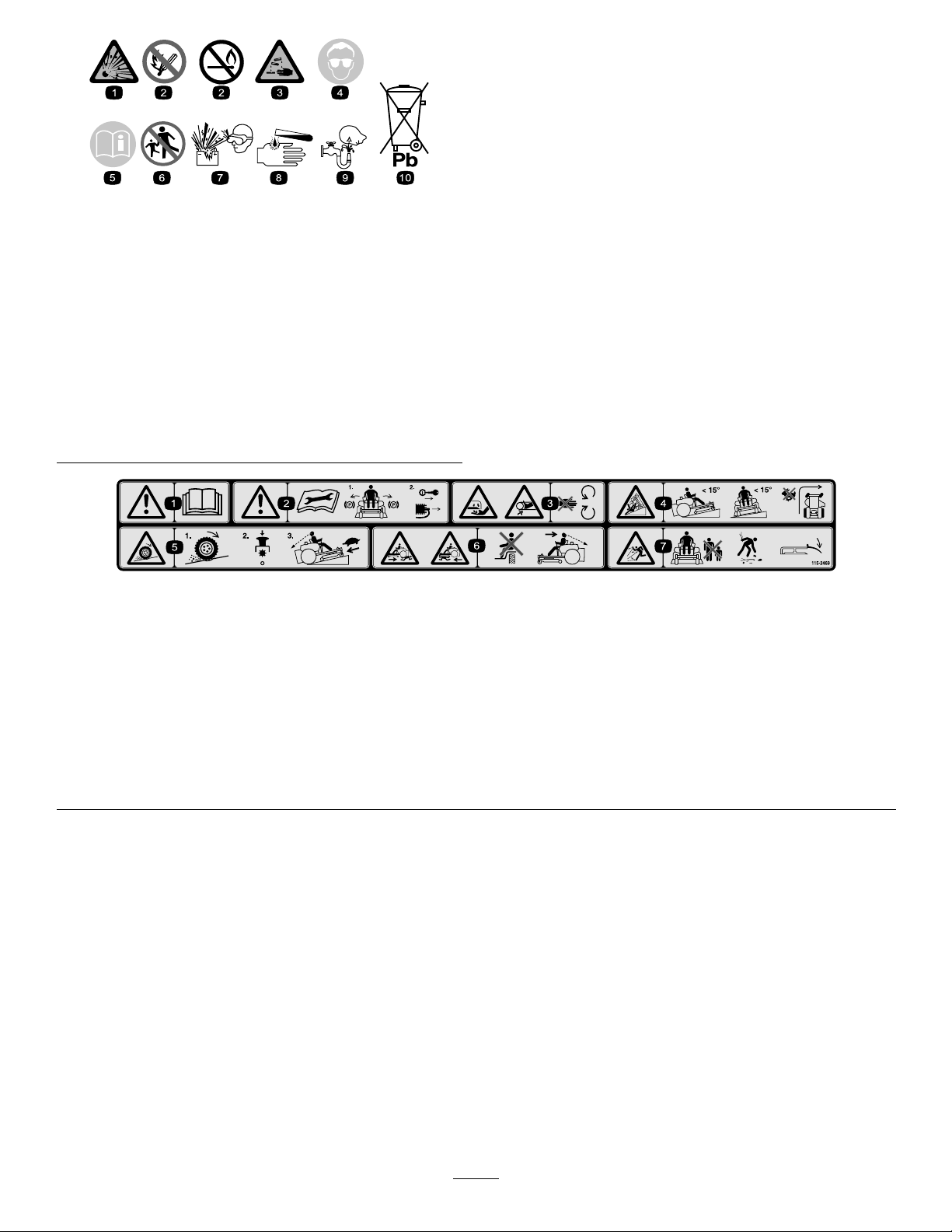

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

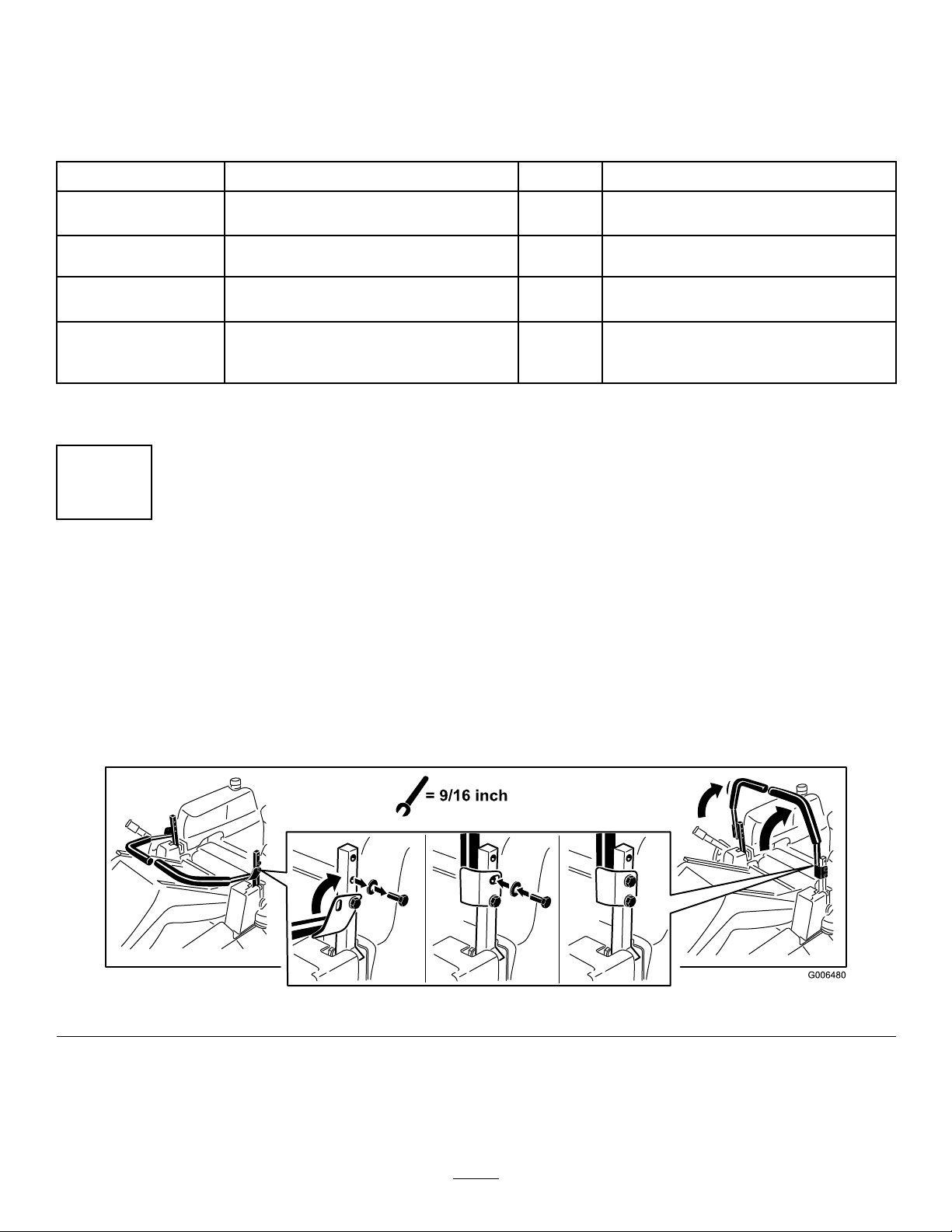

115-2469

1.Warning—readtheOperator’sManual.

2.Warning—readtheinstructionsbeforeservicingorperformingmaintenance;movethemotioncontrolleverstothepark(brake)

position,removetheignitionkeyanddisconnectthesparkplugwire.

3.Cutting/dismembermenthazard,mowerblade;entanglementhazard,belt—donotopenorremovesafetyshieldswhileengineis

running.

4.Tippinghazard—donotmowslopesgreaterthan15degrees,avoidsuddenandsharpturnswhileonslopes.

5.Lossoftraction/controlhazard,slopes—lossoftraction/controlonaslope,disengagethebladecontrolswitch(PTO),proceed

offtheslopeslowly .

6.Crushing/dismembermenthazardofbystanders,reversing;crushing/dismembermenthazardofbystanders—donotcarry

passengers,lookbehindanddownwhenreversing.

7.Thrownobjecthazard—keepbystandersasafedistancefromthemachine,pickupdebrisbeforeoperating,keepdeectorinplace.

