Page 1

R

INSTRUCTIONS

ADJUSTABLE PORT VALVES

These instructions are intended for use only by experienced, qualified combustion start-up

personnel.

Adjustment of this equipment and its component s, by unqualified personnel, can r esult in fire,

explosion, severe personal injury, or even death.

Table Of Contents

Subject

A. General Information ……………………………………………………….…..….……. 2

B. Receiving and Inspection ………………………………………….…….…...…….….. 2

C. Capacities ………….……………………………………………………………………. 3

D. Dimensions …………….………………………………………………………………... 4

E. Installation ………….……………………………………………………………….…… 5

F. Operation…………………………………………………………………………………. 6

G. Maintenance …………………………………………………………………..………… 7

Page

These instructions are int ended to serve as guidelines c overing the ins tallat ion, operation, and mai ntenance of Hauc k equipment . W hile

every attempt has been m ade to ensure completeness, unforeseen or uns pecified applications, details, and variations may preclude

covering every possible conti ngency.

OPERATE ANY EQUIPMENT OR COMPONENT WITH ANY PARTS REMOVED OR ANY PARTS NOT APPROVED BY THE

MANUFACTURER.

sufficiently for t he purchaser's purpose, contac t Hauck Mfg. Co.

HAUCK MANUFACTURING CO.,

Fax: 717-273-9882

2/04

Should further information be required or desired or should particular problems arise which are not covered

WARNING: TO PREVENT THE POSSIBILITY OF SERIOUS BODILY INJURY, DO NOT USE O

P.O. Box 90 Lebanon, PA 17042-0090 717-272-3051

www.hauckburner.com

WARNING

APV-9

Page 2

Page 2

APV-9

This equipment is potentially dangerous with the possibilit y of serious personal injury

and property damage. Hauck Manufacturing Company recommends the use of flame

supervisory equipment and fuel safety shutoff valves. Furthermore, Hauck ur ges rigid

adherence to National Fire Protection Association (NFPA) st andar ds and insur ance

underwriter’s requirements. O per ation and regular preventative maintenance of this

equipment should be perform ed only by properly trained and qualified personnel.

Annual review and upgrading of safety equipment is recommended.

WARNING

A. GENERAL INFORMATION

The Hauck Adjustable Air and Gas Port Valves are a dependable, accurate means of controlling

the flow of air or gas to any variable pressure type of burner or system. Flow control may be

either manual or automatic. T hese valves are easily adjustable and designed to hold the desired

setting in either mode of operation. Each side of the valve is equipped with four drilled and

tapped mounting pads. This facilitates the installation of multiple valve units or an automatic

control system. These units are designed t o be used as efficient control systems, not as shutoff

valves.

B. RECEIVING AND INSPECTION

Upon receipt, check each item on the bill of lading and/or invoice to determine that all

equipment has been r eceived. A caref ul examination of all parts should be made to ascer tain if

there has been any damage in shipment.

If the installation is delayed and the equipment is

stored outside, provide adequate protection as

dictated by climate and period of exposure. Special

care should be given to all motors and bearings, if

applicable, to protect them f r om rain or excessive

moisture.

