Page 1

H15/40

HERITAGE TRACTOR

CODE145S

INSTRUCTION BOOK

FROM SERIAL NO:145S001251 MANUAL PART NO:145010 (REV.0.)

F–000794J

Page 2

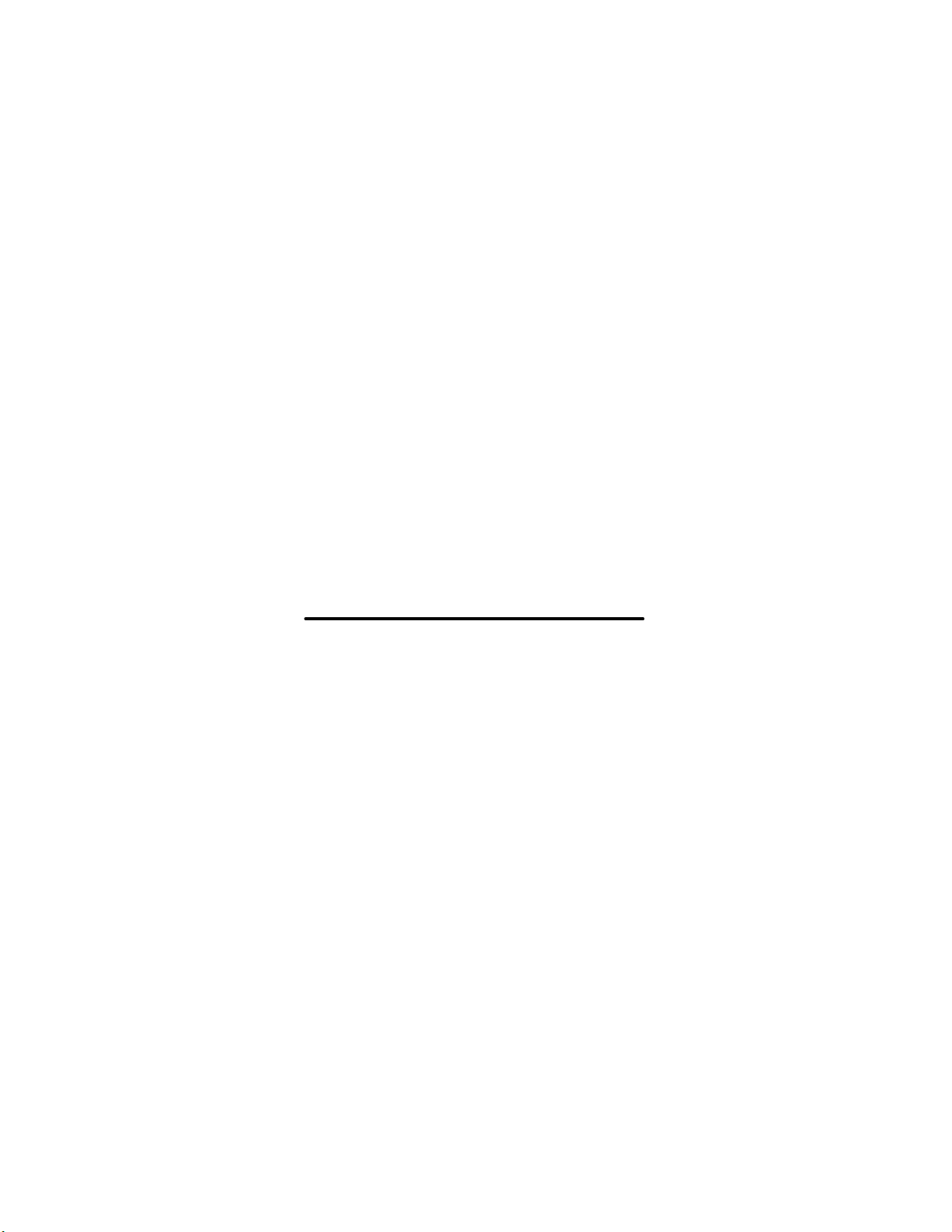

5 (0011x3)

1

2

4 (711758)

6

3

3

2

1

2

1

3

4 (711644)

1 (711719)

2 (711663)

1

2

5 (711747)

4

3

5

3

5

1

6

7

6 (711636)

7 (711680)

3

10

2

9

8

11

7

5

6

6

4

1

F–000794J

2

2

Page 3

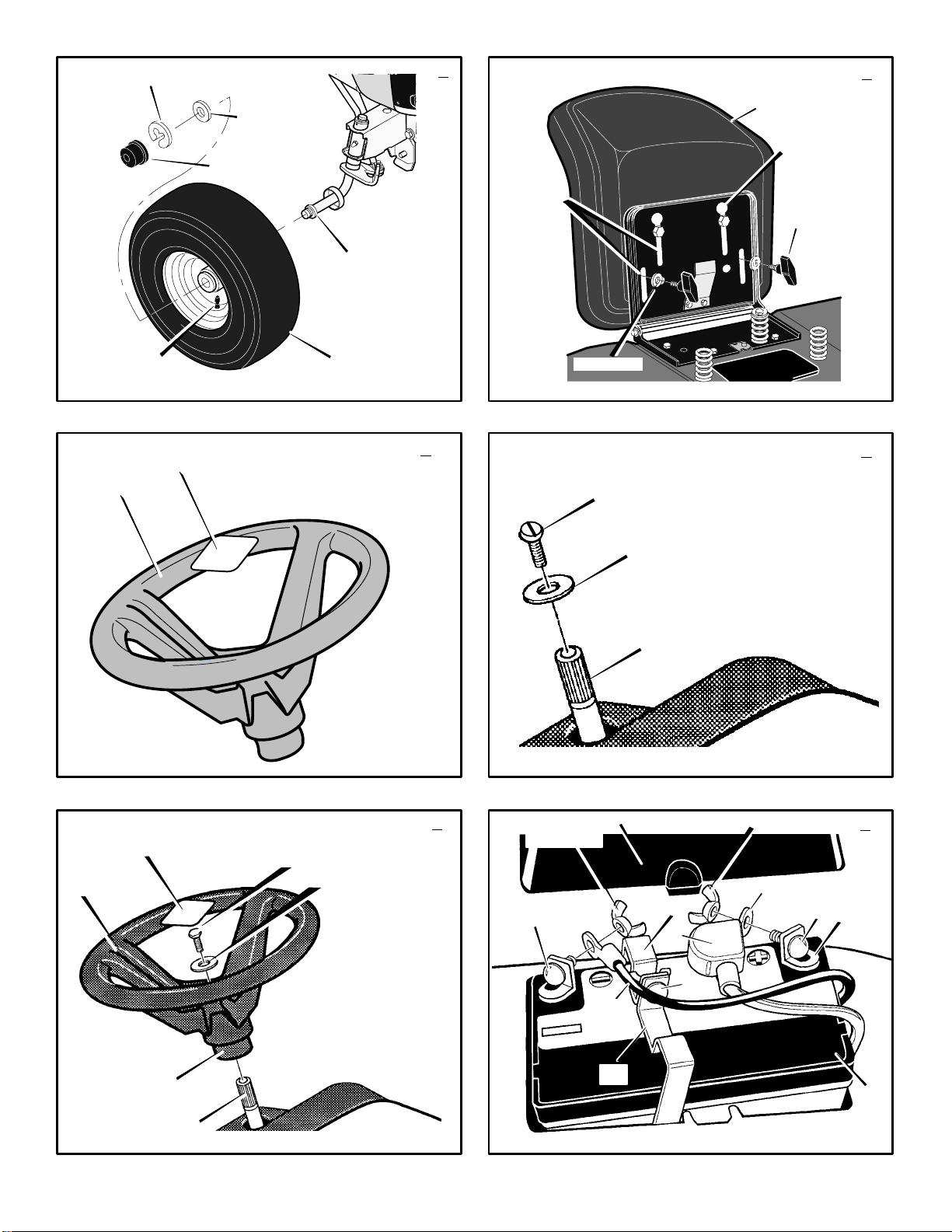

10

12

11

7

7

2

5

6

3

8

1

4

9

1

2

6

5

2

1

8

3

7

7

2

1

8

3

11

1

10

6

5

12

F–000794J

2

1

2

3

4

5

3

Page 4

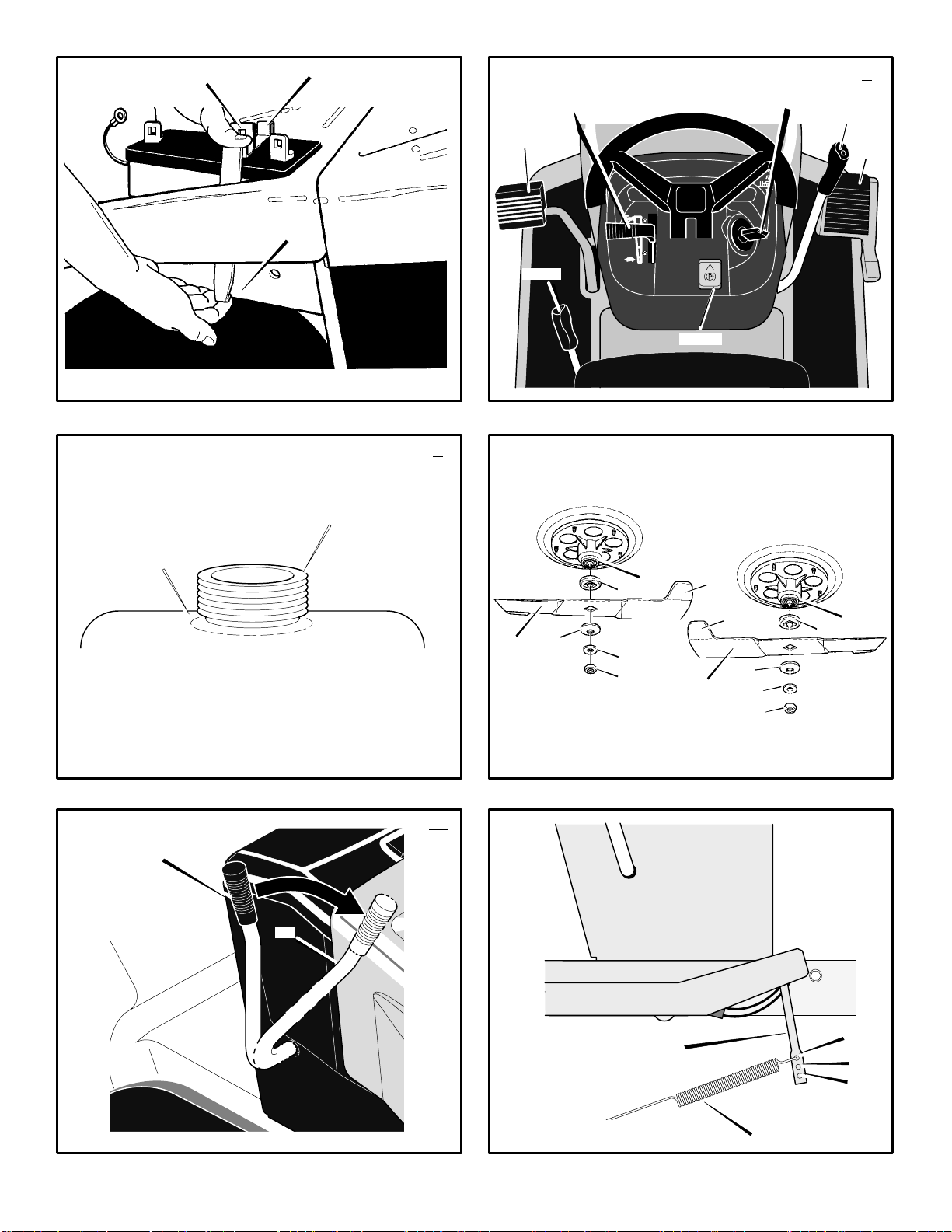

13

12

4

11

5

2

1

9

3

10

8

14

F–000794J

15

1

1

2

3

2

16

4

Page 5

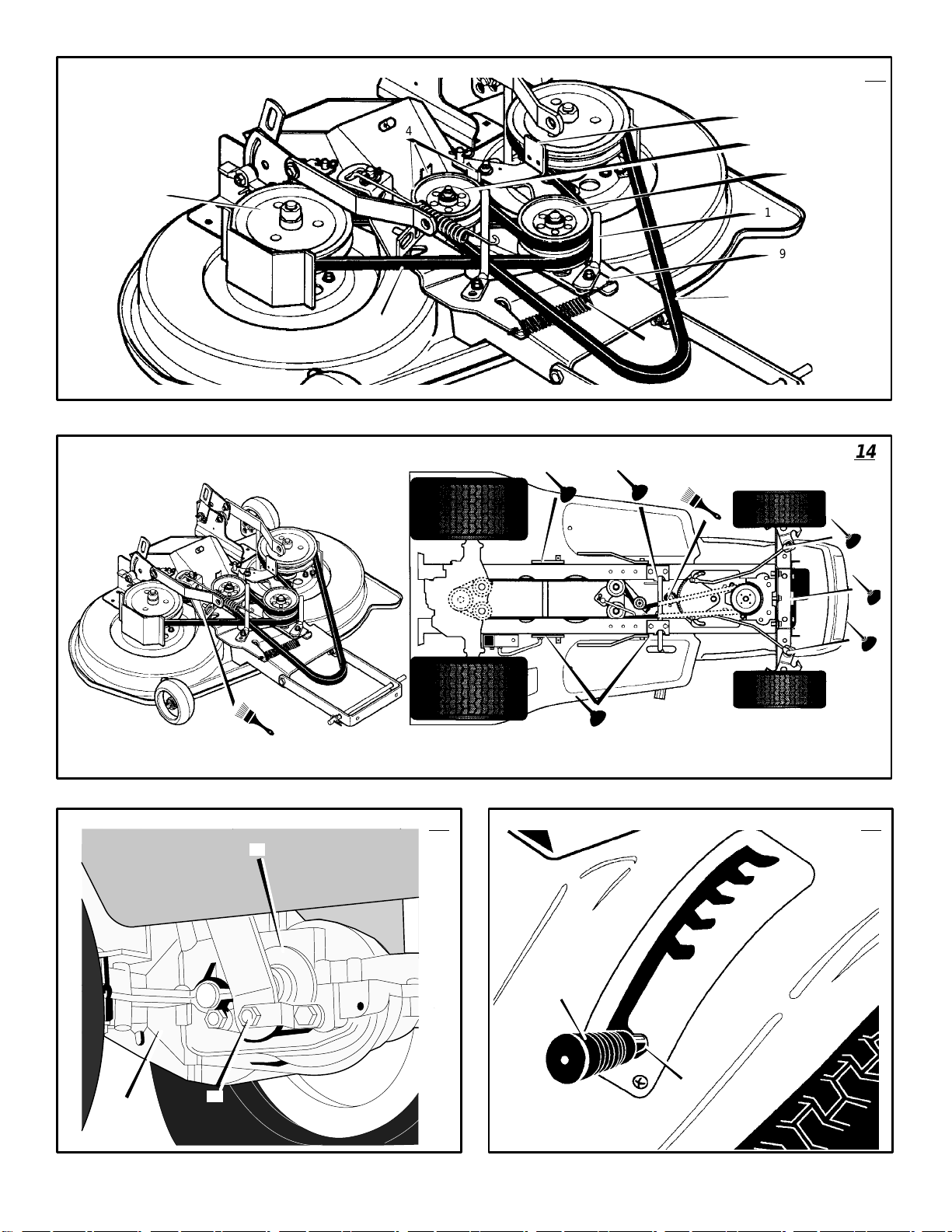

17

2

18

3

1

4

1

19

1

2

F–000794J

20

3

2

1

3

4

4

5

1

21

Page 6

22

23

3

2

1

24

1

2

1

2

25

1

3 (711909)

