Hawk Industries Spinner 550 HYDRAULIC 1, 205 User Manual

SPINMASTER

CATALOG, BROCHURE, AND TECHNICAL INFORMATION

FOR SPINMASTER 550 & 950 SERIES DRILL PIPE

SPINNERS

OPERATION, MAINTENANCE AND

SERVICE MANUAL

550 & 950 SERIES

11-18-03

HAWK INDUSTRIES, INC.

1245 East 23rd Street

Signal Hill, CA 90755

Phone: 562-424-0709

Fax: 562-490-9959

1

Introduction

Introduction

2

Introduction

The Spinmaster is a new generation drill pipe spinner from

that great tradition of its father the Spinnerhawk. The Spinmaster

has been engineered to give much more than its predecessor in

performance and reliability.

SAFETY

The Spinmaster provides a fast, safe and efficient method of

spin-up or spin-out, eliminating costly and dangerous accidents

associated with the use of spinning chains.The Spinmaster’s

unique chain gripping system transmits more torque without

slipping than any competitive spinner, regardless of pipe size.

TIME AND LABOR SAVINGS

Designed to work on the tube rather than the tool joint, the

position of the Spinmaster provides clearance to place the backup tong while spinning, thus saving rig time. The Spinmaster is

the lightest and smallest drill pipe spinner on the market today.

This makes the Spinmaster easier to work with and helps reduce

crew fatigue. Drillers and operators of the Spinmaster work more

efficiently and suffer less fatigue on long round trips; less work

and faster trips. Relatively inexperienced personnel can be

utilized for a faster trip with the Spinmaster and can work more

efficiently than would be possible using a spinning chain.

Introduction

3

Table of Contents

Introduction 2

Table of Contents 4

Warranty 7

Specification Sheet 8

Ordering Instructions 9

Installation 10

Suspension.....................................................................................10

Power Hook-Up............................................................................. 11

Hydraulic Spinmaster........................................................ 11

Air Spinmaster................................................................... 11

Hydraulic Adjustments...................................................... 12

Operation 14

Operational Adjustments.............................................................14

Adjust Pipe Size................................................................. 14

Reversing Motor Direction................................................ 16

Hydraulic Spinmaster............................................. 16

Air Spinmaster....................................................... 16

Operation.......................................................................................17

Maintenance & Repair 19

Lubrication....................................................................................19

Chain.................................................................................. 19

Drive Roller Sprocket Bearings......................................... 20

Spinner Grip Cylinders...................................................... 21

Drive Shaft Bearing........................................................... 21

Reducer Gear Box.............................................................. 22

Air Motor Gear Box........................................................... 22

Changing the Spinner Chain........................................................23

Changing the Drive Rollers..........................................................25

Changing the Drive Roller Sprocket Bearings............................27

Changing Rear Pivot Assembly.................................................... 29

Adjust Door Valve Detents............................................................30

Hydraulic Spinmaster......................................................... 30

Air Spinmaster.................................................................... 30

Air Power Pack Maintenance.......................................................31

Filling Air Lubricator......................................................... 31

Air Lubricator Adjustment................................................. 32

Air Lubricator Maintenance............................................... 32

Changing Air Filter Element.............................................. 33

Air Filter Maintenance....................................................... 33

Table of Contents

4

Continued on next page.

Table of Contents (cont.)

Air Power Pack Maintenance (Continued)

Adjusting Grip Pressure............................................... 34

Air Regulator Maintenance................................................ 34

Hydraulic Oil Level............................................................ 35

Changing Oil Filter Cartridge............................................ 35

Changing Suction Strainer................................................. 36

Repair Power Train........................................................... 37

Install Coupler Halves........................................................ 38

Trouble Shooting 39

Trouble Shooting Hydraulic Spinmaster.....................................39

Actuate Any Valve and Nothing Happens......................... 39

Actuate the Motor Valve and Nothing Happens................ 39

Actuate the Door Valve and the Lever

Does'nt Stay Shifted........................................................... 39

Spinner Torque is Insufficient to Turn Pipe....................... 39

Spinner Slips...................................................................... 40

Spinner Thrusts Off the Pipe While Spinning .................. 41

Chain Wears Prematurely.................................................. 41

Main Relief Makes Noise and Hyd Fluid Heats Up.......... 41

Spinner Runs Slower Than Normal................................... 42

All Other Rig Hydraulics Stop Working........................... 43

Trouble Shooting Air Spinmaster................................................ 44

Actuate Any Valve and Nothing Happens........................ 44

Actuate the Door Valve and Nothing Happens................. 44

Spinner Torque and Speed Insufficient............................. 45

Spinner Slips...................................................................... 46

Chain Wears Prematurely.................................................. 46

Spinner Thrusts Off the Pipe While Spinning................... 46

Spinner Chain Creeps When Spinner is Off...................... 47

Spinner Performance in Cold Wheather............................ 47

Drawings 48

550 Air Spinmaster ...................................................................... 48

550 Hydraulic Spinmaster ........................................................... 50

950 Air Spinmaster ...................................................................... 52

950 Hydraulic Spinmaster ........................................................... 54

Speed Reducer P/N 031-24625 ....................................................56

Hydraulic Motor P/N 031-*ME09 ..............................................58

Power Pack Air Motor P/N 031-P-16 ..........................................60

Table of Contents

5

Table of Contents (cont.)

Drawings (Continued)

Gear Pump (Power Pack) P/N 031-P05.......................................62

Power Pack Assembly (Air) P/N 031-550PP............................... 64

Air Drive Assembly P/N 031-24660............................................. 66

Throttle Valve Assembly (Air) P/N 031-13170............................ 68

MainValve Assembly (Hydraulic) P/N 031-*24VALVE............. 70

DoorValve Assembly (Air) P/N 031-*24VALVE-A..................... 72

Hoses (Air Spinmaster)................................................................ 74

Hoses (Hydraulic Spinmaster)..................................................... 75

Power Pack Hoses (Air Spinmaster)........................................... 76

Table of Contents

6

Warranty

STANDARD WARRANTY AND FIELD SERVICE

It is important to Hawk Industries to provide all Spinmaster users with the best tool possible along

with the highest degree of dependability and satisfaction. Because of this, we offer the following

warranty.

Your Spinmaster must be free of material and workmanship defects for a period of one year from

the date of delivery. If any items fail because of a manufacturing defect within that period of time,

that item will be replaced by the Hawk Company.

Replacement of parts will be accomplished either at the factory or at a designated service point.

This guarantee does not include the replacement of parts where failure occurred due to normal wear

and tear or misuse of the tool.

Hawk Industries will in no event be liable for consequential damages or contingent liabilities

arising out of the failure of any parts to operate properly.

No expressed, implied or statutory guarantee other than herein set forth is made or authorized to

be made by Hawk Industries.

CAUTION

Factory specifications for hydraulics, pneumatics, lubricants, adjustments and safety precautions

as set forth in the operation and maintenance manual are for the mutual protection of the owner of

the Spinmaster and the company. Failure to adhere to these specifications can reduce the efficiency

or life of the equipment and/or cause bodily injury.

