Page 1

Overhead Tank Shower and Optional Eye/Face Wash

Non-Electric, Self-Contained, Indoor, Gravity Fed

INSTALLATION, OPERATION

&

MAINTENANCE INSTRUCTIONS

1455 Kleppe Lane Sparks, NV 89431-6467 (775) 359-4712 Fax (775) 359-7424

E-mail: haws@hawsco.com Website: www.hawsco.com

No. 0510000842(1)

Model 8740 / 874301S

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 1 of 33

Page 2

IMPORTANT

Read this installation manual completely to ensure proper installation, then file it with the owner or

maintenance department. Compliance and conformity to drain requirements and other local codes and

supply to the

and a minimum fill flow rate of 15 GPM for the

ordinances is the responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for before discarding any

packaging material. If any parts are missing, do not begin installation until missing parts are obtained.

Flush the water supply lines before beginning installation and after installation is complete. Test the unit

for leaks and adequate water flow. For ANSI Z358.1 compliance, the main water

emergency fixture s hould be “ON” at all times. Prov isions should be made to prevent u nauthorized

shutoff.

The ANSI Z358.1 stand ard requires a 20 GPM flow rate for the shower and a 3 GPM flow rat e for the

optional Eye/Face Wash of flushing fluid f or 15 continuous minutes. Ha ws Model 8740 self-contained

shower requires a minimum fill pressure of 20 PSI

shower only or 20 GPM for shower and optional Eye/Face Wash combination at the automatic refill

connection to meet this requirement. Flushing fluid should be tepid per ANSI Z358.1. Haws Model 8740

should be installed in an indoor area that has an ambient temperature between 60°F and 100°F to meet

this tepid water requirement.

The tank water level should be checked weekly to ensure that the tank is full. For ANSI Z358.1

compliance, the automatic refill connection must be connected to an adequate potable water source.

This unit discharges water to the floor. It is recommended that this unit be installed in an area that

has adequate floor drainage. Failure to do so may result in major property damage.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 2 of 33

Page 3

DESCRIPTION OF PRODUCT

Haws Corporation Model 8740 non-electric, self-contained overhead tank shower and optional Model

874301S Eye/Face Wash is des igne d for us e in in door ar eas where the temper ature is norm ally between

60°F and 100°F. The 330-gallon high density polyethylene (HDPE) overhead tank is discharged by gravity

upon shower or optional Eye/Fac e Wash activation. The unit is equipped with a 1-1/4” NPT inlet water

connection and float valve for automatic refill.

The unit is designed to m eet ANSI Z358.1 s tandards for flow and duration if it is connected to a suit able

permanent potable water source. Haws Model 8740 self-contained shower requires a minimum fill pressure

of 20 PSI and a minimum fill flow rat e of 15 GPM for the sho wer only or 2 0 GPM for shower and optional

Eye/Face Wash combination at the autom atic r efill con nection to m eet this require m ent. Water should be

tepid per ANSI Z358.1. Haws Model 8740 should be installed in an indoor area that has an ambient

temperature between 60°F and 100°F to meet this tepid water requirement.

The optional Model 874301S Eye/Face W ash available for this unit uti lizes Haws Axion MSR (Medically

Superior Response®) eyewash design. The AXION MSR Eye/Face Wash uses an inverted stream design

which sweeps chem ical and particulate contaminants away from the vulnerable nasal ca vity, consistent

with medical irrigation protocols.

Although optional, the Model 9084 is recommended for use with the Mod el 8740. T he Model 9084 is an

immersible Cleansin g Stick that gives continual protection against path ogenic bacteria for water storage

systems. It balances the PH of the water preventing the build-up of bio-film, scale, and corrosion for up to

3 years with proper usage.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 3 of 33

Page 4

Model Description

Haws Overhead

Tank Shower

SHIPPING, HANDLING AND STORAGE

Dimensions

W x L x H

(Assembled)

Dry Weight

Filled (Wet)

Weight

Dimensions

W x L x H

(Shipping)

Weight

(Crated)

8740

55” x 59” x 150” 975 lbs. 3750 lbs. 60” x 49” x 79” 1025 lbs.

Recommended Equipment, Materials, and Supplies to be provided by Installer:

• Existing slab on grade. T he installer shall verif y that the following minimum requirements of the

existing slab-on-grade are satisfied.

o Allowable Soil Bearing Pressure: 1500 psf

o Slab-on-grade minimum thickness: 6 inches

o Compressive Strength of slab, f’c: 3000 psi

o Adequate footprint area (minimum 6’ x 6’ recommended)

o Adequate vertical space (minimum 14.5 ft. recommended, 13 ft. required)

• Recommended anchors (Not Included, customer to determine anchor suitability):

High strength adhesive anchors (ICC-ES Report ESR-3187): Hilti HIT-HY 200 Safe Set epoxy

adhesive anchorage s ystem and Hilti h ollow drill bit system with 5/8” d iameter Hilti HIT-Z Rod, 2

ASTM F844 flat washers , and AST M A563 Grade A nuts. Frame Feet mounting holes are 13/16”

diameter. Hilti specifies 3-3/4” m inim um embedment depth per HIT-Z specif ications. F rame F eet

have four (4) 13/16” diameter clearance holes (16 total anchors).

• A forklift capable of lifting 2,000 lbs. should be utilized to transport the unit from truck to site and to

lift tank into position.

Tools and Supplies

• Impact drill/driver with 5/16” nut driver (For Optional Eye/Face Wash Option).

• Steel Strap Shears

• Torque wrench with 7/8” and 9/16” sockets.

• 7/8” and 9/16” box end wrenches.

• Plumbing supply materials including potable water-safe thread sealant for PVC.

(Automatic refill water connection is 1-1/4” NPT male pipe fitting.)

• Appropriate personal protective equipment including safety glasses and work gloves.

Storage

The unit should be stored in a clean, dry place until ready for installation.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 4 of 33

