Page 1

INSTA L LAT ION, OPERATION

&

M A INTE NANC E IN STR UC T IO NS

1455 Kleppe Lane Sparks, NV 89431-6467 (775) 359-4712 Fax (775) 359-7424

E-mail: haws@hawsco.com website: www.hawsco.com

NOTE TO INSTALLER: Please leave this information with the Maintenance Department.

HAWS warrants that this specific product is guaranteed against defective material or poor

workmanship for a period of one year from date of shipment. HAWS liability under this

warranty shall be discharged by furnishing without charge F.O.B. HAWS Factory any

goods, or part thereof, which shall appear to the Company upon inspection to be of

defective material or not of first class workmanship, provided that claim is made in writing

to Haws within a reasonable period after receipt of the product. Where claims for defects

are made, the defective part or parts shall be delivered to the Company, prepaid, for

inspection. HAWS will not be liable for the cost of repairs, alterations or replacements, or

for any expense connected therewith made by the owner or his agents, except upon

written authority from HAWS, Sparks, Nevada. HAWS will not be liable for any damages

caused by defective materials or poor workmanship, except for replacements, as provided

above. Buyer agrees that Haws has made no other warranties either expressed or implied

in addition to those above stated, except that of title with respect to any of the products or

equipment sold hereunder and that HAWS shall not be liable for general, special, or

consequential damages claimed to arise under the contract of sale.

The emergency equipment manufactured by HAWS is warranted to function if installation

and maintenance instructions provided are adhered to. The units also must be used for the

purpose for which they were intended. This product is intended to supplement first-aid

treatment. Due to widely varying conditions, Haws cannot guarantee that the use of this

emergency equipment will prevent serious injury or the aggravation of existing or prior

injuries.

NO OTHER WARRANTIES EXPRESSED OR IMPLIED ARE AUTHORIZED, PROVIDED

OR GIVEN BY HAWS.

SHOULD YOU EXPERIENCE DIFFICULTY WITH THE INSTALLATION OF THIS

MODEL PLEASE CALL:

TECHNICAL SUPPORT: 1-800-766-5612

FOR CUSTOMER SERVICE: 1-888-640-4297

Model 8605WC Barrier Free Emergency

Shower & Eye/Face Wash Booth

LIMITED WARRANTY

No. 2080194(10)

1/14 Model 8605WC Page 1 of 4

Page 2

LOCATION OF UNIT: The Model 8605WC Barrier Free Emergency Shower &

Eye/Face Wash Booth should be installed in close proximity to potential accident

areas. It should be clearly identified free from obstructions and easy to access.

SUPPLY LINE: The minimum recommended line size is 1” IPS with 30-90 psi (2-6

ATM) flowing pressure. Where sediment or mineral content is a problem, an inlet filter

is recommended.

PLUMBING CONNECTIONS: Inlet supply is female 1” IPS. Waste outlet is 3” IC

(Inside caulk).

