Hatco DL Owner’s Manual

400

1100

1200

1300

1400

1500

500

600

700

725

750

760

775

800

Register Online!

hatcocorp.com

WARNING

ADVERTENCIA

AVERTISSEMENT

(see page 2)

S'inscrire en ligne!

(voir page 16)

Installation and Operating Manual

Manuel d'installation et d'utilisation

Decorative Lamps

Lampes Décoratives

DL Series • Série DL

Do not operate this equipment unless you

have read and understood the contents of

this manual! Failure to follow the

instructions contained in this manual may

result in serious injury or death. This

manual contains important safety

information concerning the maintenance,

use, and operation of this product. If

you’re unable to understand the contents

of this manual, please bring it to the

attention of your supervisor. Keep this

manual in a safe location for future

reference.

P/N 07.04.371.00

English = p 2

No opere este equipo al menos que haya

leído y comprendido el contenido de este

manual! Cualquier falla en el seguimiento

de las instrucciones contenidas en este

manual puede resultar en un serio lesión

o muerte. Este manual contiene

importante información sobre seguridad

concerniente al mantenimiento, uso y

operación de este producto. Si usted no

puede entender el contenido de este

manual por favor pregunte a su

supervisor. Almacenar este manual en

una localización segura para la referencia

futura.

Ne pas utiliser cet équipement sans avoir

lu et compris le contenu de ce manuel !

Le non-respect des instructions

contenues dans ce manuel peut entraîner

de graves blessures ou la mort. Ce

manuel contient des informations

importantes concernant l'entretien,

l'utilisation et le fonctionnement de ce

produit. Si vous ne comprenez pas le

contenu de ce manuel, veuillez le signaler

à votre supérieur. Conservez ce manuel

dans un endroit sûr pour pouvoir vous y

référer plus tard.

Français = p 16

© 2016 Hatco Corporation

24 Hour 7 Day Parts and Service

Assistance available in the United States

and Canada by calling 800-558-0607.

WARNING

NOTICE

CAUTION

CONTENTS

English

Important Owner Information ..............................................2

Introduction...........................................................................2

Important Safety Information...............................................3

Model Description.................................................................4

Specifications........................................................................4

Electrical Rating Chart .........................................................4

Dimensions — Lamp Shade................................................4

Model Designation................................................................5

Installation.............................................................................6

General ................................................................................6

Assembly .............................................................................7

Installing A, C, P, S, and R Mount Units ..............................8

Installing TS Mount Units (UL Recognized).........................8

Installing Track Mount Units (CT, ST, and RT) ....................8

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage, and

purchase date of the unit in the spaces below (specification

label located inside the lamp shade). Please have this

information available when calling Hatco for service assistance.

Model No. ________________________________________

Serial No. ________________________________________

Voltage __________________________________________

Operation .............................................................................11

General ..............................................................................11

Operating Retractable Units...............................................11

Maintenance ........................................................................12

General ..............................................................................12

Daily Cleaning....................................................................12

Replacing an Infrared Bulb ................................................12

Troubleshooting Guide ......................................................13

Options and Accessories...................................................14

Limited Warranty.................................................................15

Authorized Parts Distributors............................Back Cover

Business

Hours: 7:00

Telephone: 800-558-0607; 414-671-6350

e-mail: partsandservice@hatcocorp.com

AM to 5:00 PM Central Standard Time (CST)

(Summer Hours: June to September—

7:00

AM to 5:00 PM CST Monday–Thursday

7:00

AM to 4:00 PM CST Friday)

Date of Purchase __________________________________

Register your unit!

Completing online warranty registration will prevent delay in

obtaining warranty coverage. Access the Hatco website at

www.hatcocorp.com, select the Parts & Service pull-down

menu, and click on “Warranty Registration”.

INTRODUCTION

Hatco Decorative Lamps are designed to hold food at serving

temperatures as well as enhance restaurant decor. Decorative

Lamps provide light and supplemental heat. A “Luminaire”

option (lighting only) is available for applications that do not

require supplemental heat but would benefit from the style and

focus of a Decorative Lamp.

Decorative Lamps are quality built to meet the demands of

foodservice operations and provide years of trouble-free

performance.

Hatco Decorative Lamps are products of extensive research and

field testing. The materials used were selected for maximum

durability, attractive appearance, and optimum performance.

Every unit is inspected and tested thoroughly prior to shipment.

Additional information can be found by visiting our web site at

www.hatcocorp.com.

This manual provides the installation, safety, and operating

instructions for Decorative Lamps. Hatco recommends all

installation, operating, and safety instructions appearing in this

manual be read prior to installation or operation of a unit.

Safety information that appears in this manual is identified by

the following signal word panels:

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

2

Form No. DHLM-0916

English

WARNING

NOTICE

CAUTION

WARNING

IMPORTANT SAFETY INFORMATION

Read the following important safety information before using this equipment to avoid serious

injury or death and to avoid damage to equipment or property.

ELECTRIC SHOCK HAZARD:

• Unit must be installed by a qualified electrician. Installation

must conform to all local electrical codes. Installation by

unqualified personnel will void unit warranty and may lead

to electric shock or burn, as well as damage to unit and/or

its surroundings.

• Turn OFF power at mounting location before installation

of unit.

• Failure to ground unit properly could result in serious

personal injury or death.

• Turn OFF power at fused disconnect switch/circuit breaker

and allow unit to cool before performing any cleaning,

adjustments, or maintenance.

• DO NOT submerge or saturate with water. Unit is not

waterproof. Do not operate if unit has been submerged or

saturated with water.

• Unit is not weatherproof. Locate the unit indoors.

• Do not steam clean or use excessive water on unit.

• Do not install track system above a steam table or other

steam generating appliance.

• This unit is not “jet-proof” construction. Do not use jetclean spray to clean this unit.

• This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

• Use only Genuine Hatco Replacement Parts when service

is required. Failure to use Genuine Hatco Replacement

Parts will void all warranties and may subject operators of

the equipment to hazardous electrical voltage, resulting in

electrical shock or burn. Genuine Hatco Replacement

Parts are specified to operate safely in the environments in

which they are used. Some aftermarket or generic

replacement parts do not have the characteristics that will

allow them to operate safely in Hatco equipment.

FIRE HAZARD:

• Locate unit a minimum of 1″ (25 mm) from combustible

walls and materials. If safe distances are not maintained,

discoloration or combustion could occur.

• DL standard watt lamps (250 W bulb) and Luminaires

(200 W bulb maximum) must have a minimum of 16″

(406 mm) above a combustible surface or minimum

clearance of 5″ (127 mm) above a non-combustible

surface. If safe distances are not maintained, discoloration

or combustion could occur.

• DLH high watt lamps (375 W bulb) must have a minimum

of 27″ (686 mm) above a combustible surface or minimum

clearance of 5″ (127 mm) above a non-combustible

surface. If safe distances are not maintained, discoloration

or combustion could occur.

• Do not install a 375 W bulb into a DL standard watt lamp or

a Luminaire unit.

Hatco Corporation is not responsible for actual food product

serving temperature. It is the responsibility of the user to

ensure that food product is held and served at a safe

temperature.

Make sure all operators have been instructed on the safe and

proper use of the unit.

This unit is not intended for use by children or persons with

reduced physical, sensory, or mental capabilities. Ensure proper

supervision of children and keep them away from unit.

This unit has no “user-serviceable” parts. If service is required

on this unit, contact an Authorized Hatco Service Agent or

contact the Hatco Service Department at 800-558-0607 or

414-671-6350.

BURN HAZARD: Some exterior surfaces on unit will get hot.

Use caution when touching these areas.

