Page 1

THERMO-FINISHER

™

Food Finisher

TF-1900 & TF-4600 Series

Installation &

Operating Manual

I & W #07.05.117.00

This manual contains important safety

information concerning the maintenance, use

and operation of this product. Failure to follow

the instructions contained in this manual may

result in serious injury. If you are unable to

understand the contents of this manual, please

bring it to the attention of your supervisor. Do not

operate this equipment unless you have read

and understood the contents of this manual.

Este manual contiene importante información

sobre seguridad concerniente al mantenimiento,

uso y operación de este producto. Cualquier falla

en el seguimiento de las instrucciones

contenidas en este manual puede resultar en un

serio daño. Si usted no puede entender el

contenido de este manual por favor pregunte a

su supervisor. No opere este equipo al menos

que haya leído y comprendido el contenido de

este manual.

Page 2

Form No. TF1946M-1004

i

INTRODUCTION

The Hatco Thermo-Finisher is designed to rapidly

heat or thermalize a wide range of food products

which allows operators to serve customers faster,

thereby improving customer satisfaction. The

Thermo-Finisher is perfect for melting toppings or

finishing soup and foods like Mexican entrees,

nachos and potato skins. It also thermalizes frozen

foods such as appetizers, french fries and pizza.

Thermo-Finisher can also be used to heat plates

prior to serving.

This manual provides the installation, safety and

operating instructions for the Thermo-Finisher Food

Finisher. We recommend all installation, operating

and safety instructions appearing in this manual be

read prior to installation or operation of your Hatco

Food Finisher. Safety instructions that appear in this

manual after a warning symbol and the words

WARNING or CAUTION printed in bold face are

very important. WARNING means there is the

possibility of serious personal injury or death to

yourself or others. CAUTION means there is the

possibility of minor or moderate injury. CAUTION

without the symbol signifies the possibility of

equipment or property damage only.

Your Hatco Thermo-Finisher Food Finisher is a

product of extensive research and field testing. The

materials used were selected for maximum

durability, attractive appearance and optimum

performance. Every unit is thoroughly inspected and

tested prior to shipment.

CONTENTS

Important Owner Information............................i

Introduction.........................................................i

Important Safety Instructions...........................1

Model Descriptions ...........................................2

All Models.........................................................2

TF-1919............................................................2

TF-4619............................................................2

TF-461R ...........................................................2

TFW-461R........................................................2

Specifications....................................................3

Electrical Rating Chart ..................................3

Plug Configurations......................................3

Dimensions...................................................4

Installation..........................................................5

Unpacking.....................................................5

Location........................................................5

Electrical Connections (TFW-461R).............6

Appliance Legs (TFW-461R)........................6

IMPORTANT OWNER INFORMATION

Programming The Unit......................................7

General.........................................................7

Programming Controller...................................8

Programming a Selection.............................8

Idle Mode....................................................10

Auto-Off Mode............................................10

Programming Hints.....................................10

Operation..........................................................12

Basic Food Finishing..................................12

Food Finishing Hints ...................................12

Maintenance.....................................................13

General.......................................................13

Cleaning-Exterior........................................13

Blower Motors.............................................13

Cleaning-Interior.........................................13

Recommended Food Finishing Guide...........14

Hatco Limited Warranty..................................17

Authorized Parts Distributors..........Back Cover

Record the model number, serial number

(identification decal located on the back or side of

the unit), voltage and purchase date of your

Thermo-Finisher

™

Food Finisher in the spaces

below. Please have this information available when

calling Hatco for service assistance.

Model No. ________________________________

Serial No. ________________________________

Voltage __________________________________

Date of Purchase __________________________

Business 8:00 a.m. to 5:00 p.m.

Hours: Central Standard Time

(Summer Hours: June to September –

8:00 a.m. to 5:00 p.m. C.D.T.

Monday through Thursday

8:00 a.m. to 2:30 p.m. C.D.T. Friday)

Telephone: (800) 558-0607; (414) 671-6350

Fax: (800) 690-2966 (Parts & Service)

(414) 671-3976 (International)

Additional information can be found by visiting our

web site at www.hatcocorp.com.

24-Hour 7-Day Parts & Service

Assistance available in the

United States and Canada by

calling (800) 558-0607.

Page 3

WARNINGS

Plug unit into a properly grounded electrical

outlet of the correct voltage, size and plug

configuration. If the plug and receptacle do

not match, contact a qualified electrician to

determine the proper voltage and size and

install the proper electrical outlet.

To avoid any injury or damage to the unit do

not pull unit by power cord.

To prevent any injury, discontinue use if

power cord is frayed or worn.

To prevent injury or damage to the unit,

TFW-461R model must be installed by a

qualified electrician.

For safe and proper operation, the unit must

be located a reasonable distance from

combustible walls and materials. If safe

distances are not maintained, discoloration or

combustion could occur. Do not locate unit

under shelving or closer than 12" (305 mm)

from the ceiling.

On TF-1919, TF-4619 and TF-461R models

allow a minimum of 1" (25 mm) clearance

along the sides and back. Allow a clearance of

26" (660 mm) along the front discharge to

ensure proper operation and safety.

On TFW-461R models allow a minimum of 1"

(25 mm) clearance along the right wall and

back wall when facing controls. Allow 3"

(76 mm) along the left wall. Allow a clearance

of 26" (660 mm) along the front discharge to

ensure proper operation and safety.

To reduce the risk of fire, the TFW-461R

appliance is to be mounted on floors of

noncombustible flooring and surface finish

with no combustible material against the

underside, or on noncombustible slabs or

arches, have no combustible material against

the underside. Such construction shall in all

cases extend not less than 12" (305 mm)

beyond the equipment on all sides.

To avoid any injury, turn the power switch

OFF, unplug the unit from the power source

and allow to cool before performing any

maintenance.

Unit is not waterproof. DO NOT submerge in

water. Do not operate if it has been

submerged in water. Do not steam clean the

interior or flood with water or liquid solution.

Form No. TF1946M-1004

1

IMPORTANT SAFETY INSTRUCTIONS

To avoid electrical shock or personal injury,

do not steam clean or use excessive water on

the unit.

If service is required on this unit, contact your

Authorized Hatco Service Agent, or contact

the Hatco Service Department at 800-5580607 or 414-671-6350; fax 800-690-2966 or

International fax 414-671-3976.

This product has no “user” serviceable parts.

To avoid damage to the unit or injury to

personnel, use only Authorized Hatco Service

Agents and Genuine Hatco Replacement

Parts when service is required.

Genuine Hatco Replacement Parts are

specified to operate safely in the

environments in which they are used. Some

aftermarket or generic replacement parts do

not have the characteristics that will allow

them to operate safely in Hatco equipment. It

is essential to use Hatco Replacement Parts

when repairing Hatco equipment. Failure to

use Hatco Replacement Parts may subject

operators of the equipment to hazardous

electrical voltage, resulting in electrical

shock or burn.

CAUTIONS

Some exterior surfaces on the unit will get

hot. Use caution when touching these areas

to avoid injury.

Unit is not weatherproof. For safe and proper

operation locate the unit indoors

where the

ambient air temperature is a minimum of 70°F

(21°C).

To avoid any injury or damage to the unit do

not operate appliance without installation of

supplied legs.

DO NOT use “Pyrex” glass plates or serving

pieces in the finisher. “Pyrex” glass may

break causing personal injury and/or food

contamination.

DO NOT use paper or plastic serving pieces

in the finisher. These materials may melt or

burn causing a fire hazard and/or food

contamination and may damage the unit.

Plate/ tray will be very hot upon removal; use

oven mitt, protective clothing, or pan gripper

to remove.

IMPORTANT! Read the following important safety instructions to avoid personal injury or

death, and to avoid damage to the equipment or property.

