Page 1

01/14

9326/9327

Page 1 of 12

INSTALLATION, OPERATION

&

MAINTENANCE INSTRUCTIONS

1455 Kleppe Lane Sparks, NV 89431-6467 (775) 359-4712 Fax (775) 359-7424

E-mail: haws@hawsco.com website: www.hawsco.com

NOTE TO INSTALLER: Please leave this information with the Maintenance Department.

HAWS warrants that this specific product is guaranteed against defective material or poor

workmanship for a period of one year from date of shipment. HAWS liability under this

warranty shall be discharged by furnishing without charge F.O.B. HAWS Factory any goods,

or part thereof, which shall appear to the Company upon inspection to be of defective

material or not of first class workmanship, provided that claim is made in writing to Haws

within a reasonable period after receipt of the product. Where claims for defects are made,

the defective part or parts shall be delivered to the Company, prepaid, for inspection. HAWS

will not be liable for the cost of repairs, alterations or replacements, or for any expense

connected therewith made by the owner or his agents, except upon written authority from

HAWS, Sparks, Nevada. HAWS will not be liable for any damages caused by defective

materials or poor workmanship, except for replacements, as provided above. Buyer agrees

that Haws has made no other warranties either expressed or implied in addition to those

above stated, except that of title with respect to any of the products or equipment sold

hereunder and that HAWS shall not be liable for general, special, or consequential damages

claimed to arise under the contract of sale.

The emergency equipment manufactured by HAWS is warranted to function if installation

and maintenance instructions provided are adhered to. The units also must be used for the

purpose for which they were intended. This product is intended to supplement first-aid

treatment. Due to widely varying conditions, Haws cannot guarantee that the use of this

emergency equipment will prevent serious injury or the aggravation of existing or prior

injuries.

NO OTHER WARRANTIES EXPRESSED OR IMPLIED ARE AUTHORIZED, PROVIDED

OR GIVEN BY HAWS.

SHOULD YOU EXPERIENCE DIFFICULTY WITH THE INSTALLATION OF THIS

MODEL PLEASE CALL:

TECHNICAL SUPPORT: 1-800-766-5612

FOR CUSTOMER SERVICE: 1-888-640-4297

Instantaneous Water Heater

Model 9326/9327

LIMITED WARRANTY

No. 2080089(0)

Page 2

C

01/14

9326/9327

Page 2 of 12

Haws Cor por ation - All Rights Reserved.

2014

HAWS and other tradem ark s us ed in these materials ar e t he ex c lusive property of Haws Cor poration.

