Haws 9202 Installation, Operation & Maintenance Instructions Manual

04/08 Model 9202

1455 Kleppe Lane Sparks, NV 89431-6467 (775) 359-4712 Fax (775) 359-7424

HAWS AG Bachweg 3 CH-3401 Burgdorf Switzerland

Haws Mfg. Pte Lt. 2A Sungei Kadet Drive Singapore 729554

Avlis-Avenido Senador, Testonio Vilela 505 Jardim Aeroporto Itu, S.P. 13304-550 Brasil

E-mail: haws@ hawsco.com website: www.hawsco.com

Model 9202-Tempered Water

Blending System

INSTALLATION, OPERATION

&

MAINTENANCE INSTRUCTIONS

LIMITED WARRANTY

HAWS®warrants t hat all of its products are guarant eed against defective material or poor

workmanship for a period of one year from date of shipment. HAWS liability under this

warranty shall be discharged by furnishing without charge F.O.B. HAWS Factory any

goods, or part thereof, which shall appear to the Company upon inspection to be of

defective material or not of first class workmanship, provided that claim is made in writing

to company within a reasonable period after r eceipt of the product. Where claims for

defects are made, th e defect ive part or parts shall be delivered to the Company, prepaid,

for inspect ion. HAWS will not be liable for the cost of repairs, alterations or replacements,

or for any expense connected therewith made by the owner or his agents, except upon

written authority from HAWS, Sparks, Nevada. HAWS will not be liable for any damages

caused by defective materials or poor workmanship, except for replacements, as provided

above. Buyer agrees that Haws has made no other warranties either expressed or implied

in addition to those above stated, except that of title with respect to any of the products or

equipment sold hereunder and that HAWS shall not be liable for general, special, or

consequential damages claimed to arise under the contract of sale.

The emergency equipment manufactured by HAWS is warranted to function if installation

and maintenance instructions provided are adhered to. The units also must be used for

the purpose, which they were intended. This product is intended to s upplement first-aid

treatment. Due to widely varying conditions HAW S cannot guarantee that the use of this

emergency equipment will prevent serious injury or the aggravation of existing or prior

injuries.

NO OTHER WARRANTIES EXPRESSED OR IMPLIED ARE AUTHORIZED, PROVIDED

OR GIVEN BY HAWS.

NOTE TO INSTALLER: Please leave this information with the Maintenance Department.

SHOULD YOU EXPERIENCE DIFFICULTY WITH THE INSTALLATION OF THIS

MODEL, PLEASE CALL:

1-800-766-5612

FOR PARTS CALL:

