Page 1

Operator ’sManual

RT380HTractor

G006889

withRecycling/SideDischargeDeck

Code135E

SerialNo.280000001

ManualPartNo.111-2091RevC

Page 2

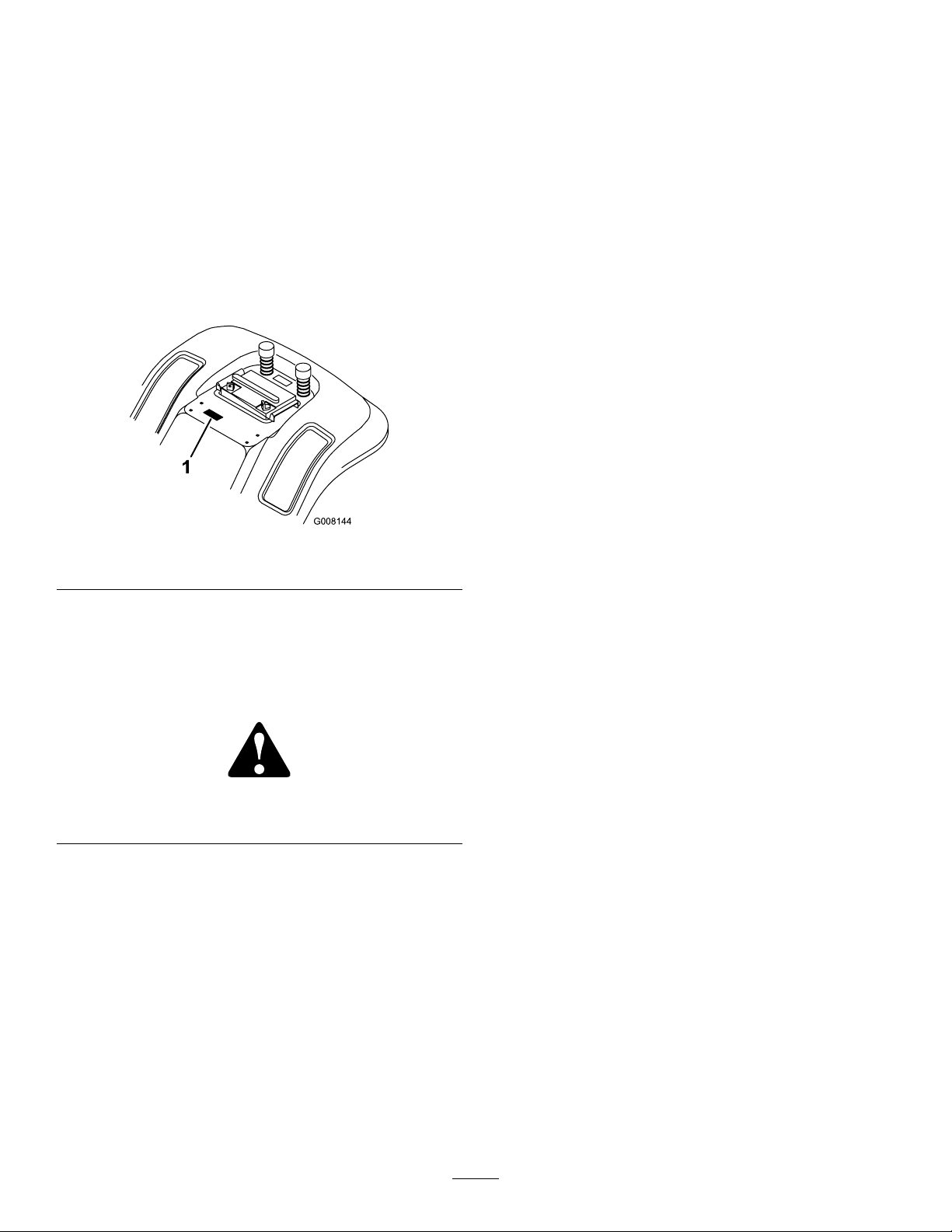

1

G008144

Contents

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

Wheneveryouneedservice,genuineparts,oradditional

information,contactanAuthorizedServiceDealer

orCustomerServiceandhavethemodelandserial

numbersofyourproductready.Figure1identiesthe

locationofthemodelandserialnumbersontheproduct.

Figure1

1.Modelandserialnumberlocation

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Introduction.................................................................2

Safety...........................................................................3

SafeOperationPracticesforRide-on(Riding)

RotaryLawnMowers........................................3

SoundPressure.....................................................5

SoundPower........................................................5

Vibration..............................................................5

SlopeChart..........................................................6

SafetyandInstructionalDecals.............................7

Setup..........................................................................10

1InstallingtheFrontWheels..............................11

2CheckingtheTyrePressure..............................11

3InstallingtheSteeringWheel............................11

4InstallingtheSeat.............................................12

5ActivatingtheBattery......................................12

6CheckingtheEngineOilLevel.........................13

7InstallingtheAnti-ScalpWheels.......................13

8PreparingtheCutterDeckDischarge

Chute.............................................................14

9LubricatingtheTractor....................................14

10CheckingtheSafetyInterlockSystem..............14

11PurgingtheHydroTransaxle..........................14

12CheckingtheHydroNeutralPosition..............15

13CheckingtheTractionControlPedal..............15

ProductOverview......................................................16

Controls.............................................................16

Operation...................................................................17

PetrolandOil.....................................................17

UsingtheParkingBrake......................................18

PositioningtheSeat............................................18

OperatingtheHeadlights....................................18

OperatingtheBladeControl(PTO)....................19

SettingtheHeight-of-Cut...................................19

StartingtheEngine.............................................19

StoppingtheEngine...........................................20

UsingtheSafetyInterlockSystem.......................20

TestingtheSafetyInterlockSystem.....................21

PushingtheTractorManually.............................21

DrivingForwardorBackward.............................22

StoppingtheTractor...........................................22

SideDischargeorMulchGrass...........................22

InstallingtheDischargeCover............................22

OperatingTips...................................................23

Maintenance...............................................................24

RecommendedMaintenanceSchedule(s)................24

Lubrication.............................................................25

GreasingandLubricatingtheTractor..................25

EngineMaintenance...............................................25

ServicingtheEngineOil.....................................25

ServicingtheAirCleaner....................................26

ServicingtheSparkPlug.....................................27

©2008—HayterLimited,

AllRightsReserved

2

Page 3

FuelSystemMaintenance.......................................28

DrainingtheFuelTank.......................................28

ReplacingtheFuelFilter.....................................29

ElectricalSystemMaintenance................................29

ServicingtheBattery...........................................29

ServicingtheFuse..............................................31

ServicingtheHeadlights.....................................31

DriveSystemMaintenance.....................................32

CheckingtheTyrePressure.................................32

ServicingtheTransaxleFluid..............................32

CoolingSystemMaintenance..................................33

CleaningtheCoolingSystem...............................33

BrakeMaintenance.................................................34

ServicingtheParkingBrake................................34

BeltMaintenance....................................................35

ReplacingtheBladeDriveBelt............................35

CutterDeckMaintenance.......................................35

ServicingtheBlades............................................35

LevelingtheCutterDeckfrom

Side-to-Side....................................................39

AdjustingtheFront-to-RearBladeSlope.............40

Cleaning.................................................................41

WashingtheUndersideoftheCutter

Deck..............................................................41

Storage.......................................................................42

Troubleshooting.........................................................44

Schematics.................................................................46

Safety

SafeOperationPracticesfor

Ride-on(Riding)RotaryLawn

Mowers

Readandunderstandthecontentsofthismanualbefore

operatingthetractor.

ThefollowinginstructionsarefromtheCENstandard

EN836:1997.

Thisproductiscapableofamputatinghandsandfeet

andofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Training

•Readtheinstructionscarefully.Befamiliarwiththe

controlsandtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethelawnmower.Localregulations

canrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby.

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessional

andpracticalinstruction.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

Preparation

•Whilemowing,alwayswearsubstantialfootwearand

longtrousers.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

3

Page 4

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning—Fuelishighlyammable.

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

•Usecarewhenpullingloadsorusingheavy

equipment.

–Useonlyapproveddrawbarhitchpoints.

–Limitloadstothoseyoucansafelycontrol.

–Donotturnsharply.Usecarewhenreversing.

–Usecounterweight(s)orwheelweightswhen

suggestedintheinstructionhandbook.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladeboltsandcutterassemblyarenotworn

ordamaged.Replacewornordamagedbladesand

boltsinsetstopreservebalance.

•Onmulti-bladedmachines,takecareasrotatingone

bladecancauseotherbladestorotate.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutchesandshiftintoneutral.

•Donotuseonslopesofmorethan

–5°whenmowingonsidehills;

–10°whenmowinguphill;

–15°whenmowingdownhill.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–engageclutchslowly,alwayskeepmachinein

gear,especiallywhentravellingdownhill;

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguardsor

withoutsafetyprotectivedevicesinplace.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengineat

excessivespeedcanincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator’sposition:

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachments,stoptheengine,

anddisconnectthesparkplugwire(s)orremovethe

ignitionkey

–beforeclearingblockagesoruncloggingchute;

–beforechecking,cleaningorworkingonthelawn

mower;

–afterstrikingaforeignobject.Inspectthelawn

mowerfordamageandmakerepairsbefore

restartingandoperatingtheequipment;

–ifthemachinestartstovibrateabnormally(check

immediately).

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment

–machinespeedsshouldbekeptlowonslopes

andduringtightturns;

–stayalertforhumpsandhollowsandother

hiddenhazards;

–nevermowacrossthefaceoftheslope,unless

thelawnmowerisdesignedforthispurpose.

–beforerefuelling;

–beforeremovingthegrasscatcher;

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’s

position.

4

Page 5

•Reducethethrottlesettingduringenginerun-out

and,iftheengineisprovidedwithashut-offvalve,

turnthefueloffattheconclusionofmowing.

•UseonlyHayter-approvedattachments.The

warrantymaybevoidedifyouusethetractorwith

unapprovedattachments.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumescanreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,silencer,

batterycompartmentandfuelstorageareafreeof

grass,leaves,orexcessivegrease.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,thisshouldbe

doneoutdoors.

•Onmulti-bladedmachines,takecareasrotatingone

bladecancauseotherbladestorotate.

•Whenmachineistobeparked,storedorleft

unattended,lowerthecuttingmeansunlessapositive

mechanicallockisused.

SoundPressure

Thisunithasamaximumsoundpressurelevelatthe

operator’searof89dBA,basedonmeasurementsof

identicalmachinesperEN836andISO11201.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof100

dBA,basedonmeasurementsofidenticalmachinesper

ISO11094.

Vibration

Thisunitdoesnotexceedahand/armvibrationlevelof

2.4m/s2,basedonmeasurementsofidenticalmachines

perEN836andEN1033.