9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Nopartsrequired

Clevispin

HairPin1

Nopartsrequired

IgnitionKey1

Operator’sManual

EngineOperator’sManual

Qty.

–

1

–

1

1

1

SettingUptheMotionControlLevers

NoPartsRequired

Use

Setupthemotioncontrollevers.

Installtheseatcable.

Connectthebattery .

CompletetheSetup.

Procedure

1.Removetheupperbolt(3/8x1inch)andwasher;loosenthelowerbolt(3/8x1inch)asshowninFigure3.

Raisethemotioncontrollevers.

2.Aligntheholesinthemotioncontrolleverwiththeholesinthecontrolarmshaftandinstalltheboltandwasher

removedpreviously(Figure3).Handtightenallfasteners.Repeatthisforbothcontrolslevers.

Figure3

10

3.Openthemotioncontrolleversandraisetheseat(Figure4).Movethecontrolleversbacktothecenter

G006481

G006482

position(neutral).

Figure4

4.Verifythemotioncontrolleversareproperlyaligned(Figure5).Adjustasnecessary.Tightenallfasteners.

Figure5

11

2

G005280

1 2 543

3

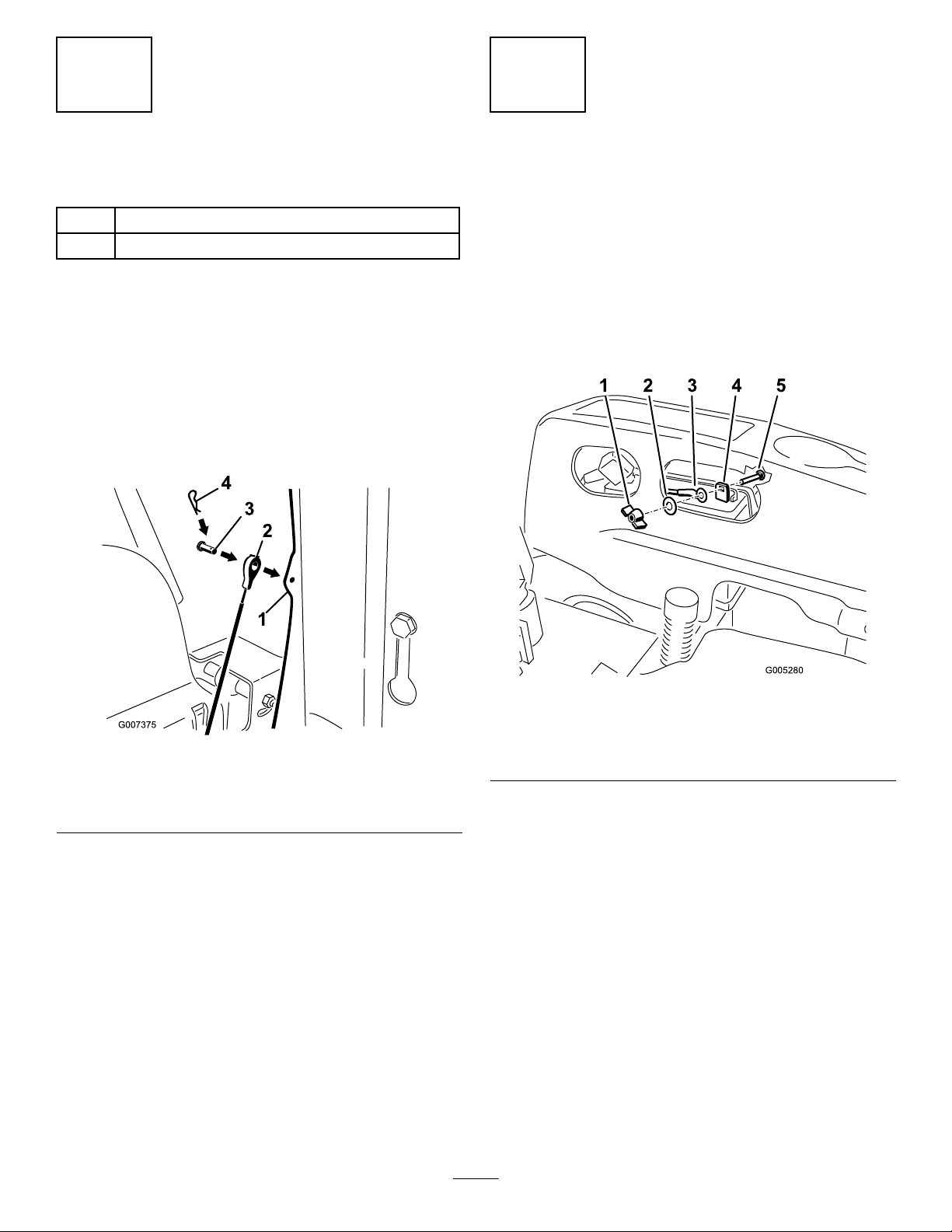

InstallingtheSeatCable

Partsneededforthisprocedure:

1

Clevispin

1HairPin

Procedure

1.Openthemotioncontrolleversandraisetheseat.

2.Locatetheseatcablesecuredtotheframe.Locate

theclevisandhairpinsinstalledonthelooseendof

theseatcable.

3.Securethelooseendoftheseatcabletotheframeas

shownusingtheclevisandhairpins(Figure6).

ConnectingtheBattery

NoPartsRequired

Procedure

1.Locatethebatteryandnegativebatterycableinthe

lefthandconsoleofthemachine.

2.Removethefastenersonthenegativebatterypost

andusethemtosecurethenegativebatterycableto

thenegativebatterycable(Figure7).

1.Seatframeunderside,left

side

2.Seatcable

Figure6

3.Clevispin

4.Hairpin

Figure7

1.Wingnut4.Negativebatterypost

2.Washer

3.Negativebatterycable

3.Lifttheseatfromtheoorboardandplaceitinto

theoperationposition.

5.Carriagebolt

12

4

CompletingtheSetup

Partsneededforthisprocedure:

1IgnitionKey

1

Operator’sManual

1

EngineOperator’sManual

Procedure

CheckingtheTyrePressure

Checkthefrontandreartyresforproperination.Refer

toCheckingtheTyrePressureintheOperator’ sManual

fortherecommendedinationpressure.

CheckingtheSideDischargeChute

Removethepackingrestraintholdingthesidedischarge

chuteupandlowerthechuteintoplace.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

theOilLevelintheOperator’ sManual.

CheckingtheCutterDeckAdjustment

Thecutterdeckwasleveledatthefactory.Ifthecutter

deckisnotcuttinglevel,adjusttheside-to-sideleveland

thefront-to-rearbladeslope.SeetheOperator’sManual

fortheproperprocedure.

ReviewtheRemainingParts

Keepallthefollowingitemswiththemachine:

•IgnitionKey

•Operator’sManual

•EngineOperator’sManual

13

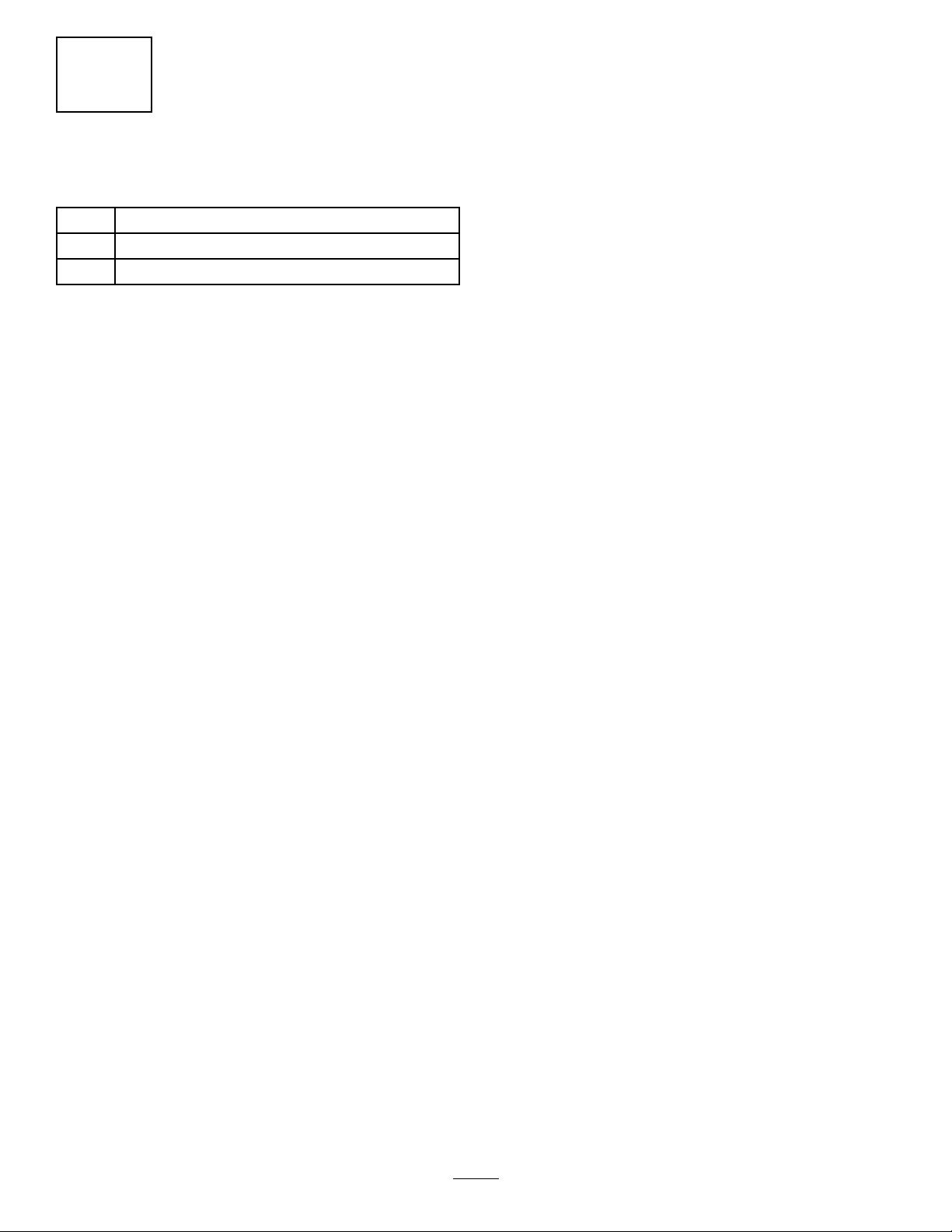

ProductOverview

1.Footrest

2.Heightofcutlever

3.Fuelgauge

Figure8

4.Controlpanel

5.Motioncontrollevers

6.Operatorseat9.Cutterdeck

7.Reardrivewheel10.Anti-scalproller

8.Washouttting

