Page 1

TECHNICAL MANUAL

888-2517-001

eCDi ™

Enhanced Transmitter

Network Interface

Enhanced Transmitter

Network Interface

T.M. No. 888-2517-001

© Copyright Harris Corporation 2003, 2004, 2005

All rights reserved

Rev H, January 3, 2005

Page 2

Returns And Exchanges

Damaged or undamaged equipment should not be returned unless written approval

and a Return Authorization is received from HARRIS Broadcast Communications

Division. Special shipping instructions and coding will be provided to assure proper

handling. Complete details regarding circumstances and reasons for return are to be

included in the request for return. Custom equipment or special order equipment is

not returnable. In those instances where return or exchange of equipment is at the

request of the customer, or convenience of the customer, a restocking fee will be

charged. All returns will be sent freight prepaid and properly insured by the

customer. When communicating with HARRIS Broadcast Communications

Division, specify the HARRIS Order Number or Invoice Number.

Unpacking

Carefully unpack the equipment and preform a visual inspection to determine that

no apparent damage was incurred during shipment. Retain the shipping materials

until it has been determined that all received equipment is not damaged. Locate and

retain all PACKING CHECK LISTs. Use the PACKING CHECK LIST to help

locate and identify any components or assemblies which are removed for shipping

and must be reinstalled. Also remove any shipping supports, straps, and packing

materials prior to initial turn on.

Technical Assistance

HARRIS Technical and Troubleshooting assistance is available from HARRIS

Field Service during normal business hours (8:00 AM - 5:00 PM Central Time).

Emergency service is available 24 hours a day. Telephone 217/222-8200 to contact

the Field Service Department or address correspondence to Field Service

Department, HARRIS Broadcast Communications Division, P.O. Box 4290,

Quincy, Illinois 62305-4290, USA. Technical Support by e-mail:

tsupport@harris.com. The HARRIS factory may also be contacted through a FAX

facility (217/221-7096).

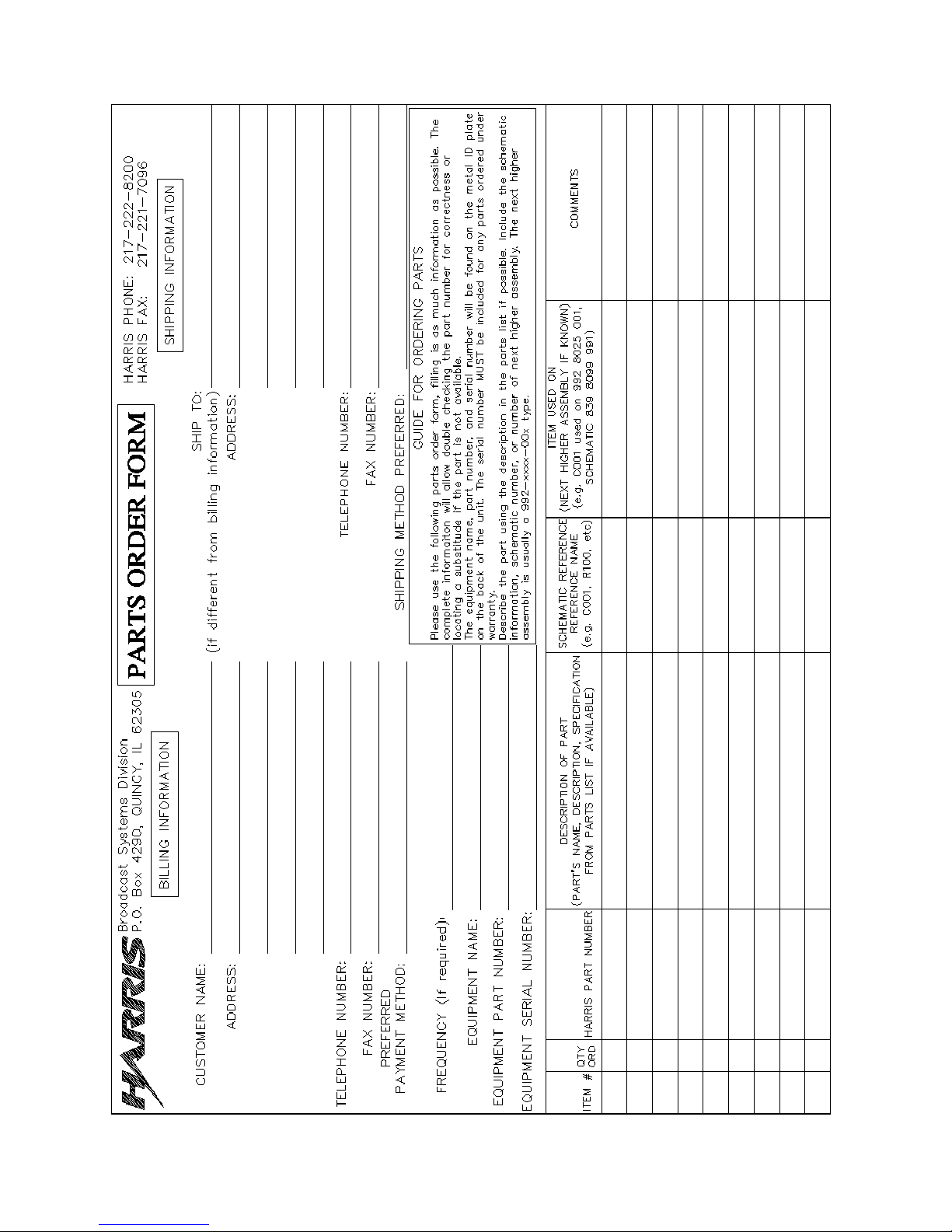

Replaceable Parts Service

Replacement parts are available 24 hours a day, seven days a week from the

HARRIS Service Parts Department. Telephone 217/222-8200 to contact the service

parts department or address correspondence to Service Parts Department, HARRIS

CORPORATION, Broadcast Systems Division, P.O. Box 4290, Quincy, Illinois

62305-4290, USA. The HARRIS factory may also be contacted through a FAX

facility (217/221-7096).

NOTE:

The # symbol used in the parts list means used with (e.g. #C001 = used with C001).

ii 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 3

Manual Revision History

eCDi ™ Technical Manual

REV. DATE ECN Pages Affected

Preliminary 02/17/2003 Created

Rev 0 08/14/2003 Manual Sent to Review

Rev A 9/22/2003 Manual Released

Rev B 10/31/2003 Added CD-1A note on page 2-4. Added page 2-21. Modified page

2-28 to reflect new features.

Rev C 11/13/2003 Added Sigma and Diamond Software requirements for connection

to eCDi, Pages 2-6 and 2-10.

Rev D 01/06/2004 Updated paragraph “2.4.5.3 Exciter Connections” for Platinum Z

FM and IBOC. Added Section 5, Interconnect Diagram. Changed

Appendix A to Section 6 and Appendix B to Section 7 (this caused

all Appendices to change designation, C becomes A etc). Added

Appendices D, E, F and G. Added note on page 2-16 referring to

Appendix G Platinum TV Monitor Board Upgrade.

Rev E 02/20/2004 Updated Sections 2, 3 and 4 to reflect the change in the

configuration port IP address and minor screen changes in software

revisions 2.6.K and higher. Specifically pages 2-22, 2-25, 2-26, 227, 3-10, 3-11 and 4-1.

Rev F 03/30/2004 M10248 Added CE markings and FCC notifications to Title Pages. Added

note to pages 2-1 and 2-24 concerning use of shielded cable.

Rev G 12/14/2004 50632 Updated Configuration information and screens in Section 2, pages

2-34 and 2-36 thru 2-39. Also updated Firewall port information in

Section 7. Minor corrections throughout the manual.

Rev H 01/03/2005 50767 Updated manual to include PowerCD (Display Unit/eCDi™).

Pages 1-2, 2-4, 2-21 and 7-4.

1/3/05 888-2517-001 MRH-1

WARNING: Disconnect primary power prior to servicing.

