Hartell A2-X-1965 DV Installation Manual

201 Ivyland Road Phone: 215-322-0730

Ivyland, PA Fax: 800-322-5519

18974 Web: www.hartell.com

Email: info@hartell.com

A2-X-1965 DV

Plenum Rated* - Dual Voltage Capable

Commercial Grade Condensate Removal Pump

INSTALLATION, OPERATION

& MAINTENANCE

INTRODUCTION

HARTELL condensate pumps are designed to collect and automatically remove the water produced

by an air conditioner evaporative coil and/or a gas-condensing furnace. This pump has been

carefully engineered to provide long, trouble free service and is of the highest quality workmanship

and materials.

These pumps have been thoroughly inspected and tested, then carefully packaged to insure safe

delivery and operation. When you receive your pump, examine it carefully to determine that there

are no damaged or broken parts. If damage is detected, notify the firm from where the pump was

purchased. They will assist with a repair or replacement.

See the precautions listed below before continuing.

CAUTION: READ ALL INSTRUCTIONS CAREFULLY BEFORE STARTING INSTALLATION

— Pump should only be used with liquids compatible with pump component materials. Do not use to pump flam-

mable or explosive fluids. Do not use in explosive atmospheres.

— The pump is designed for grounded installation. To reduce the risk of electrical shock be certain that it is connected

to a properly grounded, grounding receptacle.

— In any installation where property damage and/or personal injury might result from an inoperative or leaking pump

due to power outages, discharge line blockage, or any other reason, a back up system(s) (aux. switch and/or alarm)

should be used.

— Do not handle pump with wet hands or when standing on a wet or damp surface, or in water.

— Shut off the electrical power at the fuse box before making any connections. All wiring must comply with local codes.

ONE YEAR LIMITED WARRANTY

HARTELL’S A2-X-1965 DV series condensate pump is guaranteed to be free from defects in workmanship or materials

and to function satisfactorily, when properly installed, for a period of ONE (1) year from date of installation. See our

website for additional warranty information at www.hartell.com.

This guarantee does not apply if the product has been misapplied or mechanically damaged, HARTELL assumes no

liability for resultant damages of any kind arising out of the use of its products.

