Page 1

Mini Display Warmer

MDW Series

Installation and Operating Manual

I&W #07.05.176.00

Do not operate this equipment unless

you have read and understood the

contents of this manual! Failure to follow

the instructions contained in this manual

may result in serious injury or death. This

manual contains important safety

information concerning the maintenance,

use, and operation of this product. If

you’re unable to understand the contents

of this manual, please bring it to the

attention of your supervisor. Keep this

manual in a safe location for future

reference.

No opere este equipo al menos que haya

leído y comprendido el contenido de este

manual! Cualquier falla en el seguimiento

de las instrucciones contenidas en este

manual puede resultar en un serio lesión

o muerte. Este manual contiene

importante información sobre seguridad

concerniente al mantenimiento, uso y

operación de este producto. Si usted no

puede entender el contenido de este

manual por favor pregunte a su

supervisor. Almacenar este manual en

una localización segura para la referencia

futura.

© 2008 Hatco Corporation

Page 2

CONTENTS

NOTICE

CAUTION

WARNING

Important Owner Information...............................i

Introduction ...........................................................i

Important Safety Information ..............................1

Model Description................................................2

Model Designation ...............................................2

Specifications.......................................................3

Plug Configurations .........................................3

Electrical Rating Chart.....................................3

Dimensions......................................................3

Installation ............................................................4

General............................................................4

Reversible Access Door ..................................5

Configurable Access Door...............................5

Operation ..............................................................6

Maintenance .........................................................7

Options..................................................................9

Troubleshooting.................................................10

Hatco Limited Warranty.....................................11

Authorized Parts Distributors ...........Back Cover

IMPORTANT OWNER INFORMATION

Record the model number, serial number (located on

the side of the unit), voltage and purchase date of

your Mini Display Warmer in the spaces below.

Please have this information available when calling

Hatco for service assistance.

Model No. ________________________________

Serial No. ________________________________

Voltage __________________________________

Date of Purchase __________________________

Business 8:00 a.m. to 5:00 p.m.

Hours: Central Standard Time

Telephone: (800) 558-0607; (414) 671-6350

Fax: (800) 690-2966 (Parts and Service)

General............................................................6

General............................................................7

Cleaning...........................................................7

Display Light Bulb Replacement .....................8

Installing a Graphic Image...............................9

Relocating the Graphic Panel..........................9

(Summer Hours: June to September –

8:00 a.m. to 5:00 p.m. C.S.T.

Monday through Thursday

8:00 a.m. to 2:30 p.m. C.S.T. Friday)

(414) 671-3976 (International)

24 Hour 7 Day Parts and Service

Assistance available in the

United States and Canada

by calling (800) 558-0607.