Page 4

MRH-2 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 5

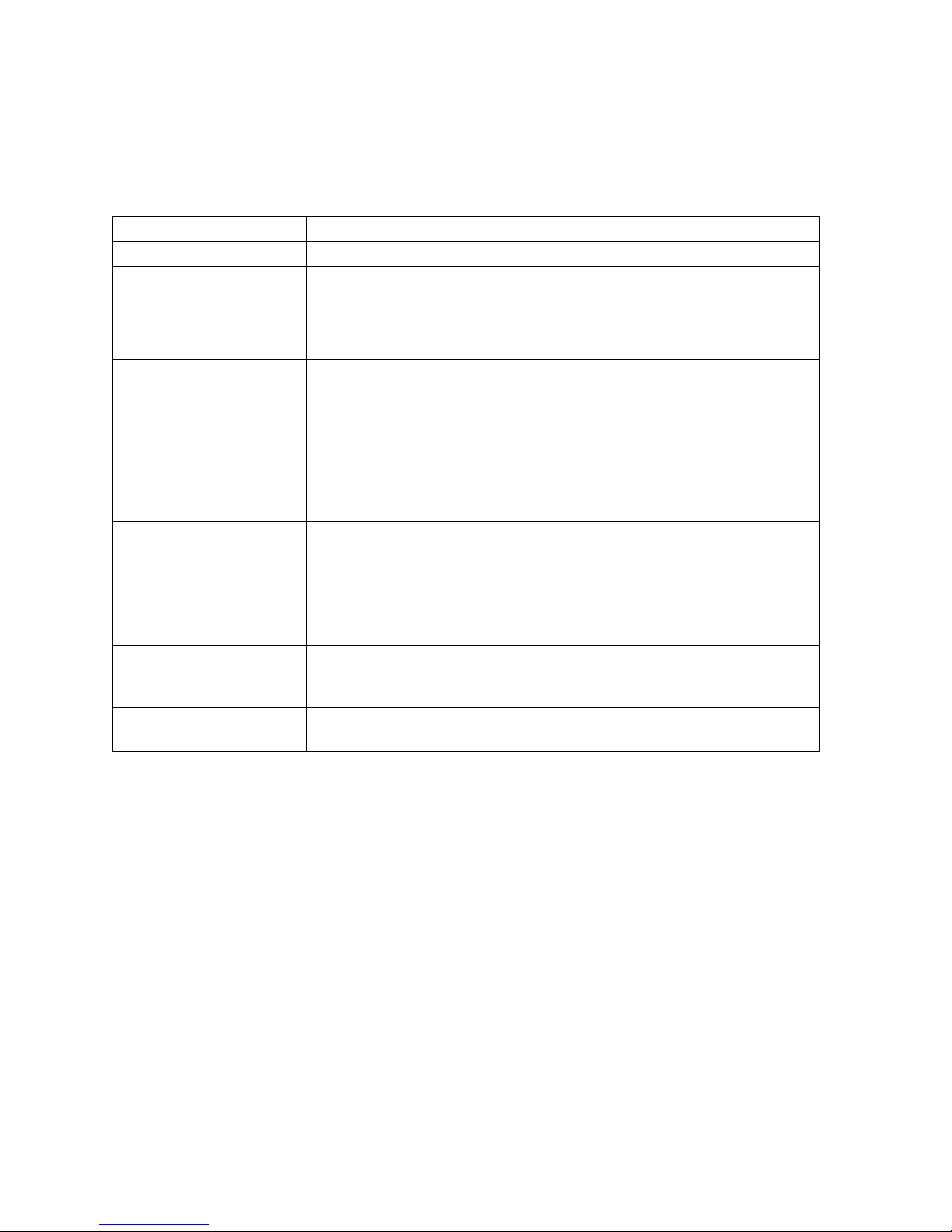

Guide to Using Harris Parts List Information

The Harris Replaceable Parts List Index portrays a tree structure with the major items being leftmost in the index. The

example below shows the Transmitter as the highest item in the tree structure. If you were to look at the bill of materials

table for the Transmitter you would find the Control Cabinet, the PA Cabinet, and the Output Cabinet. In the Replaceable

Parts List Index the Control Cabinet, PA Cabinet, and Output Cabinet show up one indentation level below the Transmitter

and implies that they are used in the Transmitter. The Controller Board is indented one level below the Control Cabinet so

it will show up in the bill of material for the Control Cabinet. The tree structure of this same index is shown to the right of

the table and shows indentation level versus tree structure level.

Example of Replaceable Parts List Index and equivalent tree structure:

Replaceable Parts List Index Part Number Page

Table 7-1. Transmitter 994 9283 001 7-2

Table 7-2. Control Cabinet 992 9244 002 7-3

Table 7-3. Controller Board 992 8344 002 7-6

Table 7-4. PA Cabinet 992 9400 002 7-7

Table 7-5. PA Amplifier 994 7894 002 7-9

Table 7-6. PA Amplifier Board 992 7904 002 7-10

Table 7-7. Output Cabinet 992 9450 001 7-12

The part number of the item is shown to the right of the description as is the page in the manual where the bill for that part

number starts. Inside the actual tables, four main headings are used:

Control Cabinet

992 9244 002

Controller Board

992 8344 002

Transmitter

994 9283 001

PA Cabinet

992 9400 002

PA Amplifier

992 7894 002

PA Amplifier Board

992 7904 002

Output Cabinet

992 9450 001

• Table #-#. ITEM NAME - HARRIS PART NUMBER - this line gives the information that corresponds to the

• Replaceable Parts List Index entry;

• HARRIS P/N column gives the ten digit Harris part number (usually in ascending order);

• DESCRIPTION column gives a 25 character or less description of the part number;

• REF. SYMBOLS/EXPLANATIONS column 1) gives the reference designators for the item (i.e., C001, R102,

etc.) that corresponds to the number found in the schematics (C001 in a bill of material is equivalent to C1 on the

schematic) or 2) gives added information or further explanation (i.e., “Used for 208V operation only,” or “Used

for HT 10LS only,” etc.).

Inside the individual tables some standard conventions are used:

• A # symbol in front of a component such as #C001 under the REF. SYMBOLS/EXPLANATIONS column

means that this item is used on or with C001 and is not the actual part number for C001.

• In the ten digit part numbers, if the last three numbers are 000, the item is a part that Harris has purchased and has

not manufactured or modified. If the last three numbers are other than 000, the item is either manufactured by

Harris or is purchased from a vendor and modified for use in the Harris product.

• The first three digits of the ten digit part number tell which family the part number belongs to - for example, all

electrolytic (can) capacitors will be in the same family (524 xxxx 000). If an electrolytic (can) capacitor is found

to have a 9xx xxxx xxx part number (a number outside of the normal family of numbers), it has probably been

modified in some manner at the Harris factory and will therefore show up farther down into the individual parts

list (because each table is normally sorted in ascending order). Most Harris made or modified assemblies will

have 9xx xxxx xxx numbers associated with them.

The term “SEE HIGHER LEVEL BILL” in the description column implies that the reference designated part number will

show up in a bill that is higher in the tree structure. This is often the case for components that may be

frequency determinant or voltage determinant and are called out in a higher level bill structure that is more

customer dependent than the bill at a lower level.

1/3/05 888-2517-001 v

WARNING: Disconnect primary power prior to servicing.

Page 6

vi 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 7

!

WARNING:

THE CURRENTS AND VOLTAGES IN THIS EQUIPMENT ARE DANGEROUS. PERSONNEL MUST AT ALL TIMES OBSERVE SAFETY WARNINGS, INSTRUCTIONS AND REGULATIONS.

This manual is intended as a general guide for trained and qualified personnel who are aware of the

dangers inherent in handling potentially hazardous electrical/electronic circuits. It is not intended to

contain a complete statement of all safety precautions which should be observed by personnel in

using this or other electronic equipment.

The installation, operation, maintenance and service of this equipment involves risks both to

personnel and equipment, and must be performed only by qualified personnel exercising due care.

HARRIS CORPORATION shall not be responsible for injury or damage resulting from improper

procedures or from the use of improperly trained or inexperienced personnel performing such tasks.

During installation and operation of this equipment, local building codes and fire protection

standards must be observed.

The following National Fire Protection Association (NFPA) standards are recommended as reference:

- Automatic Fire Detectors, No. 72E

- Installation, Maintenance, and Use of Portable Fire Extinguishers, No. 10

- Halogenated Fire Extinguishing Agent Systems, No. 12A

!

WARNING:

ALWAYS DISCONNECT POWER BEFORE OPENING COVERS, DOORS, ENCLOSURES, GATES, PANELS OR SHIELDS. ALWAYS USE GROUNDING STICKS AND

SHORT OUT HIGH VOLTAGE POINTS BEFORE SERVICING. NEVER MAKE INTERNAL

ADJUSTMENTS, PERFORM MAINTENANCE OR SERVICE WHEN ALONE OR WHEN

FATIGUED.