Thisunitdoesnotexceedawholebodyvibration

levelof0.5m/s2,basedonmeasurementsofidentical

machinesperEN836andEN1032.

5

Page 6

SlopeChart6SafetyandInstructionalDecals

Page 7

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

92-5730

1.Choke3.Continuousvariable

2.Fast

setting

4.Slow

93-6674

1.Crushinghazard,hand—readtheinstructionsbefore

servicingorperformingmaintenance.

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

114-3236

1.Parkingbrake—toengage,pressthebrake/clutchpedal

andlifttheparkingbrakelever;todisengagepressand

releasethebrake/clutchpedal.

2.Brakeandclutch—toengage,pressthebrake/clutchpedal.

3.Tractiondrive—todriveinreverse,pressthebottomofthe

tractioncontrolpedalrearwardanddown;todriveforward,

pressthetopofthetractioncontrolpedalforwardanddown.

4.Warning—readtheOperator’sManual.

5.Warning—removetheignitionkeyandreadtheinstructions

beforeservicingorperformingmaintenance.

6.Tippinghazard—donotusethemachineonaslopegreater

than10degrees.

7.Crushing/dismembermentofabystander;thrownobject

hazard—keepbystandersasafedistancefromthe

machine.

8.Cutting/dismembermenthazardofhandorfoot,mower

blade;thrownobjecthazard,mower—stayawayfrom

movingparts;keepallguardsandshieldsinplace.

7

Page 8

93-6677

1.Warning—don’toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

93-6679

1.Engine

99-2986

1.Crushing/dismembermenthazardofbystanders—donot

turnthekeywhilechildrenarepresent;keepchildrenasafe

distancefromthemachine.

99-5340

1.Reverseinterlockkey—turntoenablereversemowing.

93-7009

1.Warning—don’toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

93-7317

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—keepthedeectorinplace.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

1.Mowinginreverseenabled

2.Engine—Stop

3.Engine—Run

99-8141

4.Engine—Start

5.Headlights

8

Page 9

1.Pulltheleverouttopush

themachine.

2.Pushtheleverintorideon

themachine.

100-7449

3.Readtheinstructions

beforeservicingor

performingmaintenance.

4.Donottowthemachine.

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

107-4922

1.Warning—toavoidtippingthetractor,donotdriveacross

slopesgreaterthan5degrees,upslopesgreaterthan10

degrees,ordownslopesgreaterthan15degrees.

2.Disengage

3.Engage

4.Powertake-off(PTO)

5.Parkingbrake

9

Page 10

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

Frontwheels2

Shimwashers(asrequired)

Flatwashers2

Cotterpins

Hubcaps2

Nopartsrequired

Steeringwheel

Spirolpin

Seat

Knobs2

Flat-washer2

Bulkelectrolyte,1.260specicgravity

(purchaseseparately)

Bolt(1/4x3/4inch)

Wingnut2

Nopartsrequired

Anti-scalpwheels2

Wheelbolt2

Locknut2

Nopartsrequired

needed

Qty.

As

Use

2

Installthefrontwheels.

2

–

1

1

1

2

–

–

Checkthetyrepressure.

Installthesteeringwheel.

Installtheseat.

Activatethebattery.

Checktheengineoillevel.

Installtheanti-scalpwheels.

Preparingthecutterdeckdischarge

chute.

9

10

11

12

13

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

–

–

–

–

–

MediaandAdditionalParts

Description

Ignitionkey1

Reverseinterlockkey1Enablemowingoperationinreverse.

Liftassistspringremovaltool

Operator’sManual

CerticateofConformance

Noisecerticate

Qty.

Starttheengine.

1

1

1

1

Saveforfuturemaintenanceuse.

Readbeforeoperating.

CEconformance

Lubricatethetractor.

Checkthesafetyinterlocksystem.

Purgethehydrotransaxle,

Checkthehydroneutralposition.

Checkthetractioncontrolpedal.

Use

10

Page 11

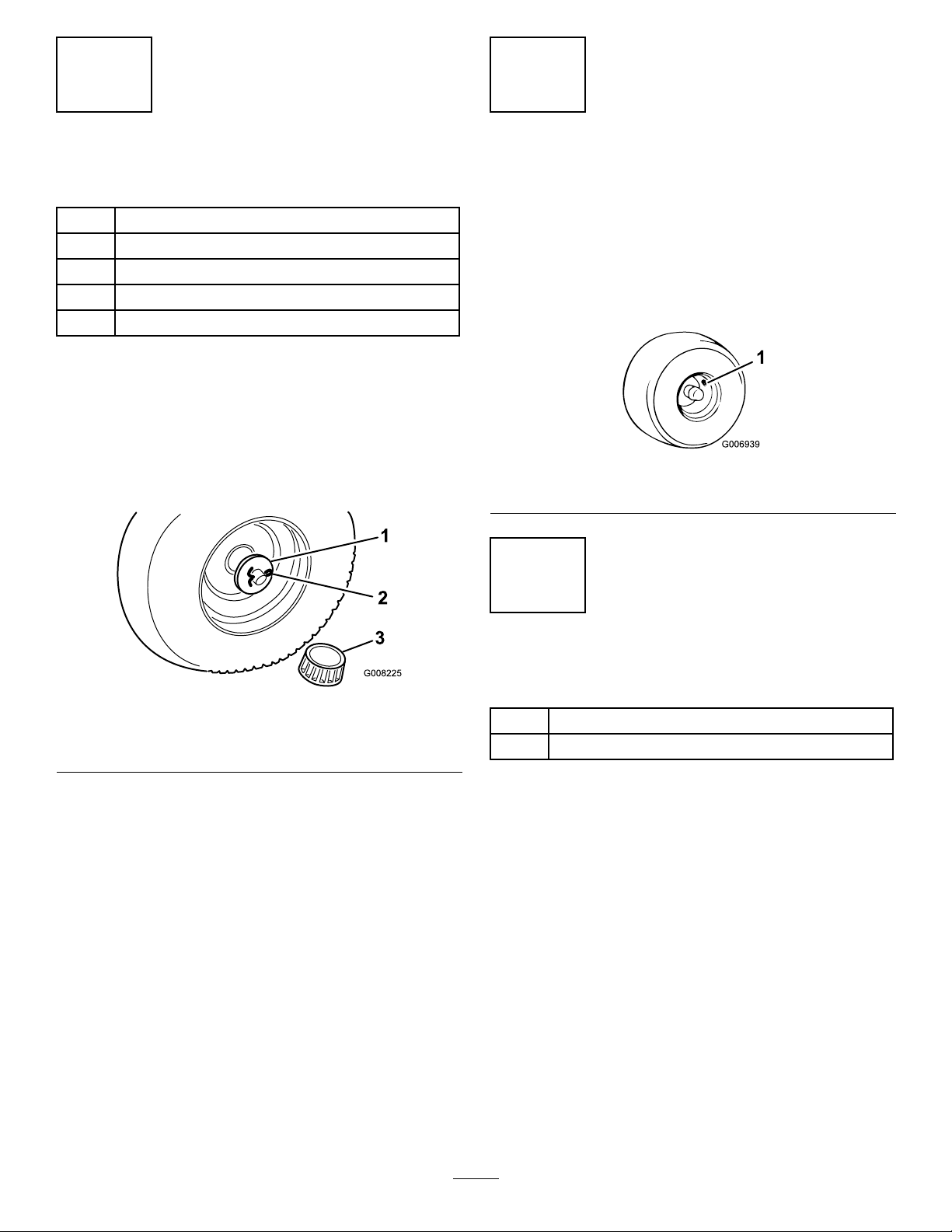

1

2

InstallingtheFrontWheels

Partsneededforthisprocedure:

2Frontwheels

2

Shimwashers(asrequired)

2Flatwashers

2

Cotterpins

2Hubcaps

Procedure

1.Installtheshimwashersontotheaxle.

2.Installthewheelontotheaxlewiththevalvestem

facingout.

3.Slidetheatwasherontotheaxle(Figure3).

CheckingtheTyrePressure

NoPartsRequired

Procedure

Ensurethattheairpressureinthefrontandreartyres

are20psi(138kPa).Checkthepressureatthevalve

stem(Figure4).

Figure4

1.Valvestem

Figure3

1.Flatwasher3.Hubcap

2.Cotterpin

4.Insertthecotterpinthroughtheaxleandbendthe

endsofthepinapart(Figure3).

Note:Ifthecotterpindoesnott,removethe

shimwasher(s)asneeded.

5.Pushthehubcap(Figure3)ontotheendoftheaxle.

6.Repeatsteps1through5ontheoppositesideof

thetractor.

7.Greasethewheelbearingsuntilthegreasecomesout

ofthebearingsealarea.

3

InstallingtheSteeringWheel

Partsneededforthisprocedure:

1

Steeringwheel

1

Spirolpin

Procedure

1.Movethefrontwheelssothattheyfacestraight

ahead.

2.Slidethesteeringwheeloverthesteeringshaftand

lineuptheholeinthesteeringwheelwiththeholein

theshaft(Figure5).

Note:Fromtheseatyoushouldbeabletoreadthe

brandlogoonthesteeringwheel.