1-800-758-9378

(U.S.A. AND CANADA ONLY) MONDA Y-THURSDAY: 6:00 A.M. – 4:00 P.M. PST

FRIDAY: 6:00 A.M – 1:00 P.M. PST

Page 1 of 7

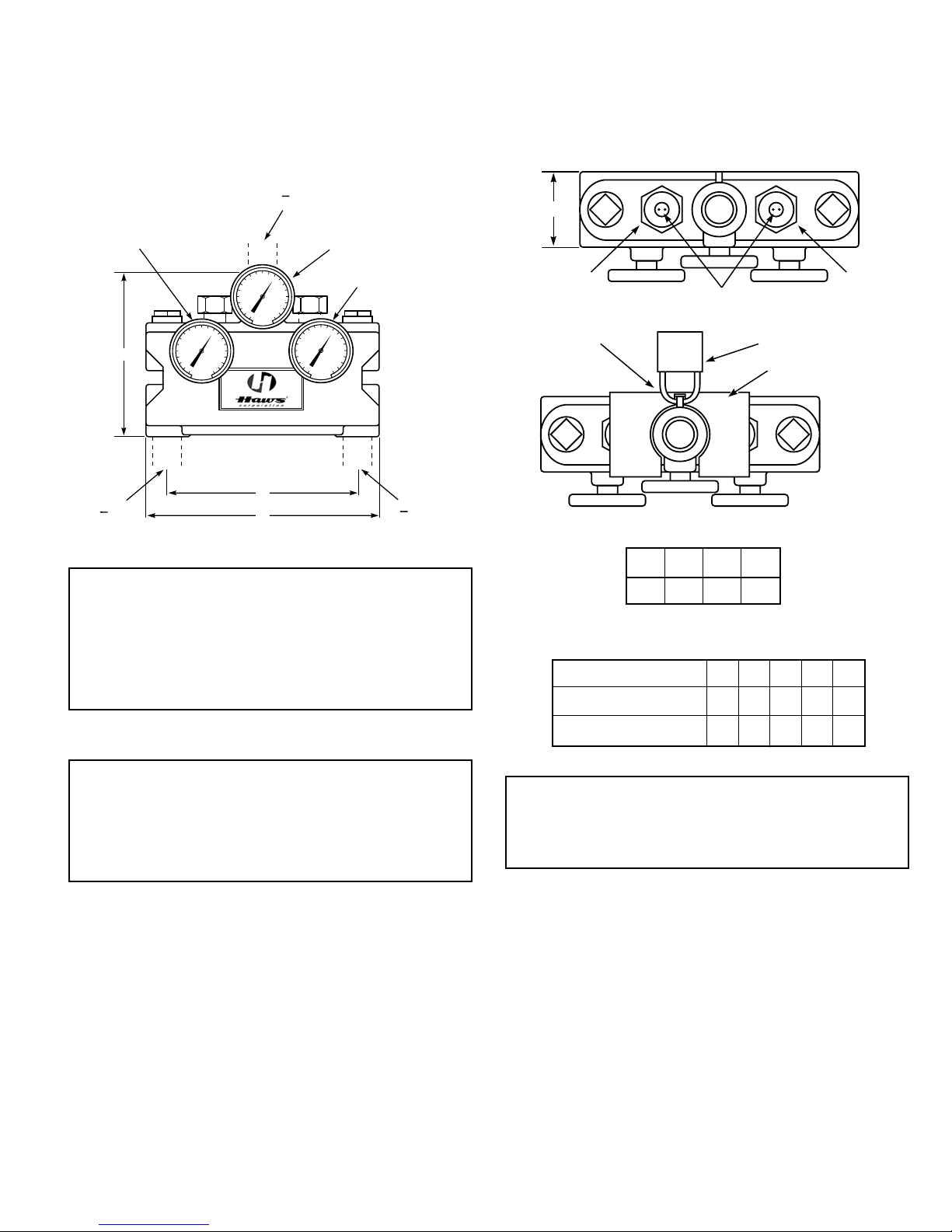

Caution: When maintaining and adjusting the mix-

D

V2V1

#3 CAP SCREWS

SAFETY LATCH #1 PADLOCK (optional)

#2 LOCKOUT PLATE

(optional)

30

40

50

60

70 80

90

110

120

130

30

40

50

60

70 80

90

110

120

130

30

40

50

60

70 80

90

110

120

130

1 w

4

N.P.T.

COLD

INLET

N.P.T.

HOT

INLET

1 w

4

A

B

C

1

1

N.P.T. TEMPERED

OUTLET

1 w

4

1

T2

T3

T1

ing valve, the delivered flushing fluid temperature

shall be 60°F (15°C) to 95°F (35°C). In circumstances where chemical reaction is accelerated

by flushing fluid temperature, a medical advisor

should be consulted for the optimum temperature

for each application.

DIMENSIONS:

A B C D

11″ 9″ 8″ 41/4″

CAPACITIES

Pressure Drop PSI 5 10 20 30 45

Tempered Flow

25 35 50 60 72

Setting the Mixing Valve

Caution: When maintaining and adjusting the

mixing valve, all fixtures should be isolated from

use. We recommend that you work safely at all

times and in a manner consistent with the OSHA

Lock/Tagout standard, 29 CFR 1910.147 and other

applicable standards.