Do not remove, short-circuit or tamper with interlock switches on access covers, doors, enclosures,

gates, panels or shields. Keep away from live circuits, know your equipment and don’t take chances.

!

WARNING:

IN CASE OF EMERGENCY ENSURE THAT POWER HAS BEEN DISCONNECTED.

!

WARNING:

IF OIL FILLED OR ELECTROLYTIC CAPACITORS ARE UTILIZED IN YOUR EQUIPMENT, AND IF A LEAK OR BULGE IS APPARENT ON THE CAPACITOR CASE WHEN

THE UNIT IS OPENED FOR SERVICE OR MAINTENANCE, ALLOW THE UNIT TO COOL

DOWN BEFORE ATTEMPTING TO REMOVE THE DEFECTIVE CAPACITOR. DO NOT

ATTEMPT TO SERVICE A DEFECTIVE CAPACITOR WHILE IT IS HOT DUE TO THE

POSSIBILITY OF A CASE RUPTURE AND SUBSEQUENT INJURY.

1/3/05 888-2517-001 vii

WARNING: Disconnect primary power prior to servicing.

Page 8

viii 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 9

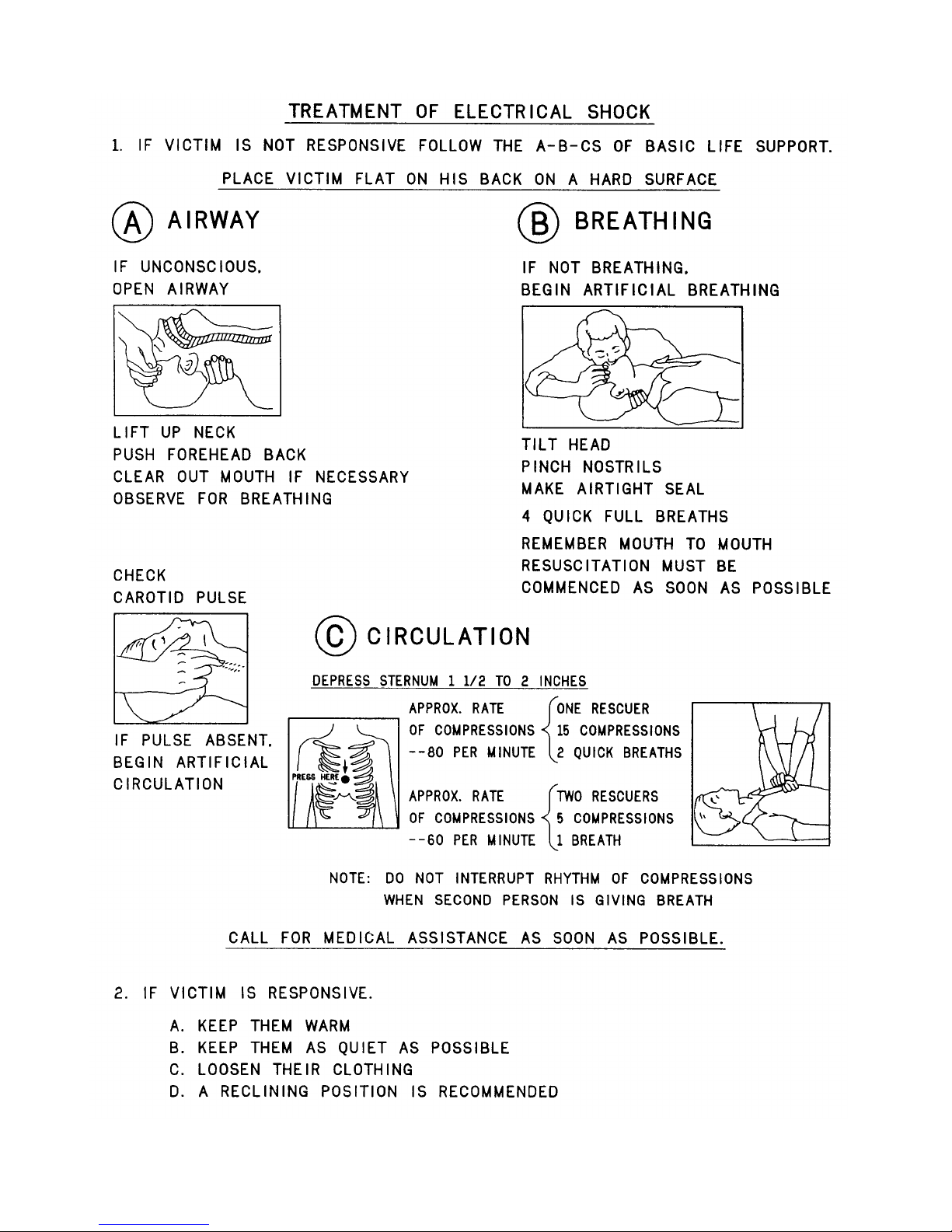

FIRST-AID

Personnel engaged in the installation, operation, maintenance or servicing of this equipment

are urged to become familiar with first-aid theory and practices. The following information is

not intended to be complete first-aid procedures, it is a brief and is only to be used as a

reference. It is the duty of all personnel using the equipment to be prepared to give adequate

Emergency First Aid and there by prevent avoidable loss of life.

Treatment of Electrical Burns

1. Extensive burned and broken skin

a. Cover area with clean sheet or cloth. (Cleanest available cloth

article.)

b. Do not break blisters, remove tissue, remove adhered particles of

clothing, or apply any salve or ointment.

c. Treat victim for shock as required.

d. Arrange transportation to a hospital as quickly as possible.

e. If arms or legs are affected keep them elevated.

NOTE:

If medical help will not be available within an hour and the victim is conscious and

not vomiting, give him a weak solution of salt and soda: 1 level teaspoonful of salt

and 1/2 level teaspoonful of baking soda to each quart of water (neither hot or

cold). Allow victim to sip slowly about 4 ounces (a half of glass) over a period of

15 minutes. Discontinue fluid if vomiting occurs. (Do not give alcohol.)

2. Less severe burns - (1st & 2nd degree)

a. Apply cool (not ice cold) compresses using the cleanest available

cloth article.

b. Do not break blisters, remove tissue, remove adhered particles of

clothing, or apply salve or ointment.

c. Apply clean dry dressing if necessary.

d. Treat victim for shock as required.

e. Arrange transportation to a hospital as quickly as possible.

f. If arms or legs are affected keep them elevated.

REFERENCE:

ILLINOIS HEART ASSOCIATION

AMERICAN RED CROSS STANDARD FIRST AID AND PERSONAL SAFETY

MANUAL (SECOND EDITION)

1/3/05 888-2517-001 ix

WARNING: Disconnect primary power prior to servicing.

Page 10

NOTE:

its are designed to provide reasonable protection against harmful interference

harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user

This device complies with part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

NOTE:

NOTE: This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC Rules. These lim-

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause

will be required to correct the interference at his own expense.