11.Frontcasterwheel

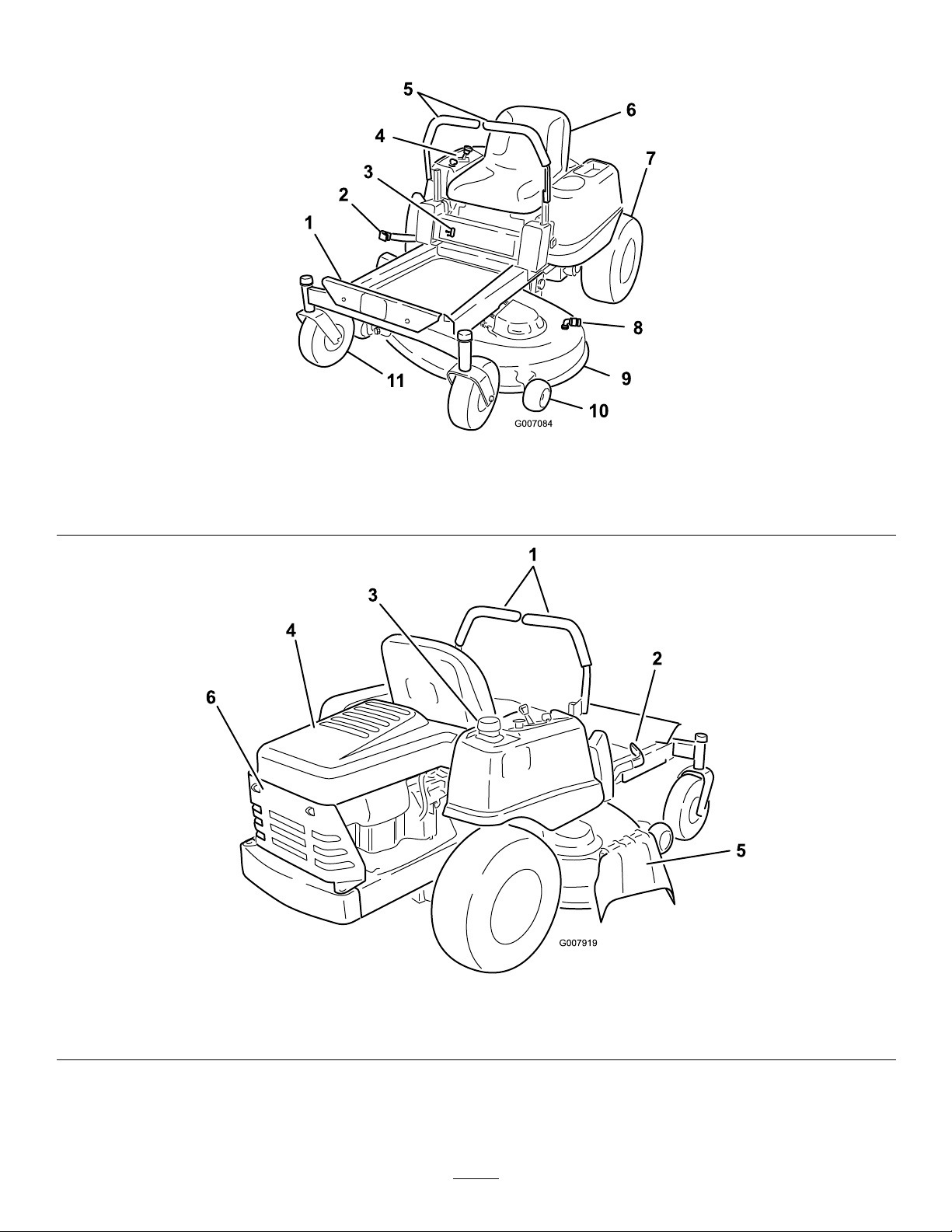

1.Motioncontrollevers3.Fueltankcap

2.Heightofcutlever

4.Enginecover6.Engineguard

Figure9

5.Deector

14

Controls

G005055

1

2

3

BecomefamiliarwithallofthecontrolsinFigure8,

Figure9,andFigure10beforeyoustarttheengineand

operatethemachine.