2

4 (711632)

2

1

3

26

711653

711653

27

2

F–000794J

3

6

Page 7

28

29

5

30

3

6

1

6

5

7 (711741)

31

F–000794J

4

1

32

33

2

1

7

Page 8

34

1

2

35

1

1

2

1

3

37

4

3

2

36

F–000794J

4

3

2

5

8

Page 9

38

J

8

4

2

1

A

2

1

4

6

5

E

B

3

11

C

F

3

9

F–000794J

D

10

H

9

Page 10

39

12 3 5467

9

16 18

10

17

1211 13

14 15

8

40

12 3456 78 9

10 11 12 13 14 15

0011x3

711758

711719

711663

711644

711680

41

327350

711747

711636

F–000794J

711909

711653

10

711632

711741

Page 11

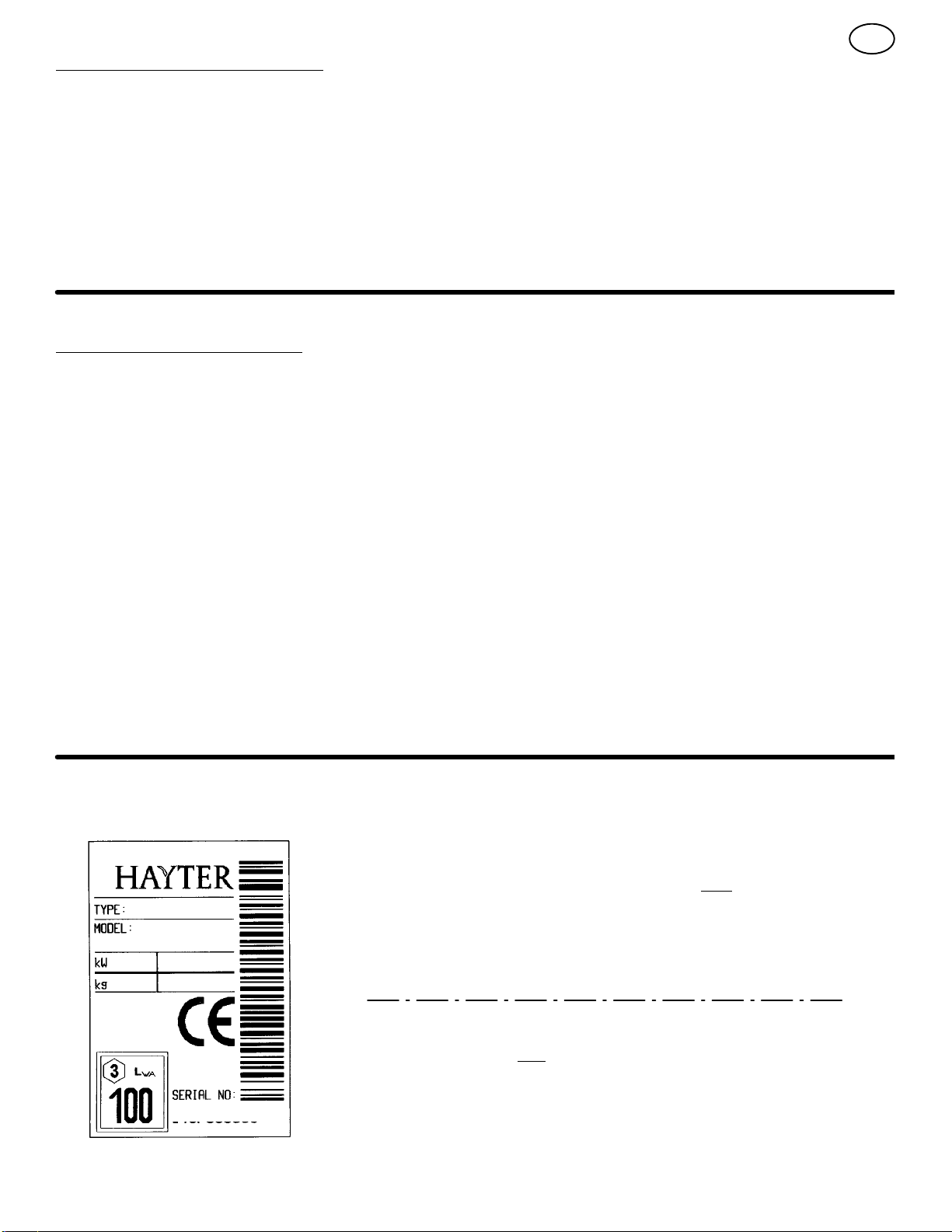

LIMITED WARRANTY

Hayter Limited warrants to the original user / purchaser that this unit shall be free from defects in material and

workmanship under normal use and service for a period of three years from the date of purchase. The manufacturers of the engine and battery pack system (where applicable) furnish their own warranty and services are provided through their authorised network (Refer to “Engine/Battery Pack Warranty Statement”). To qualify for the

full benefit of the warranty , the warranty registration card must be returned within 60 days of purchase. Subject to

the conditions and exclusions noted in this limited warranty, we shall at our option, repair or replace any warranted part during the applicable period. If you are in doubt or experience any difficulty, please consult a Hayter

Authorised Service Dealer for clarification..

To qualify for the extended warranty (second and third year) of the three year limited warranty , the machine must

have annual services carried out by an Authorised Hayter Service Dealer. These chargeable services should be

carried out within 12 and 24 months of the date of purchase.

Excluded from the extended warranty period are those items which are subject to normal wear and tear e.g. tyres,

wheels, cutterbars, cables, batteries and other consumable wearing parts.

All consumer machines which are fitted with a genuine Hayter friction disc as original equipment, before use, are

covered by a Lifetime Warranty against the engine crankshaft bending. Note: friction washers, blade brake

units and other such devices are not applicable. Only machines fitted with a genuine Hayter friction disc, which

are used in accordance with the recommended operating and maintenance procedures, are covered.

This warranty does not apply to any unit that has been tampered with, altered, misused, abused or used for hire,

and will become invalid if non genuine Hayter parts are fitted. This warranty does not cover minor mechanical

adjustments unless they are due to defective materials or workmanship. Consult the Owner’s Handbook or a

Hayter Authorised Service Dealer for assistance when making these adjustments.

A warranty period of 90 days applies to machines used for commercial purposes.

To make a warranty claim, return the unit to a Hayter authorised dealer along with proof of purchase stating the

machine serial number and date of purchase. The service receipt(s) or this Owner’s Handbook with the 1st/2nd

year service boxes fully completed, must be produced as proof of entitlement to the extended warranty period.

Subject to the conditions and exclusions in this limited warranty , the authorised dealer will, at our option, repair or

replace any warranted part within the duration of the warranty period.

This limited warranty gives you specific legal rights and is in addition to any statutory rights to which you may be

entitled and your statutory rights are not affected by this warranty. If you need additional information concerning

this written warranty, or assistance in obtaining services, please write to:

HAYTER LIMITED, Service Department, Spellbrook, Bishop’s Stortford, Hertfordshire. CM23 4BU.

GB

F–000794J

UK ONLY: Details of your local Hayter authorised dealer are contained in Y ellow Pages or contact: Freephone 0800 616298.

1st

Year

Service

Record

Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2nd

Year

Service

Record

Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

Page 12

CONTENTS

LIMITED WARRANTY 11

INTERNATIONAL PICTORIALS 12

OWNER’S INFORMATION 13

SAFE OPERATION PRACTICES 13

ASSEMBLY 14

OPERATION 15

MAINTENANCE 17

TROUBLE SHOOTING CHART 20

GB

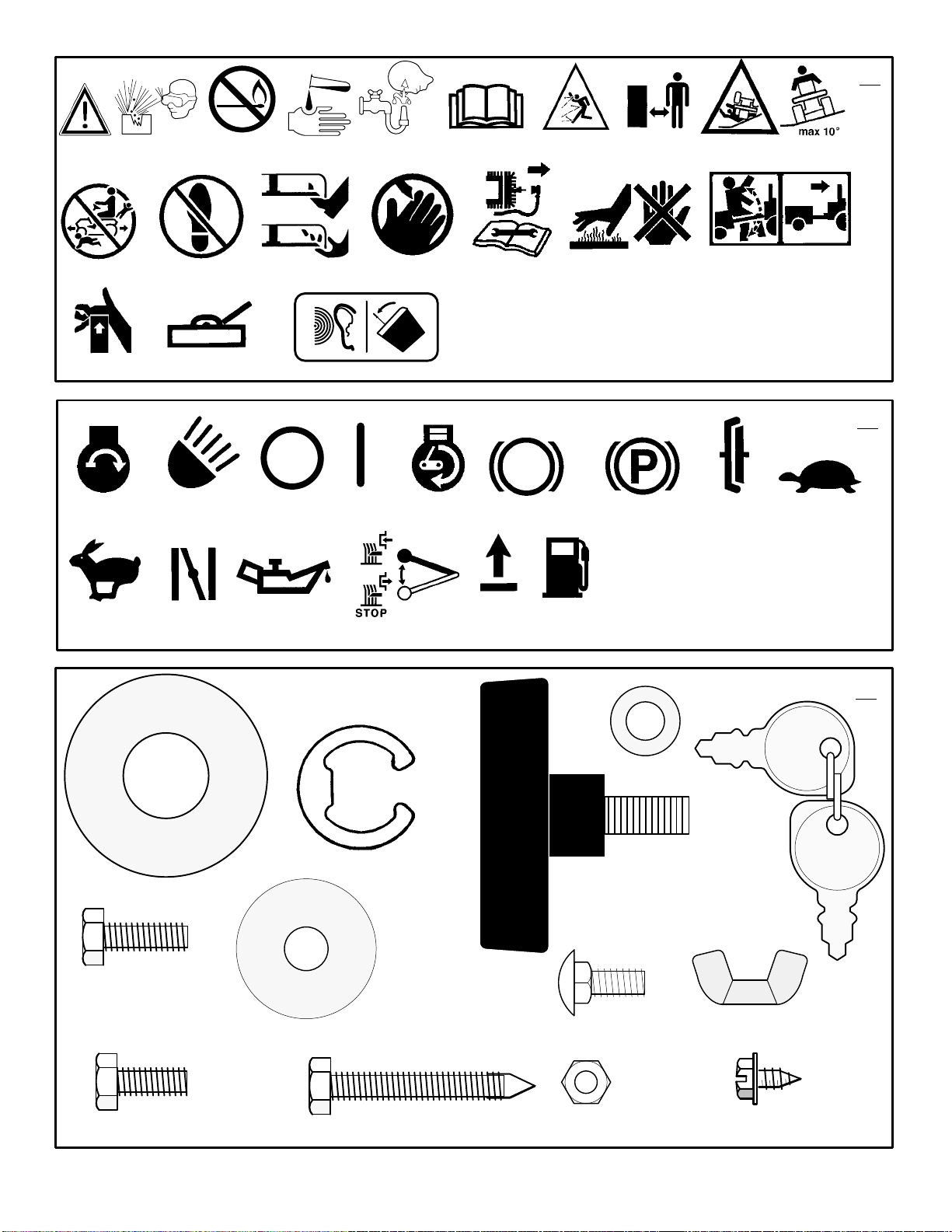

INTERNATIONAL PICTORIALS

IMPORTANT: The following pictorials are located on your unit or on literature supplied

with the product. Before you operate the

unit, learn and understand the purpose for

each pictorial.

NOTE: Illustrations and pictorials begin

on page 2.

Safety Warning Pictorials

1 WARNING

2 Shield Eyes. Explosive Gases Can Cause

Blindness Or Injury.

3 No Sparks, Flames or Smoking.

4 Sulphuric Acid Can Cause Blindness Or

Severe Burns

5 Flush Eyes Immediately With Water. Get

Medical Help Fast.