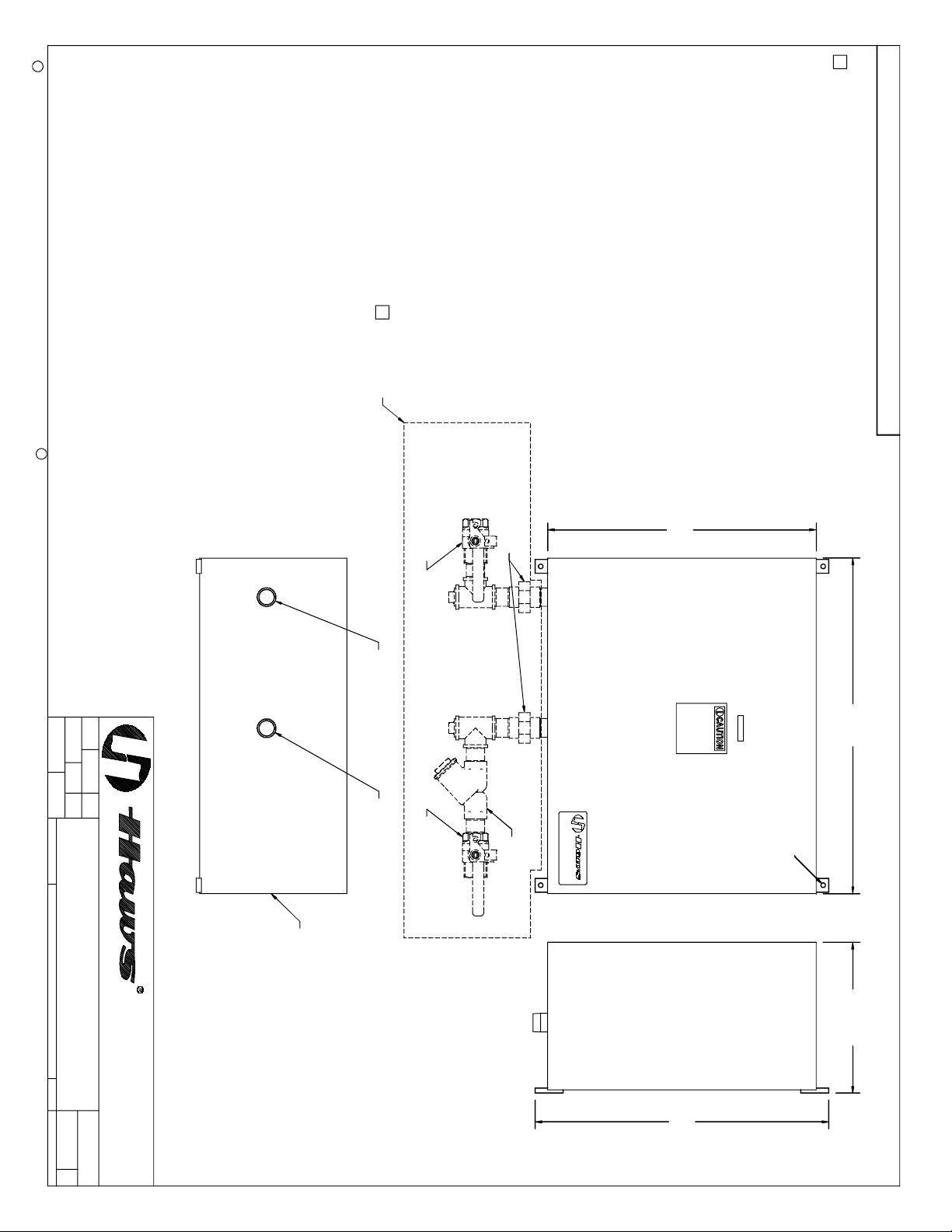

1

NOT SUPPLIED

MAKE SPECIFICATIONS AND MEASUREMENTS SUBJECT TO CHANGE WITHOUT NOTICE.

1 ITEMS SHOWN DASHED (IN BOX) ARE SHOWN FOR REFERENCE ONLY AND ARE

NOT SUPPLIED. MANUFACTURER REQUIRES "Y" STRAINER INSTALLATION FOR

UNIT DEBRIS PROTECTION AND WARRANTY COVERAGE. OTHER PARTS (UNIONS,

PLUGS, FULL-FLOW BALL VALVES, ETC., ARE RECOMMENDED TO PROVIDE

FUTURE SERVICEABILITY.

2. REFER TO EEMAX OWNER'S MANUAL FOR INSTALLATION INSTRUCTIONS.

THIS DOCUMENT IS TRUE AND CORRECT AT TIME OF PUBLICATION. CONTINUED PRODUCT IMPROVEMENTS

NOTES: (UNLESS OTHERWISE SPECIFIED)

R

1 1/4" NPT - HOT

WATER O UTLET

APPROVED:

DRAWN:

4886

VWC

REVISE D PER

ECN:

DATE:

1-30-14

DATE:

CHK'D.:

BY:ECN NO.

SCALE:

MODEL(S)

NA

INSTANTANEOUS HEATER

DRAWING TYPE: SIZE: A

1 1/4" NPT - COLD

WATER INLET

LOCKABLE BALL VALVE

LOCKABLE BALL VALVE

1 1/4" UNION

24.00

30.00

(MOUNTING HARDWARE

NOT SUPPLIED.)

4X ø.406 THRU

"Y" STRAINER

9326, 9327

INSTA LLATION

0002080089.D

DRAWING NO.

SHEET OF

16308A 0

11

REV

MODEL 9326 IS NEMA 4

MODEL 9327 IS NEMA 4X.

WATER HEATING UNIT

2X 13.47

(775) 359-4712 FAX (775) 359-7424

E-MAIL: HAWS@HAWSCO.COM

WEBSITE: WWW.HAWSCO.COM

SPARKS, NEVADA 89431

1455 KLEPPE LANE

PART NUMBER

26.25

Page 3

INSTALLATION INSTRUCTIONS

01/14

9326/9327

Page 3 of 12

AND

OWNER’S MANUAL

ELECTRIC INSTANTANEOUS WATER HEATERS WITH PhD

208 and 480 VAC three phase 32 – 126 kW

BEFORE ATTEMPTING ANY INSTALLATION OR SERVICE OF THIS

HEATER, MAKE SURE THE ELECTRICAL POWER IS DISCONNECTED.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN

SERIOUS INJURY, DEATH AND/OR PROPERTY DAMAGE.