IMPORTANT

Page 3

Page 3

APV-9

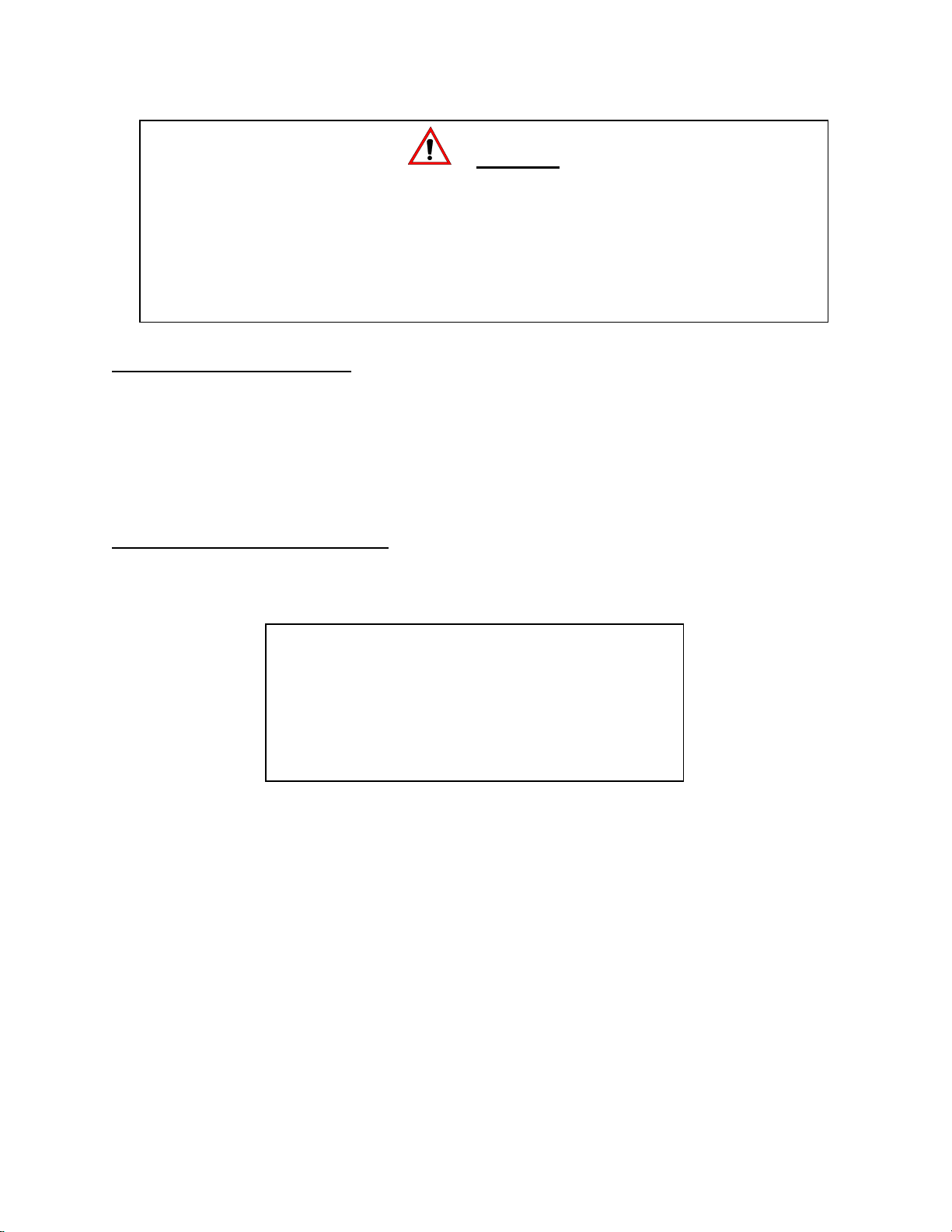

C. CAPACITIES

NATURAL GAS AIR

NOTES:

1. Capacities based on gas @ 0.60 s.g., air @ 1.0 s.g., and

68°F temperature.

2. Static pressure drop measured across full open val ve, i .e.,

pointer at position 10 and adjust i ng screw turned in fully.

3. Maximum inlet pressure is

5 psig

4. Maximum temperature is

for 6" and larger valve size.

15 psig

200°F

up to 4" valve size and

.

Q137

SPECIFIC GRAVITY (GAS Correction Factor C3)

Coke Blast

Gas Oven Natural Gas Furnace Propane Butane

Specific Gravity .40 .59 .60 .61 1.02 1.52 2.01

Multiplier 1.224 1.007 1.000 .992 .767 .628 .547

CORRECTION FACTORS

PRESSURE (GAS OR AIR Correc tion Factor C

Pressure Inlet Pressure (psig)

Drop (psig) 5 10 15

1 1.15 1.29 1.42

2 1.63 1.80 1.95

3 1.95 2.25 2.45

4 2.20 2.50 2.85

5 2.45 2.75 3.00

10 3.70 4.05

15 4.70

TEMPERATURE (GAS OR AIR Correction Factor C2)

Temperature (°F) 68 100 150 200

Multiplier 1.00 1.03 1.07 1.12

)

1

EXAMPLE:

Determine the corrected vol umetric flow rate in standard cubic feet per hour for a

PVS2A20 (2") adjustable port val ve f or propane gas at 100°F having an inlet

pressure of 15 psig and a pressure drop of 5 psig.