When installing track lighting systems, use only fixture

assemblies marked for use with HALO

Fittings marked for use with L-650 Series Track.

Power-Trac systems are not intended for use with a power

supply cord or convenience receptacle adapter.

The maximum capacity of Power-Trac track lighting systems is

20 A per circuit. Check fuses and circuits carefully before

installing. The 20 A maximum includes all lights and

appliances connected to circuit (120 V only, maximum 1920 W

per any length track).

Use caution when drilling during track installation to avoid

damaging buss bar insulators. If insulators are damaged,

discard the section—DO NOT use.

For non-CE units NOT equipped with a Hatco-supplied switch,

a qualified electrician must choose an appropriate switch for

the application based on amperage and in-rush rating of the

switch.

For all CE units, a qualified electrician must choose and install

an appropriate double-pole switch for the application based on

amperage and in-rush rating of the switch.

All canopy mount units are designed to fit a standard 4″

(102 mm) octagonal junction box. Junction box must be

anchored securely to building structure.

Multiple installations of Decorative Lamps must have a

minimum clearance of 12" (305 mm) on center of shade

between each unit.

Damage to any countertop material caused by heat generated

from Hatco equipment is not covered under the Hatco

warranty. Contact manufacturer of countertop material for

application information.

Retractable models and track mounted units must be installed

on a flat, horizontal ceiling or damage to unit could occur.

Hatco Decorative Lamps are built to fit

®

Power-Trac and Track

L-650 Series HALO

Power-Trac lighting systems only. Do not attempt to use on

any other track lighting system.

Use non-abrasive cleaners and cloths only. Abrasive cleaners

and cloths could scratch the finish of the unit, marring its

appearance and making it susceptible to soil accumulation.

Do not use ammonia-based cleaners on unit.

This unit is intended for commercial use only—NOT for

household use.