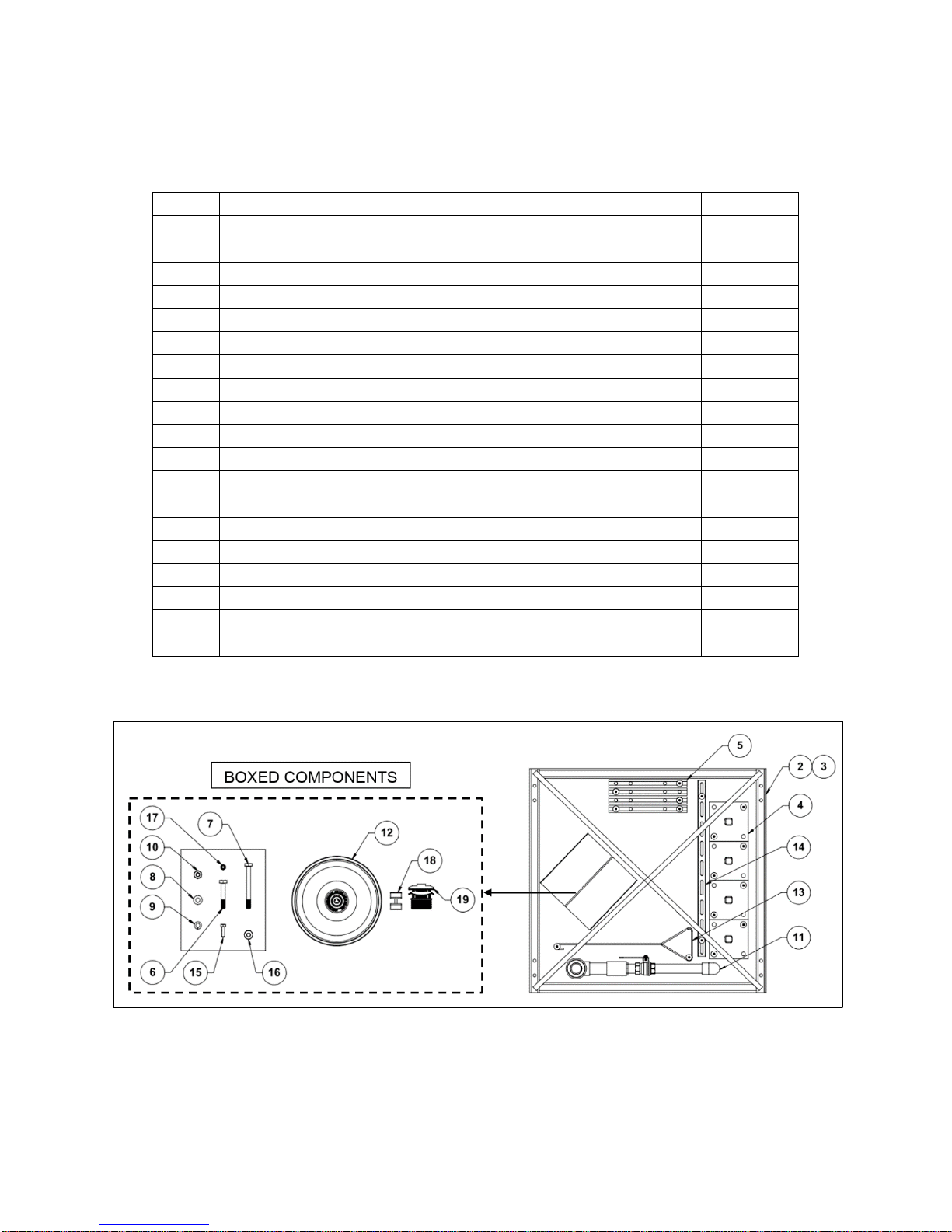

Page 5

PALLET CONTENTS

ITEM #

DESCRIPTION

QUANTITY

1

Tank Assembly

1

2

Frame Back Panel

2

6

½-13 X 3” Bolt

16

7

½-13 X 5” Bolt

16

8

½” Flat Washer

64

9

½” Lock Washer

32

10

½-13 Nut

32

11

Shower Piping Assembly

1

12

Shower Head

1

17

3/8-16 Nut

2

18

1-1/2” Strut Pipe Clamp Assembly (2 straps, 1 bolt, 1 nut)

1

19

Tank Breather Vent, 2” NPT

1

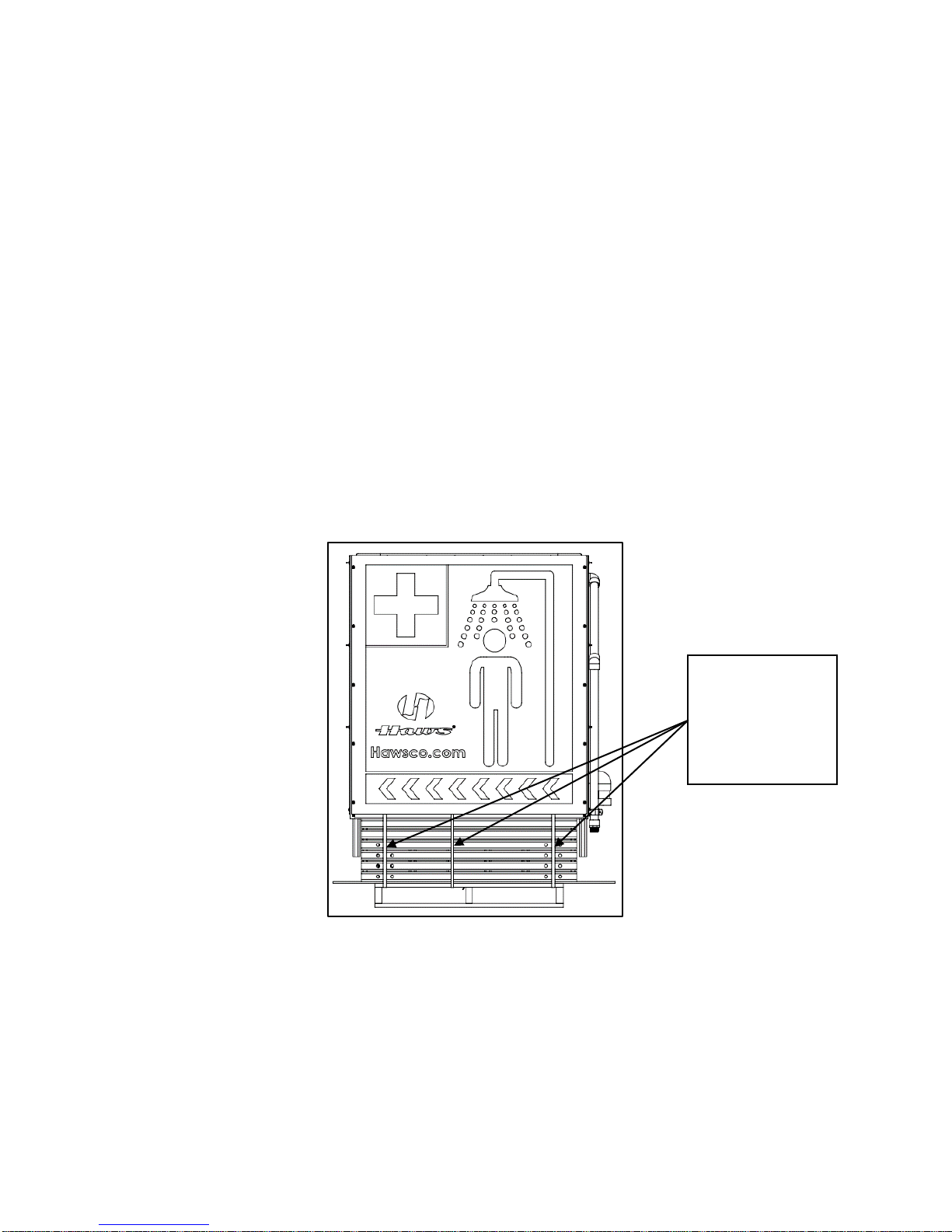

NOTE: Confirm all components listed for the Model 8740 are present before assembly. See Figure 1.

(For optional Model 874301S Eye/Face Wash Assembly components see page 21.)

3 Frame Side Panel 4

4 Frame Feet 4

5 Frame Connection Bars 4

13 Shower Pull Rod 1

14 1-5/8” x 38” Steel Strut 1

15 3/8-16 X 1-1/4” Bolt 2

16 3/8” Flat Washer 4

Figure 1. Pallet Contents Model 8740; Item #1 Tank Assembly Removed

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 5 of 33

Page 6

MODEL 8740 ASSEMBLY & INSTALLATION PROCEDURE

1. Transport the p allet ized uni t to the install ation po int via f o rk lift, ensuring the forks are ins er ted through

the shipping pallet.

2. The installation area should be located indoors on a level floor capable supporting up to 4,000lbs spread

across the four Frame Feet. Suitable concrete flooring is preferred. If unit is to be placed over a drain,

the drain should be able to handle a flow of 35 GPM; otherwise, the slab should allow the water to drain

away from the unit.

3. Confirm there is suitable available vertical space where the unit is to be installed . T he unit r equ ires a

minimum of 13ft vertical space for installation, 13.5ft of vertical space for assembly, and 14.5ft of vertical

space to insert or remove the optional Model 9084 Cleansing Stick if utilized.

