Page 1

No. 2080045(15)

Model 7501/7501T/7501TH/7501T240/7501T240H

Portable Eyewash/Portable Eyewash with Heater

INSTALLATION, OPERATION

&

MAINTENANCE INSTRUCTIONS

LIMITED WARRANTY

OR GIVEN BY HAWS.

NOTE TO INSTALLER: Please leave this information with the Maintenance Department.

SHOULD YOU EXPERIENCE DIFFICULTY WITH THE INSTALLATION OF THIS

1455 Kleppe Lane Sparks, NV 89431-6467 (775) 359-4712 Fax (775) 359-7424

E-mail: haws@hawsco.com website: www.hawsco.com

HAWS warrants that this specific product is guaranteed against defective material or poor

workmanship for a period of one year from date of shipment. HAWS liability under this

warranty shall be discharged by furnishing without charge F.O.B. HAW S Factory any goods,

or part thereof, which shall appear to the Company upon inspection to be of defective

material or not of first class workmanship, provided that claim is made in writing to Haws

within a reasonable period after receipt of the product. Where claims for defects are made,

the defective part or parts shall be delivered to the Company, prepaid, for inspection. HAWS

will not be liable for the cost of repairs, alterations or replacements, or for any expense

connected therewith made by the owner or his agents, except upon written authority from

HAWS, Sparks, Nevada. HAWS will not be liable for any damages caused by defective

materials or poor workmanship, except for replacements, as provided above. Buyer agrees

that Haws has made no other warranties either expressed or implied in addition to those

above stated, except that of title with respect to any of the products or equipment sold

hereunder and that HAWS shall not be liable for general, special, or consequential damages

claimed to arise under the contract of sale.

The emergency equipment manufactured by HAWS is warranted to function if installation

and maintenance instructions provided are adhered to. The units also must be used for the

purpose for which they were intended. This product is intended to supplement first-aid

treatment. Due to widely varying conditions, Haws cannot guarantee that the use of this

emergency equipment will prevent serious injury or the aggravation of existing or prior

injuries.

NO OTHER WARRANTIES EXPRESSED OR IMPLIED ARE AUTHORIZED, PROVIDED

MODEL PLEASE CALL:

TECHNICAL SUPPORT: 1-800-766-5612

FOR CUSTOMER SERVICE: 1-888-640-4297

08/16 Model 7501/7501T/7501TH/7501T240/7501T240H Page 1 of 8

Page 2

RECOMMENDED TOOLS: Three 1/4" diameter anchors suitable for supporting filled

eyewash (approximately 80 pounds), and tools needed to install these anchors.

LOCATION OF UNIT: The Model 7501/7501T/7501TH/7501T240/7501T240H Portable

Eyewash should be installed in close proximity to potential accident areas. It should be clearly

identified, free from obstructions and easily accessible. NOTE: Personal wash unit Model

7501T/7501TH/7501T240/7501T240H shall be protected from freezing. Models

7501/7501T/7501TH/7501T240/7501T240H shall not be exposed to ambient temperatures

exceeding 38⁰C (100⁰F).

ELECTRICAL CONNECTIONS:

Model 7501T requires a 120VAC, three-pro ng outlet , and is supplied with a heavy-duty 8 foot

power cord with GFCI plug.

Model 7501T240 requires a 240VAC outlet and is not supplied with a power cord which must

be installed by the user.

Model 7501T240 MUST BE PROTECTED BY a Class A GROUND FAULT CIRCUIT

INTERRUPTER (GFCI).

Models 7501TH and 7501T240H must be protected by a Class A Ground Fault Circuit

Interrupter (GFCI)- No power cord is supplied – Units are suitable for installation and use in

Class 1, Division 2, Group B, C, D, T6, Class 2, Division 2, Group E, F, G areas and MUST

BE INSTALLED IN COMPLIANCE WITH LOCAL, STATE AND/OR FEDERAL CODES.

INSTALLATION INSTRUCTIONS

NOTES: Instructions apply to all models unless otherwise specified.

STEP 1: Model 7501: Mount unit to wall utilizing “J” bracket (supplied). Note: ¼” mounting

hardware not supplied. See Installation Drawing on Page 7 of 8.

