Hartell LTP-1 801284, LTS-1 801285 Installation Manual

Literature # 900917 2019

100 East Graham Place

Burbank, CA 91502

Web: www.hartell.com

Email: info@hartell.com

INSTALLATION • OPERATION • MAINTENANCE

NTRODUCTION

HARTELL LTS and LTP are general-purpose reservoir pumps developed for laundry and wet bar

applications. These models are utilized to pump wastewater from an area with no floor drains to

an overhead or remote drain line. The pump must be installed in conjunction with a (laundry) tub/

sink. This pump has been carefully engineered to provide long, trouble free service and is of the

highest quality workmanship and materials.

These pumps have been thoroughly inspected and tested, then carefully packaged to insure safe

delivery and operation. When you receive your pump, examine it carefully to determine that there

are no damaged or broken parts. If damage is detected, notify the firm from where the pump was

purchased. They will assist with a repair or replacement.

See the precautions listed below before continuing.

CAUTION: READ ALL INSTRUCTIONS CAREFULLY BEFORE STARTING INSTALLATION

- Pump should only be used with liquids compatible with pump component materials. Do not use

to pump flammable or explosive fluids. Do not use in explosive atmospheres.

- The pump is supplied with a grounding type plug. To reduce the risk of electrical shock be

certain that it is connected to a properly grounded, grounding receptacle.

- Do not handle pump with wet hands or when standing on a wet or damp surface, or in water.

- Shut off the electrical power at the fuse box before making any connections. All wiring must

comply with local codes.

- A strainer must be installed in the tub to prevent foreign objects, (buttons, screws, etc.), from

entering and damaging the pump. In laundry applications a lint trap must be installed to prevent

an excessive build-up of lint that could interfere with proper float/switch and impeller operation.

A nylon stocking works well as a lint trap.

- Applying heat directly to the tank with a torch, or indirectly by heat transfer through copper

tubing can melt the tank. This will void the warranty. Solder fittings and tubing first, allow to cool,

and then assemble to the tank. The use of some pipe dopes will soften and/or crack the plastic

used in this pump. This will void the warranty. Use only Teflon tape when installing threaded

fittings to the tank.

ONE YEAR LIMITED WARRANTY

HARTELL LTP and LTS waste water pumps are guaranteed to be free from defects in

workmanship or materials and to function satisfactorily, when properly installed, for a period of

ONE (1) year from date of installation. HARTELL will replace, without charge, any HARTELL

product found to be defective upon examination at our factory if returned within the guarantee

period, transportation charges prepaid.

This guarantee does not apply if the product has been misapplied or mechanically damaged,

HARTELL assumes no liability for resultant damages of any kind arising out of the use of its

products.

Keep these sheets with the pump. They may be valuable if service is needed under

the terms of the warranty.