x 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 11

English

Finnish

Dutch

Bij deze verklaart HARRIS Broadcast Communications dat deze

French

Swedish

Danish

German

Greek

Italian

Spanish Por medio de la presente HARRIS Broadcast Communications

Portuguese

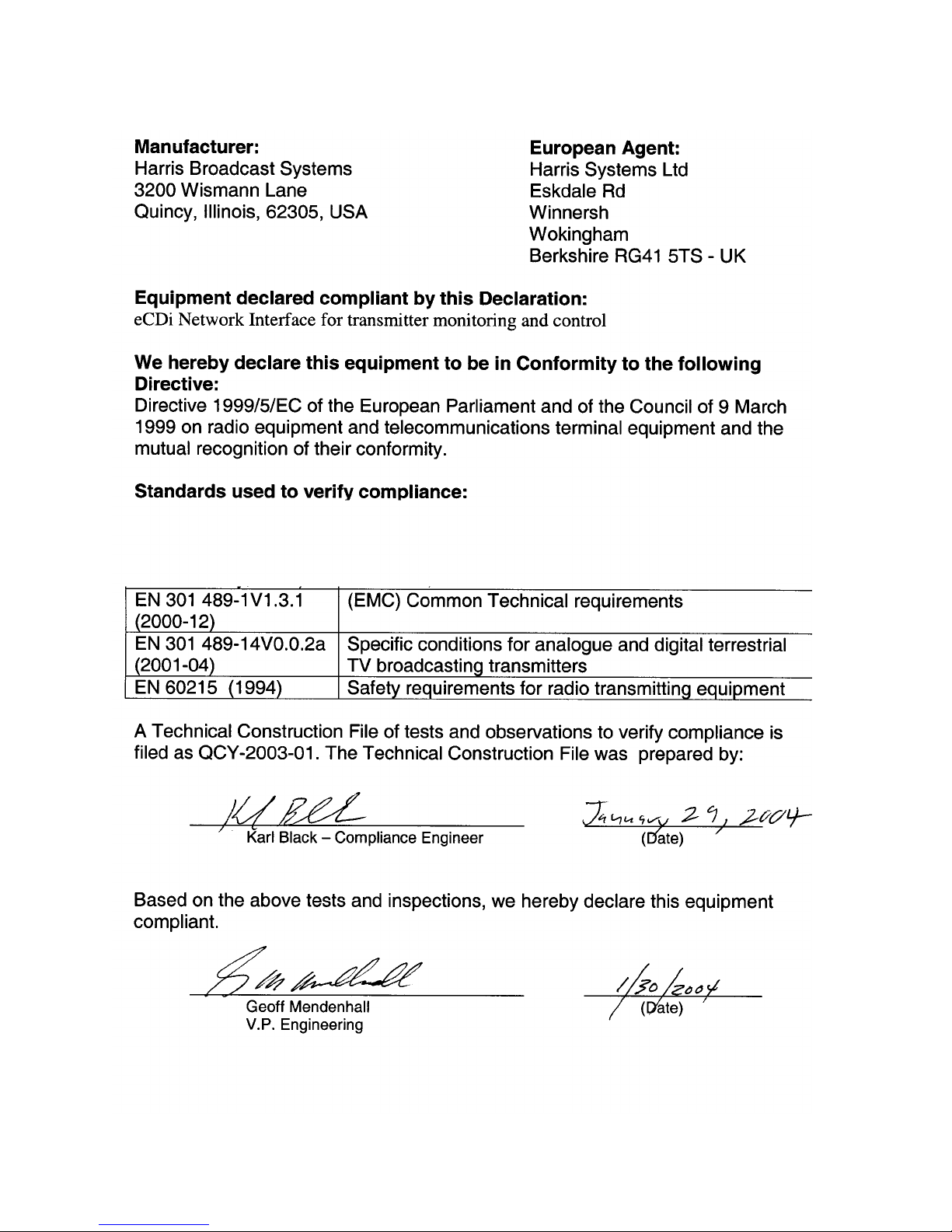

Hereby, HARRIS Broadcast Communications declares that this eCDi

Enhanced Transmitter Network Interface is in compliance with the

essential requirements and other relevant provisions of Directive

1999/5/EC.

HARRIS Broadcast Communications vakuuttaa täten että eCDi

Enhanced Transmitter Network Interface tyyppinen laite on direktiivin

1999/5/EY oleellisten vaatimusten ja sitä koskevien direktiivin muiden

ehtojen mukainen.

Hierbij verklaart HARRIS Broadcast Communications dat het toestel

eCDi Enhanced Transmitter Network Interface in overeenstemming

is met de essentiële eisen en de andere relevante bepalingen van

richtlijn 1999/5/EG

eCDi Enhanced Transmitter Network Interface voldoet aan de

essentiële eisen en aan de overige relevante bepalingen van Richtlijn

1999/5/EC.

Par la présente HARRIS Broadcast Communications déclare que

l'appareil eCDi Enhanced Transmitter Network Interface est

conforme aux exigences essentielles et aux autres dispositions

pertinentes de la directive 1999/5/CE

Par la présente, HARRIS Broadcast Communications déclare que ce

eCDi Enhanced Transmitter Network Interface est conforme aux

exigences essentielles et aux autres dispositions de la directive

999/5/CE qui lui sont applicables

Härmed intygar HARRIS Broadcast Communications att denna eCDi

Enhanced Transmitter Network Interface står I överensstämmelse

med de väsentliga egenskapskrav och övriga relevanta

bestämmelser som framgår av direktiv 1999/5/EG.

Undertegnede HARRIS Broadcast Communications erklærer herved,

at følgende udstyr eCDi Enhanced Transmitter Network Interface

overholder de væsentlige krav og øvrige relevante krav i direktiv

1999/5/EF

Hiermit erklärt HARRIS Broadcast Communications, dass sich

dieser/diese/dieses eCDi Enhanced Transmitter Network Interface in

Übereinstimmung mit den grundlegenden Anforderungen und den

anderen relevanten Vorschriften der Richtlinie 1999/5/EG befindet".

(BMWi)

Hiermit erklärt HARRIS Broadcast Communications die

Übereinstimmung des Gerätes eCDi Enhanced Transmitter Network

Interface mit den grundlegenden Anforderungen und den anderen

relevanten Festlegungen der Richtlinie 1999/5/EG. (Wien)

?? ??? ?????S? HARRIS Broadcast Communications ???O???

??? eCDi Enhanced Transmitter Network Interface

S?????FO????? ???S ??S ??S?O???S ??????S??S ??? ??S

?????S S??????S ????????S ??S ???G??S 1999/5/??

Con la presente HARRIS Broadcast Communications dichiara che

questo eCDi Enhanced Transmitter Network Interface è conforme ai

requisiti essenziali ed alle altre disposizioni pertinenti stabilite dalla

direttiva 1999/5/CE.

declara que el eCDi Enhanced Transmitter Network Interface

cumple con los requisitos esenciales y cualesquiera otras

disposiciones aplicables o exigibles de la Directiva 1999/5/CE

HARRIS Broadcast Communications declara que este eCDi

Enhanced Transmitter Network Interface stá conforme com os

requisitos essenciais e outras disposições da Directiva 1999/5/CE.

1/3/05 888-2517-001 xi

WARNING: Disconnect primary power prior to servicing.

Page 12

xii 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 13

Table of Contents

Section 1

Introduction

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

eCDi™ and the PowerCD™ Transmitter . . . . . . . 1-2

Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

eCDi™ Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Web GUI (Graphical User Interface) . . . . . . . . . 1-5

SNMP Agent. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Level 1 / Level 2 Functionality . . . . . . . . . . . . . . . 1-6

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Remote Computer Requirements . . . . . . . . . . . . . 1-7

Section 2

Installation & Setup

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Hardware Installation . . . . . . . . . . . . . . . . . . . . . . 2-2

Connection Overview . . . . . . . . . . . . . . . . . . . . . . 2-3

Detailed Installation Procedures by Transmitter. . 2-4

SigmaCD Transmitter. . . . . . . . . . . . . . . . . . . . . 2-5

AC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Transmitter Serial Connection. . . . . . . . . . . . . 2-5

Sigma Main Controller Setup . . . . . . . . . . . . . 2-6

Exciter Connections. . . . . . . . . . . . . . . . . . . . . 2-7

DiamondCD Series™ Transmitter . . . . . . . . . . . 2-9

AC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Transmitter Serial Connection. . . . . . . . . . . . . 2-9

DiamondCD Main Controller Setup . . . . . . . 2-10

Exciter Connections. . . . . . . . . . . . . . . . . . . . 2-11

PlatinumCD and Platinum Analog TV Transmitters2-

13

Mounting and AC Power . . . . . . . . . . . . . . . . 2-13

Transmitter Serial Connection. . . . . . . . . . . . 2-13

Exciter Connections. . . . . . . . . . . . . . . . . . . . 2-14

Platinum TV Transmitter Settings . . . . . . . . . 2-16

Ranger Transmitter. . . . . . . . . . . . . . . . . . . . . . 2-17

Mounting and AC Power . . . . . . . . . . . . . . . . 2-17

Transmitter Serial Connection. . . . . . . . . . . . 2-17

Exciter Connections. . . . . . . . . . . . . . . . . . . . 2-17

Platinum Z FM and IBOC Transmitters. . . . . . 2-18

Mounting and AC Power . . . . . . . . . . . . . . . . 2-18

Transmitter Serial Connection. . . . . . . . . . . . 2-18

Exciter Connections. . . . . . . . . . . . . . . . . . . . 2-19

Atlas Transmitter . . . . . . . . . . . . . . . . . . . . . . . 2-20

Atlas Digital Mounting and AC Power . . . . . 2-20

Atlas Analog Mounting and AC Power. . . . . .2-20

Transmitter Serial Connection. . . . . . . . . . . . .2-20

Exciter Connections. . . . . . . . . . . . . . . . . . . . .2-20

PowerCD™ Digital UHF Transmitter . . . . . . . . .2-21

APEX Exciter Setup . . . . . . . . . . . . . . . . . . . . . . .2-22

Setting APEX IP Address . . . . . . . . . . . . . . . . .2-23

CD-1A Electronic Serial Number Reset. . . . . . . .2-24

Initial Turn-On . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

eCDi™ Configuration. . . . . . . . . . . . . . . . . . . . . .2-26

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . .2-28

Apply Changes. . . . . . . . . . . . . . . . . . . . . . . . . .2-41

Backing Up the Configuration . . . . . . . . . . . . . .2-42

Restoring a Configuration File. . . . . . . . . . . . . .2-42

Reset Computer IP Address . . . . . . . . . . . . . . . .2-42

Section 3

Operation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Logging In. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Web Browser Interface . . . . . . . . . . . . . . . . . . . . . .3-3