Page 4

Form No. TF1946M-1004

2

ALL MODELS

The Thermo-Finisher Food Finisher models have an

easy-to-clean interior, constructed of stainless steel

and heavy duty glass. The units feature quickheating infrared ribbon elements with a

microprocessor to control the radiant heat and

heating time. All models come with a user friendly

control panel which accepts up to five

preprogrammed recipe times. All models

accommodate a half-size sheet pan. A plate rack is

included.

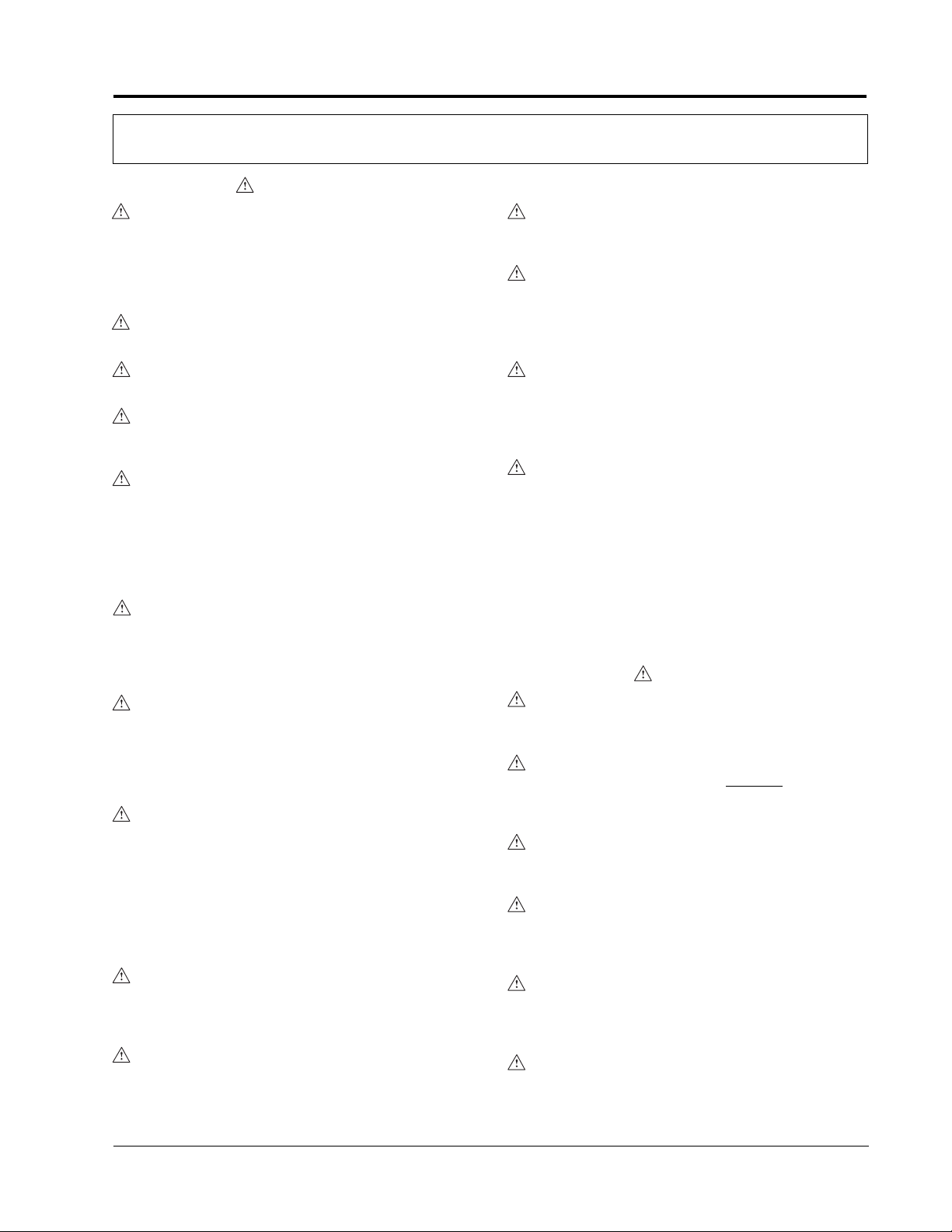

MODEL TF-1919

The TF-1919 model features one upper element to

heat the food product on the plate and one lower

element to heat the center of the plate. Loading and

unloading of food is done on the control side of the

unit. An attached cord and plug set is included.

MODEL TF-4619

The TF-4619 model features four upper elements

that heat food product on the plate and one lower

element that heats the center of the plate. Loading

and unloading of food is done on the control side of

the unit. An attached cord and plug set is included.

Figure 1. Thermo-Finisher – Model TF-4619

MODEL DESCRIPTIONS

IMPORTANT SAFETY INSTRUCTIONS

MODEL TF-461R

The TF-461R features four upper circular elements

and one lower rectangular element for even heat

distribution from corner to corner. Loading and

unloading of food is done on the control side of the

unit. An attached cord and plug set is included.

MODEL TFW-461R

The TF-461R features four upper circular elements

and one lower rectangular element for even heat

distribution from corner to corner. Loading and

unloading of food is done on the control side of the

unit. This model must be electrically hard wire

connected by a qualified electrician.

CAUTIONS

Do not remove the glass from the unit for

cleaning purposes. Doing so may cause

injury or damage to the unit.

To avoid any injury or damage locate the unit

at the proper counter height, in an area that is

convenient for use. The location should be

level to prevent the unit or its contents from

accidentally falling, and strong enough to

support the weight of the unit.

Do not place anything on top of the unit;

doing so could damage the unit or subject

personnel to possible injury.

To avoid any injury or damage to the unit

make sure the plate rack is not in direct

contact with the glass base.

The National Sanitation Foundation (NSF)

requires TFW-461R units to be either sealed

or raised on the installation surface. If this

unit cannot be sealed at the point of use, 4"

(102 mm) legs are included to allow for proper

cleaning access below unit.

CAUTIONS

Do not place any objects on the metal rack

during preheat. Doing so will most likely

over-cook the product.

Use only non-abrasive cleaners. Abrasive

cleaners could scratch the finish of your

Thermo-Finisher, marring its appearance and

making it susceptible to dirt accumulation.

Page 5

3

Form No. TF1946M-1004

WARNING

Plug unit into a properly grounded electrical

outlet of the correct voltage, size and plug

configuration. If the plug and receptacle do not

match, contact a qualified electrician to

determine the proper voltage and size and install

the proper electrical outlet.

WARNING

To prevent injury or damage to the unit,

TFW-461R model must be installed by a qualified

electrician.