4. Remove the plastic wrap packaging around the palletized unit.

5. Cut the three (3) steel bands that st rap the unit to the wooden pal let as shown in Figure 2. DO NOT

cut the steel bands on top of the tank ass em bly (th ese 4 bands retain the tank on the tank fram e and

will not be removed).

Cut and remove

three steel bands

that strap the unit

to the wooden

pallet ONLY.

Figure 2. Removing 3 Steel Bands

6. Use a forklift to lift the Tank Assembly (Item #1) from the palletized unit, using the fork slots on the Tank

Assembly, and set the Tank Assembly aside.

7. Remove box of com ponents from the pallet and rem ove components from the box. Next, remove

shipping screws/washers holding frame components to pallet. Discard shipping/screws. Place all

components in a secure area until needed.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 6 of 33

Page 7

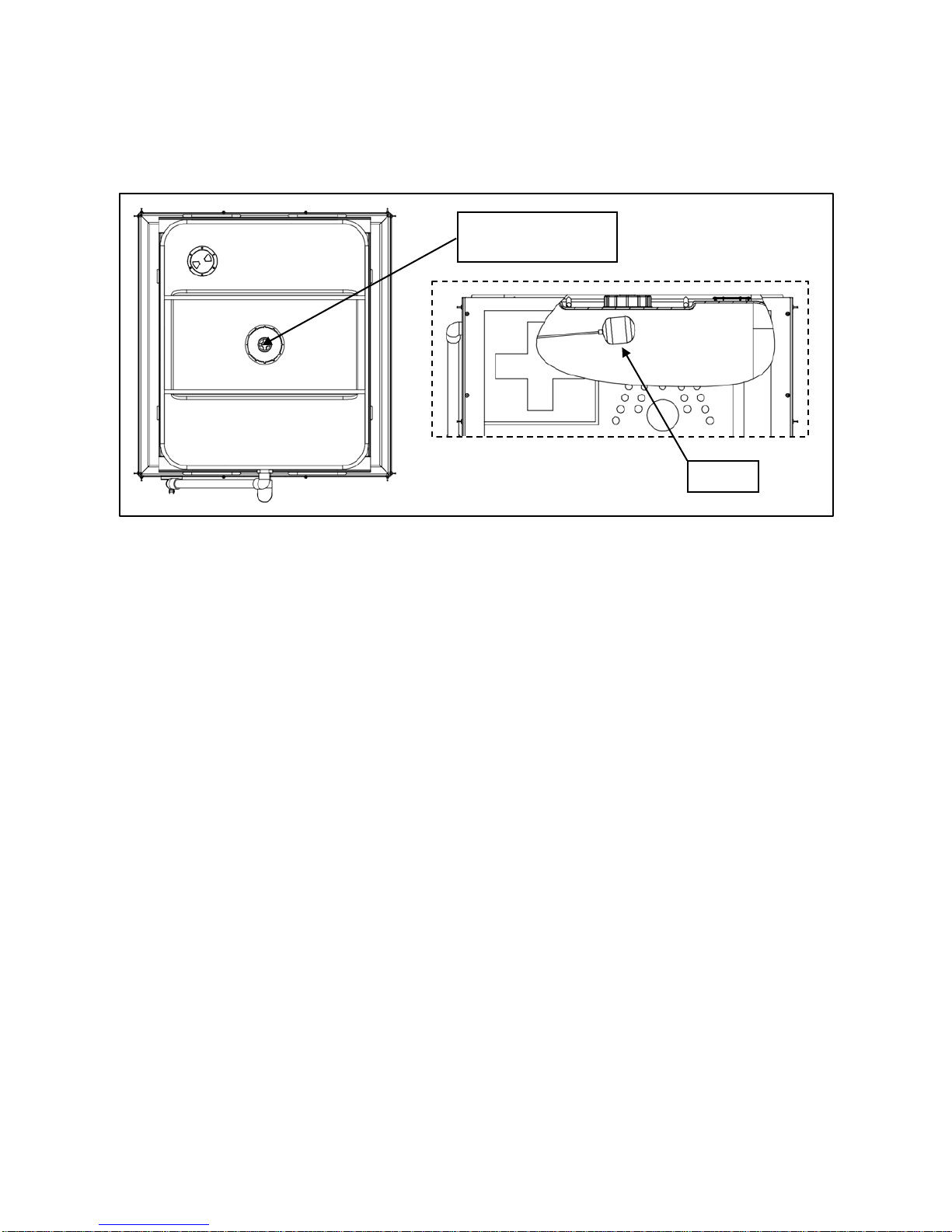

8. At the top of the tank, remove t he shipping plug from top cap and c ut cable tie holding the float f or

Remove shipping

plug & cut cable tie

Float

shipping protection. Ensure the cable tie does not drop into the tank. See Figure 3.