INTRODUCTION

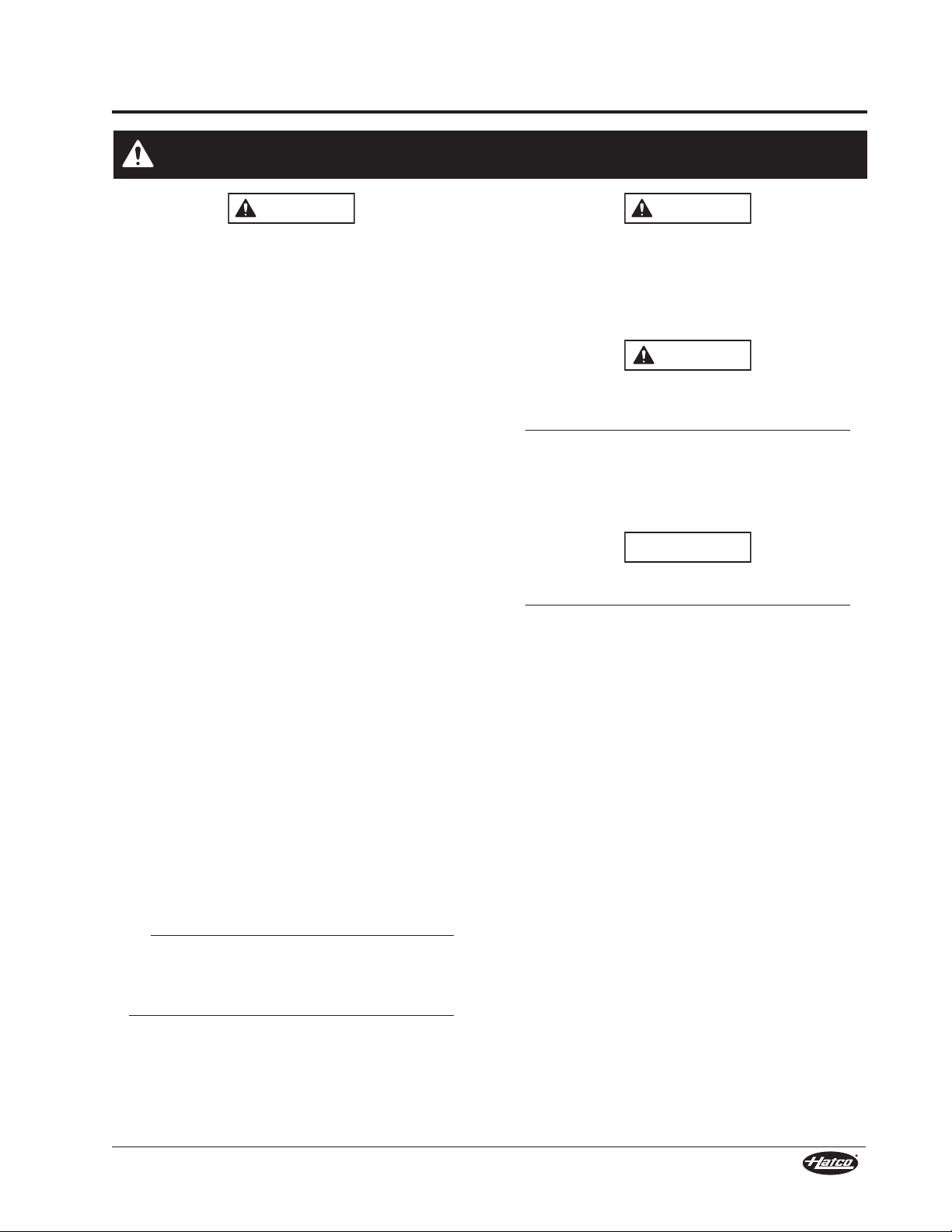

The Hatco Mini Display Warmer is designed to hold

prepared foods for prolonged periods of time while

maintaining that “just-made” quality. Mini Display

Warmer cabinets provide the best environment for

products like sandwiches, cookies, pretzels, muffins,

and desserts by regulating the air temperature.

The Mini Display Warmer air flow pattern is designed

to maintain consistent cabinet temperature. The heat

sources create a “blanket” effect around the food.

The air flow rate enables the cabinet to rapidly

recover temperature after opening and closing the

door. Configurable access doors and magnetic

adjustable shelves make the Hatco Mini Display

Warmer perfect for any food service application.

The Mini Display Warmer is a product of extensive

research and field testing. The materials used were

selected for maximum durability, attractive

appearance, and optimum performance. Every unit

is inspected and tested thoroughly prior to shipment.

This manual provides installation, safety, and

operating information for the Mini Display Warmer.

Additional information can be found by visiting our

web site at www.hatcocorp.com.

Hatco recommends all installation, operating, and

safety information appearing in this manual be read

prior to installation or operation of the Hatco Mini

Display Warmer.

Safety information that appears in this manual is

identified by the following signal word panels:

WARNING indicates a hazardous situation

which, if not avoided, could result in death or

serious injury.

CAUTION indicates a hazardous situation which,

if not avoided, could result in minor or moderate

injury.

NOTICE is used to address practices not related

to personal injury.

i

Form No. MDWM-0608

Page 3

IMPORTANT SAFETY INFORMATION

WARNING

NOTICE

CAUTION

WARNING

Read the following important safety information to avoid serious injury or death and to

avoid damage to equipment or property.

ELECTRIC SHOCK HAZARD:

• Plug unit into a properly grounded electrical

outlet of the correct voltage, size, and plug

configuration. If the plug and receptacle do

not match, contact a qualified electrician to

determine and install the proper voltage and

size electrical outlet.

• Turn the power switch OFF, unplug the power

cord, and allow the unit to cool before

performing any maintenance or cleaning.

• DO NOT submerge or saturate with water.

Unit is not waterproof. Do not operate if unit

has been submerged or saturated with water.

• Unit is not weatherproof. Locate the unit

indoors where the ambient air temperature is

a minimum of 70°F (21°C) and a maximum of

85°F (29°C).

• Do not steam clean or use excessive water on

the unit.

• Do not pull unit by power cord.

• Discontinue use if power cord is frayed or

worn.

• Do not attempt to repair or replace a damaged

power cord. The cord must be replaced by

Hatco, an Authorized Hatco Service Agent, or

a person with similar qualifications.

• Use only Genuine Hatco Replacement Parts

when service is required. Failure to use

Genuine Hatco Replacement Parts will void

all warranties and may subject operators of

the equipment to hazardous electrical

voltage, resulting in electrical shock or burn.

Genuine Hatco Replacement Parts are

specified to operate safely in the

environments in which they are used. Some

aftermarket or generic replacement parts do

not have the characteristics that will allow

them to operate safely in Hatco equipment.

This unit has no “user-serviceable” parts. If

service is required on this unit, contact an

Authorized Hatco Service Agent or contact the

Hatco Service Department at 800-558-0607 or

414-671-6350; fax 800-690-2966; or International

fax 414-671-3976.

BURN HAZARD: Some exterior surfaces on the

unit will get hot. Use caution when touching

these areas.

Locate the unit at the proper counter height in an

area that is convenient for use. The location

should be level to prevent the unit or its contents

from falling accidentally and strong enough to

support the weight of the unit and contents.

Do not lay unit on the side with the control panel

or damage to the unit could occur.

Use non-abrasive cleaners only. Abrasive

cleaners could scratch the finish of the unit,

marring its appearance and making it

susceptible to soil accumulation.

FIRE HAZARD: Locate the unit a minimum of

1″ (25 mm) from combustible walls and

materials. If safe distances are not maintained,

combustion or discoloration could occur.

Use only light bulbs that meet or exceed

(National Sanitation Foundation (NSF) standards

and are specifically designed for food holding

areas. Breakage of light bulbs not specially

coated could result in personal injury and/or

food contamination.