11

Page 12

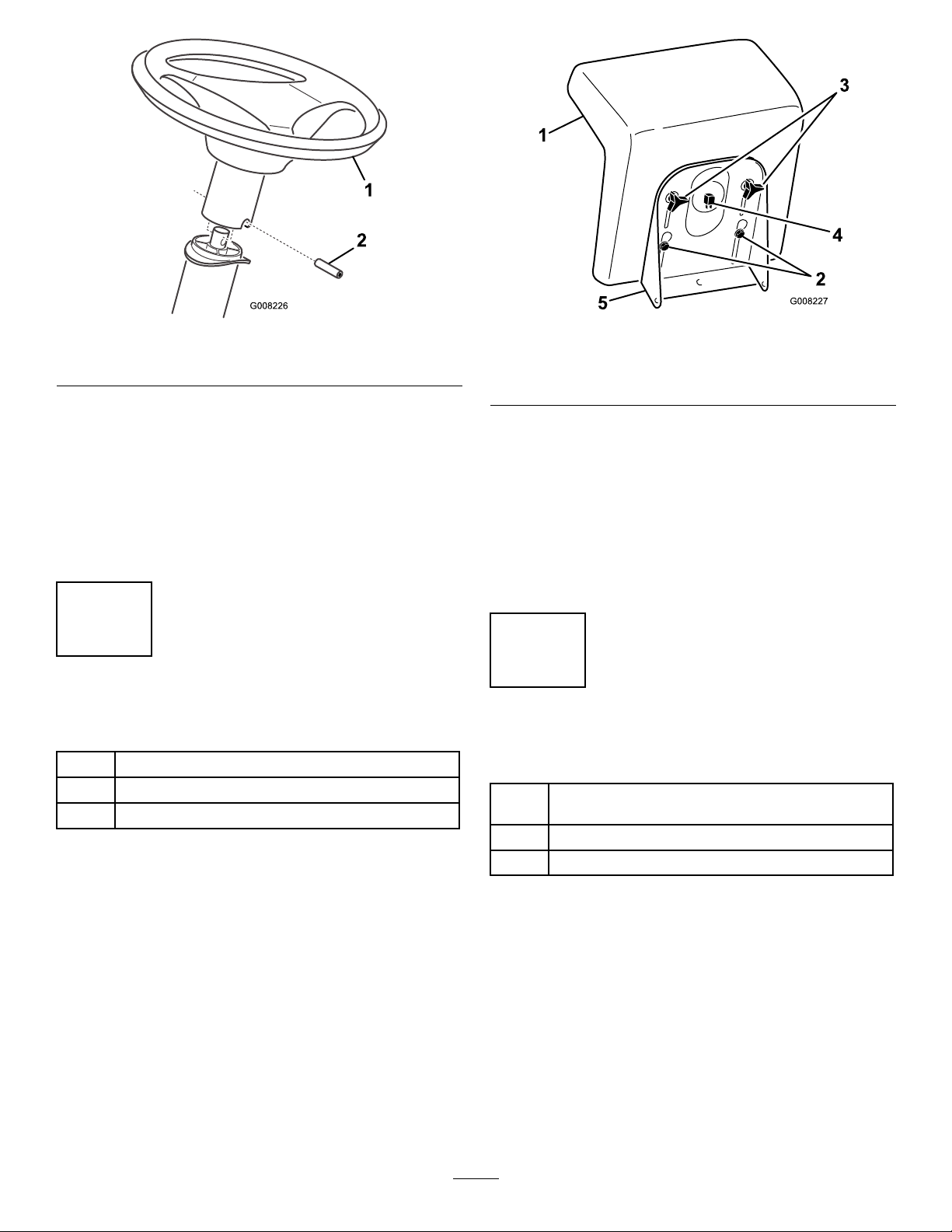

Figure5

1.Steeringwheel2.Spirolpin

3.Aligntheholesbyinsertingapunchoralongnail

partiallythroughtheholesinthesteeringwheeland

shaft.

Figure6

1.Seat4.Seatswitch

2.Shoulderbolts5.Seatbase

3.Knobsandatwashers

2.Threadtheknobsandatwashersthroughtheslots

andintotherearcenterholesintheseat(Figure6).

4.Insertthespirolpinintotheholeontheopposite

side(Figure5).

5.Usingahammer,drivethespirolpininuntilitisush

withtheoutsideofthesteeringwheel(Figure5).

4

InstallingtheSeat

Partsneededforthisprocedure:

1

Seat

2Knobs

2Flat-washer

Procedure

1.Positiontheseatontotheseatbasebyinserting2

shoulderboltsthroughthekeyholeopeningsatthe

endofbothslots(Figure6).

3.Adjusttheseatandtightentheknobs.

4.Connecttheseatswitchtothewireharness

connector(Figure6).

Note:Ensurethatthewiringisnotpinchedinthe

seatbrackets.

5

ActivatingtheBattery

Partsneededforthisprocedure:

As

needed

Procedure

Purchasebulkelectrolytewith1.260specicgravity

fromalocalbatterysupplyoutlet.

Bulkelectrolyte,1.260specicgravity(purchase

separately)

2

Bolt(1/4x3/4inch)

2Wingnut

Important:Neverllthebatterywithelectrolyte

whilethebatteryisinstalledinthetractor.

Electrolytecouldbespilledonotherpartsand

corrodethem.

1.Removethebatteryandbatteryboxfromthetractor;

refertoRemovingtheBatteryinMaintenance.

12

Page 13

Batteryelectrolytecontainssulfuricacid,a

deadlypoisonthatcanseverelyburnyouand

others.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyes,orclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

•Followallinstructionsandcomplywithall

safetymessagesontheelectrolytecontainer.

2.Removetheventcapsfromthebattery.

3.Slowlypourelectrolyteintoeachbatterycelluntil

theelectrolytelevelisuptotheUpperlineonthe

batterycase(Figure7).

Important:Donotoverllthebatterybecause

electrolyte(sulfuricacid)canseverelycorrode

anddamagethechassis.

Figure8

1.Positivepost

2.Negativepost

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfromthebattery.

8.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(Figure8).

9.Installthebatteryandbatteryboxinthetractorand

connectthebatterycables,usingthe2bolts(1/4x

3/4inch)andwingnutssuppliedinthelooseparts;

refertoInstallingtheBatteryinMaintenance.

3.Chargerred(+)wire

4.Chargerblack(–)wire

Figure7

1.Ventcaps3.Lowerline

2.Upperline

4.Wait5to10minutesafterllingthebatterycells.

5.Addelectrolyte,ifnecessary,untiltheelectrolytelevel

isuptotheUpperline(Figure7)onthebatterycase

6.Installthebatteryventcaps.

7.Chargethebatteryfor10to15minutesat25to30

ampsor30minutesat4to6amps(Figure8).Do

notoverchargethebattery.

6

CheckingtheEngineOilLevel

NoPartsRequired

Procedure

Beforeyoustarttheengineandusethetractor,check

theoillevelintheenginecrankcase;refertoChecking

theEngineOilLevel,inMaintenance.

13

Page 14

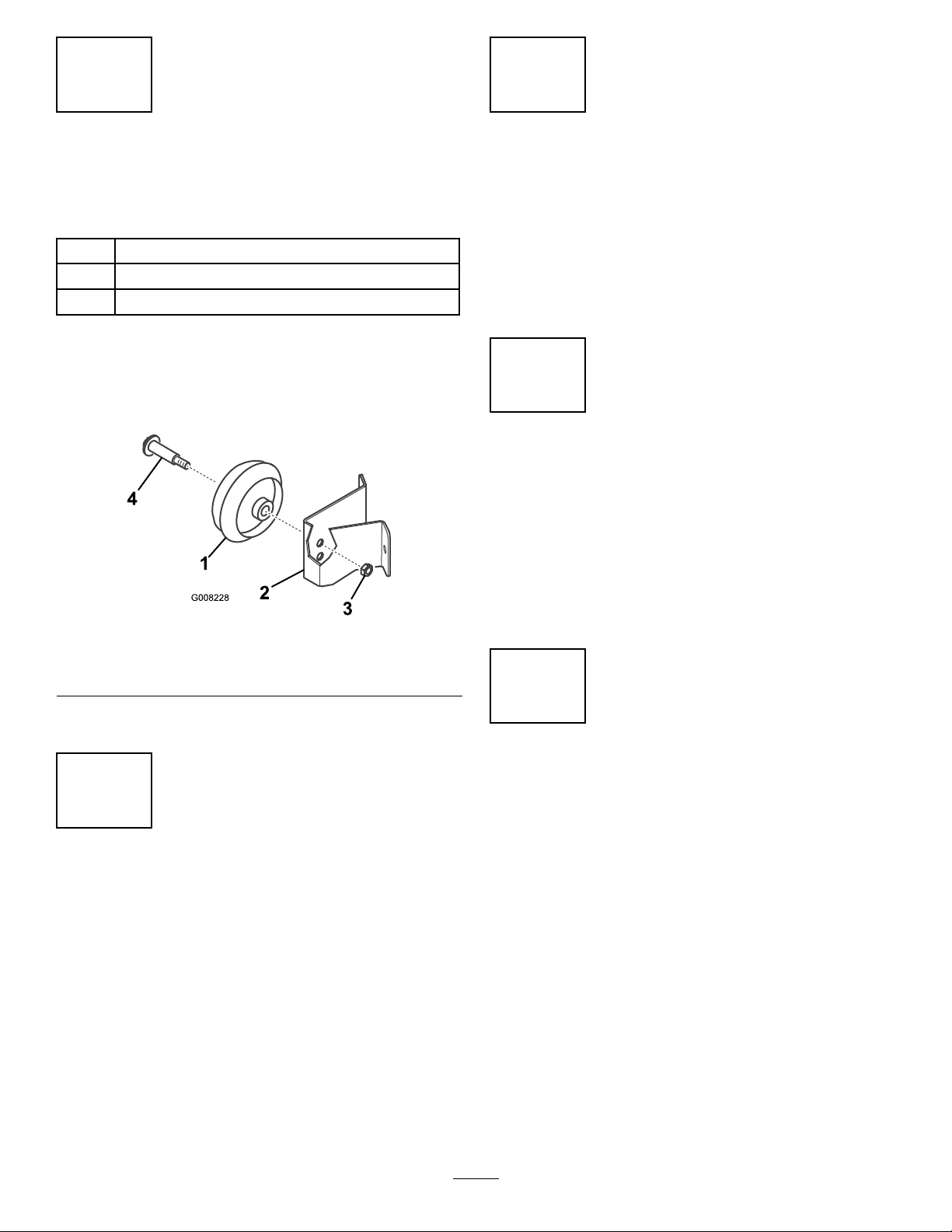

7

9

InstallingtheAnti-Scalp

Wheels

Partsneededforthisprocedure:

2Anti-scalpwheels

2Wheelbolt

2Locknut

Procedure

Mounttheanti-scalpwheelsontothewheelbrackets

withthewheelboltsandlocknut(Figure9).

LubricatingtheTractor

NoPartsRequired

Procedure

Ensurethatallofthenecessarypointsonthetractorare

lubricated;refertoGreasingandLubricatingtheTractor

inMaintenance.

10

CheckingtheSafetyInterlock

System

NoPartsRequired

Procedure

Figure9

1.Wheel3.Locknut

2.Wheelbracket4.Wheelbolt

Note:Usethesameholeheightonbothsides.

8

PreparingtheCutterDeck

DischargeChute

NoPartsRequired

Procedure

1.Removetherollpinfromthedischargechutespring

anddiscardthepin.

Checkthesafetyinterlocksystem;refertoTestingthe

SafetyInterlockSysteminOperation.

11

PurgingtheHydroTransaxle

NoPartsRequired

Procedure

Shippingandhandlingcanintroduceairintothehydro

transaxle.Forproperperformance,removeallthe

trappedair.

1.Movethetractortoaat,levelsurface

2.PlacethedrivecontrolinthePushposition

(Figure10).

Note:Therollpinisforshipmentonly

2.Ensurethatthespringreturnsthedischargechute

tothefulldownposition.

14

Page 15

4.Stoptheengineandwaitforallmovingpartstostop.

5.Removetheignitionkey.

6.Raisetherightrearwheeloffthegroundandsupport

itwithajackstand.

Note:Ensurethattheleftrearwheelstaysonthe

ground.

Mechanicalorhydraulicjacksmayfailto

supportthetractorandcauseaseriousinjury.

Figure10

1.Operateposition

3.Runtheengineatalowidleandmovethetraction

controlpedalforwardfor5seconds,thenreversefor

5seconds.Repeatthisstep3times.

