Page 1

FR6822+ Frames

Installation and Operation Manual

Edition E

175-100048-00

Page 2

Page 3

FR6822+ Frames

Installation and Operation Manual

Edition E

July 2011

Page 4

Harris Corporation

Broadcast Communications

Division

4393 Digital Way

Mason, OH USA 45040

Copyright © 2008-2011 Harris Corporation, 1025 West NASA Boulevard, Melbourne, Florida

32919-0001 U.S.A. All rights reserved. This publication supersedes all previous releases. No

part of this documentation may be reproduced in any form or by any means or used to make

any derivative work without permission from Harris Corporation.

Harris Corporation reserves the right to revise this documentation and to make changes in

content from time to time without obligation on the part of Harris Corporation to provide

notification of such revision or change.

UNITED STATES GOVERNMENT LEGEND If you are a United States government agency,

then this documentation and the software described herein are provided to you subject to

the following:

All technical data and computer software are commercial in nature and developed solely at

private expense. Software is delivered as “Commercial Computer Software” as defined in

DFARS 252.227-7014 (June 1995) or as a “commercial item” as defined in FAR 2.101(a) and

as such is provided with only such rights as are provided by Harris’ standard commercial

license for the Software. Technical data is provided with limited rights only as provided in

DFAR 252.227-7015 (Nov 1995) or FAR 52.227-14 (June 1987), whichever is applicable. You

agree not to remove or deface any portion of any legend provided on any licensed program

or documentation contained in, or delivered to you in conjunction with, this User Guide.

This publication, or any part thereof, may not be reproduced in any form, by any method, for

any purpose, without the written consent of Harris Corporation.

Contact Harris Corporation for permission to use materials as well as guidelines concerning

foreign language translation and publication.

Harris Corporation reserves the right to revise and improve its products as it chooses. This

publication is designed to assist in the use of the product, as it exists on the date of

publication of this manual, and may not reflect the product at the current time or an

unknown time in the future. This publication does not in any way warrant description

accuracy or guarantee the use for the product to which it refers.

The Harris logo and assured communications are registered trademarks of Harris

Corporation. D-Series is a trademark of Harris Corporation. All other trademarks are held by

their respective owners.

This user guide was created for FR6822+, Revision E.

Windows is a registered trademark of Microsoft Corporation. AMD and Operton are

trademarks of Advanced Micro Devices, Inc. Dolby Digital is a registered trademark of Dolby

Laboratories. Java is a trademark of Sun Microsystems, Inc. or its subsidiaries in the United

States and other countries.

All other trademarks are the property of their respective holders.

Publication Date: July 2011

Page 5

Contents

Preface........................................................................................................................vii

Manual Information ........................................ ............................. ............................. ...vii

Purpose .............................................................................. ...................................... vii

Audience ............................... ............................................. ...................................... vii

Revision History ........................................................................................................vii

Writing Conventions ....... ... .... ... ... ... .... ................................................... .................. viii

Obtaining Documents ........ .... ... ... ... .................................................... ... ... ............... viii

Unpacking/Shipping Information .............................................................................. viii

Unpacking a Product ............................................................................................... viii

Product Servicing .......................................................................................................ix

Returning a Product ...................................................................................................ix

Restriction on Hazardous Substances (RoHS) Compliance .........................................ix

Waste from Electrical and Electronic Equipment (WEEE) Compliance .......................x

Safety .................................. ....................................................... ..................................... x

Safety Terms and Symbols in this Manual ..................................................................xi

iii

Chapter 1 Introduction.............................................................................................................. 1

FR6822+ Product Description ........................................................... ............................. 1

Backwards Compatibility .......................................................................................... 1

Main Features ............................................................................................................1

Component Descriptions .............................................................................................. 2

Front Panel ................................................................................................................2

Rear Panel ......................................... ... ... ... .... ... ................................................ ... .... 3

Fan Assembly ............................................................................................................4

Power Supply ............................................................................................................5

6800+ETH Resource Module ...................................................................................... 5

Signal Flow .................................................................................................................... 7

Chapter 2 Installation............................................................................................................... 9

Unpacking the Frame .......................................... ............................. ............................. 9

Checking the Packing List .......................................................................................... 9

Available Frame Configurations .......................... ................................................... .. 10

Choosing 6800+ETH Upgrade Options ..................................................................... 10

Copyright © 2008-2011, Harris Corporation

Page 6

Contents

iv

Maximum 6800+ Frame Power Ratings ................................................ ...... ...... .... ......11

Meeting Location and Electrical Requirements .........................................................11

Installing the Frame in a Rack ....................................................................................12

Attaching Optional Rear-Support Brackets ............................................................... 12

Installing and Removing Resource Modules .............................................................14

Installing a Resource Module ................................. ................ ................ ................ ...15

Removing a Resource Module ..................................................................................15

Installing and Removing 6800+ Modules ...................................................................16

Installing 6800+ Modules in an FR6822+ Series Frame ..............................................17

Removing 6800+ Modules .......................................................................................19

Replacing a Failed Fan Unit ........................................................................................20

Making System Connections ......................................................................................22

Connecting to a Power Source .................................................................................22

Making Genlock Connections for Signal Synchronization .........................................22

Chaining Legacy Frames ..........................................................................................23

Connecting the GPI Alarm Relay to a Monitoring System .........................................25

Chapter 3 FR6822+F Frame and Module Operation...................................................27

Monitoring the Frame Using Frame Status LEDs ...................................................... 27

Operating Installed Modules ................................................... ................................... 28

Using Card-Edge Controls .......................................................................................29

Introducing Parameter Types ....................................................................................29

Operating Notes ......................................................................................................30

Alarms .......................................................................................................................... 30

Chapter 4 FR6822+QXFE Configuration, Monitoring, and Control ...................31

Overview ..................... ....................... ....................... ...................... ................... ..........3 1

Using CCS Software with FR6822+QXFE .................................................................... 31

Preparing for Configuration .....................................................................................32

Discovering Frames and Modules Using a CCS Application .................... ... ... ... .... ......32

Monitoring 6800+ Modules in CCS Navigator ..........................................................33

Using Q-SEE Compliant Modules in FR6822+QXFE Frames .......................................33

Upgrading Module Firmware Using CCS Software ...................................................37

Correcting a Failed Upgrading Procedure .................................................................40

Activating a 6800+ETH License in CCS Software ......... ... ... .... ... ... ... ..........................43

Using an HTTP Browser with FR6822+QXFE ..............................................................44

System Requirements for Device Monitoring Using HTTP ..........................................44

Logging In To 6800+ HTTP Control Interface ............................................................44

Managing User Accounts .........................................................................................46

Logging Off from 6800+ HTTP Control Interface ......................................................49

Control and Monitoring 6800+ Modules and Frames over HTTP ...............................49

Streaming Video ......................................................................................................52

Using Presets With 6800+ETH .................................................................................. 55

Upgrading Module Firmware Using an HTTP Browser ...............................................57

Activating a 6800+ETH License Using an HTTP Browser ............................................59

Discovering HTTP Devices in CCS Navigator .... ... .... ... ... ... ... .... ...................................5 9

Copyright © 2008-2011, Harris Corporation

Page 7

Installation and Operation Manual

FR6822+ Frames

Control and Monitoring FR6822+QXFE Using SNMP ................................................ 60

Configuring SNMP Settings Using HTTP ....................................................... ... ... ... ... 61

Configuring SNMP Agent and System Settings ........................................................ 64

Configuring SNMP Settings in CCS Software .................. ... ... ... .... ... ......................... 64

Configuring Third-Party SNMP Software Control ...................................................... 66

Monitoring and Control Using MIBs ......................................................................... 68

Basic 6800+ETH Module Operation ......................................................... ................... 69

Setting 6800+ETH Remote Control Parameters ........................................................69

Telnet Commands ................................................................................................... 70

Chapter 5 Power Supplies......................................................................................................75

Overview ..................................................................................................................... 75

Installing a Power Supply ..................................................... ............................. ......... 75

Disconnecting and Removing an Existing Power Supply ........................................... 75

Installing a New Power Supply ................................................................................. 76

Protecting the Power Supply ..................................................................................... 77

Alarm Signals and Indicators ................................................... ... .... ... ......................... 77

v

Chapter 6 Specifications........................................................................................................ 79

FR6822+ Frame Specifications .................................................................................... 79

6800+ETH Specifications ............................................................................................. 79

Power Supply Specifications ...................................................................................... 80

6822+AC ....................................... ............................. ............................. ................ 80

6800+48V ............................................................................................................... 81

Appendix A Servicing Instructions....................................................................................... 83

Overview ..................................................................................................................... 83

Battery Use Caution ....................................... ............................................................. 83

Fuse Replacement Caution ......................................................................................... 84

Appendix B Troubleshooting.................................................................................................... 87

Ethernet Network or FR6822+QXFE Frame Failure ................................................... 87

Discovering, Controlling, and Monitoring Devices ................................................... 87

Resetting the 6800+ETH IP Address ......................................................................... 87

Pinging an Installed 6800+ETH Module .............. ... ................................................ ... 88

Using 6800 Series Modules in FR6822+ Frames ........................................................ 89

Slow Response Time During Discovery ..................................................................... 89

CCS Application Cannot Control 6800+Eth Module ................................................. 90

Hardware Fails to Communicate with PC after Power Failure ................................. 90

Index........................................................................................................................... 91

Copyright © 2008-2011, Harris Corporation

Page 8

Contents

vi

Copyright © 2008-2011, Harris Corporation

Page 9

Preface

Manual Information

vii

Purpose

Audience

Revision

History

This manual details the features, installation, operation, maintenance, and specifications for

the FR6822+ Mounting Frames.

This manual is written for engineers, technicians, and operators responsible for installation ,

setup, maintenance, and/or operation of the FR6822+

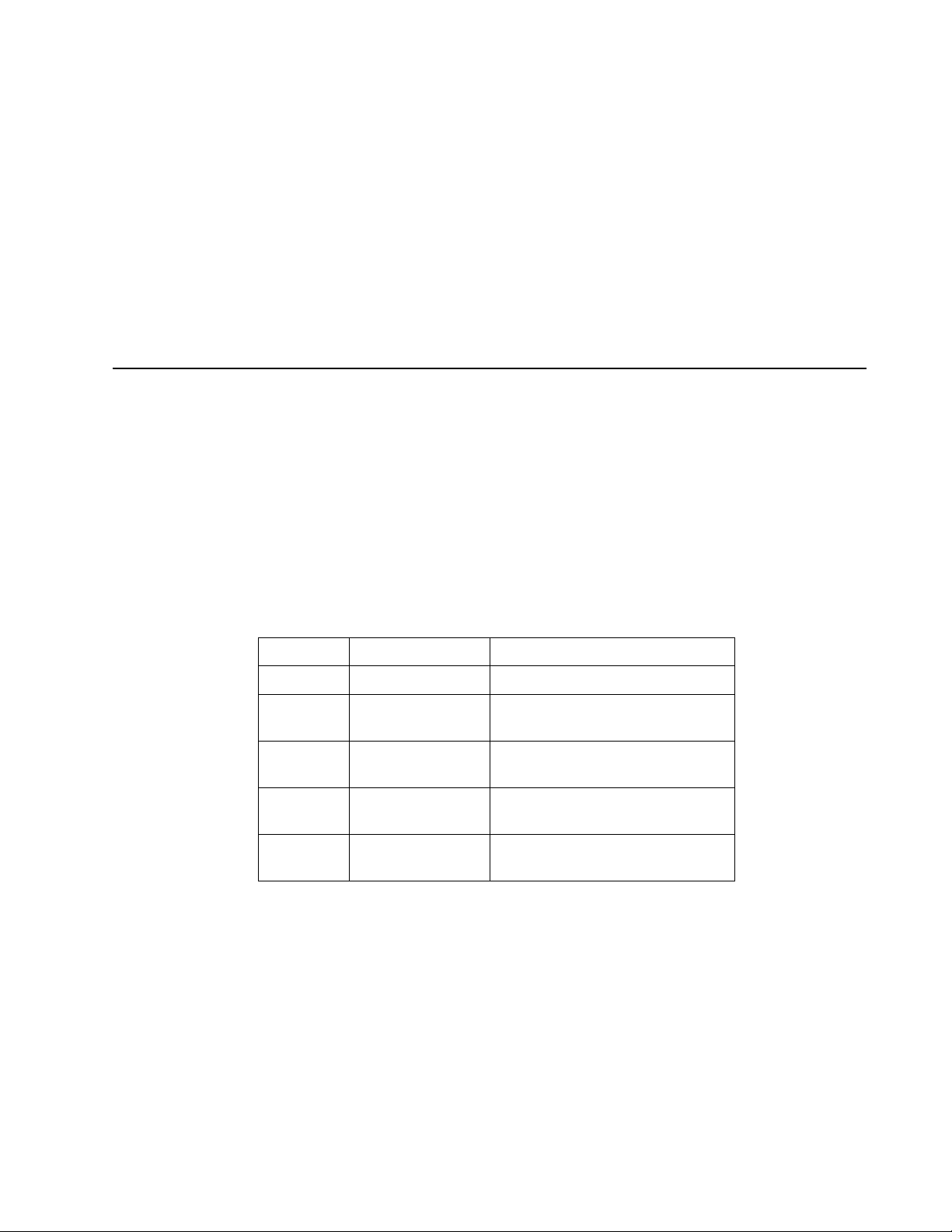

Table P-1 Revision History of Manual

Edition Date Comments

A September 2008 Initial release

B December 2008 Updates to firmware upgrade

section

C August 2009 Addition of temperature sensing

submodule

D February 2010 Addition of security features and

video streaming to HTTP browser

E July 2011 Reformatting; parallel software

upgrade

Mounting Frames.