Warranty

7

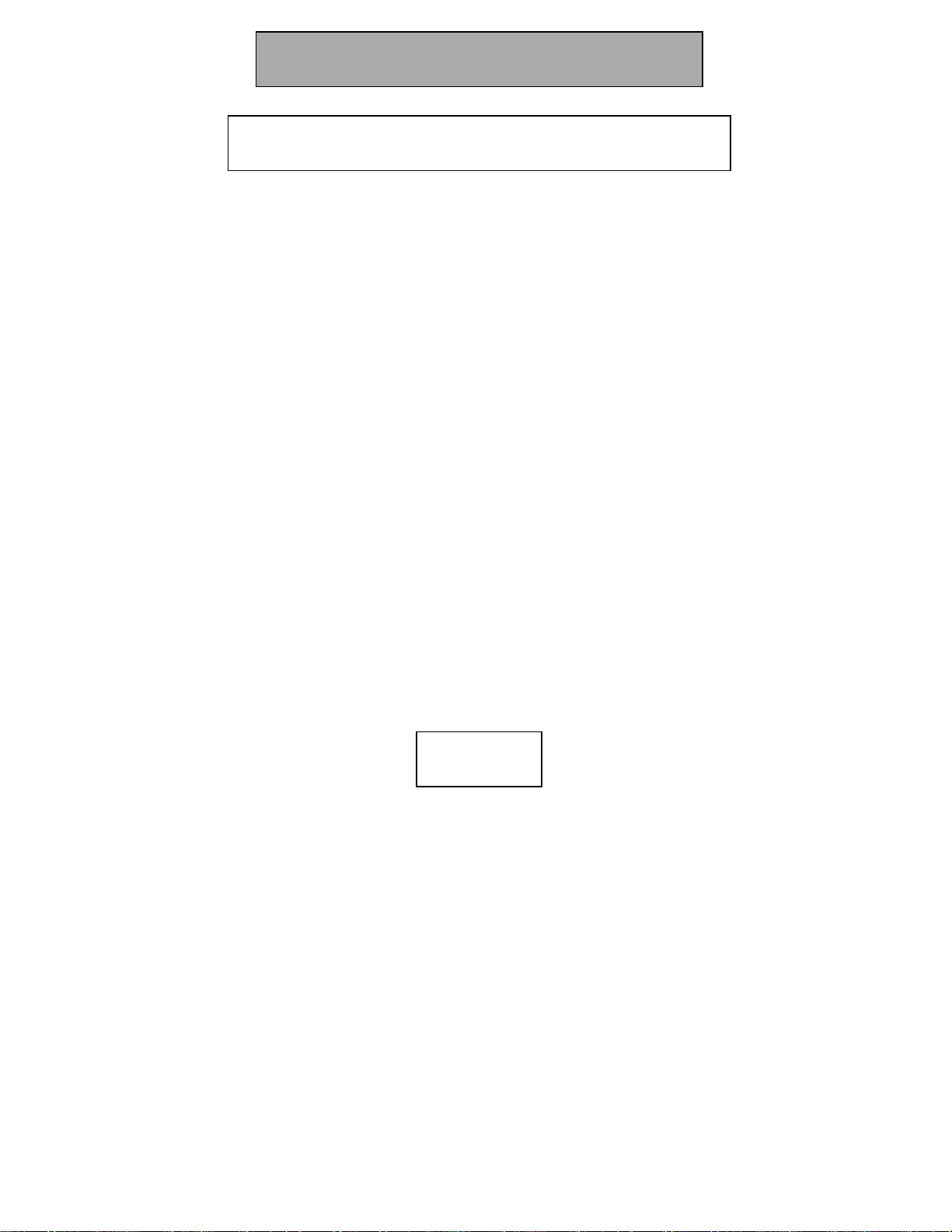

Specification Sheet

8

Specification Sheet

Ordering Instructions

Example

Quantity

2 031-24731 254 550-H Bearing

3 031-25CYL25-AS 254 550-H Grip Cylinder

1 031-25CHAIN 254 550-H Chain

Part # Serial #

Model #

Part Name

Ordering

9

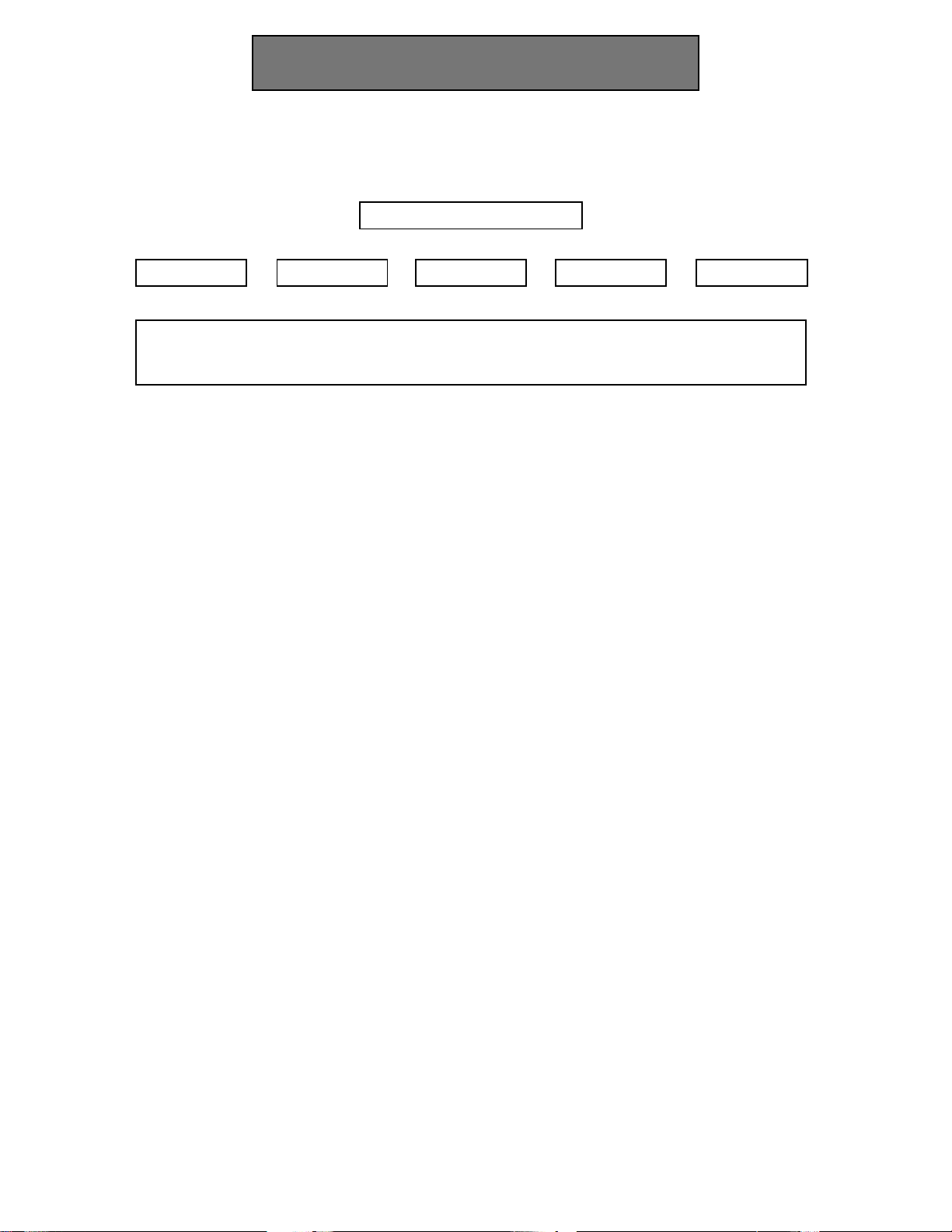

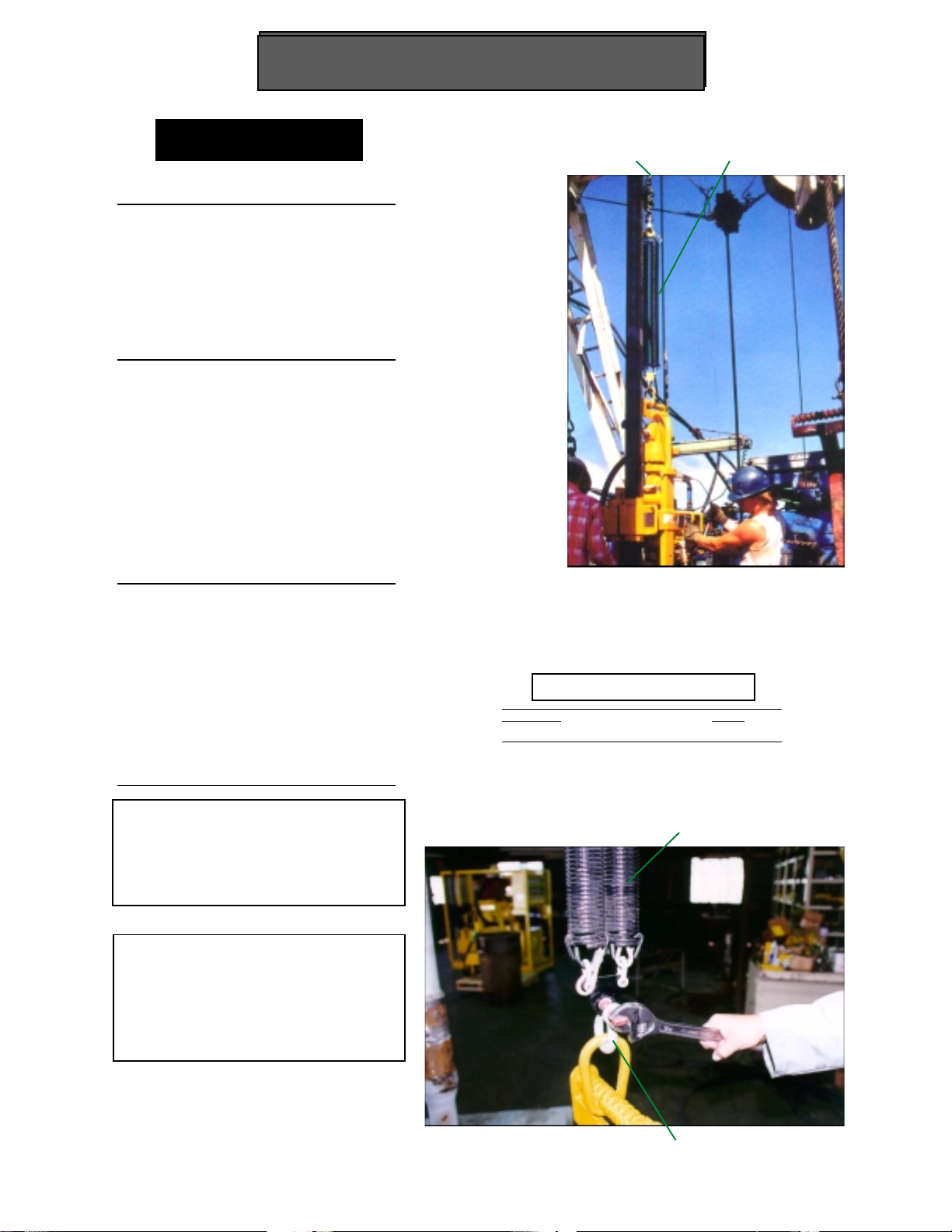

Suspension

1. Connect the Spring Hanger

(SH) to at least a 3/8"diameter

Steel Cable (SC) suspended

from a high point (as near the

crown as possible) in the derrick

no more than 5 ft. from the

center of the Rotary Table.

2. Connect the lower end of the

spring hanger (SH) to the

Spinmaster as shown. Make

sure the shackles (S) are tightened securely. Make sure that

the Spinmaster hangs in the

derrick at a level that assures no

contact with any part of the

stabbed tool joint (including the

upset) when gripped on tube.