Model #: _______________________ Date of installation: ______________

Installer: ________________________ Date Code: ____________________

Dealer: _________________________

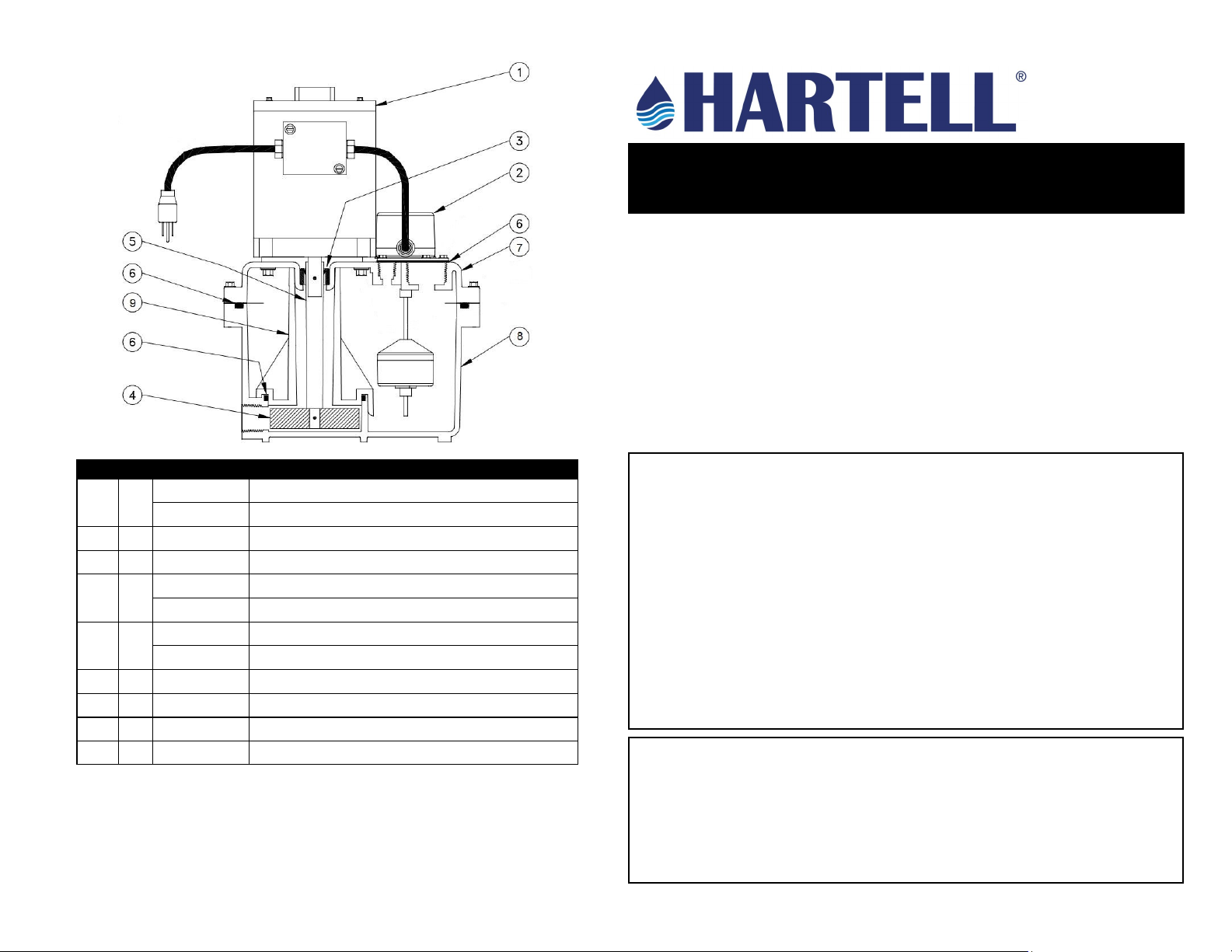

MODEL LTP-1 801284 & LTS-1 801285

WASTE WATER REMOVAL PUMP

Item Qty Part # Descripon

1 1

630092 Motor LTS-1, 115 VAC, 1/3 hp

630090 Motor LTP-1, 115 VAC, 1/4 hp

2 1 620172 L-211S SJE Switch Float Assembly w/Gasket (2000 to present)

3 1 640087 P-107 Impeller Sha Seal

4 1

630057 PS-103 Impeller with Set Screw, LTS

650030 PA-103 Impeller with Set Screw, LTP

5 1

640089 PS-106 Impeller Sha with Sleeve

640069 PA-106 Impeller Sha with Sleeve

6 1 620155 P115 Gasket Set (Perimeter Seal, Switch & Impeller Seals)