This mixing valve has been set at the factory to

deliver 85°F outlet flow. Should the valve require

adjustment, or an application require a different set

temperature, proceed as follows:

1. Contact the proper medical and safety authorities

to determine correct water temperature for the

specific application.

Cold Water Bypass

14 20 28 40 45

Note: Valve must be installed with check valves. If

shut off valves are installed in the shower line for

maintenance purposes, provisions shall be made

to prevent unauthorized shut off.

2. If the valve is outfitted with a padlock #1 and

lockout plate #2, unlock and remove.

3. Use a spanner wrench to remove the tamperresistant cap screws #3.

4. Create a draw on the mixing valve by opening a

downstream shower fixture.

Page 2 of 7

5. Insert a 5/32″ allen key into the cap opening of

valve 1 (V1) and seat in the adjustment screw

(not shown). Set the outlet temperature by turning the adjustment screw-clockwise to reduce

temperature, counterclockwise to increase temperature. Use thermometer (T1) to measure the

outlet temperature.

6. Adjust valve 2 (V2) using the same procedure

used to adjust valve 1 (V1).

7. Examine thermometers T1 and T2. Valve 1 and

valve 2 should be set to the same temperature

and the outlet temperature should be 85°F

or as specified for your application. Adjust if

necessary.

8. Replace cap screws #3, lockout plate #2 and

padlock #1.

Testing the Mixing Valve

The mixing valve and the emergency fixtures it serves

should be tested weekly for proper operation.

2. Shut off the hot water supply to the mixing valve.

Observe the outlet flow from the emergency fixtures to ensure an adequate flow of cold water.

A slight drop in flow may occur after shutting

down the hot water supply to the mixing valve;

however, the drop should be minimal and for a

short duration.

3. Open the hot water supply to the mixing valve.

Thermometers T1 and T2 should return to their

set temperatures and T3 to the proper outlet

temperature.

4. Shut off the cold water supply to the mixing valve.

The flow of water should shut down rapidly.

5. Open the cold water supply. Thermometers T1

and T2 should return to their set temperatures

and T3 to the proper outlet temperature.

Note: Thermometers T1, T2, and T3 should be

checked at least every six months.