3. Hook a backup line to the rear

of the Spinmaster securing the

other end to the derrick. Make

sure the backup line is horizon-

tal and leaves little slack when

the Spinmaster is gripped on the

pipe so that no kick-back can

occur when changing spinner

motor directions.

Installation

SC SH

Part Numbers

Part Name Part #

Spring Hanger Assy. (SH) 002-50274

Warning

Failure to properly hook up backup line could cause bodily injury.

Caution

Hooking up the back-up line on an

angle not level with the spinner can

cause damage to the spinner case.

10

Installation

SH

S

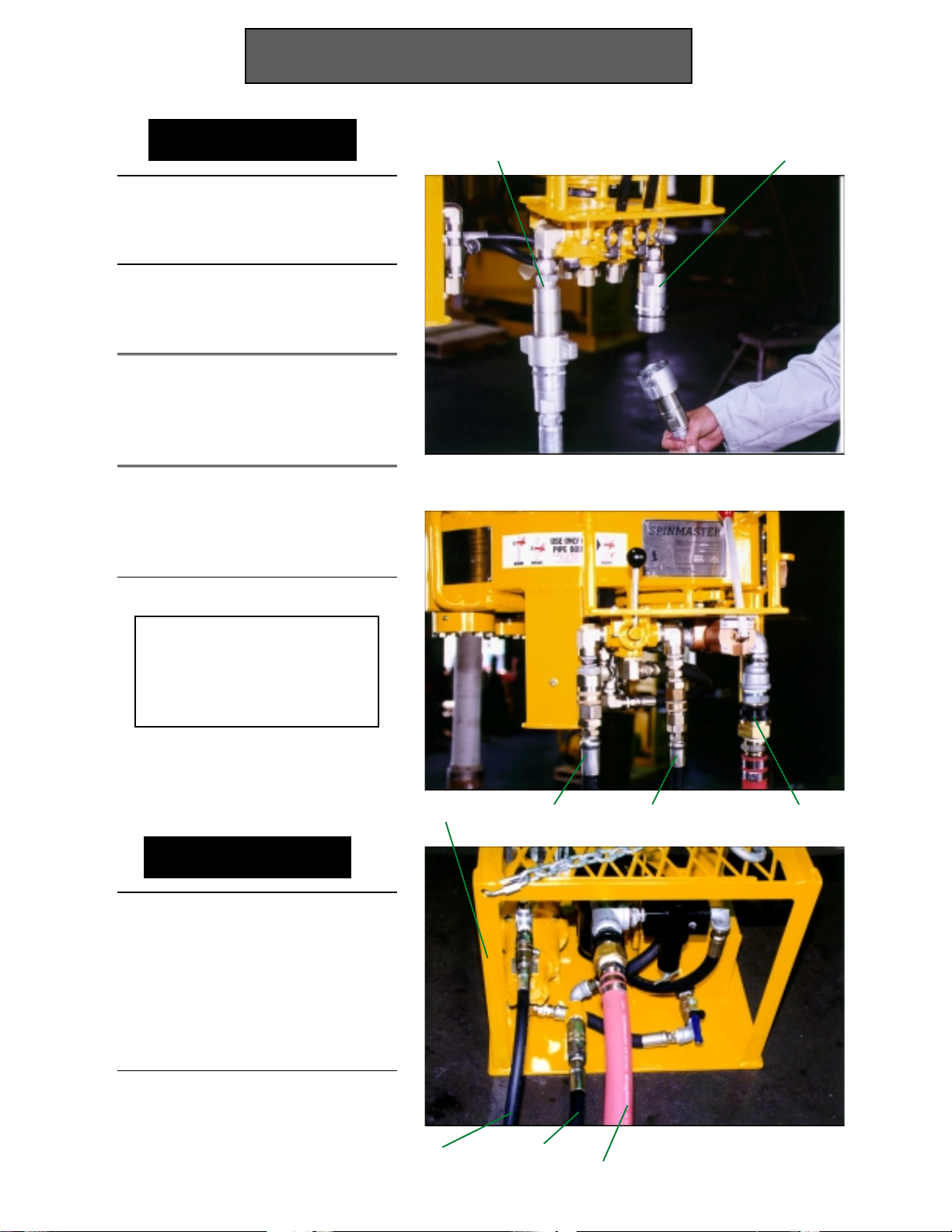

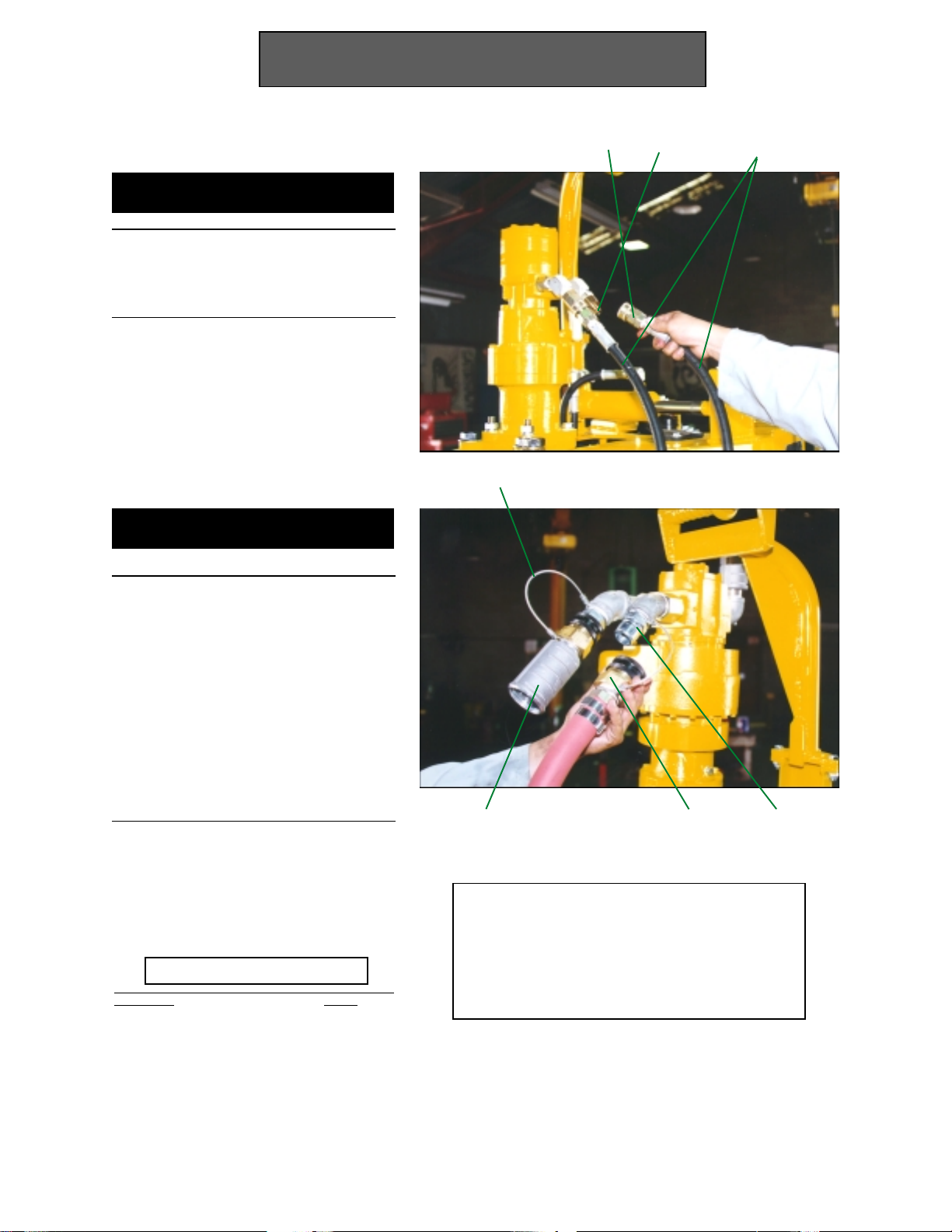

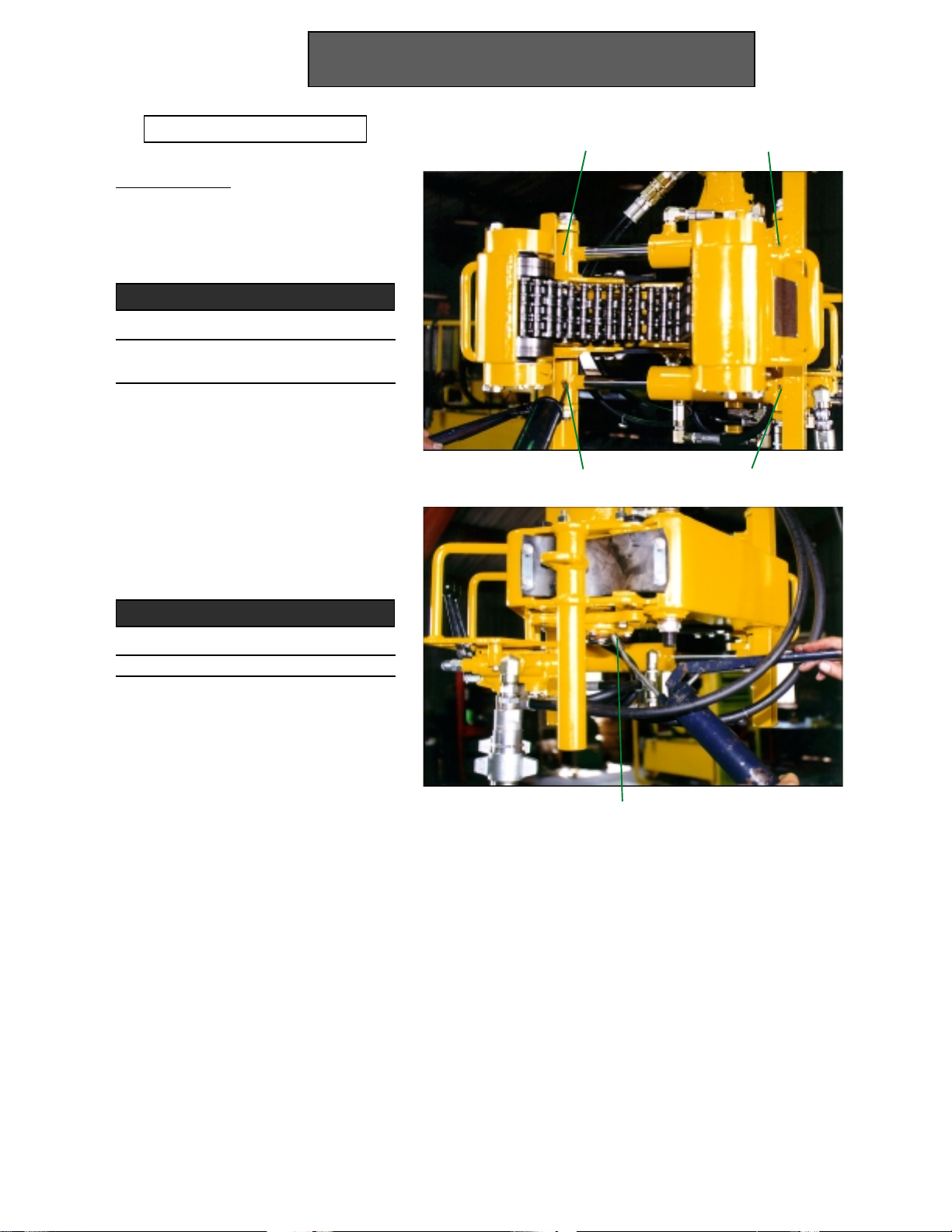

Hydraulic Spinmaster

1. The hydraulic Spinmaster

requires a minimum hydraulic

pressure of 2000psi and a maxi-

mum pressure of 2500psi.