Read and understand these instructions thoroughly before attempting the installation or service of this water

heater. This heater must be used to heat water only and be in a location where it is not subject to freezing

temperatures. If a water softener is used, the softener must be well-maintained and in good working order.

Any maintenance issues with a water softener could be detrimental to the operation or longevity of your

Eemax tankless water heater. The manufacturer is not liable for any damages resulting from improper

installation or misuse. The warranty of this water heater will depend upon the proper installation according

to these instructions.

This installation must conform to the latest requirements of the National Electrical Code and all applicable

state and local codes. This information is available through your local authorities. You must understand and

comply with these requirements before beginning this installation. Eemax recommends your heater be

installed by a licensed plumber and electrician. User instructions for the unit controls start on page 6.

This unit is not required by UL 499 to have a Temperature and Pressure relief valve (T&P). You should check

with local codes to find out if one is required in your area. If it is, it must be installed in the outlet hot water

pipe between the heater and the isolation valve.

This heater features a user friendly digital interface for ease of operation. Information is displayed through

a 16 character alpha numeric LCD and is controlled by 4 simple push buttons. The unit features silent

operation and internal diagnostics. The desired temperature can easily be set or altered as necessary. Once

the desired temperature is achieved, the control can be locked to avoid tampering.

EX07200-15 Rev. 1

1

Page 4

SAVE THESE INSTRUCTIONS

1) MOUNTING THE HEATER TO THE WALL

PAGE 3

2) PLUMBING HOOK-UP

PAGE 3

3) ELECTRICAL HOOK-UP

PAGE 4

4) COMMISSIONING THE HEATER

PAGE 5

5) CONTROL FEATURES

PAGE 6

6) REPAIR PARTS

PAGE 9

01/14

9326/9327

Page 4 of 12

TABLE OF CONTENTS

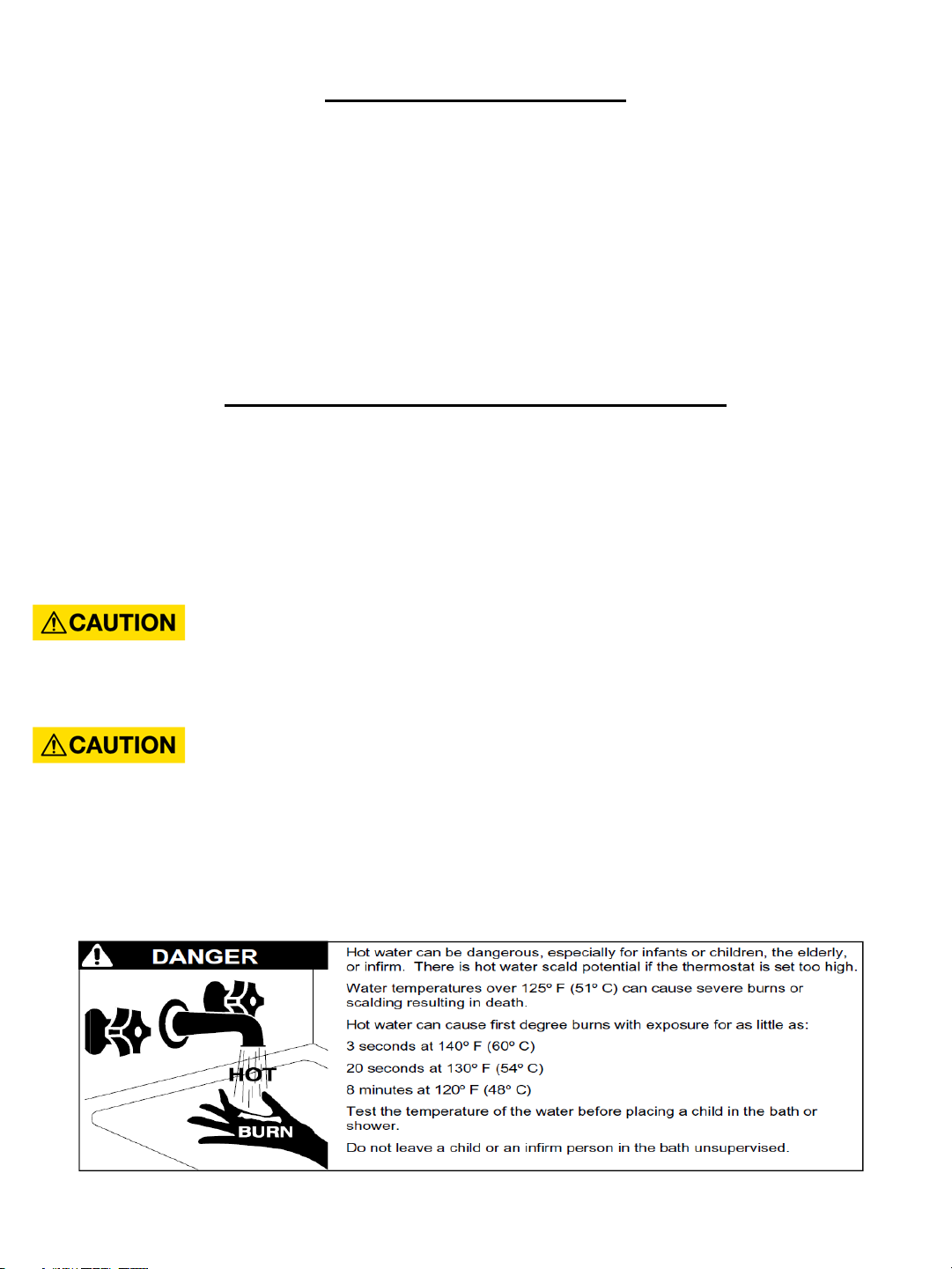

IMPORTANT SAFETY INSTRUCTIONS

The following instructions are provided pursuant to Canadian UL/Electrical Code requirements:

A green terminal (or a wire connector marked “G”, “GR, “Ground”, or “GROUNDING”) is provided within