Model 7501T/7501T240: Install blanket and power cord per instructions provided

with blanket. Mount unit to wall utilizing “J” bracket and three aluminum spacers

(supplied). Locate one aluminum spacer behind each bolt hole in “J” bracket. Note:

¼” mounting hardware is not supplied. See Installation Drawing on Page 8 of 8.

STEP 2: Make sure portable eyewash unit is level from front to back and left to right before

securing bracket to wall. Eyewash nozzles should be between 33 inches (83.8 cm)

and 53 inches (164.6 cm) above the floor when eyewash arm is in the active

(lowered) position (See Installation Drawings, pages 7 and 8 of 8).

IMPORTANT:

DO NOT FILL PAST WATER FILL LINE AS LEAKAGE WILL OCCUR AT THE

EYEWASH HEADS.

Filled eyewash unit is heavy (approximately 80 pounds). Wall bracket anchors

(Quantity 3 - not supplied) must be strong enough to support the filled eyewash

and the weight of a worker leaning on eyewash.

STEP 3: Fill up to fill line (see important note above). Requires 8.75 gallons (max) of water,

(make sure that no debris or contaminants of any kind are present in the flushing

fluid). Make sure unit is level from front to back and left to right. If installed as

indicated, eyewash unit will provide 15-minute duration of flow.

CAUTION – MAKE SURE MODEL 7501T/7501TH/7501T240/7501T240H EYEWASH UNIT IS

FILLED WITH FLUSHING FLUID (UP TO FIL L LINE) BE FORE CONNECTING HEATER TO

POWER SOURCE.

08/16 Model 7501/7501T/7501TH/7501T240/7501T240H Page 2 of 8

Page 3

STEP 4: Model 7501T/7501TH/7501T240/7501T240H: Connect heater to power source

(See Electrical Connections above).

STEP 5: Take proper precautions to help prevent the growth of potentially harmful bacteria

in eyewash tanks. (Refer to Maintenance Instructions).

OPERATING INSTRUCTIONS

Instruct all employees in the use of this Emergency Eyewash. Personnel should be assigned to

check eyewash liquid level daily.

STEP 1: Lead patient to nearest eyewash station. Seconds can make the difference in

preventing serious eye injury.

STEP 2: Pull ye llow eyewash arm firmly. Eyewash arm will drop to activate eyewash.

STEP 3: Lower head until eyes enter eyewash stream. Use thumbs and forefingers to hold

eyelids open. Flush for 15 minutes.

STEP 4: Seek qualified medical attention immediately.

MAINTENANCE INSTRUCTIONS

NOTE:

• Customer must provide an inspection tag and maintain a record of inspection dates and

type of maintenance performed (i.e. adding Sterile Antimicrobial Preservative Model

9082, etc.)

• Acanthamoeba survive mild chlorination and are commonly found in tap water. Sterile

Antimicrobial Preservative Model 9082 will prevent the growth of Acanthamoeba. Hot

water, 158º F (70º C) or hotter will destroy Acanthamoeba but must be allowed to cool

prior to use in eyewash units.

STEP 1: Self cont ained eyewash equipment shall be visually checked to determine if

flushing fluid needs to be changed or supplemented. See STEP 3 for additional

information regarding activated units.

Frequency of inspection: Depending on environmental conditions, visual

inspections should be performed on either a daily, weekly or monthly basis as

some water loss will occur due to natural evaporation process.

STEP 2: T ake proper precautions to help prevent the growth of potentially harmful bacteria

in eyewash tanks. We recommend either of the following procedures:

A. Procedure 1: Use suitable Sterile Antimicrobial Preservative Model 9082 to

help prevent the growth of bacteria in eyewash tank. Eyewash tank should be

drained, flushed and refilled with clean potable water and Sterile Antimicrobial

Preservative Model 9082 as directed by the preservative’s manufacturer.

NOTE: Disconnect Model 7501T/7501TH/7501T240/7501T240H from power source

before performing maintenance.

B. Procedure 2: Drain, flush and refill portable units with clean potable water at

least once every week. Thoroughly cleanse tank at least once every month.