2. The hydraulic Spinmaster re-

quires a minimum hydraulic

volume of 20 GPM and a maximum of volume of 30GPM.

3. Connect (at least) a 3/4" hy-

draulic pressure hose (3000psi

working) to the hydraulic inlet

side ( HIS ) of the Spinmaster

valve as shown.

4. Connect (at least) a 1" hydrau-

lic return hose (250psi working)

to the hydraulic outlet side(HOS)

of the Spinmaster valve as

shown.

Power Hook-Up

HOS

HIS

Note

Hydraulic filtration (at least 25

micron) is highly recommended

for Spinmaster for performance

and reliablity.

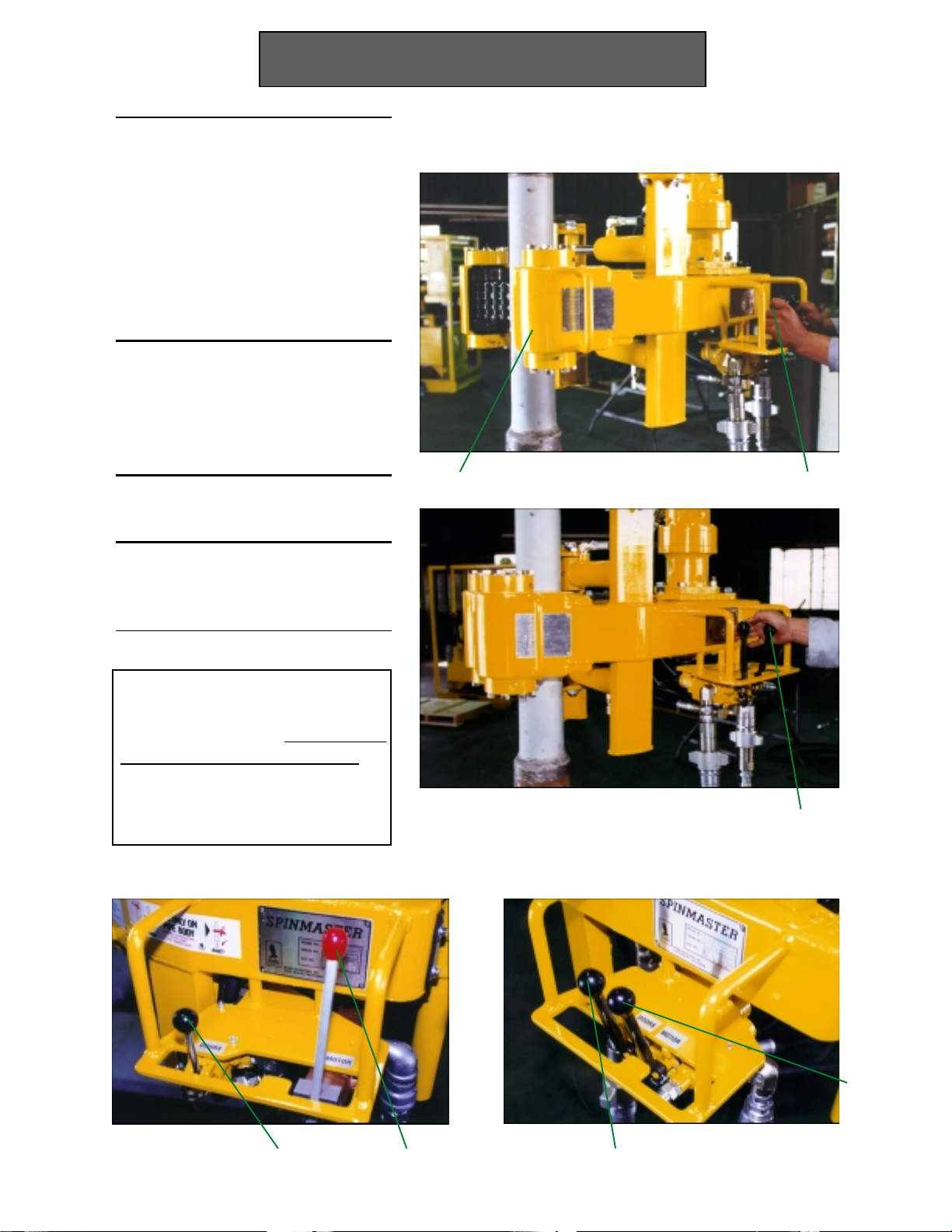

Air Spinmaster

1. Connect the three supply hoses

(supplied with the Spinmaster):

the Hydraulic Return Line

(HRL), the Hydraulic Pressure

Line (HPL), and the Air Supply

Line (ASL) to the Spinmaster

and the Air Power Pack (APP)

as shown.