4.PlacethedrivecontrolintheOperateposition

(Figure10)anddrivethetractorforwardabout5

feet(1.5m),thenreverseforabout5feet(1.5m).

Repeatthisstep3times.

2.Pushposition

12

CheckingtheHydroNeutral

Position

NoPartsRequired

•Usejackstandswhensupportingthetractor.

•Donotusehydraulicjacks.

Note:Togainaccesstotheadjustingpuck

(Figure11),youmayneedtoremovethetire.

Figure11

1.Adjustingpuckscrew2.Adjustingpuck

Procedure

Ensurethattheneutralpositionissetproperly.Ifthe

tractormoveswhenthetractioncontrolpedalisnot

pressed,adjusttheneutralposition.

1.WiththetractorintheNeutralposition,runthe

engineatalowidleandmovethetractioncontrol

pedalforward,thenrelease.

2.Movethetractioncontrolpedaltoreverse,then

release.

IfthetractormoveswhileitisintheNeutralposition,

completethefollowingproceduretoadjustit:

1.Runthetractorfor5to10minutestowarmupthe

transaxle.

2.Disengagetheblade(PTO).

3.Settheparkingbrake.

7.Loosentheadjustingpuckscrew(Figure11).

8.Starttheengineandrunitatfullthrottle.

9.Rotatetheadjustingpuck(Figure11)inboth

directionsuntilyoundthemidpointwheretheaxle

nolongerrotatesforwardorreverse.

10.Holdthepuckwithanadjustablewrenchsothatit

willnotmoveandtorquetheadjustingpuckscrew

to21to27ft-lb(28to36N-m).

11.Stoptheengineandwaitforallmovingpartstostop

12.Removetheignitionkey.

13.Lowerthetractorfromthejackstand.

14.Checktheadjustment.

15

Page 16

ProductOverview

13

CheckingtheTractionControl

Pedal

NoPartsRequired

Procedure

Ifthetractordrivestoofastorslowwiththetraction

controlpedalfullypressedineitherdirection,youcan

adjustittosettheoptimumforwardandreversespeeds,

asfollows:

1.Loosenthescrewsbelowtherightfootrest.

2.Slidethepedalforwardforafasterreversespeedor

backwardforafasterforwardspeed(Figure12).

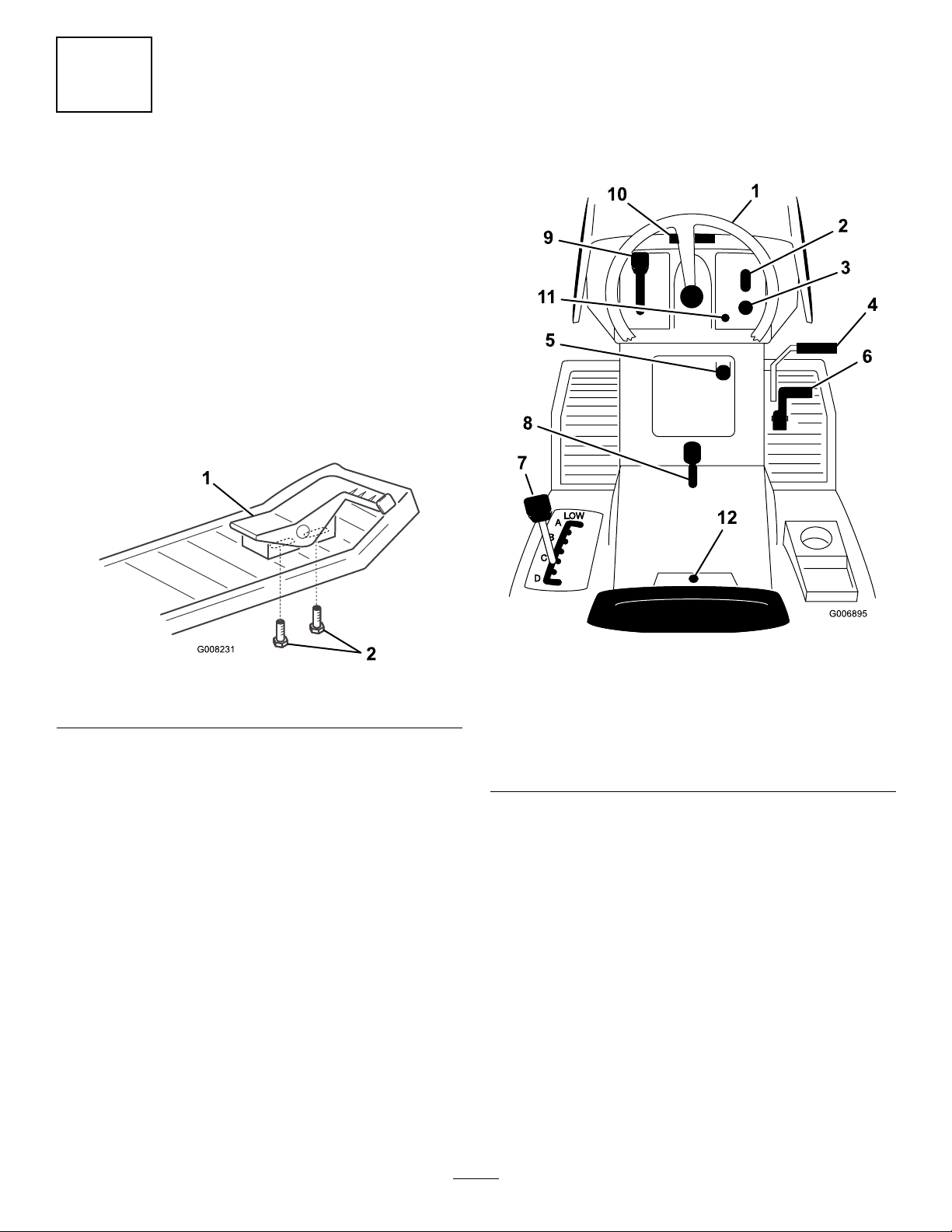

Controls

Becomefamiliarwiththecontrols(Figure13)before

youstarttheengineandoperatethetractor.

Figure12

1.Tractioncontrolpedal2.Adjustingscrews

3.Tightenthescrews.

4.Checkthetractioncontrolpedal.

Figure13

1.Steeringwheel7.Height-of-cutlever

2.Lightswitch—on/off

3.Ignitionswitch9.Throttlelever

4.Clutch/brakepedal

5.Bladecontrol(PTO)11.Operating-in-reverselight

6.Tractioncontrolpedal12.Reverseinterlockswitch

8.Parkingbrakelever

10.Hoodopening

16

Page 17

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

PetrolandOil

Useunleadedpetrolsuitableforautomotiveuse(85

pumpoctaneminimum).

Incertainconditions,petrolisextremely

ammableandhighlyexplosive.Areor

explosionfrompetrolcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoorsinanopenarea

whentheengineiscold.Wipeupanypetrol

thatspills.

•Donotllthefueltankcompletelyfull.Add

petroltothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsthepetroltoexpand.

•Neversmokewhenhandlingpetrol,andstay

awayfromanopenameorwhereaspark

mayignitethepetrolfumes.

•Storepetrolinanapprovedcontainerand

keepitoutofthereachofchildren.

•Neverbuymorethana30-daysupplyof

petrol.

•Alwaysplacepetrolcontainersonthe

groundawayfromyourvehiclebeforelling .

•Donotllpetrolcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,refuelsuchequipment

onatruckortrailerfromaportable

container,notfromapetroldispenser

nozzle.

•Ifyoumustuseapetroldispenser,keepthe

nozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthetractorto

providethefollowingbenets:

•Itkeepspetrolfreshduringstorageforupto90

days.Forlongerstorage,drainthefueltank.

17

Page 18

•Itcleanstheenginewhileitruns.

•Iteliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothepetrol.

Note:Afuelstabilizer/conditionerismosteffective

whenitismixedwithfreshpetrol.Tominimizethe

chanceofvarnishdepositsinthefuelsystem,useafuel

stabilizer/conditioneratalltimes.

FillingtheFuelTank

1.Settheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanaroundthefueltankcapandremovethecap.

4.Addunleadedpetroltothefueltankuntilthe

levelis1/4to1/2inch(6to13mm)belowthe

bottomofthellerneck.Donotllthefueltank

completelyfull.

Note:Thespaceinthetankallowspetrolto

expand.

5.Installthefueltankcapsecurely .

6.Wipeupanypetrolthatspills.

Figure14

1.Brakepedal2.Parkingbrakelever

2.Lifttheparkingbrakelever(Figure14)upand

graduallytakeyourfootoffofthebrakepedal.

Note:Thebrakepedalshouldstayinthedepressed

(locked)position.

ReleasingtheParkingBrake

1.Pushdownonthebrakepedal(Figure14).

Note:Theparkingbrakelevershouldrelease.

2.Graduallyreleasethebrakepedal.

PositioningtheSeat

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthetractor

andaremostcomfortable.

1.Raisetheseatandloosentheadjustmentknobs

(Figure15).

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Beforeyoustarttheengineandusethetractor,check

theoillevelintheenginecrankcase;refertoChecking

theEngineOilLevel,inMaintenance.

UsingtheParkingBrake

Alwayssettheparkingbrakewheneveryoustopthe

tractororleaveitunattended.

SettingtheParkingBrake

1.Pushthebrakepedal(Figure14)downandholdit.

Figure15

1.Adjustmentknobs

2.Movetheseattothedesiredpositionandtighten

theknobs.

OperatingtheHeadlights

Adash-mountedOn/Offswitch(Figure13)controls

theheadlights.Thelightsonlyshinewhiletheengineis

runningandtheswitchisOn.

18

Page 19

OperatingtheBladeControl

StartingtheEngine

(PTO)

Thebladecontrol(PTO)engagesanddisengages

powertotheelectricclutch.

EngagingthePowerTakeOff(PTO)

1.Presstheclutch/brakepedaltostopthetractor.

2.Pullthebladecontrol(PTO)toon(Figure16).

Figure16

1.Off—disengaged2.On—engaged

DisengagingtheBladeControl(PTO)

1.Presstheclutch/brakepedaltostopthetractor.

2.Pushthebladecontrol(PTO)tooff(Figure16).

1.Sitdownontheseat.

2.Settheparkingbrake;refertoSettingtheParking

Brake.

Note:Theenginedoesnotstartunlessyousetthe

parkingbrakeorfullydepressthebrakepedal.

3.Pushthebladecontrol(PTO)tooff(Figure16).

4.ShiftthethrottlelevertoChoke(Figure18).

Figure18

1.Choke3.Slow

2.Fast4.Throttlelever

SettingtheHeight-of-Cut

Usetheheight-of-cutlevertoraiseandlowerthe

cutterdecktothedesiredcuttingheight.Youcan

settheheight-of-cuttooneofsevenpositionsfrom

approximately1-1/2to4-1/2inches(38to116mm).