Figure 3. Remove Shipping Plug and Detach Shipping Protection for Float

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 7 of 33

Page 8

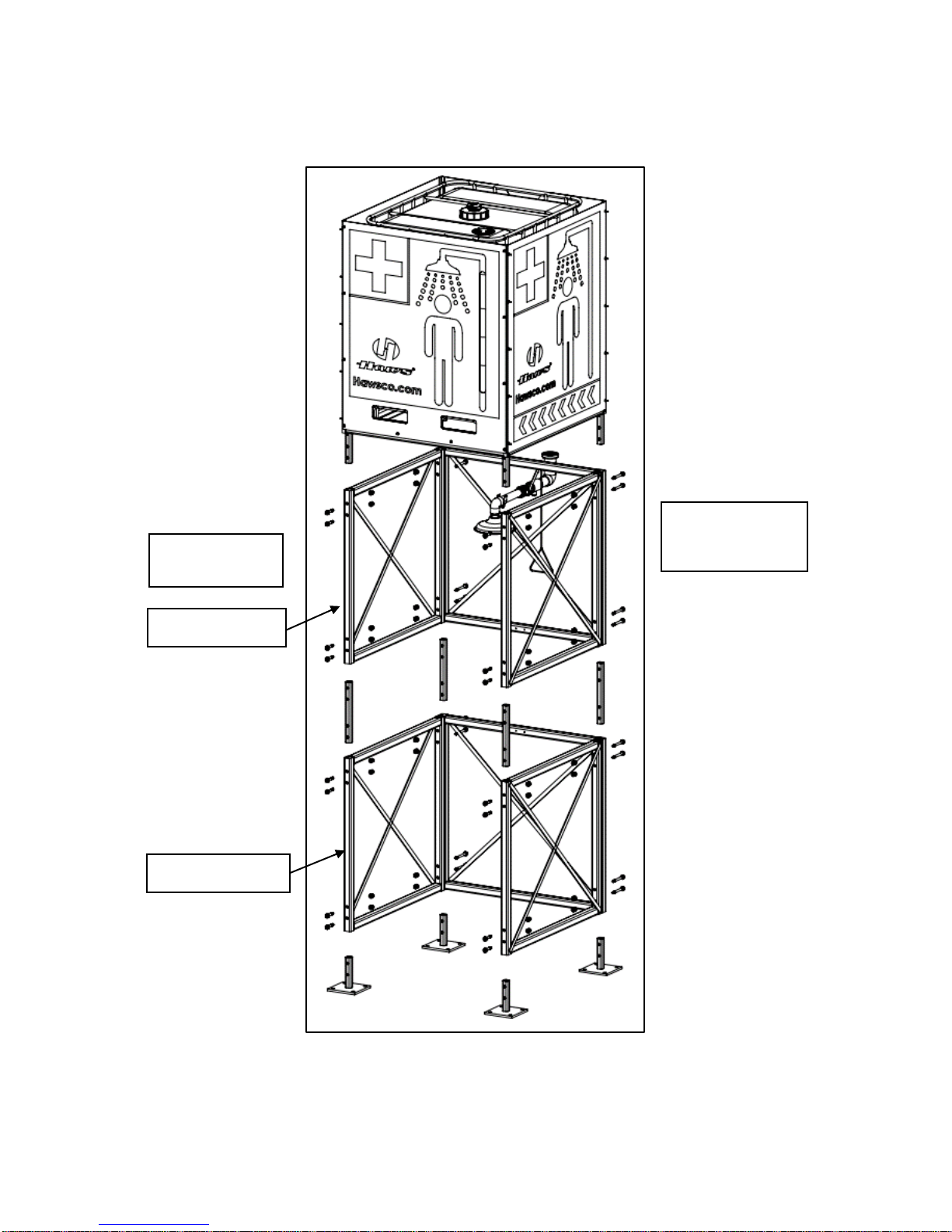

9. Figure 4 shows an exploded view of the assembly.

IN FRONT

5-INCH BOLTS

BACK PANEL

3-INCH BOLTS

UPPER FRAME

LOWER FRAME

USED FOR

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 8 of 33

Figure 4. Exploded View of Model 8740

Page 9

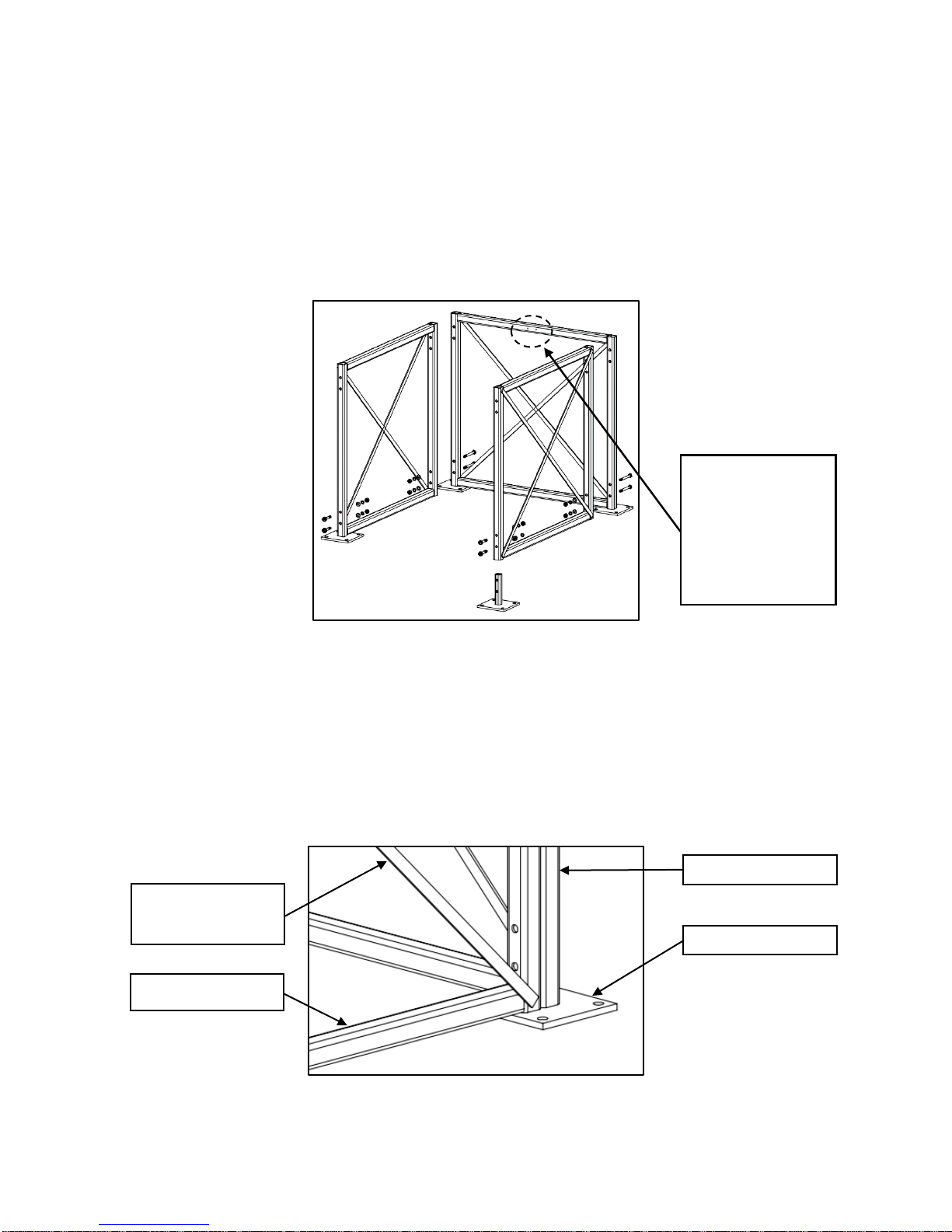

10. Begin by assembling the lower f rame shown in Figure 5. With all four (4) Fram e Feet present, place

Frame Back Panel

Frame Foot Plate

Frame Side Panel

one Frame Back Panel over two back Frame Feet posts. Holes must be aligned front to back and panel

cross-bracing strips must be on the outs i de (toward the back) as shown in Figure 5.

IMPORTANT!! The two (2) mounting ho les must be oriented as shown in Figure 5 to ensur e unit can

accept optional Model 874301S Eye/Face Wash in the future.

IMPORTANT!!

Two Eye/Face

Wash mounting

holes must be

located here on

the lower frame

assembly!

Figure 5. Lower Frame

11. Place one (1) Frame Side Panel over each of the t wo (2) front Frame Feet posts with the panel crossbracing strips to the outside as shown in Figure 5.

12. Set the back of each of the two (2) Side Frame Panels on the Frame Feet plates of the Back Panel with

the mounting holes aligned as sho wn in Figure 6. Confirm the pane l cross-bracing strips are on the

outside.