APP

HPL

ASLHRL

Continued on Next Page

HPL

HRL

ASL

Installation

11

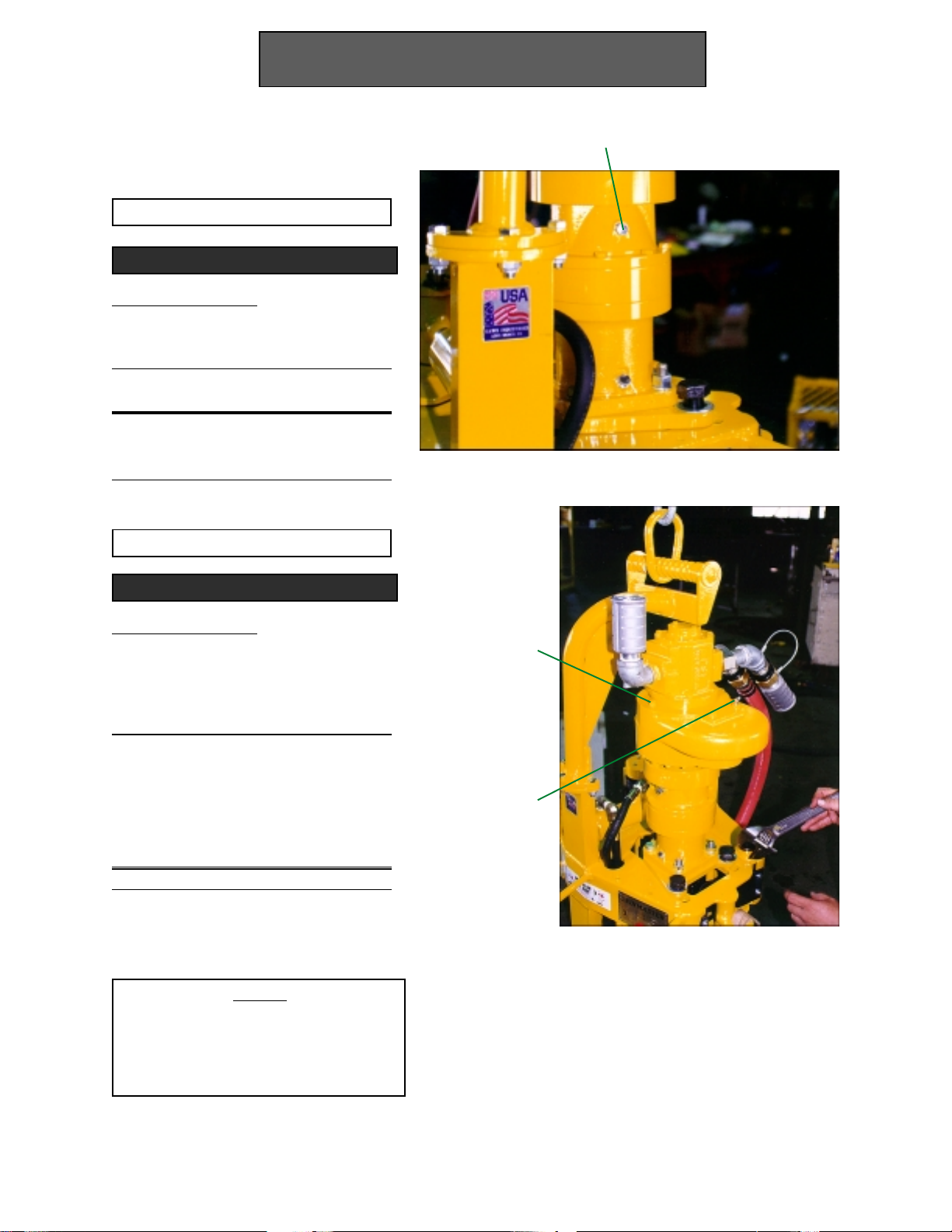

Power Hook-Up, Con't

2. Connect a 1 1/4" air supply line

(ASL) from the air source to the

Air Power Pack (APP) as shown.

3. To turn on air, rotate Air Supply

Valve (ASV) counterclockwise

as shown.

WARNING

It is recommended that a air

regulator from the source air to the

power pack be used (1 1/4"Pipe or

larger). Excess chain and drive

roller wear do to slipping may

result if the Spinmaster air power

pack receives more than 100 psi air

pressure.

Hydraulic Adjustments

APP

ASV

ASL

1. Always adjust the Spinmaster

relief valve (RV) above main

system hydraulic pressure or

over heating of oil may result.

To adjust the relief valve, grip

the Hydraulic Spinmaster on

the pipe (see item #1 on page

#17). Use a 4mm Allen wrench

to screw the Spinmaster Relief

Valve (RV) counter-clockwise

until a hydraulic flow sound is

heard, then rotate clockwise

until sound (flow) stops.

2. The hydraulic Spinmaster

comes standard with an open

center valve configuration. The

standard valve can be re-config-

ured to closed center by removing the Open Center Plug

shown (PS) and replacing it

with a Closed Center Plug

(CCP).

RV

Part Numbers

Part Name Part #

Closed Center Plug (CCP) 031-24VALVE-1

Open Center Plug (PS) 031-24VALVE-4

12

Installation

CCP

PS

Notes

Installation

13

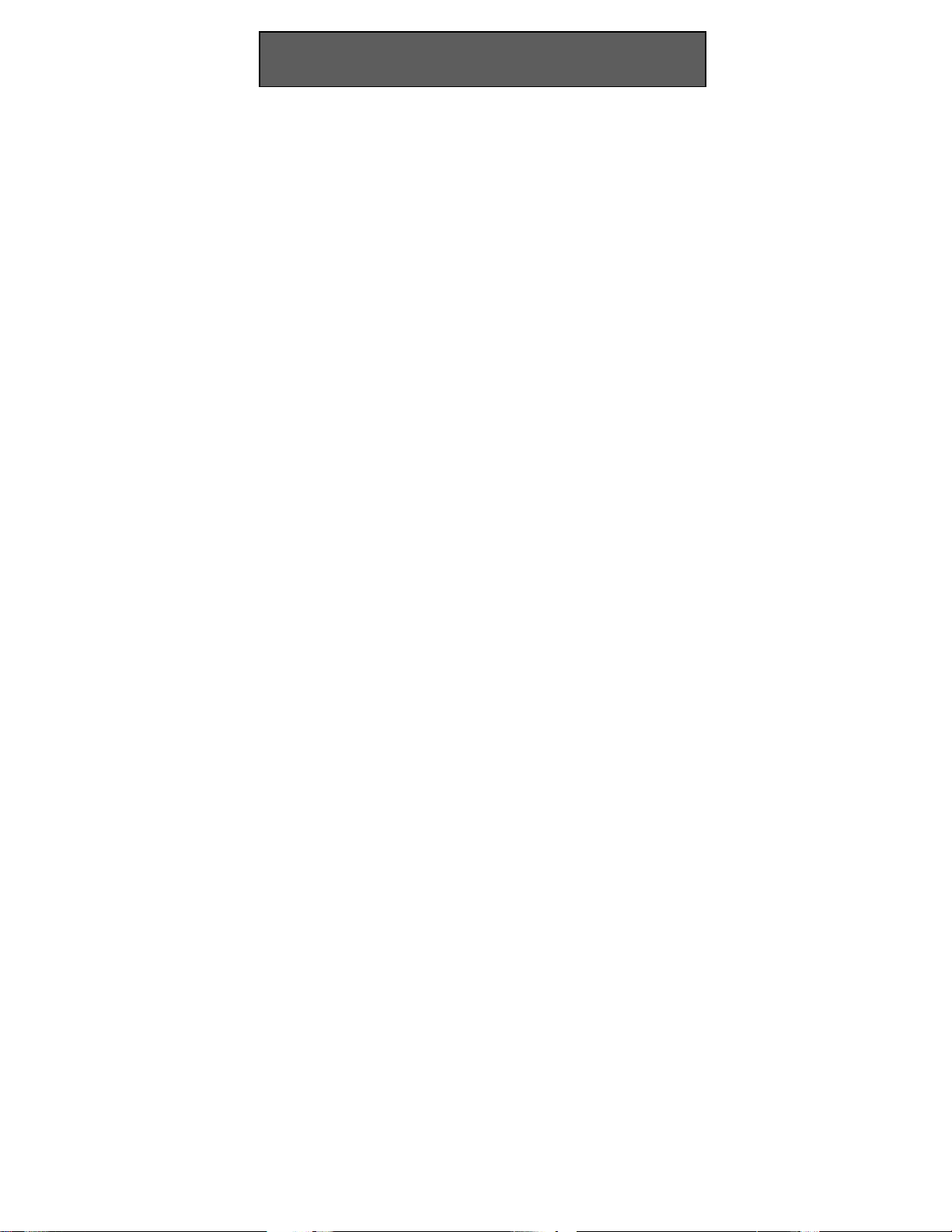

Operational Adjustment

14

Operation

Operational Adjustment

Adjust Pipe Size

1. Remove both Adjust Pins (AB)

2. Slide Drive System (DS) forward

or back to allign with the desired

pipe size adjustment holes. See

prior page(diagram) or this page

(photos) for correct adjustment

location.

3. Replace Adjust Pins (AB). New

Quick Release Pins look different

than shown on photo.

AB

Note

If the drive rollers are touching each

other while gripped on pipe, slipping may occur. This is caused by

chain stretch (pin wear). To remedy

this problem, adjust the Spinmaster

to the next smallest setting. If this

smaller setting causes the

Spinmaster to thrust itself from the

pipe while spinning, replace the

chain. See Changing the Chain

pg.23.

950 Spinmaster 550 Spinmaster

DS

9 1/2"

8" 7" 6" 5" 4 1/2"-5" 3 1/2"-4" 2 7/8" 4 1/2"-5 1/2" 3 1/2"-4"

Operation

2 7/8"