08/16 Model 7501/7501T/7501TH/7501T240/7501T240H Page 3 of 8

Page 4

STEP 3: After activating units for whatever reason, ensure the following steps are

follow Procedure 1 or Procedure 2 of

implemented:

A. Refill tank with potable water to the watermark line.

B. If water is discharged for any reason –

__Step 2 above to ensure that water quality is maintained.

08/16 Model 7501/7501T/7501TH/7501T240/7501T240H Page 4 of 8

Page 5

TROUBLESHOOTING

PROBLEM

REPAIR CHECKLIST

1.

No flow.

1.

a.

Tank empty. Refill tank (8.75 gallons).

b.

Obstruction in line or fitting. Clear

obstruction.

2.

Poor flow from eyewash head(s).

2.

a.

Tighten head assembly.

b.

Check for obstructions. If necessary,

Check for leaks.

3.

Water leak between joints or fitt ing s .

3.

a.

Pull hose off fitting. Smooth r aised plastic

b.

Tighten hose clamp(s) wit h pli er s.

4.

Water leaking from eyew ash heads.

4.

a.

Check to see if water level has exceeded

reached.

b.

Make sure unit is level from front to back

and left to right.

5.

Eyewash flows for less th an 15 minutes.

5.

a.

Fill water level in eyewash tank even with

water fill line (indicated on side of unit.

6.

Excessive water loss

6.

a.

Check unit for leaks. Some loss due to

7.

Heater doesn’t turn on. (Model

7.

a.1

7501T/7501T240: Not plugged in or no

b.

Check GFCI and/or circuit breaker.

Installation Drawing page 8 of 8.

remove eyewash head(s) , clean and

reassemble. To reasse mb le he ad, place

cap screw through head and t hread into

head anchor two or three turns. Ti lt head

assembly and work anchor legs i nt o

eyewash armholes. Tight en assembly.

edge on center of fitting. Retur n hose and

hose clamp to original position.

water fill line (indicated on side of unit). If

so, remove excess water t il l fil l l ine is

7501T/7501TH/7501T240/7501T240H)

© 2016 Haws

HAWS

®

Corporation – All Rights Reserved

®

and other trademarks used in these materials are the exclusive property of Haws Corporation

evaporation is normal.

power to outlet.

a.2

7501TH/7501T240H: No pow er to unit.

c.

If ambient temperature is hig h and doesn’t

allow the water temperatu r e t o dr op below

68°F (20°C) the heater m ay not switch on.

Heater settings are: Non-adjustable

thermostat preset to switch at 73°F ± 5°F

(23° ± 3°C). Test the thermostat and heater

function by applying ice in a circ ular motion

to thermostat location. Apply ice to this

location for approximately 3-5 minutes. The

heat trace cable should b ecome warm to

the touch when operating pr operly.

Thermostat locations are i ndicated on

08/16 Model 7501/7501T/7501TH/7501T240/7501T240H Page 5 of 8

Page 6

THIS DOCUMENT IS TRUE AND CORRECT AT TIME OF PUBLICATION. CONTINUED PRODUCT IMPROVEMENTS

MAKE SPECIFICATIONS AND MEASUREMENTS SUBJECT TO CHANGE WITHOUT NOTICE.

PARTS BREAKDOWN

STANDBY

"OFF"

POSITION

2

NOT SH O WN

4

3

ITEM DESCRIPTION

EYEWASH HEAD ASSY

1

BRACKET

2

CAP 3

4

LABEL, CAP, REFILL

STERILE ANTIMICROBIAL PRESER VAT IVE

5

6

ALUMINUM SPACER

BLANKET

7

7

ACTIVE

"ON"

POSITION

PART NO .

SP19

0001217418

SP131

0003163925

9082

0310000166

*SEE TABLE

3X

6

(7501T SHOWN)

5

(NOT SUPPLIED, MUST BE ORDERED SEPARATELY)

2

STANDBY

"OFF"

POSITION

MODELS 7501T/7501TH/

7501T240/7501T240H

NOT SH O WN

4

3

1

*

MODEL BLANKET P/N

7501T

7501T240

7501TH

7501T240H

7501BL

7501BL240

7501BLH

7501BL240H

1

5

MODELS 7501

(NOT SUPPLIED, MUST BE ORDERED SEPARATELY)

BYECN NO.