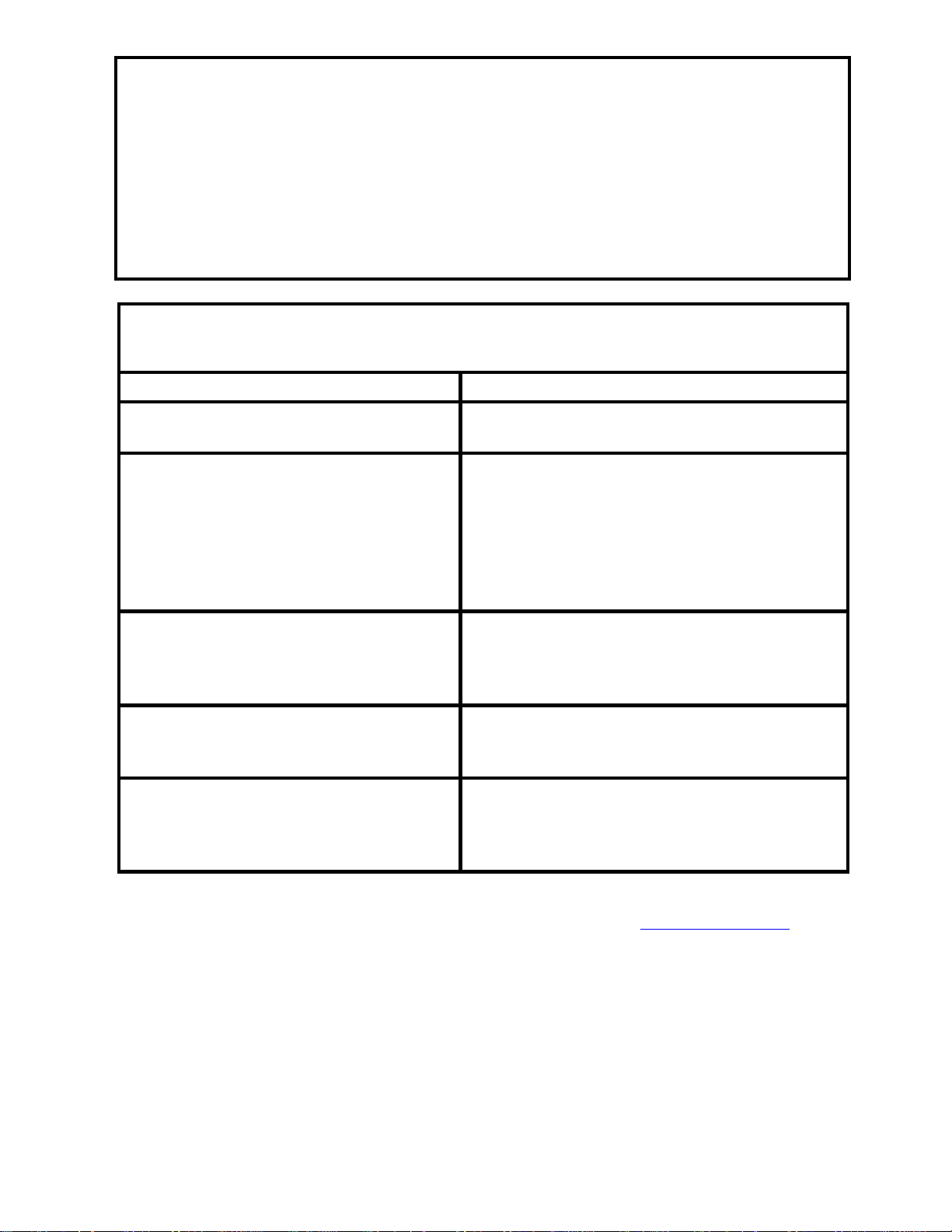

TROUBLESHOOTING

PROBLEM REPAIR CHECKLIST

1. No flow. 1. Check the main shut-off valve.

2. Insufficient water flow. 2. Verify minimum 30 psi (2 ATM)

flowing supply line pressure.

3. Insufficient water flow. On

eyewash, however, shower is

sufficient.

3. a.

Probable clogging of flow control

due to inadequate line flushing.

Unscrew eye/face wash head and

remove the four screws to

disassemble the head. Clean flow

control and reassemble head. See

SP65 Installation Drawing for details.

4. Insufficient water flow at the

showerhead, however,

eyewash is sufficient.

4. Probable clogging of flow control

inside showerhead. Unscrew

showerhead off of elbow and clean

rubber flow control.

5. Eyewash stream does not meet

desired eye level.

5. Possible blocked flow control, see

above solution. Possible nonleveled eyewash assembly.

6. Water does not drain properly. 6. Check the main waste line of your

building to see if it does handle the

capacity required for the entire

drainage system.

For more information on Haws products, see our website: www.hawsco.com

© 2014 Haws® Corporation – All Rights Reserved

HAWS

1/14 Model 8605WC Page 2 of 4

®

and other trademarks used in these materials are the exclusive property of Haws Corporation.

Page 3

THIS DOCUMENT IS TRUE AND CORRECT AT TIME OF PUBLICATION. CONTINUED PRODUCT IMPROVEMENTS

MAKE SPECIFICATIONS AND MEASUREMENTS SUBJECT TO CHANGE WITHOUT NOTICE.

ITEM DESCRIPTION

EYE/FACE WASH ASSEMBLY

1

PART NO .

SP65

PARTS BREAKDOWN

4

3

VALVE ASSEMBLY

2

PULL ROD

3

SHOWER/EYEWASH SIGN

4

TEST TAG

5

SHOWER/EYEWASH LABEL

76SHOWER HEAD

SHOWER VALVE ASSEMBLY8

7

8

SP229

SP202

SP178

SP170

SP178LG

SP829

-

6

2

1

BYECN NO.

REVISED PER

ECN:

4888

DATE

DRAWN

RTM

WHEN ORDERING PARTS PLEASE SPECIFY MODEL NUMBER.

C

2014

Haws Corporation - All Rights Reserved

HAWS and othe r trademarks used in these ma terials are the exc lus ive property of Haws Corporation.