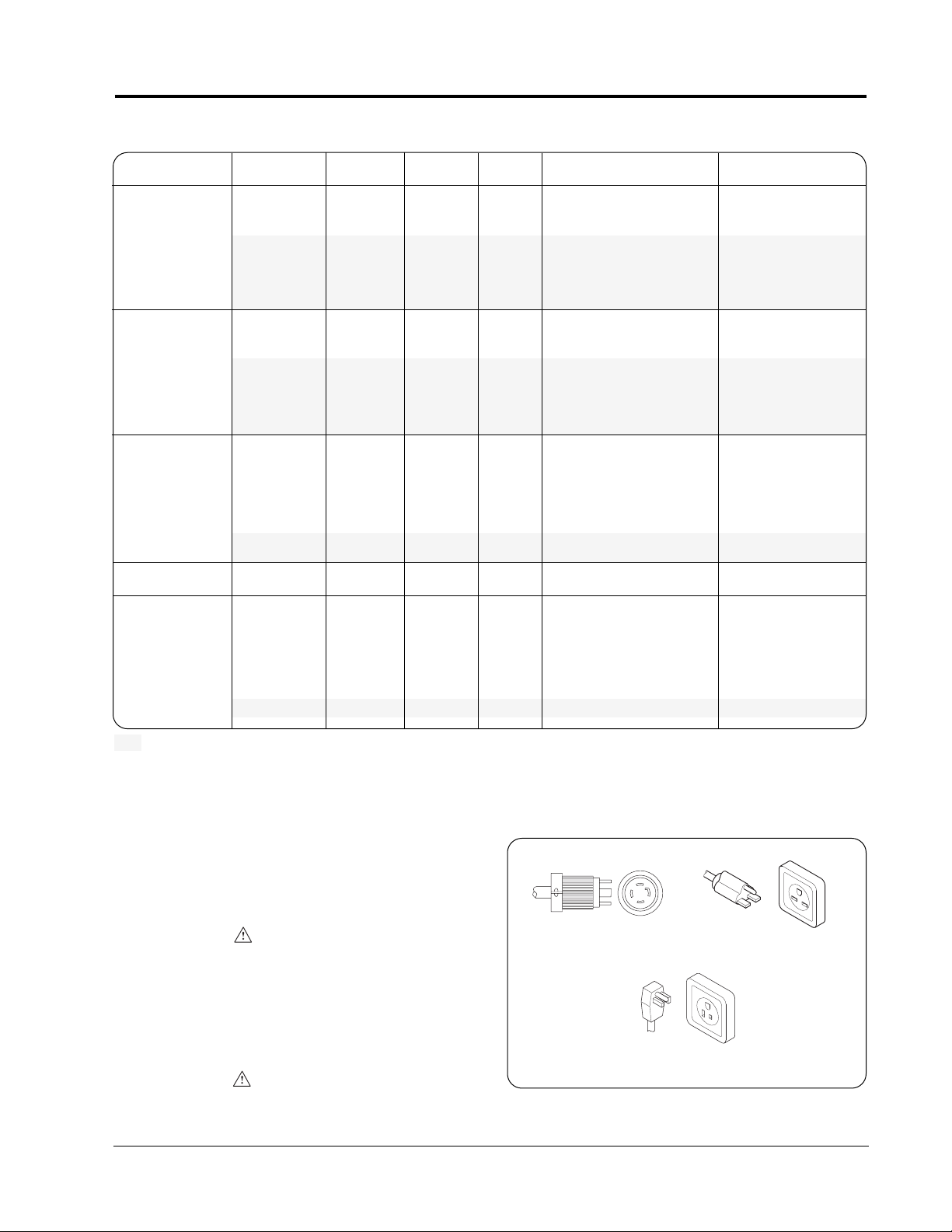

PLUG CONFIGURATIONS

Units are supplied from the factory with an electrical

cord and plug on the back of the unit.

(See Figure 2.)

NEMA L15-30P

Figure 2. Plug Configurations

ELECTRICAL RATING CHART

SPECIFICATIONS

NEMA 6-30P

The electrical information in the shaded areas pertains to Export models only.

NEMA 6-50P

Power cord is attached without a plug.

*NOTE: Model TFW-461R must be properly hard wire connected by a qualified electrician.

This model cannot be used with a cord and plug.

†

Model Voltage Watts Amps Phase Plug Configuration Shipping Weight

TF-1919 208 4800 23.1 1 NEMA 6-30P 88 lbs. (40 kg)

240 5000 20.8 1 NEMA 6-30P 88 lbs. (40 kg)

220 4201 19.1 1 NONE† 88 lbs. (40 kg)

240 5000 20.8 1 NONE† 88 lbs. (40 kg)

380 (CE) 4513 11.9 1 NONE† 88 lbs. (40 kg)

TF-4619 208 7200 20.1 3 NEMA L15-30P 90 lbs. (41 kg)

240 7300 17.6 3 NEMA L15-30P 90 lbs. (41 kg)

220 6134 16.1 3 NONE† 90 lbs. (41 kg)

240 7300 17.6 3 NONE† 90 lbs. (41 kg)

380 (CE) 6588 10.1 3 NONE† 90 lbs. (41 kg)

TF-461R 208 6250 30.0 1 NEMA 6-50P 93 lbs. (42 kg)

208 6250 19.0 3 NEMA L15-30P 93 lbs. (42 kg)

240 8320 34.7 1 NEMA 6-50P 93 lbs. (42 kg)

240 8320 21.9 3 NEMA L15-30P 93 lbs. (42 kg)

220 6992 20.1 3 NONE† 93 lbs. (42 kg)

Model Voltage Watts Amps Phase Circuit Breaker Size

*

Shipping Weight

TFW-461R 208 6250 30.0 1 40 93 lbs. (42 kg)

208 6250 19.0 3 30 93 lbs. (42 kg)

240 8320 34.7 1 50 93 lbs. (42 kg)

240 8320 21.9 3 30 93 lbs. (42 kg)

220 6992 20.1 3 30 93 lbs. (42 kg)