®

Form No. DHLM-0916

3

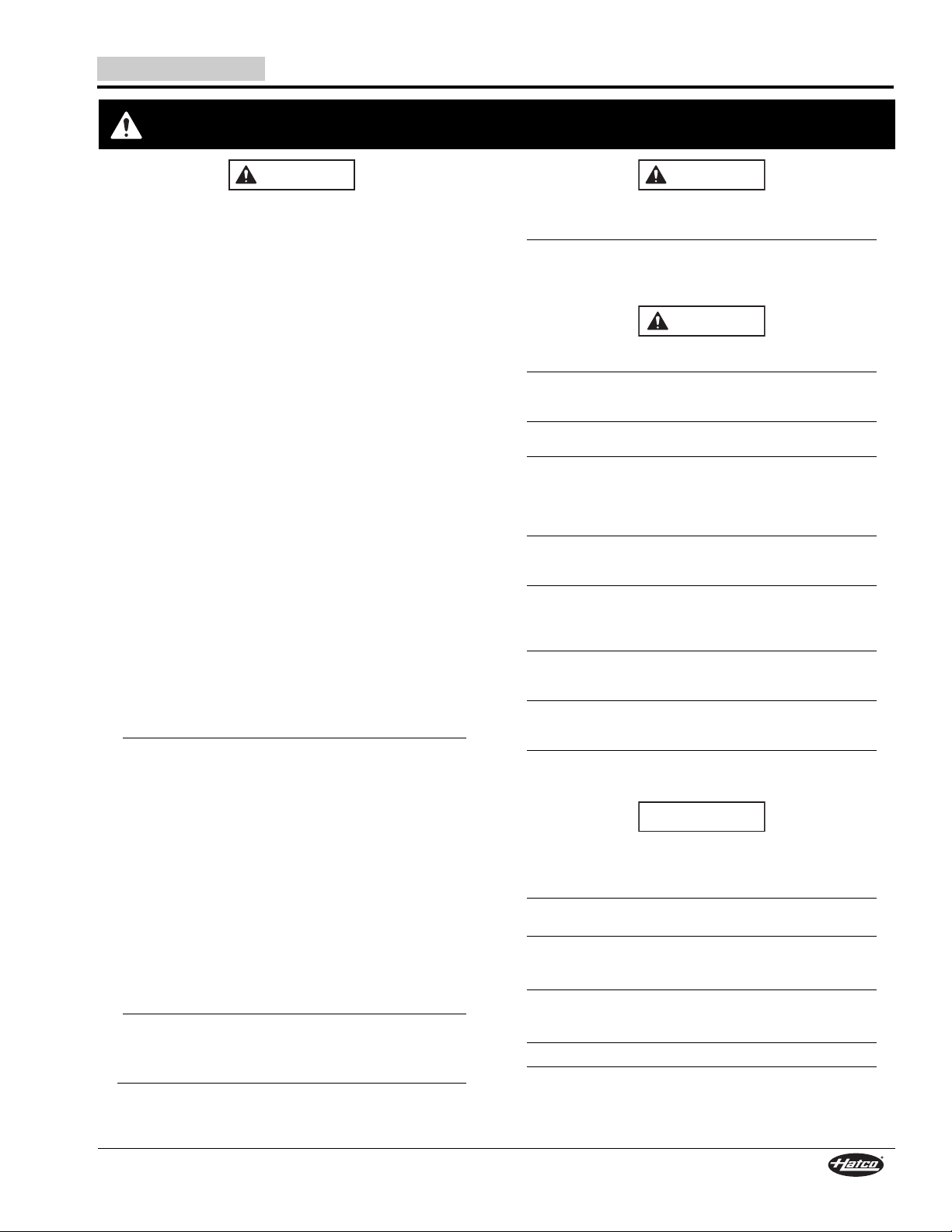

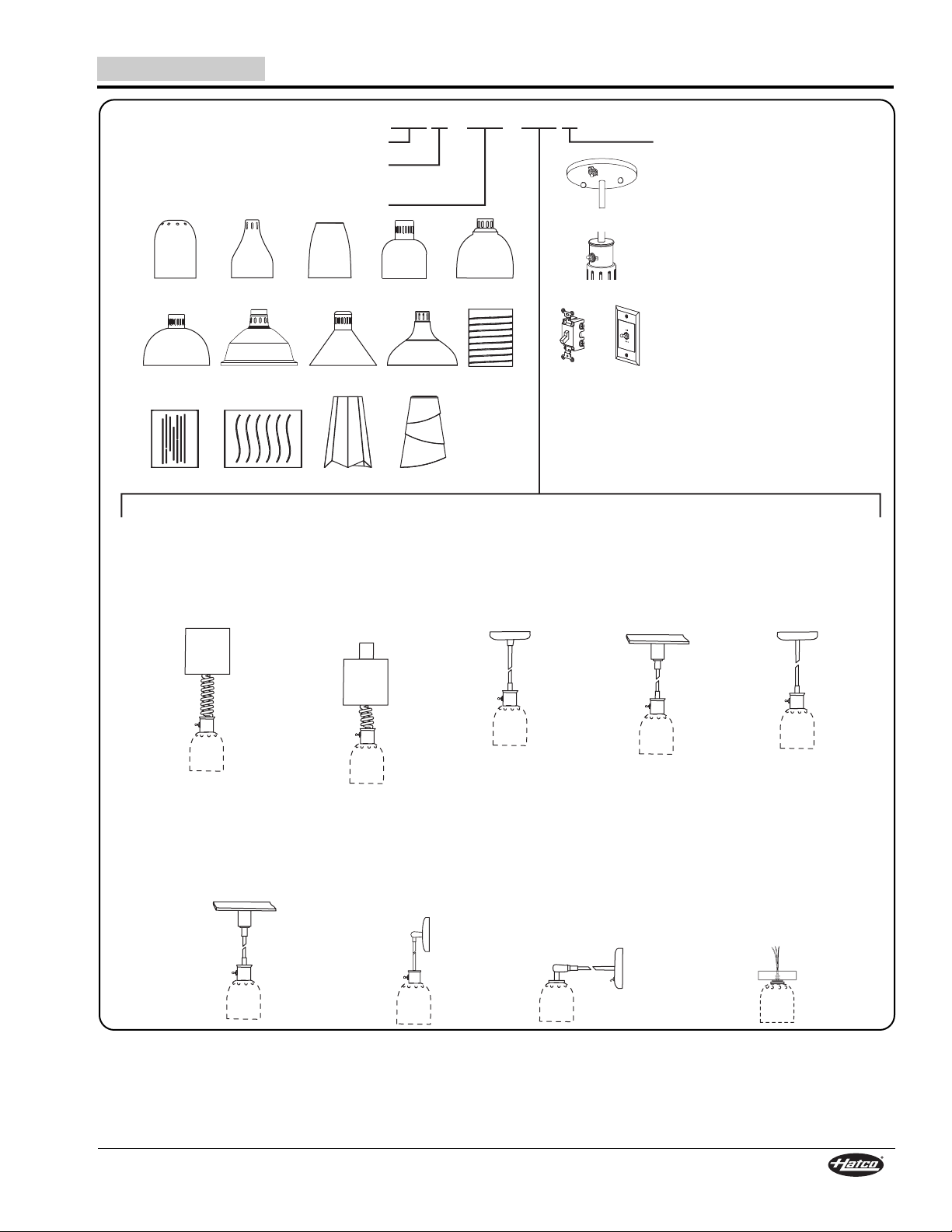

MODEL DESCRIPTION

CAUTION

A

DL-400 DL-500

DL-700

B

A

DL-725

B

A

DL-750

B

A

B

DL-600

A

B

A

B

A

DL-760

DL-775 DL-800

B

A

B

A

DL-1100

DL-1200

DL-1300

DL-1400

DL-1500

B

A

B

A

B

A

B

A

B

A

B

English

All Models

All Decorative Lamps are constructed of aluminum and steel and

include heavy-duty mounting hardware. Each Decorative Lamp

is available with an accessory infrared bulb contained in a vented

shade. The shade is available in powdercoated Designer colors,

Gloss finishes, or Plated finishes.

DL Models (Standard Wattage)

Standard wattage models (DL) use a 250 W infrared bulb (bulb not

included) and include a built-in ON/OFF (I/O)switch located at the

stem or canopy for independent control. DL units may be ordered

with the optional remote switch (REM) or with no switch.

A Luminaire option is available for DL Models for lighting only

(no heat). The Luminaire model uses a maximum of a 200 W

bulb (Luminaire bulb not included).

DLH Models (High Wattage)

High wattage models (DLH) use a 375 W infrared bulb (bulb not

included) and are available with either the remote switch (REM)

or with no switch.

For non-CE units NOT equipped with a Hatco-supplied

switch, a qualified electrician must choose an appropriate

switch for the application based on amperage and in-rush

rating of the switch.

For all CE units, a qualified electrician must choose and

install an appropriate double-pole switch for the application

based on amperage and in-rush rating of the switch.

Accessories are available for the Decorative Lamps. Refer to the

OPTIONSAND ACCESSORIES section in this manual for details.

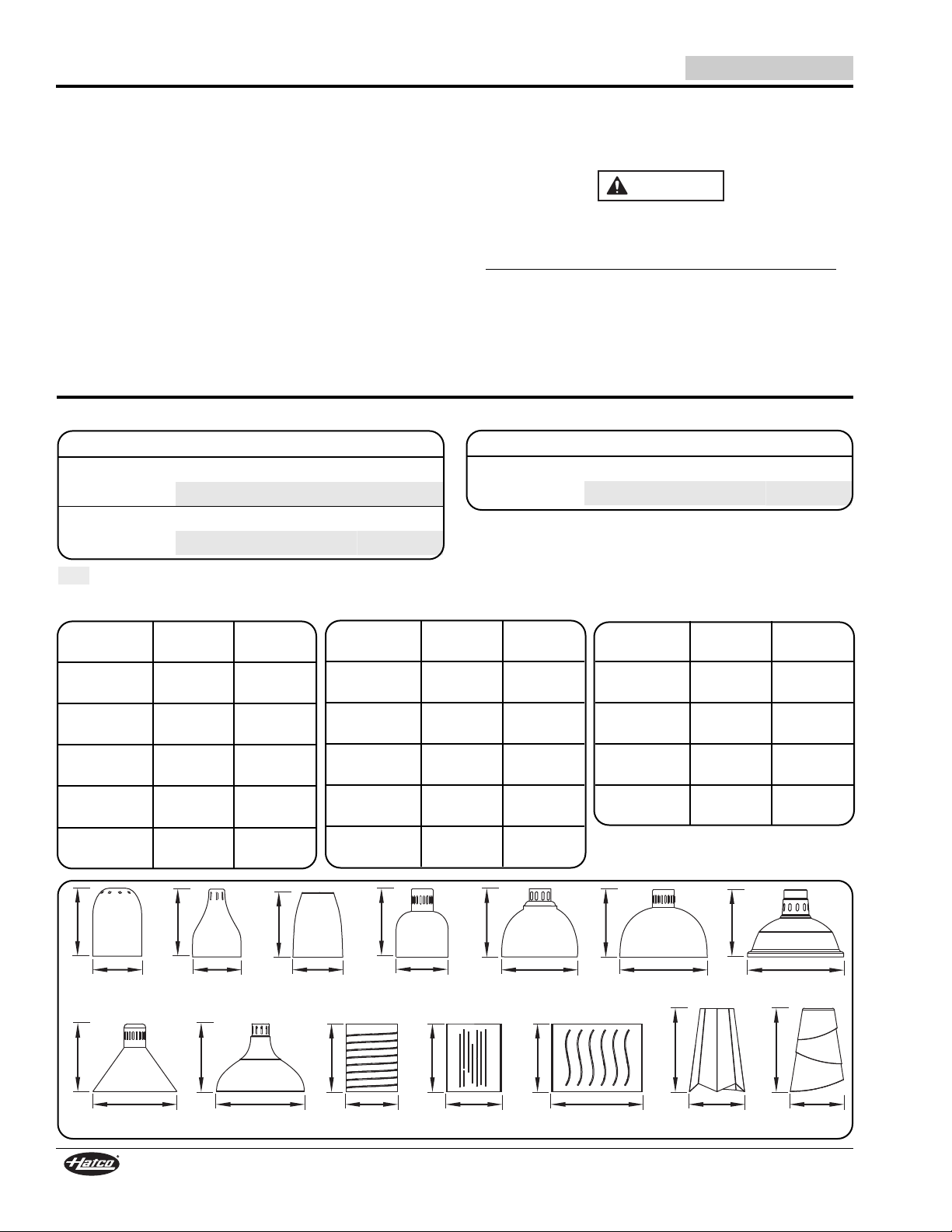

SPECIFICATIONS

Electrical Rating Chart

Model Volts Watts Amps

DL Series 120 250 2.1

240 (CE) 250 1.0

DLH Series 120 375 3.1

240 (CE) 375 1.6

The shaded areas contain electrical information for International models only.

DL Luminaire 120 200 1.7

NOTE: The specification label is located inside the lamp shade.

Model Volts Watts Amps

240 (CE) 200 0.8

See the label for the serial number and verification of

unit electrical information.