7 1 640095 P-100 Tank Cover

8 1 640096 P-112 Tank

9 1 200500 P-104 Impeller Chamber Cover

Literature # 900917 2019

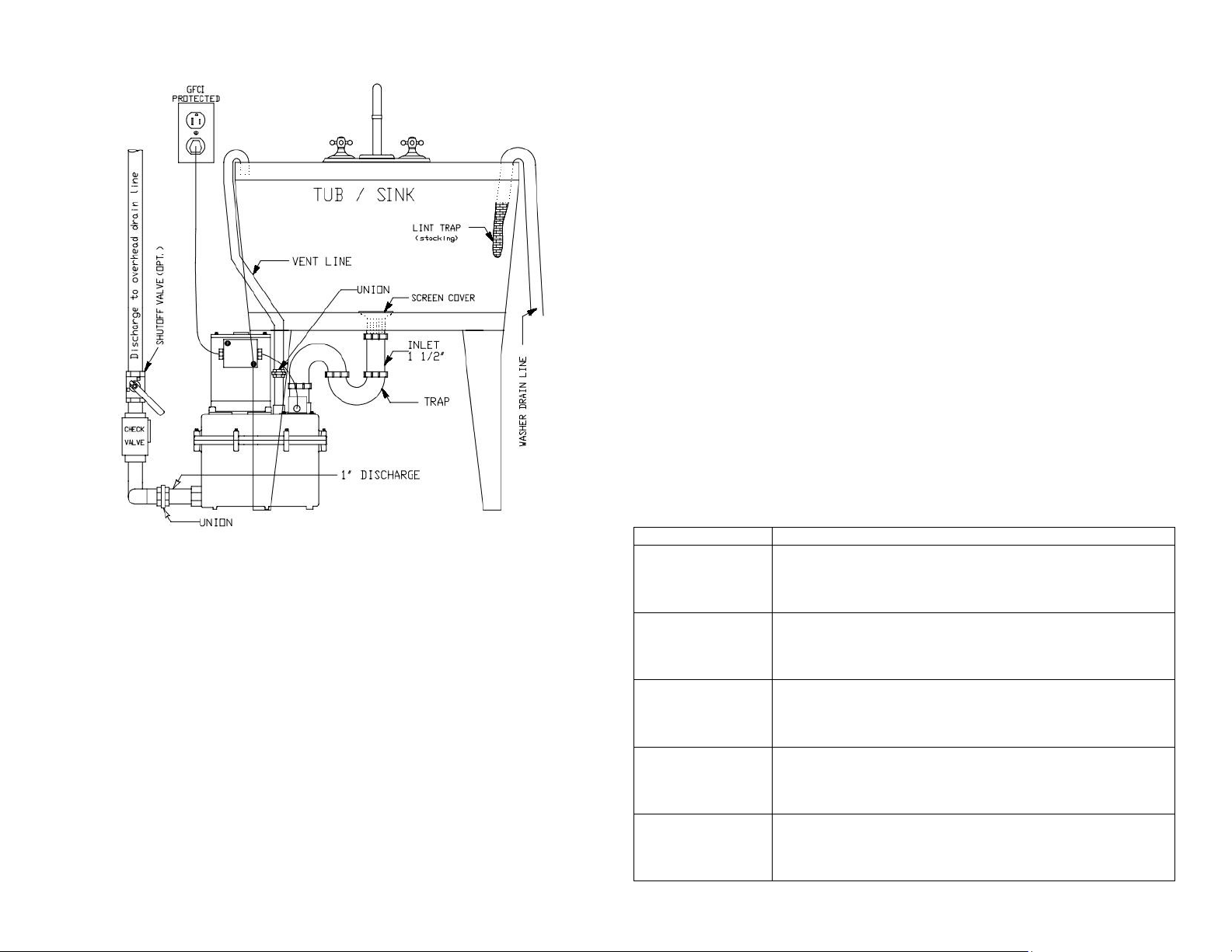

INSTALLATION

1. Place the pump in the desired location under the tub/sink.

2. Install the piping necessary to connect the drain to the 1 ½” inlet. A trap is

recommended. The use of unions or slip fittings is also recommended to

encourage proper pump maintenance. Install the vent line and run it over the top

and into the tub/sink. This allows proper venting of the tank and the discharge of

soap foam back into the tub/sink in laundry applications.

3. A check valve is required and should be of a soft seat swing check design. A

spring loaded ball check is permissible if the lift is one half of the pump shut off

level and the spring pressure is equal to, or less than one (1) psi.

4. The installation of a shutoff valve is recommended in the discharge line. This will

allow the discharge flow rate to be modified, if required to match inlet flow and

prevent short cycling of the pump in low lift installations. In addition, it will allow

service to the check valve or the pump without draining the discharge line.

ELECTRICAL CONNECTIONS

Plug the pump into a properly grounded electrical receptacle. A ground fault style

receptacle or breaker is recommended. Alternatively, the power cord can be removed

and the pump hard wired into an existing circuit. Be sure to follow all applicable

electrical codes.

OPERATION

The LTS & LTP pumps operate automatically. Water from the tub/sink drains into the

tank where it raises the float to a pre-set power on point. The water is pumped out

the discharge and through the check valve to the drain line. The float drops with the

water level to a pre-set power off point. The check valve keeps the water from

draining back to the tank.

MAINTENANCE

The majority of maintenance is preventative. Keep foreign objects out of the inlet and

tank by using an inlet screen and lint trap. Be aware that the vent line, check valve,

and discharge piping contribute to system performance. Turn off power to the pump

before performing any maintenance or tests.

To inspect the tank interior and float/switch, remove the five (5) switch screws that

attach it to the tank. Inspect and clean the float as required. If the tank requires

cleaning the pump must be

removed from the plumbing lines first. Remove the eight (8) perimeter screws and lift

the motor and top portion of the tank as a single unit from the tank bottom. Inspect

and clean as required

including O-ring of impeller chamber cover and tank perimeter seal. Reverse the

above procedure to assemble. Be sure all seals, gaskets and O-rings are in place

and not pinched. Replace if worn or not sealing.

Tub/sink use, water conditions, soap and cleaning agents will impact the frequency of

maintenance required. Establish a maintenance procedure and follow it to prevent

system-related problems.

TROUBLESHOOTING

Problem Probable Cause

Pump does not run

when water is poured

into the sink/tub.

- check that pump is plugged in

- check power to outlet or circuit

- fuse/breaker blown or tripped

- pump plugged into a switched outlet

Pump runs when

plugged in with no

water in tub/sink.

- damaged float/switch

- float “hanging-up” on tank wall due to buildup of soap scum or debris

- check valve leaking back to tank

Pump runs but doesn’t

empty sink/tub

- clogged discharge line

- ball check valve spring pressure too high

- lift too high and/or run is too long (shutoff @ 13’ LTP & 16.5’ LTS)

- broken impeller/shaft

Pump leaks around

motor and/or float/

switch

- damaged float/switch

- discharge too high

- discharge clogged

Pump doesn’t run, but

has water standing in

stink/tub.

- clogged vent line

- float “hanging-up” on tank wall due to buildup of soap scum or debris

- damaged float/switch

Loading...

Loading...