Page 6

SPECIFICATIONS

Form No. TF1946M-1004

4

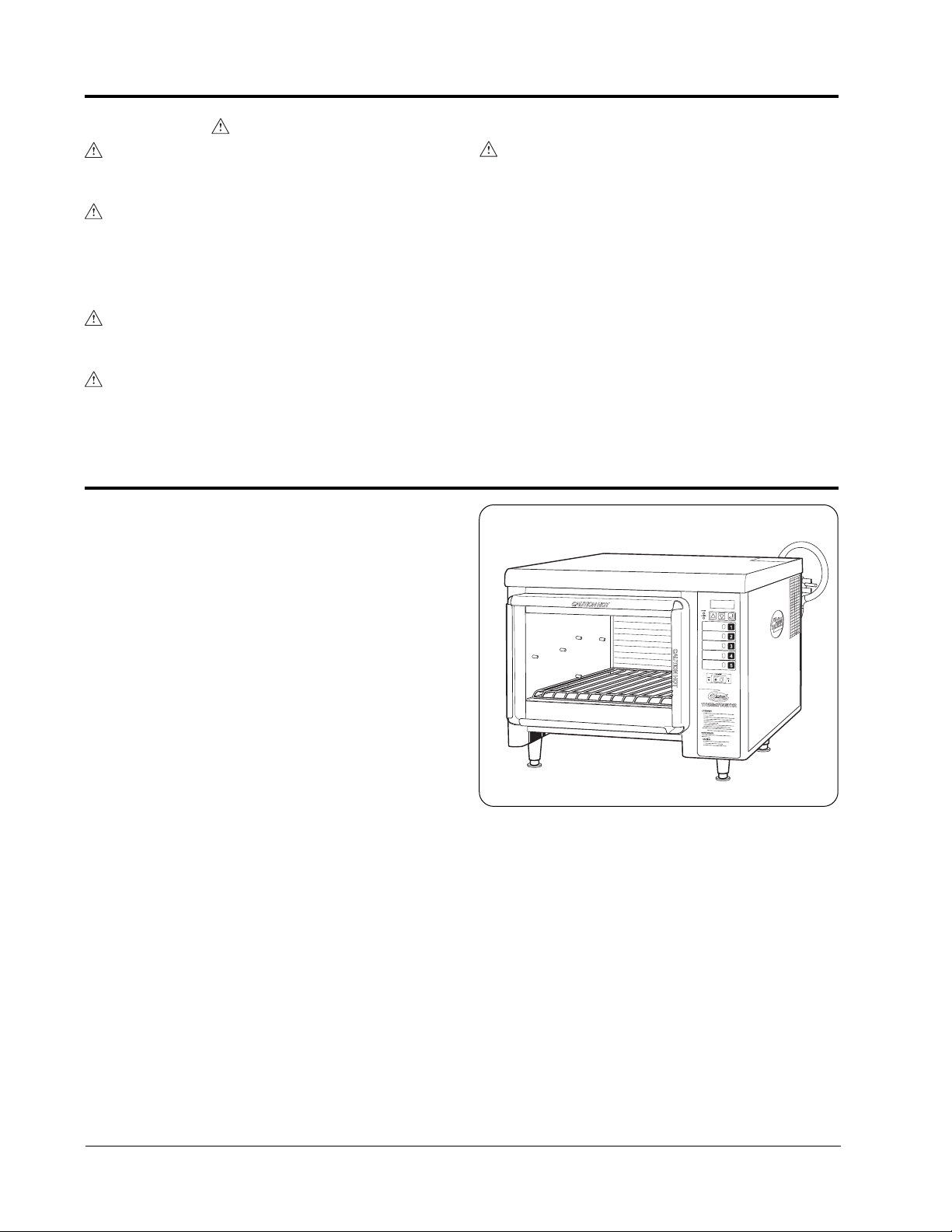

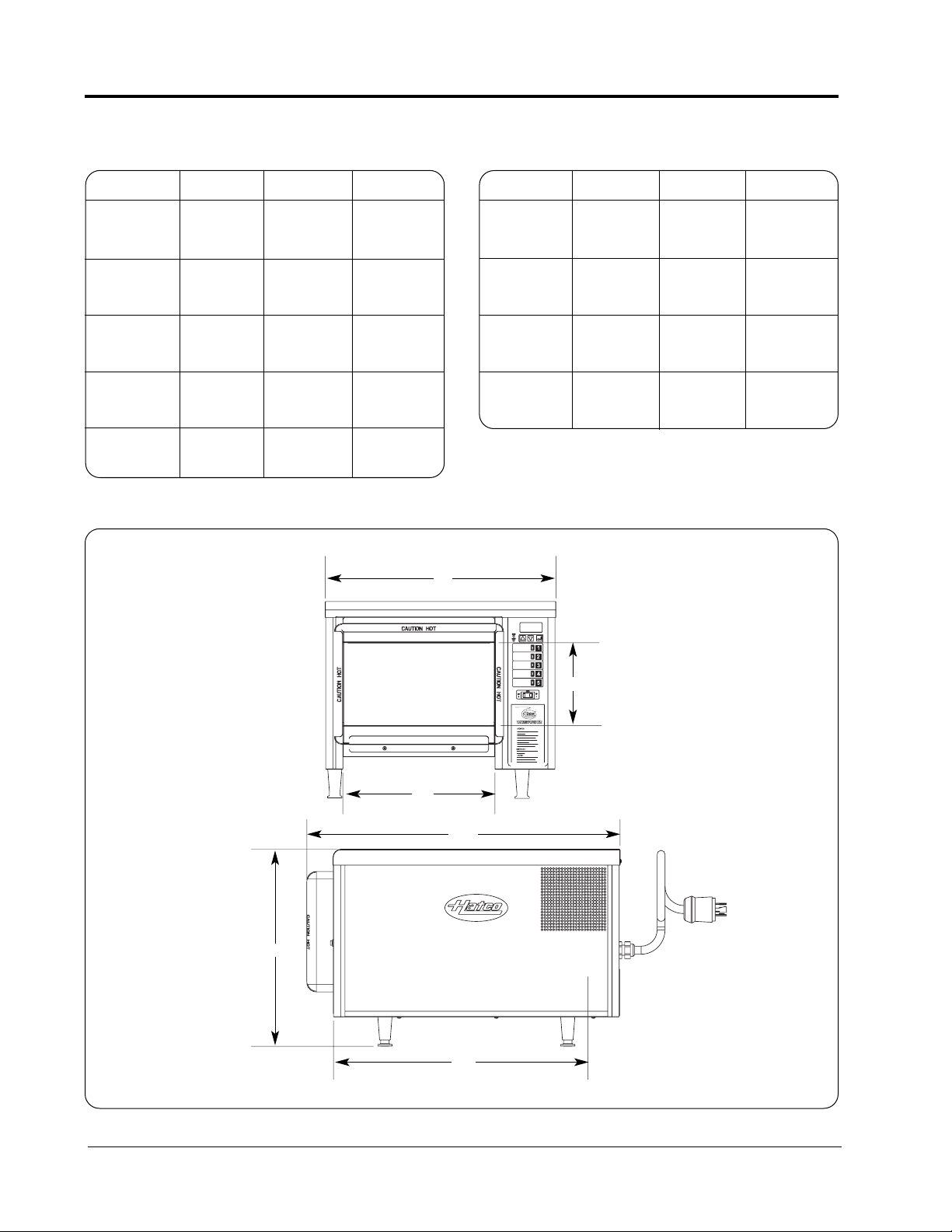

Model (A) Width (B) Depth* (C) Height

TF-1919 20-1/4" 27-1/2"* 17"

(514 mm) (699 mm) (432 mm)

TF-4619 20-1/4" 27-1/2"* 17"

(514 mm) (699 mm) (432 mm)

TF-461R 23-1/8" 30-7/8" 17"

1 Phase Units

(587 mm) (784 mm) (432 mm)

TF-461R 22-1/8" 30-7/8" 17"

3 Phase Units (562 mm) (784 mm) (432 mm)

TFW-461R 25-1/2" 20-7/8" 18-1/2"♦

(648 mm) (530 mm) (470 mm)

DIMENSIONS

Model (D) Width (E) Depth (F) Height

TF-1919 13" 18" 6-3/8"

(330 mm) (457 mm) (162 mm)

TF-4619 13" 18" 6-3/8"

(330 mm) (457 mm) (162 mm)

TF-461R 13" 18" 6-3/8"

(330 mm) (457 mm) (162 mm)

TFW-461R 18" 13" 6-3/8"

(457 mm) (330 mm) (162 mm)

EXTERIOR DIMENSIONS EFFECTIVE FINISHING AREA

Figure 3. Dimensions

A

F

D

C

E

B*

*Allow an additional 2" (51 mm) minimum for power cord.

♦ Height of unit is 14-5/8" (159 mm) without legs attached.

Page 7

UNPACKING

1. Remove unit from box.

2. Remove information packet. To prevent delay

in obtaining warranty coverage, fill out and

mail in warranty card to Hatco.

3. Remove tape, glass protection corners and

packaging material from all surfaces of unit.

4. The unit is equipped with both a top set and

bottom set of pins for supporting the wire plate

rack. Properly position the wire plate rack using

either set, making sure the wire rack is placed

between the three lower pins and the upper pin

on each side. (See Figure 4).

NOTE: Top wire plate position is recommended for

quick flash heating only. All items listed in the Food

Finishing Guide are utilizing the bottom set of pins

for supporting the wire plate rack.

LOCATION

WARNING

To reduce the risk of fire, the TFW-461R

appliance is to be mounted on floors of

noncombustible flooring and surface finish with

no combustible material against the underside,

or on noncombustible slabs or arches, have no

combustible material against the underside.

Such construction shall in all cases extend not

less than 12" (305 mm) beyond the equipment

on all sides.

WARNING

For safe and proper operation, the unit must be

located a reasonable distance from combustible

walls and materials. If safe distances are not

maintained, discoloration or combustion could

occur. Do not locate unit under shelving or

closer than 12" (305 mm) from the ceiling.

WARNING

On TF-1919, TF-4619 and TF-461R models allow

a minimum of 1" (25 mm) clearance along the

sides and back. Allow a clearance of 26"

(660 mm) along the front discharge to ensure

proper operation and safety.

WARNING

To avoid any injury or damage to the unit do not

pull unit by power cord.

WARNING

To prevent any injury, discontinue use if power

cord is frayed or worn.