Browser Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Fault Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Meter Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

System Log . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Web GUI Navigation . . . . . . . . . . . . . . . . . . . . . .3-12

Title Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Control Interface . . . . . . . . . . . . . . . . . . . . . . . .3-13

Fault Log / Help . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Monitoring Interface . . . . . . . . . . . . . . . . . . . . .3-15

Monitoring Navigation . . . . . . . . . . . . . . . . . .3-15

GUI Navigation Summary . . . . . . . . . . . . . . . . .3-18

Performance Monitoring. . . . . . . . . . . . . . . . . . . .3-19

Performance Summary Screen. . . . . . . . . . . . . .3-19

Performance Faults Screen. . . . . . . . . . . . . . . . .3-20

Performance Meters Screen . . . . . . . . . . . . . . . .3-21

EVM / SNR . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

BenchMarks. . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

View Functions . . . . . . . . . . . . . . . . . . . . . . . .3-24

Details Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Performance Control Screen . . . . . . . . . . . . . . .3-25

CD-1A RTAC Control. . . . . . . . . . . . . . . . . . .3-25

APEX RTAC Control . . . . . . . . . . . . . . . . . . .3-26

xiii

Page 14

Table of Contents (continued)

Section 4

Software Updates

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Updating the eCDi™ . . . . . . . . . . . . . . . . . . . . . . . 4-2

Before Starting.... . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Section 5

Interconnect Diagram

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Section 6

SNMP Connectivity

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

SNMP Configuration. . . . . . . . . . . . . . . . . . . . . . . 6-1

Downloading the MIBs . . . . . . . . . . . . . . . . . . . . . 6-2

General MIB Description. . . . . . . . . . . . . . . . . . . . 6-3

MIB Functionality. . . . . . . . . . . . . . . . . . . . . . . . 6-4

Supported MIBs . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Shortcuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Section 7

Network Firewall Setup

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Firewall Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Optional Port Settings . . . . . . . . . . . . . . . . . . . . . 7-2

PowerCD™ IP address and Port Settings . . . . . . 7-4

Appendix A

SigmaCD Fault and

Meter Log Reference

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Fault Log Reference. . . . . . . . . . . . . . . . . . . . . . . .A-2

Meter Log Reference . . . . . . . . . . . . . . . . . . . . . . .A-8

Appendix B

DiamondCD Fault and

Meter Log Reference

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Fault Log Reference. . . . . . . . . . . . . . . . . . . . . . . .B-2

Meter Log Reference . . . . . . . . . . . . . . . . . . . . . . .B-7

Appendix C

Atlas Fault and

Meter Log Reference

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Fault Log Reference . . . . . . . . . . . . . . . . . . . . . . . C-2

Meter Log Reference. . . . . . . . . . . . . . . . . . . . . . . C-7

Appendix D

Ranger Fault and

Meter Log Reference

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Fault Log Reference . . . . . . . . . . . . . . . . . . . . . . . D-2

Meter Log Reference. . . . . . . . . . . . . . . . . . . . . . .D-6

Appendix E

Platinum TV Fault and

Meter Log Reference

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Fault Log Reference . . . . . . . . . . . . . . . . . . . . . . . E-2

Meter Log Reference. . . . . . . . . . . . . . . . . . . . . . . E-6

Appendix F

Platinum Z Fault and

Meter Log Reference

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Fault Log Reference . . . . . . . . . . . . . . . . . . . . . . . F-2

Meter Log Reference. . . . . . . . . . . . . . . . . . . . . . . F-9

Appendix G

Platinum TV Monitor Board Upgrade

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

Upgrading Early Monitor Boards . . . . . . . . . . . . .G-2

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

Required Installation Time . . . . . . . . . . . . . . . . . G-2

Installing Firmware and Memory . . . . . . . . . . . . G-3

Control Activation Jumpers . . . . . . . . . . . . . . . . G-5

Jumper Installation. . . . . . . . . . . . . . . . . . . . . . G-5

xiv

Page 15

eCDi ™

•

•

Ranger

Section 1

Introduction

Legal Notice

Before using the screens and programs associated with this product

you acknowledge that such are protected under the United States

and international copyright laws; the programs may be used only as

authorized under the terms of license from Harris Corporation and

its licensors, and that you are informed as to such license terms.

1.1 Introduction

eCDi™ is a Transmitter Network Interface appliance that provides a network

connection for control and monitoring of Harris transmitters that have a serial

connection port. Transmitters supported include:

Sigma CD

• Diamond CD

• Platinum CD

• Platinum (Analog)

!

WARNING:

ECDI™ IS A REMOTE CONTROL DEVICE. MAINTENANCE PERSONNEL SHOULD

TAKE ALL NECESSARY PRECAUTIONS TO DISABLE THE ECDI™ DURING TRANSMITTER MAINTENANCE. SPECIFICALLY, THE TRANSMITTER SHOULD BE PLACED

IN THE REMOTE DISABLE (LOCAL) MODE BEFORE SERVICING. ALWAYS DISCONNECT PRIMARY POWER BEFORE SERVICING EQUIPMENT.

• Platinum Z FM/IBOC

• Atlas Digital (DVB-T)

• Atlas Analog

1/3/05 888-2517-001 1-1

WARNING: Disconnect primary power prior to servicing.

Page 16

Section 1 Introduction

1.2 eCDi™ and the PowerCD™ Transmitter

For the Harris PowerCD Digital UHF Transmitter, the eCDi™ has been modified to

include a local GUI touchscreen interface in addition to its normal networking

capabilities. In the PowerCD transmitter the eCDi™ is the local transmitter control

interface using the attached 12" VGA touchscreen and has been renamed the "Display

Unit." This means that the eCDi™ provides both local and remote control for the

PowerCD transmitter.

The PowerCD transmitter will have a Display Unit (an eCDi™) in the Driver Cabinet

for system control and monitoring and one in each PA cabinet for individual cabinet

control and monitoring.

Information in this manual covers the basic setup and operation of the remote

networking side of the Display Unit (eCDi™). Operation of the Local GUI screens,

mounted on the front of the transmitter Display Units, is covered in the PowerCD

Transmitter Operators manual 888-2574-001.

eCDi ™

Also note that the PowerCD Display Unit (eCDi™) is a 2 rack unit high box (standard

eCDi™ is 1 rack unit) but uses the same software as all other eCDi™ units.

PowerCD

Driver

Cabinet

PowerCD Display Unit (modified eCDi™)

Local Transmitter touchscreen

display. Detailed operation of

these screens is covered in the

PowerCD Transmitter Operators

Manual 888-2574-001.