Using the equation:

1. From the standard flow curve for Natural Gas (Q137) at 27.7 "w.c. pressure

drop, determine the rated flow:

2. From the Pressure c orrection factor table, determine the pressure correct i on

factor: C

3. From the Temperature correction factor table, det ermine the temperature

correction factor: C

4. From the Specifi c Gravity correction fact or table, determine the spec i fic

gravity correction factor for Propane: C

Then,

= 27,170 scfh of propane gas

= 3.00

1

Q

(corrected) = (3.00) x (1.03) x (0.628) x (14,000)

Q

(corrected) = C1 x C2 x C3 x Q(rated)

Q

(rated) = 14,000 scfh.

= 1.03

2

= 0.628

3

Figure 1. Capacities

Q140

Page 4

Page 4

APV-9

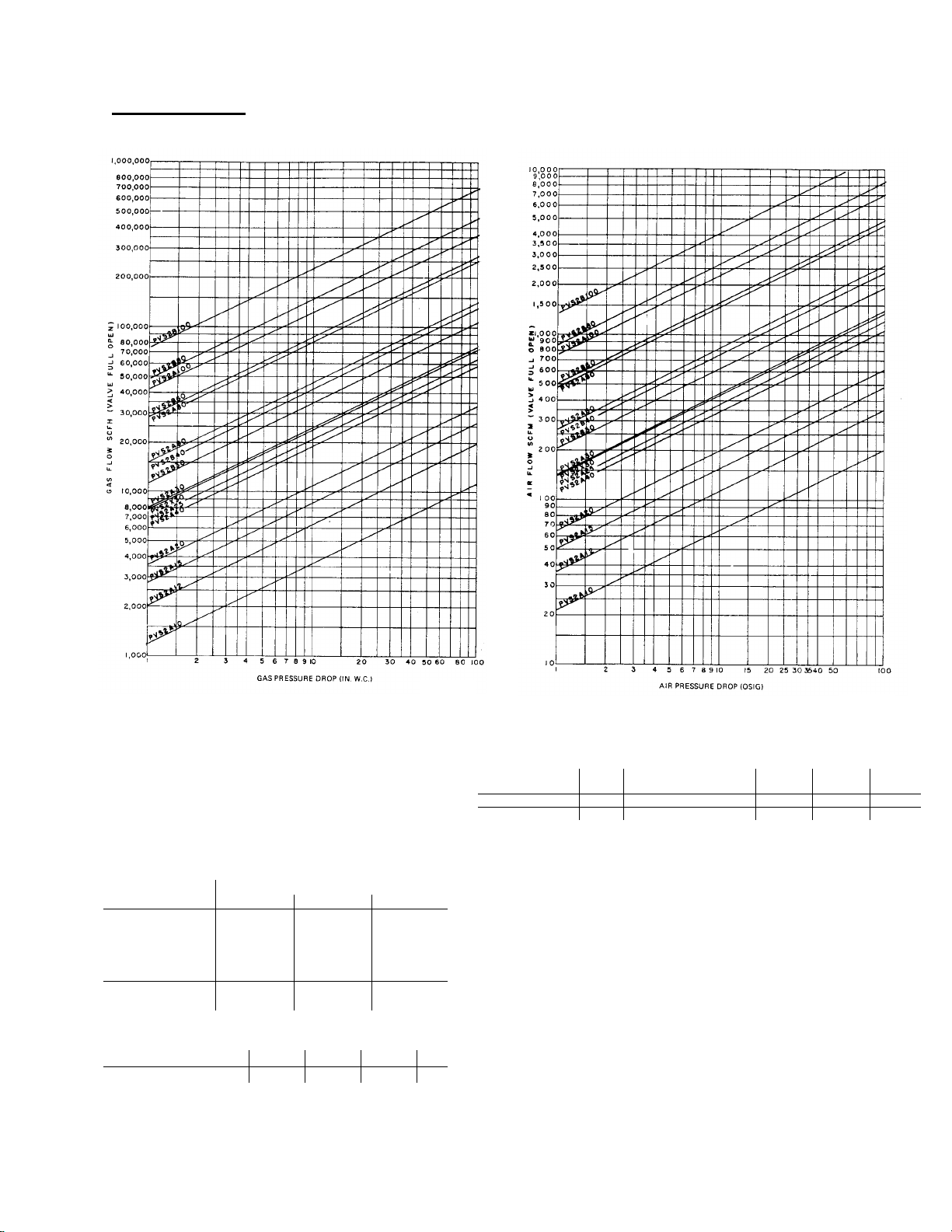

D. DIMENSIONS

GY231

(NOT TO SCALE)