Form No. MDWM-0608

1

Page 4

MODEL DESCRIPTION

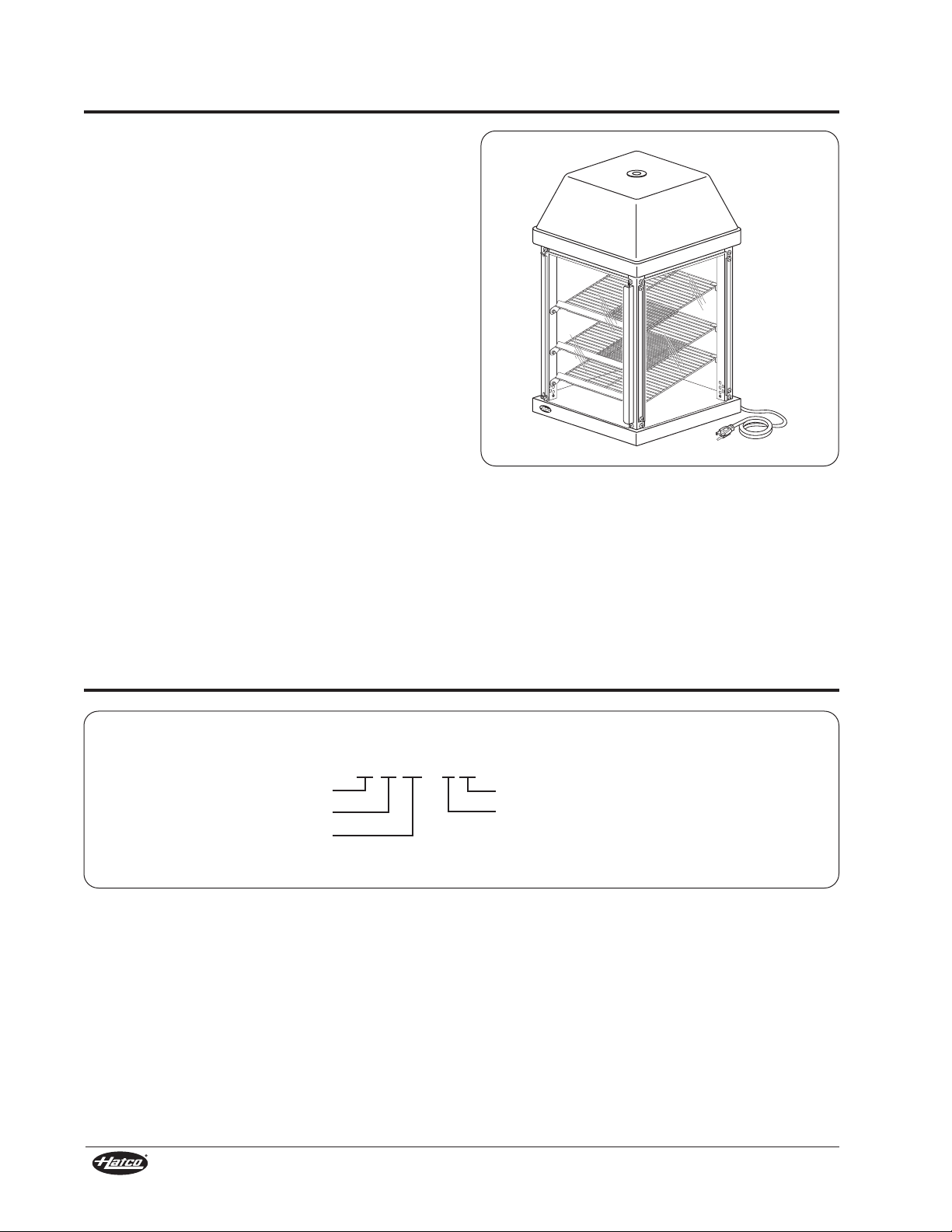

M D W - 1 X

Mini

Warmer

Display

Quantity Of Doors

No Revolving Display

All Models

Mini Display Warmers are powder-coated, painted

steel and feature tempered glass sides. The access

door(s) can be hinged left or right and are

configurable for any side to allow “pass-through”

from the side or back to the service area. The

cabinet interior top and bottom are made of easy-toclean stainless steel. The unit’s dry heat system is

suitable for all boxed or wrapped food products as

well as unwrapped muffins, turnovers, and desserts.

Three magnetically adjustable shelves for horizontal

or slanted displays provide flexibility for a variety of

product choices. Shelf height is also adjustable to

accommodate a variety of food package sizes. The

unit has incandescent lighting to heighten product

awareness.

The Hatco Mini Display Warmer holds and serves

products at temperatures up to 180°F (82°C).

Perfect for convenience stores, restaurants,

recreational facilities, theme parks, and anywhere

there is limited counterspace.

Available in six Designer colors: Warm Red, Black,

Gray Granite, White Granite, Navy Blue and Hunter

Green.

Figure 1. Model MDW-2X

NOTE: The top cover of the Mini Display Warmer is

always black.