6 IMPORTANT: Read Owner’s Manual

Before Operating This Machine.

7 WARNING: Thrown Objects. Keep

(Figure 39)

Bystanders Away. Read User Instructions

Before Operating This Machine.

8 WARNING: Do Not Use This Machine On

Slopes Greater Than 10 Degrees.

9 DANGER: Keep People, Especially

Children, Away From Unit.

10 DANGER: No Step.

11 DANGER: Keep Feet And Hands Away

From Rotating Blade.

12 DANGER: Keep Hands Away From

Rotating Blade.

13 DANGER: Disconnect Spark Plug Wire

Before Servicing Unit.

14 WARNING: Hot Surface.

15 WARNING: Use Caution When Connecting

Or Disconnecting Accessories.

16 WARNING: Crushed Fingers.

17 IMPORTANT: Follow Instructions In

Owner’s Manual To Level The Deck.

18 WARNING: When you hear the audible

alarm it is time to empty the grass bagger.

Control And Operating Pictorials

(Figure 40)

1 Engine Start

2 Lights

3 Engine Run

4 Engine Stop

5 Engine Run

6 Brake

7 Parking Brake

8 Clutch

9 Slow

10 Fast

11 Choke

12 Oil

13 Blade Rotation Control

14 Raise

15 Fuel

MADE IN USA BY MURRAY INC.

JACKSON, TENNESSEE

FOR

CODE145S

15/40 TRACTOR

HYDRO/REAR COLLECT

249

F–000794J

RPM 2600

2000

145S001251

Declared vibration emission values in accordance with Directive 89/392/EEC.

Vibration Emission according to BS EN 1032: Seat < 0,50 m/s2,

Right Running Board < 0,50 m/s2, Left Running Board 0,54 m/s2

Vibration Emission according to BS EN 1033: Steering Wheel 3,85 m/s

Values determined with operator in operating position when the machine was

operated stationary on a grass covered surface at 2600 min–1.

Declared airborne noise emissions in accordance with Directive 84/538/EEC.

Sound Power Level 100 dB(A)

Sound Pressure Levels

at operator ears 85,3 dB(A) left; 85,2 dB(A) right.

Values determined at ear according to the specifications of 81/1051/EEC.

2

12

Page 13

OWNER’S INFORMATION

Know your product: If you understand the unit

and how the unit operates, you will get the best

performance. As you read this manual, compare

the illustrations to the unit. Learn the location

and the function of the controls. To help prevent

an accident, follow the operating instructions

and the safety rules. Keep this manual for future

reference.

WARNING: Look for this symbol to indicate

important safety precautions. This symbol

indicates: “Attention! Become Alert! Your

Safety Is At Risk.”

Responsibility Of The Owner

WARNING: This cutting machine is

capable of amputating hands and

feet and throwing objects. Failure

to observe the following safety instructions

could result in serious injury or death to

the operator or bystanders.

The responsibility of the owner is to

follow the instructions below.

SAFE OPERATION PRACTICES

For Ride–On (Riding)

Rotary Mower Machines

Training

1. Read the instructions carefully. Be familiar

with the controls and the proper use of the

equipment.

2. Never allow children or people unfamiliar

with these instructions to use the mower.

Local regulations may restrict the age of

the operator.

3. Never mow while people, especially

children, or pets are nearby.

4. Keep in mind that the operator or user is

responsible for accidents or hazards occurring to other people or their property.

5. Do not carry passengers.

6. All drivers should seek and obtain professional and practical instruction. Such

instruction should emphasize:

a. the need for care and concentration

when working with ride–on machines;

b. control of a ride–on machine sliding

on a slope will not be regained by the

application of the brake. The main

reasons for loss of control are:

insufficient wheel grip;

being driven too fast;

inadequate braking

the type of machine is unsuitable

for its task;

lack of awareness of the effect of

ground conditions, especially

slopes;

incorrect hitching and load dis-

tribution.

Preparation

1. While mowing, always wear substantial

footwear and long trousers. Do not operate

the equipment when barefoot or wearing

open sandals.

F–000794J

2. Thoroughly inspect the area where the

equipment is to be used and remove all objects which may be thrown by the machine.

3. WARNING – Petrol is highly flammable.

a. Store fuel in containers specifically de-

signed for this purpose.

b. Refuel outdoors only and do not

smoke while refuelling.

c. Add fuel before starting the engine.

Never remove the cap of the fuel tank

or add petrol while the engine is running or when the engine is hot.

d. If petrol is spilled, do not attempt to

start the engine but move the machine

away from the area of spillage and

avoid creating any source of ignition

until petrol vapours have dissipated.

e. Replace all fuel tanks and container

caps securely.

4. Replace faulty silencers.

5. Before using, always visually inspect to see

that the blades, blade bolts and cutter assembly are not worn or damaged. Replace

worn or damaged blades and bolts in sets

to preserve balance.

6. On multi–blade machines, take care as rotating one blade can cause other blades to

rotate.

Operation

1. Do not operate the engine in a confined

space where dangerous carbon monoxide

fumes can collect.

2. Mow only in daylight or in good artificial

light.

3. Before attempting to start the engine, disengage all blade attachment clutches and

shift into neutral.

4. Do not use on slopes of more than 10 degrees.

5. Remember there is no such thing as a

“safe” slope. Travel on grass slopes requires particular care. To guard against

overturning:

a. do not stop or start suddenly when

going up or downhill;

b. engage clutch slowly, always keep

machine in gear, especially when travelling downhill;

c. machine speeds should be kept low

on slopes and during tight turns;

d. stay alert for humps and hollows and

other hidden hazards;

e. never mow across the face of the

slope, unless the mower is designed

for this purpose.

6. Use care when pulling loads or using heavy

equipment.

a. Use only approved drawbar hitch

points.

b. Limit loads to those you can safely

control.

c. Do not turn sharply. Use care when

reversing.

d. Use counterweight(s) or wheel

weights when suggested in the Instruction Book.

7. Watch out for traffic when crossing or near

roadways.

8. Stop the blades rotating before crossing

surfaces other than grass.

9. When using any attachments, never direct

discharge of material toward bystanders

13

GB

nor allow anyone near the machine while in

operation.

10. Never operate the mower with defective

guards or shields, or without safety protective devices in place.

11. Do not change the engine governor settings or overspeed the engine. Operating

an engine at excessive speed may increase the hazard of personal injury.

12. Before leaving the operator’s position

a. disengage the power take–off and

lower the attachments;

b. change into neutral and set the park-

ing brake;

c. stop the engine and remove the key.

13. Disengage drive to attachments, stop the

engine, and disconnect the spark plug

wire(s) or remove the ignition key

a. before cleaning blockages or unclog-

ging chute;

b. before checking, cleaning or working

on the mower;

c. after striking a foreign object. Inspect

the mower for damage and make repairs before restarting and operating

the equipment;

d. if the machine starts to vibrate abnor-

mally (check immediately).

14. Disengage drive to attachments when

transporting or not in use.

15. Stop the engine and disengage drive to attachment

a. before refuelling;

b. before removing the grass catcher;

c. before making height adjustment un-

less adjustment can be made from the

operator’s position.

16. Reduce the throttle setting during engine

run–out and, if the engine is provided with a

shut–off valve, turn the fuel off at the conclusion of mowing.

17. Before and when backing, look behind and

down for small children.

18. Use extra care when approaching blind

corners, shrubs, trees or other objects that

may obscure vision.

Maintenance and Storage

1. On multi–blade machines, take care as rotating one blade can cause other blades to

rotate.

2. When machine is to be parked, stored or

left unattended, lower the cutting means

unless a positive mechanical lock is used.

3. Keep all nuts, bolts, and screws tight to be

sure the equipment is in safe working

condition.

4. Never store the equipment with petrol in the

tank inside a building where fumes may

reach an open flame or spark.

5. Allow the engine to cool before storing in

any enclosure.

6. To reduce the fire hazard, keep the engine,

silencer, battery compartment and petrol

storage area free of grass, leaves, or excessive grease.

7. Check the grass catcher frequently for

wear or deterioration.

8. Replace worn or damaged parts for safety.

9. If the fuel tank has to be drained, this

should be done outdoors.

Page 14

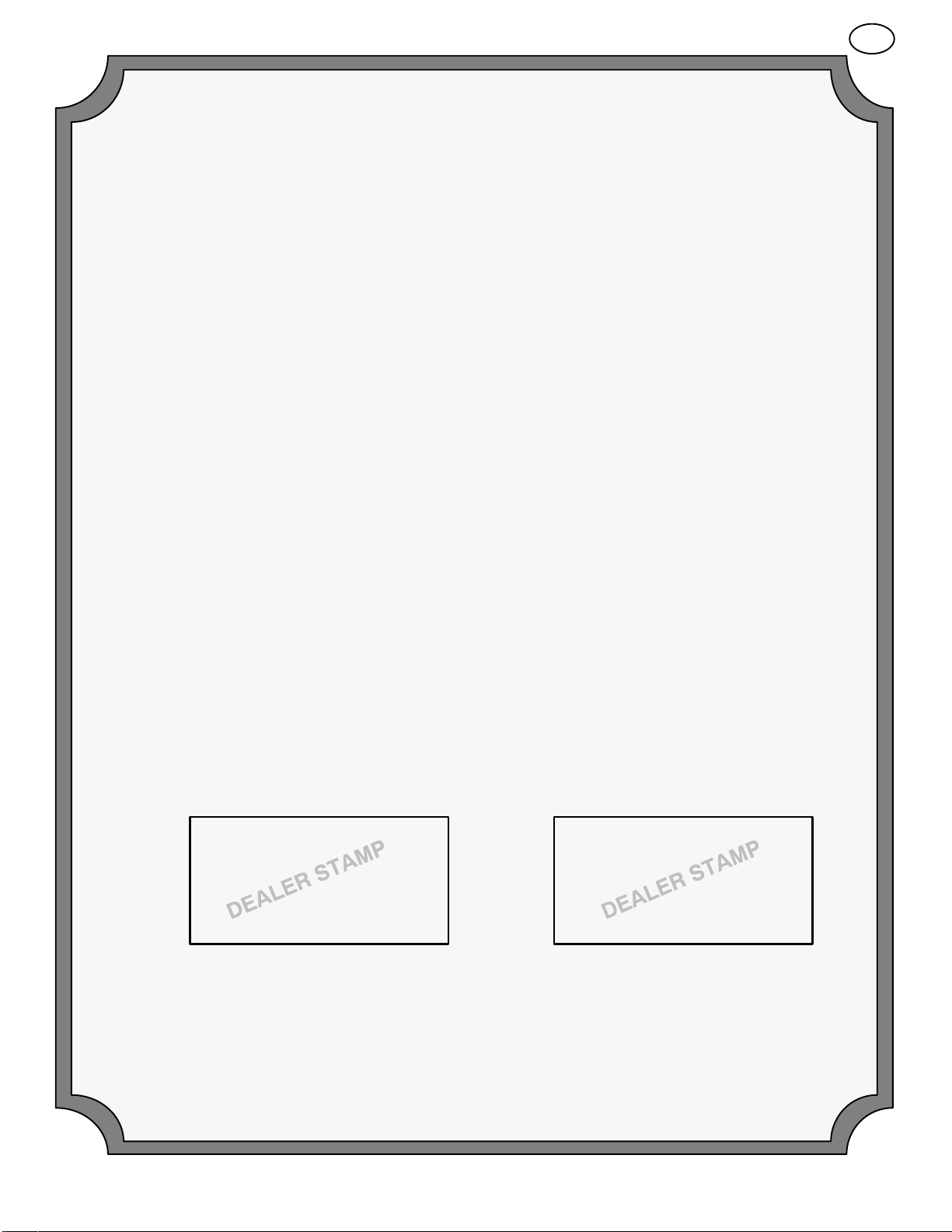

ASSEMBLY

n

f

All fasteners are in the parts bag. Do not discard

any parts or material until the unit is assembled.

WARNING: Before doing any assembly or maintenance to the

mower, remove the wire from the

spark plug.

NOTE: In this instruction book, left and right

describe the location of a part with the operator on the seat.

NOTE: Illustrations and pictorials begin on

page 2.

NOTE: To assemble the following loose

parts, use the fasteners shown at full size in

Figure 41.