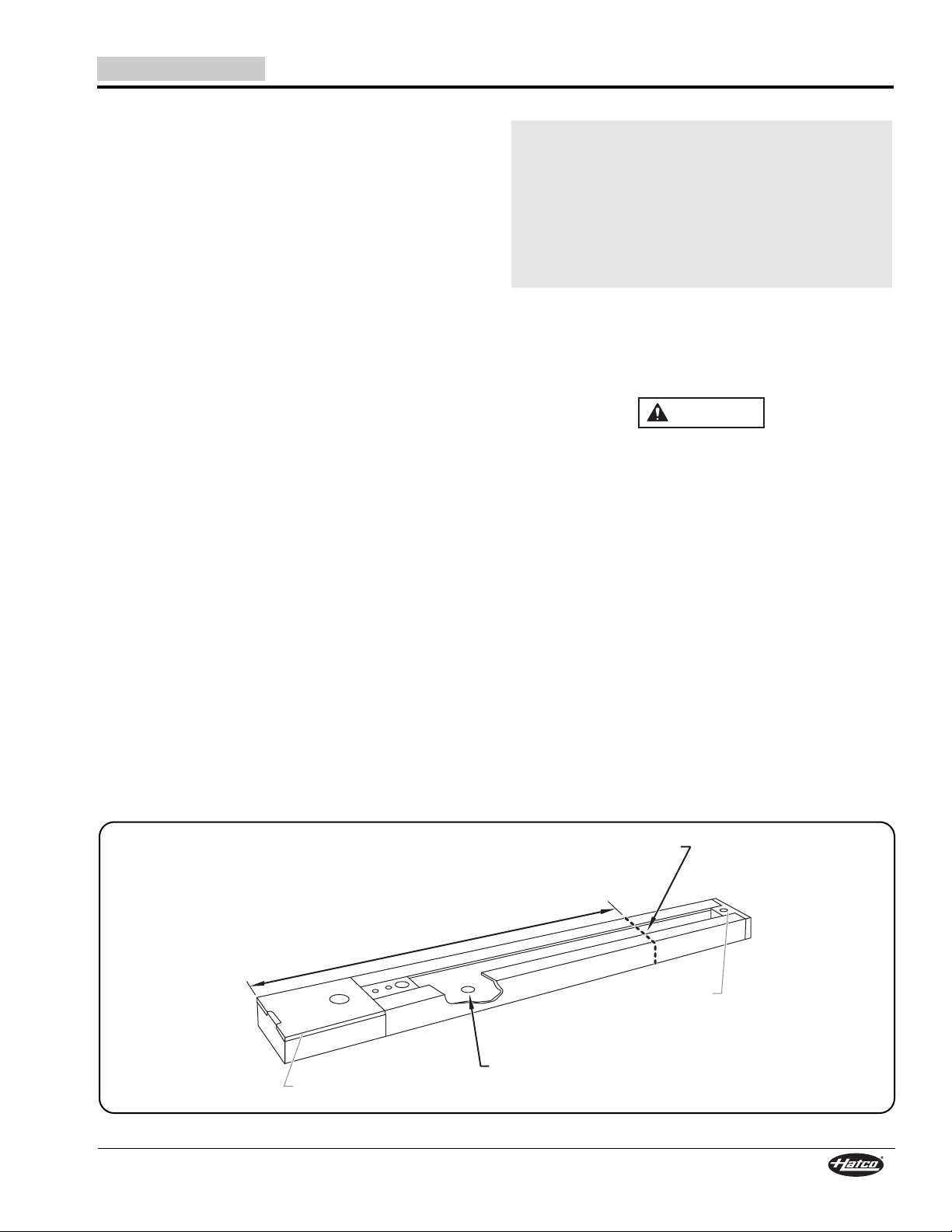

Dimensions — Lamp Shade

Lamp Shade

Style

DL-400 6-1/8″

DL-500 6-1/8″

DL-600 6-1/4″

DL-700 6-1/2″

DL-725 9-1/2″

Width

(A)

(156 mm)

(156 mm)

(159 mm)

(165 mm)

(241 mm)

Height

(B)

8-1/2″

(216 mm)

8-1/2″

(216 mm)

8-1/2″

(216 mm)

8-1/2″

(216 mm)

8-1/2″

(216 mm)

Lamp Shade

Style

DL-750 11″

DL-760 12-1/2″

DL-775 10-1/2″

DL-800 11″

DL-1100 6-1/2″

(279 mm)

(318 mm)

(267 mm)

(279 mm)

(165 mm)

Width

(A)

Height

(B)

8-1/2″

(216 mm)

8-1/2″

(216 mm)

8-1/2″

(216 mm)

8-1/2″

(216 mm)

8-1/2″

(216 mm)

Lamp Shade

Style

DL-1200 7″

DL-1300 11-9/16″

DL-1400 7″

DL-1500 6-11/16″

NOTE: The height dimension of the shade

increases by 2" (51 mm) when

utilizing the “L” lower switch location.

Width

(A)

(178 mm)

(293 mm)

(178 mm)

(169 mm)

Height

(B)

8-1/2″

(216 mm)

8-1/2″

(216 mm)

10-1/2″

(267 mm)

10-1/2″

(267 mm)

4

Form No. DHLM-0916

English

D L H - 700 - S T U

Mounting Style

1200

1300

1400

1500

R Mount

Lamp mounts with

adjustable cord. Cord

adjusts up-down from

31″ (787 mm) to

69-1/2″ (1765 mm).

ST Mount

Lamp mounts with

rigid stem to track adapter.

Overall length from

17″ (432 mm) to

71″ (1803 mm).

P Mount

Lamp mounts with

rigid stem to canopy

with adjustable pivot

adjacent to canopy.

Overall length from

17″ (432 mm) to

71″ (1803 mm).

A Mount

Lamp mounts with

rigid stem to canopy

with adjustable pivot

adjacent to lamp.

Overall horizontal length

from 7″ (178 mm) to

20″ (508 mm). Vertical

drop length to bottom of

shade 10-1/4″ (260 mm).

TS Mount

Lamp mounts with

threaded stem

to fixture above

(fixture supplied by others).

Threaded stem mount is

available only as a

UL recognized (UR)

component.

RT Mount

Lamp mounts with

adjustable cord to track

adapter. Cord adjusts

up-down from

33-3/8″ (848 mm) to

71-7/8″ (1826 mm).

C Mount

Lamp mounts with

cord to the canopy.

Overall length from

17″ (432 mm) to

any length.

CT Mount

Lamp mounts with

cord to track adapter.

Overall length from

17″ (432 mm) to

any length.

S Mount

Lamp mounts with

rigid stem to canopy.

Overall length from

14″ (356 mm) to

71″ (1803 mm).

Switch Location:

U = Upper ON/OFF (I/O) Switch

(not available with High Watt,

Trac Mount, or R Mount)

L = Lower ON/OFF (I/O) Switch

(not available with High Watt

or A Mount)

N = None (supplied by installer)

Decorative Lamp

No Character = Standard Watt/Luminaire

H

= High Watt

Shade Style

400 500 600 700 725

750 760 775 800 1100

R = Remote ON/OFF (I/O) Switch

(switch plate not included

with 120 V switch)

(120 V) (240 V)

MODEL DESIGNATION

NOTE: Do not install track system over a steam table or other

NOTE: Track mount units are not available in 240 V.

NOTE: The height dimension of the shade increases by

Form No. DHLM-0916

steam generating appliance.

2″ (51 mm) when utilizing the “L” lower switch location.

NOTE: For 120 V units, the remote ON/OFF (I/O) switch is

5

capable of handling up to nine 200 W Luminaires,

seven 250 W lamps, or five 375 W lamps.