Copyright © 2008-2011, Harris Corporation

Page 10

viii

Preface

Writing

Conventions

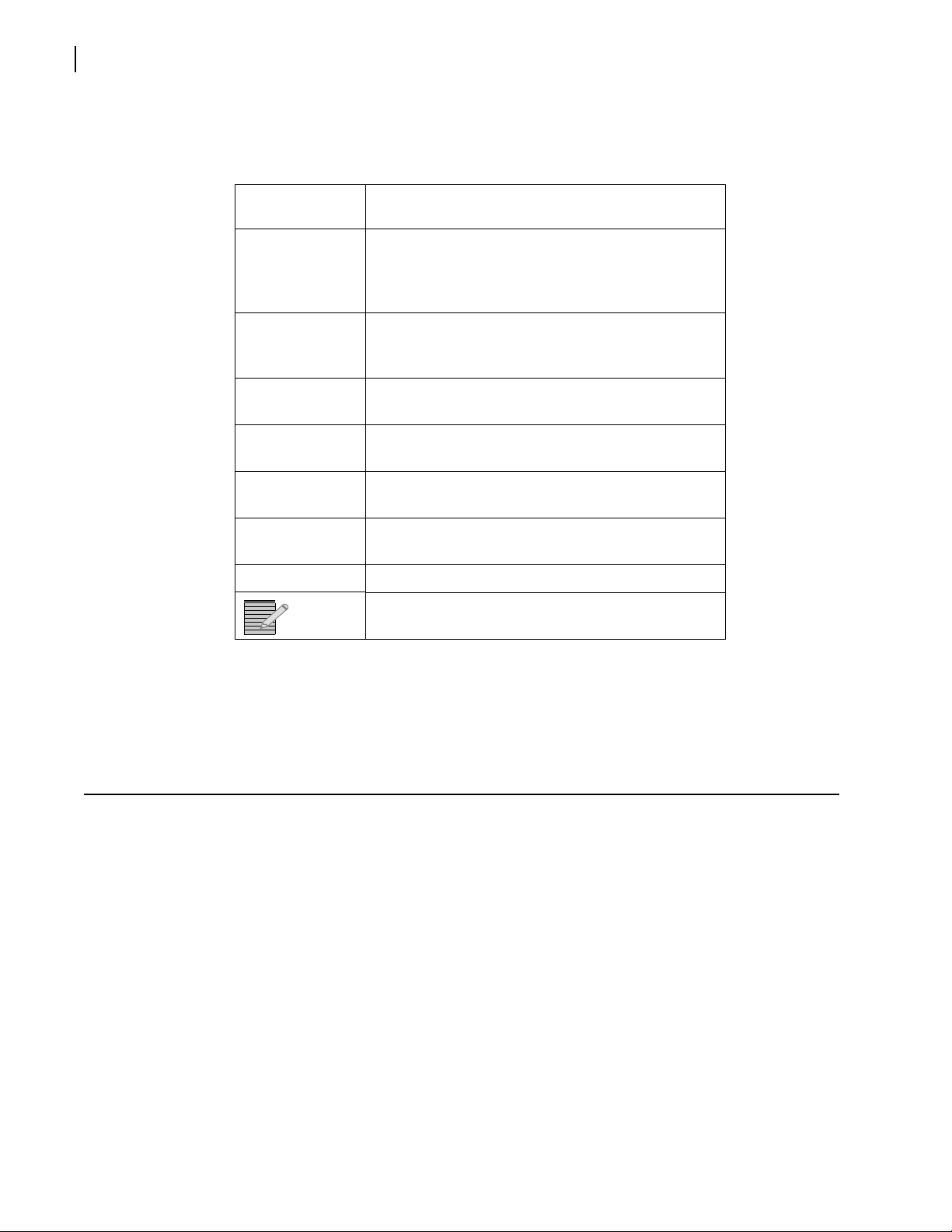

To enhance your understanding, the authors of this manual have adhered to the following

text conventions:

Table P-2 Writing Conventions

Term or

Convention

Bold Indicates dialog boxes, property sheets, fields,

Italics Indicates E-mail addresses, the names of books or

CAPS Indicates a specific key on the keyboard, such as

Code Indicates variables or command-line entries, such as

> Indicates the direction of navigation through a

hyperlink Indicates a jump to another location within the

Description

buttons, check boxes, list boxes, combo boxes,

menus, submenus, windows, lists, and selection

names

publications, and the first instances of new terms

and specialized words that need emphasis

ENTER, TAB, CTRL, ALT, or DELETE

a DOS entry or something you type into a field

hierarchy of menus and windows

electronic document or elsewhere

Internet address Indicates a jump to a website or URL

Indicates important information that helps to avoid

and troubleshoot problems

Obtaining

Documents

Product support documents can be viewed or downloaded from our website. Alternatively,

contact your Customer Service representative to request a document.

Unpacking/Shipping Information

Unpacking a

Product

This product was carefully inspected, tested, and calibrated before shipment to ensure years

of stable and trouble-free service.

1 Check equipment for any visible damage that may have occurred during transit.

2 Confirm that you have received all items listed on the packing list.

3 Contact your dealer if any item on the packing list is missing.

4 Contact the carrier if any item is damaged.

5 Remove all packaging material from the prod uct and its associated compon ents before you

install the unit.

Keep at least one set of original packaging, in the event that you need to return a product

for servicing.

Copyright © 2008-2011, Harris Corporation

Page 11

Installation and Operation Manual

FR6822+ Frames

ix

Product

Servicing

Returning a

Product

Except for firmware upgrades, FR6822+ Frames and 6800+ETH resource modules are not

designed for field servicing. All hardware upgrades, modifications, or repairs require you to

return the modules to the Customer Service center.

In the unlikely event that your product fails to operate properly, please contact Customer

Service to obtain a Return Authorization (RA) number, then send the unit back for servicing.

Keep at least one set of original packaging in the event that a product needs to be returned

for service. If the original package is not available, you can supply your own packaging as

long as it meets the following criteria:

The packaging must be able to withstand the product’s weight.

The product must be held rigid within the packaging.

There must be at least 2 in. (5 cm) of space between the product and the container.

The corners of the product must be protected.

Ship products back to us for servicing prepaid and, if possible, in the original packaging

material. If the product is still within the warranty period, we will return the product prepaid

after servicing.

Restriction on Hazardous Substances (RoHS) Compliance

Directive 2002/95/EC—commonly known as the European Union (EU) Restriction on

Hazardous Substances (RoHS)—sets limits on the use of certain substances found in

electrical and electronic equipment. The intent of this legislation is to reduce t he amount of

hazardous chemicals that may leach out of landfill sites or otherwise contaminate the

environment during end-of-life recycling. The Directive took effect on July 1, 2006, and

refers to the following hazardous substances:

Lead (Pb)

Mercury (Hg)

Cadmium (Cd)

Hexavalent Chromium (Cr-V1)

Polybrominated Biphenyls (PBB)

Polybrominated Diphenyl Ethers (PBDE)

According to this EU Directive, all products sold in the European Union will be fully

RoHS-compliant and “lead-free.” (See our website for more information on dates and

deadlines for compliance.) Spare parts s upplied for the repair and upgrade of equipment

sold before July 1, 2006 are exempt from the legislatio n. Equipm ent that complies with the

EU directive will be marked with a RoHS-compliant emblem, as shown in Figure P-1.

Figure P-1 RoHS Compliance Emblem

Copyright © 2008-2011, Harris Corporation

Page 12

Preface

x

Waste from Electrical and Electronic Equipment (WEEE) Compliance

The European Union (EU) Directive 2002/96/EC on Waste from Electrical and Electronic

Equipment (WEEE) deals with the collection, treatment, recovery, and recycling of electrical

and electronic waste products. The objective of the WEEE Directive is to assign the

responsibility for the disposal of associated hazardous waste to either the producers or users

of these products. Effective August 13, 2005, producers or users are required to recycle

electrical and electronic equipment at end of its useful life, and may not dispose of the

equipment in landfills or by using other unapproved methods. (Some EU member states

may have different deadlines.)

In accordance with this EU Directive, companies selling electric or electronic devices in the

EU will affix labels indicating that such products must be properly r ecycled. (See our website

for more information on dates and deadlines for compliance.) Contact your local Sales

representative for information on returning these products for recycling. Equipment that

complies with the EU directive will be marked with a WEEE-compliant emblem, as shown in

Figure P-2.

Figure P-2 WEEE Compliance Emblem

Safety Carefully review all safety p recautions to avoid injury and prevent d amage to this pr oduct or

any products connected to it. If this product is rack-mountable, it should be mounted in an

appropriate rack using the rack-mounting positions and rear support guides provided. It is

recommended that each frame be connected to a separate electrical circuit for protection

against circuit overloading. If this product relies on forced air cooling, it is recommended

that all obstructions to the air flow be removed prior to mounting the f rame i n the rack.

If this product has a provision for external earth grounding, it is recommended that the

frame be grounded to earth via the protective earth ground on the rear panel.

IMPORTANT! Only qualified personnel sh ould perform service procedures.

Copyright © 2008-2011, Harris Corporation

Page 13

Installation and Operation Manual

FR6822+ Frames

xi

Safety Terms

and Symbols

in this

Manual

WARNING

Statements identifying conditions or practices that may

result in personal injury or loss of life. High voltage is

present.

CAUTION

Statements identifying conditions or practices that can

result in damage to the equipment or other property.

Copyright © 2008-2011, Harris Corporation

Page 14

xii

Preface

Copyright © 2008-2011, Harris Corporation

Page 15

Introduction

1

FR6822+ Product Description

The 2RU FR6822+ frames accommodate the entire 6800+ line of analog/digital, audio/video

products for conversion, distribution, interface, generation, and router applications.

FR6822+ frames provide central genlock distribution, GPI for alarms, 2 types of remote

control interfaces, 20-slot capacity, support for multi-standard products (including HD, SD,

analog, and fiber optics). There are no cooling limits on multiple frames stacked together.

FR6822+ frames are specifically designed to weigh noticeably less than other products. Each

feature has been carefully designed to ensure a product that is reliable, dependable, and

easy-to-use.