MODEL DESIGNATION

Figure 2. Model Designation

2

Form No. MDWM-0608

Page 5

SPECIFICATIONS

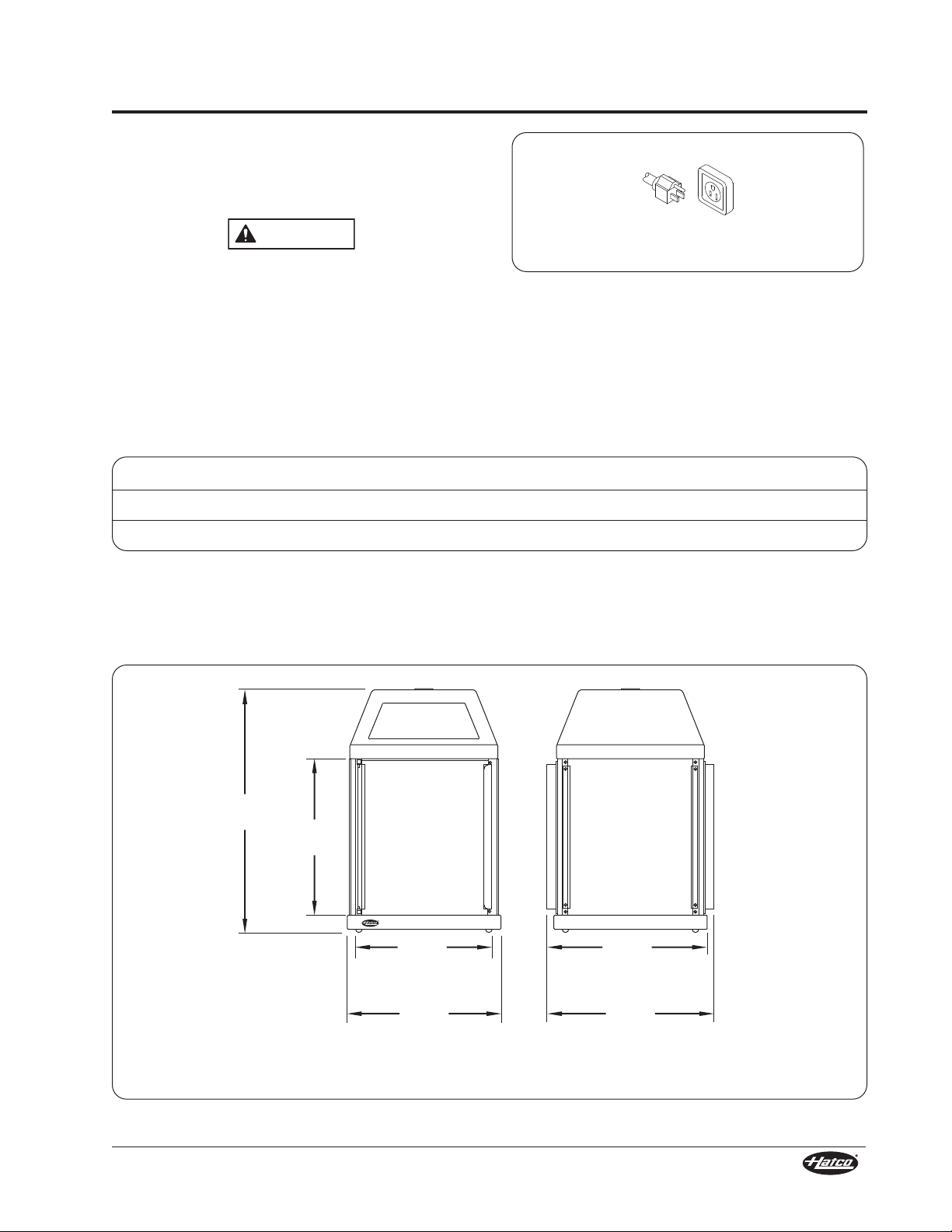

NEMA 5-15P

WARNING

15-3/4″

(400 mm)

Square Base

17-1/4″

(438 mm)

2 Doors

16-1/2″

(419 mm)

1 Door

14-1/8″

(359 mm)

Square Footprint

25-1/8″

(638 mm)

16″

(406 mm)

Front View Side View

Plug Configuration

Units are supplied from the factory with a 6'

(1829 mm) electrical cord and NEMA 5-15P plug

installed (see Figure 3).

ELECTRIC SHOCK HAZARD: Plug unit into a

properly grounded electrical outlet of the correct

voltage, size, and plug configuration. If the plug

and receptacle do not match, contact a qualified

electrician to determine and install the proper

NOTE: Receptacle not supplied by Hatco.

voltage and size electrical outlet.

Electrical Rating Chart

Model Voltage Watts Amps Plug Configuration Shipping Weight

MDW-1X 120 470 3.9 NEMA 5-15P 46 lbs (21 kg)

MDW-2X 120 470 3.9 NEMA 5-15P 48 lbs (22 kg)

Figure 3. Plug Configuration

Dimensions

Figure 4. Dimensions

Form No. MDWM-0608

3

Page 6

NOTICE

CAUTION

WARNING

Product Stop

Magnet

Shelves may be

inserted horizontally

or inclined.

INSTALLATION

General

The Mini Display Warmer is shipped with most

components installed and ready for operation. The

following installation instructions must be performed

before plugging in and operating the unit.

FIRE HAZARD: Locate the unit a minimum of 1″

(25 mm) from combustible walls and materials. If

safe distances are not maintained, combustion

or discoloration could occur.

Unit is not weatherproof. Locate the unit indoors

where the ambient air temperature is a minimum

of 70°F (21°C) and a maximum of 85°F (29°C).

Locate the unit at the proper counter height in an

area that is convenient for use. The location

should be level to prevent the unit or its contents

from falling accidentally and strong enough to

support the weight of the unit and contents.

Do not lay unit on the side with the control panel

or damage to the unit could occur.