For 240 V units, the remote ON/OFF (I/O) switch is

capable of handling up to four 250 W lamps or three

375 W lamps.

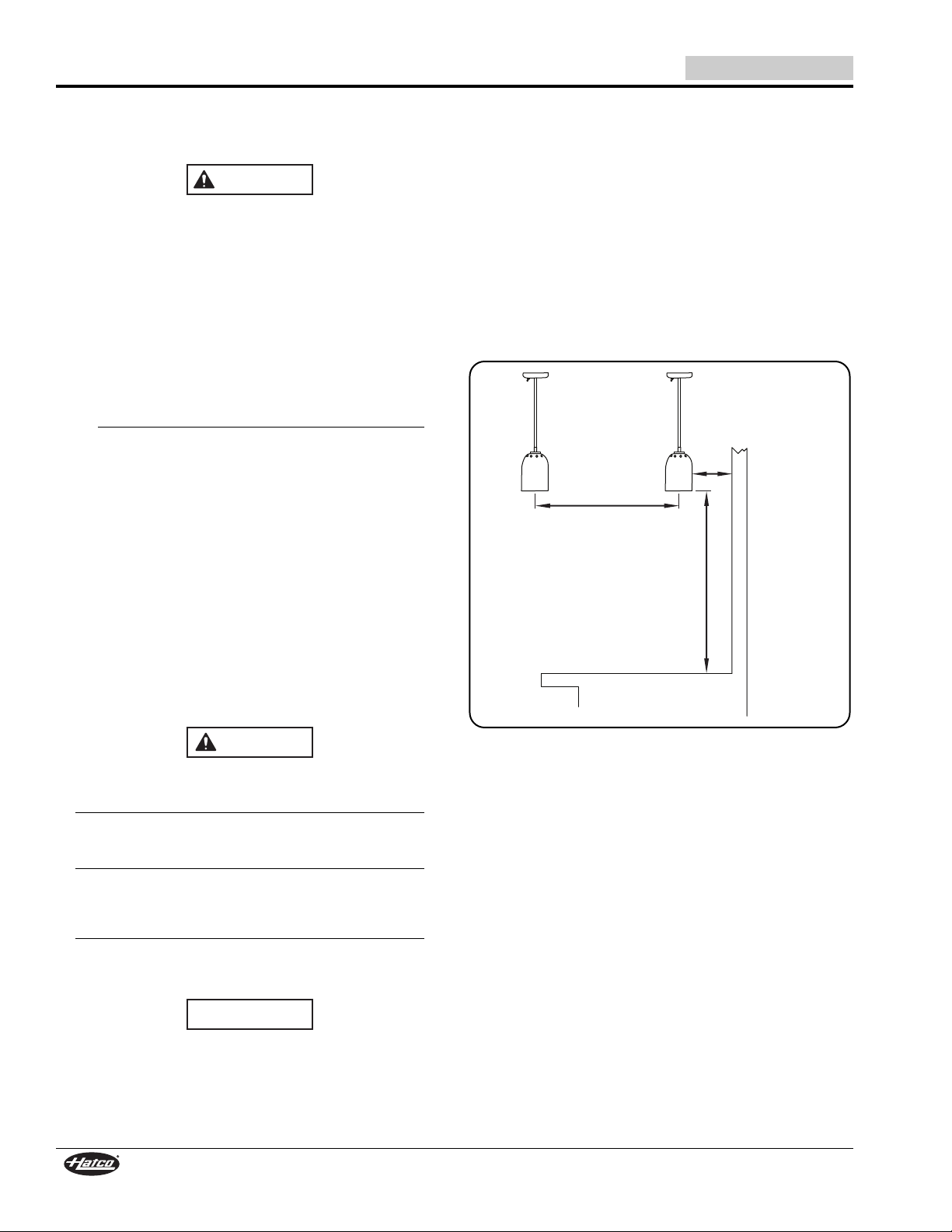

INSTALLATION

NOTICE

CAUTION

WARNING

Minimum of 12″

(305 mm) on

center of shades.

Minimum of 1″ (25 mm)

from combustible

walls and materials.

Minimum height above

combustible surface:

DL and Luminaire = 16″ (406 mm)

DLH = 27″ (686 mm)

Minimum height above

non-combustible surface:

DL and Lumimaire = 5″ (127 mm)

DLH = 5″ (127 mm)

Countertop

English

General

Use the following information and procedures to install

Decorative Lamps.

ELECTRIC SHOCK HAZARD:

• Unit must be installed by a qualified electrician.

Installation must conform to all local electrical codes.

Installation by unqualified personnel will void the unit

warranty and may lead to electric shock or burn, as well

as damage to unit and/or its surroundings.

• Turn OFF power at mounting location before

installation of unit.

• Do not install track system above a steam table or other

steam generating appliance.

• Failure to ground unit properly could result in serious

personal injury or death.

• Unit is not weatherproof. Locate unit indoors.

FIRE HAZARD:

• Locate unit a minimum of 1″ (25 mm) from combustible

walls and materials. If safe distances are not

maintained, discoloration or combustion could occur.

• DL standard watt lamps (250 W bulb) and Luminaires

(200 W bulb maximum) must have a minimum of 16″

(406 mm) above a combustible surface or minimum

clearance of 5″ (127 mm) above a non-combustible

surface. If safe distances are not maintained,

discoloration or combustion could occur.

• DLH high watt lamps (375 W bulb) must have a

minimum of 27″ (686 mm) above a combustible surface

or minimum clearance of 5″ (127 mm) above a noncombustible surface. If safe distances are not

maintained, discoloration or combustion could occur.

• Do not install a 375 W bulb into a DL standard watt lamp

or a Luminaire unit.

1. Remove the decorative lamp assembly from the carton.

2. Remove tape and protective packaging from all surfaces

of unit.

NOTE: To prevent delay in obtaining warranty coverage,

complete online warranty registration. See the

IMPORTANT OWNER INFORMATION section for

details.

3. Make sure the installation site provides the proper

installation clearances for the unit (see below).

NOTE: For even heating, install multiple units a distance of 12″

(305 mm) on center of shades.

NOTE: Non-CE Decorative Lamps can be installed over a

steam table. Follow the clearance requirements

appropriate for the installation.

Multiple installations of Decorative Lamps must have a

minimum clearance of 12" (305 mm) on center of shade

between each unit.

All canopy mount units are designed to fit a standard 4″

(102 mm) octagonal junction box. Junction box must be

anchored securely to building structure.

For non-CE units NOT equipped with a Hatco-supplied

switch, a qualified electrician must choose an appropriate

switch for the application based on amperage and in-rush

rating of the switch.

For all CE units, a qualified electrician must choose and

install an appropriate double-pole switch for the application

based on amperage and in-rush rating of the switch.

Damage to any countertop material caused by heat

generated from Hatco equipment is not covered under the

Hatco warranty. Contact manufacturer of countertop

material for application information.