Form No. TF1946M-1004

5

INSTALLATION

WARNING

On TFW-461R models allow a minimum of 1"

(25 mm) clearance along the right wall and back

wall when facing controls. Allow 3" (76 mm)

along the left wall. Allow a clearance of 26"

(660 mm) along the front discharge to ensure

proper operation and safety.

CAUTION

To avoid any injury or damage to the unit make

sure the plate rack is not in direct contact with

the glass base.

CAUTION

To avoid any injury or damage locate the unit at

the proper counter height, in an area that is

convenient for use. The location should be level

to prevent the unit or its contents from

accidentally falling, and strong enough to

support the weight of the unit.

CAUTION

Do not place anything on top of the unit; doing

so could damage the unit or subject personnel

to possible injury.

Figure 4. Rack Support Placement

Page 8

Form No. TF1946M-1004 6

INSTALLATION

Figure 5. Leg Bolt Hole Centers – TFW-461R

CAUTION

Unit is not weatherproof. For safe and proper

operation locate the unit indoors where the

ambient air temperature is a minimum of 70°F

(21°C).

ELECTRICAL CONNECTIONS

(TFW-461R)

WARNING

To prevent injury or damage to the unit,

TFW-461R model must be installed by a qualified

electrician.

1. Remove wire inspection cover located on the

right side of the unit when facing the controls.

2. Locate the terminal block inside the unit.

3. Bring power leads from a properly sized circuit

breaker or disconnect switch through the

knockout provided on the unit.

NOTE: TFW-461R have two knockout locations,

one on the bottom of the unit and one on the back.

4. Use copper wire only. Tighten connections

properly to a minimum of 40 inch pounds.

5. A grounding screw is provided near the electrical

terminals. An equipment grounding conductor

must be properly connected to it.

6. Replace and secure wire inspection cover.

APPLIANCE LEGS (TFW-461R)

The TFW-461R Series unit can be installed with or

without the 4" (1016 mm) appliance legs supplied.

If the appliance is used without the legs the unit

must be sealed and secured to the countertop.

21.688"

(551 mm)

Leg Bolt Hole

Centers

2.958"

(75 mm)

2.896"

(74 mm)

12.374"

(314 mm)

Leg Bolt Hole

Centers

To secure unit to countertop material use four

3/8"-16 bolts placed through the countertop and

threaded into the leg bolt holes. See Figure 5 for leg

bolt hole centers.

CAUTION

The National Sanitation Foundation (NSF)

requires TFW-461R units to be either sealed or

raised on the installation surface. If this unit

cannot be sealed at the point of use, 4" (102 mm)

legs are included to allow for proper cleaning

access below unit.

Page 9

Form No. TF1946M-10047

PROGRAMMING THE UNIT

GENERAL

Thermo-Finisher™units have both an upper and

lower heating zone. The upper elements heat the

product on the plate and the lower elements heat

the center of the plate.

Five adjustable program button selections allow the

operator to fine tune the radiant heat input and

heating time for a variety of menu items. This

adjustable feature assures optimum serving

temperatures without effecting quality.

Thermo-Finisher units also feature an adjustable

“Idle” mode and adjustable “Auto-Off” mode, which

allow for additional flexibility.

NOTE: After reading and understanding how to

program the unit, see PROGRAMMING HINTS and

RECOMMENDED FOOD FINISHING GUIDE in this

manual for further helpful information.

NOTE: If at anytime during the programming or

operation of the unit the display is not reading

correctly or the unit is unable to be programmed,

turn the unit off. Next, turn the unit back on and

restart.

Figure 6. Control Panel

Power

ON/OFF

Switch

Lower

Heat

Indicator

Upper

Heat

Indicator

UP Button

DOWN Button

Digital Display

Enter Button

Program

Indicator

Lamp

Program

Selection

Buttons

Page 10

Form No. TF1946M-1004 8

PROGRAMMING CONTROLLER

PROGRAMMING A SELECTION

The following terms are used when programming

the unit:

UP = Upper Power Value: Controls the power

setting on the upper heating element(s)

UT = Upper Time Value: Controls the time setting

on the upper heating element(s)

LP = Lower Power Value: Controls the power

setting on the lower heating element(s)

LT = Lower Time Value: Controls the time setting

on the lower heating element(s)

When the unit display shows a Power Value (UP for

upper heating zone or LP for lower heating zone)

the number indicates the value set at a percentage:

example P20 = 20%. These values are adjustable

from 5-100% in 5% increments.

When the unit display shows a Time Value (UT for

upper heating zone or L Tfor lower heating zone) the

number indicates the time in seconds the heating

element will be on: example T35 = 35 seconds.

These values are adjustable from zero to nine

minutes fifty nine seconds.

NOTE: The arrow keys are used to enter values

when programming the unit. Pressing a key

changes the value incrementally. Holding down the

key rapidly changes the value.

1. Plug unit into an electrical outlet of the correct

voltage, size and plug configuration.

(See SPECIFICATIONS for details.)

2. Turn power switch to the “ON” position. The unit

will make an audible beep, automatically go into

preheat and display will indicate (Figure

7A).

After one minute and ten seconds, the preheat

cycle is complete the unit will display

(Figure 7B). The unit is now ready to be

programmed.

3. With display showing , push and hold the

desired Numbered Program Selection button,

while at the same time push and hold the Enter

button for 5 seconds

(Figure 7C).

4. Upper Power Value (UP): After 3 seconds, the

upper heat indicator will glow and the unit will

display (Figure 7D). Press the UP or

DOWN arrow key until you reach the desired

setting. Values change by 5% every time an

arrow key is pressed. Press the ENTER

button when you have reached the desired

setting.

5. Upper Time Value (UT): The unit will display

(Figure 7E). Press the UP or DOWN

arrow key until you reach the desired setting.

Values change by 1 second every time an arrow

key is pressed. Holding down an arrow key will

cause the numbers to change rapidly. Time can

be adjusted from zero to nine minutes fifty nine

seconds. Press the ENTER button when you

have reached the desired setting.

6. Lower Power Value (LP): The lower heat

indicator will glow and the unit will display

(Figure 7F). Press the UP or DOWN

arrow key until you reach the desired setting.

Values change by 5% every time an arrow key is

pressed. Press the ENTER button when you

have reached the desired setting.

7. Lower Time Value (LT): The unit will display

(Figure 7G). Press the UP or DOWN

arrow key until you reach the desired setting.

Values change by 1 second every time an arrow

key is pressed. Press the ENTER button

when you have reached the desired setting.

8. Press the Numbered Program Selection button

selected in step 3 to enter all the settings into

memory. The display will show .

IMPORTANT NOTE: If no adjustments are made

within 15 seconds, the controller will revert back to

the “READY” mode and will not accept any

changes. Also, pressing any of the other Numbered

Program Selection buttons will take the unit out of

the programming mode without accepting any

changes.

9. If ready to finish food, place product in unit on

center of metal rack and press desired

Numbered Program Selection button.

10.Using a grease pencil or “China” pencil, record

the specific menu item on the control panel next

to the selected Numbered Program button.

1 1.Repeat steps 3-10 for the other Program buttons.

NOTE: All units keep the power and timing settings

in memory, even when the unit is turned off or is

unplugged from the power source.

Page 11

Form No. TF1946M-10049

PROGRAMMING CONTROLLER

7B

7A

7C

7D 7E

7F

7G

Figure 7. Programming a Selection

UPPER HEAT

LOWER HEAT

1

2

3

4

5

Page 12

Form No. TF1946M-1004

10

PROGRAMMING CONTROLLER

IDLE MODE

The Thermo-Finisher™features an “Idle” mode.