R

APPROVED

8/16/01

DATE

MODEL(S)

HM

CHKD

SCALE:

SP65 EYE/FACE WASH ASSEMBLY

EMERGENCY SHOWER

DRAWING TYP E: SIZE: A

1:10

8605WC

PARTS BREAKDOWN

5

1455 KLEPPE LANE

SPARKS, NEVADA 89431

(775) 359-4712 FAX (775) 359-7424

E-MAIL: HAWS@HAW SCO.COM

WEBSITE: WWW.HAWSCO.COM

PAGE

PART NUMBER

0002080194

DRAWING NO.

15124C00

SHEET OF

11

3 of 4

REV

10

Page 4

C

Haws Corporation - All Rights Reserved.

2014

HAWS and other trademarks used in these materials are the exclusive property of Haws Corporation.

2184mm

3. FLOW RATE FOR EYE/FACE WASH IS 3.7 GPM AND 1.32 GPM FOR EYEWASH CONVERSION. BOTH EXCEED ANSI Z358.1-2009 STANDARD .

MAKE SPECIFICATIONS AND MEASUREMENTS SUBJECT TO CHANGE WITHOUT NOTICE.

THIS DOCUMENT IS TRUE AND CORRECT AT TIME OF PUBLICATION. CONTINUED PRODUCT IMPROVEMENTS

NOTES:

1. DIMENSIONS MAY VARY BY ± 1/2 INCH [13mm].

2. TO COMPLY WITH ANSI Z358.1- 2009 FOR EMERGENCY EYEWASH OR EYE/FACE WASH AND SHOWER EQUIPMENT:

- UNIT SHALL BE INSTALLED IN ACCORDANCE WITH MANUFACTURER'S INSTRUCTIONS AND ACCEPTABLE PLUMBING PRACTICES.

- EYEWASH OR EYE/FACE WASH SHAL L BE POSITION ED WITH NOZZLES NOT LESS THEN 83.8 CM (33 IN.) AND NO GREATER THAN

114.3 CM (45 IN.) FROM SURFACE ON WHICH USER STANDS AND 15.3 CM (6 IN.) MINIMUM FROM WALL OR NEAREST OBSTRUCTION.

- SHOWER SHALL BE POSITIONED SO THAT SHOWER HEAD IS NOT LESS THAN 208.3 CM (82 IN.) NOR MORE THAN 243.8 CM (96 IN.)

FROM SURFACE ON WHICH USER STANDS.

- SHOWER SPRAY PATTERN SHALL HAVE A MINIMUM DIAMETER OF 50 .8 CM (20 IN.) AT 152.4 CM (60 IN.) ABOVE SURFACE ON WHICH

USER STANDS, AND CENTER OF SPRAY PATTERN SHALL BE LOCATED AT LEAST 40.6 CM (16 IN.) FROM ANY OBSTRUCTION.

86"

BOLT ASSEMBLY

1/2" (12.7mm)

ANCHOR

4X

2108mm

83"

36"

1181mm

46-1/2"

AA

2318mm

91-1/4"

RECESS FOR

WHEELCHAIR

ACCESS

57mm

2-1/4"

R

36" MAX

914mm

27" MIN

686mm

17-3/4"

327mm

12-7/8"

3" DRAI N

OPTIONAL

SUPPLY

1029mm

1" IPS

40-1/2"

2289mm

APPROVED:

DRAWN:

RTM

REVISE D PER

ECN:

DATE:

8/10/01

4888

DATE:

BY:ECN NO.

CHK'D.:

HM

SCALE:

MODEL(S)

1:24

DRAWING TYPE: SIZE: A

EMERGENCY SHOWER

98mm

3-7/8"

FLOOR LINE

SUPPLY

1" IPS

978mm

38-1/2"

MOUN T I N G DETAI L

SECTION A-A

8605WC

90-1/8"

HOLE THRU

Ø 16mm

Ø 5/8"

19-1/4"

489mm

4X

330mm

13"

660mm

26"

INSTALLATION

(775) 359-4712 FAX (775) 359-7424

E-MAIL: HAWS@HAWSCO.COM

WEBSITE: WWW.HAWSCO.COM

SPARKS, NEVADA 89431

1455 KLEPPE LANE

514mm

20-1/4"

0002080194.D

DRAWING NO.

PART NUMBER

SHEET OF

15123A00 10

11

REV

279mm

11"

559mm

22"

PAGE

4 of 4

Loading...

Loading...