Figure 1-1 PowerCD™ Display Unit (modified eCDi™)

1-2 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 17

eCDi ™

1.3 Hardware

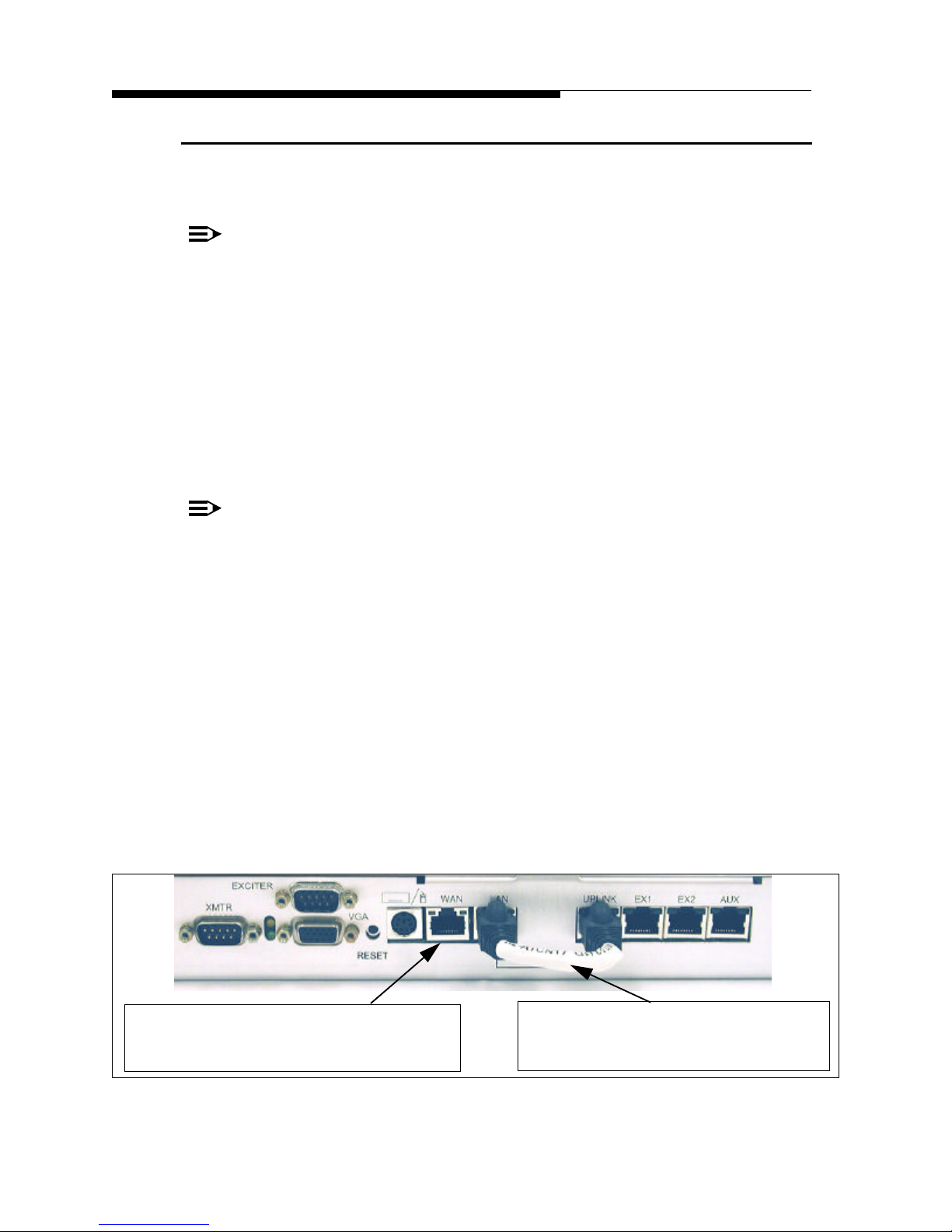

• 1U device mounted in or near the transmitter control cabinet.

NOTE:

Due to the limitation of the length of the serial cables (50ft) that connect to the

transmitter, the eCDi™ hardware must be mounted within the reach of the maximum 50 ft. serial cables.

• Single Board Computer. Includes a 20GB hard drive, 4 port internal ethernet switch

and power supply.

• 1 ethernet port mounted on the front of the unit for configuration and utility monitor-

ing. Eliminates the need to access the rear of the unit after installation.

• 1 ethernet port mounted on the rear for connection to the station LAN or WAN.

• 3 ethernet ports mounted on the rear for permanent interconnect to transmitters and

exciters that have an ethernet interface (RJ-45).

• 2 serial ports mounted on the rear for connection to transmitters and exciters with a

serial interface.

Section 1 Introduction

Figure 1-2 eCDi™ Hardware Front Panel

This port connects to the Station LAN or

WAN or possibly a LAN modem if network

connection does not exist at the site.

1/3/05 888-2517-001 1-3

WARNING: Disconnect primary power prior to servicing.

Uplink jumper. This jumper should be

installed from the LAN connection to the

Figure 1-3 eCDi Connections

Page 18

Section 1 Introduction

1.4 Features

Web GUI Interface - The Web GUI interface allows access to transmitter control,

status and logging for any of the supported transmitters via a standard web browser

interface (Netscape or IE). The only other software required is a Java plugin and it is

downloaded from the eCDi™ the first time a computer accesses the unit.

Performance Monitoring - An optional software upgrade provides for performance

monitoring of DTV transmitters by networking an embedded version of the CD-EYE™

application.

Common Interface - The Web GUI creates a common display platform for all

transmitters. This allows immediate understanding of transmitter control and

monitoring regardless of the transmitter model.

Fault Logging - The fault log will hold up to 1000 events, is viewable on-line or can be

downloaded to Microsoft Excel or another common spreadsheet program.

eCDi ™

Meter Logging - Meter logging occurs periodically at a customer configured time

interval. The Meter log will hold up to 1000 events and can be downloaded to Microsoft

Excel or another common spreadsheet program.

Email Notification - faults and warnings are automatically sent to a customer

configured email address.

SNMP Agent - provides for connection to the Harris Broadcast Manager (HBM)or

RECON remote control system. It can also be connected, in a limited form, to other

non-Harris based SNMP Network Managers. For more information about SNMP

connectivity see " Section 6 SNMP Connectivity".

Remote Software Updates and Upgrades - eCDi™ uses In-System Programming

(ISP) that allows remote loading of software updates and upgrades. For more

information on ISP, see " Section 4 Software Updates".

1-4 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 19

eCDi ™

1.5 eCDi™ Interfaces

eCDi™ allows access to transmitter control and monitoring via the following

interfaces:

• Web GUI

• SNMP Agent

• WAP (Wireless Access Protocol) via Cell Phone

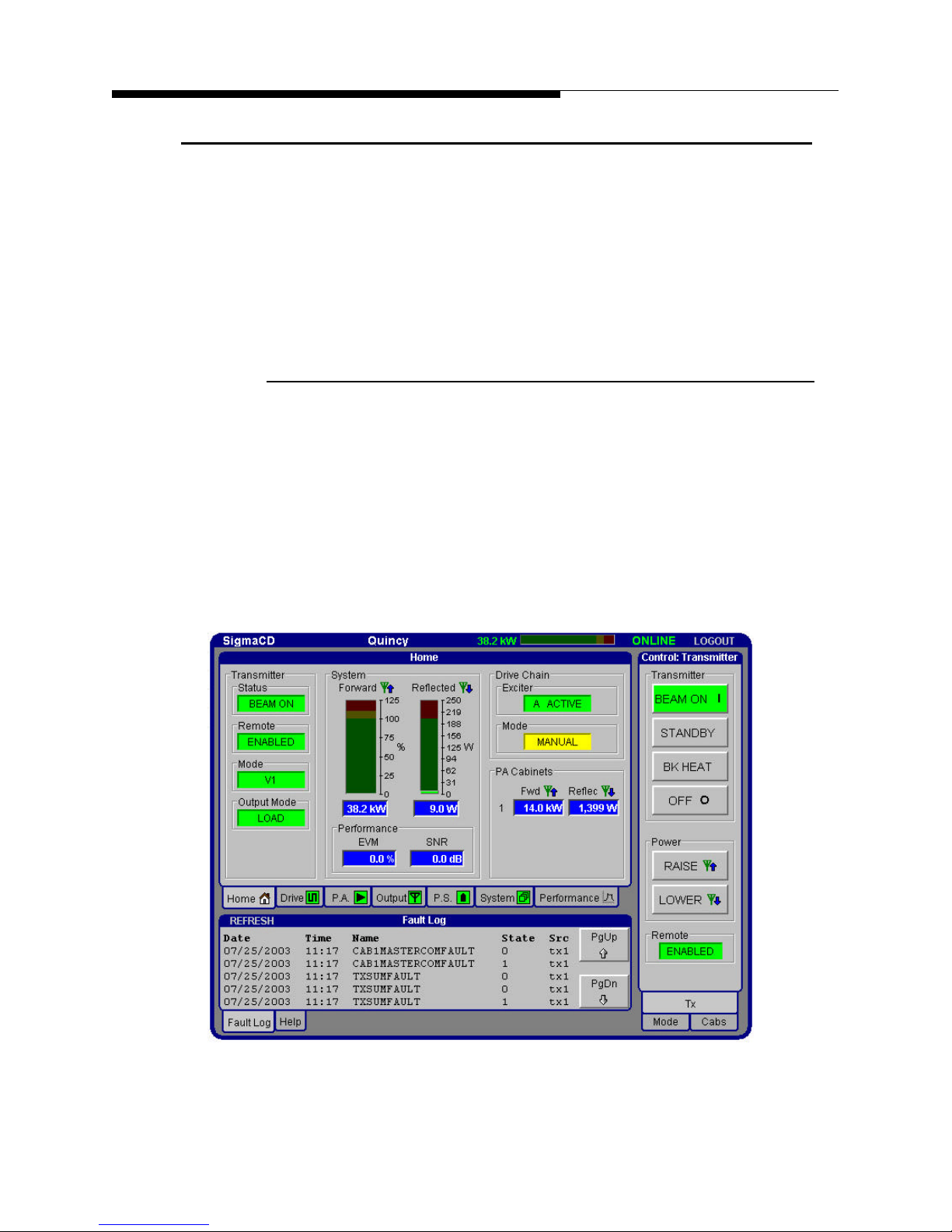

1.5.1 Web GUI (Graphical User Interface)

The Web GUI allows broadcasters to control and monitor their transmitter(s) through a

standard web browser (Netscape or IE) from anywhere network access is available.

This is the standard interface supplied with all eCDi™ units. An example of the Web

GUI main screen is shown in Figure 1-4. This main menu structure and layout is

basically the same for all transmitters, allowing operators to only have to learn one type

of interface for multiple types of transmitters. Actual readings and control buttons

available will be determined by the transmitter application. For more information on the

Web GUI see " Section 3 Operation".

Section 1 Introduction

Figure 1-4 Web GUI Interface Example

1/3/05 888-2517-001 1-5

WARNING: Disconnect primary power prior to servicing.

Page 20

Section 1 Introduction

1.5.2 SNMP Agent

The SNMP (Simple Network Management Protocol) Agent in eCDi™ provides

network connectivity using the Harris Broadcast Manager (HBM). HBM is a network

manager application that allows the centralized control and monitoring of multiple

transmitters and sites, but does not come with eCDi™. For more information on SNMP

control and the eCDi™, see " Appendix A SigmaCD Fault and Meter Log Reference".

NOTE:

The eCDi can also be accessed by other non-Harris SNMP Network Managers. In

this case, the MIB (Management Information Base) is a common MIB that is

used by nearly all Harris transmitters. A second “Extended” MIB exists and is

exclusively used by the Harris Broadcast Manager.

1.6 Level 1 / Level 2 Functionality

eCDi™ has 2 levels of software functionality that can be used with either the Web GUI

or the SNMP connection using the HBM Network Manager:

eCDi ™

a. Level 1 - Transmitter Remote Status Monitoring and Control. This allows

monitoring and control of virtually all transmitter parameters (limited to the

information that is available on the serial port of the transmitter). For most of the

listed transmitters, if it is available locally at the transmitter, it will be available

via the Web GUI. This level of functionality is included on all eCDi™ units.

b. Level 2 (optional upgrade) - Performance Monitoring and Control (only

available for DTV transmitters). This is an integrated form of the CD-EYE, 8VSB monitoring software and is an optional add-on to the base Level 1 software.

This allows performance monitoring of DTV transmitters with either CD-1A or

APEX exciters. Parameters to be monitored include:

1. Spectral Emissions - Equivalent to a spectrum analyzer plot of the system

output. Used to confirm compliance with FCC DTV emission mask.

2. EVM (Error Vector Magnitude) and SNR (Signal-to-Noise Ratio) mea-

surements and the Eye Diagram.

3. Constellation Diagram - This is an I (symbol) versus Q plot. Can be used to

show amplifier non-linearity.

4. RTAC (Real Time Adaptive Correction) Linear Correction - This plot

shows the gain and phase correction employed for linear distortions (Frequency response and Group delay) versus the frequency across the channel.

5. RTAC Non-Linear Correction (APEX exciter only) - This plot will display

the AM-AM and AM-PM correction employed for non-linear distortions in

the amplifier chain.

1-6 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 21

eCDi ™

1.7 Security

eCDi™ provides password protection using 3 levels of security functionality:

1. Engineer - allows access to all functions

2. Operator - allows access to all status monitoring but limits transmitter

3. Monitor - allows access to all status monitoring with no control capability.

!

CAUTION:

OVERALL NETWORK SECURITY IS THE RESPONSIBILITY OF THE

CUSTOMER. INTEGRATION OF THE UNIT SHOULD BE BEHIND THE

CUSTOMERS FIREWALL WITH ACCESS THROUGH A VPN (VIRTUAL

PRIVATE NETWORK). SEE " SECTION 7 NETWORK FIREWALL SETUP" FOR

MORE INFORMATION.

Section 1 Introduction

control and configuration.

1.8 Downloading the Manual

The electronic version of this manual is available as a download from the eCDi™ Help

menu. See "3.4 Browser Menus" on page 3-4 for more information.

1/3/05 888-2517-001 1-7

WARNING: Disconnect primary power prior to servicing.

Page 22

Section 1 Introduction

1.9 Remote Computer Requirements

The following lists the minimum recommended requirements for a remote computer

that will be used to access the eCDi™ via the WEB Browser interface.

Hardware:

• Pentium III 400 MHz (Intel PIII+-compatible, 1GHz+ recommended)

• 128MB RAM (256MB or more recommended)

• 75MB of available hard drive space

• Mouse (mouse-wheel recommended)

• 28.8k modem (56k modem recommended or high speed TCP/IP network if

available)

• SVGA monitor running in at least 800x600 resolution

• SVGA Video card (hardware acceleration with Direct3D driver support

recommended)

eCDi ™

Operating System

• Windows 98 (1st edition) or newer

• Windows ME

• Windows 2000 with Service Pack 2 or newer

• Windows XP

Web Browser

• Internet Explorer 5.5 or higher with default security permissions

• Netscape 7.0 or higher

NOTE:

Microsoft DirectX 7.0 or later is highly recommended (comes pre-installed on

Windows 2000 and Windows XP).

1-8 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 23

eCDi ™

Section 2

Installation &

Setup

2.1 Introduction

The information contained in this section is intended to explain the following:

• Hardware installation of the eCDi™ unit into a transmitter/control cabinet or

into a standard 19" rack.

• Connection of all required cables between the eCDi™ unit and the

transmitter and exciters and to the station LAN or WAN.

• Setup and configuration of the eCDi™ unit for connection to the station

LAN or WAN to provide Web GUI access.

!

CAUTION:

OVERALL NETWORK SECURITY IS THE RESPONSIBILITY OF THE CUSTOMER.

INTEGRATION OF THE UNIT SHOULD BE BEHIND THE CUSTOMERS FIREWALL

WITH ACCESS THROUGH A VPN (VIRTUAL PRIVATE NETWORK).

NOTE:

For SNMP connection to a network manager such as the Harris Broadcast

Manager, refer to " Section 6 SNMP Connectivity" after installing the eCDi™.

Use of the Web Browser interface is discussed in " Section 3 Operation".

IMPORTANT:

All ethernet cables connected to the eCDi™ should be shielded twisted pair

(STP) category 5 (Cat 5) cable. All cables supplied with the eCDi™ are shielded.

1/3/05 888-2517-001 2-1

WARNING: Disconnect primary power prior to servicing.

Page 24

Section 2 Installation & Setup

2.2 Hardware Installation

The eCDi™ fits in a standard 19" equipment rack or can be installed in a transmitter or

transmitter control cabinet if there is adequate room. Installation is a simple matter of

securing the front panel using 4 rack screws. Once eCDi™ is installed, the only port

that maintenance personnel will normally need access is the ethernet port on the front of

the unit for setup/configuration.

!

CAUTION:

DUE TO THE LIGHT WEIGHT OF THE UNIT AND THE LOCATION OF THE FANS,

NO REAR SUPPORT IS PROVIDED FOR RACK MOUNTING. THE ECDI™ SHOULD

NOT BE USED TO SUPPORT ANY WEIGHT OTHER THAN ITS OWN.