Once the unit reaches the mode, the upper

heating element(s) automatically go into a

programmed idle power setting. (The display will still

show during the idle mode). The unit will stay

in this mode until one of the five Program buttons is

pressed, or the unit goes into auto-shut off.

NOTE: Begin by setting the idle mode power setting

at 30% and adjust the program accordingly to

achieve optimum performance.

To change the idle mode power setting, follow these

steps:

1. Press and hold the UP arrow while, at the

same time, press and hold the ENTER

button for three seconds

. The display will

show the current programmed power value

(Figure 8A).

2. To adjust the idle mode, press either the UP or

DOWN arrow until you reach the desired

setting (Figure 8B). Each time you press an

arrow, the setting will change by 10.

3. To accept the new value, push the ENTER

button a second time (Figure 8C).

Note: If no adjustments are made within 15

seconds, the controller goes back to its original

settings without accepting the change. Pushing any

of the numbered program buttons will also take the

controller out of programming mode without

accepting the change.

AUTO-OFF MODE

The Thermo-Finisher features an Auto-Off mode

that turns all the elements off if the unit has not been

used for a programmed length of time. This feature

can be adjusted from 1 - 60 minutes in one minute

increments, or it can be set to never shut off by itself.

To change the Auto-Off mode to a new setting, make

sure unit is in “READY” mode and follow these

steps:

1. Press and hold the DOWN arrow while at the

same time press and hold the ENTER button

for three seconds

. The display will show the

current programmed Auto-Off value (Figure 9A).

2. To adjust the Auto-Off time push either the UP

or DOWN arrow until you reach the desired

setting (Figure 9B). The Auto-Off mode can be

adjusted from “0” (indicating unit will not turn off)

to 60 minutes, in single minute increments.

3. To accept the new Auto-Off time value, push the

ENTER button a second time (Figure 9C).

Note: If no adjustments are made within 15 seconds

the controller goes back to its original settings

without accepting the change. Pressing any of the

numbered buttons will also take the controller out of

programming mode without accepting the change.

To get the unit out of the Auto-Off Mode, push any

one of the five numbered program buttons and the

unit will begin operating.

PROGRAMMING HINTS:

• On menu items in which internal temperatures

are critical (such as chicken or pork), the primary

heat source comes from the bottom. On menu

items in which the surface temperatures are

critical (such as cheese melting), the primary

heat source comes from the top. See

RECOMMENDED FOOD FINISHING GUIDE for

specific menu examples.

• When performing product testing, use three

plates with the same product and run through the

unit in succession. Adjust program accordingly to

achieve optimum product temperature.

• When testing a menu item not listed in the

Recommended Food Finishing Guide start by

dividing the conventional cooking time by three

and use that number as your cooking time. Set

top and bottom heat at 50% and adjust from

there. Program setting will vary based on model

and food product.

Page 13

Form No. TF1946M-100411

PROGRAMMING CONTROLLER

8B

8A

8C

9B

9A

9C

Figure 8. Programming Idle Mode

Figure 9. Programming Auto-Off Mode

Page 14

OPERATION

Form No. TF1946M-1004 12

Figure 10. Control Panel

Power

ON/OFF

Switch

Lower

Heat

Indicator

Upper

Heat

Indicator

UP Button

DOWN Button

Digital Display

Enter

Button

Program

Indicator

Lamp

Program

Selection

Buttons

BASIC FOOD FINISHING

CAUTION

Some exterior surfaces on the unit will get hot.

Use caution when touching these areas to avoid

injury.

CAUTION

DO NOT use “Pyrex” glass plates or serving

pieces in the finisher. “Pyrex” glass may break

causing personal injury and/or food

contamination.

CAUTION

DO NOT use paper or plastic serving pieces in

the finisher. These materials may melt or burn

causing a fire hazard and/or food contamination

and may damage the unit.

CAUTION

To avoid any injury or damage to the unit do not

operate appliance without installation of

supplied legs.

NOTE: See RECOMMENDED FOOD FINISHING

GUIDE for specific information.

1. Plug unit into an electrical outlet of the correct

voltage, size and plug configuration. See

SPECIFICATIONS for details.

2. Turn the Power Switch to the “ON” position. (See

Figure 10). The unit will make an audible beep,

automatically go into “Preheat” and the display

will indicate . If the unit displays “OFF”,

press one of the five product selection keys to

put the unit into “Preheat” mode.

CAUTION

Do not place any objects on the metal rack

during preheat. Doing so will most likely overcook the product.

3. When the Finisher has reached temperature and

is ready for product, the unit will display .

Place plate/tray with food product on the center

of the metal rack when unit is in mode.

4. Select one of five preprogrammed finishing

cycles. Unit will beep and the display will begin

counting down the programmed finishing time.

Note: If you make an incorrect selection it can be

cancelled by selecting any of the buttons on the

Control Panel.

5. Finishing is complete when the display flashes

, the control panel lights flash and the unit

beeps for five seconds. Remove product at this

time.

CAUTION

Plate/tray will be very hot upon removal; use

oven mitt, protective clothing, or pan gripper to

remove.

Note: The beeping sound can be stopped before the

five seconds have elapsed by selecting any of the

buttons on the control panel.

6. Another plate/tray with food product can be

placed on the rack when Finisher is in the

mode. To heat, repeat steps 3, 4, and 5.

FOOD FINISHING HINTS:

• Most menu items will require the Lower Power

Value to be set higher than the Upper Power

Value.

• Frozen or refrigerated food product can be

heated in the unit. Frozen items do not have to

be thawed first.

• Menu items that have completed a food finishing

cycle but are not hot enough can be put back in

the unit for additional heating.

• When testing a menu item not listed in the

RECOMMENDED FOOD FINISHING GUIDE

start by dividing the conventional cooking time by

three and use that number as your cooking time.

Set top and bottom heat at 50% and adjust from

there. Program setting will vary based on model

and food product.

NOTE: See RECOMMENDED FOOD FINISHING

GUIDE for specific information.

Page 15

Form No. TF1946M-100413

MAINTENANCE

GENERAL

The Hatco Thermo-Finisher™ warmers are

designed for maximum durability and performance

with minimum maintenance.

WARNING

To avoid any injury, turn the power switch OFF,

unplug the unit from the power source and allow

to cool before performing any maintenance.

NOTE: When the unit is HOT the blower fans will

remain on even when the power switch is turned off.

CLEANING - EXTERIOR

To preserve the bright finish of the unit, it is

recommended that the exterior surfaces be wiped

daily with a damp cloth. Stubborn stains may be

removed with a good stainless steel cleaner or a

non-abrasive cleaner.

CAUTION

Use only non-abrasive cleaners. Abrasive

cleaners could scratch the finish of your

Thermo-Finisher, marring its appearance and

making it susceptible to dirt accumulation.

BLOWER MOTORS

Inspect rear blower motors for food and/or grease

build up and clean off if necessary.

CLEANING - INTERIOR

WIRE PLATE RACK

Remove rack from unit and wash with a mild soap

and water solution and rinse.

GLASS SURFACES

WARNING

To avoid any injury, turn the power switch OFF,

unplug the unit from the power source and allow

to cool before performing any maintenance.

Upper and lower glass surfaces can be cleaned

after the unit has cooled for at least one hour.

With the wire plate rack removed carefully use a

“grill scraper” or other small hand held scraper and

scrape loose any food debris that has accumulated

on the glass.

CAUTION

Do not remove the glass from the unit for

cleaning purposes. Doing so may cause injury

or damage to the unit.

Remove any stains from the heating surfaces by

wiping off the glass using a moist cloth and ceramic

cooking top cleaner.

WARNING

Unit is not waterproof. DO NOT submerge in

water. Do not operate if it has been submerged

in water. Do not steam clean the interior or flood

with water or liquid solution.