the control box. To reduce the risk of electric shock, connect this terminal or connector to the grounding

terminal of the electric service or supply panel with a continuous copper wire in accordance with the

Canadian Electrical Code, Part I. (Canadian Installations Only)

Connect only to a circuit protected by a Class A ground fault circuit interrupter.

Attention: Brancher uniquement à un circuit protégé par un disjoncteur de fuite de

terre de Classe A. (Canadian Installations Only)

Do not install in a bath enclosure or shower stall or connect to a salt-regenerated water

softener or a water supply of salt water. Attention: Ne pas installer dans une baignoire

ou une cabine de douche et ne pas brancher à un adoucisseur d’eau régénéré avec du

sel ou à un approvisionnement en eau salée. (Canadian Installations Only)

Use copper conductors only. Use bonding conductor in accordance with the Canadian Electrical Code Part I.

Utilisez dez conducteurs en cuive uniquement. Utilisez des conducteurs de mize à la masse conformement

au Code Canadien de L’Électricité, Partie I. (Canadian Installations Only)

2

Page 5

1) MOUNTING THE HEATER TO THE WALL

01/14

9326/9327

Page 5 of 12

Please follow the mounting instructions as appropriate to your installation. Whenever possible, locate the

heater as close to the point of hot water use as possible. Time-to-temperature performance will improve

the closer the heater is installed to the point of use.

This heater must be installed in a location where

it is not subject to freezing temperatures.**

Make sure the brass fittings are at the bottom of the

heater and pointing “DOWN”. No other heater

orientation is permitted.

Install the heater with cabinet using the supplied

mounting feet following the instructions provided with

the cabinet. Be sure to use appropriately rated fasteners

to hold the cabinet/heater in place.

2) PLUMBING HOOK-UP

The heater is equipped with NPT brass fittings. Make

sure ONLY NPT fittings are used for connection to this

heater.

Make the cold water inlet connection to the lower RIGHT

fitting and the hot water outlet connection to the lower

LEFT fitting. Reversed connections will cause erratic

operation and premature heater failure.

HOT

WATER

OUT

NEVER USE PIPE DOPE WHEN MAKING PLUMBING CONNECTIONS TO THIS HEATER.