REVI SED PER

5086

ECN:

5139

RTM

DATE

04/16/04

DATE

FV

DRAWN

WHEN ORDERING PARTS PLEASE SPECIFY MODEL NUMBER.

C

2016

Haws Corporation - All Rights Reserved

HAWS and other trademarks used in these materials are the exclusive property of Haws Corporation.

R

APPROVED

CHKD

09/21/16

CC

VWC

MODEL(S)

7501/7501T/7501TH/7501T240/7501T240H

SCALE:

PORTABLE EYEWASH

DRAWING TYPE: SIZE: A

1:1

PARTS BREAKDOWN

ACTIVE

"ON"

POSITION

1455 KLEPPE LANE

SPARKS, NEVADA 89431

(775) 359-4712 FAX (775) 359-7424

E-MAIL : HAWS @H AW S C O.C O M

WEBSITE: WWW.HAWSCO.COM

PAGE

PART NUMBER

0002080045

REVISION

15

SHEET OF

11

6 of 8

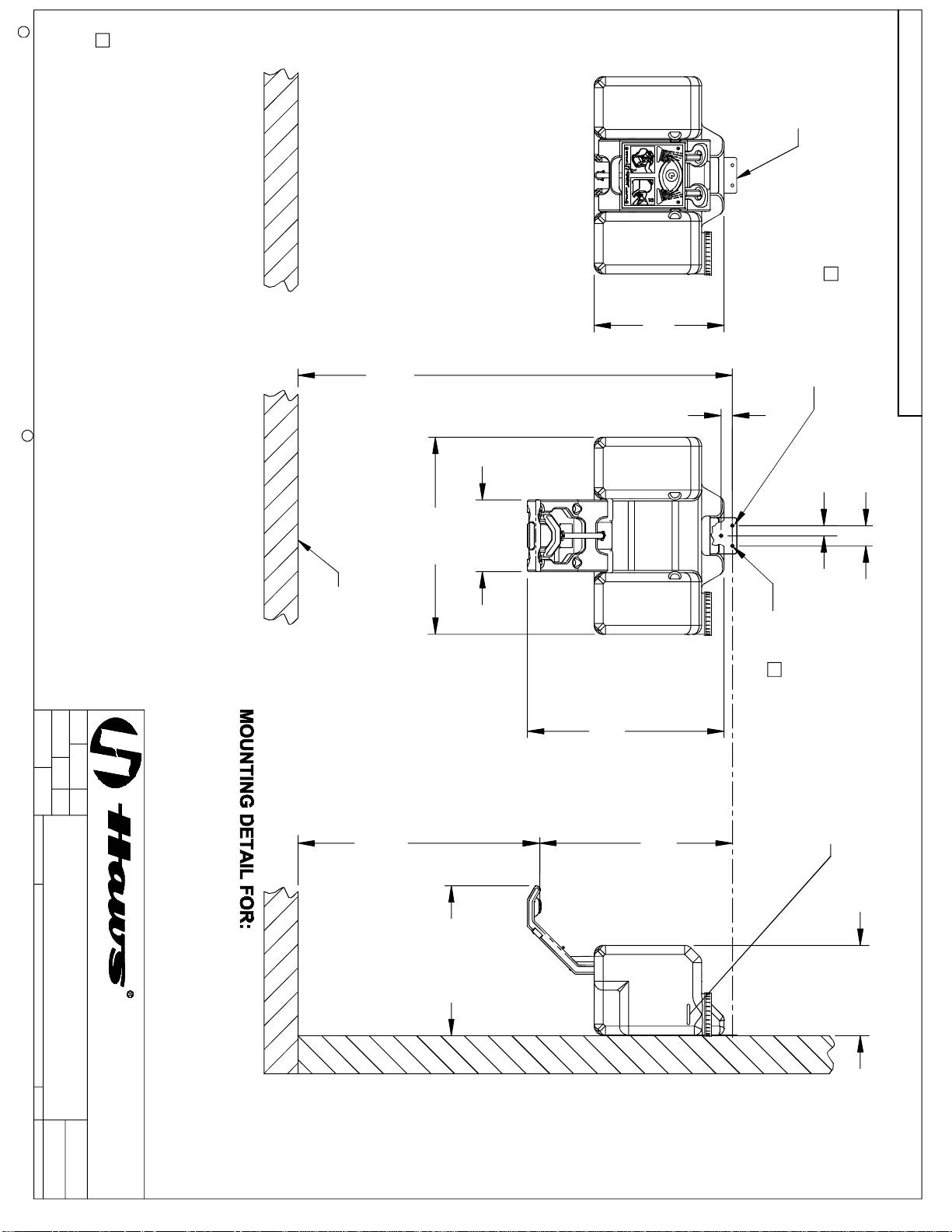

Page 7

Haws Corporation - All Rights Reserved.

2016

HAWS and other trademarks used in these materials are the exclusive property of Haws Corporation.

MAKE SPECIFICATI ON S AND MEASUREMENTS SUBJECT TO CHANGE W ITHOUT NOTICE.

C

(NOTES CONTINUED ON SHEET 2 OF 2)

2. UNIT MUST BE LEVEL FROM FRONT TO BACK AND SIDE TO SIDE.

ALL THREE MOUNTING HOLES ON MOUNTING-BRACKET MUST BE USED TO PROPERLY

SECURE EYEWASH UNIT TO WALL.

3

ACCEPTABLE PLUMBING PRACTICES.