1. Remove unit from box.

2. Remove the information packet.

NOTE: To prevent delay in obtaining warranty

coverage, fill out and mail in the warranty

card to Hatco.

3. Remove tape and protective film from all

surfaces of unit.

4. The stainless steel floor in all units is protected

during shipping with a sheet of corrugated

cardboard. This protection must be removed

prior to cabinet operation.

5. The shelves have packing material and

cardboard attached for protection during

shipping. This protection must be removed prior

to cabinet operation.

6. Position the shelves at adequate heights to

accommodate your product. The shelves may

be inserted horizontally or inclined with the

product stops toward the service area access

(see Figure 5).

7. If the unit is equipped with an optional

Merchandising Display Cover, see the

Accessories section for installation instructions.

NOTE: The unit must be transported in the upright

position. If laid on its side, all glass surfaces

must be secured with tape.

Figure 5. Shelves

4

Form No. MDWM-0608

Page 7

INSTALLATION

Attach fixed glass panels

using inner holes.

Attach reversible accessdoors

using outer holes.

Bracket

Hinge/Pivot Pin

Reversible Access Door

Any door may be changed from hinged left to hinged

right.

1. While holding the door securely, remove the

screw attaching the top left hinge/pivot pin to the

cabinet.

2. Carefully lift the door off of the bottom

hinge/pivot pin. Also remove the nylon washer

and save.

3. Rotate the removed hinge and attach (with the

pivot pin facing up) using the removed screw to

the bottom-most outer hole on the right-hand

side of the cabinet (see Figure 6).

4. Remove the screw attaching the bottom left

hinge/pivot pin to the cabinet.

5. Rotate the door 180° and install the nylon

washer and the door onto the newly attached

bottom right hinge/pivot pin.

6. Rotate the removed hinge (the pivot pin now

facing down) and insert it into the top of the door.

7. Line up the hinge’s hole with the top-most hole

in the cabinet and attach with the removed

screw.

Configurable Access Door

Any door may be exchanged with a fixed glass panel

to suit the installation.

1. While holding the door securely, remove the screw

attaching the top hinge/pivot pin to the cabinet.

2. Carefully lift the door off of the bottom

hinge/pivot pin. Also remove the nylon washer

and save.

3. Remove the screw attaching the bottom

hinge/pivot pin to the cabinet. Keep the nylon

washer and hardware.

4. While holding the fixed glass panel securely,

remove the four screws attaching the two

brackets to the cabinet.

5. Carefully move the fixed glass panel to the side

of the unit from which the door was removed.

6. Line up the holes in one bracket with the inner

holes in the cabinet and attach with the screws

(see Figure 6). Repeat on the opposite side of

the fixed glass panel.

7. On the side of the unit from which the fixed glass

panel was removed, line up the hole in the

hinge/pivot pin (with the pivot pin facing up) with

the bottom-most hole in the unit and attach with

a removed screw.

8. Install the nylon washer and the door onto the

newly attached bottom hinge/pivot pin.

9. Insert the remaining hinge/pivot pin (the pivot pin

facing down) into the top of the door.

10. Line up the hinge’s hole with the top-most hole

in the cabinet and attach with the other removed

screw.

Form No. MDWM-0608

Figure 6. Reversible Access Door and Fixed Glass Panel

5

Page 8

OPERATION

Interior

Thermometer

Power Switch

Temperature

Control

CAUTION

WARNING

General

Use the following procedure to turn on and operate

the Hatco Mini Display Warmer.

Read all safety messages in the IMPORTANT

SAFETY INFORMATION section before operating

this equipment.

1. Plug unit into an electrical outlet of the correct

voltage, size and plug configuration. See the

SPECIFICATIONS section for details.

2. Move the Power switch on the control panel to

the On position (see Figure 7).

3. Set the Temperature Control to the desired level

between MIN and MAX.

BURN HAZARD: Some exterior surfaces on the

unit will get hot. Use caution when touching

these areas.

4. Allow 30 minutes to preheat, check the interior

thermometer and adjust the Temperature

Control if necessary.

NOTE: Temperature settings may vary depending

upon product make-up and consistency. The

interior thermometer displays temperature

inside the cabinet, not the food product

temperature.

Figure 7. Control Panel

6

Form No. MDWM-0608

Page 9

MAINTENANCE

Screw

Bracket

NOTICE

WARNING

General

The Hatco Mini Display Warmer is designed for

maximum durability and performance, with minimum

maintenance.

ELECTRIC SHOCK HAZARD:

• Turn the power switch OFF, unplug the power

cord, and allow the unit to cool before

performing any maintenance or cleaning.

• DO NOT submerge or saturate with water.

Unit is not waterproof. Do not operate if unit

has been submerged or saturated with water.

• Do not steam clean or use excessive water on

the unit.

This unit has no “user-serviceable” parts. If

service is required on this unit, contact an

Authorized Hatco Service Agent or contact the

Hatco Service Department at 800-558-0607 or

414-671-6350; fax 800-690-2966; or International

fax 414-671-3976.

Cleaning

Removing Glass for Cleaning

1. While holding the fixed glass panel securely,

remove the four screws attaching the two

brackets to the cabinet. Keep hardware.

2. Carefully lift the fixed glass panel off to clean.

Installing Glass

1. Return the fixed glass panel to the side of the

cabinet.

2. Line up the holes in one bracket with the inner

holes in the cabinet and attach with two screws.

Repeat on the opposite side of the panel.