How To Install The Front Wheels

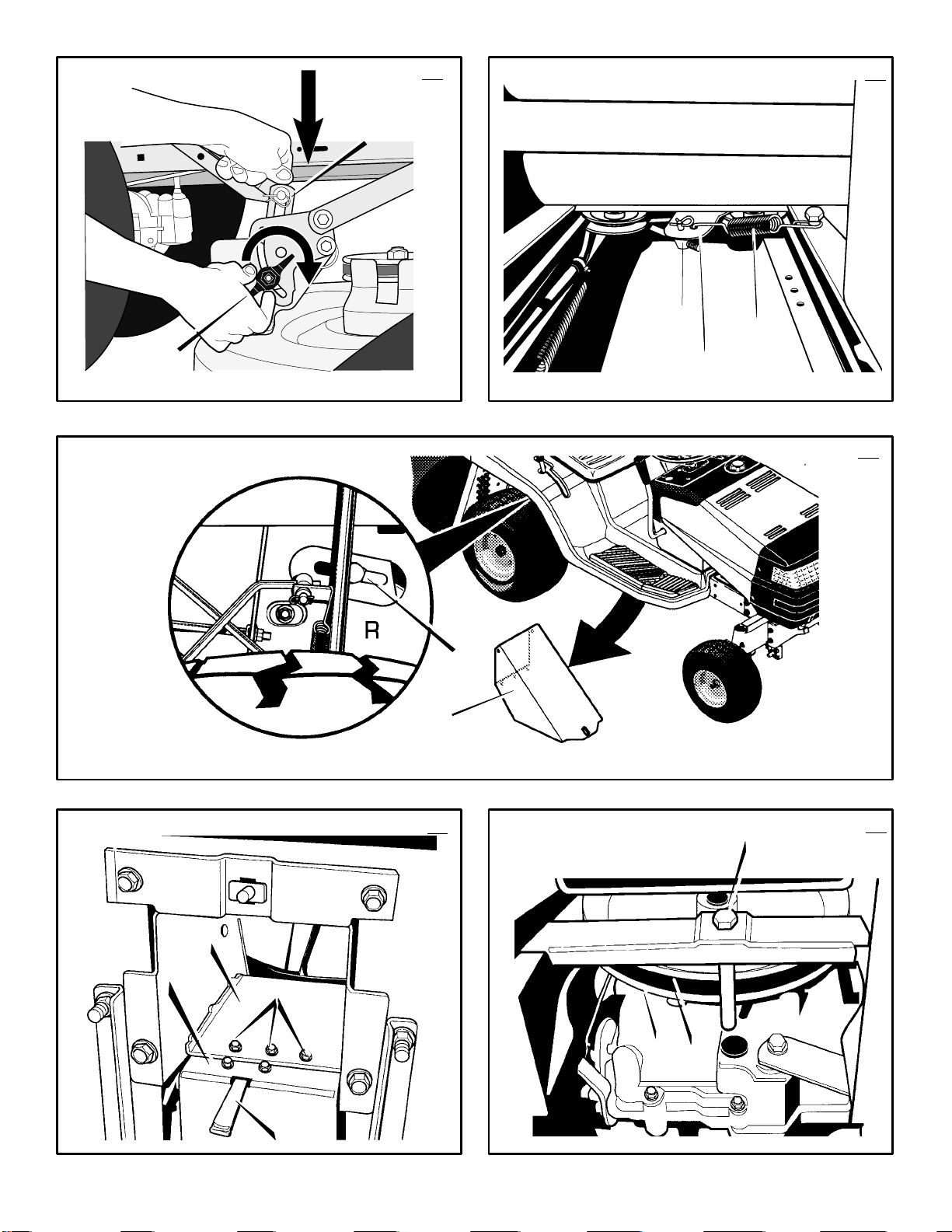

(Figure 1)

Use a knife and cut the four sides of the container.

Install the front wheels (1) in the container.

NOTE: Use a piece of wood about 4 feet (1.25

meters) long to raise the front of the tractor.

If a piece of wood cannot be found, get

another person to help lift the tractor. Be

careful, do not let the tractor fall.

1. Raise the front of the tractor. Set a support

(block of wood) under the tractor.

2. Make sure the valve stem (2) is to the outside of the tractor. Slide the front wheel (1)

on the spindle (3).

3. Fasten each front wheel (1) with washer (4)

and e–ring (5).

4. After the front wheels (1) are installed, lift

the tractor from the support. Roll the tractor

off of the container.

5. If your tractor has hub caps (6), install the

hub caps (6). Make sure the washers (4)

hold the hub caps (6) in place.

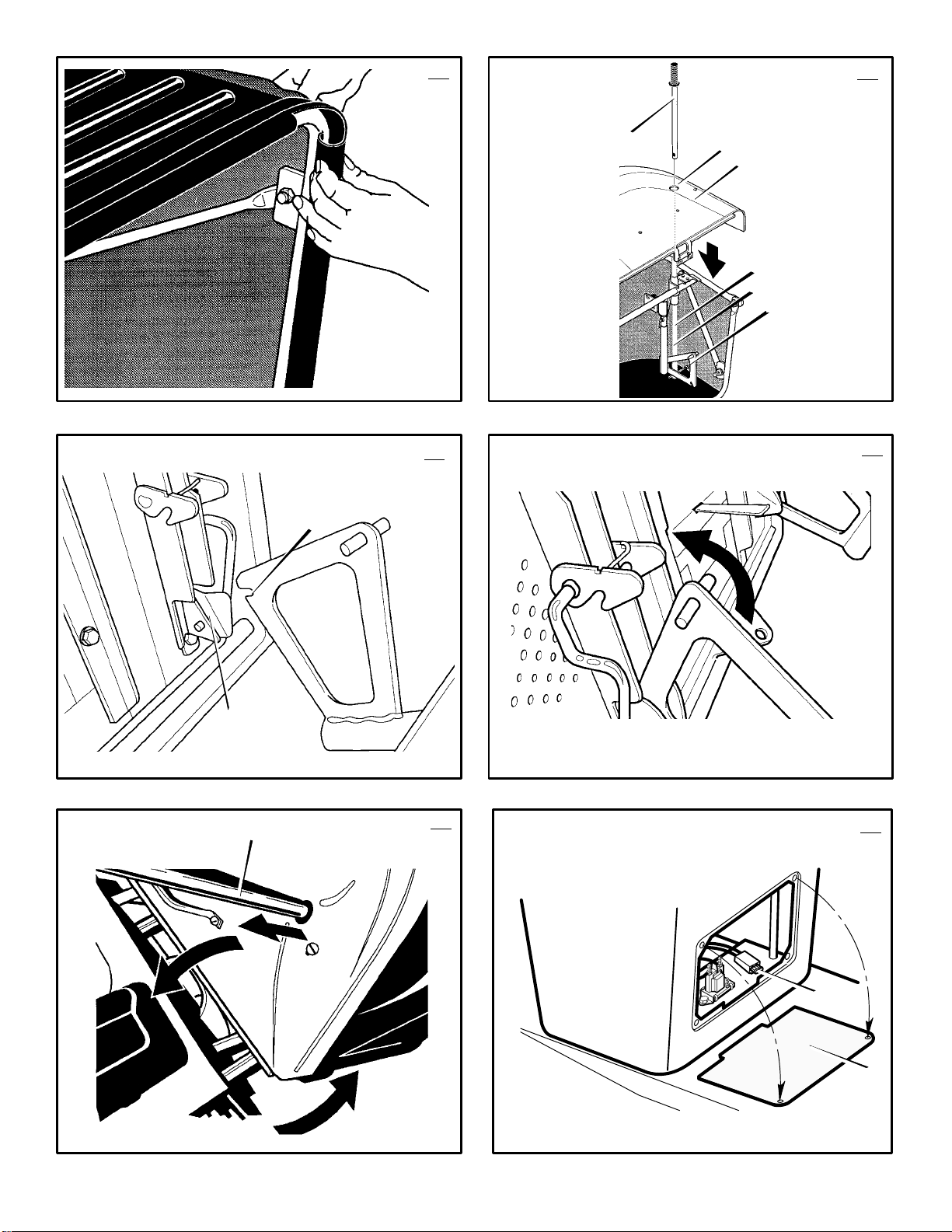

How To Install The Seat

1. Carefully remove the plastic bag from the

seat (1).

NOTE: For shipping purposes, the fas-

teners may be attached to the seat. Before proceeding, remove the fasteners.

2. Align the holes in the seat hinge (2) to the

bolts in the seat (1). Fasten the seat (1) to

the seat hinge (2) with the fasteners (4) and

(5).

3. Check the operating position of the seat (1).

If the seat (1) needs to be adjusted, loosen

the two wing bolts (5). Slide the seat (1) for-

ward or backward along the seat adjusting

holes (3). Tighten the wing bolts (5).

How To Assemble The Steering Wheel

1.

(Figure 3)

cover (1) is taped to the center of the steer-

ing wheel (2). Remove the hub cover (1)

and set aside.

2.

(Figure 4)

(2) from the steering post (3) and set aside.

3. Make sure the front wheels point forward.

4.

(Figure 5)

make sure the split spoke (5) of the steering

wheel in pointing toward you. Slide the steer-

ing wheel (1) onto the steering post (2).

5. Use screw (6) and washer (7), set aside

earlier, to secure the steering wheel (1).

Tighten the screw (6). DO NOT over tighten.

F–000794J

For shipping purposes, the hub

Remove screw (1) and washers

From the operator’s position,

(Figure 2)

6. Remove the adhesive backing from the hub

cover (3) that was set aside earlier. Attach

the hub cover (3) to the center of the steering wheel (1).

7. Some models have an

parts bag. Attach the decal to the center of

the steering wheel (1).

Maintenance Free Battery

IMPORTANT: Before you attach the battery

cables to the battery, check the battery date.

The battery date tells if the battery must be

charged.

1. Check the top of the battery (1) for the location of the battery date.

2. If the battery (1) is put into service

the battery date, the battery cables can be

attached without charging the battery (1).

See “How To Install The Battery Cables”.

3. If the battery (1) is put into service

battery date, the battery (1) must be

charged. See “How To Charge The Maintenance Free Battery”.

optional

(Figure 6)

decal in the

before

after

the

How To Charge The Battery

WARNING: When you charge the

battery, do not smoke. Keep the bat-

fumes from the battery acid can cause an

explosion.

1.

2. Remove the fasteners (9) from the battery

3.

4. Remove battery bracket (11).

5. Remove the battery (1).

6. Remove the protective caps from the battery

7. Use a 12 volt battery charger to charge the

8. Install the battery (1).

9. Install battery brackets (10, 11).

NOTE: Make sure battery brackets (10, 11)

are installed into the slots in the frame (12)

before tightening the fasteners.

tery away from any sparks. The

(Figure 6)

brackets (10, 11).

(Figure 7)

(10) and remove battery bracket (10) from

frame (12) as shown.

terminals.

battery (1). Charge at a rate of 6 amperes

for one hour. If you do not have a battery

charger, have an authorized service centre

charge the battery.

Remove the battery cover (3).

WARNING: To prevent sparks, do

not touch the battery brackets to

the terminals.

Apply pressure to battery bracket

How To Install The Battery Cables

(Figure 6)

WARNING: To prevent sparks, faste

the red cable to the positive (+) ter-

cable.

1. Remove the protective caps from the battery

2. Fasten the red cable (5) to the positive (+)

minal before you connect the black

terminals.

NOTE: For shipping purposes, the fasteners may be attached to the battery terminals. Remove the fasteners before

proceeding.

terminal (4) with the fasteners (6) and (7).

Slide the terminal cover (2) onto the positive (+) terminal (4).

14

GB

3. Fasten the black cable 8 to the negative (–)

terminal with the fasteners (6) and (7).

4. Install the battery cover (3).

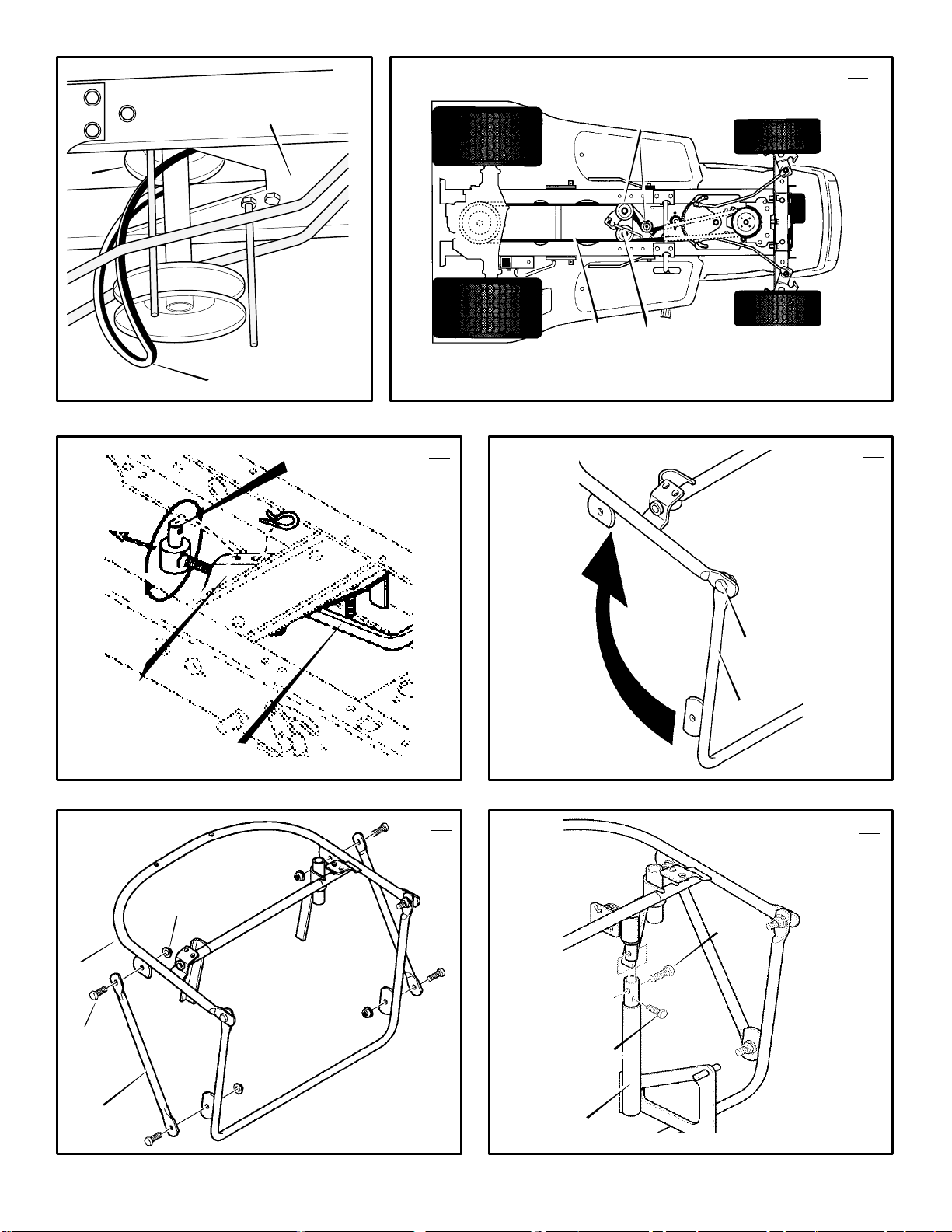

How To Assemble The Grass Bagger

1. Put the grass bagger on a flat surface.

2.