1.Parkthemachineonalevelsurface.

2.Disengagethebladecontrol(PTO).

3.Settheparkingbrake.

4.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

5.Pullontheheight-of-cutleveronthetractorand

moveittothedesiredposition(Figure17).

Note:Anenginethathasbeenrunningandis

warmmaynotrequirestep4.

5.Turntheignitionkeyclockwiseandholditinthe

Startposition(Figure19).Whentheenginestarts,

releasethekey.

Figure19

1.Start3.Off

2.On

Important:Iftheenginedoesnotstartafter

30secondsofcontinuouscranking,turnthe

ignitionkeytoOffandletthestartermotor

cool;refertoTroubleshooting.

1.Height-of-cutlever

Figure17

6.Aftertheenginestarts,slowlyshiftthethrottlelever

toFast(Figure18).Iftheenginestallsorhesitates,

shiftthethrottleleverbacktoChokeforafew

secondsandthenshiftthethrottlelevertoFast.

Repeatthisstepasrequired.

19

Page 20

StoppingtheEngine

1

G006903

1.ShiftthethrottlelevertoFast(Figure18).

2.TurntheignitionkeytoOff,waitforallmoving

partstostop,andremovethekeybeforeleavingthe

operatingposition.(Figure19).

UsingtheSafetyInterlock

System

ServiceInterval:Beforeeachuseordaily

Ifthesafetyinterlockswitchesaredisconnected

ordamaged,thetractorcouldoperate

unexpectedly,causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthetractor.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Youaresittingontheseat.

•Thebrakepedalisdepressed.

running),theenginewillstop.Donotmowinreverse

unlessitisabsolutelynecessary.

Ifyouneedtousethebladecontrol(PTO)while

backingup,turnofftheinterlockfeatureusingthe

reverseinterlockswitchlocatedneartheseatbracket

(Figure20).

Figure20

1.Reverseinterlockswitch

Youcouldbackoverachildorbystanderwhile

thecutterdeckbladesorotherattachmentis

engagedandcauseseriousinjuryordeath.

•Donotmowinreverseunlessitisabsolutely

necessary.

•Donotinsertthereverseinterlockkey

unlessitisabsolutelynecessary.

•Alwayslookbackwardanddownbefore

backingup.

•Thebladecontrol(PTO)isintheDisengage

position.

Thesafetyinterlocksystemisdesignedtostopthe

engineifyoudothefollowing:

•Yourisefromtheseatwhenthebrakepedalis

released.

•Yourisefromtheseatwhilethebladecontrol

(PTO)isintheEngageposition.

•Youshiftintoreversewhilethebladecontrol(PTO)

isintheEngageposition.

SettingtheTractortoOperatein

Reverse

Aninterlockfeatureonthetractorpreventsthepower

take-off(PTO)fromoperatingwhenyoubackup

thetractor.Ifyoushiftthetractioncontrolswitch

intoReversewiththebladecontrol(PTO)engaged

(i.e.,withthecutterdeckbladesorotherattachment

•Usethereverseinterlockswitchonlyifyou

arecertainnochildrenorotherbystanders

willenterthemowingarea.

•Beveryobservantafterdeactivatingthe

interlockbecausethesoundoftheengine

maypreventyoufromnoticingthatachild

orbystanderhasenteredtheworkarea.

•Alwaysremoveboththeignitionandreverse

interlockkeysandputtheminasafeplace

outofthereachofchildrenorunauthorized

userswhenleavingthetractorunattended.

1.Engagethebladecontrol(PTO).

2.Insertthereverseinterlockkeyintotheswitch

(Figure20).

3.Turnthereverseinterlockkey.

Note:Aredlightonthefrontconsole(Figure21)

turnson,indicatingthattheinterlockisdisabled.

20

Page 21

Figure21

1.Operating-in-reverselight

4.ShiftthetractioncontrolswitchintoReverseand

completeyourtask.

5.Disengagethebladecontrol(PTO)toactivatethe

interlock.

releasetheparkingbrakeandriseslightlyfromthe

seat:Theengineshouldstop.

4.Shiftthebladecontrol(PTO)toDisengage,move

thetractioncontrolpedaltoNeutral,settheparking

brake,andstarttheengine.Whiletheengineis

running,shiftthebladecontrol(PTO)switchto

Engageandmovethetractioncontrolpedalto

Reverse:Theengineshouldstop.

5.Shiftthebladecontrol(PTO)toDisengage,

movethetractioncontrolpedaltoNeutral,and

settheparkingbrake.Starttheengine,shift

thebladecontrol(PTO)switchtoEngage,and

turnthereverseinterlockkeyandreleaseit:The

operating-in-reversewarninglightshouldilluminate.

6.Shiftthebladecontrol(PTO)toDisengage:The

operating-in-reversewarninglightshouldturnoff.

6.Removethereverseinterlockkeyandputitinasafe

placeoutofthereachofchildren.

TestingtheSafetyInterlock

System

Ifsafetyinterlockswitchesaredisconnected

ordamaged,thetractorcouldoperate

unexpectedly,causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthetractor.

•Replaceswitchesevery2yearsregardlessof

whethertheyareoperatingproperlyornot.

Testthesafetysystembeforeyouusethetractoreach

time.Ifthesafetyinterlocksystemdoesnotoperateas

describedbelow,haveanAuthorizedServiceDealer

repairthesafetyinterlocksystemimmediately.While

sittingintheseat,performthefollowingchecks:

1.Settheparkingbrake.Shiftthebladecontrol(PTO)

toEngage,andturntheignitionkeytoStart:The

engineshouldnotcrank.

PushingtheTractorManually

Important:Alwayspushthetractormanually.

Nevertowthetractorbecauseyoumaydamage

thetransaxle.

ToPushtheTractor

1.Disengagethebladecontrol(PTO).

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.PullthedrivecontrolouttothePushposition.

Note:Thisdisengagesthedrivesystemandallows

thewheelstoturnfreely(Figure22).

Figure22

1.Operateposition

2.Pushposition

2.Shiftthebladecontrol(PTO)toDisengageand

releasetheparkingbrake.Turntheignitionkeyto

Start:Theengineshouldnotcrank.

3.WiththegroundspeedinNeutral,settheparking

brake,shiftthebladecontrol(PTO)toDisengage,

andstarttheengine.Whiletheengineisrunning,

ToOperatetheTractor

PushthedrivecontrolintotheOperateposition.This

engagesthedrivesystem(Figure22).

Note:Thetractorwillnotdriveunlessthedrive

controlisintheOperateposition.

21

Page 22

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedas

measuredinRPM(revolutionsperminute).Shiftthe

throttlecontrolleverintotheFastpositionforbest

performance.

Togoforwardorbackward:

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake.

2.Placeyourfootonthetractioncontrolpedaland

slowlypressonthetopofthetractioncontrolpedal

tomoveforwardoronthebottomofthepedalto

movebackward(Figure23).

Note:Thefartheryoumovethetractioncontrol

pedalineitherdirection,thefasterthetractorwill

moveinthatdirection.

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileit

isunattended.

Alwaysremovetheignitionandreverse

interlockkeysandsettheparkingbrakewhen

leavingthetractorunattended,evenifjustfora

fewminutes.

SideDischargeorMulch

Grass

Withoutthegrassdeector,dischargecover,

orcompletegrasscatcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingcutterdeckbladesandthrowndebris

willcauseinjuryordeath.

Figure23

1.Tractioncontrolpedal3.Backward

2.Forward

Note:Toslowdown,releasethepressureonthe

tractioncontrolpedal.

Important:Toavoidtransmissiondamage,

alwaysreleasetheparkingbrakebeforemoving

thetractioncontrolpedal.

Note:Toreversethetractorwiththebladecontrol

(PTO)engaged,deactivatetheoperating-in-reverse

interlockusingthereverseinterlockswitchlocated

infrontofandbelowtheseat.

StoppingtheTractor

1.Releasethetractioncontrolpedal.

2.Disengagethebladecontrol(PTO).

3.TurntheignitionkeytoOfftostoptheengine.

4.Settheparkingbrakeifyouleavethetractor

unattended;refertoSettingtheParkingBrake.

5.Removetheignitionkeyfromtheswitch.

•Neverremovethegrassdeectorfromthe

cutterdeckbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

cutterdeck.

•Nevertrytocleardischargeareaorcutter

deckbladesunlessyoudisengagetheblade

control(PTO)androtatetheignitionkey

toOff.

Thecutterdeckhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardtheturf.

Tomulchgrassclippingsyoumustinstallthedischarge

coverintotheopeninginthesideofthecutterdeck;

refertoInstallingtheDischargeCover.

InstallingtheDischargeCover

Toconvertfromasidedischargetoamulchingcutter

deck,installthedischargecoverintotheopeningatthe

sideofthecutterdeck.

1.Stoptheengine,waitforallmovingpartstostop,

andremovethekeybeforeleavingtheoperating

position.

22

Page 23

2.Liftthegrassdeectorandslidethetabsontop

G008145

1

2

3

4

5

5

6

6

ofthedischargecoverunderthegrassdeector

retainingrod.

3.Rotatethedischargecoverdownovertheopening,

andontothelowerlipofthecutterdeck(Figure24).

•Grassgrowsatdifferentratesatdifferenttimesof

theseason.Tomaintainthesamecuttingheight,

whichisagoodpractice,mowmoreofteninearly

spring.Asthegrassgrowthrateslowsinmid

summer,mowlessfrequently.

•Toimprovethequalityofcut,useaslowerground

speed.Forbestoperationonaveragelawns,operate

theengineatfullthrottlewhilecontrollingthe

groundspeed.Youshouldoperatethetractor

between2to3.5mph(3.2to5.6km/h)while

mowing.

•Ifthegrassislongerthannormal,orifitcontains

ahighdegreeofmoisture,raisethecuttingheight

higherthanusual,cutthegrassatthatsetting,and

thencutthegrassagainatthelower,normalsetting.

•Ifyoumuststopthetractorwhilemowing,youmay

leaveaclumpofgrassclippingsonyourlawn.To

avoidthis,dothefollowing:

Figure24

1.Grassdeector

2.Tabsunderrod5.Bolt

3.Dischargecover6.Nut

4.Lowerlip

–Engagethebladeandmovetoapreviouslycut

area.

–Dispersetheclippingsevenlybyraisingthe

cutterdeck1or2height-of-cutsettingswhile

4.Securethedischargecovertothelowerlipofthe

cutterdeckwithboltsandnuts(Figure24).

Note:Donotovertightenthenuts,whichcould

distortthecoverandcausebladecontact.

5.Toconvertbacktoasidedischargecutterdeck,

removethedischargecoverandlowerthegrass

deectoroverthedischargeopening.