Use non-abrasive cleaners only. Abrasive

cleaners could scratch the finish of the unit,

marring its appearance and making it

susceptible to soil accumulation.

To preserve the finish of the Mini Display Warmer

cabinet, it is recommended that the exterior and

interior surfaces be wiped daily with a damp cloth.

Shelves should be removed and washed. Stubborn

stains may be removed with a good stainless steel

cleaner or a non-abrasive cleaner. Hard to reach

areas should be cleaned with a small brush and mild

soap.

Clean the glass sides using a common glass

cleaner. In almost all cases, glass panels should be

cleaned while remaining in the unit. Only for difficult

or hard to clean stains is removal of the fixed glass

panels suggested.

Figure 8. Glass Panel Removal

Form No. MDWM-0608

7

Page 10

MAINTENANCE

Threaded Cap

Top Cover

Hood Filler Panel

Light Bulb

WARNING

Display Light Bulb Replacement

The display light is an incandescent bulb that

illuminates the warming area. This bulb has a

special coating to guard against injury and food

contamination in the event of breakage.

Use only light bulbs that meet or exceed

(National Sanitation Foundation (NSF) standards

and are specifically designed for food holding

areas. Breakage of light bulbs not specially

coated could result in personal injury and/or

food contamination.

Use only Genuine Hatco Replacement Parts

when service is required. Failure to use Genuine

Hatco Replacement Parts will void all warranties

and may subject operators of the equipment to

hazardous electrical voltage, resulting in

electrical shock or burn. Genuine Hatco

Replacement Parts are specified to operate

safely in the environments in which they are

used. Some aftermarket or generic replacement

parts do not have the characteristics that will

allow them to operate safely in Hatco equipment.

1. Disconnect the power supply and wait until the

unit has cooled.

2. Unscrew and remove the threaded cap from the

the top cover (see Figure 9).

3. Remove the top cover from the cabinet (see

Figure 9).

4. Remove one hood filler panel. (Two screws

need to be removed to remove the hood filler

panel.)

5. Unscrew the bulb from the unit and replace it

with a new specially coated incandescent bulb

(display light bulbs have a threaded base).

Hatco shatter-resistant bulbs meet NSF

standards for food holding and display areas.

When replacing the light bulb, use Hatco part

number 02.30.043.00.

6. Reinstall the hood filler panel.

7. Securely place the top cover back onto the

cabinet.

8. Reinstall the threaded cap to secure the top

cover.

Figure 9. Bulb Replacement

8

Form No. MDWM-0608

Page 11

OPTIONS

Hood Filler Panel

Hood Filler Panel

Top Cover

Frame

Top Cover

Top Cover

Frame

Threaded Cap

Graphic Panel

Tab

Graphic Decal

Notch

Installing A Graphic Image

Use the following procedure to apply a graphic

image to the plexiglass graphic panel in the top

cover of the unit.

1. Disconnect the power supply and wait until the

unit has cooled.

2. Unscrew and remove the threaded cap from the

top cover (see Figure 10).

3. Remove the top cover.

4. Remove the graphic panel from the top cover

frame.

5. Apply the graphic image:

• If the graphic image is a decal, peel off the

backing paper from the graphic decal and

apply the decal to the graphic panel.

• If the graphic image is non-adhesive, trim the

image to the shape of the graphic panel leaving

no more than an 1/8″ gap between the image

and the edge of the panel. Then, tape the

image to the inside face of the graphic panel.

Make sure to tape around the entire edge of

the image so that it does not hang loose.

6. Install the graphic panel with the tabs on the

panel resting in the corner notches of the top

cover frame (see Figure 10).

7. Securely place the cover back onto the cabinet.

Make sure the cut-out in the top cover is over the

graphic panel.

8. Reinstall the threaded cap to secure the top cover.

Relocating the Graphic Panel

Use the following procedure to change the location

of the graphic panel at the top of the unit. The

graphic panel can be installed into any of the four

openings of the top cover frame.

1. Disconnect the power supply and wait until the

unit has cooled.

2. Unscrew and remove the threaded cap from the

top cover (see Figure 10).

3. Remove the top cover.

4. Remove the graphic panel from its existing

location in the top cover frame.

5. Remove the hood filler panel from the side

where the graphic panel needs to be installed.

(Two screws need to be removed to remove the

hood filler panel.)

6. Install the hood filler panel onto the side where

the graphic panel was originally located. Make

sure the top lip of the hood filler panel fits over

the edge of the top cover frame and the two

screws are installed (see Figure 10).

7. Install the graphic panel into the new position

with the tabs on the graphic panel resting in the

corner notches of the top cover frame.

8. Securely place the top cover back onto the

cabinet. Make sure the cut-out in the top cover is

over the graphic panel.

9. Reinstall the threaded cap to secure the top cover.

Form No. MDWM-0608

Figure 10. Merchandising Display Sign

9

Page 12

TROUBLESHOOTING

WARNING

WARNING

This unit must be serviced by qualified

personnel only. Service by unqualified personnel

may lead to electric shock or burn.

ELECTRIC SHOCK HAZARD: Turn the power

switch OFF, unplug the power cord, and allow

the unit to cool before performing any

maintenance or cleaning.

Symptom Probable Cause Corrective Action

Light bulb not working. Light bulb defective.

Power turned OFF.

Food cavity not hot enough. Temperature control set too low.

Heating element(s) not working.

Temperature control not working

properly.