Figure 2. Dimensions

GY229

(NOT TO SCALE)

Page 5

Page 5

APV-9

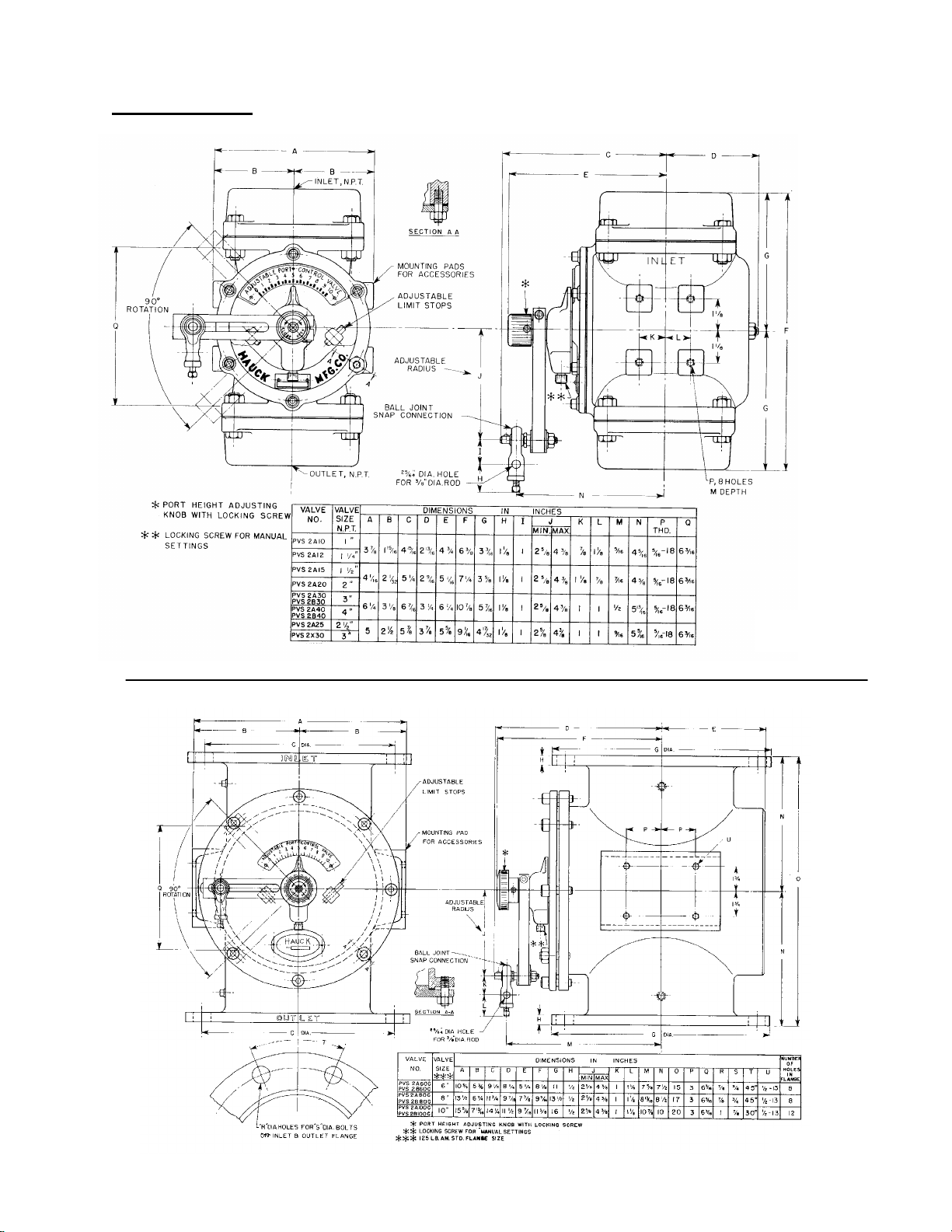

E. INSTALLATION

1. The port valve can be installed in any position, at any convenient location in the air or gas

line. When inst alling this valve, provide a means for measuring the line pr essure downstream