15

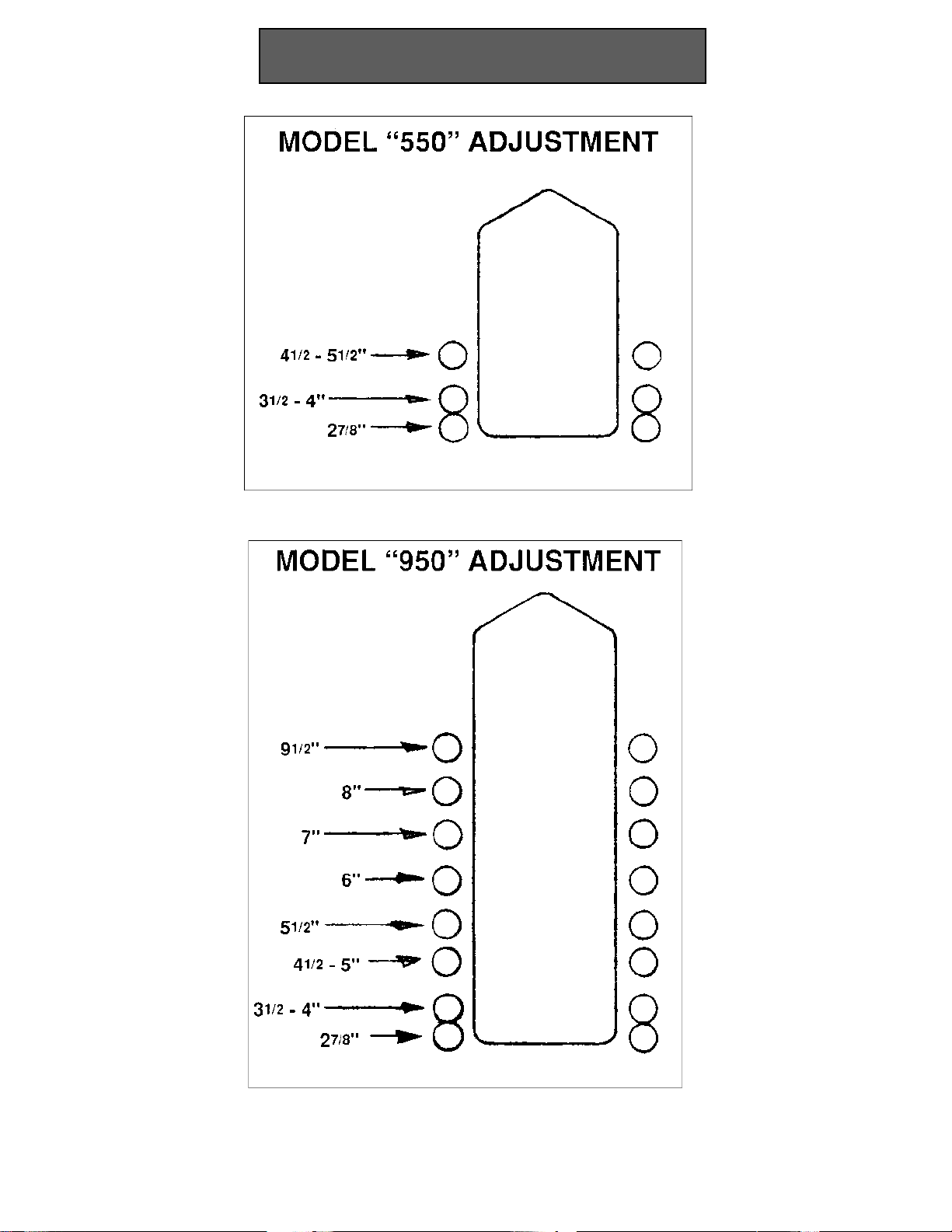

Operational Adjustments

Reverse Hydraulic Spimaster

1. To reverse Hydraulic Spinmaster

motor direction, switch motor

supply (HMSH) hoses on motor

ports as shown.

Reverse Air Spinmaster

1. To reverse Air Spinmaster motor

direction, switch motor supply

hose (AFQD) and muffler

(MUF) on motor ports as shown.

The air quick disconnect will

release only when the slott on its

slidding sleeve alligns with the

partially submerged ball. After

engaging quick disconnect, lock

the sleeve by rotating the sleeve

out of allignment with the ball.

MUF

SC

HFQD HMQD

AFQD

HMSH

AMQD

Part Numbers

Part Name Part #

Quick Disc. (HFQD) 031-VHC8-8F

Quick Disc. (HMQD) 031-VHN8-8F

Quick Disc. (AFQD) 002-10S41SL

Quick Disc. (AMQD) 002-10T40

Air Muffler (MUF) 031-MUF-1

Safety Cable (SC) 002-50201-235

Operation

16

Warning

For safety, always lock air quick disconnects

when reversing motor direction.

1. Swing Spinmaster toward pipe

until its chain is touching the

pipe tube. While continuing to

load Spinmaster (SM) against

the pipe, push door valve (DV)

handle away from you, fully

toward the Spinmaster (Detented

Position). The doors will close

and the Spinmaster will grip the

pipe.

2. To spinning is complete, pull

out on the Air Motor Valve

Lever (PMV), or push in on the

Hydraulic Motor Valve Lever

(HMV) depending on which unit

you are operating.

3. After the pipe shoulders,

release the motor valve and the

Spinmaster will stop.

4. To remove the Spinmaster from

the pipe, pull back on the Door

Valve Lever (DV) and pull the

Spinmaster away from the pipe.

Operation

SM

DV

Warning

When gripping the Spinmaster on

the drill pipe, always keep pushing

the Spinmaster toward the pipe

while doors are closing or damage

may result to the front of the

Spinmaster.

AIR SPINNER CONTROLS

HMV

HYDRAULIC SPINNER CONTROLS

HMV

DV

PMV

DV

Operation

17

Warning

Do not operate the Spinmaster on

drill pipe protectors or drill pipe

upset, or damage may result. See

the correct way sticker on the side

of the Spinmaster.

Warning

Never operate the Spinmaster off

the pipe.

Operation

18

Operation

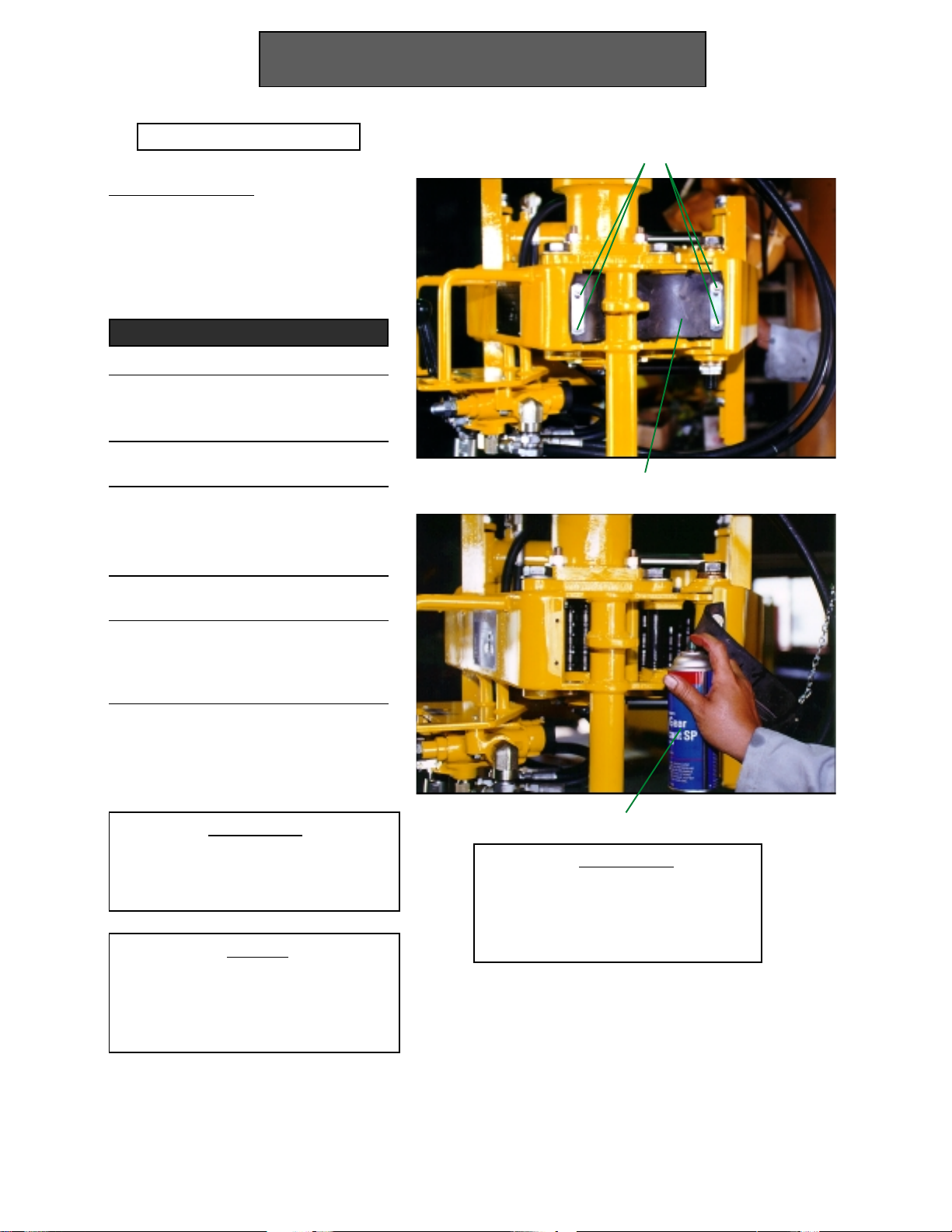

Grease Once per Week

Lubricant Required

Chevron Pinion Grease Spray

(Part # MS-SP), 7/16" wrench

Chain

1. Use the 7/16" wrench to remove

the rubber Safety shield bolts

(B).

2. Remove rubber Safety shield

(S).

3. While spinning out of the hole,

from the back of the spinner,

apply Pinion Grease Spray

(PGS) to all links of the chain.

4. Replace rubber Safety shield

(S).

5. Use the 7/16" wrench to replace

Lubrication

B

S

the rubber Safety shield bolts

(B).

WARNING

Run spinner only when gripped on

a pipe body.

NOTE

Never under any conditions apply

weight materials or any other dry

materials to the chain.

PGS

WARNING

Keep hands away from the main

drive sprocket while spraying the

chain.