1

When a 6800+ETH module is installed in a FR6822+ frame, the frame becomes a

FR6822+QXFE frame. This frame provides monitoring thumbnails and enhanced alarm

monitoring options for compatible modules. To determine whether the modules installed in

your frame have these capabilities, see the manuals applicable to those products.An

interface to Ethernet via the 6800+ETH allows connectivity with all other Command and

Control System (CCS

Backwards Compatibility

FR6822+ frames are designed t o house and power both 6800 and 6800+ modules. Th ough

various 6800+ modules have different feat ures and controls, all work in any combination in

a FR6822+ frame.

Main

Features

FR6822+ frames have the following main features:

Work with 6800+ modules and most 6800 modules (using a “6800-style” r ear module)

Configurable to a wide variety of multi-standard audio and video conversion, routing,

generation, and distribution module combinations (HD, SDI, audio, fiber optics)

2RU frame provides space for 6 triple-s lot modules, 10 double-slot modules, 20

single-slot modules, or a combination of single-, double-, and triple-slot modules

Provides looping reference input for video genlock, with buffered reference distribution

to all modules

™

) controlled products. FR6822+ frames are Q-SEE™ Compliant.

Thermal/Fan

Provides refined fan-cooling for a <120 W load

Copyright © 2008-2011, Harris Corporation

Page 16

2

Chapter 1

Introduction

Cools modules using a front-to-back airflow with alarm-monitored, low-noise fans

Control and Monitoring Using a 6800+ETH Module

Regulates and reports major frame operation and perfor mance data to the control

system

Provides access to Ethernet for control and monitoring using CCS Navigator or a web

browser

Provides additional control via SNMP with the 6800+ETHSNMP option

Supports thumbnail transmission at a rate of three frames per second, for all modules

that support this feature within the frame, in CCS Navigator only

Power Supply

Houses two power supplies for full redundancy and load-sharing

Displays power and fault indicators on front panel

Includes captivated power cord(s) for AC power supplies to prevent accidental

unplugging (note: cords are not provided for the DC power supply configurations)

Provides choice of 6822+AC for AC power or 6800+48V for DC power; frame can

house two of either power supply or one of each

Includes a temperature-sensing submodule that provides alarm generation when the

frame is monitored by CCS Navigator

Component Descriptions

Components of the FR6822+ frame are described in the following sections:

Front Panel on page 2

Rear Panel on page 3

Fan Assembly on page 4

Power Supply on page 5

6800+ETH Resource Module on page 5

Front Panel

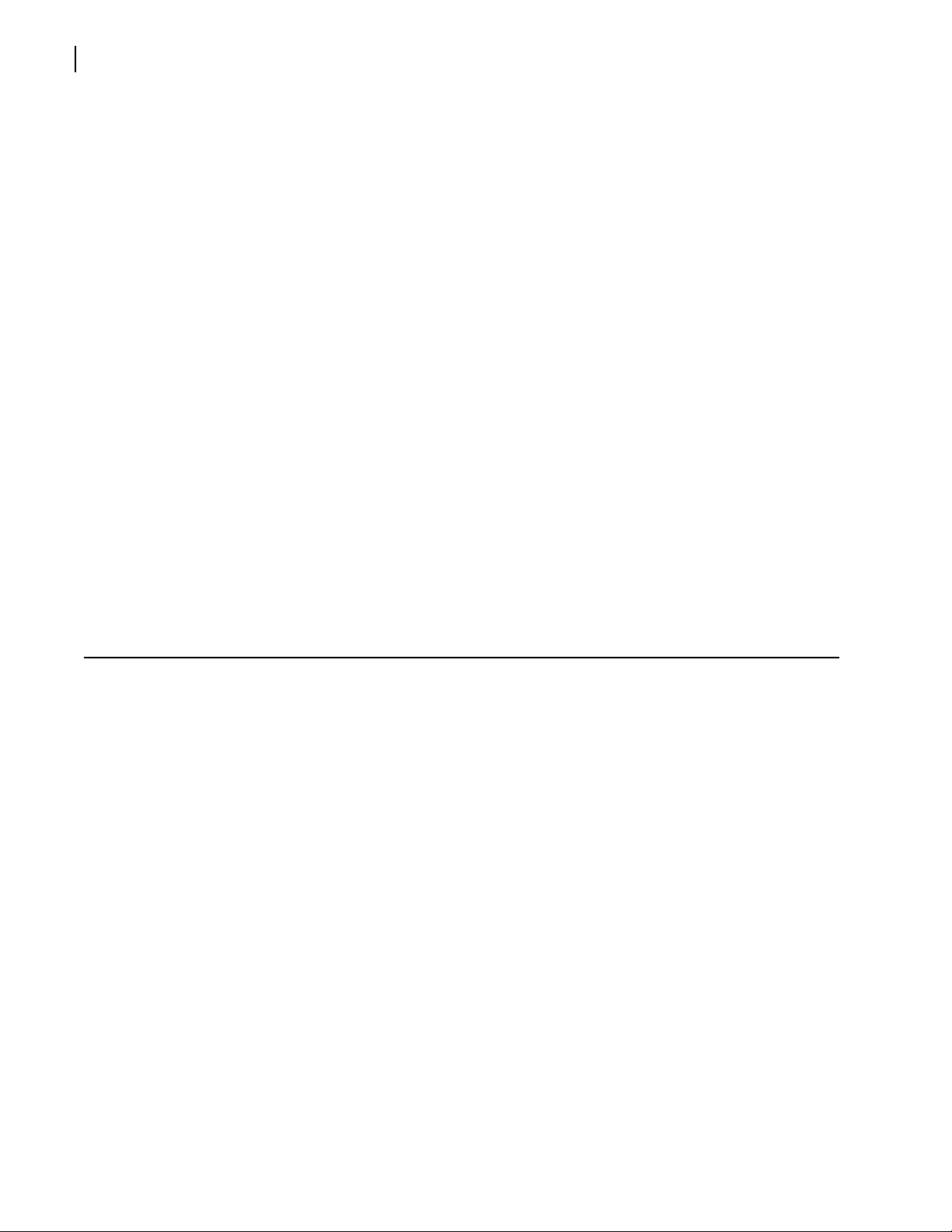

Figure 1-1 shows the front view of a FR6822+ frame; and identifies the location of status

LEDs, cooling fans, and front panel release screws. Figure 1-2 shows the inside of the

frame with the front panel removed.

Copyright © 2008-2011, Harris Corporation

Page 17

Figure 1-1 FR6822+ Frame Front Panel

Cooling fans

(built into front panel)

Finger-release screws

Status LEDs

Cooling Failure/Alarm/Power

Redundant power supplies

Front

mounting ear

20 single-slot 6800/

6800+ card guides

(floor and roof)

Front

mounting ear

Installation and Operation Manual

FR6822+ Frames

3

Figure 1-2 FR6822+ Frames Frame with Front Panel Removed

Rear Panel

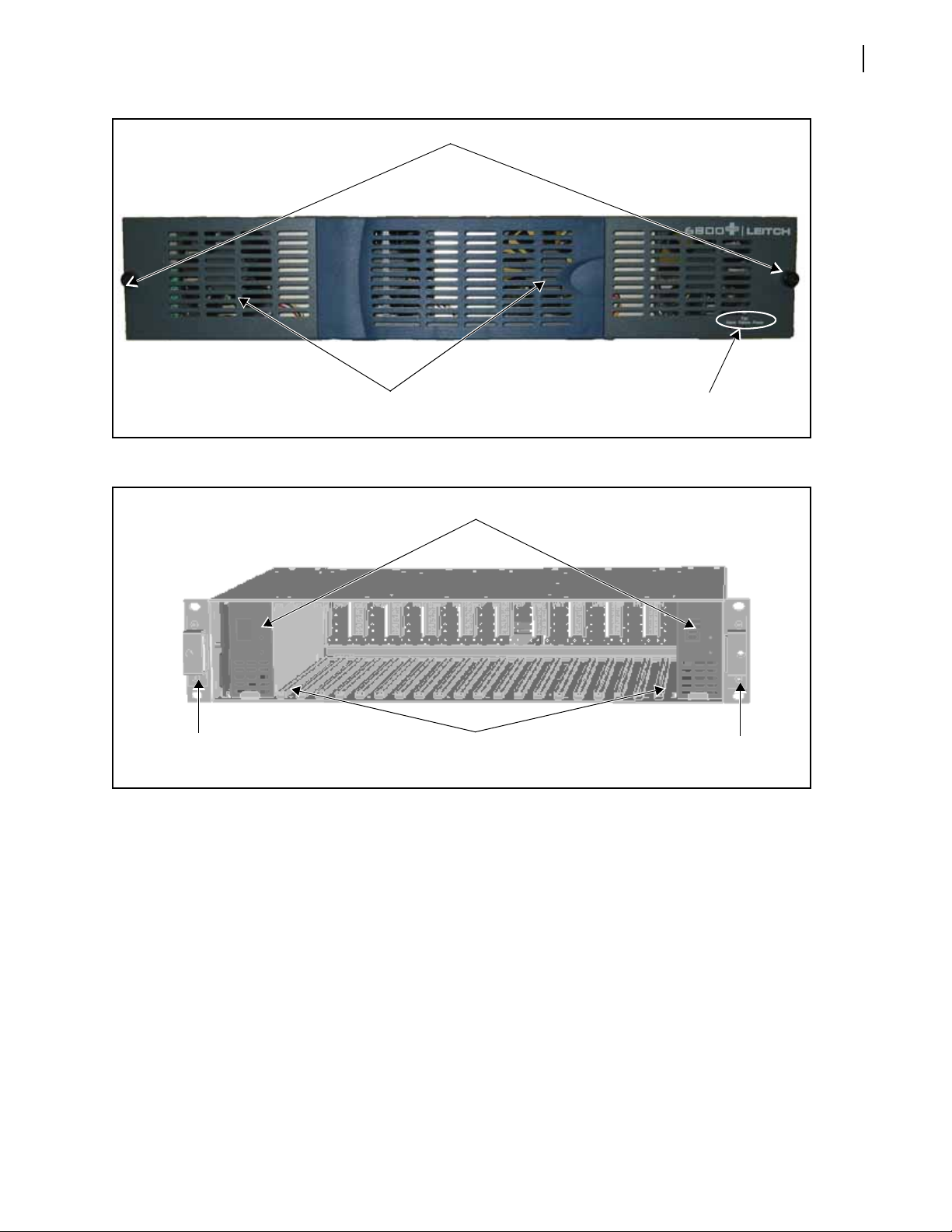

Figure 1-3 identifies the location of FR6822+ rear panel components. Table 1-1 briefly

describes each of the connectors and switches found on the rear panel. See Making

System Connections on page 22 for more information on system connections.

Copyright © 2008-2011, Harris Corporation

Page 18

Chapter 1

Frame ID

rocker

switch

Genlock loop

through BNCs

Power mains inlets

(one for each redundant PSU)

Rear module

connectors

Communication

loop through

BNCs

GPI

connector

Ethernet

connector

4

Introduction

Figure 1-3 FR6822+ Frame Rear Panel

Fan

Assembly

Table 1-1 Rear Panel Components

Item Description

Power mains inlets Independent power source connections

GPI connector Alarm relay connection between an

FR6822+ frame and a third-party control

monitoring system

Frame ID rocker switches Unique frame identification switch (four

possible frame ID combinations)

Communication loop

through BNCs (COM LOOP)

Communication network input/output

serial connections for chained frames

Genlock loop through BNCs Video synchronization connections

A fan assembly is located in the front panel o f an FR 682 2 + fram e (s ee Figure 1-4). The fa n

assembly draws in air from the front of the unit, and expels it through the back.

Copyright © 2008-2011, Harris Corporation

Figure 1-4 Fan Assembly (Back View of Front Panel)

All fans are equipped with RPM monitoring circuitry. Either the standard 6800+RESC

resource module or th e 6800+ETH Ethernet resource module (described in 6800+ETH

Resource Module on page 5) decodes and monitors these signal to determine fan health.

Local and remote alarms report undesirable conditions that may arise.