of the valve. These valves are designed to operate with pressures up to 15 psi g (103 kPa)

for 1" through 4" valve size, and 5 psig (34 kPa) for 6" and larger valve size. The 1" to 4"

valves are designed with female connections threaded for standar d pipe. The 6" and larger

valves have ANSI 125lb flange connections. These valves should not be used when the

temperature exceeds 200°F (93°C). Ensure that all piping both to and from the valve is

properly aligned and supported to prevent undue strain on the valve.

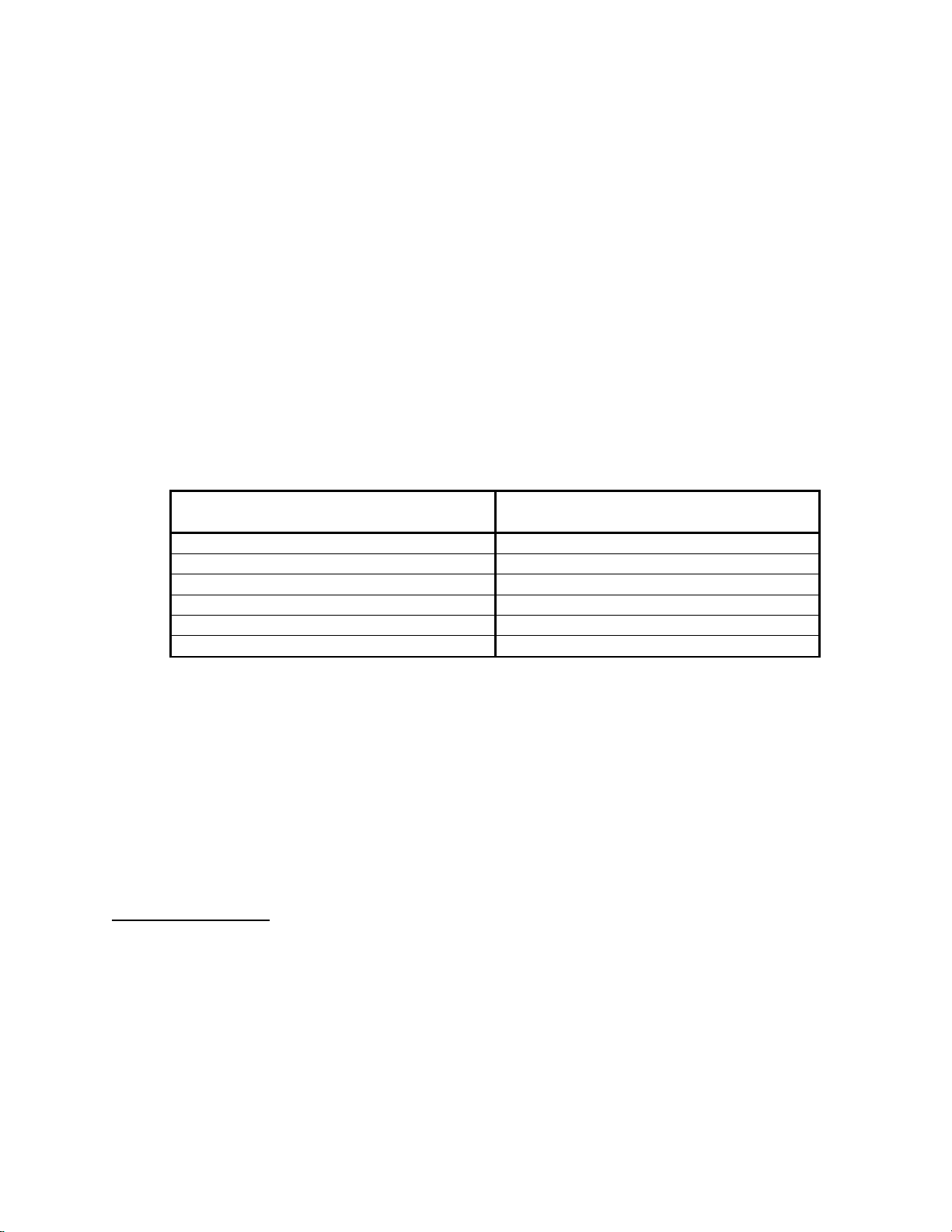

Figure 3. Adjustable Port Valve Cutaway Diagram

2. When an aut om at ic operation is to be used, a control motor should be mount ed to the valve

or some other nearby rigid support. Recomm ended m otor torque requirement for the 1" to 4"