Maintenance & Repair

19

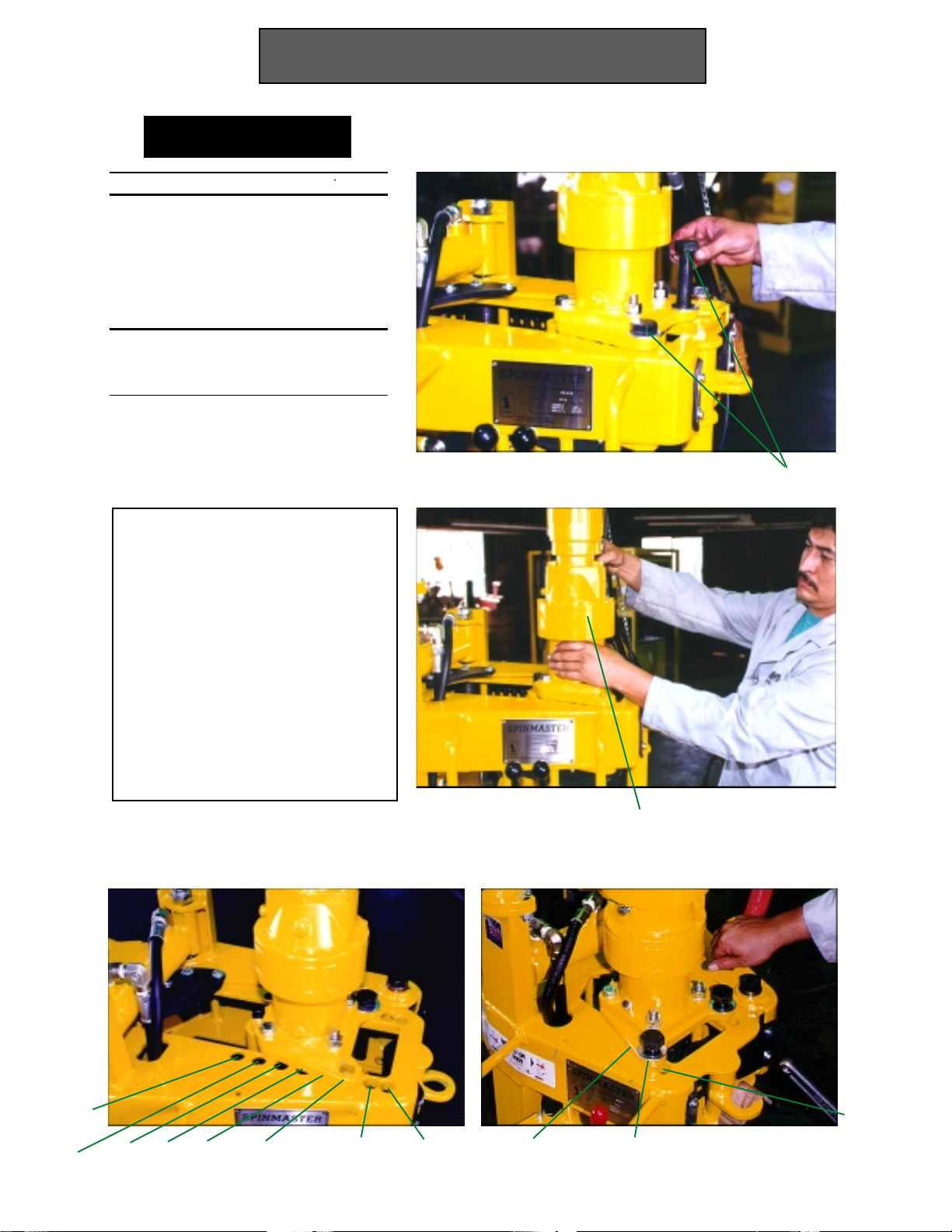

Grease Once per Month

Lubrication

Tools Required

Grease gun, 7/16" wrench

Initial Steps

1. Make sure the Spinmaster is off

the drill pipe connection and in

the rest position on the derrick.

2. Shut down the power unit.

3. Bleed any hydraulic and/or air

pressure from the Spinmaster,

by cycling the door valve lever.

4. Assume that there is still a load

on every actuator. Proceed with

caution.