FOLLOW STANDARD INDUSTRY PRACTICE WITH CAREFUL APPLICATION OF TEFLON

TAPE. DO NOT ALLOW TEFLON TAPE TO GET INTO THE HEATER.

NEVER SOLDER ANY PIPE CONNECTIONS WHILE ATTACHED TO THIS HEATER - DAMAGE

TO THE HEATER WILL RESULT. DOING THIS WILL VOID THE WARRANTY.

** Does not apply to SafeAdvantage with

Freeze Protection option.

COLD

WATER

IN

3

Page 6

Eemax requires an inlet Y-strainer be installed for

01/14

9326/9327

Page 6 of 12

unit debris protection and warranty coverage.

Eemax also commends 2 unions, 2 full flow ball valves

and two drain plugs be installed for future

serviceability. These components are supplied by

others. (See photo to right.)

Run water through the cold water inlet pipe to purge

it of any debris before making final plumbing

connections to the heater.

Open both ball valves, check for leaks and repair as needed. Finally, open all hot water outlets – one at a time

– and purge the system from any air pockets. Allow water to run until water flow is continuous and then close

the hot water outlets

3) ELECTRICAL HOOK-UP

Installation and service is to be performed by a licensed

electrician or qualified serviceman.

BEFORE BEGINNING ANY WORK ON THIS INSTALLATION, BE SURE THAT THE

ELECTRICAL BREAKER IS “OFF” AND THAT ALL MOUNTING AND PLUMBING

WORK HAS BEEN COMPLETED PER THESE INSTRUCTIONS.

This heater must have its own independent circuit using insulated, UL listed wire conductors of the

appropriate size suitable for up to 75° C and protected by the correctly rated circuit breaker.

See chart on next page.

Before starting any electrical work VERIFY there is no

power at the heater before proceeding !

L1 L2 L3 gnd

The power conductors are to be secured to the L1, L2

and L3 connectors on the terminal block. The ground

is to be secured to the GND connector to the right of

the terminal block.

FAILURE TO GROUND THE SYSTEM MAY RESULT IN SERIOUS INJURY,

DEATH AND/OR PROPERTY DAMAGE.

4

Page 7

4) COMMISSIONING THE HEATER

ELECTRICAL SPECIFICATIONS

VOLTS

AMPS

RECOMMENDED

MODEL

3-PHASE DELTA

Kw

PER PHASE

WIRE SIZE (CU) 75° C

AP032208

208

32

89

3 AWG

AP041208

208

41

114

2 AWG

AP054208

208

54

150

1/0

AP064208

208

64

178

3/0

AP036480

480

36

44

8 AWG

AP048480

480

48

58

6 AWG

AP054480

480

54

65

6 AWG

AP072480

480

72

86

3 AWG

AP108480

480

108

130

1 AWG

AP126480

480

126

152

2/0

01/14

9326/9327

Page 7 of 12

BEFORE SWITCHING THE ELECTRICAL BREAKER “ON”, MAKE SURE

THE INLET AND OUTLET BALL VALVES ARE FULLY OPEN AND WATER

IS FLOWING THROUGH ALL POINTS OF USE FOR A MINUTE OR TWO

UNTIL THE FLOW IS CONTINUOUS AND FREE FROM AIR POCKETS.

DO NOT SWITCH THE BREAKER “ON” IF THERE IS ANY POSSIBILITY

THE WATER IN THE HEATER IS FROZEN.

After verifying the heater has been

purged of air (see above) turn the circuit

breaker/disconnect “ON” and observe

the start-up sequence on the display.

The LCD screen will display the SETPOINT

TEMPERATURE in degrees F.

Below the display are 4 push buttons that

are used to control the function of the

heater. Press the UP or DOWN buttons to

establish your desired temperature. Refer

to the CONTROL FEATURES section of this

manual for additional information.

The heater is fully installed and ready for use.

5

Page 8

TEMPERATURE RISE AT SPECIFIED FLOW RATE, DEGREES F:

TURN-ON

3.0

4.0

6.0

8.0

12.0

20.0

25.0

30.0

MODEL

GPM

GPM

GPM

GPM

GPM

GPM

GPM

GPM

GPM

AP032208

1.5

7355362718

---

AP041208

1.5

9370473523

---

AP054208

1.5

*

9261463118

-

-

AP064208

1.5

*

*

7355362217

-

AP036480

1.5

8261413120

12

-

-

AP048480

1.5

*

8255412716

-

-

AP054480

1.5

*

92

614631

18

-

-

AP072480

2.5

*

*

8261412520

-

AP108480

2.5

***

926137

30

-

AP126480

2.5

***

*

724334

29

* Temperature limited to preset value

1) The SETPOINT TEMP or ACTUAL TEMP screen can be

selected for display as the home screen. Either of these

screens will remain on the display when the backlight timer

expires.