- EYEWASH OR EYE/FACE WASH SHALL BE POSITIONED WITH NOZZLES NOT LESS THEN

83.8 CM (33 IN.) AND NO GREATER THAN 134.6 CM (53 IN.) FROM SURFACE ON WHICH USER

STANDS AND 15.3 CM (6 IN.) MINIMUM FROM WALL OR NEAREST OBSTRUCTION.

- UNIT SHALL BE INSTALLED IN ACCORDANCE WITH MANUFACTURER'S INSTRUCTIONS AND

NOTES:

1. TO COMPLY WITH ANSI Z358.1-2014 FOR EMERGENCY EYEWASH OR EYE/FACE WASH AND

SHOWER EQUIPMENT:

(SUPPLIED)

MOUNTING

BRACKET

THIS DOCUMENT IS TRUE AND CORRECT AT TIME OF PUBLICATION. CONTINUED PRODUCT IMPROVEMENTS

STAND BY

"OFF"

3

3X 1/4" MOUNTING

[32mm]

(NOT SUPPLIED)

HARDWARE

1 1/4"

[29mm]

[57mm]

1 1/8"

2 1/4"

[368mm]

[1384 m m TO 1689mm]

TO FINISH ED FL O OR

54-1/2" TO 66-1/2"

R

* 14-1/2"

FV

09/21/16

SCALE:

1:1

DRAWING TYPE: SIZE: A

APPROVED:

MJ

06/30/16

DATE:

VWC

7501/7501T/7501TH/7501T240/7501T240H

DRAWN:

DATE:

CHK'D.:

PORTABLE EYEWASH

5086

REVISED PER

ECN:

5139

BY:ECN NO.

CC

MODEL(S)

(SEE SHEET 2 OF 2)

MODELS 7501T/7501TH/7501T240/7501T240H - WITH

HEATED BLANKET

LINE

[559mm]

FLOOR

[203mm]

* 22"

* 8"

ø [8mm]

ø 5/16"

3X

PROPER FILLING PROCEDURES.