WARNING

To avoid electrical shock or personal injury, do

not steam clean or use excessive water on the

unit.

WARNING

If service is required on this unit, contact your

Authorized Hatco Service Agent, or contact the

Hatco service Department at 800-558-0607 or

414-671-6350; fax 800-690-2966 or International

fax 414-671-3976.

WARNING

This product has no “user” serviceable parts. To

avoid damage to the unit or injury to personnel,

use only Authorized Hatco Service Agents and

Genuine Hatco Replacement Parts when service

is required.

WARNING

Genuine Hatco Replacement Parts are specified

to operate safely in the environments in which

they are used. Some aftermarket or generic

replacement parts do not have the

characteristics that will allow them to operate

safely in Hatco equipment. It is essential to use

Hatco Replacement Parts when repairing Hatco

equipment. Failure to use Hatco Replacement

Parts may subject operators of the equipment to

hazardous electrical voltage, resulting in

electrical shock or burn.

Page 16

Upper Power Value Upper Time Value Lower Power Value Lower Time Value

Food Item (UP) (UT) (LP) (LT)

Biscuits 10 2 minutes 55 4 minutes

Refrigerated, premade. 30 seconds

PAN USED: Half

sheet pan, greased

lightly.

Bacon 75 5 minutes 70 5 minutes

Pork, thick sliced.

PAN USED: Half

sheet pan, greased

lightly.

Cheese Bread 45 4 minutes 30 3 minutes

Slacked, topped with

5 cheeses.

PAN USED:

Hardcoated

half sheet pan.

Cheese Sandwich 45 1 minute 100 55 seconds

1-3 sandwiches 15 seconds

at once; assembled,

2 slices of white bread

& 2 slices of

American cheese

each. PAN USED:

Hardcoated half sheet

pan, 2" (5 cm) deep.

Cheese Sandwich 50 1 minute 100 1 minute

4 sandwiches at once; 15 seconds 23 seconds

assembled, 2 slices of

white bread & 2 slices

of American cheese

each. PAN USED:

Hardcoated half sheet

pan, 2" (5 cm) deep.

Chicken Patty 60 4 minutes 40 4 minutes

4 oz., breaded, 30 seconds 30 seconds

refrigerated,

precooked.

PAN USED:

hardcoated half sheet

pan.

Chicken Skewers 85 5 minutes 80 4 minutes

Filleted and marinated. 45 seconds

PAN USED: Hatco

skewer holder.

Chicken Wings 70 5 minutes 60 4 minutes

Buffalo style, slacked, 30 seconds

fully cooked, sauce

coated. PAN USED:

Half sheet pan.

Form No. TF1946M-1004 14

RECOMMENDED FOOD FINISHING GUIDE

NOTE: All food items listed are utilizing the bottom set of pins for supporting the wire plate rack.

Page 17

Form No. TF1946M-100415

RECOMMENDED FOOD FINISHING GUIDE

Upper Power Value Upper Time Value Lower Power Value Lower Time Value

Food Item (UP) (UT) (LP) (LT)

Egg Rolls 35 4 minutes 35 4 minutes

Refrigerated, chicken 45 seconds

& pork. PAN USED:

Half sheet pan.

French Fries 90 3 minutes 80 3 minutes

Frozen, fast-food oven

bake style. PAN USED:

Half sheet pan.

French Onion Soup 95 35 seconds 5 0 minutes

Soup already hot, for

melting cheese.

PAN USED: Standard

soup crock placed

on a half sheet pan.

Hamburgers 70 2 minutes 75 2 minutes

Pre-cooked, quarter 15 seconds

pound patty.

PAN USED: Half

sheet pan.

Mozzarella Sticks 40 5 minutes 50 5 minutes

Breaded, refrigerated.

PAN USED: Half

sheet pan.

Nachos 75 1 minute 70 1 minute

Corn chips topped with

shredded cheddar

cheese. PAN USED:

Ceramic plate.

Pizza, 12" (31 cm)

Thin Crust 20 4 minutes 20 3 minutes

Frozen, to thaw or

rethermalize.

PAN USED: 12"

(31 cm) pizza screen.

Pizza, 12" (31 cm)

Thin Crust 50 3 minutes 45 2 minutes

Frozen thawed, to cook 30 seconds

after Rethermalizing.

PAN USED: 12"

(31 cm) pizza screen.

Pizza, 12" (31 cm)

Self-Rising Crust 50 5 minutes 40 5 minutes

Frozen, slacked. 20 seconds

PAN USED: 12"

(31 cm) round, 2"

(5 cm) deep,

hardcoated

pan, greased lightly.

NOTE: All food items listed are utilizing the bottom set of pins for supporting the wire plate rack.

Page 18

Form No. TF1946M-1004 16

RECOMMENDED FOOD FINISHING GUIDE

Upper Power Value Upper Time Value Lower Power Value Lower Time Value

Food Item (UP) (UT) (LP) (LT)

Pork Sausage Links 70 4 minutes 65 5 minutes

Skinless, raw. 30 seconds

PAN USED: Half

sheet pan, greased

lightly.

Potato Skins 40 4 minutes 35 4 minutes

Frozen, pre-prepared. 15 seconds 10 seconds

PAN USED:

Hardcoated half sheet

pan.

Quesadillas 30 1 minute 40 1 minute

10 " (25 cm) flour 45 seconds

tortillas, stuffed with

sauteed peppers,

onions & cheddar

cheese. PAN USED:

10" (25 cm) aluminum

pizza screen.

Tomato Halves, Broiled 75 3 minutes 60 3 minutes

Lightly seasoned. 30 seconds

PAN USED: Half

sheet pan.

NOTE: When testing a menu item not listed above start by dividing the conventional cooking time by three

and use that number as your cooking time. Set top and bottom heat at 50% and adjust from there. This Food

Guide is based on a Thermo-Finisher model TF-4619. Program setting will vary based on model and food

product.

NOTE: All food items listed are utilizing the bottom set of pins for supporting the wire plate rack.

Page 19

Form No. TF1946M-1004

17

HATCO LIMITED WARRANTY

1. PRODUCT WARRANTY

Hatco warrants the products that it manufactures

(the “Products”) to be free from defects in

materials and workmanship, under normal

use and service, for a period of one (1) year from

the date of purchase when installed and

maintained in accordance with Hatco’s written

instructions or 18 months from the date of

shipment from Hatco. Buyer must establish the

product’s purchase date by returning Hatco’s

Warranty Registration Card or by other means

satisfactory to Hatco in its sole discretion.

Hatco warrants the following Product

components to be free from defects in materials

and workmanship from the date of purchase

(subject to the foregoing conditions) for the

period(s) of time and on the conditions listed

below:

a) One (1) Year Parts and Labor PLUS One

(1) Additional Year Parts-Only Warranty:

Toaster Elements (metal sheathed)

Drawer Warmer Elements (metal sheathed)

Drawer Warmer Drawer Rollers and Slides

Food Warmer Elements (metal sheathed)

Display Warmer Elements (met al sheathed air

heating)

Holding Cabinet Elements (metal sheathed air

heating)

b) One (1) Year Parts and Labor PLUS Four

(4) Years Parts-Only Warranty on

pro-rated terms that Hatco will explain

at Buyer’s request:

3CS and FR Tanks

c) One (1) Year Parts and Labor PLUS Nine

(9) Years Parts-Only Warranty on:

Electric Booster Heater Tanks

Gas Booster Heater Tanks

THE FOREGOING WARRANTIES ARE

EXCLUSIVE AND IN LIEU OF ANY OTHER

WARRANTY, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE

OR PATENT OR OTHER INTELLECTUAL

PROPERTY RIGHT INFRINGEMENT. Without

limiting the generality of the foregoing, SUCH

WARRANTIES DO NOT COVER: Coated

incandescent light bulbs, fluorescent lights, lamp

warmer heat bulbs, glass components, Product

failure in booster tank, fin tube heat exchanger, or

other water heating equipment, caused

by liming, sediment buildup, chemical attack or

freezing, Product misuse, tampering or

misapplication, improper installation or application

of improper voltage.