Safe Mounting Distances

NOTE: For 120 V units, the remote ON/OFF (I/O) switch is

6

capable of handling up to nine 200 W Luminaires, seven

250 W lamps, or five 375 W lamps.

For 240 V units, the remote ON/OFF (I/O) switch is

capable of handling up to four 250 W lamps or three

375 W lamps.

Form No. DHLM-0916

English

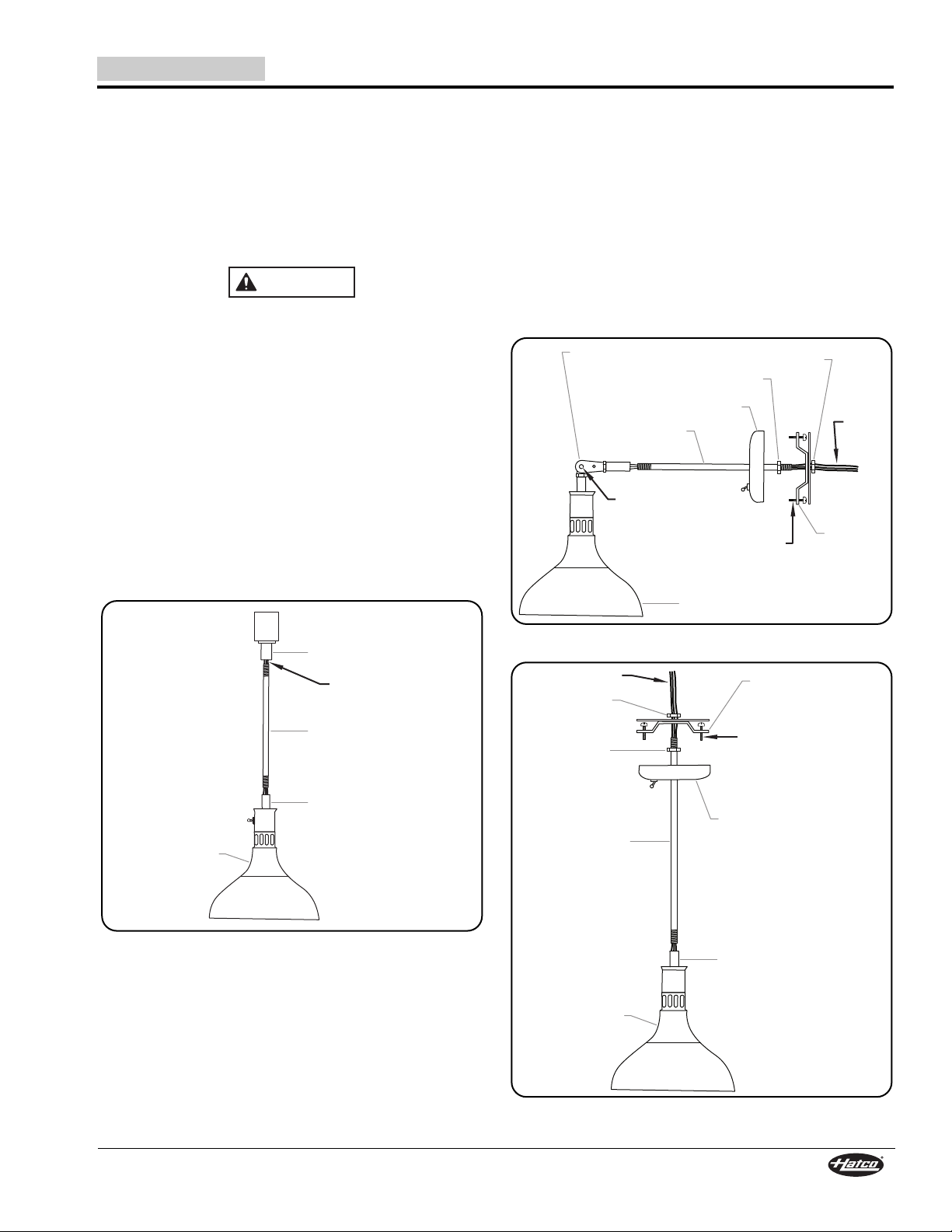

Track Pendant

Wire Leads

Stem

Coupling

Lamp

WARNING

Stem

Pivot (“A” mount

shown, “P” mount

pivot is at canopy.)

Mounting

Bracket

Wire

Leads

Lamp

Loosen screw

to adjust pivot.

Leave 1/4″ (6 mm) exposed

for canopy mounting.

Canopy

Jam Nut

Jam Nut

Mounting

Bracket

Canopy

Leave 1/4″ (6 mm)

exposed for

canopy mounting.

Jam Nut

Wire Leads

Jam Nut

Stem

Lamp

Coupling

INSTALLATION

Assembly

Models with Mounting Styles C, CT, R, and RT are cord hung

fixtures and are shipped fully assembled and ready for

installation. All other models will require some assembly before

mounting. Refer to the appropriate assembly procedure below

for each mounting style.

NOTE: If the shade comes equipped with plastic nut and nipple

in stem mounting hole, both nut and nipple must be

removed before installing stem to shade.

Turn OFF power at mounting location before installation of

unit.

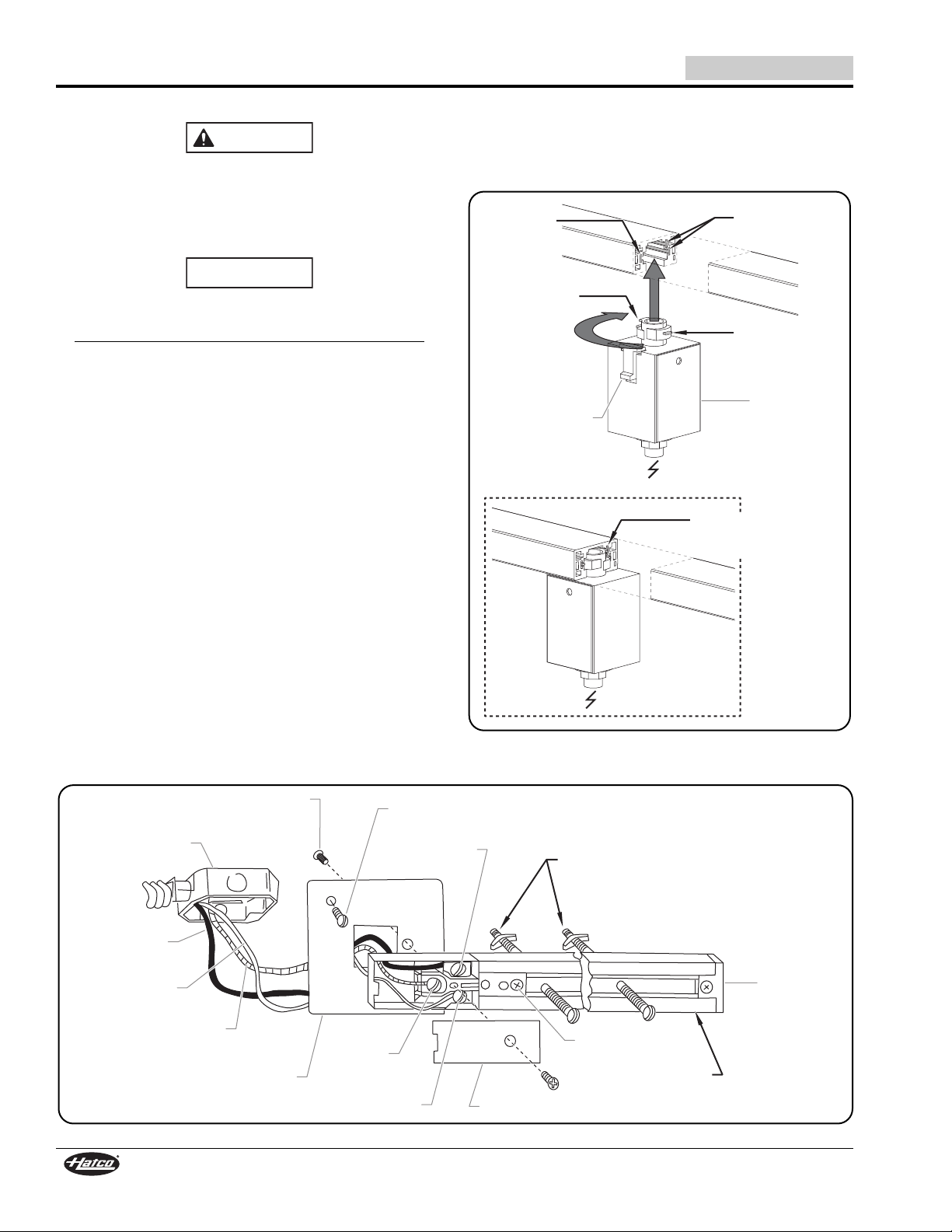

Assembling an ST Mount Unit

1. Remove the plastic caps covering each end of the stem, if

present.