Features of the FR6822+ fan assembly include the following:

Low fan-noise emissions

Page 19

Installation and Operation Manual

Alarm RPM monitoring and recording and bus reporting of fan failure

Automatic fan shut-down when front panel is removed

FR6822+ Frames

5

Power Supply

6800+ETH

Resource

Module

Each FR6822+ frame can house two redundant, modular, and fully self-contained power

supply units (PSU). All FR6822+ frames come with one AC or DC power supply, which can

support an entire frame load. An optional redundant AC or DC power supply can be

ordered separately. Power supply configurations can be a mix of AC and DC units.

Each PSU is hot-swappable, ensuring no disruption to frame operation. Other features of

both power supplies include the following:

Allows frame monitoring of PSU

Includes power switch on front of PSU unit

Maintains compatible output rails ±6.8 V for 6800 and 6800+ products

The 6822+AC auto-switches 90 to 240 V AC, at 47 to 63 Hz. “Power” and “Fault”

indicators are located on the front of the PSU.

The 6800+48V supports a -48 VDC input and provides DC PSU protections including input

fuse, inrush current limiting, input transient protection, short circuit protection on all

outputs, and reverse input voltage protection. It provides a Power Good green LED and an

Overheat red LED.

See Figure 1-2 on page 3 to locate the PSU units in the FR6822+ frame, or

Power Supplies on page 75 for a more detailed description.

If a frame has no resource module, no remote control will be available, and control of the

frame’s modules will be at the card edge only.

The 6800+ETH resource card allows communication between 6800+ devices and CCS™

software applications such Navigator™, and provides a communication interface between

CCS control panels such as NUCLEUS.

The 6800+ETH module provides 10/100Base-T Ethernet access, while the CCS software

application provides a graphical user interface (GUI).

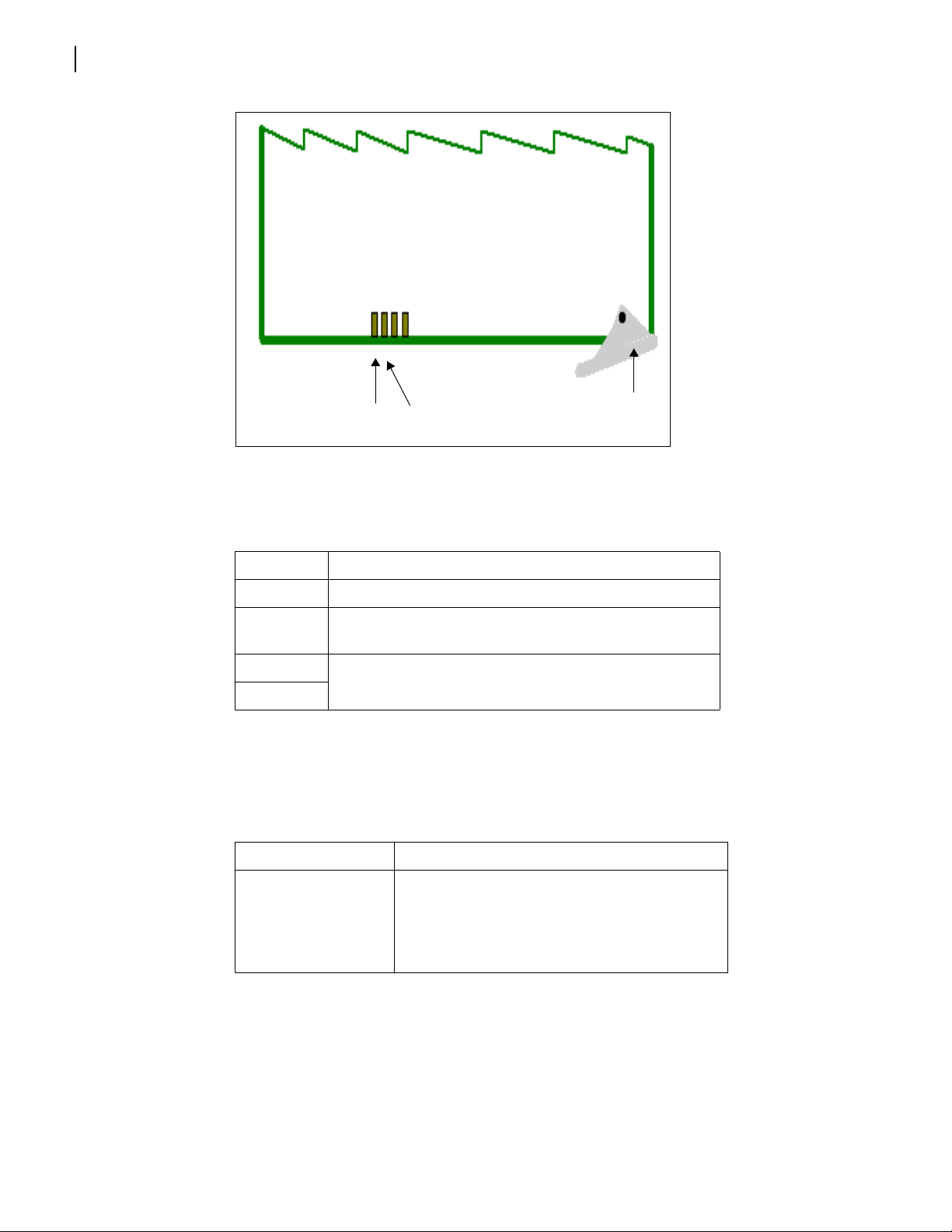

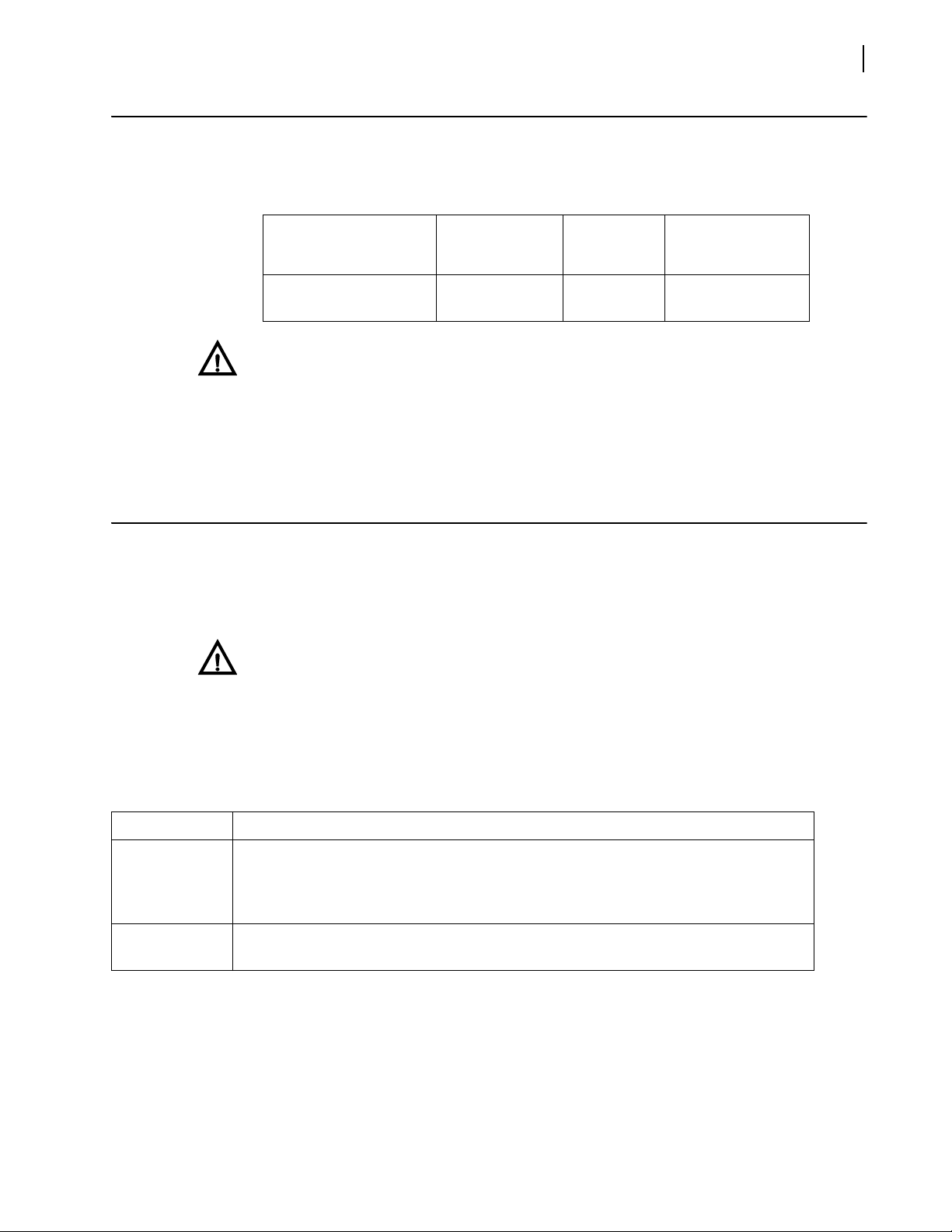

Figure 1-5 is a top-front view of the 6800+ETH module. Descriptions of card-edge

components are found in Table 1-2.

Copyright © 2008-2011, Harris Corporation

Page 20

6

LED 1

LED 2

Extractor

handle

Chapter 1

Introduction

Figure 1-5 6800+ETH Front Module

Card-edge LEDs are described in Table 1-2.

Table 1-2 Card-Edge LED and Connector Descriptions

Item Description

LED 1 When on (red), indicates that the FPGA is not configured

LED 2 When lit (green), indicates that the card is operating

normally

LED 3 Reserved for future use

LED 4

The 6800+ETH high-end resource card is described in full in FR6822+QXFE

Configuration, Monitoring, and Control on page 31.

6800+ETH has the following license key option.

Table 1-3 6800+ETH License Key Options

Option Function

6800+OPT+SNMP Use this optional upgrade with any SNMP-based

control application to monitor and control

modules in the host frame. See Control and

Monitoring FR6822+QXFE Using SNMP on

page 60.

See Installing and Removing Resource Modules on page 14 for information on

locating, removing, and installing resource modules.