(Figure 25)

teners (2).

3.

(Figure 26)

assembly (1) with screws (3) and nuts (4).

Make sure all fasteners are tight.

4.

(Figure 27)

brackets (3) with the fasteners as shown.

5.

(Figure 28)

6.

(Figure 29)

bagger assembly (1), slide the handle (5) in

the tube (6).

7. Fasten the handle (5) with screw (7).

How To Mount

The Grass Bagger On The Tractor

1.

(Figure 30)

brackets (3) onto the pins (4) on the back

plate of the tractor.

2.

(Figure 31)

grass bagger in operating position. Snap into

place.

How To Prepare The Engine

NOTE: The engine was shipped from the factory filled with oil. Check the level of the oil.

Add oil as needed.

See the engine manufacturer’s instructions for the

type of petrol and oil to use. Before you use the

unit, read the information on safety, operation,

maintenance, and storage.

safety petrol container. Do not smoke when

adding petrol to the engine. When inside an

enclosure, do not fill with petrol. Before you

add petrol, stop the engine. Let the engine

cool for several minutes.

Check The Tyres

Check the air pressure in the tyres. Tyres with too

much air pressure will cause the unit to ride rough.

Also, the wrong air pressure will keep the mower

housing from cutting level. The correct air pressure is: Front Tyres 1,38 BAR (20 PSI), Rear

Tyres 0,97 BAR (14 PSI). The tyres were over inflated for shipment.

Check The Level Of The Mower Housing

Make sure the level of cut is still correct. After you

mow a short distance, look at the area that was cut.

If the mower housing does not cut level, see the instructions on “How To Level The Mower Housing”

in the Maintenance section of this instruction book.

Important! Before You Start Mowing

Check the engine oil.

Fill the fuel tank with petrol.

Check the level of the mower housing.

Check the air pressure of the tyres.

Attach the battery cables.

Open the frame (1). Tighten fas-

Attach braces (2) to the frame

Attach the bag support

Secure the bag to the frame.

On the left side of the grass

Mount the slots on the support

Hold rear handle and rotate the

WARNING: Follow the engine manufacturer’s instructions for the type o

petrol and oil to use. Always use a

Page 15

OPERATION

NOTE: Illustrations and pictorials begin on

page 2.

Location Of Controls

Blade Rotation Control (1): Use the blade

rotation control to start and stop the rotation of the

blade.

Brake Pedal (2): Use the brake pedal to quickly

stop.

Headlight Switch (3): The headlight switch is the

first part of the ignition switch. T o use the lights with

the engine running, turn the key to the position for

the lights.

Ignition Switch (3): Use the ignition switch to

start and stop the engine.

Speed Control Pedal (4): Use the speed control

pedal to change the speed and the direction of the

unit.

Lift Lever (5): Use the lift lever to change the

height of cut.

Parking Brake Lever (6): Use the parking brake

lever to engage the brake when you leave the unit.

Throttle Control Lever (7): Use the throttle

control lever to increase or decrease the speed of

the engine. For models without a choke control

button, the choke is regulated with the throttle

control lever.

Choke Control Button (9): If equipped, used to

start cold engine.

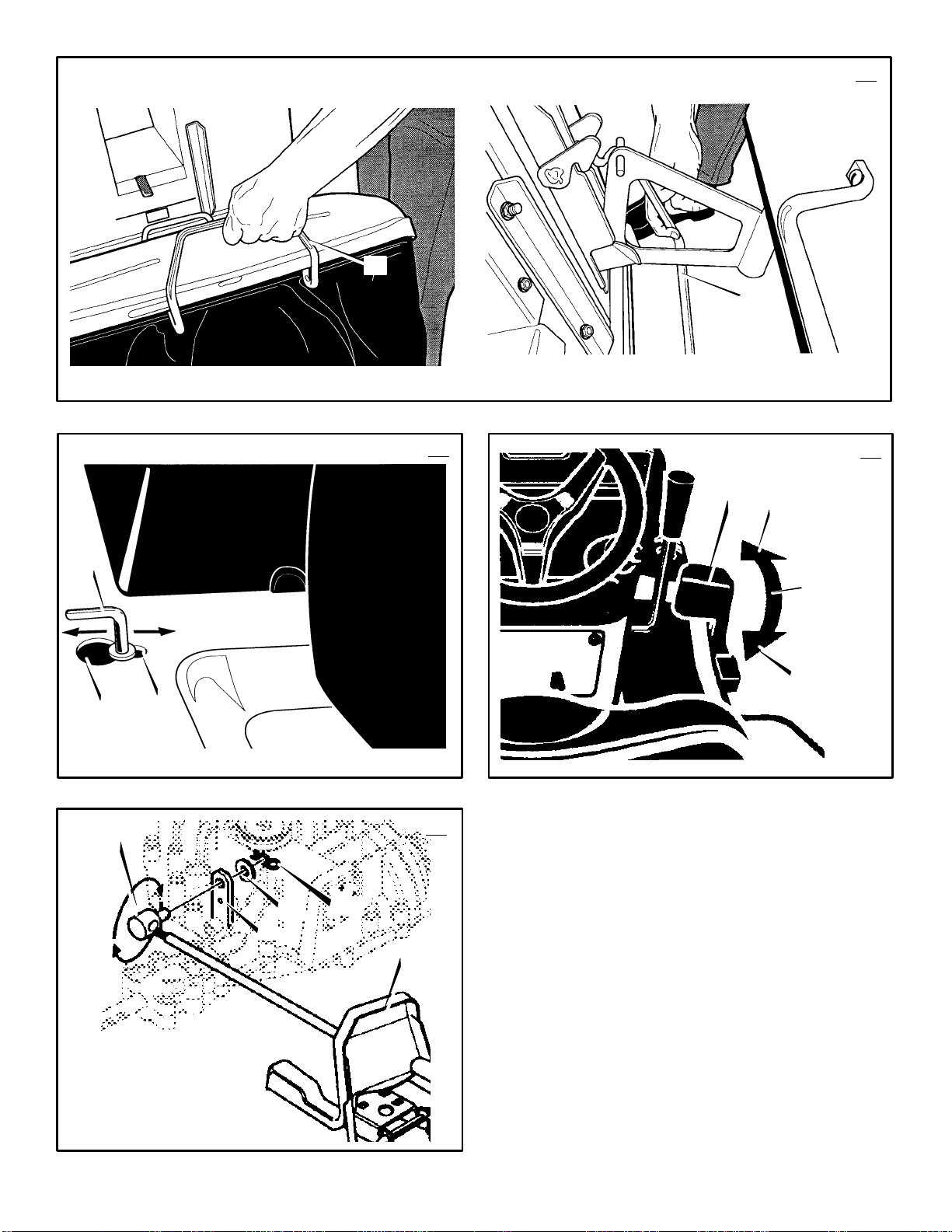

(Figure 35)

Use the automatic drive disconnect, located at the

left back corner of the seat, to disengage the

transmission.

Grass Bagger Full Indicator (10): When you

hear the audible alarm the grass bagger is full.

Move the blade rotation control (1) to the

DISENGAGE position to turn audible alarm off and

see the “How To Empty The Grass Bagger”

instructions in this section.

IMPORTANT: For the diagnostic dash to operate properly the engine MUST use a resistor spark plug. When replacing the spark

plug see the engine owner’s manual for the

correct spark plug.

Automatic Drive Disconnect (1):

Diagnostic Dash

PTO/Clutch engaged. To start the

engine, disengage the

PTO/Clutch.

Service Light. Refer to Hour

Meter, Instruction Book and

Engine Manual for scheduled

service. Service Light stays ON

until reset procedure is followed.

25

F–000794J

Hour Meter. Records the engine

runtime in hours.

Low Fuel. Fill fuel tank.

Low Oil Pressure. STOP

ENGINE!. Check and add oil.

Low Battery Voltage. Check

battery, battery cables and engine

charging system.

(Figure 8)

How To Reset The Service Light

To alert the operator that scheduled service is due,

the service light will automatically come ON. After

the scheduled service is performed, the service

light can be easily reset as follows.

1. Raise the hood. Locate the reset button. The

reset button is above the fuel tank on the

right side of the console. The following decal

is next to the reset button.

2. Turn the ignition key to the ON/RUN position.

Do not turn the ignition key to the START

position. Do not start the engine.

3. All indicator lights will come on for two seconds.

4. After two seconds, the service light will begin

flashing for ten seconds.

5. Depress and release the reset switch while

the service light is flashing. The service light

will go off.

6. The reset switch will only turn off the service

light. The hour meter cannot be reset.

Diagnostic Fuse

Replace fuse only with a 3 AMP 32 volt fuse. For

location of fuse see “How To Replace The Fuse”

in the Maintenance section.

Attachments

This unit can use many different attachments. This

unit can pull attachments like a lawn sweeper, a

lawn aerator, or a hopper spreader. This unit can

not use attachments that engage the ground like

a plough, a disk harrow, or a cultivator.

For trailer and pull–behind attachments, the

maximum weight is 113 kg (250 lbs.).

How To Use The Throttle Control

(Figure 8)

Use the throttle control (7) to increase or

decrease the speed of the engine.

1. The FAST position is marked with a detent.

For normal operation and when using a

grass bagger, move the throttle control to the

FAST position. For maximum charging of the

battery and for a cooler running engine, operate the engine in the FAST position.

2. The engine governor is set at the factory for

maximum performance. Do not adjust the

governor to increase the speed of the engine.

How To Use The Blade Rotation Control

(Figure 8)

Use the blade rotation control (1) to engage the

blade(s).

1. Before you start the engine, make sure the

blade rotation control (1) is in the DISENGAGE position.

2. Move the blade rotation control (1) to the

ENGAGE position to rotate the blade(s).

NOTE: If the engine stops when you engage the blade(s), the seat switch is not

activated or the bag is not closed properly. Make sure you sit in the middle of the

seat.

3. Move the blade rotation control (1) to the

DISENGAGE position to stop the blade(s).

15

GB

Before you leave the operator’s position,

make sure the blade(s) has stopped rotating.

4. Before you ride the unit across a sidewalk or

a road, move the blade rotation control (1)

to the DISENGAGE position.

WARNING: Always keep your

hands and feet away from the

blade, deflector opening, and the

mower housing when the engine runs.

How To Use The Speed Control Pedal

(Figure 8)

The drive system uses a Hydrostatic Automatic

Drive transmission. The Hydrostatic transmission

is very easy to operate. This type of drive system

does not require a shift lever or a clutch pedal.

The speed and direction of travel is controlled by

a single speed control pedal (4) operated with

your right foot. Do not use the left brake pedal in

normal operation. Only use the left brake pedal to

quickly stop in an emergency.

How To Drive Forward

1.

(Figure 35)

nect (1) must be in the DRIVE position (2).

2. Slowly release your left foot from the brake

pedal.

3. Move the throttle control to the FAST position.

4.

(Figure 36)

pedal (1) forward (4) to the desired speed.

5. To increase forward speed, slowly move the

speed control pedal (1) forward. To reduce

forward speed, slowly release the speed

control pedal (1) until the unit slows to the

desired speed.

How To Drive In Reverse

1. Look to the rear.

2. Slowly push the speed control pedal (1) to

the REVERSE position (2).

How To Change Directions

CAUTION: To change directions, do not use

the left brake pedal. Use only the speed control pedal.

1. Slowly remove your foot from the speed

control pedal (1). The speed control pedal

(1) will automatically return to the NEUTRAL

position (3).

2. When the unit stops, slowly move the speed

control pedal (1) to the desired direction.

How To Disconnect The Transmission

(Figure 35)

To push the unit, use the automatic drive

disconnect (1) to release the transmission. The

automatic drive disconnect (1) is at the left rear

corner of the seat.

1. The engine must be off.

2. Raise the seat. The automatic drive dis-

connect (1) is at the left rear corner of the

seat.

3. Raise the automatic drive disconnect (1) to

the PUSH position (3). The transmission is

now

NOTE: In cold weather, the heavy viscosity oil in the transmission will make the

unit difficult to push.

4. To engage the transmission, lower the automatic drive disconnect (1) to the DRIVE

The automatic drive discon-

Slowly push the speed control

released

and the unit can be pushed.

Page 16

position (2). The transmission is now

nected

and ready to operate.

con-

How To Use The Parking Brake

(Figure 8)

1. Completely push the brake pedal (2) forward.

2. Lift the parking brake lever (6).

3. Remove your foot from the brake pedal (2)

and then release the parking brake lever

(6). Make sure the parking brake will hold the

unit.

4. To release the parking brake (6), completely

push the brake pedal (2) forward. The parking brake will automatically release.

WARNING: Before you leave the

operator’s position, set the parking

brake. Move the blade rotation control to the DISENGAGE position. Stop the

engine and remove the ignition key.

How To Change The Cutting Height

(Figure 8)

T o change the cutting height, raise or lower the lift

lever (5) as follows.

1. Move the lift lever (5) forward to lower the

mower housing and back to raise the mower

housing.

2. When you ride on a sidewalk or road, move

the lift lever (5) to the highest position and

move the blade rotation control to the DISENGAGE position.

How To Stop The Unit

1. Slowly remove your foot from the speed

control pedal (4). The speed control pedal

(1) will automatically return to the NEUTRAL

position and the unit will stop.

2. Move the blade rotation control (1) to the

DISENGAGE position.

3. Set the parking brake (6).

WARNING: Make sure the parking

brake will hold the unit.

4. Move the throttle control (7) to the SLOW

position.

5. To stop the engine, turn the ignition key (3)

to the OFF position. Remove the key.