Cross-Bracing

Strips

Figure 6. Frame Side Panel on Back Frame Foot

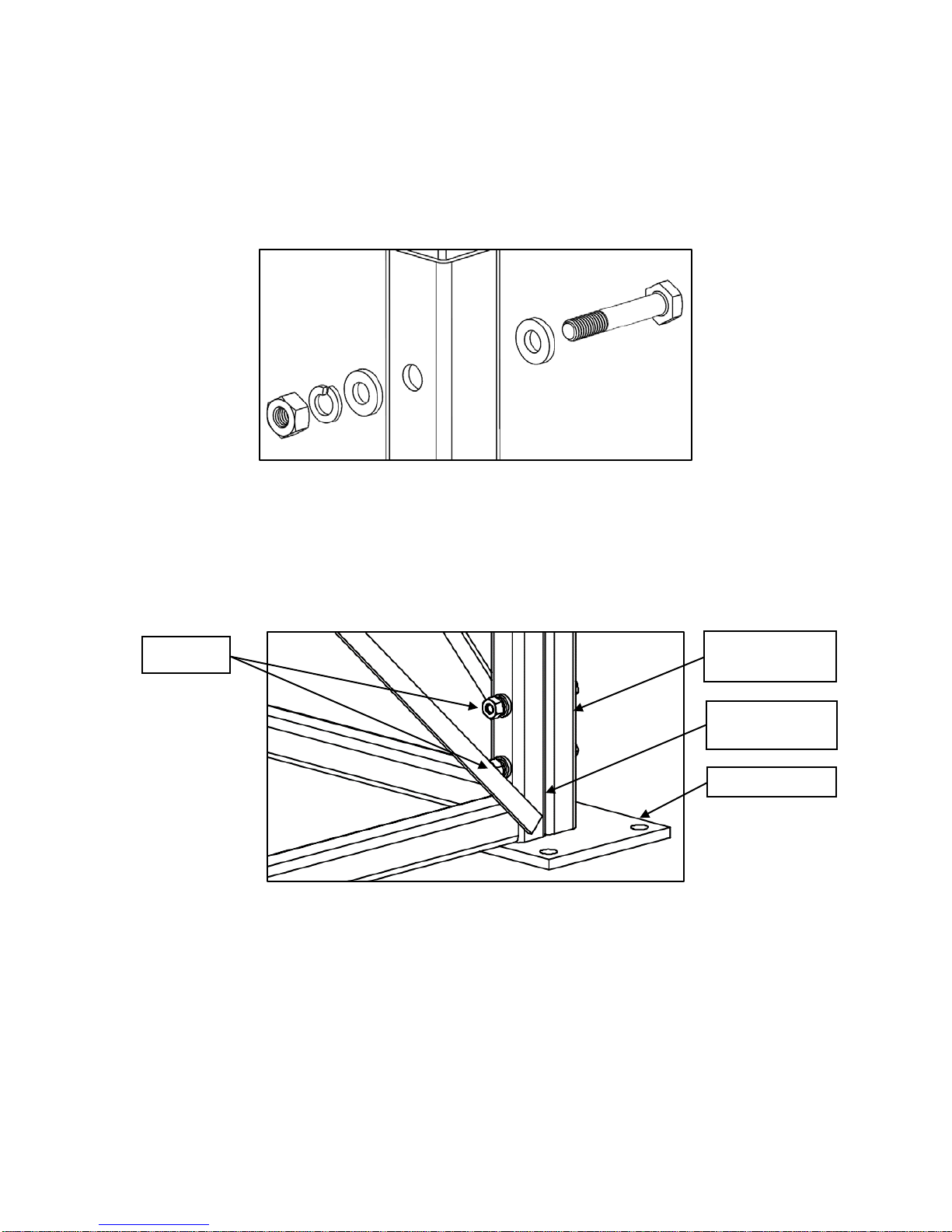

13. Typical bolting arrangement is shown in Figure 7 for reference in the next steps.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 9 of 33

Page 10

• 5” bolting is for attachment of back panels through feet or connectors to side panels and 3” bolting

Frame Back

Panel

Frame Foot

Frame Side

Panel

5-INCH

is for side panels through connectors or feet only.

• Bolting should consist of one 1/2-13 x 5” bolt (Item #7) or 1/2-13 x 3” bolt (Item #6), two 1/2” flat

washers (Item #8), one 1/2” lock washer (Item #9), and one 1/2-13 nut (Item #10).

Figure 7. Typical Bolting Ar rangement (3” Bolt Shown)

14. With mounting holes aligned as shown in Figure 8, place four (4) each 5” bolts from back to front in the

lower frame holes only to secure Frame Side Pa nels to Fr am e Back Panel and Frame Feet. Refer to

Figure 7 for bolting arrangement.

Figure 8. Connecting Frame Side Panels to Frame Back Panel

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 10 of 33

Page 11

15. Place four (4) eac h 3” bolts from front to back in the front portion of lower Fr ame Side Panel holes to

Frame Foot

Frame Side Panel

secure the front Frame Feet as shown in Figure 9. Refer to Figure 7 for bolting arrangement.

3-INCH

Figure 9. Securing Side Panels to Frame Feet

16. Install the Fram e Connection Bars (Item #5) as show n in Figure 10 by inserting two (2) bars in the

Frame Back Panel an d one (1) bar in the front por tion of each F rame Side Panels. Align the bottom

two holes of the bars with top two holes of the frame panels and bolt in place wi t h four (4) total 5” bolts

in the back and four (4) total 3” bolts in the front. Refer to Figure 7 for bolting arrangement.

5-INCH

3-INCH

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 11 of 33

Figure 10. Installing Frame Connection Bars

Page 12

17. Next, build the up per fr ame assem bly. Form the upper frame as sembly by placi ng the back and side

frame panels as shown in Figure 11. Verify the cross-bracing strips on each panel are to the outsi de

of the assembly, and bolt together with four (4) each 5” bolts f rom back to front in th e bottom of the

frame, finger-tight. Refer to Figure 7 for bolting arrangement.

NOTE: These bolts are installed temporarily and will need to be removed and reinstalled in a future step.

IMPORTANT!! The two (2) mounting holes must be orient ed as shown in Figure 11 t o ensure unit can

accept optional Model 874301S Eye/Face Wash in the future.

IMPORTANT!!

Two Eye/Face

Wash mounting

holes must be

5-INCH

located here on

the upper frame

assembly!

5-INCH

Figure 11. Installing Lower Bolts (5-inch) Temporarily to Form Upper Frame Assembly

IMPORTANT!! Ensure the cabl e tie (shi pping float suppor t) is cut and shippi ng p lug is removed from the

6” cover on the top of the tank . Ins pect th e floa t and conf irm the f loat is firm l y installed on the f loat valv e.

Inspect the inlet p iping for an y shipping dam age and inspec t the bulkhead f itting where the float valv e is

installed. It is better to address any concerns about the tank before it is on top of the frame

IMPORTANT!! Haws strongly recommends the use of the Haws Model 908 4 Cleansing St ick to provide

prolonged (up to 3 years) water treatment for the wat er in this tank. If this product has been purc hased,

install it in the tank now. Instructions for install ati on loc ated on page 26.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 12 of 33

Page 13

18. Install Tank Breather Vent (Item #19) where the s hipping plug was located in the 6” cap as shown in

Figure 12.

Breather

Vent

Figure 12. Installing Breather Vent (Item #19)

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 13 of 33

Page 14

19. Use a suitable forklift t o lift the Tank Assem bly (Item #1) over the upper fram e assem bly as shown in

WARNING: Never place fingers, hands, or any other body part between upper

frame assembly and Tank/Tank Frame Assembly while installing the unit!

Figure 13. Carefully align and insert the tank frame legs into the upper frame assembly while carefully

lowering the tank.

WARNING:

Never place fingers,

hands, or any other

body part between

Tank Assembly and

upper frame assembly

while installing the unit!

Figure 13. Setting Tank Assembly on Upper Frame

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 14 of 33

Page 15

20. Use the forklift as needed to align bolt holes and install four (4) each 5” bolts from back to front through

WARNING: Never place fingers, hands, or any other body part between upper

frame assembly and Tank Assembly while installing the unit!

Back Frame Panel and Sid e Fram e Panels and four ( 4) each 3” bolts from front to back of the F rame

Side Panels as shown in Figure 14. Refer to Figure 7 for bolting arrangement.

3-INCH

Figure 14. Bolting the Tank Assembly to the Upper Frame

5-INCH

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 15 of 33

Page 16

21. Use two (2) each 3/8-16 X 1-1/4” bolts (Item #15) to install Steel Strut (Item #14) to the underside of

Steel

Strut

the two (2) tabs under the Tank Assembly as shown in Figure 15. The 1-1/4” bolting should consist of

one 3/8-16 X 1-1/ 4” bolt (Item #15), two 3/8” Flat Washers (Item #16), and one 3/8-16 Nut (I tem #17).

The open side of the channel should face dow n. Tight en the t wo (2) bolts with a tor que wr ench t o 23

ft-lb.