MAINTENANCE MANUAL" FOR

LINE.REFER TO INSTALLATION

INSTRUCTIONS IN "OPERATION AND

DO NOT EXCEED WATER FILL

3

POSITIONPOSITION

ACTIVE

MODEL 7501 (SHOWN)

TO FINI SHED FLO OR

[838mm TO 1346mm]

"ON"

33" TO 53"

[425mm]

* 16-3/4"

[559mm]

* 22"

[546mm]

* 21-1/2"

INSTALLATION

0002080045.D

PART NUMBER

REVISION

SHEET OF

12

15

[257mm]

* 10-1/8"

(775) 359-4712 FAX (775) 359-7424

E-MAIL: HAWS @H AW SCO.COM

WEBSITE: WWW.HAWSCO.COM

SPARKS, NEV ADA 89431

1455 KLEPPE LA NE

PAGE

7 of 8

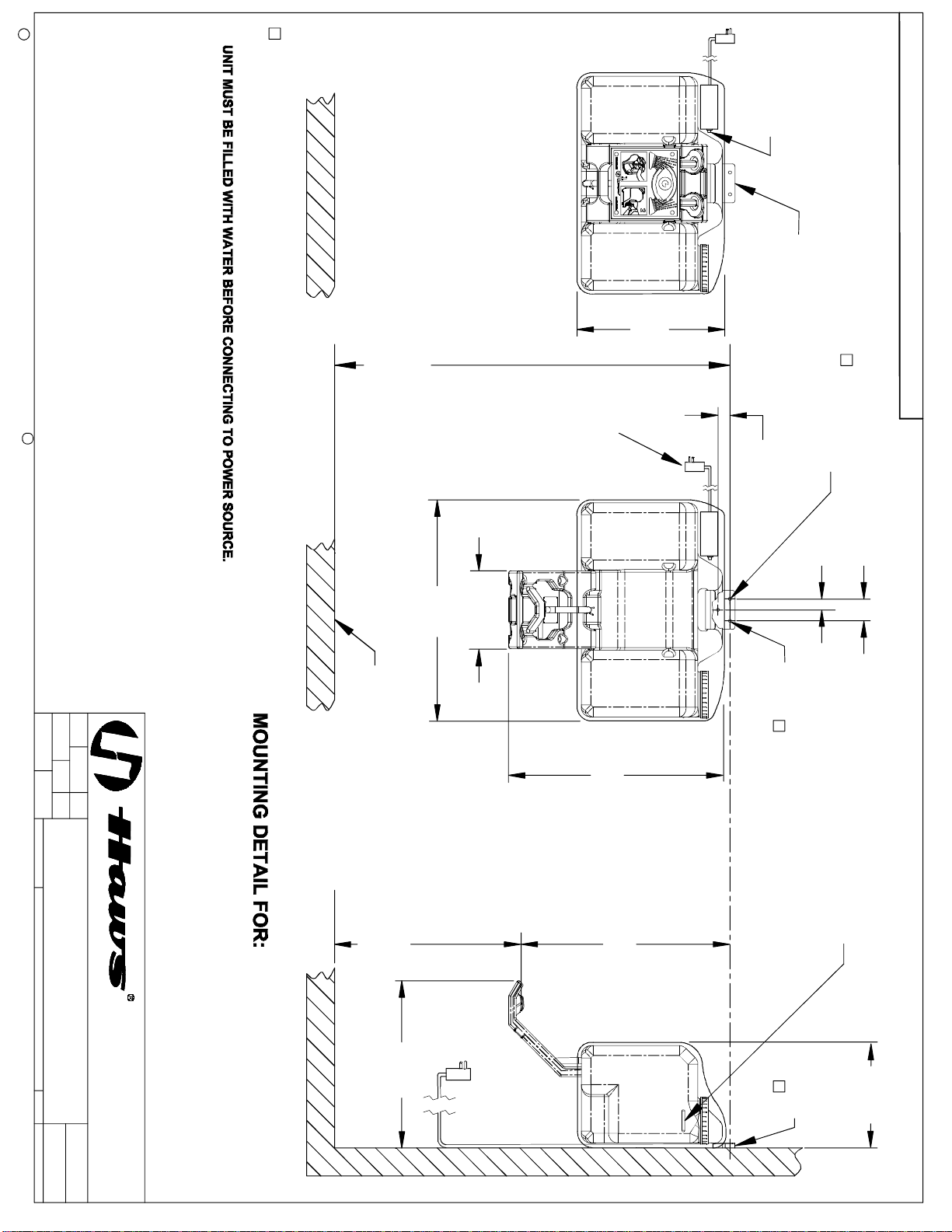

Page 8

C

Haws Corporation - All Rights Reserve d.