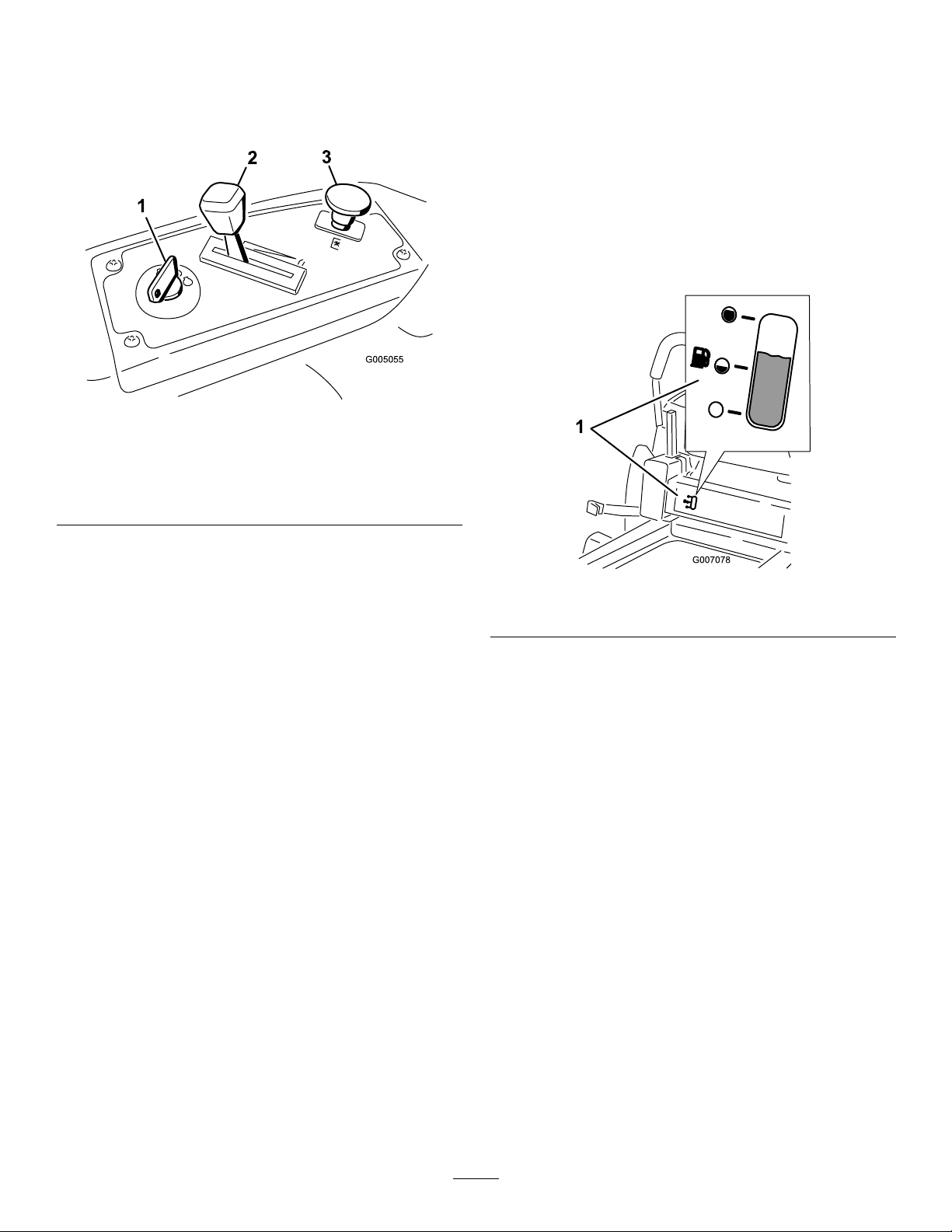

Figure10

ControlPanel

reverse;wheelspeedisproportionaltotheamountthe

leverismoved.Movethecontrolleversoutwardfrom

thecentertotheparkpositionandexitthemachine

(Figure20).Alwayspositionthemotioncontrollevers

intotheparkpositionwhenyoustopthemachineor

leaveitunattended.

FuelGauge

Thefuelwindowlocatedbelowtheoperatorposition

canbeusedtoverifythelevelofpetrolinthetank

(Figure11).

1.Ignitionswitch3.Bladecontrolswitch

(powertake-off)

2.Throttle/Choke

IgnitionSwitch

Theignitionswitchhasthreepositions,Off,Runand

Start.ThekeywillturntoStartandmovebackto

Runuponrelease.TurningthekeytotheOffposition

willstoptheengine;however,alwaysremovethekey

whenleavingthemachinetopreventsomeonefrom

accidentallystartingtheengine(Figure10).

Throttle/ChokeControl

Thethrottleandchokeiscombinedintoonecontrol

lever.Thethrottlecontrolstheenginespeedandithasa

continuousvariablesettingfromSlowtoFast.Engage

thechokebymovingtheleverpasttheFastsettinguntil

itstops(Figure10).

BladeControlSwitch(PowerTake-Off)

Figure11

1.Fuelgaugewindow

Height-of-CutLever

Theheightofcutleverallowstheoperatortolower

andraisethedeckfromtheseatedposition.Whenthe

leverismovedup,towardtheoperatorthedeckisraised

fromthegroundandwhenmoveddown,awayfromthe

operatoritisloweredtowardtheground.Onlyadjustthe

heightofcutwhilemachineisnotmoving(Figure21).

Thebladecontrolswitch,representedbyapower

take-off(PTO)symbol,engagesanddisengagespower

tothecutterdeckblades(Figure10).

MotionControlLeversandPark

Position

Themotioncontrolleversarespeedsensitivecontrolsof

independentwheelmotors.Movingaleverforwardor

backwardturnsthewheelonthesamesideforwardorin

15

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyou,yourfamily,petsorbystandersavoid

injury.

Mowingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityof

rollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

•Avoidsuddenturnsorrapidspeedchanges.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdownthe

slopereducestraction.

•Attachmentschangethehandling

characteristicsofthemachine.Useextra

cautionwhenusingattachmentswiththe

machine.