2. LIMITATION OF REMEDIES AND

DAMAGES

Hatco’s liability and Buyer’s exclusive remedy

hereunder will be limited solely, at Hatco’s

option, to repair or replacement by a Hatcoauthorized service agency (other than where

Buyer is located outside of the United States,

Canada, United Kingdom or Australia in which

case Hatco’s liability and Buyer’s exclusive

remedy hereunder will be limited solely to

replacement of part under warranty) with respect

to any claim made within the applicable warranty

period referred to above. Hatco reserves the

right to accept or reject any such claim in whole

or in part. Hatco will not accept the return of any

Product without prior written approval from

Hatco, and all such approved returns shall be

made at Buyer’s sole expense. HATCO WILL

NOT BE LIABLE, UNDER ANY

CIRCUMSTANCES, FOR CONSEQUENTIAL

OR INCIDENTAL DAMAGES, INCLUDING BUT

NOT LIMITED TO LABOR COSTS OR LOST

PROFITS RESULTING FROM THE USE OF

OR INABILITY TO USE THE PRODUCTS OR

FROM THE PRODUCTS BEING

INCORPORATED IN OR BECOMING A

COMPONENT OF ANY OTHER PRODUCT OR

GOODS.

Page 20

HATCO CORPORATION

P.O. Box 340500, Milwaukee, WI 53234-0500 U.S.A.

(800) 558-0607 (414) 671-6350

Parts & Service Fax (800) 690-2966 Int’l. Fax (414) 671-3976

www.hatcocorp.com

HATCO AUTHORIZED PARTS DISTRIBUTORS

Printed in U.S.A. October 2004

ALABAMA

Jones McLeod Appl. Svc.

Birmingham 205-251-0159

ARIZONA

Auth. Comm. Food Equip.

Phoenix 602-234-2443

Byassee Equipment Co.

Phoenix 602-252-0402

CALIFORNIA

Industrial Electric

Huntington Beach 714-379-7100

Chapman Appl. Service

San Diego 619-298-7106

P & D Appliance

S. San Francisco 650-635-1900

COLORADO

Hawkins Commercial Appliance

Englewood 303-781-5548

DELA

WARE

Food Equipment Service

Wilmington 302-996-9363

FLORIDA

Whaley Foodservice Repair

Jacksonville 904-725-7800

Universal Restaurant Services

Miami 305-593-5488

Nass Service Co., Inc.

Orlando 407-425-2681

B.G.S.I.

Pompano Beach 954-971-0456

Comm. Appliance Service

Tampa 813-663-0313

GEORGIA

TWC Services

Lake City 404-361-8010

Heritage Service Group

Norcross 866-388-9837

Southeastern Rest. Svc.

Norcross 770-446-6177

HA

WAII

Burney’s Comm. Service, Inc.

Honolulu 808-848-1466

Food Equip Parts & Service

Honolulu 808-847-4871

ILLINOIS

Parts Town

Lombard 708-865-7278

Eichenauer Elec. Service

Decatur 217-429-4229

Midwest Elec. Appl. Service

Elmhurst 630-279-8000

Cone’s Repair Service

Moline 309-797-5323

INDIANA

GCS Service

Indianapolis 317-545-9655

IOW

A

Electric Motor Service Co.

Davenport 319-323-1823

Goodwin Tucker Group

Des Moines 515-262-8308

KENTUCKY

GCS Service

Louisville 502-367-1788

LOUISIANA

Chandlers Parts & Service

Baton Rouge 225-272-6620

Bana Comm. Parts, Inc.

Harahan 504-734-0076

MAR

YLAND

Electric Motor Service

Baltimore 410-467-8080

GCS Service

Silver Spring 301-585-7550

MASSACHUSETTS

Ace Service Co., Inc.

Needham 781-449-4220

MICHIGAN

Commercial Kitchen Service

Bay City 517-893-4561

Bildons Appliance Service

Detroit 248-478-3320

Midwest Food Equip. Service

Grandville 616-261-2000

MINNESOT

A

GCS Service

Minneapolis 612-546-4221

MISSOURI

General Parts

Kansas City 816-421-5400

Commercial Kitchen Services

St. Louis 314-890-0700

Kaemmerlen Parts & Service

St. Louis 314-535-2222

NEBRASKA

Anderson Electric

Omaha 402-341-1414

NEV

ADA

Burney’s Commercial

Las Vegas 702-736-0006

Hi. Tech Commercial Service

N. Las Vegas 702-649-4616

NEW JERSEY

Jay Hill Repair

Fairfield 973-575-9145

Service Plus

Flanders 973-691-6300

NEW

YORK

Acme American Repairs, Inc.

Brooklyn 718-456-6544

Alpro Service Co.

Brooklyn 718-386-2515

Appliance Installation

Buffalo 716-884-7425

Northern Parts Dist.

Plattsburgh 518-563-3200

J.B. Brady, Inc.

Syracuse 315-422-9271

NORTH CAROLINA

Authorized Appliance

Charlotte 704-377-4501

OHIO

Akron/Canton Comm. Svc. Inc.

Akron 330-753-6635

Certified Service Center

Cincinnati 513-772-6600

Commercial Parts and Service

Columbus 614-221-0057

Electrical Appl. Repair Service

Independence 216-459-8700

E. A. Wichman Co.

Toledo 419-385-9121

OKLAHOMA

Hagar Rest. Service, Inc.

Oklahoma City 405-235-2184

Krueger, Inc.

Oklahoma City 405-528-8883

OREGON

Bressie Electric Co.

Portland 503-231-7171

Ron’s Service, Inc.

Portland 503-624-0890

PENNSYL

VANIA

Elmer Schultz Services

Philadelphia 215-627-5401

FAST Comm. Appl. Service

Philadelphia 215-288-4800

GCS Service

Pittsburgh 412-787-1970

K & D Service Co.

Harrisburg 717-236-9039

Electric Repair Co.

Reading 610-376-5444

RHODE ISLAND

Marshall Electric Co.

Providence 401-331-1163

SOUTH CAROLINA

Whaley Foodservice Repair

W. Columbia 803-791-4420

TENNESSEE

Camp Electric

Memphis 901-527-7543

TEXAS

Stove Parts Supply

Fort Worth 817-831-0381

Armstrong Repair Service

Houston 713-666-7100

Commercial Kitchen Repair Co.

San Antonio 210-735-281 1

San Antonio Rest. Equip.

San Antonio 210-532-1660

UT

AH

La Monica’s Rest. Equip. Service

Murray 801-263-3221

VIRGINIA

Daubers

Norfolk 757-855-4097

Daubers

Springfield 703-866-3600

W

ASHINGTON

Restaurant Appl. Service

Seattle 206-524-8200

WISCONSIN

A.S.C., Inc.

Madison 608-246-3160

A.S.C., Inc.

Milwaukee 414-543-6460

CANADA

BRITISH COLUMBIA

Key Food Equipment Service

Vancouver 604-433-4484

MANIT

OBA

Denko Mechanical Ltd.

Winnipeg 204-233-8003

ONT

ARIO

R.G. Henderson Ltd.

Toronto 416-422-5580

Choquette CKS

Ottawa 613-739-8458

QUÉBEC

Choquette CKS

Montreal 514-722-2000

Choquette CKS

Québec City 418-681-3944

Part No. 07.04.341.00 Form No. TF1946M-1004

Loading...

Loading...