Figure 15. Mounting Steel Strut for Shower Piping (Side Frame Panels Not Shown for Clarity)

3/8 Bolts

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 16 of 33

Page 17

22. Install the Shower Piping Assembly (Item #11) from the back of the shower by threading the union nut

Union

Nut

on the assembly to the union end on the tank as shown in Figure 16.

Figure 16. Installing the Shower Pipe Mount Steel Strut and Shower Piping Assembly to the Tank Union

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 17 of 33

Page 18

23. Remove the nut and bolt from the 1-1/2” Strut Pipe Clamp Assembly (Item #18), insert the two (2) clamp

Elbow

halves onto the Shower Pipe Mou nt Steel Str ut ( It em #14) around either si de of the s ho wer pi pe, and

re-install the clamp bolt and nut as shown in Figure 17. Center the shower approximately, push elbow

closely toward s trut and tighten the bolt and nut until the sho wer pipe is h eld firm ly. (T ake c are to not

overtighten.)

24. Thread Shower Head (Item #12) onto end of Shower Piping Assembly. See Figure 17.

Strut Pipe

Clamp

Shower

Head

Figure 17. Strut Pipe Clamp Assembly and Shower Head/Bell

25. Remove the four (4) 5” bolts holding the bottom of the upper frame panels together that were previously

temporarily installed from Step 17. Reference Figure 11.

26. Confirm the lower frame is located as desired for long term installation.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 18 of 33

Page 19

27. From the front, use the forklift to lift the Tank Assembly and upper frame assembly over the lower frame

WARNING: Never place fingers, hands, or any other body part between upper

frame assembly and Tank/Tank Frame Assembly while installing the unit!

WARNING:

while installing the unit!

assembly. Caref ully set the upper ha lf of the frame on the lower half of the frame over the four (4)

Frame Connection Bars.

Never place fingers,

hands, or any other

body part between

Tank Assembly/upper

frame assembly and

lower frame assembly

Figure 18. Mounting Tank Assembly and Upper Frame to Lower Frame

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 19 of 33

Page 20

28. Bolt the T ank Assembly and up per frame ass embly to the lower fram e assembly through t he Frame

Connection Bars as s hown in Figure 18. Use t he forklift as ne eded to align bolt holes. Replace the

four (4) 5” bolts removed in Step 27 from back to front through the Frame Back Panel and Frame Side

Panels of the upper frame assembly and install four (4) 3” bolts from front to back in the front mounting

holes of the Frame Side Panels. Refer to Figure 7 for bolting arrangement.

IMPORTANT!! Using a torque wre nch and 7/8” socket, tighten ALL 1/2-13 frame bolts to 100 ft-lbs.

3-INCH

5-INCH

Figure 18. Bolting Upper Frame Assembly to Frame Connection Bars in Lower Frame Assembly

29. Insert end of Shower Pull Rod (Item #13) through hole in Shower Piping Assembly ball valve handle.

30. Install suitable concrete anchors through mounting holes in Frame Feet per the manufacturer’s

instructions. Customer to determine anchor suitability.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 20 of 33

Page 21

OPTIONAL MODEL 874301S EYE/FACE WASH ASSEMBLY (If Applicable)

ITEM #

DESCRIPTION

QUANTITY

1

Eye/Face Wash Piping Assembly

1

2

Eye/Face Wash Mount Steel Strut

2

3

½” Strut Pipe Clamp Assembly

2

4

½” NPT x 1/2” Nylon Hose Barb

1

5

¼” Fender Washer

4

6

#12-24 X 7/8” Self-Drilling Screw (5/16” Hex Head)

4

7

1/2” X 36” Flexible Tube

1

8

Push Flag

1

9

AXION MSR Eye/Face Wash Head

1

10

AXION MSR Eye/Face Wash Cover

1

11

Small Cable Tie

2

12

Large Cable Tie

1

PACKAGE CONTENTS

NOTE: Confirm all components for the Model 874301S listed are present before assembly. See Figure

19.

Figure 19. Eye/Face Wash Carton Contents

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 21 of 33

Page 22

MODEL 874301S ASSEMBLY PROCEDURE

Steel

Strut

Fender

Washer

Screw

1. Place one (1) Eye/Face Wash Mount Steel Strut (Item #2) approximately in the center of the lower bar

over the two Eye/Face W ash mounting holes as shown in Figure 20. The h oles are drilled, but not

tapped.

Figure 20. Eye/Face Wash Mount Steel Strut Placement

2. Place two (2) 1/4” Fender Washers (Item #5) over two (2) #12-24 X 7/8” Self-Drilling Screws (Item #6).

Work the fender washer/screw into either end of the strut. Use an impact driver with a 5/16” hex driver

to drive the self-dr ill ing screws into the mounti ng hol es through the slot in the strut as shown in Figure

21.

Self-Drilling

Figure 21. Washer and Screw Placement

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 22 of 33

Page 23

3. Repeat Steps 1 and 2 for second Eye/Face Wash Mount Steel Strut. Results shoul d res emble Figure

Step 8:

Wash Cover

Step 7:

Nut

Step 8:

Wash Head

22.

Figure 22. Two (2) Eye/Face Wash Mount Steel Struts Installed

4. Remove the nut and bolt f rom one 1/2” Str ut Pip e Cla m p Assem bly (Item #3) and work the two clam p

halves into the upper Eye/Face Wash Mount S tee l Stru t ( Item #2) by twisting them sidew a ys bet w een

the two screw heads.

5. Place the vertical pipe from the Eye/Face Wash Piping Assembly (Item #1) int o the clamp, then install

the bolt and nut into the clamp. Center the clamp in the strut and finger tighten the clamp as shown in

Figure 23.

6. Repeat step 4 with the sec ond 1/2” Strut Pipe Clamp As sembly, placing the clam p assembly in the

lower Eye/Face Wash Mount Steel Strut and around the Eye/Face Wash Piping Assembly.

Steps 4-6:

Strut Pipe

Hose Barb

Clamps

Eye/Face

Wash

Piping

Assembly

Eye/Face

Step 7:

Push Flag

Eye/Face

Figure 23. Eye/Face Wash Assembly (Frame Hidden for Clarity)

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 23 of 33

Page 24

7. Remove hex nut from ball valve handle, place Push Flag (Item #8) on val ve stem as shown in Figur e

23, then replace and tighten nut.

8. Place ring of Eye/F ace Wash cover (Item #10) over nipple on Eye/Face W ash Head (Item #9) and

install the head as shown in Figure 23.

9. Use a measuring tape to measur e the distance between t he floor and the top of t he Eye/Face W ash

head. Adjust the vertical location of the Eye/Face Wash Piping Assembly until the top of the Eye/Face

Wash head is approximately 40”. T ighten the bolts and nuts i n the two clam ps to hold the Eye/Face

Wash Piping Assembly firmly in place.

NOTE: This s hould res u lt i n an AN SI Z358.1 compliant stream height , ho we ver t h is s hou ld be t es ted and

adjusted after water supply is connected.

10. Carefull y push one e nd of the 1/2” X 36” F lexi ble T ube (Item #7) over the hose b arb on th e top of the

Eye/Face Was h Piping Assembly as shown in Figure 24. If necessary, the union at the top of the

Eye/Face Wash Piping Assembly can be l oosened and re-adjus ted to rotate the tu bing as required.

Place the natural be nd in t he tubing suc h that t he ben d is toward the back of the sho wer. Ref erence

Figure 26.

Flexible

Tube

Hose Barb

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 24 of 33

Figure 24. Attaching Flexible Tube

Page 25

11. Ensure there is no water in the overhead tank and remove the 1/2” NPT plug in the tee from the Shower

Piping Assembly directly above the Eye/Face Wash Assembly. Reference Figure 25.