Copyright © 2008-2011, Harris Corporation

Page 21

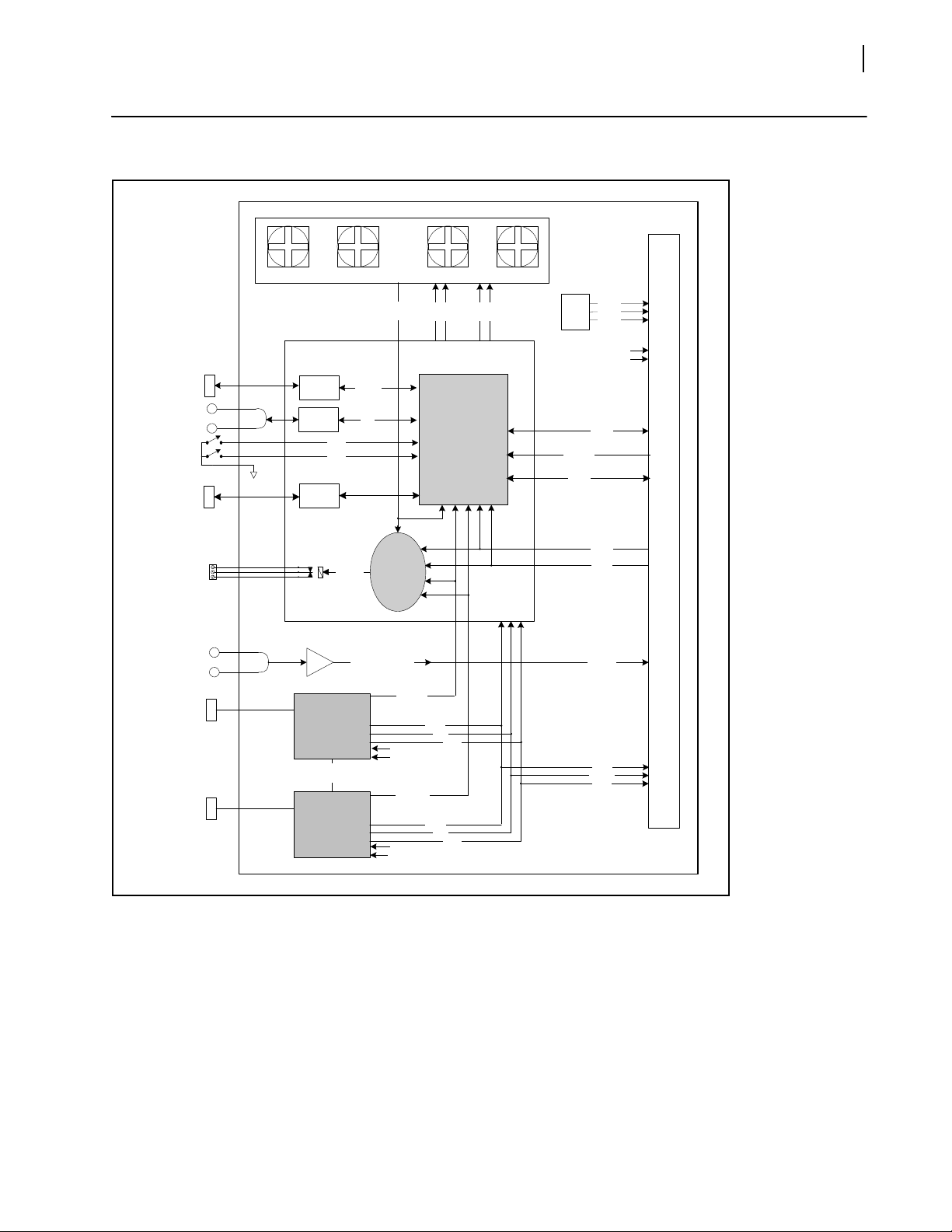

Signal Flow

Genlock

Loopthru

Alarm GPI

Relay

Status

Bus

Genlock

Video

Alarm

Bus

Ground

+6.8 V

Comm

Bus

Relay

Drive

Mains Inle t 1

Mains Inle t 2

Powersupply 2

(right)

PSU 1 Fail

Resource

Module

CPU Core

Mid plan e PCB

Alarm

Logic

Fan

Power

Slot ID

Slot ID

Slot ID

Coded

for

each

slot

LED

Drives

-6.8V

Frame ID0

Frame ID1

Powersupply 1

(left)

Current

share

Fan

Tachs (4)

Buffered Genlock

Video

Front Door

Resour ce Module

LCN Control

Loopthru

LC

N

LCN xcvr

Frame ID

UART to

USB

Convertor

USB Type-B

Connector

232 /

422

Ethernet

Physical

RJ-45

Jack

Frame

ID0

Frame

ID1

Highspeed

Bus

Aux

Comms

Frame ID1

Frame ID0

Frame ID0

Frame ID1

PSU 2 Fail

Gnd

-6.8V

+6.8V

-6.8V

+6.8V

Gnd

Installation and Operation Manual

FR6822+ Frames

7

Figure 1-6 FR6822+ Signal Flow Diagram

Copyright © 2008-2011, Harris Corporation

Page 22

8

Chapter 1

Introduction

Copyright © 2008-2011, Harris Corporation

Page 23

2

9

Installation

Unpacking the Frame

Checking the

Packing List

Contact your Customer Service representative if parts are missing or damaged. See

Unpacking/Shipping Information on page viii for pre-installation information, and for

information about returning a product for servicing.

Your shipment contains the following items:

Standard Equipment

One FR6822+ frame

One power supply unit (installed)

One AC power cord (if the frame contains an AC power supply)

One pair of spade terminals, LPN 138-000003Q00 (if the frame contains a DC power

supply)

Sufficient blank back connectors, as required

One CD containing the Installation and Operation Manual for each of the installed front

module/back connector product packages

One FR6822+ Frames Installation and Operation Manual

One 6800+ Series Safety Instructions and Standards Manual

Options

Additional power supply unit (installed)

Additional AC power cord for a second AC PSU

Additional pair of spade terminals for a second DC PSU, LPN 138-000003Q00

Back connector product packages (installed)

One left and one right rear support bracket, each with a corresponding slotted bracket

One cable support bar

Copyright © 2008-2011, Harris Corporation

Page 24

Chapter 2

10

Installation

Available Frame Configurations

There are several FR6822+ frame products and packages available. The FR6822+ family

includes the following:

Table 2-1 FR6822+ Frames and Accessories

Product Code Description

FR6822+QXFE 2RU frame with thumbnails, fan module, Ethernet module, and one

FR6822+QXFE+48 2RU frame with thumbnails, fan module, Ethernet module, and one

FR6822+QXFE+S 2RU frame with thumbnails, fan module, Ethernet module with SNMP

FR6822+QXFE+S48 2RU frame with thumbnails, fan module, Ethernet module with SNMP

FR6822+F 2RU frame with fan module and one 6822+AC power supply

FR6822+F+48 2RU frame with fan module, resource module, and one 48-volt power

6822+AC power supply

48-volt power supply

license, and one 6822+AC power supply

license, and one 48-volt power supply

supply

FR6822+RM Rear support extension rail, 6800+ series frames

6800+ETH Ethernet resource card for FR6822+QXFE, CCS

6800+ETHSNMP Ethernet resource module with SNMP

6800+48V 48-volt power supply

6822+AC Redundant, single 6822+AC power supply

Choosing 6800+ETH Upgrade Options

The basic 6800+ETH module is enabled for CCS and HTTP control. The following upgrade is

available:

Table 2-2 Available Soft-Key Upgrades

Ordered Product Content Description

6800+OPT+SNMP Optional soft-key upgrade to allow the host

frame and its modules to be controlled and

monitored using SNMP-based control

applications

To purchase additional license keys, contact your Sales representative. To activate a license

key, see Activating a 6800+ETH License in CCS Software on page 43 or Activating a

6800+ETH License Using an HTTP Browser on page 59.

Copyright © 2008-2011, Harris Corporation

Page 25

Maximum 6800+ Frame Power Ratings

Table 2-3 describes the maximum allowable power ratings for a FR6822+ frame.

Table 2-3 Maximum Power Ratings for FR6822+ Frames

Installation and Operation Manual

FR6822+ Frames

11

6800+ Frame Type

FR6822+ (frame with

AC or DC power supply)

CAUTION

Before installing 6800+ modules, see Maximum 6800+ Frame Power Ratin gs on

page 11

See Power Supplies on page 75 for information on installing 6822+AC or 6800+48V

power supplies.

.

Max. Frame

Power

Dissipation

120 W 20 6 W

Number

of Usable

Slots

Meeting Location and Electrical Requirements

The FR6822+ frame is cooled by forced air that is drawn in from the front and expelled

through the rear. You can stack any number of FR6822+ frames in a rack as long as you

maintain proper ventilation and remove all obstructions to air flow.

CAUTION

To ensure proper ventilation, keep the front panel of the frame closed during

operation, and install blank back connectors behind empty module slots. The

frame will overheat if you do not observe this precaution.

Max. Power

Dissipation

Per Slot

Ambient temperature should be maintained at between 32°F (0°C) and 113°F (45°C) at a

relative humidity of 10%-90% (non-condensin g) .

Table 2-4 Electrical Requirements

Item Specification

Load Limitations Each FR6822+ frame can contain two redundant, modular, self-contained power

supply units with standard IEC mains connectors. One PSU can support an entire

frame load. An AC unit requires an independent supply of 100 to 250 V AC, at 47 to

63 Hz. DC units require an independent supply of 36 to 72 V DC.

Voltage

Selection

FR6822+ frames do not have voltage selector switches. Voltage selection is automatic

upon power-up.

Copyright © 2008-2011, Harris Corporation

Page 26

Chapter 2

12

Installation

Table 2-4 Electrical Requirements

Item Specification

Maximum

Power

Dissipation

These ratings refer to the

total module power

consumption (excluding

that of the power supply)

allowable within an

FR6822+ frame. The limits

are based on the ability of

the unit to dissipate heat

over a temperature range

of 32° to 113°F (0° to

45°C).

Installing the Frame in a Rack

The FR6822+ frame is designed to mount into a standard-width 19-in. (483-mm) rack and

occupies a vertical space of 2RU.

Frames are secured to the rack with standard front-mounting ears built into the chassis.

Ensure you have provided adequate space behind the mounting ears, and appropriate

clearance for the connecting cables at the rear of the frame.

Power

Supply

AC power

supply

DC power

supply

Maximum Dissipation

(per Module)

Triple-slot module: 18 W

Double-slot module: 12 W

Single-slot module: 6 W

Triple-slot module: 18 W

Double-slot module: 12 W

Single-slot module: 6W

Maximum

Dissipation

(per Frame)

120 W

120 W

Attaching Optional Rear-Support Brackets

During normal operation, the frame’s front mounting ears provide sufficient supp ort for the

frame. However, in some circumstances, the front mounting ears may not be sufficient to

support the entire weight of the frame and the cables attached to it. These circumstances

may include:

When using heavy breakout cables

Where the frame is exposed to motion

In order to protect the f rame and the modules installed within it, you may choose to add

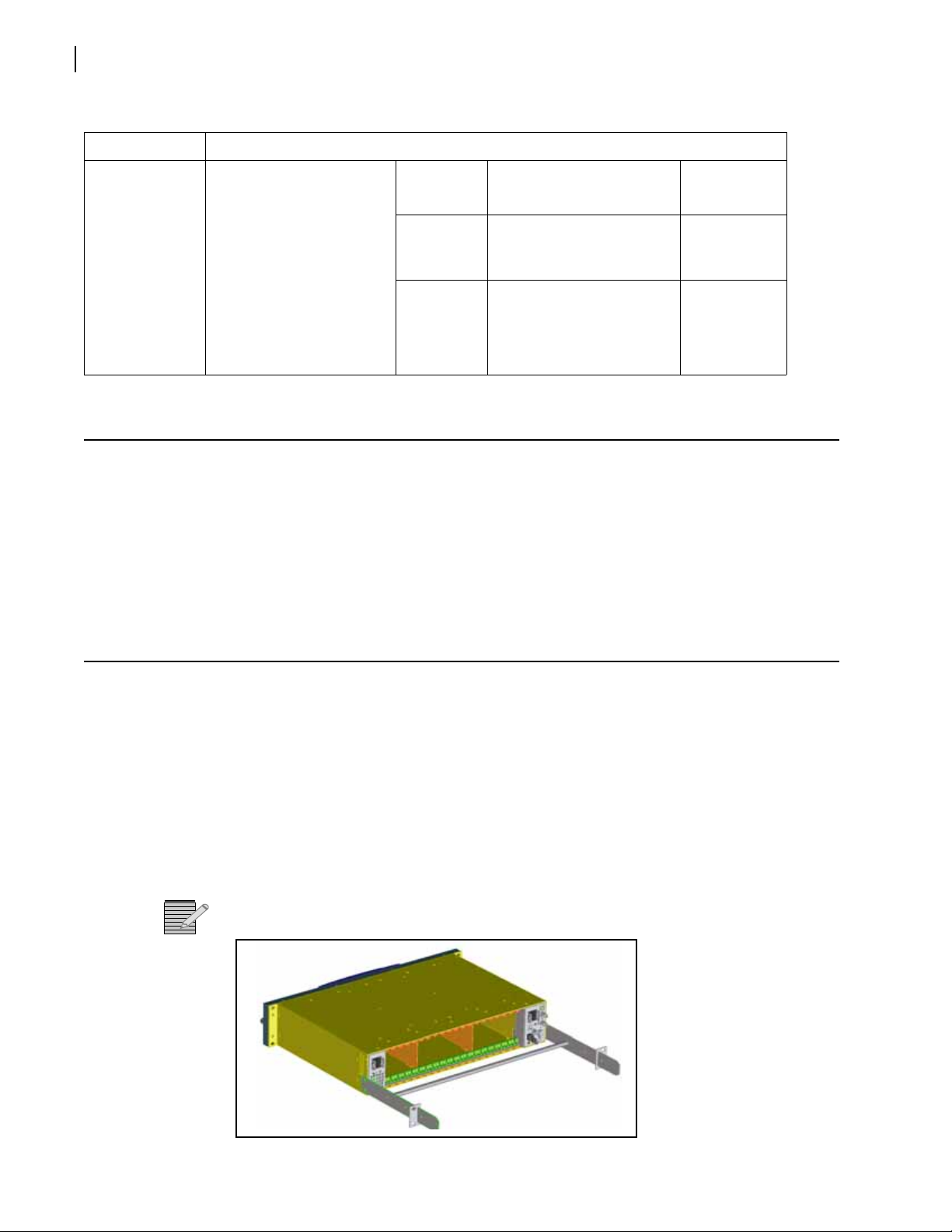

rear brackets to the frame.