•Usethewashoutporttocleanclippingsanddirt

•Maintainasharpbladethroughouttheseason.A

drivingforwardwiththebladeengaged.

fromtheundersideofthecutterdeckaftereachuse.

Ifgrassanddirtbuildupinsidethecutterdeck,the

cuttingqualitywilleventuallybecomeunsatisfactory.

sharpbladecutsgrasscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

thegrassturnsitbrownattheedges,whichslows

OperatingTips

•Forthebestperformance,operatetheengineatthe

maximumspeed.Thecutterdeckrequiresairto

itsgrowthandincreasesthechanceofdisease.

Every30days,checkthebladeforsharpnessand

ledownanynicks.

thoroughlycutgrassclippings,sodonotsetthe

height-of-cuttooloworcompletelysurroundthe

cutterdeckinuncutgrass.Alwaysleaveonesideof

thecutterdeckfreefromuncutgrasstoallowthe

airtobedrawnintothecutterdeck.

•Cutthegrassslightlylongerthannormaltoensure

thatthecuttingheightofthecutterdeckdoes

notscalpanyunevenground.Whencuttinggrass

longerthan6inch(15cm)tall,cutthelawntwiceto

ensureanacceptableappearance.

•Itisbesttocutonlyabout1/3ofthegrassblade.

Donotcutmorethanthatunlessthegrassissparse

oritislatefallwhengrassgrowsmoreslowly.

•Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings

andenhancesdecompositionandfertilization.

23

Page 24

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Beforestorage

MaintenanceProcedure

•Changetheengineoil.

•Checktheengineoillevel.

•Checkthesafetysystem.

•Checktheoillevel.

•Checkthebatteryelectrolyte.

•Checktheparkingbrake.

•Servicetheblades.

•Washtheundersideofthecutterdeck.

•Greaseandlubricatethetractor.Moreoftenindustyordirtyconditions.

•Cleantheaircleanerfoamelement.

•Servicethesparkplug.

•Checkthetyrepressure.

•Changetheengineoil.Changeitmoreoftenunderaheavyloadorinhigh

temperatures.

•Changetheoillter.

•Replacetheaircleanerpaperelement.

•Replacethesparkplug.

•Replacethefuellter.

•Servicethetransaxleuid.

•Cleanthecoolingsystem.

•Drainthefueltank.

•Performallthemaintenanceprocedureslistedabove.

•Paintanychippedsurfaces.

•Checkthetyrepressure.

•Checkthesafetysystem.

•Checkthebrakes.

•Checkthesparkplug.

•Checkthebatteryelectrolyte.

•Chargethebatteryanddisconnectthecables.

•Checkthebelt(s)forwearandcracks.

Important:Refertoyourengineoperator’smanualforadditionalmaintenanceprocedures.

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

24

Page 25

Lubrication

EngineMaintenance

GreasingandLubricatingthe

Tractor

ServiceInterval:Every25hours—Greaseandlubricate

thetractor.Moreoftenindustyor

dirtyconditions.

HowtoGreasetheTractor

1.Disengagethebladecontrol(PTO).

2.Settheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Cleanthegreasettingswitharag.

Note:Ensurethatyouscrapeanypaintoffthe

frontofthettings.

5.Connectagreaseguntoeachttingandpump

greaseintoit.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,or

higher)

CrankcaseCapacity:48oz.or1-1/2qt.(1400ccor1.4

l)whenthelterisnotchanged;56oz.or1-3/4qt.

(1700ccor1.7l)whenthelterischanged.

Viscosity:Seethetablebelow.

Figure26

6.Wipeupanyexcessgrease.

WheretoAddGrease

Lubricatethefrontwheelsandsteeringspindlesuntil

greasebeginstooozeoutofthebearings(Figure25).

Figure25

CheckingtheOilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthetractoronalevelsurface.

2.Disengagethebladecontrol(PTO).

3.Settheparkingbrake.

4.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

5.Openthehood.

6.Cleanaroundtheoildipstick(Figure27)sothatdirt

cannotfallintothellholeanddamagetheengine.

Figure27

1.Oildipstick/llhole2.Oildrainplug

25

Page 26

7.Unscrewtheoildipstickandwipethemetalend

clean(Figure28).

Figure28

1.Oildipstick

2.Metalend

8.Screwtheoildipstickfullyontothellhole.

9.Unscrewthedipstickagainandlookatthemetal

end.Iftheoillevelislow,slowlypouronlyenough

oilintothellholetoraisetheleveltotheFullmark

onthedipstick.

Important:Donotoverllthecrankcasewith

oilandruntheengine;theenginedamagemay

result.

ChangingtheOil

ServiceInterval:Aftertherst5hours

Every50hoursChangeitmore

oftenunderaheavyloadorinhigh

temperatures.

1.Starttheengineandletitrunfor5minutes.

Note:Thiswarmstheoilsothatitwilldrainmore

easily.

2.Parkthetractorsothattheleftsideisslightlylower

thantherightsidetoensurethattheoildrains

completely.

3.Disengagethebladecontrol(PTO).

4.Settheparkingbrake.

5.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

6.Openthehood.

7.Placeadrainpanbelowtheoildrainplugand

removeit(Figure27).

8.Whentheoilhasdrainedcompletely ,installtheoil

drainplug.

Note:Disposeoftheusedoilatacertiedrecycling

center.

9.Changetheoillter,ifnecessary.RefertoChanging

theOilFilter.

10.Slowlypourapproximately80%ofthespecied

amountofoilintothellhole(Figure27).Checkthe

oillevel;referto4and5ofCheckingtheOilLevel.

ChangingtheOilFilter

ServiceInterval:Every100hours

Note:Changetheoilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingand

DrainingtheOil.

2.Removetheoldoillterandwipethelteradapter

(Figure29)gasketsurface.

Figure29

1.Oillter

2.Gasket

3.Filteradapter

3.Applyathincoatofnewoiltotherubbergasketon

thenewoillter(Figure29).

4.Installthenewoilltertothelteradapter.

5.Turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightentheoillter

anadditional1/2to3/4turn(Figure29).

6.Slowlypourabout80%ofthespeciedamountof

oilintothellhole(Figure27).Checktheoillevel;

referto7and8ofCheckingtheOilLevel.

7.Closethehood.

ServicingtheAirCleaner

ServiceInterval:Every25hours—Cleantheaircleaner

foamelement.

Every100hours—Replacetheair

cleanerpaperelement.

Note:Servicetheaircleanermorefrequentlyifthe

operatingconditionsareextremelydustyorsandy.

RemovingtheFoamandPaper

Elements

1.Disengagethebladecontrol(PTO).

26

Page 27

2.Settheparkingbrake.

3.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

4.Openthehood.

5.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage.

6.Pullupontheaircleanercoverhandleandrotateit

towardtheengine(Figure30).

PaperElement:

1.Lightlytaptheelementonaatsurfacetoremove

dustanddirt.

2.Carefullycleantherubbersealonthepaperelement

topreventdebrisfromenteringtheengine.

3.Inspecttheelementfortears,anoilylm,and

damagetotherubberseal.

Important:Nevercleanthepaperelement

withpressurizedairorliquidssuchassolvents,

petrol,orkerosene.Replacethepaperelementif

itisdamagedorcannotbecleanedthoroughly.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperaircleanerassemblyinstalled.

Figure30

1.Aircleanercover2.Aircleanercoverhandle

Note:Removetheaircleanercover.

7.Carefullyslidethepaperelementandthefoam

elementfromtheblowerhousing(Figure31).

Figure31

1.Paperelement4.Tab

2.Foamelement

3.Aircleanercover

5.Slot

1.Placethefoamelementandpaperelementintothe

blowerhousing.

Note:Makesurethattherubbersealisatagainst

theaircleanerbase.

2.Alignthetabsontheaircleanercoverwiththeslots

oftheblowerhousing(Figure31).

3.Hookthehandleontothecoverandpressdownon

thehandletolockthecoverinplace.

4.Closethehood.

ServicingtheSparkPlug

ServiceInterval:Every25hours—Servicethespark

plug.

Every100hours—Replacethespark

plug.

UseaChampionQC12YCorequivalentsparkplug.

Makesurethattheairgapbetweenthecenterandside

electrodesis0.030inch(0.76mm)beforeinstallingthe

sparkplug.Useasparkplugwrenchforremovingand

installingthesparkplugandagappingtool/feelergauge

tocheckandadjusttheairgap.

CleaningtheFoamandPaperElements

FoamElement:

1.Washthefoamelementinliquidsoapandwarm

water.Whentheelementisclean,rinseitthoroughly .

2.Drytheelementbysqueezingitinacleancloth.Do

notoiltheelement.

Important:Replacethefoamelementifitis

tornorworn.

RemovingtheSparkPlug

1.Disengagethebladecontrol(PTO).

2.Settheparkingbrake.

3.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

4.Openthehood.

5.Disconnectthewirefromthesparkplug(Figure32).

27

Page 28

FuelSystem

Maintenance

DrainingtheFuelTank

ServiceInterval:Beforestorage

Figure32

1.Spark-plugwire

6.Cleanaroundthesparkplugtopreventdirtfrom

fallingintotheengineandpotentiallycausing

damage.

7.Removethesparkplugandmetalwasher.

CheckingtheSparkPlug

1.Lookatthecenterofthesparkplug(Figure33).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly .Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty.

Incertainconditions,petrolisextremely

ammableandhighlyexplosive.Areor

explosionfrompetrolcanburnyouandothers

andcandamageproperty.

•Drainpetrolfromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopen

area.Wipeupanypetrolthatspills.

•Neversmokewhendrainingpetrol,andstay

awayfromanopenameorwhereaspark

mayignitethepetrolfumes.

1.Parkthetractorsothattheleftfrontsideisslightly

lowerthantherightsidetoensurethatthefueltank

drainscompletely.

2.Disengagethebladecontrol(PTO).

3.Settheparkingbrake.

4.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

5.Openthehoodandlocatethefuellter(Figure34).

Figure33

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Nevercleanthesparkplug.Always

replacethesparkplugwhenithasablack

coating,wornelectrodes,anoilylm,orcracks.

2.Checkthegapbetweenthecenterandsideelectrodes

(Figure33).Bendthesideelectrodeifthegapisnot

correct.

InstallingtheSparkPlug

1.Installthesparkplugandmetalwasher.

Note:Ensurethattheairgapissetcorrectly.

2.Tightenthesparkplugto15ft-lb(20N⋅m).

3.Connectthewiretothesparkplug(Figure32).

4.Closethehood.

28

Page 29

1.Hoseclamp

2.Fuelline

Figure34

3.Fuellter

ElectricalSystem

Maintenance

ServicingtheBattery

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatteryandbatterybox.If

thebatteryterminalsarecorroded,cleanthemwitha

solutionof4partswaterand1partbakingsoda.Apply

alightcoatingofgreasetothebatteryterminalsto

preventcorrosion.