12. Apply potable water safe thread sealant for PVC to the 1/2” NPT x 1/2” Nylon Hose Barb (Item #4) and

install the hose barb in the shower piping tee in place of the plug removed in Step 11.

13. Carefully push the loose end of the 1/2” X 36” Flexible Tube (Item #7) over the hose barb in the tee.

Hose Barb

Flexible

Tube

Figure 25. Removing Plug in Tee and Attaching Hose Barb/Flexible Tubing

14. Use two (2) Small Cable Ties (Item #11) to secure ends of the tubing on the barbs. See Figure 26.

15. Use the L arge Cable Tie (Item #12) to gently secur e the mid-section of the tubin g to the upper back

cross support straps on the Frame Back Panel of the upper frame. See Figure 26.

Cable Tie

Locations

Figure 26. Cable Tie Locations on Eye Wash

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 25 of 33

Page 26

OPTIONAL MODEL 9084 CLEANSING STICK (If Applicable)

The Model 9084 Cleansing Stick is shown in Figure 27.

Figure 27. Model 9084 Cleansing Stick

MODEL 9084 INSTALLATION PROCEDURE

1. Remove the thr eaded c ove r on th e Cleansing Stick access port in the front right c orner of the t ank as

shown in Figure 28. Tur n counter-clockwise to remove. Note the small hole through the center of the

cover.

Cleansing Stick

access port in front

right corner on top of

the tank.

Figure 28. Model 9084 Cleansing Stick Access Port Location

2. The Model 9084 Cleansing Stick comes with a retrieval str ing connec ted to one end. Mar k the str ing

approximately 17” from the connection point on the stick.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 26 of 33

Page 27

3. From the underside of the cover, pass the end of the Cleansing Stick retrieval string through the small

String

hole in the middle. See Figure 29.

Access Port

Cover

Hole for

Retrieval

Figure 29. Access Port for Cleaning Stick

4. Tie a knot in the string on the top side of the cover at the 17” mark on the string.

5. Place the Cleansing Stick through the hole into the tank. The end of the Cleansing Stick must rest on

the bottom of the tank as shown in Figure 30. This mounting provision prevents the Cleansing Stick

from obstructing the tank outlet or automatic refill float valve.

Figure 30. Model 9084 Cleansing Stick Installed

6. Reattach cover and t hr ead c losed. Follo w the i nstr uc ti ons that comes with the Model 90 84 C le ans ing

Stick for maintenance and replacement intervals.

NOTE: For more information, refer to the Model 9084 Cleansing Stick, 2000 Liter O&M manual.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 27 of 33

Page 28

CONNECTING THE MODEL 8740 AUTOM ATIC REFILL VALVE TO A POTABLE WATER SOURC E

The Model 8740 is equ ippe d with a 1-1/ 4” m ale NPT fitting (Figure 31) on t he fill pipe located on the b ack

of the unit. This pipe should be connected to a permanent potable water source. To meet the ANSI Z358.1

standard for flow a nd dur ati on, the unit requires a minim um f ill pr es sur e of 20 PSI and a m inimum fill flow

rate of 15 GPM for the shower only or 20 GPM for shower and optional Eye/Face Wash combination at the

automatic refill connection. Pressure should not exceed 60 PSIG. Use a pressure reducing device if

necessary.

Figure 31. Model 8740 Automatic Refill Port Location on Back of Unit

IMPORTANT! 60 PSIG

Maximum Inlet Pressure

1-1/4” NPT Male Water

Connection Fitting to Automatic

Refill Float Valve in Tank.

For ANSI Z358.1 compliance,

a minimum 20 PSI fill pressure

and a minimum fill flow rate of

15 GPM for the shower only or

20 GPM for shower and

optional Eye/Face Wash

combination at the automatic

refill connection is required.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 28 of 33

Page 29

FILLING THE MODEL 8740 TANK WITH POTABLE WATER

1. Connect a suitable sourc e of potabl e water to the inlet connection on the back of the unit as shown in

Figure 31.

IMPORTANT!! For ANSI Z358.1 compliance, the m ain water supp ly to the em ergency fixture sho uld be

“ON” at all times. Provisions should be made to prevent unauthorized shutoff. Refer to your facility’s lockout

tagout procedure.

2. Ensure the shower (and Eye/Face Wash if equipped) valves are closed.

3. Turn on the water source and monitor the water level in the tank via the slot in the front tank panel.

4. If little or no water enters the tank, confirm the shipping protection strap on the float valve was properly

removed during assembly.

5. Allow the tank to fill. The float valve in th e tank wil l automatically shut off the flow as the water level

approaches the top of the tank. The tank should not fill completely to the top or exit the vent on the top

of the tank.

6. Check the inlet piping, tank, and shower piping for leaks and address as required.

7. If the optional Eye/Face Wash assembly has been instal led, chec k for leak age in the hose and piping

to the unit before and after activating the Eye/Face Wash.

TESTING THE INSTALLATION

1. With the tank full of water, pull the s hower activa tion handle. It is recomm ended to stand be hind the

unit to avoid drenching of the shower.

2. Confirm the handle pulls smoothly, but firmly both on and off .

3. Confirm the shower flows freely and shuts off completely. If water does not flow or flow freely, confirm

the tank ball valve at the tank outlet is fully open (handle parallel to pipe).

IMPORTANT!! For ANSI Z358.1 compliance, the m ain water supp ly to the em ergency fixture sho uld be

“ON” at all times. Provisions should be made to prevent unauthorized shutoff. Refer to your facility’s lockout

tagout procedure.

4. If the optional Eye/Face Wash assembly has been installed, push the Eye/Face Wash activation flag.

5. Confirm the Eye/Face Wash assembly actuation flag moves smoothly on and off.

6. Confirm the Eye/Face Wash flows freely and shuts off completely.

7. Confirm the automatic refill functions properly and that the tank is refilled.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 29 of 33

Page 30

ANSI Z358.1 TESTING

ANSI Z358.1 Standar d requires this self-contained emergency shower be tested at least once annually.

Refer to the latest version of the standard to test this unit for flow rate, duration, and temperature.

MAINTENANCE

The Haws Model 8740 Emergency Shower is a compliant unit that requires basic mechanical maintenance.

The primary maintenance requirement for this unit is maintaining water quality. Regular testing and

replacement of water will a id in maintaining appropriate w ater quality. Take proper precautions to help

prevent the growth of potentiall y harmful bacteri a in eyewash ta nks. W e recommend one of the following

procedures:

Procedure 1: Use suit able Sterile Antimicrobial Pres ervative Model 9082 to help pre vent the growth of

bacteria in tank (use per the manufacturer’s instructions for 300 gallons of water). Tank should be

drained, flushed and refille d with clean potable water and Sterile Antimicrobial Preservat iv e Mod el

9082 as directed by the preservative’s manufacturer.

Procedure 2: Use Cleansing Stick Model 9084 to help prevent the growth of bacteria in tank. Tank should

be drained, flushed and refilled with clean potable water and Cleansing Stick Model 9084 as

directed by the manufacturer.

Procedure 3: Drain, flush and refill portable units with clean potable water at least once every week.

Thoroughly cleanse tank at least once every month.

NOTE: Acanthamoeba survive mild chlorination and are commonly found in tap water. Sterile Antimicrobial

Preservative Model 9082 will prevent the growth of Acanthamoeba. Hot water, 158º F (70º C) or hotter will

destroy Acanthamoeba but must be allowed to cool prior to use in Eye/Face Wash units.