(Figure 8)

How To Transport The Unit

To transport the unit, follow the steps below.

1. Move the blade rotation control to the DISENGAGE position.

2. Raise the lift lever to the highest position.

3. Move the throttle control to a position between SLOW and FAST.

4. Slowly push the speed control pedal forward

to the desired speed.

How To Operate With The Mower

Housing

IMPORTANT: When you operate with the

mower housing, always operate with the

throttle control in the FAST position.

1. Start the engine.

2. Release the parking brake.

F–000794J

3. Move the lift lever to a height of cut position.

In high or thick grass, cut the grass in the

highest position first and then lower the

mower housing to a lower position.

4. Move the throttle control to the SLOW position.

5. Slowly move the blade rotation control to the

ENGAGE position.

6. Slowly push the speed control pedal to the

desired speed.

7. Make sure the level of cut is still correct.

After you mow a short distance, look at the

area that was cut. If the mower housing does

not cut level, see the instructions on “How To

Level The Mower Housing” in the Maintenance section.

WARNING: For better control of the

unit, select a safe speed.

How To Operate On Hills

WARNING: Do not ride up or down

slopes that are too steep to back

straight up. Never ride the unit

across a slope.

1. Control the speed only with the speed control

pedal. Do not use the brake pedal on a hill.

2. To help prevent an accident, slowly move the

speed control pedal. Avoid sudden turns or

changes in speed.

3. To reduce forward speed when going down a

hill, slowly release the speed control pedal

until the unit slows to the desired speed.

How To Stop On a Hill

1. Avoid stopping on a hill. If you must quickly

stop in an emergency, remove your right foot

from the speed control pedal and quickly depress the left brake pedal.

2. Set the parking brake.

3. Before you dismount from the seat, move the

throttle control to SLOW position, move the

blade rotation control to the DISENGAGED

position, turn off the engine and set the parking brake.

How To Start Operation On A Hill

1. Start the engine

2. Move the blade rotation control to the ENGAGED position.

3. Move the throttle control to the FAST position.

4. Depress the brake pedal and release the

parking brake. As you release the parking

brake, push the speed control pedal to the

desired speed.

Slowly push the speed control

pedal as you release the parking

brake. The parking brake must be

disengaged before the speed control pedal

is able to engage the transmission.

WARNING: Do not operate unless

the entire grass bagger attachment

is in place.

16

GB

How To Empty The Grass Bagger

(Figure 32)

1. Move the blade rotation control to the DISENGAGED position.

2. While sitting on the seat, lift and pull the

handle (1) forward to the DUMP position.

3. Drive slowly forward to allow the grass to fall

out of the bag.

4. Push the handle rearward and down to the

OPERATING position.

NOTE: If the engine stops when you engage

the blade(s), the seat switch is not activated

or the grass bagger is not locked in place.

Before Starting The Engine

Check the oil

NOTE: The engine was shipped from the factory filled with oil. Check the level of the oil.

Add oil as needed. See the engine manufacturer’s instructions for the type of petrol and

oil to use.

1. Make sure the unit is level.

NOTE: Do not check the level of the oil

while the engine runs.

2. Check the oil. Follow the procedure in the

engine manufacturer’s instructions.

3. If necessary, add oil until the oil reaches the

FULL mark on the dipstick. The quantity of oil

needed from ADD to FULL is shown on the

dipstick. Do not add too much oil.

Add Petrol

WARNING: Always use a safety

petrol container. Do not smoke

when adding petrol to the fuel tank.

Do not add petrol when you are inside an

enclosure. Before you add petrol, stop the

engine and let the engine cool for several

minutes.

(Figure 9)

position with regular unleaded petrol. Do not use

premium unleaded petrol. Make sure the petrol is

fresh and clean. Leaded petrol will increase

deposits and shorten the life of the valves.

How To Start The Engine

the seat. These components tell the

electrical system if the operator is sitting

on the seat. This system will stop the

engine when the operator leaves the seat if

the blade rotation control is engaged or if

the transmission is engaged. For your

protection, always make sure this system

operates correctly.

NOTE: The engine will not start unless you

depress the brake pedal or engage the

parking brake and move the blade rotation

control to the DISENGAGE position.

1. Push the brake pedal completely forward.

2. Make sure the blade rotation control is in the

3. Move the throttle control completely forward

Fill the fuel tank (1) to the FULL (2)

WARNING: The electrical system

has an operator presence system

that includes a sensor switch for

Keep your foot on the pedal.

DISENGAGE position.

to the CHOKE or FAST position. Some models have a separate choke knob. Pull the

choke knob to the full CHOKE position.

Page 17

4. Turn the ignition key to the START position.

NOTE: If the engine does not start after

four or five tries, move the throttle control

to the FAST position. Again try to start the

engine. If the engine will not start, see the

TROUBLE SHOOTING CHART.

5. Slowly move the throttle control to the SLOW

position.

6. To start a hot engine, move the throttle control to a position between FAST and SLOW.

Mowing And Bagging Tips

1. For a lawn to look better, check the cutting

level of the mower housing. See “How To

Level The Mower Housing” in the Maintenance section.

2. For the mower housing to cut level, make

sure the tyres have the correct amount of air

pressure.

3. Every time you use the unit, check the blade.

If the blade is bent or damaged, immediately

replace the blade. Also, make sure the nut

for the blade is tight.

4. Keep the blade(s) sharpened. Worn blades

will cause the ends of the grass to turn

brown.

5. Do not cut or bag grass that is wet. Wet

grass will not discharge correctly. Let the

grass dry before cutting.

6. If the grass is very high, cut two times to decrease the load on the engine. First cut with

the mower housing in the highest position

and then lower the mower housing for the

second cut.

7. Operate the engine with the throttle in FAST

position and the shift lever in first or second

gear.

8. After each use, clean the bottom and top of

the mower housing for better performance.

Also, a clean mower housing will help prevent a fire.

MAINTENANCE

NOTE: Illustrations and pictorials begin on

page 2.

General Recommendations

1. The owner’s responsibility is to maintain this

product. This will extend the life of the product and is also necessary to maintain warranty coverage.

2. Check the spark plug, drive brake, lubricate

the unit, and clean the air filter once a year.

3. Check the fasteners. Make sure all fasteners

are tight.

4. Follow the Maintenance section to keep the

unit in good operating condition.

WARNING: Before you make an inspection, adjustment, or repair to

the unit, disconnect the wire to the

spark plug. Remove the wire from the

spark plug to prevent the engine from

starting by accident.

NOTE: Torque is measured in foot pounds

(metric Nm). This measurement describes

how tight a nut or bolt must be. The torque is

measured with a torque wrench.

F–000794J

Inspect Blade

hits an object, stop the engine. Check the

unit for damage. The blade has sharp

edges. When you hold the blade, use

gloves or cloth material to protect your

hands.

If you keep the blade (1) sharp and inspect the

blade for damage, the blade will cut better and be

more safe to operate. Frequently check the blade

for excessive wear, cracks, or other damage.

Frequently check the nut (3) that holds the blade

(1). Keep the nut (3) tight. If the blade hits an

object, stop the engine. Disconnect the wire to the

spark plug. See if the blade is bent or damaged.

Check the blade adapter (5) for damage. Before

you operate the unit, replace damaged parts with

original equipment parts. See the authorized

service centre in your area. Every three years,

have an authorized service person inspect the

blade or replace the old blade with an original

equipment part.

(Figure 10)

WARNING: Before you inspect or

remove the blade, disconnect the

wire to the spark plug. If the blade

How To Remove And Install The Blade

(Figure 10)

1. Remove the mower housing. See the instructions on “How To Remove The Mower Housing”.

2. Use a piece of wood to keep the blade from

rotating.

3. Remove the nut (3) that holds the blade (1).

4. Check the blade (1) and the blade adapter

(5) according to the instructions for “Inspect

Blade”. Replace a badly worn or damaged

blade with an original equipment blade. See

an authorized service centre in your area.

5. Clean the top and bottom of the mower housing. Remove all the grass and debris.

6. Mount the blade (1) and blade adapter (5)

on the mandrel (6).

7. Mount the left blade (1) and the right blade

(1) so that the hi–lift edges (7) are up. If the

blade is upside down, the blade will not cut

correctly and can cause an accident.

8. Fasten the blade (1) with the original

washers (2,8) and nut (3). Make sure the

outside rim of the Belleville washer (2) is

against the blade (1).

WARNING: Always keep the nut (3)

tight that holds the blade (1). A

accident.

9. Tighten the nut (3) that holds the blade (1) to

10.Install the mower housing. See “How To Re-

loose nut or blade can cause an

a torque of 45 foot pounds (62 Nm).

move The Mower Housing”.

How To Adjust The Blade Rotation

Control

WARNING: To prevent an injury, the

blade rotation control must operate

correctly.

In normal usage, the blade rotation control will not

require an adjustment. However, if the cutting

performance decreases or the quality of cut is

poor, make the following changes.

1. When you mow, make sure the throttle control is in the FAST position.

17

GB

2.

(Figure 11

to the DISENGAGE position (1).

3. Stop the engine. Disconnect the wire from

the spark plug.

4. Check the blade(s). Keep a sharp edge on

the blade(s). A blade that is not sharp will

cause the tips of the grass to become brown.

5.

(Figure 12)

spring (2) from the blade control rod (1).

Move the blade drive spring (2) to the

middle hole (4). This will increase the ten-

sion on the mower drive belt.

6. Attach the wire to the spark plug. Mow for a

short distance and again check the quality of

cut. If necessary, move the blade drive

spring (2) to the bottom hole (5)

7. Again check the quality of cut. If the quality of

cut has not improved, replace the mower

drive belt. See “How To Replace The Mower

Drive Belt”. If the replacing the belt does not

correct the problem, take the unit to an authorized service centre.

8. Move the blade rotation control to the DISENGAGE position. Stop the engine.

9.

(Figure 13)

brake. Rotate the pulleys with your hand.

Make sure the brake pads (12) are pressed

tightly against the pulleys

ized service centre.

10.

(Figure 11)

to the ENGAGE position (2).

11.

(Figure 13)

brake (12). If the pads are excessively worn

or damaged, replace the brake pad assemblies. Correct replacement parts and assistance are available from an authorized

service centre.

12.Attach the wire to the spark plug. Mow for a

short distance and again check the operation

of the blade rotation control.

13.When you move the blade rotation control to

the DISENGAGE position, all movement will

stop within five seconds. If there is movement of the belt or the blades continue to rotate, engage and disengage the blade

rotation control five times to remove any excess rubber from a new mower drive belt. If

you need assistance, take the unit to an

authorized service centre.

14.

(Figure 12)

belt, move the blade drive spring (2) to the

top hole

How To Adjust The Speed Control Pedal

(Figure 37)

If the unit will not go into REVERSE or if the unit

moves very slowly in REVERSE, adjust the speed

control pedal as follows.

1. Stop the engine.

2. Set the parking brake.

3. Remove the hair pin (2) from the adjuster

nut (1). Disconnect the adjuster nut (1) from

the transaxle lever (3).

4. Rotate the adjuster nut (1)

direction shown in Figure 37.

NOTE: Too much adjustment will cause

REVERSE speed to be too fast and the

FORWARD speed to be reduced.

5. Attach the adjuster nut (1) to the transaxle

lever (3) with the hair pin (2).

) Move the blade rotation control

Disconnect the blade drive

Check the operation of the blade

WARNING: If the brake pads (12) do

not press tightly against the

pulleys, take the unit to an author-

Move the blade rotation control

Check the pads for the blade

If you replace the mower drive

(3).

one turn

in the

Page 18

6. To check the adjustment, drive the unit. If the

adjustment is correct, the unit will now go

into REVERSE.

IMPORTANT: If you need assistance, go to

the nearest Authorized Service Centre. They

have the equipment and experience to make

the adjustment.

How To Check And Adjust The Motion

Drive Belt

If the motion drive belt is loose, the belt will slip

when; going up a hill, pulling a heavy load, or the

unit will not move forward.

IMPORTANT: Always operate with the engine

speed in the FAST position. If the engine

speed is in a slow or moderate position, the

engine and transmission can become too hot

and cause problems that are similar to a

loose motion drive belt.

spark plug. Remove the wire from the

spark plug to prevent the engine from

starting by accident.

1. Check the routing of the motion drive belt.

Make sure the belt is installed correctly and

is inside all the belt guides.

2. Disconnect the adjustable nut (1) from the

motion drive idler assembly (2).

3. Pull the clutch rod (3) until tight. Turn the

adjustable nut (1) until the nut will fit through

the hole in the motion drive idler assembly

(2).

4. Remove the adjustable nut (1) from the

hole. To lengthen the clutch rod (3), rotate

the adjustable nut (1) 3 to 4 turns counter–

clockwise.

5. Assemble the adjustable nut (1) to the mo-

tion drive idler assembly (2).

6. If the belt still slips after the belt has been

adjusted, then the motion drive belt is worn

or damaged and must be replaced. See

“How To Replace The Motion Drive Belt”.

(Figure 24)

WARNING: Before you make an inspection, adjustment, or repair to

the unit, disconnect the wire to the

How To Check And Adjust The Drive

(Figure 15)

Brake

Completely push the brake pedal forward. Set the

parking brake. Push the unit. If the rear wheels

rotate, adjust or replace the brake pads. Adjust the

drive brake (1) as follows.

1. The location of the drive brake (1) is on the

side of the gearbox (3).

2. Make sure the parking brake is set. Turn the

hex nut (2) in a clockwise direction until the

rear wheels do not turn when the unit is

pushed forward.

3. Release the parking brake and push the unit.

If the unit does not roll, turn the hex nut (2)

in a counter–clockwise direction until the unit

rolls.

4. Set the parking brake. Push the unit. If the

rear wheels do not turn, the drive brake (1)

is correctly adjusted. Release the parking

brake.