Air circulating fan not working

properly.

Food cavity too hot. Temperature control set too high.

Temperature control not working

properly.

Replace light bulb.

Turn unit ON.

Adjust temperature control to a

higher setting.

Contact Authorized Service Agent

or Hatco for assistance.

Contact Authorized Service Agent

or Hatco for assistance.

Contact Authorized Service Agent

or Hatco for assistance.

Adjust temperature control to a

lower setting.

Contact Authorized Service Agent

or Hatco for assistance.

No heat, but light works. Temperature control set too low.

Heating element(s) not working.

Temperature control not working

properly.

No heat and no light. Unit turned OFF.

Circuit breaker tripped.

Adjust temperature control to a

higher setting.

Contact Authorized Service Agent

or Hatco for assistance.

Contact Authorized Service Agent

or Hatco for assistance.

Turn unit ON.

Reset circuit breaker. If circuit

breaker continues to trip, contact

Authorized Service Agent or

Hatco for assistance.

10

Form No. MDWM-0608

Page 13

HATCO LIMITED WARRANTY

1. PRODUCT WARRANTY

Hatco warrants the products that it manufactures

(the “Products”) to be free from defects in materials

and workmanship, under normal use and service, for

a period of one (1) year from the date of purchase

when installed and maintained in accordance with

Hatco’s written instructions or 18 months from the

date of shipment from Hatco. Buyer must establish

the Product’s purchase date by returning Hatco’s

Warranty Registration Card or by other means

satisfactory to Hatco in its sole discretion.

Hatco warrants the following Product components to

be free from defects in materials and workmanship

from the date of purchase (subject to the foregoing

conditions) for the period(s) of time and on the

conditions listed below:

a) One (1) Year Parts and Labor PLUS One

(1) Additional Year Parts-Only Warranty:

Conveyor Toaster Elements (metal sheathed)

Drawer Warmer Elements (metal sheathed)

Drawer Warmer Drawer Rollers and Slides

Food Warmer Elements (metal sheathed)

Display Warmer Elements (metal sheathed air

heating)

Holding Cabinet Elements (metal sheathed air

heating)

Built-In Heated Well Elements

(metal sheathed)

b) One (1) Year Parts and Labor PLUS Four

(4) Years Parts-Only Warranty on

pro-rated terms that Hatco will explain

at Buyer’s request:

3CS and FR Tanks

c) One (1) Year Parts and Labor PLUS Nine

(9) Years Parts-Only Warranty on:

Electric Booster Heater Tanks

Gas Booster Heater Tanks

THE FOREGOING WARRANTIES ARE

EXCLUSIVE AND IN LIEU OF ANY OTHER

WARRANTY, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE OR PATENT OR

OTHER INTELLECTUAL PROPERTY RIGHT

INFRINGEMENT. Without limiting the generality of

the foregoing, SUCH WARRANTIES DO NOT

COVER: Coated incandescent light bulbs, fluorescent

lights, decorative heat lamp bulbs, coated halogen light

bulbs, halogen heat lamp bulbs, heated glass shelves,

glass components, Product failure in booster tank, fin

tube heat exchanger, or other water heating

equipment caused by liming, sediment buildup,

chemical attack or freezing, Product misuse, tampering

or misapplication, improper installation, or application of

improper voltage.

2. LIMITATION OF REMEDIES AND DAMAGES

Hatco’s liability and Buyer’s exclusive remedy

hereunder will be limited solely, at Hatco’s option, to

repair or replacement by a Hatco-authorized service

agency (other than where Buyer is located outside of

the United States, Canada, United Kingdom or

Australia in which case Hatco’s liability and Buyer’s

exclusive remedy hereunder will be limited solely to

replacement of part under warranty) with respect to

any claim made within the applicable warranty

period referred to above. Hatco reserves the right to

accept or reject any such claim in whole or in part.

Hatco will not accept the return of any Product

without prior written approval from Hatco, and all

such approved returns shall be made at Buyer’s sole

expense. HATCO WILL NOT BE LIABLE, UNDER

ANY CIRCUMSTANCES, FOR CONSEQUENTIAL

OR INCIDENTAL DAMAGES, INCLUDING BUT

NOT LIMITED TO LABOR COSTS OR LOST

PROFITS RESULTING FROM THE USE OF OR

INABILITY TO USE THE PRODUCTS OR FROM

THE PRODUCTS BEING INCORPORATED IN OR

BECOMING A COMPONENT OF ANY OTHER

PRODUCT OR GOODS.

Form No. MDWM-0608

11

Page 14

HATCO CORPORATION

P.O. Box 340500

Milwaukee, WI 53234-0500 U.S.A.

(800) 558-0607 (414) 671-6350

Parts and Service Fax (800) 690-2966

International Fax (414) 671-3976

www.hatcocorp.com

HATCO AUTHORIZED PARTS DISTRIBUTORS

ALABAMA

Jones McLeod Appl. Svc.

Birmingham 205-251-0159

ARIZONA

Auth. Comm. Food Equip.

Phoenix 602-234-2443

Byassee Equipment Co.

Phoenix 602-252-0402

CALIFORNIA

Industrial Electric

Commercial Parts & Service, Inc.

Huntington Beach 714-379-7100

Chapman Appl. Service

San Diego 619-298-7106

P & D Appliance

Commercial Parts & Service, Inc.