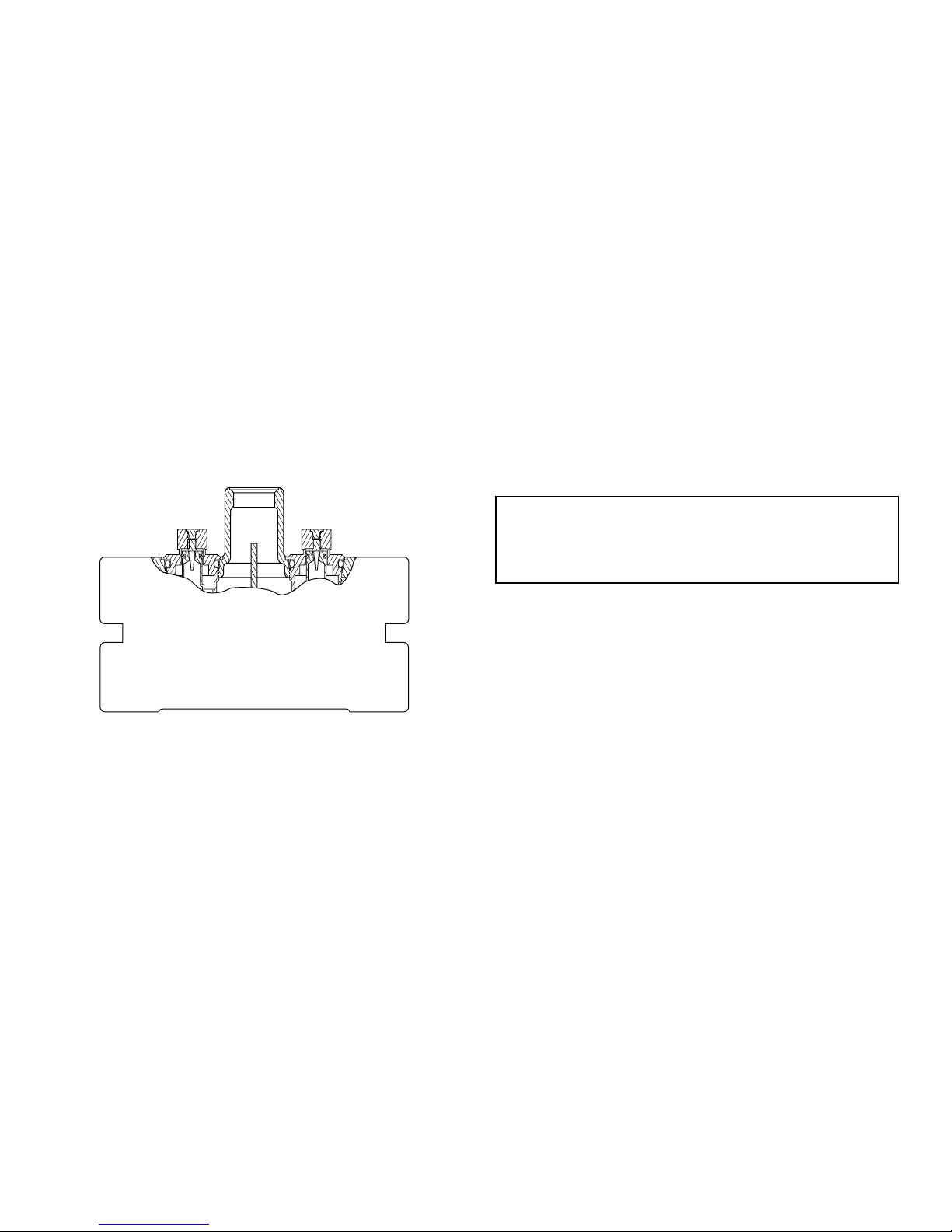

Replacing a Thermostat Cartridge

Valve 1

(V1)

Valve temperature test procedure is as follows:

1. Activate shower fixtures to observe and record

the temperature of the thermometers T1, T2, and

T3. The valve is functioning properly if the T1

and T2 temperatures are equal and T3 is at the

proper outlet temperature. If the temperature of

thermometers T1 and T2 are not equal, readjust

the mixing valve according to the section “Setting

the Mixing Valve.” Slight variations between the

valve set temperatures and the outlet temperatures may occur.

2. Observe the flow from the emergency fixtures to

ensure an adequate flow of water.

In addition to testing for proper temperature, the cold

water by-pass and hot water shut down features of

the mixing valve should be tested weekly.

The test procedure is as follows:

1. Test valve temperature as described in Step 1

and Step 2 above.

Valve 2

(V2)

The thermostat replacement procedure is as follows:

NOTE: We recommend that you work safely at all

times and in a manner consistent with the OSHA

Lock/Tagout standard, 29 CFR 1910.147 and other

applicable standards.

1. Shut off the hot water supply and cold water

supply to the mixing valve.

2. Unscrew valve V1 or V2 (depending on which

valve is not operating properly) and install a new

thermostat cartridge assembly.

3. Open the hot water supply and the cold water

supply to the mixing valve. Check the temperature to see if the replacement cartridge is

operating correctly. If the temperature requires

adjustment refer to the section “Setting the Mixing Valve.”

Operating Principle

The Mixing Valve is made of two independent

thermostats housed in a single casting. The twin

thermostatic cartridges respond independently to

incoming hot and cold water temperatures and

provide backup protection against element failure.

If one element fails, the other should continue to

function properly. If only one element is operating the valve will experience a decrease in outlet

temperature (T3). For this reason the Valve requires testing and maintenance on a regular basis.

In the event of element failure, the cartridge will

provide full cold water flow. The resulting temperature

difference between the two valves will be reflected

by T1 and T2.

Page 3 of 7

Loading...

Loading...