2) There is a 5 minute time delay built into the control.

Regardless of which screen is being displayed, after 5

minutes of inactivity, the display will revert to the SETPOINT

TEMP screen.

3) The 4 push buttons are used to control the operation of

the heater. The LEFT and RIGHT buttons shift the display

from one screen to another. The DOWN and UP buttons

may change the values within selected screens.

4) As an example, when the screen displays SETPOINT

TEMP, the desired hot water temperature will increase 1

degree for each press of the UP button and decrease 1

degree for each press of the DOWN button. Note that

minimum and maximum setpoint temperatures are

established at the factory.

01/14

9326/9327

Page 8 of 12

5) CONTROL FEATURES

BEFORE USING THIS CONTROL, MAKE SURE ALL PRIOR INSTALLATION STEPS HAVE

BEEN PROPERLY COMPLETED, ELECTRICAL POWER IS ON AND WATER IS PRESENT

IN THE HEATER.

PUSH BUTTON FLOW CHART

OR

6

Page 9

5) The LEFT and RIGHT buttons shift the display from one

screen to another. From the INLET TEMP screen, one

press of the RIGHT button will shift the display to the

SETPOINT TEMP screen. INLET TEMP shows the actual

temperature of the water entering the heater.

6) From the SETPOINT TEMP screen, one press of the

RIGHT button will shift the display to the ACTUAL TEMP

screen. This shows the actual temperature of the water

leaving the heater.

7) From the ACTUAL TEMP screen, one press of the RIGHT

button will shift the display to the LOAD PCT screen. This

shows the electrical power consumption as a percentage

of full power.

8) From the LOAD PCT screen, one press of the RIGHT

button will shift the display to the FLOWRATE screen. This

shows the rate of flow of water through the heater.

9) From the FLOWRATE screen, one press of the RIGHT

button will shift the display to the UNITS screen. This

shows the units of measure in either the ENGLISH or

METRIC systems. ENGLISH units are degrees Fahrenheit

and gallons per minute. METRIC units are degrees Celsius

and liters per second. Use the UP and Down buttons to

select the desired units of measure.

10) From the UNITS screen, one press of the RIGHT button

will shift the display to the SOFTWARE REVISION screen.

This shows the revision level of the software in the

control.

11) From the SOFTWARE REVISION screen, one press of

the RIGHT button will shift the display to the ERRORS

screen. This shows the error history of the heater.

“0 ERRORS” means that no errors have occurred.

If the heater has an error history of 4 errors; this history

will be displayed on the screen as shown. “CODE 1:E0”

refers to the first error and indicates it to be an E0 error.

One press of the UP button will show the second error as

“CODE 2:E0” and having the same E0 error.

Continued pressing of the UP or Down buttons will scroll

through each of the errors in the history (in this case a

total of 4). ERRORS indicate an undesirable condition but

will not shut down the operation of the heater.

01/14

9326/9327

Page 9 of 12

7

Page 10

12) FAULTS are communicated through the LCD display.

The display will switch from the SETPOINT screen to the

FAULT screen and back again every 3 seconds. FAULTS

indicate an undesirable condition and will immediately

shut down the operation of the heater. If faults are

appearing on your heater call Eemax Technical Support

for assistance.

ERROR CODES:

13) The security of the heater settings is provided by

pressing and holding the LEFT and UP buttons for 3

seconds to lock the buttons. Once locked, the buttons

have no function. Press and hold the same LEFT and UP

buttons for 3 seconds to unlock the buttons.

The security status can be checked at any time by

pressing any one button. If the system is locked, the

screen will display “BUTTONS LOCKED”.

[ + ] =

01/14

9326/9327

Page 10 of 12

E0: Excessive water flow detected

Corrective action: Using the OUTLET BALL VALVE, slowly reduce water flow until

the desired temperature is achieved. The temperature is proportional to the flow through the

heater; the lower the flow, the higher the temperature and vice versa.