6.Squeezetheendsofthehoseclamptogether

andslideitupthefuellinetowardthefueltank

(Figure34).

7.Pullthefuellineoffofthefuellter(Figure34)and

allowpetroltodrainintoafuelcontaineroradrain

pan.

Note:Nowisthebesttimetoinstallanewfuel

lterbecausethefueltankisempty .

8.Installthefuellineontothefuellter.

9.Slidethehoseclampclosetothefuelltertosecure

boththefuellineandthefuellter.

ReplacingtheFuelFilter

ServiceInterval:Every100hours—Replacethefuel

lter.

Thebesttimetoreplacethefuellter(Figure34)is

whenthefueltankisempty.Neverinstalladirtyfuel

lterafterithasbeenremovedfromthefuelline.

1.Disengagethebladecontrol(PTO)andsetthe

parkingbrake.

Batteryvoltageandamperage:12volts,155

cold-crankingamps

RemovingtheBattery

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponents,causing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthetractor.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

tractor.

1.Disengagethebladecontrol(PTO)andsetthe

parkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

2.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

3.Openthehood.

4.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthefuellter(Figure34).

5.Removethefuellterfromthefuellines.

6.Installanewfuellterandmovethehoseclamps

closetothefuellter.

7.Closethehood.

3.Tiptheseatforwardtoseethebattery.

4.Disconnectthenegative(black)groundcablefrom

thebatterypost(Figure35).

29

Page 30

2.Lookatthesideofthebattery.Theelectrolytemust

beuptotheUpperline(Figure36).

Figure35

1.Negativecable(black)

2.Rubbercover5.Boltandwingnut

3.Positivecable(red)

4.Batterybox

Incorrectlyroutingthebatterycablecould

damagethetractorandcables,causingsparks.

Sparkscancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Always

disconnect

thenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Always

connect

thepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

5.Slidetherubbercoverupthepositive(red)cable.

Disconnectthepositive(red)cablefromthebattery

post(Figure35).

Figure36

1.Ventcaps3.Lowerline

2.Upperline

Note:Donotallowtheelectrolytetofallbelowthe

Lowerline(Figure36).

3.Iftheelectrolyteislow ,addtherequiredamountof

distilledwater;refertoAddingWatertotheBattery.

Batteryelectrolytecontainssulfuricacid,a

deadlypoisonthatcanseverelyburnyouand

others.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyes,orclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

6.Removethebatteryboxandbatteryfromthechassis

(Figure35).

InstallingtheBattery

1.Putthebatteryintothebatteryboxandinstallitinto

thechassis(Figure35).

2.Usingtheboltandwingnut,connectthepositive

(red)cabletothepositive(+)batterypost(Figure35).

3.Slidetherubbercoveroverthebatterypost.

4.Usingtheboltandthewingnut,connectthe

negative(black)cabletothenegative(–)batterypost

(Figure35).

CheckingtheElectrolyteLevel

ServiceInterval:Beforeeachuseordaily

1.Tiptheseatforwardtoseethebattery.

AddingWatertotheBattery

Thebesttimetoadddistilledwatertothebatteryisjust

beforeyouoperatethetractor.Thisletsthewatermix

thoroughlywiththeelectrolytesolution.

1.Removethebatteryfromthetractor;referto

RemovingtheBattery.

2.Cleanthetopofthebatterywithapapertowel.

Important:Neverllthebatterywithdistilled

waterwhilethebatteryisinstalledinthetractor.

Youcouldspillelectrolyteonotherpartsand

causecorrosion.

3.Removetheventcapsfromthebattery(Figure36).

4.Slowlypourdistilledwaterintoeachbatterycell

untiltheelectrolytelevelisuptotheUpperline

(Figure36)onthebatterycase.

30

Page 31

Important:Donotoverllthebatterybecause

electrolyte(sulfuricacid)cancausesevere

corrosionanddamagetothechassis.

5.Wait5to10minutesafterllingthebatterycells.

Adddistilledwater,ifnecessary,untiltheelectrolyte

levelisuptotheUpperline(Figure36)onthe

batterycase.

6.Installthebatteryventcaps.

ChargingtheBattery

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebattery.Keepsparksand

amesawayfrombattery.

Note:Donotrunthetractorwiththebattery

disconnected;electricaldamagemayoccur.

ServicingtheFuse

Theelectricalsystemisprotectedby10amp,blade-type

fuses.

1.Pulluponthefuse(Figure38)toremoveitfrom

thesocket.

Important:Alwayskeepthebatteryfullycharged

(1.260specicgravity),especiallywhenthe

temperatureisbelow32°F(0°C)topreventbattery

damage.

1.Removethebatteryfromthechassis;referto

RemovingtheBattery.

2.Checktheelectrolytelevel;refertoCheckingthe

ElectrolyteLevel.

3.Makesurethattheventcapsareinstalledinthe

battery,andchargeitfor1hourat25to30amps

or6hoursat4to6amps.Donotoverchargethe

battery.

4.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet.

5.Disconnectthechargerleadsfromthebatteryposts

(Figure37).

Figure38

1.Fuse

2.Socket

2.Insertthefuseintosocketandpushdownonthe

fusetoinstallit.

ServicingtheHeadlights

Theheadlightsusean1156,automotive-typebulb.

RemovingtheBulb

1.Openthehood.

2.Disconnectthewireconnectorsfrombothofthe

bulbholderterminals.

3.Rotatethebulbholder1/4turncounterclockwise

andremoveitfromthereector(Figure39).

Figure37

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(–)chargerlead

6.Installthebatteryinthetractorandconnectthe

batterycables;refertoInstallingtheBattery.

31

Page 32

Figure39

1.Bulbholder

2.Reector

3.Tabs

4.Insertandrotatethebulbcounterclockwiseuntilit

stops(approx.1/4turn),andremovethebulbfrom

thebulbholder(Figure40).

4.Slots

5.Terminals

DriveSystem

Maintenance

CheckingtheTyrePressure

ServiceInterval:Every25hours

Maintaintheairpressureinthefrontandreartyresat

20psi(138kPa).Checkthepressureatthevalvestem

(Figure41)afterevery25operatinghoursoryearly,

whicheveroccursrst.Checkthetyreswhentheyare

coldtogetthemostaccuratepressurereading.

Figure41

1.Valvestem

Figure40

1.Bulb3.Bulbholder

2.Metalpins

4.Slots

InstallingtheBulb

1.Alignthemetalpinsonthesideofthebulbbase

withtheslotsinthebulbholder.

2.Insertthebaseintotheholder(Figure40).

3.Pushandrotatethebulbclockwiseuntilitstops.

4.Alignthetabsonthebulbholder(Figure39)with

theslotsinthereector,insertthebulbholderinto

thereector,androtateit1/4turnclockwiseuntil

itstops.

5.Connectthewireconnectorstotheterminalsonthe

bulbholder.

ServicingtheTransaxleFluid

ServiceInterval:Every100hours—Servicethe

transaxleuid.

Alwayskeeptheuidlevelatthefulllevelwhenthe

transaxleiscold.

Note:Thetransaxleisfactorysealedanddoesnot

requireoilchanges.

FluidType:SAE20W-50engineoil(APIservice

SH/CDisrecommended)

CheckingtheFluidLevel

1.Parkthetractoronalevelsurface.

2.Disengagethebladecontrol(PTO)andsetthe

parkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Cleanaroundthellplug(Figure42)sothatdirt

cannotfallintothereservoirifyouneedtoadduid.

32

Page 33

Figure42

1.Fillplug

5.Removethellplugandchecktheuidlevel.

Note:Thelevelshouldbeamaximumof1-1/4inch

(32mm)belowthetopofthellport(Figure42).

Adduidifnecessary.

6.Installthellplug.

CoolingSystem

Maintenance

CleaningtheCoolingSystem

ServiceInterval:Every100hours

Useadrybrushtocleangrassandaccumulateddebris

fromtheenginedaily.

Important:T opreventcontaminatingthefuel

system,donotusewatertocleantheengine.

33

Page 34

BrakeMaintenance

6.Installanewcotterpinandattachthebrakearm

spring.

ServicingtheParkingBrake

ServiceInterval:Beforeeachuseordaily

Theparkingbrakeisontherightsideoftherearaxle,

insidethereartyre(Figure43).Iftheparkingbrakedoes

notholdsecurely,adjustit.

Figure43

1.Brakearmspring2.Brakeadjustingnut

CheckingtheParkingBrake

7.Checktheparkingbrakeoperationagain;referto

CheckingtheParkingBrake.

Important:Withtheparkingbrakereleased,the

rearwheelsmustrotatefreelywhenyoupushthe

tractor.Ifyoucannotachievethe.015inch(0.38

mm)clearanceandfreewheelrotation,contact

anAuthorizedServiceDealerimmediately .

1.Parkthetractoronalevelsurface.

2.Disengagethebladecontrol(PTO)andsetthe

parkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.MovethedrivecontrolwiretothePushposition;

refertoPushingtheTractorManually.

5.Iftherearwheelslockandskidwhenyoupush

thetractorforward,youdonotneedtoadjustthe

parkingbrake.Adjusttheparkingbrakeifthewheels

turnanddonotlock;refertoAdjustingtheParking

Brake.

AdjustingtheParkingBrake

1.Checktheparkingbrakebeforeyouadjustit;referto

CheckingtheBrake.

2.Removethebrakearmspring(Figure43).

3.Removethecotterpinthatsecuresthebrake

adjustingnutandslightlyloosenthenut(Figure43).

4.Inserta0.015inch(0.38mm)feelergaugebetween

thebrakediscandbrakepuck(Figure43).

5.Tightenthenutuntilyoufeelaslightresistanceon

thefeelergaugewhenyouslideitinandout.

34

Page 35

BeltMaintenance

CutterDeckMaintenance

ReplacingtheBladeDriveBelt

RemovingtheBladeDriveBelt

1.Removethecutterdeck;refertoRemovingthe

CutterDeck.

2.Removethepulleycovermountingscrewsandpulley

coversfrombothbladepulleys(Figure44).

Figure44

1.Pulleycover3.cutterdeckbelt

2.Idlerpulleybeltguide

position

ServicingtheBlades

ServiceInterval:Beforeeachuseordaily

Toensureasuperiorqualityofcut,keeptheblades

sharp.Forconvenientsharpeningandreplacement,

keepextrablades.

Awornordamagedbladecanbreakandapiece

ofthebladecouldbethrownintotheoperator’s

orbystander’sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

InspectingtheBlades

1.Removethecutterdeck;refertoRemovingthe

CutterDeck.

2.Inspectthecuttingedges(Figure45).Iftheedges

arenotsharporhavenicks,removethebladesand

sharpenthem;refertoSharpeningtheBlades.