Note: For mobile deployment of frames, rear mounting brackets are mandatory.

Figure 2-1 Frame With Rear-Support Bracket

Copyright © 2008-2011, Harris Corporation

Page 27

Installation and Operation Manual

Tongue-shaped

frame-support

bracket

Slotted-rack support bracket

Cable

support bar

FR6822+ Frames

If you do not install rear mounting brackets and the frame becomes warp ed, please contact

your Customer Service representative. Do not use a warped frame. If rear modules pop out

as the frame warps, do not attempt to replace them in the frame. Damage to a frame due

to improper installation will not be covered under warranty.

Follow this procedure to identify rear-support brackets and attach them to the frame:

1 Locate two tongue-shaped frame support brackets, two slotted rack-support brackets, and

one cable support bar from the packing box (if ordered). See Figure 2-2.

13

Figure 2-2 Optional Support Brackets and Cable Support Bar

2 Thread the cable support bar into each rear-support bracket, and then secure with the

provided screws. See Figure 2-3.

Figure 2-3 Installing a Cable Support Bar

Note: Attach the two tongue-shaped frame-support brackets to the sides of the FR6822+ frame,

using the provided screws. See Figure 2-4.

Copyright © 2008-2011, Harris Corporation

Page 28

14

Rear of frame

Securing a bracket to the frame

Remove these screws from the

frame, and then reinsert them

through the rear-support bracket

Rack frame

Slotted rack-support brackets

Frame-support brackets slide

Back of frame

Chapter 2

Installation

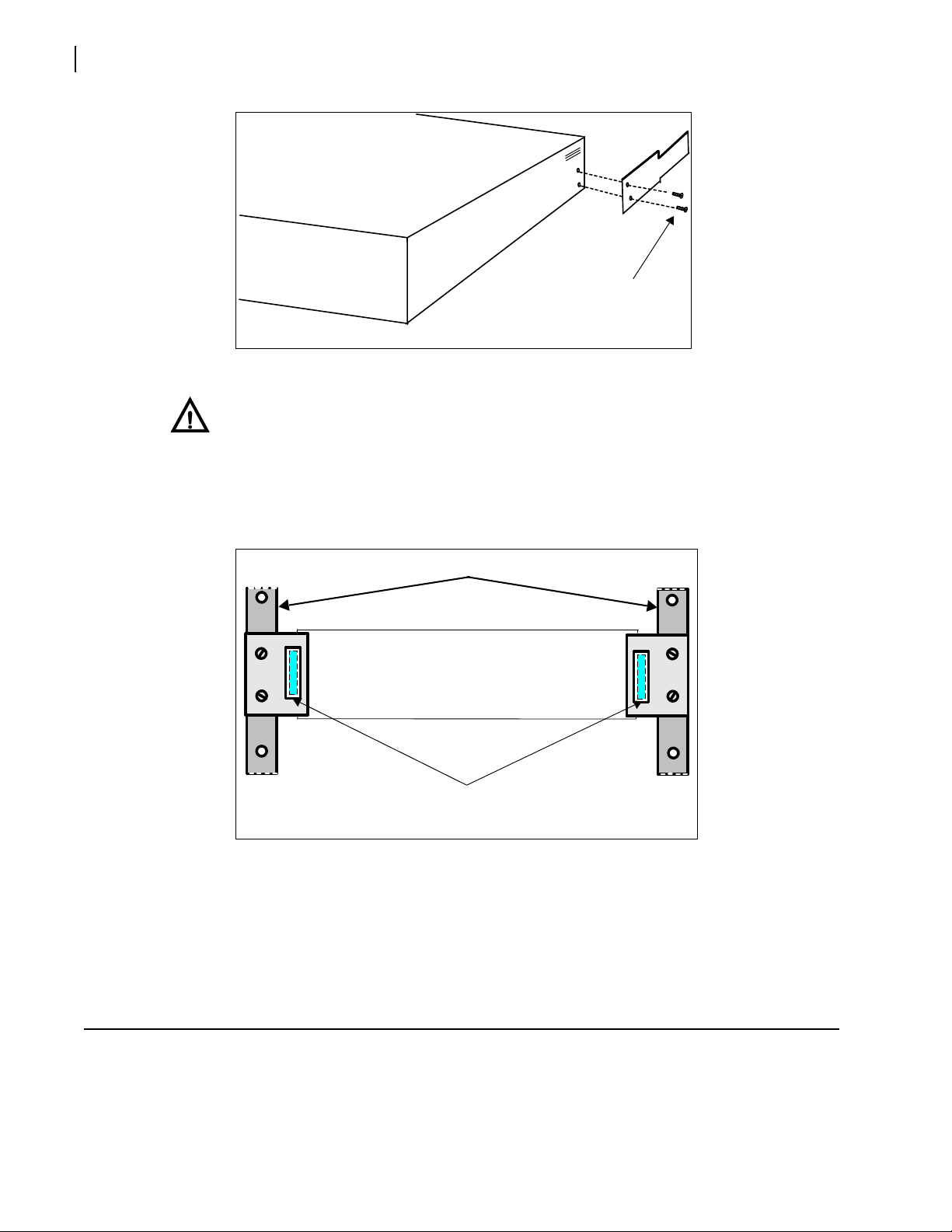

Figure 2-4 Installing a Rear-Support Bracket

CAUTION

When mounting the rear support brackets, use the screws provided, or use four

4-40×1/4-inch flat head screws. Longer screws could cause internal damage to the

frame.

3 Attach the two slotted rack-support brackets at the rear of the rack, with the slots facing

inward. See Figure 2-5.

Figure 2-5 Installing Rack-Support Brackets

4 Position the FR6822+ into the rack, ensuring that the frame-support brackets slide into the

installed slotted rack supports.

5 Attach the front-mounting ears on the chassis to the rack, using the appropriate rack

screws.

Installing and Removing Resource Modules

Resource modules can be upgraded in the field. To purchase a resource module, contact

Customer Service. See Table 2-1 on page 10 for a list of available modules and their part

numbers.

Copyright © 2008-2011, Harris Corporation

Page 29

A FR6822+ frame must contain a resource module for remote control. Without a resource

module installed, your frame will supply power to the modules. You will be able to control

the modules at the card edge only.

Your frame may have come with one of the following resource modules:

6800+ETH module for controlling and monitoring modules using a CCS network or

web browser

6800+ETHSNMP for controlling and monitoring modules using a CCS network, web

browser, or SNMP-based control application

There are no card-edge controls on resource modules.

Installing a Resource Module

1 Pull out the finger-release screws on the right and left sides of the front panel, and then

open it.

2 Slide the new module into the frame.

3 Locate the slot that corresponds resource module on the left side of the frame, beside the

power supply. (See Figure 2-6 on page 16.)

4 Slide the module into the guides on the frame floor.

The module is properly seated when its edge is flush with the guide edge and the extractor

handle closes. (See Figure 2-10 on page 19.)

Installation and Operation Manual

FR6822+ Frames

15

5 Close the front panel.

Removing a Resource Module

You may need to remove a resource module if you wish to change the DIP switch settings,

either to set the IP address to default, or to set the module to Fail-Safe mode.

To remove an existing resource module, follow these steps:

1 Pull out the finger-release screws on the right and left sides of the front panel, and then

open it.

Copyright © 2008-2011, Harris Corporation

Page 30

16

This slot must contain a 6800+ETH

resource module if you intend to

operate the frame remotely .

Chapter 2

Installation

2 Locate the resource module on the left side of the frame, beside the power supply. (See

Figure 2-6.)

Figure 2-6 Location of Resource Module within a FR6822+ Frame

3 Grasp the extractor handle on the installed module, and then pull the module out of its slot

using the handle as a lever.

4 Close the front panel to ensure proper frame ventilation.

Installing and Removing 6800+ Modules

There are different module and connector types that may require installation:

Triple-slot back connectors

Double-slot back connectors

Single-slot back connectors

Front modules

Depending on the product type, there are various back connectors, front modules, and

frame types that are available, interchangeable, and compatible. For example, module back

connectors can come in either triple-slot, double-slot, or single-slot sizes; and certain 680 0+

modules and/or back connectors can be installed in either an FR6822+, FR6802+QXF,

FR6802+DM, FR6822+, or 6800/7000 series frame. Check the individual module manual

that comes with your product to identify which back connector types work with your

module, and which frames are compatible with the module.

Up to 20 front modules connected to single -slot back connectors fit in an FR6822+ frame.

Up to 10 front modules can fit in an FR6822+ frame if they are connected to double-slot

back connectors (2 spaces are required to accommodate the extra width of the back

connector).

Copyright © 2008-2011, Harris Corporation

Page 31

You can install most 6800+ modules in any unused slot without interfering with other

Single-slot

back

connector

Double-slot

back

connector

frame functions.

CAUTION

Before installing your modules, see Maximum 6800+ Frame Power Ratings on

page 11.

Installing 6800+ Modules in an FR6822+ Series Frame

Follow these steps to install modules into an FR6822+ frame. All front modules are

hot-swappable and can be installed with the power supply either turned on or turned off.

1 Remove a blank back connector from the frame. See Figure 2-7.

Do not discard the blank back connectors. They may be needed for future configurations.

Installation and Operation Manual

FR6822+ Frames

17

Figure 2-7 Blank Back Connectors

2 Install the new back connector by inserting the bottom lip into the required frame slot and

then screwing it into place. See Figure 2-8 on page 18.

Note: The module lip must be inserted fully and securely into the bottom frame slot to

ensure proper module operation.

Copyright © 2008-2011, Harris Corporation

Page 32

18

Insert the bottom lip of the back connector into the

slot on the bottom-edge of the frame.

After inserting the bottom lip of

the back connector into the

required slot (see the graphic

“Close-up, bottom” below), screw

the top of the back connector

Back of frame

Close-up, bottom

Chapter 2

Installation

Ensure that the EMI gaskets on the right side of the back connector remain in place during

the installation. (The gaskets fit tightly.)

Figure 2-8 Installation of Back Connectors, Rear View

CAUTION

The front module must match the corresponding back connector; otherwise, the

modules will not operate correctly. Some module insertions may be prevented if

the modules are incompatible.

3 Apply the back connector labels to the back connecting module if these are supplied

separately.

4 Pull out the finger-release screws on the right and left side of the front panel, and then

open it.

5 Locate the front module slot that corresponds with the matching back connector.

6 Slide the module into the guides on the frame floor. See Figure 2-9 on page 19.

The module is properly seated when its edge is flush with the guide edge and the extractor

handle closes. See Figure 2-10 on page 19.

Copyright © 2008-2011, Harris Corporation

Page 33

Figure 2-9 Frame Module Guides, Disassembled View

Module guides

(on frame floor

and ceiling)

Rear of frame

Front of frame

Guide edge

Fully installed module

(module is correctly mated

with corresponding back

connector)

Closed extractor handle

Opened extractor handle

Installation and Operation Manual

FR6822+ Frames

19

Figure 2-10 Extractor Handle in Closed and Opened Positions

7 Install the remaining modules and back connectors, and then make all of the necessary

system connections.

8 Close the front panel to ensure proper frame ventilation.

CAUTION

To prevent overheating during general frame operation and to maintain proper

airflow, keep the front panel closed and all back connector slots covered during

operation.

9 Return power to the frame.

Once you have installed your 6800+ modules, you can connect them to the appropriate

inputs and outputs.

Removing 6800+ Modules

Note: Front and back modules are hot -swappable and can be removed or re placed without

powering down the frame.