2016

HAWS and other trademarks used in these materials are the exclusive property of Haws Corporation.

PERSONNEL.

MAKE SP ECIFI C A TIONS AN D MEASUR EMENTS SU BJECT TO CHANGE WITHOU T NO T I CE.

10. LISTED ST RAIN RELIEF BUSHI NG SUITABLE FOR COR D SET SIZE AND OUTDOO R USE SHALL BE USED.

11. THE FIELD INSTALLED POW ER SUPPLY CORD SET NEEDS TO BE INSTA LLED BY QUALIFIED

8. THE FLEXIBLE CORD TYPE SHALL BE TYPE S, SE, SJ, SJE, SJO, SJOO, SJT, SJTO, SJTOO, SO , SOO, ST,

9. THE CORD SET SHALL BE MIN. 6 FT IN LENGTH AND MIN 18 AWG SI ZE FOR FLEXIBLE POW ER SUPPLY

STO, OR STOO AND HAVE A TYPE LETTER SUFFIX OF "W," "W-A" OR "OUTDOOR."

CORD.

GROUNDING TYPE ATTACHMENT PLUG RATED 24 0 V, MIN. 15 A.

7. CORD SET SHA LL BE LISTED TO UL 817 AND CSA-C22.2 NO. 21 AND PROVID ED W ITH 3 WIRE

(FOR MOD ELS 7501T240 & 7501BL2 40:)

5. * DIMENSIO NS MAY VARY ±1/2" [12.7mm].

6.

BRACKET AS SHOWN.

NOTES: (CONTI NUED FROM SHEET 1 OF 2)

4 LOCATE ONE 1/2" THICK SPACER (QTY. 3 SUPPLIED) BEHIND EACH HOLE IN THE MOUNTING

[1384mm TO 1689mm]

TO FINISHED FLOOR

OVER-TEMP

THERMOSTAT

POSITION

STAND BY

"OFF"

MOUNTING

BRACKET

(SUPPLIED)

54 1/2" TO 6 6 1/2"

* 15-3/4 "

[400mm]

3 3X 1/4" MOUNTING

HARDWARE

(NOT SUPPLIED)

POWER CORD

(120VAC , 60Hz,

200W)

7501T SUPPLIED

WITH GFCI 8'

THIS DOCUMENT IS TRUE AND CORRECT AT TIME OF PUBLICATION. CONTINUED PRODUCT IMPROVEMENTS

R

[203mm]

[610mm]

* 24"

* 8"

FLOOR

LINE

MODELS 7501T/7501TH/7501T240/75 01T240H -

WITH HEATED BLANKET (SHOWN)

[559mm]

POSITION

"ON"

ACTIVE

* 22"

FV

09/21/16

SCALE:

APPROVED:

MJ

06/30/16

DATE:

VWC

DRAWN:

5086

REVISED PER

ECN:

DATE:

5139

BY:ECN NO.

CHK'D.:

CC

MODEL(S)

MODEL 7501 (SEE SHEET 1 OF 2)

[32mm]

Ø [8mm]

1 1/4"

[57mm]

[29mm]

Ø 5/16" 3

3X

2 1/4"

1 1/8"

INSTRUCTIONS IN "OPERATION AND

DO NOT EXCEED WATER FILL

LINE. R EFER TO I NS TALL ATION

MAINTENANCE MANUAL" FOR

PROPER FILLING PROCEDURES.

7501/7501T/7501TH/7501T240/7501T240H

1:1

DRAWING TYPE: SIZE: A

PORTABLE EYEWASH

33" TO 53"

838mm TO 1346mm

TO FINISHED FLOOR

[546mm]

* 21-1/2"

INSTALLATION

0002080045.D

REVISION

PART NUMBER

SHEET OF

22

15

WEBSITE: WWW.HAWSCO.COM

(775) 359-47 12 FAX (775) 359-7424

E-MAIL: HAWS@HAWSCO.C OM

SPARKS, N EVADA 89431

1455 KLEPPE LANE

[457mm]

1/2" THICK

SPACERS

* 18"

PAGE

4

8 of 8

[318mm]

* 12-1/2"

Loading...

Loading...