Keep the INLET BALL VALVE fully “OPEN”. NEVER RESTRICT THE WATER

FLOW USING THE INLET VALVE.

E1: Inlet temperature too hot to generate heat

FAULT CODES:

F0: Thermistor out of range

F1: No change in water temperature detected

F2: Leak detected

8

Page 11

6) REPAIR PARTS

13) The display can be turned off or on. Press and hold

the DOWN and RIGHT buttons for 3 seconds. If the

display is off, it can be turned on by pressing and

holding the same DOWN and RIGHT buttons for 3

seconds.

+[+ + ]=

01/14

9326/9327

Page 11 of 12

Service and repairs are to be performed by licensed

electricians or qualified servicemen.

BEFORE ATTEMPTING ANY REPAIRS TO THE HEATER, MAKE SURE THAT THE

ELECTRICAL BREAKER IS “OFF” AND CONFIRM THAT THERE IS NO VOLTAGE AT

THE HEATER.

Contactor

Emergency

Cut Off

Optical

Sensor

Board

Heating

Element

Assembly *

Transformer

Control

Board

Fuse

Hall Effect Board

(behind Flow Meter)

Flow Meter Kit **

Triac

* Heating element assembly consists of one heater core and wire element(s) complete.

** Flow meter kit consists of paddle wheel, dowel pin, O ring and 4 mounting screws.

9

Page 12

REPAIR PARTS

Control

Flow Meter

Hall Effect

Model

Transformer

Board

Fuse

Kit

Board

AP032208

EX08303-07

EX08300-00

EX198

EX78000-00

EX08601-00

AP041208

EX08303-07

EX08300-00

EX08200-11

EX78000-00

EX08601-00

AP054208

EX08303-07

EX08300-00

EX198

EX78000-00

EX08601-00

AP064208

EX08303-07

EX08300-00

EX08200-11

EX78000-01

EX08601-00

AP036480

EX08303-05

EX08300-00

N/A

EX78000-00

EX08601-00

AP048480

EX08303-05

EX08300-00

N/A

EX78000-00

EX08601-00

AP054480

EX08303-08

EX08300-00

EX08200-07

EX78000-00

EX08601-00

AP072480

EX08303-08

EX08300-00

EX198

EX78000-01

EX08601-00

AP108480

EX08303-08

EX08300-00

EX198

EX78000-01

EX08601-00

AP126480

EX08303-08

EX08300-00

EX08200-11

EX78000-01

EX08601-00

Heating

Optical

Element

Sensor

Emergency

Model

Triac

Assembly

Board

Cut Off **

Contactor

AP032208

EX78002-00

EX77000-08.2

EX78001-00

EX278A-KIT

EX08306-02

AP041208

EX78002-00

EX77000-06.4

EX78001-00

EX278A-KIT

EX08306-00

AP054208

EX78002-00

EX77000-04.8

EX78001-00

EX278A-KIT

EX08306-02

AP064208

EX78002-00

EX77000-04.1

EX78001-00

EX278A-KIT

EX08306-02

AP036480

EX78002-00

EX77000-09.6

EX78001-00

EX278A-KIT

EX08306-02

AP048480

EX78002-00

EX77000-14.4

EX78001-00

EX278A-KIT

EX08306-00

AP054480

EX78002-00

EX77000-06.4

EX78001-00

EX278A-KIT

EX08309-00

AP072480

EX78002-00

EX77000-09.6

EX78001-00

EX278A-KIT

EX08309-00

AP108480

EX78002-00

EX77000-06.4

EX78001-00

EX278A-KIT

EX08309-00

AP126480

EX78002-00

EX77000-05.5

EX78001-00

EX278A-KIT

EX08309-00

01/14

9326/9327

Page 12 of 12

** Use EX278-A for all models EXCEPT:

- ‘S’ and ‘DB’ options use EX278D-KIT

-‘EE’ and ‘EFD’ options use EX278E-KIT

If you need any assistance from our Technical Service Department,

make sure you can identify this water heater by having the model no: ____________________

and serial number: _____________________. Call 203-267-7890 or toll free: 800-543-6163.

Email: info@eemaxinc.com Web: www.Eemax.com

Eemax Inc., 400 Captain Neville Drive, Waterbury, CT 06705

10

Loading...

Loading...