valves is 20 in-lbs (2.3Nm); 40 in-lbs (4.5Nm) for the 6" or larger valves. The valves operating

arm moves in a clockwise direction to open the valve over an arc of about 90° at an adjust -

able radius from 2-5/8" to 4-3/8" (67 to 111mm).

A. Connect the valve lever to the control motor arm by a 3/8" (9.5mm) rod through the snap

connection pin on the valve lever. A setscrew is provided on the snap pin to secure the

rod at the proper point.

B. Loosen the locking screw located on the base of the dial indicator. This will allow easy

movement of the valve pointer.

C. Adjust the two limit stops until they allow movement of the pointer over the entire range of

dial positions.

D. Adjust the length of the control motor arm so that the valve pointer moves through the

desired range on the valve dial. Be sure that the contr ol m otor does not move the valve

lever beyond the stops on the dial as this can damage the valve if sufficient force is

applied.

Page 6

Page 6

APV-9

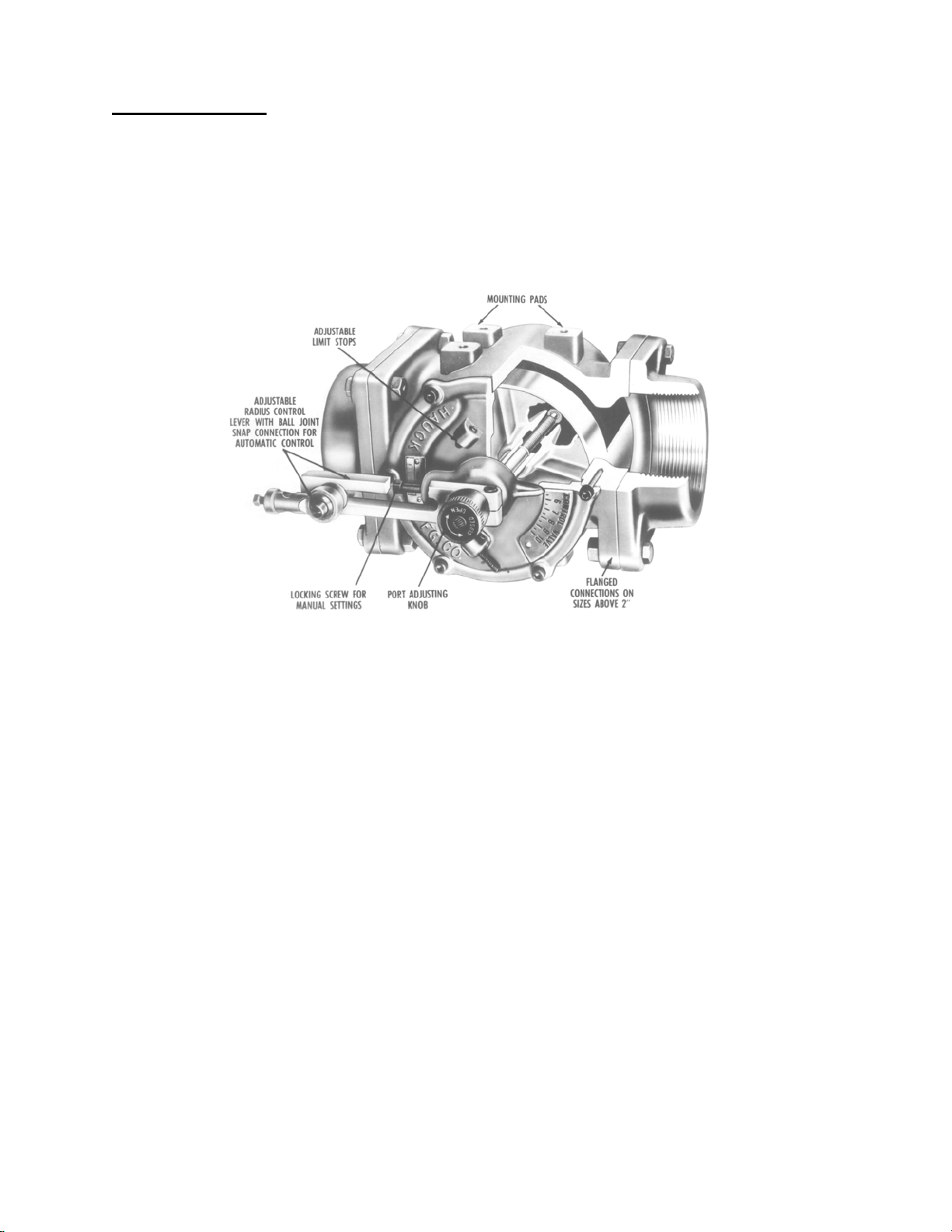

F. OPERATION

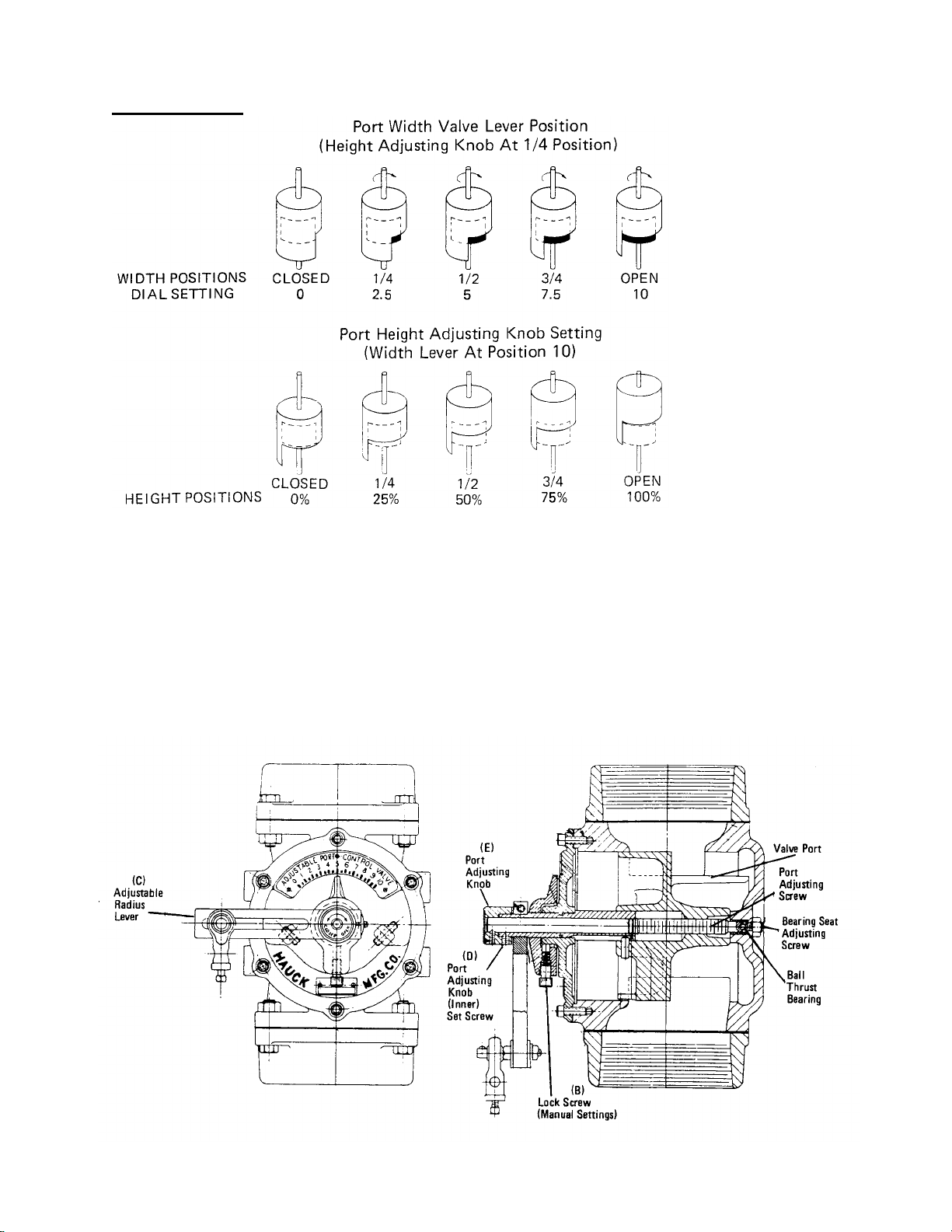

Figure 4. Illustration of Valve Height and Width Adjustments

Manual or automatic control is accomplished by moving the port adjusting k nob and the radius