G1

G2

BC

G3

G4

S

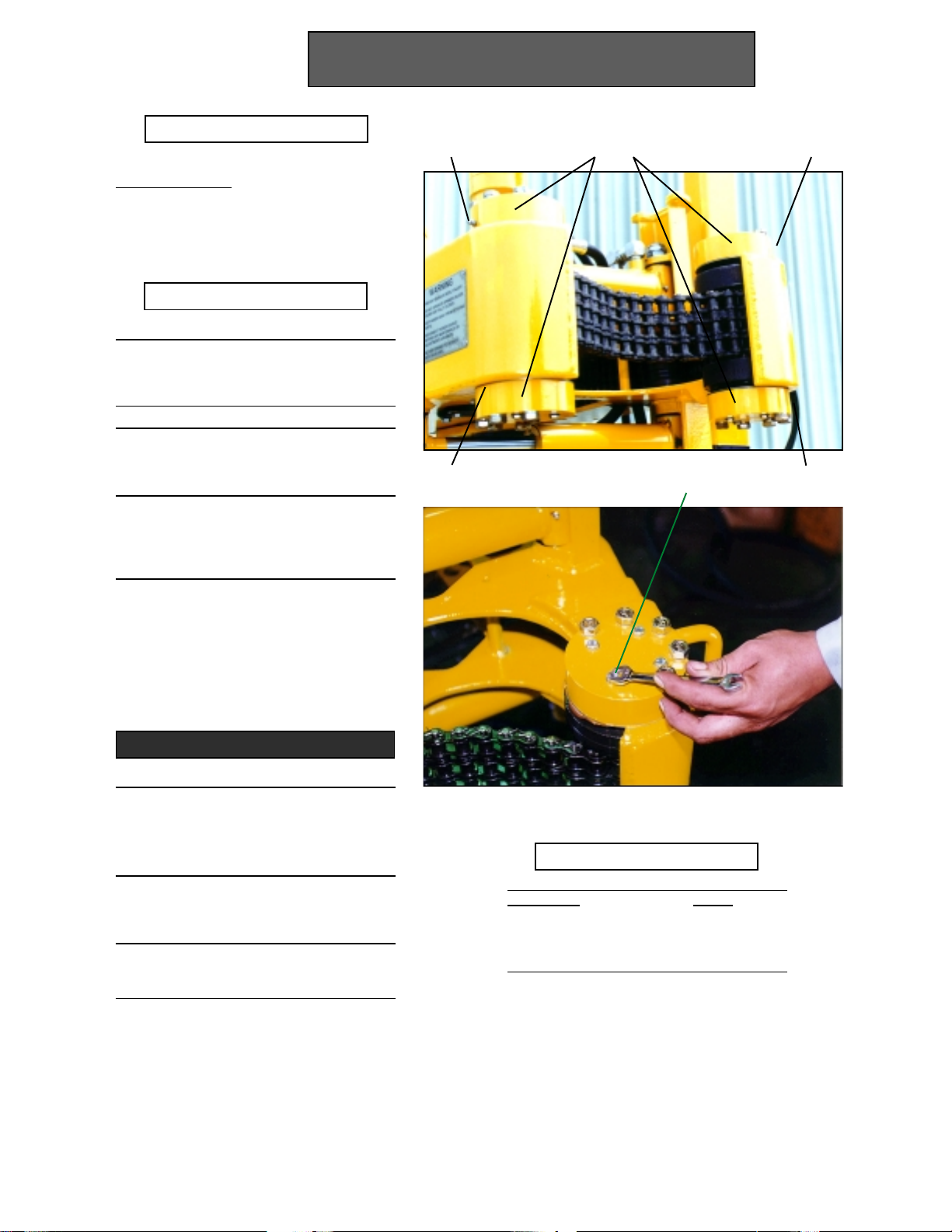

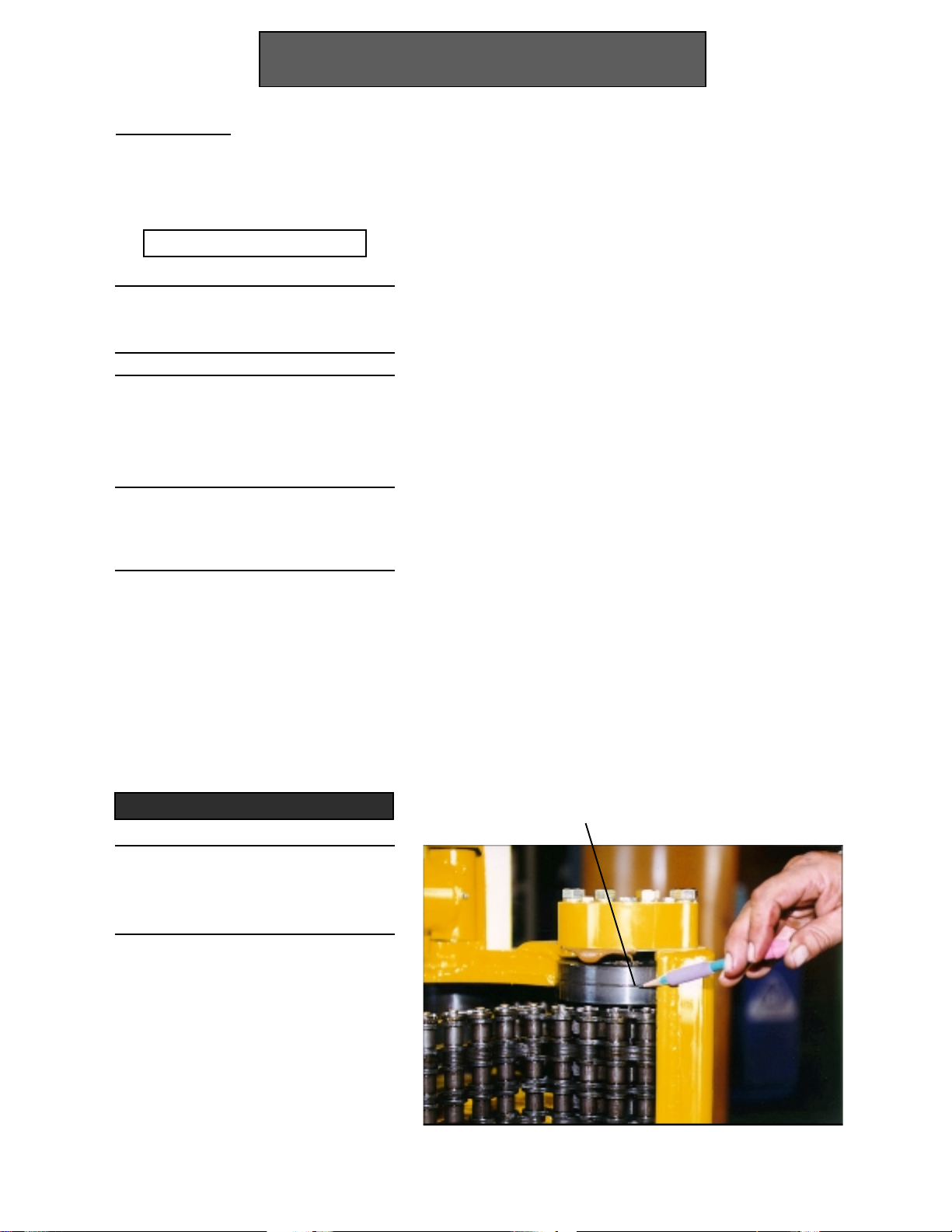

Drive Roller Sprocket Bearings

1. Use the 7/16" wrench to remove

one of the four small screws (S)

from the top of each bearing

cap (BC).

2. Pump the four grease fittings

G1-G4 until grease comes out of

the small screw hole.

3. Use the 7/16" wrench to replace

the small screw (S).

20

Maintenance & Repair

Part Numbers

Part Name Part #

Bearing Cap Screw (S) 999-805834

Straight Grease Fitting 061-1103K1

Grease Once per Month

Tools Required

Grease gun

Spinner Grip Cylinders

1. Pump the four grease fittings

SC1-SC4.

Lubrication

SC2SC1

SC3 SC4

Drive Shaft Bearing

1. Pump grease fitting CB1.

CB1

Maintenance & Repair

21

Check Oil Level Once per Month

Reducer Gear Box

Lubricant Required

85-90 weight gear oil

SAE #AGMA5

1. Make sure the gear box oil level

reaches the top pipe plug (RP).

2. Check for any oil leakage from

the gear box seal by looking at

the top or the drive shaft.

Lubrication

RP

Grease after overhaul

Air Motor Gear Box

Lubricant Required

Lithium Base #2 High Temperature

Grease. Use Lo-Temp Grease in

temperatures -20 deg. F or below.

1.Remove motor grease vent plug

(MGV). Use a grease gun to fill

the air motor gear box at the

motor grease fitting (MGF) until

grease begins to flow from the

vent (MGV).

2. Replace the vent plug (MGV).

MGV

MGF

NOTE

Consistent lubrication of the Spinner

increases performance and

componnent life.

Maintenance & Repair

22

Tools Required

Changing the Spinner Chain

7/8" wrench, 7/16" wrench, Hammer,

Needle-Nose Pliers

Initial Steps

1. Make sure the Spinmaster is off

the drill pipe connection and in

the rest position on the derrick.

2. Shut down the Air Power Pack

or the hydraulic power unit.

3. Bleed any hydraulic and/or air

pressure from the Spinmaster ,

by cycling the door valve lever;

Make sure the doors are fully

open.

4. Assume that there is still a load

on every actuator. Proceed with

caution.

SD

SB

Chain

1. Make sure the Spinner doors

(SD) are fully open.

2. Use the 7/8" wrench to loosen

the Spacer Bolts (B).

3. Use the 7/16" wrench to remove

the four rubber Safety shield

bolts (SB).

4. Remove the rubber Safety shield

(SS).

5. Remove the Spacer Bolts (B)

and Spacers (S).

Continued on next page.

SB

Maintenance & Repair

SS

23

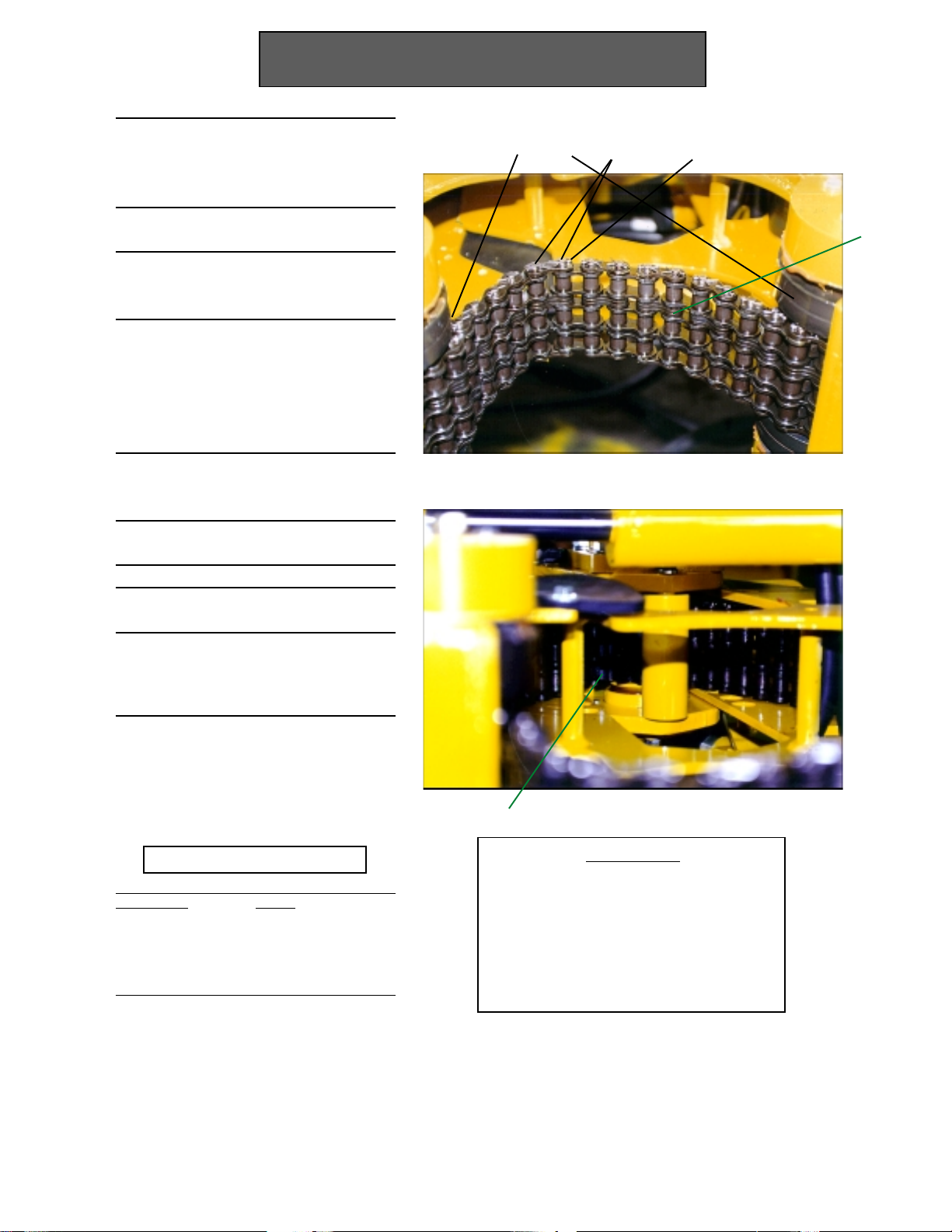

Changing the Spinner Chain (cont.)

6. From the front of the unit, use the

Needle-nose pliers to remove the

Cotter pins (CP) in one of the

Chain links.

7. Use the hammer to remove the

Chain link pins (CLP).

8. Pull out the old chain. Make

sure the chain does not catch on

the Drive Sprocket (DS).

9. Feed the new chain into the

spinner behind the Drive

Sprocket (DS), tripple link up

until both ends of the new chain

meet at the Drive roller sprockets

(DRS).

10. Feed the ends of the chain

around the outside of the Drive

roller sprockets (DRS).

11. Place the ends of the new chain

together.

12. Insert the Master Link.

13. Place the End Cap on the

Master Link.

14. Use the Needle-nose pliers to

CLPDRS

CP

Tripple

Link

Up

insert the Master Link Cotter

Pins.

Part Numbers

Part Name Part #

Chain (950 Series) 031-25CHAIN

Chain (550 Series) 031-24CHAIN

Chain Repair Kit 031-25CHAIN-RK

DS

WARNING

Running a new chain with worn

Drive Rollers severely shortens

chain life. If the Drive Roller

Groove is no longer visible, replace

the Drive Roller.

24

Maintenance & Repair

Changing the Drive Rollers

Tools Required

3/4" wrench

Initial Steps

1. Make sure the Spinmaster is off

the drill pipe connection and in

the rest position on the derrick.

2. Shut down the power unit.

3. Bleed any hydraulic and/or air

pressure from the Spinmaster,

by cycling the door valve lever.

Make sure the doors are fully

open.

4. Assume that there is still a load

on every actuator. Proceed with

caution.

Changing Drive Roller

1. When the Drive Roller Groove

(DRG) is worn down so that it is

no longer visible, the Drive

Rollers need to be replaced.

DRG

Continued on next page.

Maintenance & Repair

25

Loading...

Loading...