IMPORTANT!! For ANSI Z358.1 compliance, the main water s upply to the em ergency fixtur e should be

“ON” at all times. Provisions should be made to prevent unauthorized shutoff. Refer to your facility’s lockout

tagout procedure.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 30 of 33

Page 31

LIMITED WARRANTY

HAWS warrants that this specific product is guaranteed against defective material or poor

. HAWS liability under this

warranty shall be discharged by furnishing without charge F.O.B. HAWS Factory any goods,

for the cost of repairs, alterations or replacements, or for any expense connected therewith

made by the owner or his agents, except upon written authority from HAWS, Sparks, Nevada.

except for replacements, as provided above. Buyer agrees that Haws has made no other

reunder and that HAWS shall not be liable

The emergency equipment manufactured by HAWS is warranted to function if installation and

ed are adhered to. The units also must be used for the purpose

GIVEN BY HAWS.

SHOULD YOU EXPERIENCE DIFFICULTY WITH THE INSTALLATION OF THIS

HAWS SERVICES:

1-800-766-5612

FOR CUSTOMER SERVICE:

1-888-640-4297

workmanship for a period of one year from date of shipment

or part thereof, which shall appear to the Company upon inspection to be of defective material

or not of first class workmanship, provided that claim is made in writing to Haws within a

reasonable period after receipt of the product. Where claims for defects are made, the defective

part or parts shall be delivered to the Company, prepaid, for inspection. HAWS will not be liable

HAWS will not be liable for any damages caused by defective materials or poor workmanship,

warranties either expressed or implied in addition to those above stated, except that of title with

respect to any of the products or equipment sold he

for general, special, or consequential damages claimed to arise under the contract of sale.

maintenance instructions provid

for which they were intended. This product is intended to supplement first-aid treatment. Due

to widely varying conditions, Haws cannot guarantee that the use of this emergency equipment

will prevent serious injury or the aggravation of existing or prior injuries

NO OTHER WARRANTIES EXPRESSED OR IMPLIED ARE AUTHORIZED, PROVIDED OR

.

MODEL PLEASE CALL:

For more information on Haws products, see our website: www.hawsco.com

© 2018 Haws

HAWS

®

®

Corporation – All Rights Reserved

and other trademarks used in these materials are the exclusive property of Haws Corporation.

HAWS® P/N 0510000842 Rev.1 06/18 Model 8740 / 874301S Page 31 of 33

Page 32

C

Haws Corporation - All Rights Reserved.

HAWS and other trademarks used in these materials are the exclusive property of Haws Corporation.

R

MAKE SPECIFICATIONS AND MEASUREMENTS SUBJECT TO CHANGE WITHOUT NOTICE.

THIS DOCUMENT IS TRUE AND CORRECT AT TIME OF PUBLICATION. CONTINUED PRODUCT IMPROVEMENTS

OPTIONAL EYE/FACE WASH

APPROVED:

DRAWN:

H0213

MH

MJ

REVISED PER

ECN:

DATE:

7/11/18

H0213

DATE:

10/09/18

CHK'D.:

BY:ECN NO.

GC

SCALE:

MODEL(S)

1

OVERHEAD TANK SHOWER

DRAWING TYPE: SIZE: A

MODEL 8740

P&ID

(775) 359-4712 FAX (775) 359-7424

E-MAIL: HAWS@HAWSCO.COM

WEBSITE: WWW.HAWSCO.COM

SPARKS, NEVADA 89431

1455 KLEPPE LANE

MODEL 874301S

xxx

PART NUMBER

REVISION

SHEET OF

0510000842

11

1

PAGE

32 OF 33

Page 33

PAGE 33 OF 33

© 2018 Haws Corporation - All Rights Reserved. HAWS® and other trademarks used in these materials are the exclusive property of Haws Corporation.

6. ANSI Z358.1 COMPLIANCE REQUIREMENTS:

INTERNATIONAL BUILDING CODE (IBC) 2012

EARTHQUAKE DESIGN

4. ESTIMATED WEIGHT:

5. FRAME IS IN ACCORDANCE WITH

1. DIMENSIONS IN INCHES

2. ALL TOLERANCES: ±1/2"

3. MATERIAL:

THIS DOCUMENT IS TRUE AND CORRECT AT TIME OF PUBLICATION. CONTINUED PRODUCT

IMPROVEMENTS MAKE SPECIFICATIONS AND MEASUREMENTS SUBJECT TO CHANGE WITHOUT NOTICE.

NOTES:

56"

20 GPM FOR SHOWER AND EYE/FACE WASH

DS

RISK CATEGORY: II

SITE CLASS: D

SPECTRAL RESPONSE COEFFICIENT:

S

MIN FILL PRESSURE: 20 PSIG

MAX FILL PRESSURE: 60 PSIG

MIN FILL FLOW RATE: 15 GPM FOR SHOWER ONLY &

WET: 3450 LBS

FRAME: GALVANIZED STEEL

TANK: HDPE

PIPE & FITTINGS: PVC; SCH 80.

VALVE: BRONZE

DRY: 975LBS

= .333 g

SHOWER

HEIGHT

PULL ROD

HEIGHT

67"

81 1/2"

150"

FORKLIFT

SLOTS

EYE/FACE WASH

MODEL 874301S

ECN:

APPROVED:

DRAWN:

H0213

MH

MJ

REV. ECN:

DATE:

06/12/18

H0213

DATE:

10/09/18

CHK'D.:

BY:

GC

SCALE:

MODEL(S)

1:56

DRAWING TYPE:

8740 -OTS, IBC TANK

SHOWN WITH OPTIONAL

MODEL 8740

AA

ASSEMBLED BY

INCLUDED;

OTHERS)

(HARDWARE

INCLUDED;

ASSEMBLED

BY OTHERS)

ACCCORDANCE

TO ANSI Z358.1

(HARDWARE

6-PIECE FRAME

SUPPLY

INLET

OPTIONAL

EYE/FACE WASH

EYE/FACE WASH

SET OPTIONAL

HEIGHT IN

ACTIVATION

BALL VALVE

90 1/2"

49"

SHOWER

SHOWER

ACTIVATION ROD

BREATHER VENT

SHOWER ONLY

SHOWER

6 1/2"

SECTION A-A

B

CUSTOMER CONNECTION TANK FILL

4X 52 1/2"

FOR ANSI Z358.1 COMPLIANCE:

MINIMUM PRESSURE = 20 PSIG

MINIMUM FLOW = 15 GPM FOR

MAX PRESSURE: 60 PSIG

1-1/4" NPT (MALE)

AUTO-REFILL

MOUNTING

PROVISION

FOR CLEANSING

STICK,

MODEL 9084

4X 54 1/2"

56 1/2"

2X 6"

8"

54 1/2"

FOR DETAILED EYE-FACEWASH ASSEMBLY

HDPE TANK, 330GAL

AND INSTALLATION INSTRUCTIONS

REFER TO MODEL 8740 MANUAL

INSTALLATION

(775) 359-4712 FAX (775) 359-7424

E-MAIL: HAWS@HAWSCO.COM

WEBSITE: WWW.HAWSCO.COM

SPARKS, NEVADA 89431

1455 KLEPPE LANE

FORKLIFT

SIZE: A

REVISION

PART NUMBER

0510000842.D

SHEET 1 OF 1

1

SLOTS

CONNECTION

2" UNION;

REMOVE

PRIOR

TO

DISASSEMBLING

UNIT

SHOWER

TO ANSI Z358.1)

SCALE 1 : 16

DETAIL B

TANK

SHUTOFF

2" BALL VALVE

(PROVISIONS

SHALL BE MADE

2X 6"

8"

MOUNTING

HOLE

(HARDWARE

BY OTHERS)

7/8" TYP

PAGE 33 OF 33

Loading...

Loading...