To remove a module from an FR6822+ series frame, follow these steps:

1 Pull out the finger-release screws on the right and left side of the front panel, and then

open it.

Copyright © 2008-2011, Harris Corporation

Page 34

Chapter 2

Front of front panel

Fan assembly securing screws

Remove these screws to free the fan

assembly from front panel (four top,

four bottom)

Fan assembly securing screws

20

Installation

2 Grasp the extractor handle on the installed module, and then pull the module out of its slot

using the handle as a lever.

3 Close the front panel to ensure proper frame ventilation.

4 Remove the back connector from an FR6822+ series frame in this way:

a Unscrew the top of the corresponding back connector, and tip it towards you.

b Pull the bottom lip of the back connector from its slot.

c Reinstall a new or blank back connector in the empty slot to ensure proper frame

ventilation.

CAUTION

To prevent overheating during general frame operation and to maintain proper

airflow, keep the front panel closed and all back connector slots covered during

operation.

Replacing a Failed Fan Unit

In the event that one of the fan units fails in the FR6822+ fan assembly panel, you should

install a replacement as soon as possible to prevent overheating. Replacement fans are

available from Customer Service.

To replace a failed fan unit from the front panel, follow these steps:

1 Remove all power from the frame.

2 Pull out the finger-release screws on the right and left side of the front panel, and then

open it.

3 Remove the screws on the top and bottom edges of the front panel that hold the fan

assembly cover in place (see Figure 2-11).

Figure 2-11 Removing the Fan Assembly from the Front Panel

4 Remove the fan assembly from the front panel.

5 Identify the fan you are replacing, and then remove the corresponding header wires from

the PCB board along the top of the assembly (see Figure 2-12).

Copyright © 2008-2011, Harris Corporation

Page 35

Installation and Operation Manual

Header wires

Connector

PCB board

(along top of fan assembly)

Header wires

A. Remove

screws

B. Pull fan off

its two

standoffs

FR6822+ Frames

Figure 2-12 Removing Header Wires from Fan Assembly PCB Board

6 Unscrew the fan, and then pull it firmly away from the assembly to remove it from the

standoffs (see Figure 2- 13).

21

Figure 2-13 Removing a Fan from the Assembly

7 Position a new fan over the assembly standoffs, and then fasten the fan into place with the

supplied screws (see Figure 2-11 on page 20).

(Ensure that the fan labelling is face down, and that the header wiring is at the top left

corner of the installed fan, as shown in Figure 2-12 on page 21.)

8 Connect each new fan’s header wires to the assembly PCB board (see Figure 2-12 on

page 21).

9 Replace the fan assembly inside the front cover, and then secure the assembly into place

with the provided screws.

Ensure that the following items are aligned:

The LEDs on the fan assembly PCB with the corresponding holes on the front panel

The fan assembly screw holes with the holes on the front panel

10 Close the front panel, and then reapply power to the frame.

Copyright © 2008-2011, Harris Corporation

Page 36

Chapter 2

22

Installation

Making System Connections

Connecting

to a Power

Source

Depending on the power supply you are connecting to, choose one of the options below:

AC: A supply of 90 to 240 V AC, 47 to 63 Hz is required for both PSUs. Connect one

end of the power cable to an IEC power connector at the back of the FR6822+ frame.

Plug the other cable end into a grounded electrical source. (Repeat this procedure for

the redundant power supply using an independent power source.)

Note: Ensure that a different electrical source is used for each power supply. This ensures

true power system redundancy.

DC: A supply of 36 to 72V DC is required for each DC power supply. The DC power

supply connector has two spade terminals. You will need to connect the spade

terminals to an appropriate power source connector.

To connect the DC power supply, follow these steps:

a Open the flap that covers the screw connectors on the DC power supply.

Figure 2-14 Open Flap on DC Power Supply

b Connect the positive end of the spade connector to the + screw, and the negative end

to the - screw.

c Tighten the screws in place.

d Close the flap cover over the two screws.

e Plug the (customer-provided) cable end into a grounded electrical source.

Repeat this procedure for the r edundant power supply us ing an independent power source.

A Power switch is located on the front face of each power supply. Before operating the

frame, ensure that both PSUs are turned on to ensure full redundancy.

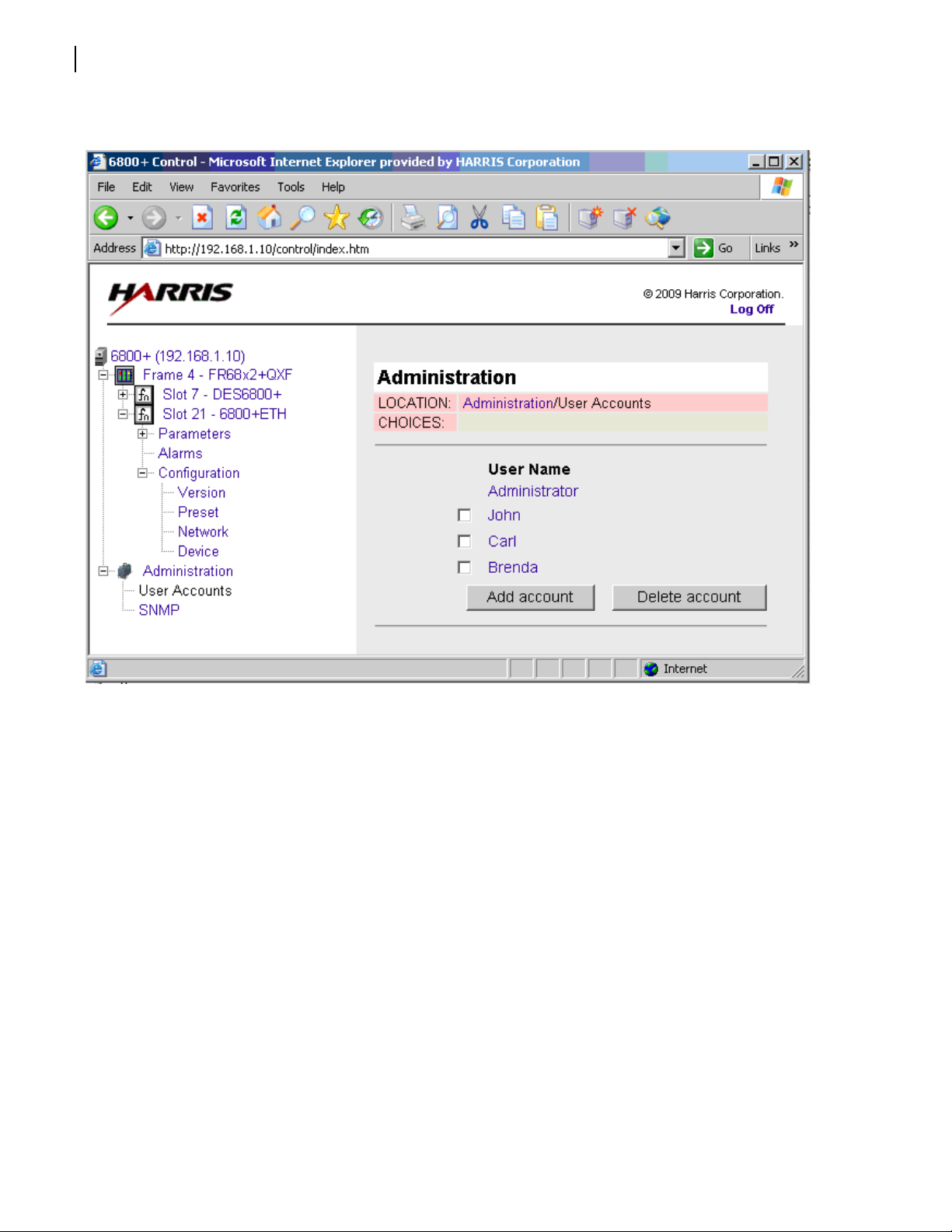

Making Genlock Connections for Signal Synchronization

The genlock connectors on the FR6822+ frame provide an input path for the genlock

signal, and have a loop-through capability. (See Figure 1-3 on page 4 for the location of

the genlock loop through.)

To make genlock connections for signal synchronization, connect the reference signal to

one of the genlock loop-through BNC connectors on the FR6822+ frame. The other

connector can be used to route the reference signal to other locations. Terminate the

reference signal at its final routed location.

Copyright © 2008-2011, Harris Corporation

Page 37

Installation and Operation Manual

Communication

loop through

RJ-45 Ethernet

connector

Genlock

loop

through

FR6822+ Frames

23

Chaining

Legacy

Frames

If you have older FR6802+QXF, FR6802+XF, and/or FR6802+DM frames that contain

low-end resource modules, you can chain them to an FR6822+QXFE frame to create a

communication network.

By chaining three of these older frames to the FR6 822+QXFE frame and connecting them

to the Ethernet network, you can monitor and control all four frames and their installed

devices.

To create a 6800+ communication control network, follow these steps:

1 Connect one FR6802+XF, FR6802+DM, or FR6822+ frame to a FR6822+QXFE frame by

using a customer-supplied BNC coaxial cable.

Connect each end of a BNC cable to the Communication loop through of each frame’s

rear panel. These BNCs have input and output functions.

Figure 2-15 Right Side Rear Panel Connections for FR6822+ Frames

2 Repeat this coaxial cable connection between other FR6802+XF, FR6802+DM, and

FR6802+QXF frames until all frames (up to a maximum of four) are connected to each

other.

Note: When connecting frames for control via 6800+ETH, no other frames in the chain

should contain a 6800+ETH or an ICE6800+. If they do, the connection will fail.

Figure 2-16 shows a typical system configuration for FR6822+ frames.

Copyright © 2008-2011, Harris Corporation

Page 38

24

Termination

point - 75

6800+ control network

BNC coax connection

6800+ control network

BNC coax connection

6800+ control network

BNC coax connection

Termination point - 75

Ethernet connection to CCS,

SNMP network, or internet

Frame ID rocker

switches

Switch 0 Switch 1

Off

On

Chapter 2

Installation

Figure 2-16 Typical System Configuration

3 Identify each frame on the network by setting a unique switch combination for every frame.

Figure 2-17 Left Rear of FR6822+ Frame

Copyright © 2008-2011, Harris Corporation

Figure 2-18 Frame ID Rocker Switches

Page 39

Installation and Operation Manual

NO (Normally open)

COM (Common)

NC (Normally closed)

FR6822+ Frames

The Frame ID rocker switches on the back of each frame can be set to one of four

combinations. Choose a different combination (a unique identifier) for each frame on the

control network. (Push down for the “On” position. ) Se e Table 2-5.

Table 2-5 Identifying Frames on the Control Network

25

Frame

Frame ID

Switch 0

Frame ID

Switch 1

1OffOff

2OnOff

3OffOn

4OnOn

4 Connect one end of a straight-through RJ-45 Ethernet cable to the RJ-45 Ethernet port on

the back right of the FR6822+QXFE frame, and connect the other end to a PC or Ethernet

hub or switch.

See FR6822+QXFE Configuration, Monitoring, and Control on page 31 for information

on setting up and using the 6800+ETH.

When the serial connection is set up correctly, after you discover or browse to the

6800+ETH module, its host frame will appear as the parent frame, with the other three

frames appearing as child frames. You can view the serially connected frames and the

modules they contain in CCS Navigator, an HTTP web browser, or a third-party SNMP-based

control application (if you have the optional SNMP license installed on the 6800+ETH

module).

Connecting the GPI Alarm Relay to a Monitoring System

To send alarm signals from the FR6822+ frame to a control monitoring system, follow these

steps:

1 Connect 1 end of a 3-conductor, 18 to 25 gauge cable to the GPI connector at the back of

the frame.

2 Connect the other end of the cable to a customer supplied monitoring panel.

Figure 2-19 shows the GPI alarm relay connector (with a terminal block connector plug),

and describes the pinouts.

Figure 2-19 GPI Alarm Connector

See Monitoring the Frame Using Frame Status LEDs on page 27 for more information

on FR6822+ alarms.