2. Feed the wire leads from the lamp through the stem.

3. Screw the stem into the coupling on the lamp. Tighten

securely.

4. Open the track pendant side access panel and feed the

wires up into the pendant enclosure.

5. Screw the stem into the track pendant and tighten securely.

The stem should not rotate after it is tightened.

6. Following the instructions supplied with the pendant,

connect together the white wire leads, connect together

the black wire leads, and connect together the green

ground wires using the provided wire nuts.

4. Screw the stem into the coupling on the lamp shade and

tighten securely. If the unit is equipped with a pivot mount,

straighten the pivot to help ease feeding the wires.

5. Place the canopy on the stem.

6. Thread one jam nut onto the stem and tighten until it

bottoms out on the threads.

7. Place the mounting bracket on the stem until it rests on the

jam nut.

8. Thread the second jam nut onto the stem and tighten it

against the mounting bracket.

9. If the unit is equipped with an upper switch, connect the

black wire from the lamp to one of the black wires on the

switch. Use the included wire nut.

Assembling an ST Mount Unit

Assembling an A, P, or S Mount Unit

1. Remove the plastic caps covering each end of the stem, if

present.

2. Remove the two jam nuts from the stem.

NOTE: The jam nuts are installed on the stem for shipping

3. Feed the wire leads from the lamp through the stem.

Form No. DHLM-0916

purposes. Both jam nuts must be removed before

assembling the unit. After assembly, both jam nuts will

be on the canopy side of the stem.

Assembling A and P Mount Units

Assembling an S Mount Unit

7

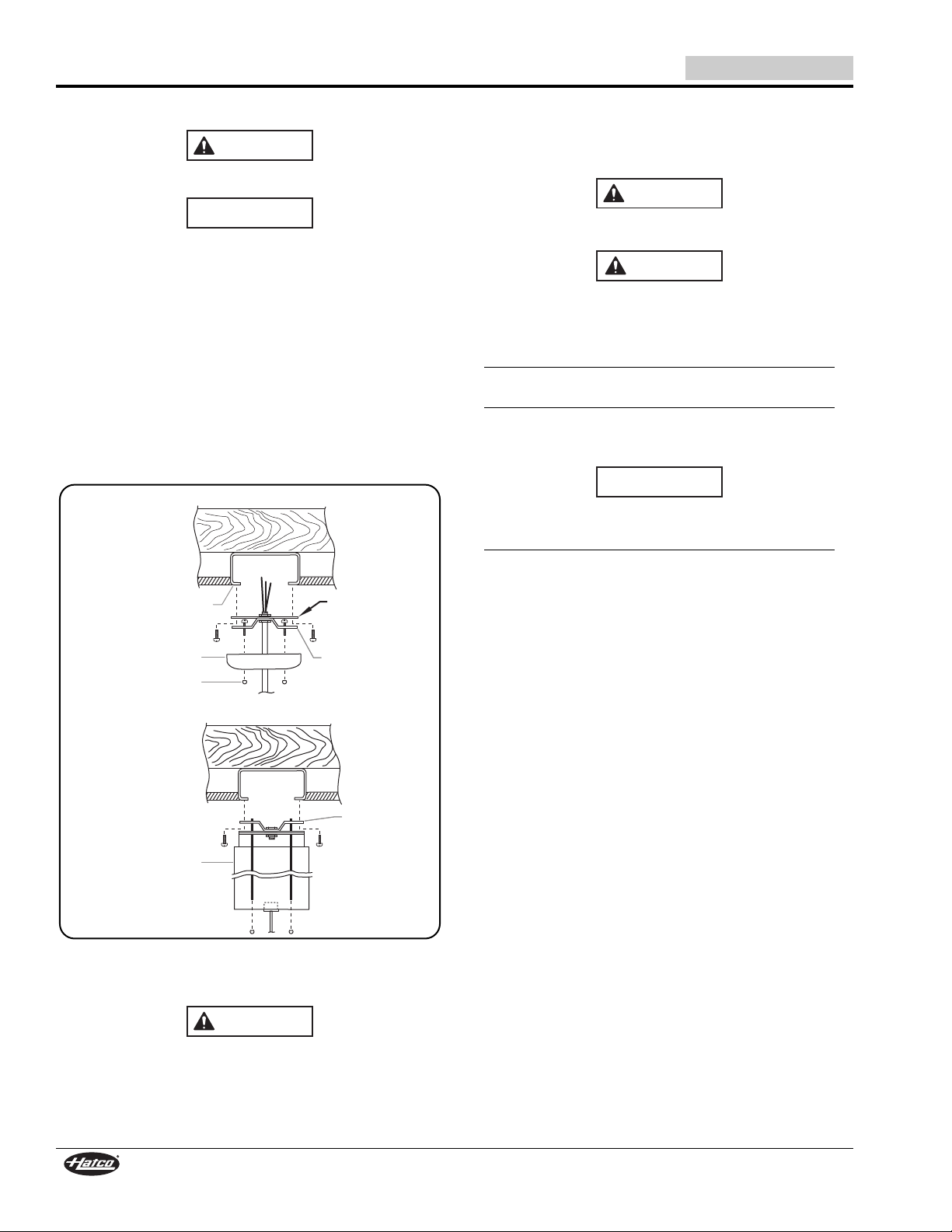

INSTALLATION

WARNING

A, C, P, and S Mount

Octagon

Junction Box

R Mount

Mounting

Bracket

Mounting

Bracket

Ball Cap Nuts

Upper

Plate

Canopy

Adjustable Cord

Housing

WARNING

NOTICE

CAUTION

NOTICE

WARNING

English

Installing A, C, P, S, and R Mount Units

Turn OFF power at mounting location before installation of

unit.

Retractable models and track mounted units must be installed

on a flat, horizontal ceiling or damage to unit could occur.

1. Mount the upper plate of the mounting bracket to a

4" (102 mm) octagon junction box using the two screws

provided with the junction box.

2. Make sure all power is OFF, and connect supply lead L1 to

the black lamp lead. Connect neutral to the white lamp lead.

If the lamp is equipped with three wires, connect ground to

the green lead. If lamp is equipped with two wires, make

proper ground wire connections from junction box. Tuck

excess wires into junction box.

3. Slide the canopy cover or cord housing up until it rests

against the ceiling and install the two ball cap nuts until

snug to the ceiling.

Installing TS Mount Units (UL Recognized)

Turn OFF power at mounting location before installation of

unit.

1. Drill a 7/16" (11 mm) hole through mounting fixture.

2. Pass wires from the lamp through hole in fixture.

3. Secure the lamp to the fixture with nut.

Mounting to a Junction Box

4. Make sure all power is OFF, and connect supply lead L1 to

the black lamp lead. Connect neutral to the white lamp lead

and the ground to the green lead.

Installing Track Mount Units (CT, ST, and RT)

ELECTRIC SHOCK HAZARD: Do not install track system

above a steam table or other steam generating appliance.

The maximum capacity of Power-Trac track lighting

systems is 20 A per circuit. Check fuses and circuits

carefully before installing. The 20 A maximum includes all

lights and appliances connected to circuit (120 V only,

maximum 1920 W per any length track).