control lever. The capacity of the air or gas flow is determined by the height and width of the

valve port opening in relation to the valve outlet. The heig ht of the port is cont rolled by the port

adjusting knob. The width of the port is cont rolled by the radius control lever. Rotating this lever

proportionally uncovers the rectangular port in the valve body.

Figure 5. Adjustable Port Valve Diagram

Page 7

Page 7

APV-9

Once installed, adjustm ents of the port adjusting k nob and the r adius control lever ar e achieved

by accomplishing the following:

A. Disconnect t he aut omatic linkage (if present ).

B. Loosen the dial point er locking screw.

C. Rotate the radius control lever to position 10.

D. Loosen the setscrew which holds the port adjusting knob at the proper set ting.

Exercise care since two setscrews exist on the knob. The inner setscrew maintains the

setting while the outer setscrew fastens the k nob to the stem. Only the inner setscrew

should be loosened.

E. Turn the adjusting cont rol knob counterclockwise until the FULLY CLOSED position is

reached.

F. Initiate the flow of air or gas through the line.

G. Rotate the adjusting knob clockwise until the pressure gauge(s) indicates the maximum

Pressure required. The pr essur e needed will vary depending on the burner , the piping,

and the application. The table given below gives the approximate number of turns from

FULL CLOSED TO FULL OPEN.

I. Connect the linkage for automatic control.

The vibration-proof locking scr ew, located at the base of t he dial pointer , should be used t o lock

any manual setting of the valve pointer. W hen operating automatically, this locking screw must

be loosened to facilitate the movement of the pointer.

Hauck adjustable port valves are designed for efficient f low control; they are not intended for

use as complete shut-off valves.

G. MAINTENANCE

All port valves are designed and constructed for maintenance free operation. Under normal

usage no service should be necessary.

If should become necessary to clean the valve, the entire port assembly can be easily removed,

in one piece, by accomplishing the following:

PVS 2A100 & PVS 2B100 66

H. Tighten the inner setscrew on the port adjust ing knob.

A. Disconnect t he aut omatic linkage (if present ).

B. Loosen and remove all of the screws, and the nut on the guide bolt, holding the dial

plate cover to the valve body.

C. Extract the entire port assembly.

D. Wipe the port cylinder clean of any part icles or residue. If scarring of the cylinder has

occurred, use an emery cloth to restore a smooth sur face.

VALVE MODEL FULL CLOSED TO FULL OPEN

PVS 2A10 & PVS 2A12 18

PVS 2A15 & PVS 2A20 22

PVS 2A30 & PVS 2B40 29

PVS 2A60 & PVS 2B60 43

PVS 2A 80 & PVS 2B80 48

APPROXIMATE NO. OF TURNS FROM

Page 8

Page 8

APV-9

MAINTENANCE (Continued)

E. Lubricate the port cylinder with Molykote or some other suitable high t emperatur e, non-

gumming lubricant.

F. Reinsert the port assembly. Use the location of the guide bolt to ensure proper

alignment. Ensure that the stem is properly seated in the bushing at the back of the

valve body.

G. Replace and properly seat the dial plate cover gaskets.

H. Replace and tighten all of the screws in the dial plate cover.

I. Move the radius control lever through its f ull range of movement. If the movement is

either binding or too free moving, adjust the bearing seat adjusting setscrew on the

valve back by accomplishing the following:

a. Loosen the locknut which secures the setscrew.

b. Slowly tighten the setscrew (clockwise rotation) until there is resistance to the

movement of the lever.

c. Rotate the setscrew 1/8 to 1/4 turn in a counterclockwise direction.

d. Tighten the lock nut.

J. Reconnect the automatic linkag e ( if used).

Loading...

Loading...