WARNING: If you cannot correctly

adjust the drive brake, replace the

brake pads. Correct replacement

parts and assistance are available from an

authorized service centre.

F–000794J

How To Remove The Battery

To charge or clean the battery (1), remove the

battery (1) from the unit as follows.

WARNING: To prevent sparks, disconnect the black battery cable (8)

from the negative (–) terminal be-

fore you disconnect the red cable (5).

WARNING: The battery contains

sulphuric acid which is harmful to

the skin, eyes and clothing. If the

acid gets on the body or clothing, wash

with water.

1. Remove the battery cover (3).

2. Remove the fasteners (9) from the battery

brackets (10,11).

To prevent sparks, do not touch

battery brackets to terminals.

3. Apply pressure to the left hand battery

bracket (10) and remove bracket from frame

(12) as shown.

4. Remove the right hand battery bracket

(11).

5. Disconnect the black cable (8) from the

negative (–) terminal.

6. Disconnect the red cable (5) from the posi-

tive (+) terminal (4).

7. Lift the battery (1) out of the unit.

How To Charge The Battery

WARNING: When you charge the

battery, do not smoke. Keep the

battery away from any sparks. The

fumes from the battery acid can cause an

explosion.

1. Before you charge the battery (1), remove

the battery (1).

2. To charge the battery (1), use a 12 volt battery charger. Charge at a rate of 6 amperes

for 1 hour.

3. Install the battery (1).

WARNING: To prevent sparks,

fasten the red cable to the positive

(+) terminal before you connect the

black cable.

4. Fasten the red cable (5) to the positive (+)

terminal (4) with the fasteners as shown.

Slide the terminal cover (2) over the posi-

tive terminal (4).

5. Fasten the black cable (8) to the negative

(–) terminal with the fasteners as shown.

(Figure 6

(Figure 6)

)

How To Level The Mower Housing

(Figure 16 and Figure 17)

If the mower housing is level, the blade will cut

easier and the lawn will look better.

WARNING: Before you make an inspection, adjustment, or repair to

spark plug. Remove the spark plug wire to

prevent the engine from starting by accident

1. Make sure the unit is on a hard flat surface.

2. Check the air pressure in the tyres. If the air

3. If equipped, remove the gauge wheels.

the unit, disconnect the wire to the

pressure is incorrect, the mower housing will

not cut level. The correct air pressure is:

Front Tyres 1,38 BAR (20 PSI), Rear Tyres

0,97 BAR (14 PSI).

18

GB

4.

(Figure 16)

level adjustment position (2).

justment position (2).

5.

(Figure 17)

juster knobs (1). Push down on each side of

the mower housing. Make sure both sides of

the mower housing are setting on a flat surface. Also, make sure the lift links (2) are

loose and can easily move up or down

6. Push down on the lift links (2) and tighten

the left and right adjuster knobs (1). If

necessary, use a wrench to tighten the ad-

juster knobs (1)

7.

(Figure 16)

8. If equipped, attach the gauge wheels.

9. Mow for a short distance. If the height of cut

is not level, repeat the above steps.

Where To Lubricate

NOTE: Apply grease to the steering gear assembly.

CAUTION: If the unit is operated in dry areas

that have sand, use a dry graphite spray to

lubricate the unit.

Check The Tyres

Check the air pressure in the tyres. Tyres with too

much air pressure will cause the unit to ride rough.

Also, the wrong air pressure will keep the mower

housing from cutting level. The correct air

pressure is: Front Tyres 1,38 BAR (20 PSI), Rear

Tyres 0,97 BAR (14 PSI).

How To Replace The Motion Drive Belt

1. Remove the mower housing. See the instructions on “How To Remove The Mower Housing”.

2.

(Figure 19)

hold each side of the middle discharge

chute (2). Remove the middle discharge

chute (2)..

3.

(Figure 18)

spring (1).

4.

(Figure 23)

(2).

5.

(Figure 18)

from the idler bracket (4).

6.

(Figure 20)

from the transaxle sheild (2). Place the

transaxle shield (2) in the tunnel (3). The

bag full indicator (4) wire harness will limit

the transaxle sheild (2) movement.

7.

(Figure 21)

drive pulley (3).

8. Remove the motion drive belt (4) from the

drive pulley (3).

9.

(Figure 22)

(1) from the stack pulley (2), pull the front

end of the belt under the stack pulley (2)

Move the lift lever (1) to the

WARNING: The lifter lever (1) is

spring loaded. Make sure the lift

lever (1) is locked in the level ad-

Loosen the left and right ad-

Raise the lift lever (1).

(Figure 14)

Models with grease fittings:

Lubricate with grease gun.

Apply grease with a brush to

the areas shown.

Lubricate the areas shown

with engine oil.

Remove the screws (1), that

Disconnect the belt tension

Remove the three idler pulleys

Remove the adjuster nut (3)

Remove the three screws (1)

Loosen the belt guide (1) at the

To remove the motion drive belt

Page 19

and then back between the stack pulley and

the steering plate (3).

10.Remove the motion drive belt. A correct replacement part or assistance is available

from an Authorized Service Centre in your

area.

11.To install the motion drive belt, reverse the

above steps.

12.

(Figure 23)

drive belt (1). Make sure the motion drive

belt is installed correctly on the idler pulleys

(2).

Check the routing of the motion

How To Replace The Mower Drive Belts

(Figure 13)

1. Remove the mower housing. See the instructions on “How To Remove The Mower Housing”.

2. Loosen and pull the belt retainer (1) away

from the double idler pulley (2). Remove

the primary mower drive belt (3) from the

double idler pulley (2).

3. Pull the belt retainers (4) away from the

single idler pulley (5). Remove the primary

mower drive belt (3) from the single idler

pulley (5).

4. Remove the primary mower drive belt (3)

from the mower housing.

5. To release tension on the secondary belt,

remove the spring (8) from the double idler

mount (9).

6. Remove the secondary mower drive belt

(10) from the double idler pulley (2) and

from the right mandrel pulley (11).

7. A correct replacement part or assistance is

available from an Authorized Service Centre

in your area.

8. To install the mower drive belt, reverse the

above steps.

How To Remove The Mower Housing

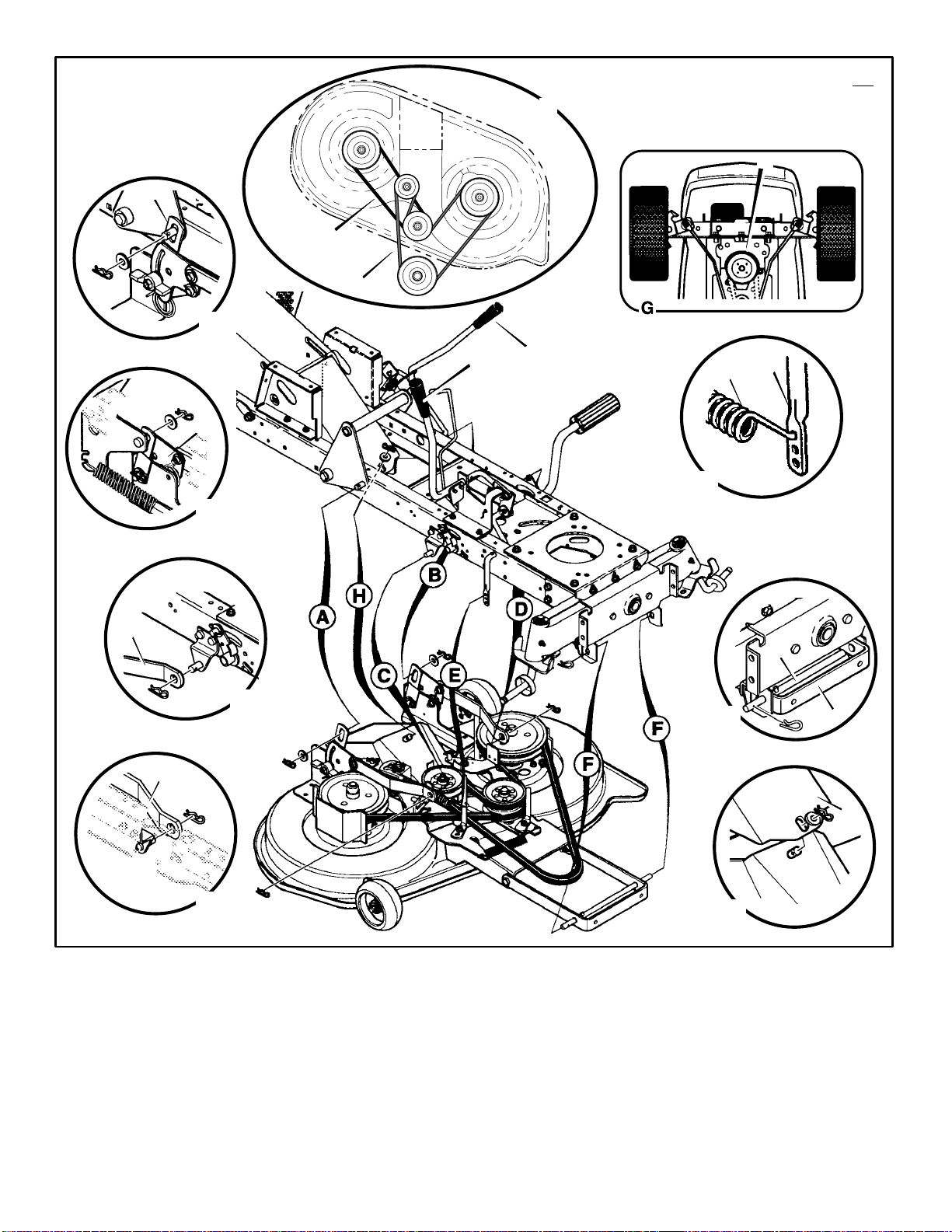

(Figure 38)

1. Move the blade rotation control (1) to the

DISENGAGE position.

2. Move the lift lever (2) to the level adjustment position.

3. Remove the hair pins and the washers from

the adjuster arms (3). See illustrations “C”

and “D”.

4. Remove the hair pins and washers from the

suspension links (4). See illustrations “A”

and “B”.

5. Disconnect the extension spring (5) from

the blade control rod (6). See illustration

“E”.

6. Disconnect the front hanger (9) from the

axle support. See illustration “F”.

NOTE: The hanger rod (11) is made with a

bend.

7. Remove the mower drive belt (7) from the

stack pulley (8). See illustration “G”.

8. Disconnect the middle discharge chute

(10) from the mower housing. See illustration

“H”.

9. Pull the mower housing away from the right

side of the unit.

10.To install the mower housing, reverse the

above steps.

11.Check belt routing of the primary mower

drive belt (1) and the secondary mower drive

belt (2). See illustration “J”.

How To Replace The Fuse

If the fuse is blown, the engine will not start.

Remove the fuse and replace with a 15 amp.

automotive fuse.

Storage (over 30 days)

At the end of each year, prepare the unit for

storage as follows.

1. Drain the fuel from the carburettor and the

fuel tank. Change the engine oil. See the engine manufacturer’s instructions.

2. Clean the entire unit.

3. Charge the battery.

GB

WARNING: Never store the grass

bagger with grass clippings in the

bags. Even a small amount of

grass or debris can generate enough heat

to start a fire.

WARNING: Do not operate unless

the entire grass bagger attachment

is in place.

How To Order Replacement Parts

Use only manufacturer’s authorized or approved

replacement parts. The letter placed on the end of

the part number denotes the type of finish for the

part, C for chrome, Z for zinc, a PA for purchased

assembly. It i s important that you include this when

ordering a part. Do not use attachments or

accessories not specifically recommended for this

unit. In order to obtain proper replacement parts

you must supply the model number of your mower

(see nameplate).

Replacement parts, except for the engine, transmission, transaxle or differential, are available

from the store where the mower was purchased or

a service shop recommended by the store.

If you are unable to obtain parts or service in the

manner outlined above, then contact:

HAYTER LIMITED, Service Department, Spellbrook, Bishop’s Stortford, Hertfordshire.

CM23 4BU.

UK ONLY : Details of your local Hayter authorised

dealer are contained in Yellow Pages or contact:

Freephone 0800 616298.

Replacement parts for the engine, transaxle, or

transmission, are available from the manufacturer’s authorized service centre found in the commercial pages of the telephone directory. Also, see

the individual engine or transmission warranties to

order replacement parts.

When ordering the following information is

required:

(1) The Model Number

(2) Serial Number

(3) Part Number

(4) Quantity

F–000794J

19

Page 20

TROUBLE SHOOTING CHART

PROBLEM: The engine will not start.

1. Follow the steps, “How To Start The Engine”

in this book.

2. Electric–Start Models: Clean the battery terminals. Tighten the cables.

3. Check for a loose wire. Tighten the limit

switches. (See the wiring diagram.)

4. Drain the fuel tank. Clean the fuel line. Replace the fuel filter.

5. Remove the spark plug(s). Move the throttle

to the SLOW position. Turn the ignition key to

the ON position. Try to start the engine several times. Install the spark plug.

6. Replace the spark plug.

7. Adjust the carburettor.

PROBLEM: The engine will not turn

over.

1. Follow the steps, “How To Start The Engine”

in this book.

2. Electric–Start Models: Check the level of the

acid in the battery. If needed, add water.

Charge the battery.

3. Replace the fuse.

4. Check the wiring harness for damage or a

loose connection. Repair the damaged wire.

5. Electric–Start Models: replace the solenoid.

Recoil–Start Models: replace the module.

PROBLEM: The engine does not run

smooth at fast speed.

1. Replace the spark plug.

2. Adjust the throttle control.

3. Clean the air filter.

4. Replace the fuel filter.

PROBLEM: The engine stops when the

blades are engaged.

1. To activate the seat sensor, always sit in the

middle of the seat.