Power-Trac systems are not intended for use with a power

supply cord or convenience receptacle adapter.

When installing track lighting systems, use only fixture

assemblies marked for use with HALO

Track Fittings marked for use with L-650 Series Track.

Hatco Decorative Lamps are built to fit L-650 Series HALO

Power-Trac lighting systems only. Do not attempt to use on

any other track lighting system.

Retractable models and track mounted units must be installed

on a flat, horizontal ceiling or damage to unit could occur.

The track system is to be supplied by a single branch circuit

120 V, 60 Hz, 20 A.

NOTE: A maximum of nine 200 W Luminaire units, seven 250 W

lamp units, or five 375 W lamp units may be installed per

each 120 V, 20 A track bar circuit. The Installer is

responsible for properly sizing the supply circuit with the

lamp load.

The standard track and cord color of Hatco track systems is

black. White is available as an option. Hatco provides track kits

in four different lengths:

• L-651 —4′ (1219 mm)

• L-652 —8′ (2438 mm)

• L-651, L-652, and L-908— 12′ (3658 mm) Track and Connector

• L-652, L-652, and L-908— 16′ (4877 mm) Track and Connector

When installing or using this track system, the following basic

safety precautions should always be followed:

• Read all of these installation instructions before installing

the track system.

• Save these instructions and refer to them when additions

to or changes in the track configuration are made.

• Do not install the track system in damp or wet locations,

including above a steam table or steam generating

appliance. Installation in these areas will void warranty.

• Do not install any part of a track system less than 5′

(1524 mm) above the floor.

• Do not install any fixture assembly closer than 1" (25 mm)

along the sides from any curtain or similar combustible

material.

®

Power-Trac and

®

8

Form No. DHLM-0916

English

CAUTION

Live End Fitting

Dead End Fitting

(To remove,

loosen screw and

slide out fitting.)

Drill mounting holes

where required.

M

e

a

s

u

r

e

t

h

e

d

e

s

i

r

e

d

l

e

n

g

t

h

f

r

o

m

t

h

e

l

i

v

e

e

n

d

.

N

O

T

E

:

T

h

e

d

e

a

d

e

n

d

f

i

t

t

i

n

g

w

i

l

l

a

d

d

1

/

8

″

(

3

m

m

)

t

o

t

h

i

s

l

e

n

g

t

h

.

New cut must be at an

exact right angle (90°).

INSTALLATION

• Disconnect electrical power before adding to or changing

the configuration of the track.

• Do not attempt to energize anything other than Power-Trac

lighting fixtures on the track. To reduce the risk of fire and

electric shock, do not attempt to connect power tools,

extension cords, appliances, etc. to the track.

The track system must be mounted using the appropriate

fasteners in the pre-drilled mounting holes as follows:

• 4' (1219 mm) Track — two places, one at each end of

track.

• 8' (2438 mm) Track — three places, one in the center and

one in each end of the track.

• 12' (3658 mm) Track — five places, one at each end of 4'

(1219 mm) track section AND one in the center and one in

each end of the 8' (2438 mm) track section.

• 16′ (4877 mm) Track — six places, one in the center and

one in each end of the two 8' (2438 mm) track sections.

If track requires field cutting, refer to the “Cutting Track to

Special Lengths” procedure. If track does not require field

cutting, proceed to “Installing the Track.”

Cutting Track to Special Lengths

NOTE: Cutting should be done from the dead end of the track.

1. Remove the dead end fitting and push the copper buss

bars and insulators flush with the live end of the track.

Measure length from the live end and mark the cut line.

2. Using a hacksaw, cut to desired length. Be sure to allow

1/8" (3 mm) for dead end fitting which must be reinstalled

to the track end.

3. Remove all burrs from the track, insulators, and copper

buss bars.

4. Push the copper buss bars into the insulators 1/2" (13 mm)

from the end of the track.

NOTE: After completing the above step, the buss bar insulators

should be flush with the track channel ends, and the

copper buss bars should be cut back from each end of

the track a minimum of 7/16" (11 mm) to a maximum of

1/2" (13 mm). If this is not the case, make appropriate

modifications.

5. Reinstall the dead end fitting and tighten the screw.

IMPORTANT NOTE:

After track has been field cut, make sure that each

4’ (1219 mm) section or less in length has one mounting hole

spaced a maximum of 6" (152 mm) from each track end

section. A single section of track that is greater than

4' (1219 mm) in length must have the mounting hole located

a maximum of 12" (305 mm) from each end of the track with

additional mounting holes located a minimum of every

4' (1219 mm) along the length of the track section. Additional

mounting holes may be drilled as needed.

If additional mounting openings are required, follow

this procedure in drilling holes:

1. Locate desired mounting holes on the inside center line of

the track section.

2. Drill a 3/16" (5 mm) hole through the track channel.

Use caution when drilling during track installation to avoid

damaging buss bar insulators. If insulators are damaged,

discard the section—DO NOT use.

3. Remove all burrs and proceed to “Installing the Track”.

Form No. DHLM-0916

Cutting the Track to Special Lengths

9

INSTALLATION

WARNING

NOTICE

Single Contact

Point

Dual Buss

Bars

Single Buss

Bar

Dual Contact

Points

Pendant installed with

contacts and buss bars

matching.

Track Pendant

Locking Tab

Live End Cover

Setscrew

Ground Contactor

Slide

Black Wire L1

(Hot)

White Wire

(Neutral)

Green Wire

(Ground)

Ceiling Plate

Dead End

Fitting

Nickel Plated Terminal

Green

Ground

Screw

Junction Box

Mounting Screw

Flat Head Screw

(Ceiling Plate to Live End Cover)

Junction Box

Brass

Terminal

To mount track: Drill holes in ceiling or wall.

Attach track with toggle bolts (or screws if

surface is solid material).

English

Installing the Track

Turn OFF power at mounting location before installation of

unit.

NOTE: 12′ (3658 mm) and 16′ (4877 mm) tracks use two track

1. Punch out the proper knockout holes in the ceiling plate.

Do not damage the special, smooth plastic finish piece on

metal ceiling plate when determining location of proper

knock out holes.

Retractable models and track mounted units must be installed

on a flat, horizontal ceiling or damage to unit could occur.

2. Remove the flat head screw(s) from the back of the live

3. Remove the cover from the live end fitting. Place track with

4. Drill the mounting holes in the ceiling or wall large enough

5. Pull the wires from the junction box through the open hole

6. Fasten the ceiling plate to the junction box with two screws.

7. Cut and strip the wire leads (3/8” [10 mm] strip) and fasten

8. Replace the cover on the live end and tighten the screw.

9. Install the lamp(s) in the desired location(s) along the track.

sections and a L-908 Track Connector for installation.

end fitting and use them to fasten the ceiling plate to the

live end fitting.

the ceiling plate attached over the junction box and mark the

position of the track mounting holes on the ceiling or wall.

for the supplied toggle bolts and install the track using the

toggle bolts. If track is to be mounted on a solid surface,

use #8 screws (not supplied) instead of toggle bolts.

in the live end.

to the screw terminals in the live end fitting. Push the

excess wires back into the junction box and fasten the

ground wire to the green ground screw.

To install the lamp(s):

a. Pull back the locking tab on the track pendant and insert

the pendant into the track.

b. Rotate the pendant approximately 90° until the pendant

locks into position.

NOTE: Make sure the contact points on the track pendant will

match up with the buss bars inside the track after

rotating the pendant into position.

Track Cutaways Showing Track Pendant Installation

Installing the Track

10

Form No. DHLM-0916

Loading...

Loading...