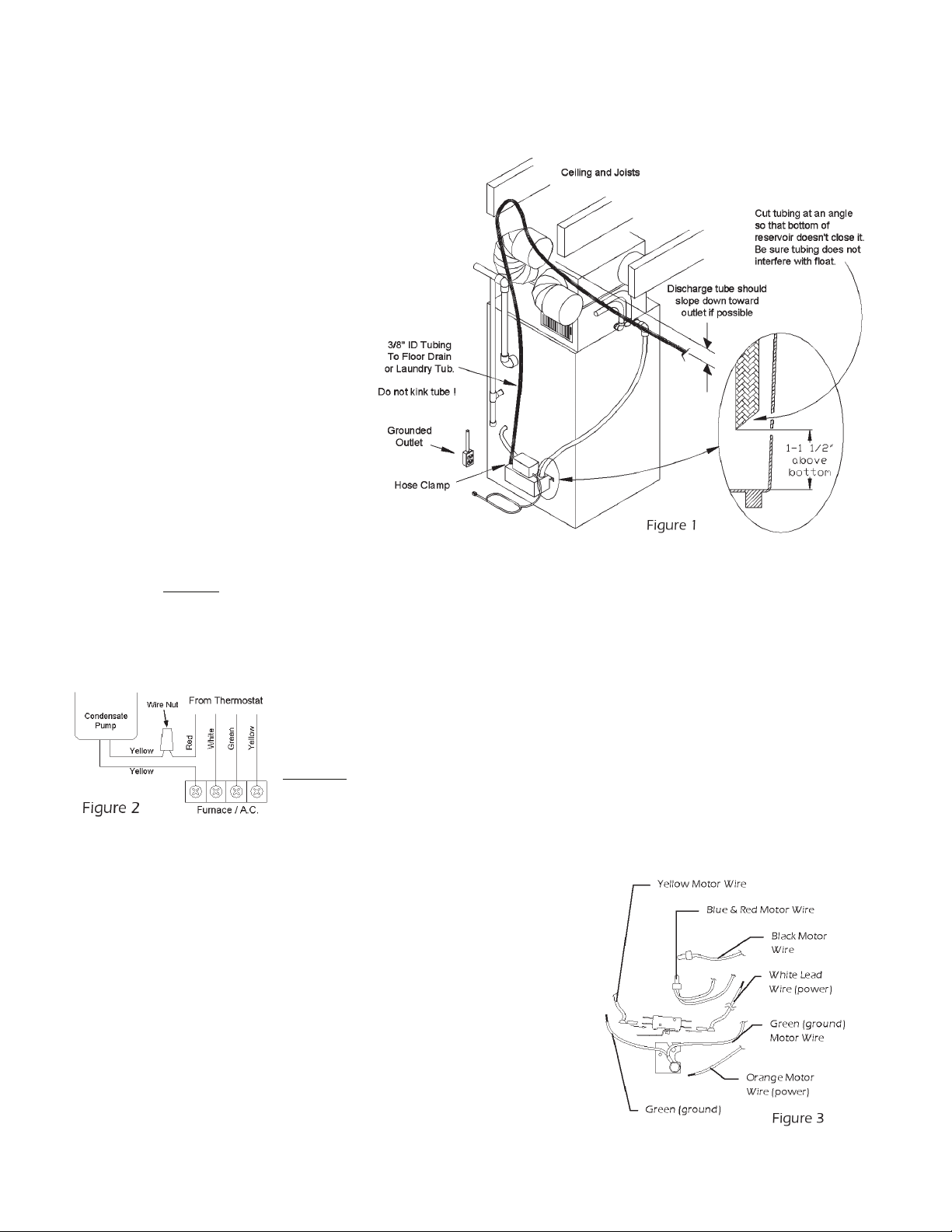

INSTALLATION

Carefully unpack the pump. Choose a location for its installation keeping in mind that the pump must be level and its inlet

must be below the lowest drain, either coil or furnace. Remove and discard the tagged shipping screw that is located on the

end of the switch cover box. This releases

the float for fully automatic operation.

PIPING—Run flexible tubing or pipe from

the evaporator and furnace to the pump.

Insert the pipe into the drain inlet hole.

Make sure the pipe does not interfere with

the float. Cut an angle on the inlet pipe so

that it doesn’t close off against the bottom

of the pump. See Figure 1 – exploded

detail.

Connect 3/8” NPT piping to the discharge

port. Extend this piping or tubing straight

up as high as necessary. (Do not extend

this tubing past the head/GPH of the

pump installed). Do not kink the tubing,

as this will block the flow. From this

high point, slope the discharge tubing

downward to a point above the drain,

then turn down and extend to a point

below or level with the bottom of the

condensate pump. If it is not possible to

slope the discharge tubing downwards,

make an inverted “U” trap directly above

the pump at the highest point. (Figure 1)

A check valve is required and should be of a soft seat swing check design. A spring loaded ball check is permissible if the lift is

one half of the pump shut off level and the spring pressure is equal to, or less than one (1) psi.

ELECTRICAL CONNECTIONS— Review precautions on previous page before proceeding!

LINE VOLTAGE—Connect only to a source of constant power, not an intermittent source such as a fan or limit control circuit.

Connect the black and white wires to the appropriate voltage source and the green wire to ground.

The A2-X-1965 is equipped with a LOW VOLTAGE—AUXILIARY SAFETY SWITCH–Connect

the leads of the auxiliary safety switch to the thermostat control circuit of the air

conditioner/furnace. This will disrupt the thermostat demand in a high water condition.

(Figure 2)

CAUTION –Thermostat demand disruption should not be utilized if cooling or heating

requirements are a necessity. An alarm system should be used with the auxiliary switch

instead.

A2-X-1965 WIRING FOR DUAL VOLTAGE—The A2-X-1965 Dual Voltage Condensate pump

is wired for 115 volts from the manufacturer. NOTE: read entire procedure

before starting.

To connect to 115 VAC power supply, wire as follows.

1. Remove the top switch cover plate.

2. Install a proper conduit fitting thru the side hole of the main switch cover

and feed the power supply wires and thermostat control leads (optional)

into the housing.

3. Connect the orange and white wire to the power supply lines.

4. Connect the green (ground) wire to the ground supplied.

5. Connect the yellow auxiliary wires as previously described to the thermostat

control circuit leads.

6. Replace the top switch cover plate.

To connect to 230 VAC power supply , wire as follows. (Figure 3)

1. Remove the entire switch cover.

2. Remove the blue/yellow motor wire connector from the switch.

3. Cut the female connector from the blue/yellow motor wires.

4. Cut the wire connector from the black/red motor wires.

Loading...

Loading...