2. Check the wiring harness for damage or a

loose connection. Repair the damaged wire.

3. Grass Bagger not closed properly. (only

applies to rear grass baggers.)

PROBLEM: On slopes, the engine

stops.

1. Mow up and down slopes. Never mow

across a slope.

2. To activate the seat sensor, always sit in the

middle of the seat.

PROBLEM: The engine will not idle.

1. Replace the spark plug.

2. Clean the air filter.

3. Adjust the carburettor.

4. Adjust the throttle control.

5. Drain the fuel tank. Clean the fuel line. Replace the fuel filter.

GB

2. Raise the height of cut.

3. Replace or sharpen the blade(s).

4. Move the shift lever to a slower speed.

5. Move the throttle control to the FAST position.

6. Replace the spring for the blade idler.

PROBLEM: The mower housing does

not cut level.

1. Check the air pressure in the tyres.

2. Adjust the level of the mower housing.

3. Check the front axle. If the front axle does

not freely pivot, loosen the axle bolt(s).

PROBLEM: The mower blades will not

rotate.

1. Check the mower drive belt. Make sure the

belt is installed correctly.

2. Replace the mower drive belt.

PROBLEM: The unit will not move when

the brake is released and the speed

control pedal is depressed.

1. Check the motion drive belt. Make sure the

belt is installed correctly.

2. Adjust the clutch.

3. Replace the motion drive belt.

4. Release the Automatic Drive Disconnect

under the seat.

PROBLEM: The engine is difficult to

start.

1. Adjust the carburettor.

2. Replace the spark plug.

3. Replace the fuel filter.

PROBLEM: The engine does not run

smooth or has a loss of power.

1. Check the oil.

2. Clean the air filter.

3. Clean the air screen.

4. Replace the spark plug.

5. The engine is working too hard. Use a slower

speed.

6. Adjust the carburettor.

7. Replace the fuel filter.

PROBLEM: A hot engine causes a decrease in power.

1. Clean the air screen.

2. Check the oil.

3. Adjust the carburettor.

4. Replace the fuel filter.

PROBLEM: Excessive vibration.

1. Replace the blade.

2. Check for loose engine bolts.

3. Decrease the air pressure in the tyres.

4. Adjust the carburettor.

5. Check for a damaged belt or damaged

pulley. Replace the damaged parts.

PROBLEM: The grass does not discharge correctly.

1. Stop the engine. Clean the mower housing.

PROBLEM: The unit moves slower or

stops when the speed control pedal is

depressed.

1. Adjust the clutch.

2. Replace the motion drive belt.

PROBLEM: When the brake pedal is released, belt noise can be heard.

1. Temporary belt noise does not change the

operation of the unit. If belt noise is continuous, check the routing of the belt. Make sure

the belt is inside all belt guides.

2. If the noise is continuous, adjust the clutch.

PROBLEM: The rear wheels spin over

uneven terrain.

1. Check the front axle. If the front axle does

not freely pivot, loosen the axle bolt(s).

F–000794J

20

Page 21

NOTES

F–000794J

21

Page 22

REPAIR PARTSCODE145S

CHASSIS & HOOD ASSEMBLY

34

46

51

33

50

26–4

36

35

49

44

26–4

26–3

32

26–4

48

26–4

47

26

27

15

19

26–3

48

26–1

17

13

21

12

22

16

20

14

10

8–2

8

8–1

REF.

CHASSIS REAR PG.

(SEAT DECK ASSY.)

EDGE TO OUTSIDE

REF.

KEY#17

NOTE

MOUNT KEY# 17 WITH EDGE FACING OUTSIDE HOOD.

23

18

5

42

40

1

2

7

6

41

F–000794J

345105A

22

Page 23

REPAIR PARTSCODE145S

CHASSIS & HOOD ASSEMBLY

Key

No. Description Part No.

1 Bracket, Grille RH MU69011–853

2 Screw, 5/16–18x1.50 MU711653

5 Grille MU94455–848

6 Nut, “J” Tinnerman MU710313

7 Screw, 1/4–20x.63 MU711642

8 Lens & Reflector MU95234

8–1 Lens MU94459

8–2 Reflector MU94460

10 Screw, 1/4–14x.50 MU710197

12 Hood Asm. MU690052–848

13 Panel, Side RH MU94458–848

Key

No. Description Part No.

26–2 Bracket, LH MU94465

26–3 Bracket, RH MU94464

26–4 Screw, 10–24x.500 MU710196

27 Screw, 5/16–18x.75 MU711606

32 Dash MU690110

33 Screw, 10–24x.500 MU711629

34 Screw, 10–24x.500 MU711629

35 Steering Bracket MU94075

36 Screw, 1/4–14x.50 MU710197

40 Strut, Grille MU94519–848

41 Screw, 1/4–20x.50 MU711642

14 Panel, Side LH MU94457–848

15 Bolt, HHSH 3/8–16 MU711625

16 Washer, Plastic MU710067

17 Pivot Base MU690114

18 Nut, 3/8–16 MU711622

19 Pivot Cap MU690113

20 Quick Release MU94474

21 Spring, Comp. MU710314

22 Nut, Wing MU325232

23 Screw, 1/4–20x1.25 MU313674

26 Console Asm. MU95291–848

26 Console Asm. MU95291–848

42 Speed Nut MU711652

44 Lanyard Hood MU643129

45 Nut, 1/4–20 MU73826

46 Screw, 1/4–20x.63 MU711674

47 Nut, “J” Tinnerman MU710313

48 Trim 9.50 Inches MU55021

49 Trim, 26.80 Inches MU55021

50 Access Panel MU95366–848

51 Screw, 10–24x.500 MU711629

–– Decal, Hayters 15/40 RH MU712184

–– Decal, Hayters 15/40 LH MU712183

–– Instruction Book & Parts List MUF–000794J

26–1 Lower Console MU95173

F–000794J

23

Page 24

30

REPAIR PARTSCODE145S

REAR CHASSIS ASSEMBLY

20–2

REF .

ELECTRICAL PG.

(TAPE SWITCH)

12

12

5

14

(4–1)

4

21

81

90

16

7

12

12

25

19

20–3

80

7

31

22

7

17

26

31

20

(20–1)

15

13

18

4–3

13

4–4

7

24

27

29

REF.

FINAL ASSEMBLED DECK PG.

(MOWER DECK)

91

4–2

344862B

F–000794J

15

13

8

9

SUB ASSY. FRAME PG.

REF.

(FRAME ASSY .)

6

7

23

344862A

24

Page 25

REPAIR PARTSCODE145S

REAR CHASSIS ASSEMBLY

Key

No. Description Part No.

4 Assy., Back Plate/Battery MU343678–853

4–1 Assy. Back Plate Flat MU95162

4–2 Battery Tray Assembly MU94563

4–3 Screw, 5/16–18x.50 MU180073

4–4 Nut, 5/16–18 Hexwdfllk MU45174

5 Weldment–Latch Lever MU95359–853

6 Rod, Brace MU690097

7 Nut, 3/8–16 Hwdfl Whiz–lock MU711906

8 Rod, Brace MU94231

9 Screw, 5/16–18x.75 MU711606

12 Screw, 5/16–18x.75 MU9357

Key

No. Description Part No.

20 Asm., T/A Shield & Chute MU690102–853

20–1 Chute Weld Asm. Upper MU94350

20–2 Shield, Transaxle MU95367

20–3 Screw, 1/4–20x.63 MU711642

21 Screw, 5/16–18x.75 MU711606

22 Bolt, Carriage 5/16–18x.75 MU340720

23 Nut, 5/16–18 MU710026

24 Middle Chute Assembly MU94296–853

25 Shoulder Bolt MU009x57

26 Flap, Chute MU94264

27 Fastener, Ratchet MU309235

13 Nut, 5/16–18 Hexwdfllk MU710026

14 Screw, 5/16–18x.75 MU711606

15 Nut, 5/16–18 Hexwdfllk MU710026

16 Bracket, Flex Switch Mting MU690245

17 Wire Clip, Adhesive MU55939

18 Flatwasher MU711666

19 Pad, Adhesive MU318197

29 Pin, Hair MU711682

30 Bolt, Carriage 5/16–18x.75 MU340720

31 Nut, 5/16–18 MU710026

80 Tape, Dble Sided Foam 3/4” MU712009

81 Tape, Dble Sided Foam 3/4” MU712009

90 Screw, 1/4–20x.63 MU711642

91 Cable Tie MU57444

F–000794J

25

Page 26

CUSTOMER

SPEC PAGE

REPAIR PARTSCODE145S

REAR CHASSIS ASSEMBLY

38

45

100

44

43

39

CUSTOMER

SPEC PAGE

42

53

35

36

84

37

85

CUSTOMER

SPEC PAGE

82

52

34

84

83

40

41

CUSTOMER

SPEC PAGE

45

46

48

47

49

2

84

3

75

75

33

F–000794J

74

NOTE

74

344862B

26

Page 27

REPAIR PARTSCODE145S

REAR CHASSIS ASSEMBLY

Key

No. Description Part No.

2 Plate, Lift Detent MU95190–853

3 Screw, #12x.50 MU711741

33 Screw, 5/16–18x.75 MU711606

34 Spring, Compression MU710136–853

35 Shoulder Bolt 1/4–20 MU711610

36 Zinc Washer Cup MU95293

37 Nut, 1/4–20 Centerlock MU302635

38 Cover, Battery MU94200

39 Support, Seat MU94154–848

40 Spring–Leaf MU94057

41 Screw, 1/4–20x.50 MU711592

Key

No. Description Part No.

45 Nut, Push Cap MU711627

46 Battery Bracket, LH MU95393–853

47 Battery Bracket, RH MU95394–853

48 Bolt, Carriage 1/4–20x.63 MU711680

49 Nut, Wing 1/4–20 MU711636

52 Washer, Flat MU711644

53 Bolt, Wing 5/16–18x.50 MU711747

74 Nut, 5/16–18 MU710026

75 Bolt, Carriage 5/16–18x.75 MU711891

82 Seat Deck Pedal MU94311–848

83 Bracket, Pivot Seat MU94153–848

42 Spring, Compression MU710109–853

43 Screw, 5/16–18x.75 MU711606

44 Hinge Seat Pivot MU95294

84 Screw, 5/16–18x.75 MU711606

85 Nut, 5/16–18 MU711634

100 Trim 41.00 Inches MU55021

F–000794J

27

Page 28

REPAIR PARTSCODE145S

GRASS BAGGER ASSEMBLY

73

72

54

104

89

REF.

DETAIL ’A’

87

57

87

101

97

56

59

102

62

71

89

87

69

86

61

67

88

68

58

DETAIL ’A’

55

58

57

59

64

63

64

70

61

64

62

60

66

103

344862B

F–000794J

28

Page 29

REPAIR PARTSCODE145S

GRASS BAGGER ASSEMBLY

Key

No. Description Part No.

54 Asm. Weld Upper Frame MU690044–853

55 Spring, Torsion RH MU690003

56 Spring, Torsion LH MU690004

57 Bracket, Spring Collector MU95339–853

58 Screw, 1/4–20x.50 MU313686

59 Nut, 1/4–20 MU73826

60 Brace, Frame Collector MU94850–853

61 Screw, 1/4–20x.62 MU711909

62 Nut, 1/4–20 MU711632

63 Asm. Support Collector MU95343–853

64 Screw, 1/4–20x1.50 MU711653

Key

No. Description Part No.

69 Top Collector Assembly MU94908–848

70 Handle, Dump Collector MU690019

71 Handle, Reba Collector MU690506–853

72 Reba Collector Bag MU95389

73 Rubber Grip MU94854

86 Washer MU712129

87 Washer MU711921

88 Nut, 1/4–20 Tinnerman MU578107

89 Screw, 1/4–20x.63 MU711674

97 Brace, Bagger MU690010–853

101 Screw, 1/4–20x1.50 MU712068

66 Asm. Front Frame Collect MU95349–853

67 Screw, 1/4–20x.62 MU711909

68 Nut, 1/4–20 MU711632

102 Nut, 1/4–20 MU711632

103 Screw, #12x.50 MU711741

104 Screw, #12x.50 MU711741

F–000794J

29

Page 30

REPAIR PARTSCODE145S

FRAME ASSEMBLY

34

6

8

12

10

5

35

7

38

4

3

41

11

1

14

17

13

39

9

2

37

40

32

29

43

44

45

37

21

33

19

32 16

30

31

20

26

18

15

36

23

36

24

27

28

343650A

F–000794J

30

Page 31

REPAIR PARTSCODE145S

FRAME ASSEMBLY

Key

No. Description Part No.

1 Frame, Rail RH MU94564

2 Frame, Rail LH MU94565

3 Support, Seat RH MU94634

4 Support, Seat LH MU94633

5 Screw, .312–18x.75 MU26X249

6 Brace, BackPlate RH MU94561

7 Brace, BackPlate LH MU94562

8 Screw, 5.312–18x.75 MU26X249

9 Bracket, Transaxle MU94008

10 Bracket, TA RH–VST LH–MS MU94234

11 Asm. Idler Mount Rear MU94236

Key

No. Description Part No.

23 Bracket, Hanger Rear MU94013

24 Screw, .312–18x.75 MU26X249

26 Gear, Sector MU94121

27 Bearing, Sector Gear MU94123

28 Screw, 5/16–18x1.00 MU001X84

29 Nut, 5/16–18 MU15X113

30 Clutch/Brake Pedal MU690033

31 Screw, .312–18x.75 MU26X249

32 Bracket, Suspension Asm. MU94285

33 Screw, .312–18x.75 MU26X249

34 Brace, Rail MU94566

12 Screw, .312–18x.75 MU26X249

13 Assy., Idler Mount, Front MU94237

14 Screw, .312–18x.75 MU26X249