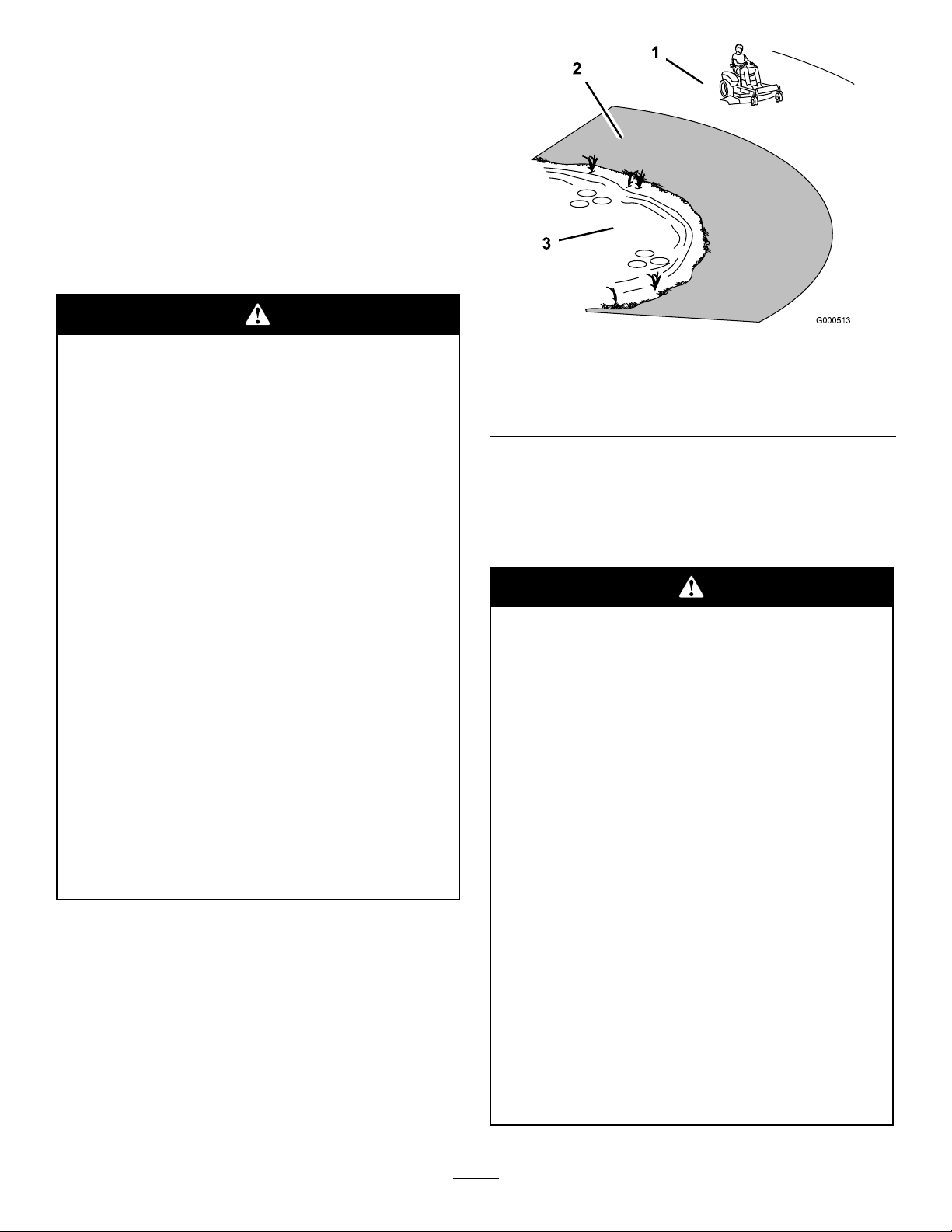

Figure12

1.SafeZone-usethemachinehere

2.Usewalkbehindmowerand/orhandtrimmerneardrop-offs

andwater.

3.Water

RecommendedFuel

Useunleadedregularpetrolsuitableforautomotive

use(87pumpoctaneminimum).

Incertainconditions,petrolisextremely

ammableandhighlyexplosive.Areor

explosionfrompetrolcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanypetrol

thatspills.

•Neverllthefueltankinsideanenclosed

space.

•Donotllthefueltankcompletelyfull.Add

petroltothefueltankuntilthebodyofthe

tankisfull.Alwaysleavetheneckemptyin

thefueltanktoallowthepetroltoexpand.

•Neversmokewhenhandlingpetrol,andstay

awayfromanopenameorwherepetrol

fumesmaybeignitedbyaspark.

•Storepetrolinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyofpetrol.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

16

Loading...

Loading...