3.Loosen,butdonotremove,theboltandnutthat

securestheidlerpulleyandthebeltguide(Figure44).

4.Removethebladedrivebeltfromthepulleys.

InstallingtheBladeDriveBelt

1.Installthenewbladedrivebeltaroundtheblade

pulleysandunderthebeltguideontheidlerpulley .

2.Positiontheidlerpulleybeltguidesothatitpoints

towardtheleft,90°totheidlerarm(Figure44).

3.Tightenthemountingboltandthelocknutthat

securetheidlerpulleyandthebeltguide.

4.Installtheleftandrightpulleycoverswiththe

mountingscrews(Figure44).

5.Installthecutterdeck;refertoInstallingtheCutter

Deck.

Figure45

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

3.Inspecttheblades,especiallythecurvedarea

(Figure45).Ifyounoticeanydamage,wear,oraslot

forminginthisarea(Figure45),immediatelyinstalla

newblade.

RemovingtheBlades

1.Removethecutterdeck;refertoRemovingthe

CutterDeck.

2.Carefullytipthecutterdeckover.

35

Page 36

3.Removethebolt(5/8inchwrench),curvedwasher,

retainer,andblade(Figure46).Useablockofwood

asawedgebetweenthebladeandthecutterdeckto

lockthebladewhenyouareremovingthebolt.

Figure46

1.Bolt

2.Retainer

3.Blade

4.Spindle

5.Curvedwasher

4.Inspectallparts;replaceanypartsthataredamaged.

SharpeningtheBlades

Important:Thecurvedpartoftheblademust

bepointingtowardtheinsideofthecutterdeck

toensurepropercutting.

2.Tightenthebladeboltto45to60ft-lb(61to81

N⋅m).

RemovingtheCutterDeck

1.Parkthetractoronalevelsurface.

2.Disengagethebladecontrol(PTO)andsetthe

parkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Movetheheight-of-cutleverintothe“D”notch.

5.Removetheheight-of-cutliftassistspringfromthe

retainingbolt(Figure49).Thespringisbetweenthe

frameandtherightrearwheel.

1.Usealetosharpenthecuttingedgeatbothendsof

eachblade(Figure47).Maintaintheoriginalangle.

Thebladeretainsitsbalanceifyouremovethesame

amountofmaterialfrombothcuttingedges.

Figure47

1.Sharpenatoriginalangle

2.Checkthebalanceofeachbladebyputtingiton

abladebalancer(Figure48).Ifthebladestaysina

horizontalposition,thebladeisbalancedandcanbe

used.Ifthebladeisnotbalanced,lesomemetal

offofthebacksideoftheblade.Repeatthisstep

untilthebladeisbalanced.

Figure48

1.Blade2.Balancer

InstallingtheBlades

1.Installeachblade,bladeretainer,curvedwasher

(cuppedsidetowardblade),andthebladebolt

(Figure46).

Figure49

1.Spring3.Springtool

2.Bolt

Note:Usethespringtoolprovidedwiththe

machine.

Whenyouremovethecutterdeck,the

spring-tensionedheight-of-cutlevercould

suddenlyreleaseandinjureyouorsomeone

else.

Movetheheight-of-cutlevertothe“D”position

andremovetheheight-of-cutassistspringto

releasethespringtension.

6.Movetheheight-of-cutleverintothe“ A ”notch.

7.Unhookthespringontheidlerpulleyarmfromthe

bracketonthecutterdeck(Figure50).

36

Page 37

Figure50

1.Idlerspring3.Idlerarm

2.Eye-bolt4.Idlerpulley

8.Removetheboltsandlocknutsandpullthetwo

cutterdeckpivotmountbracketsdownfromthe

frontaxle(Figure51).

offofthemountingpin.Installthewasherand

hairpincotterforstorage.

11.Rotatethelevelingbracketuptowardtheframe,and

hookthelongrodintooneoftheholestostore.

Securethelongrodwiththewasherandhairpin

cotter.

12.Repeat9through11ontheoppositesideofthe

cutterdeck.

13.Movetheheight-of-cutleverintothe“D”notch.

Hooktheliftassistspringontotheretainingbolt

forstorage(Figure49).

14.Removethecutterdeckbeltfromtheelectricclutch

pulley(Figure53).

Figure51

1.Pivotmountbracket3.Locknut

2.Bolt(5/16x2-1/2inch)

9.Removethehairpincotterandwasherfromtheend

ofthelongrod(Figure52).Slidetherodoutofthe

cutterdeckmount.

Figure52

1.Hairpincotterandwasher3.Levelingbracket

2.Longrod

4.CutterDeckmount

Figure53

1.CutterDeckbelt

2.Electricclutchpulley

15.Removethecutterdeckbeltfromthelowerengine

pulley(Figure53).

16.Turnthefrontwheelsfullytotheleft.Slidethe

cutterdeckouttotherighttocompleteremoval.

10.Removethehairpincotterandwasheratthecutter

decklevelingbracket(Figure52).Slidethebracket

37

Page 38

InstallingtheCutterDeck

Withoutthegrassdeector,dischargecover,

orcompletegrasscatcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwiththe

rotatingcutterdeckblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethegrassdeectorfromthe

cutterdeckbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

cutterdeck.

•Nevertrytoclearthedischargeareaor

cutterdeckbladesunlessyoumovethe

powertakeoff(PTO)toOffandrotatethe

ignitionkeytoOff.Alsoremovethekeyand

pullthewireoffthesparkplug(s).

1.Parkthemachineonalevelsurface.

9.Removetheliftassistspringbetweenthecutter

deckrightsideliftbracketandtheretainingbolt

(Figure55).

Figure55

1.Spring3.Springtool

2.Bolt

Note:Usethespringtoolprovidedwiththe

machine.

10.Movetheheight-of-cutleverintotheAnotch.

11.Slidetheendofthelongrodthroughtheholeinthe

cutterdeckmount(Figure56).

2.Disengagethebladecontrol(PTO).

3.Settheparkingbrake.

4.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

5.Turnthefrontwheelsfullytotheleft.Slidethe

cutterdeckunderthechassisfromtherightside.

6.Installthecutterdeckbeltontothelowerengine

pulley(Figure53).

7.Installthecutterdeckpivotmountbracketsontothe

frontaxlewiththeboltsandlocknuts(Figure54).

Figure54

1.Pivotmountbracket3.Locknut

2.Bolt(5/16x2-1/2inch)

Figure56

1.Hairpincotterandthick

washer

2.Longrod5.Hairpincotterandthin

3.Levelingbracket

4.CutterDeckmount

washer

12.Installthethinwasherandhairpincottertosecure

therodinplace(Figure56).

13.Mounttheslottedcutterdecklevelingbracketonto

thepinonthecutterdeckmount(Figure56).

14.Installthethickwasherandhairpincottertosecure

thecutterdeck(Figure56).

15.Repeat11through14ontheoppositesideofthe

cutterdeck.

8.Movetheheight-of-cutleverintotheDnotch.

16.Hooktheidlerspringfromtheidlerpulleyarmto

theeye–boltonthecutterdeck(Figure57).

38

Page 39

Figure57

1.Idlerspring3.Idlerarm

2.Eye-bolt4.Idlerpulley

17.Movetheheight-of-cutleverintotheDnotchto

makeiteasiertoinstalltheheight-of-cutliftassist

spring.

18.Hooktheliftassistspringbetweenthecutter

deckrightsideliftbracketandtheretainingbolt

(Figure58).

1.Parkthetractoronalevelsurface.

2.Disengagethebladecontrol(PTO)andsetthe

parkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Movetheheight-of-cutleverintotheCnotch.

5.Carefullyrotatethebladessidetoside(Figure59).

Figure59

1.Bladessidetoside3.Measurehere

2.Outsidecuttingedges

Figure58

1.Spring3.Springtool

2.Bolt

Note:Usethespringtoolprovidedwiththe

machine.

19.Checkthecutterdecklevel;refertoLevelingthe

CutterDeckfromSide-to-SideandFront-to-Rear

BladeSlope.

LevelingtheCutterDeckfrom

Side-to-Side

Thecutterdeckbladesmustbelevelfromsidetoside.

Checktheside-to-sidelevelwheneveryouinstallthe

cutterdeckorlookforanunevencutonyourlawn.

Beforeyoulevelthecutterdeck,settheairpressurein

thetyrestotherecommendedlevel;refertoChecking

theTyrePressure.

6.Measurebetweentheoutsidecuttingedgesandthe

atsurface(Figure59).Ifbothmeasurementsare

notwithin3/16inch(5mm),adjustthem;referto

7through10.

7.Removethehairpincotterandwasherfromthe

levelingbracket(Figure60).

Figure60

1.Hairpincotterandwasher3.Levelingbracket

2.Longrod

4.CutterDeckmount

8.Positionthelevelingbracketinadifferentholeand

installthewasherandhairpincotter(Figure60).

Note:Positioningthelevelingbrackettowardthe

frontholelowersthebladeheight;positioningthe

levelingbrackettowardtherearholeraisestheblade

height.

39

Page 40

9.Repeat7and8ontheoppositesideofthecutter

deck.

8.Repeat6and7ontheoppositesideofthecutter

deck.

10.Checkthefront-to-rearbladeslope;referto

AdjustingtheFront-to-RearBladeSlope.

AdjustingtheFront-to-Rear

BladeSlope

Checkthefront-to-rearbladeslopewheneveryouinstall

thecutterdeck.Beforeyouchecktheslope,settheair

pressureinthetyrestotherecommendedlevel;referto

CheckingtheTyrePressure.Ifthefrontofthecutter

deckisnotwithinarangeof1/8to3/8inch(3to10

mm)lowerthantherearofthecutterdeck,adjustthe

bladeslopeasfollows:

1.Parkthetractoronalevelsurface.

2.Disengagethebladecontrol(PTO)andsetthe

parkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Checkandadjusttheside-to-sidebladelevelifyou

havenotcheckedthesetting;refertoLevelingthe

CutterDeckfromSide-to-Side.

9.Checkthefront-to-rearslopebymeasuringbetween

thebottomofthecutterdeck(frontcenterandrear

center)andtheatsurface(Figure62).Ifthefrontis

notwithinarangeof1/8to3/8inch(3to10mm)

lowerthantherear,anadjustit.

Figure62

1.Measurefrontcenter

2.Measurerearcenter

10.Slightlyloosenthefrontpivotplatemountingbolts

(Figure63).

5.Movetheheight-of-cutleverintothe“C”notch.

6.Measurethelengthoftherodextendingoutof

thefrontoftheadjustingblockonthesidesofthe

chassis(Figure61).Iftherodlengthisnot5/8inch

(16mm),removethehairpincotterandwasherfrom

theendoftherod(Figure61)andturntheroduntil

itextendsout5/8inch(16mm).

Figure61

1.Adjustingblock3.Hairpincotterandwasher

2.Longrod