Copyright © 2008-2011, Harris Corporation

Page 40

26

Chapter 2

Installation

Copyright © 2008-2011, Harris Corporation

Page 41

3

Status LEDs

Cooling Failure/Alarm/Power

27

FR6822+F Frame and Module Operation

Note: All the frame and module functionality described in this chapter also applies to

FR6822+QXFE frames. For information on remote control and monitoring of FR6822+QXFE

frames, see Chapter 4.

Monitoring the Frame Using Frame Status LEDs

Status LEDs indicate the health of your frame. Figure 3-1 shows the location of the Status

LEDs on the FR6822+ frame. Table 3-1 describes the three LEDs located on the front panel

of the FR6822+ frame.

Figure 3-1 Location of Status LEDs on the FR6822+ Frame

Copyright © 2008-2011, Harris Corporation

Page 42

Chapter 3

28

FR6822+F Frame and Module Operation

Table 3-1 LED Descriptions

LED Color Meaning (When Lit)

Alarm Red One of the following events has occurred in the

frame:

Power supply failure

Module detection failure

Resource module failure

Fan Failure Red The fan assembly is not operating normally.

Power Green There is power in the frame; the frame and power

supply are operating within normal standards.

The FR6822+ alarms are listed in Table 3-2.

Table 3-2 FR6822+ Alarms

Alarm Name Color Meaning

Operating Installed Modules

FAN1 Failure Red The specified fan within the fan

FAN2 Failure

FAN3 Failure

FAN4 Failure

Power Supply Left

Failure

Power Supply Right

Failure

Max Temperature

Approached

Max Temperature

Exceeded

All 6800+ modules can be operated and monitored using card-edge controls. Modules can

also be monitored and controlled using a remote PC via an Ethernet connection if they are

installed in a FR6822+QXFE frame. Certain 6800/7000 series modules that may be housed

in an FR6822+ frame offer the same local operation choices, although they cannot be

monitored remotely.

Red The specified power su p ply is not

Yellow Indicates that the power supply

Red Indicates that the power supply

assembly is not operating normally

operating within normal operating

conditions

temperature is approaching the

maximum

temperature has exceeded the

maximum

Each module has a different set of operating parameters and controls. See the individual

product manual that accompanies your module for operating details.

Some modules have an On Screen Display (OSD) feature which allows you to view the

parameters on a monitor while you adjust them. See the manual for each individ ual product

for information on configuring OSD.

Copyright © 2008-2011, Harris Corporation

Page 43

Installation and Operation Manual

Mode select rotary

(hex) switch

Navigation toggle

switch

FR6822+ Frames

Some modules have a great number of parameters and alarms. If you have control and

monitoring software available and the required hardware (FR6822+QXFE frame), it is

strongly recommen ded that you use it.

29

Using

Card-Edge

Controls

Many modules contain controls that include two control switches and a series of LED

indicators on the module’s card edge.

The two card-edge switches work together to provide access to all of the parameter banks

and control options on the module: the mode select r otary switch and t he navigation toggle

switch. Figure 3-2 illustrates the location of these switches.

Figure 3-2 Card-Edge Controls

The mode select rotary switch (hex switch) selects the parameter type. Ro ta te th e switch

until you see the number (1 to 9) or letter (A to F) that corresponds with the desired

parameter. To view hex switch positions and corresponding banks and controls, see the

table entitled “Card-Edge Parameter Options” in the individual product manual that

accompanies your module.

Introducing

Parameter

Types

Note: Position “0” permits the navigation toggle switch to select a bank.

The navigation toggle switch selects a bank (when the hex switch is set to “0”) and

individual parameter values. Follow the markings on the module board (Up and Down) to

set a parameter value.

Toggle the switch Up through the list of banks or to increase the parameter value.

Toggle the switch Down through the list of banks or to decrease the parameter value.

See the section titled “Changing Parameter Settings” in the individual product manual that

accompanies your module for more information.

Note: Some 6800+ modules can be used in both horizontal and vertical configurations.

Ensure that you follow the Up and Down markings on the module to increase or decrease

parameter values, respectively.

Most 6800+ parameters are adjustable and can be set using either card-edge controls (see

Using Card-Edge Controls on page 29) or a software control ap plication. However, some

parameters are considered “read-only” and cannot be changed. These parameters

(indicated by the abbreviation “[RO]”) provide status and feedback information only.

Parameter lists may wrap or clip. If the list is set to wrap, it returns to the beginning of its

range or options after you have toggled through all of them. Clipping requires you to scroll

back through the options to re turn to the beginning of the list.

Copyright © 2008-2011, Harris Corporation

Page 44

Chapter 3

30

FR6822+F Frame and Module Operation

Wrapping is only available from the card edge. Parameters that normally wrap when

adjusted via the card edge will clip when adjusted using a control software application.

Adjustable Parameters

Two types of adjustable parameters can be changed using the card-edge controls:

Numerical parameters, which require you to select a value within a numerical range (for

example, between 0 and 524)

Selectable parameters, which require you to select a specif ic option (for example, 525

or 625)

Both numerical and selectable parameter changes are immediate.

Use the available 6800+ software controls (CCS Naviga tor, SNMP-based control appli cation,

or web browser) to view and monitor parameter selections.

Note: See the table titled “Card-Edge Parameter Options” in the individual product manual

that accompanies your module to view the various numerical and selectable parameters for

the module.

Read-Only Parameters

Many of the read-only parameters have related LEDs on the front of the module’s card

edge. See the section “Monitoring LEDs” in the individual product manual that

accompanies your module for information on the location of these LEDs.

Operating

Notes

When setting the control parameters, observe the following:

If you make changes to certain parameters, other related parameters may also be

affected. See the section “Cross-Functional Parameter Changes” in the individual

product manual that accompanies your module for more information.

When you change a parameter, the effect is immediate. However, the module requires

up to 30 seconds to save the latest change. After 30 seconds, the new settings are

saved and will be restored if the module loses power and must be restarted.

Alarms Alarms are usually logged and monitor ed within available software contr ol applications. You

can only identify alarms and differentiate between major and minor alarms within a

software control application, su ch as CCS Navigator, an HTTP web browser, or a third-party

SNMP-based control application (if your 6800+ETH module has the optional license key).

See Chapter 4, FR6822+QXFE Configuration, Monitoring, and Control for more

information.

Copyright © 2008-2011, Harris Corporation

Page 45

FR6822+QXFE Configuration,

4

Monitoring, and Control

Overview While a FR6822+ and its installed modules can be controlled at the card edge as described

in Chapter 3, FR6822+F Frame and Module Operation, there are many more control and

monitoring options with the addition of a 6800+ETH resource module. These are described

in the following sections:

Using CCS Software with FR6822+QXFE on page 31

Using an HTTP Browser with FR6822+QXFE on page 44

Control and Monitoring FR6822+QXFE Using SNMP on page 60

Basic 6800+ETH Module Operation on page 69

If you will only be using one monitoring system for your 6800+ devices (for example HTTP),

you can turn off notification methods for other communi cation pr otocols to r educe network

traffic. See Using CCS Software with FR6822+QXFE on page 31 for more information.

31

Note: Except where noted, the term 6800+ETH is used in this manual to refer to 6800+ETH

and 6800+ETHSNMP resource modules.

Using CCS Software with FR6822+QXFE

CCS configuration and control of FR6822+QXFE frames begins with the discovery process.

When you enter the IP address of the 6800 +ETH module and run a d iscovery, all modules in

theFR6822+QXFE host frame are also discovered.

Note: 6800+ETH requires CCS software version 3.2.1 or higher for full functionality.

Once a 6800+ETH module is discovered in CCS Navigator, you can update its firmware and

change its IP address. You can adjust remote control parameters for 6800+ETH and the

modules in the host frame. If other modules in the 6800+ETH host frame are Q-SEE

compliant, you can view monitoring thumbnails for th ose mo d ule s.

See the following topics for more information:

Preparing for Configuration on page 32

Discovering Frames and Modules Using a CCS Application on page 32

Monitoring 6800+ Modules in CCS Navigator on page 33

Using Q-SEE Compliant Modules in FR6822+QXFE Frames on page 33

Copyright © 2008-2011, Harris Corporation

Page 46

Chapter 4

32

FR6822+QXFE Configuration, Monitoring, and Control

Preparing for Configuration

Configuring the 6800+ETH requires the following items:

A PC connected to a LAN with CCS Navigator, or a Telnet program

At FR6822+QXFE frame installed and connected to the LAN

A standard 100 Mbps 100Base-T RJ-45 Ethernet cable segment (use a “crossover”

RJ-45 cable to connect to a PC, or a normal “straight-through” RJ-45 cab le to connect

to an Ethernet hub/switch)

Discovering Frames and Modules Using a CCS Application

If your FR6822+QXFE and its associated modules do not appear in the Navigation pane of

CCS Navigator, you will need to discover it. You may also run discoveries periodically when

you switch, add, or remove modules in the frame.

To run a discovery, follow these steps:

1 In Build mode, point to Tools on the menu bar and then click Discovery.

The Discovery pane appears.

2 Click Options… to open the Discovery Options dialog box.

3 Click Add.

The Add Host dialog box appears.

4 Beside Host IP, enter the IP address of the 6800+ETH module.

Ensure that X75, NEO, 6800+, RCP-CCS-1U, NUCLEUS is checked on the Add Hosts

dialog box.

5 Click OK to close the Add Hosts dialog box.

Note: If you do not know the IP address of your 6800+ETH, you can reset it to the default

in order to re-establish communication. See Resetting the 6800+ETH IP Address on

page 87 for more information.

The default IP address for the 6800+ETH is 192.168.100.250. You can add the default IP

address in the Discovery Options dialog by clicking Add Default.

6 Click OK to close the Discovery Options dialog box.

7 Click Start on the Discovery pane’s button bar.

Note: 10 to 20 seconds after turning on the frame, you can ping the 6800+ETH resource

module. However, it may take up to 3 or 4 minutes for an 6800+ETH to become available

for discovery.

The Discovery tool will ping all IP addresses added to the Discovery Options dialog box,

and log the IP addresses and device IDs for all responding CCS-compliant devices in the

Discovery pane’s

Status box.

If discovery is successful, your frame and the modules will appear in the Discovery pane, as

in Figure 4-1.

Copyright © 2008-2011, Harris Corporation

Page 47

Installation and Operation Manual

FR6822+ Frames

Figure 4-1 Discovering FR6822+QXFE Frames

8 In the Discovery pane, click Save to transfer the discovery results to the Discovery folder in

the Navigation pane.

If the frame and/or modules do not appear in the Discovery pane, refer to Discovering,

Controlling, and Monitoring Devices on page 87 for troubleshooting information. Your

CCS software online Help also has extensive information on discovering devices.

33

Monitoring 6800+ Modules in CCS Navigator

Once you have discovered your FR6822+QXFE frame in CCS Navigator and saved the results

of the discovery, the frame and modules will appear in the Navigation pane.

Switch Navigator to Control mode (File > Operational Mode > Control), and then

double-click on a module in the Navigation pane to open a Control dialog box. Control

dialog boxes provide navigation tools to monitor read-only parameters and adjust control

parameters.

The Diagnostics pane, which appears across the bottom of the screen in Control mode,

provides alarm information if and when errors appear.

See Volume 1: Chapter 15 of your CCS Navigator User Manual for more information about

configuring and controlling 6800+ modules using CCS software.

Using Q-SEE Compliant Modules in FR6822+QXFE Frames

A 6800+ETH module can transmit monitoring thumbnails to Navigator at up to three

frames per second for all the Q-SEE compliant modules that are installed in the host

FR6822+QXFE frame. In addition, Q-SEE compliant modules have enhanced alarm

functionality. See your Navigator documentation for more information.

Not all modules are Q-SEE compliant. To find out if any particular module is compliant,

consult our website. Some modules may requir e a firmwar e upgrade for Q-SEE compliance.

Extra System Requirements for Thumbnails

When displaying thumbnails, Navigator’s system requirements may exceed those listed in

the manual. For best results, your system should at least meet the following requirements:

P4 / 3 GHz, dual hyperthreading CPU with 1 GB of RAM