S. San Francisco 650-635-1900

COLORADO

Hawkins Commercial Appliance

Englewood 303-781-5548

FLORIDA

Whaley Foodservice Repair

Jacksonville 904-725-7800

Nass Service Co., Inc.

Orlando 407-425-2681

B.G.S.I.

Pompano Beach 954-971-0456

Comm. Appliance Service

Tampa 813-663-0313

GEORGIA

TWC Services

Smyrna 770-438-9797

Heritage Service Group

Norcross 866-388-9837

Southeastern Rest. Svc.

Norcross 770-446-6177

HAWAII

Burney’s Comm. Service, Inc.

Honolulu 808-848-1466

Food Equip Parts & Service

Honolulu 808-847-4871

ILLINOIS

Parts Town

Lombard 708-865-7278

Eichenauer Elec. Service

Decatur 217-429-4229

Midwest Elec. Appl. Service

Elmhurst 630-279-8000

Cone’s Repair Service

Moline 309-797-5323

INDIANA

GCS Service

Indianapolis 317-545-9655

IOWA

Electric Motor Service Co.

Davenport 319-323-1823

Goodwin Tucker Group

Des Moines 515-262-9308

KENTUCKY

Certified Service Center

Lexington 859-254-8854

Certified Service Center

Louisville 502-964-7007

LOUISIANA

Chandlers Parts & Service

Baton Rouge 225-272-6620

MARYLAND

Electric Motor Service

Baltimore 410-467-8080

GCS Service

Silver Spring 301-585-7550

MASSACHUSETTS

Ace Service Co., Inc.

Needham 781-449-4220

MICHIGAN

Commercial Kitchen Service

Bay City 517-893-4561

Bildons Appliance Service

Detroit 248-478-3320

Midwest Food Equip. Service

Grandville 616-261-2000

MINNESOTA

GCS Service

Minneapolis 800-822-2303

MISSOURI

General Parts

Kansas City 816-421-5400

Commercial Kitchen Services

St. Louis 314-890-0700

Kaemmerlen Parts & Service

St. Louis 314-535-2222

NEBRASKA

Anderson Electric

Omaha 402-341-1414

NEVADA

Burney’s Commercial

Las Vegas 702-736-0006

Hi. Tech Commercial Service

N. Las Vegas 702-649-4616

NEW JERSEY

Jay Hill Repair

Fairfield 973-575-9145

Service Plus

Flanders 973-691-6300

NEW YORK

Acme American Repairs, Inc.

Brooklyn 718-456-6544

Alpro Service Co.

Brooklyn 718-386-2515

Appliance Installation

Buffalo 716-884-7425

Northern Parts Dist.

Plattsburgh 518-563-3200

J.B. Brady, Inc.

Syracuse 315-422-9271

NORTH CAROLINA

Authorized Appliance

Charlotte 704-377-4501

OHIO

Akron/Canton Comm. Svc. Inc.

Akron 330-753-6635

Certified Service Center

Cincinnati 513-772-6600

Commercial Parts and Service

Columbus 614-221-0057

Electrical Appl. Repair Service

Independence 216-459-8700

E. A. Wichman Co.

Toledo 419-385-9121

OKLAHOMA

Hagar Rest. Service, Inc.

Oklahoma City 405-235-2184

Krueger, Inc.

Oklahoma City 405-528-8883

OREGON

Ron’s Service, Inc.

Portland 503-624-0890

PENNSYLVANIA

Elmer Schultz Services

Philadelphia 215-627-5401

FAST Comm. Appl. Service

Philadelphia 215-288-4800

Appliance Installation & Service

Pittsburgh 412-809-0244

K & D Service Co.

Harrisburg 717-236-9039

Electric Repair Co.

Reading 610-376-5444

RHODE ISLAND

Marshall Electric Co.

Providence 401-331-1163

SOUTH CAROLINA

Whaley Foodservice Repair

W. Columbia 803-791-4420

TENNESSEE

Camp Electric

Memphis 901-527-7543

TEXAS

GCS Service

Fort Worth 800-433-1804

Armstrong Repair Service

Houston 713-666-7100

Cooking Equipment Specialist

Mesquite 972-686-6666

Commercial Kitchen Repair Co.

San Antonio 210-735-2811

UTAH

La Monica’s Rest. Equip. Service

Murray 801-263-3221

VIRGINIA

Daubers

Norfolk 757-855-4097

Daubers

Springfield 703-866-3600

WASHINGTON

3 Wire/Restaurant Appliance

Seattle 866-770-2022

WISCONSIN

A.S.C., Inc.

Madison 608-246-3160

A.S.C., Inc.

Milwaukee 414-543-6460

CANADA

ALBERTA

Key Food Equipment Service

Edmonton 780-438-1690

BRITISH COLUMBIA

Key Food Equipment Service

Vancouver 604-433-4484

MANITOBA

Air Rite, Inc.

Winnepeg 204-895-2300

NEW BRUNSWICK

EMR Services, Ltd.

Moncton 506-855-4228

ONTARIO

R.G. Henderson Ltd.

Toronto 416-422-5580

Choquette CKS

Ottawa 613-739-8458

QUÉBEC

Choquette CKS

Montreal 514-722-2000

Choquette CKS

Québec City 418-681-3944

UNITED KINGDOM

Marren Group

Northants +44(0)1933 666233

Printed in U.S.A. June 2008 Part No. 07.04.405.00 Form No. MDWM-0608

Loading...

Loading...