IMPORTANT:

If the eCDi™ is mounted outside the transmitter, it must be mounted within reach

of the maximum 50ft serial cables that connect to the transmitter and exciter(s).

eCDi ™

2-2 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Configuration Port

Figure 2-1 eCDi™ Front Panel

Page 25

eCDi ™

2.3 Connection Overview

The following connections will need to be made to make the eCDi™ work:

NOTE:

Detailed information concerning the following connections is given in the

individual transmitter install procedures later in this section. See "2.4 Detailed

Installation Procedures by Transmitter" on page 2-4.

a. AC Power - eCDi™ is powered from a standard ac wall cord, 110/220Vac (auto-

switching). Do not turn the eCDi on at this time.

b. A short ethernet jumper cable is provided with the eCDi™. It connects the com-

puter LAN port to the Uplink port of the internal 5 port switch. It must be connected in the position shown in Figure 2-2. This is the hardware or transmitter

LAN side of the eCDi™.

NOTE:

For security reasons, the LAN port must never be connected to an outside

network. These are only to be used for connection to equipment or for local

configuration of the eCDi™ itself.

Section 2 Installation & Setup

c. The leftmost Ethernet connection is the WAN connection. This should be con-

nected to the Station LAN or WAN or possibly a LAN modem if the only connection to the site is via dial-up phone line. For more information on setting IP

addresses for this port see "2.8 eCDi™ Configuration" on page 2-26.

d. XMTR (male D connector) connects to the transmitter controller serial port.

e. Exciter (male D connector) is for serial connection to CD-1A exciters in DTV

transmitters. To connect 2 exciters, this cable must have a “Y” adaptor installed.

f. The 2 Ethernet connections labeled EX1 and EX2 will be connected primarily to

exciters with ethernet ports, such as APEX™.

This port connects to the Station LAN or

WAN or possibly a LAN modem if network

connection does not exist at the site.

Uplink jumper. This jumper should be

installed from the LAN connection to the

Uplink port of the internal 5 port switch.

Figure 2-2 Rear Panel Connection Summary

1/3/05 888-2517-001 2-3

WARNING: Disconnect primary power prior to servicing.

Page 26

Section 2 Installation & Setup

2.4 Detailed Installation Procedures by Transmitter

For AC power, serial and Ethernet connections refer to the appropriate transmitter

procedure in the following paragraphs.

(If you are viewing this document in pdf format, then click on the desired link below)

"2.4.1 SigmaCD Transmitter" on page 2-5

"2.4.2 DiamondCD Series™ Transmitter" on page 2-9

"2.4.3 PlatinumCD and Platinum Analog TV Transmitters" on page 2-13

"2.4.4 Ranger Transmitter" on page 2-17

"2.4.5 Platinum Z FM and IBOC Transmitters" on page 2-18

"2.4.6 Atlas Transmitter" on page 2-20 (Analog or Digital)

eCDi ™

"2.4.7 PowerCD™ Digital UHF Transmitter" on page 2-21

IMPORTANT:

If the eCDi™ is to be connected to one or more APEX exciters, then also be sure

to see "2.5 APEX Exciter Setup" on page 2-22.

IMPORTANT:

If you are connecting the eCDi™ to a CD-1A, 8-VSB exciter, see "2.6 CD-1A

Electronic Serial Number Reset" on page 2-24.

2-4 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 27

eCDi ™

TCP/IP port

(actually Com 3 from the

Section 2 Installation & Setup

2.4.1 SigmaCD Transmitter

2.4.1.1 AC Power

If the eCDi™ is installed in the SigmaCD control cabinet, then it can be plugged into

the already present UPS (Un-interruptible Power Supply) near the bottom front of the

cabinet. Be careful not to un-plug the local transmitter control GUI computer that is

plugged in here.

2.4.1.2 Transmitter Serial Connection

Connect the serial port labeled “XMTR” on the eCDi™ to J6 (Harris Protocol #1) or J7

(Harris Protocol #2) on the System I/O Board. A 50ft serial cable labeled “XMTR” is

provided in the cable kit.

System I/O Board

Rear View

Figure 2-3 SigmaCD Serial Connections on System I/O Board

Make sure the dipswitches, S4 or S5 (depending on the port being connected) on the

front side of the System I/O Board are set for a direct computer connection, as shown in

Figure 2-4. Only switches 3 and 4 should be ON (in the up position).

S3

S4

S5

J5

J6

J7

local GUI computer). Do not use this port

for eCDi™.

J6 and J7 also called HP1 and HP2 (Harris

Protocol). Either of these ports can be used

for connection to eCDi™. Both ports are

configurable for DTE (Tx and Rx swapped)

or DCE (Tx and Rx thru).

Do not change. Switches set for ISP to Cabinet Controller

ON

S3

1

4 5 678

2 3

Not used for eCDi™

ON

1

4 5 678

2 3

S4

ON

1

4 8

2 3

5 6

7

These settings assume a pin for pin cable

S5

J5 - TCP\IP

J6 - Harris Protocol #1

J7 - Harris Protocol #2

Figure 2-4 SigmaCD System I/O Board, Serial Port Switch Settings

1/3/05 888-2517-001 2-5

WARNING: Disconnect primary power prior to servicing.

Page 28

Section 2 Installation & Setup

2.4.1.3 Sigma Main Controller Setup

2.4.1.3.1 Sigma Software Requirements:

The SigmaCD transmitter has four (4) separate pieces of software/firmware which must

be at the following levels or higher before the eCDi™ can be connected:

• GUI Program Software for Windows® - GUI Version 5.0.0 (or higher)

• Main Controller Firmware - Version 3.0 (or higher)

• Amplifier Interface Board Firmware - Version 1.11 (or higher)

• IPA Module Firmware - Version 2.14 (or higher)

NOTE:

The most important one of the above is the Main Controller firmware but the

transmitter software/firmware is a package and all 4 should be updated to the

most current release levels at the same time. Failure to update all 4 to the levels

on the upgrade disk or CD could cause operational conflicts.

eCDi ™

To check the Firmware revision levels on the transmitter see the Introduction section

of the Sigma Software manual, 888-2469-001. Complete upgrade procedures are also

located in the software manual. Section 1 explains how to upgrade the GUI program,

while Section 3 explains how to do the ISP (In-System Programming) to update the

Main Controller, Amp Interface and IPA Module.

2.4.1.3.2 Main Controller Dipswitch Settings:

To deactivate the Main Controller password requirement (necessary for eCDi™

connection) set the S2 dipswitch on the transmitter Main Controller Board as follows:

• If eCDi™ is being connected to HP1 (J6), set S2-7 to ON

• If eCDi™ is being connected to HP2 (J7), set S2-8 to ON

NOTE:

If Remote GUI connection is not being used it is also recommended that the

Remote Access password in the Local GUI computer be set to Null (clear the

password and press enter). See the SigmaCD Software Manual for more

information.

2-6 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 29

eCDi ™

Section 2 Installation & Setup

2.4.1.4 Exciter Connections

APEX Exciters

To connect the eCDi™ to an APEX™ exciter requires a standard ethernet cable (not

cross-over) with RJ-45 connectors on each end. Two (2) 50ft ethernet cables labeled

EX1 and EX2 have been provided. Connect the exciter(s) to the RJ-45 ports on the back

of the eCDi™ labeled EX1 and EX2 in Figure 2-2.

IMPORTANT:

The IP address and Subnet mask must also be set up in the APEX exciter. See

"2.5 APEX Exciter Setup" on page 2-22.

NOTE:

When routing the ethernet cable to the back of the exciter, make sure to follow the

cable supports and wiring harness to allow the exciters to be pulled completely

out the front to the extent of the rack slides. Cable ties have been provided to

secure the cables to prevent damage when the exciter is pulled out for service.

CD-1A Exciters

CD-1A exciters connect to the eCDi™ via serial port. Connect the provided 50ft serial

cable labeled “EXCITER” to the serial port labeled “EXCITER” on the eCDi™. Route

the cable into the back of the GUI control cabinet in the transmitter. This cable connects

to the provided Y adaptor in the transmitter control cabinet. The Y adaptor allows 2

exciters to be connected to the eCDi™ on the same serial port. Connection of the Y

adaptor cable depends on the age of the control cabinet. Both types of cabinet are

covered on the next page.

NOTE:

The exciters can both be connected to the same serial cable because they only have

access to the serial port if they are the active or ON-AIR exciter in the transmitter.

1/3/05 888-2517-001 2-7

WARNING: Disconnect primary power prior to servicing.

Page 30

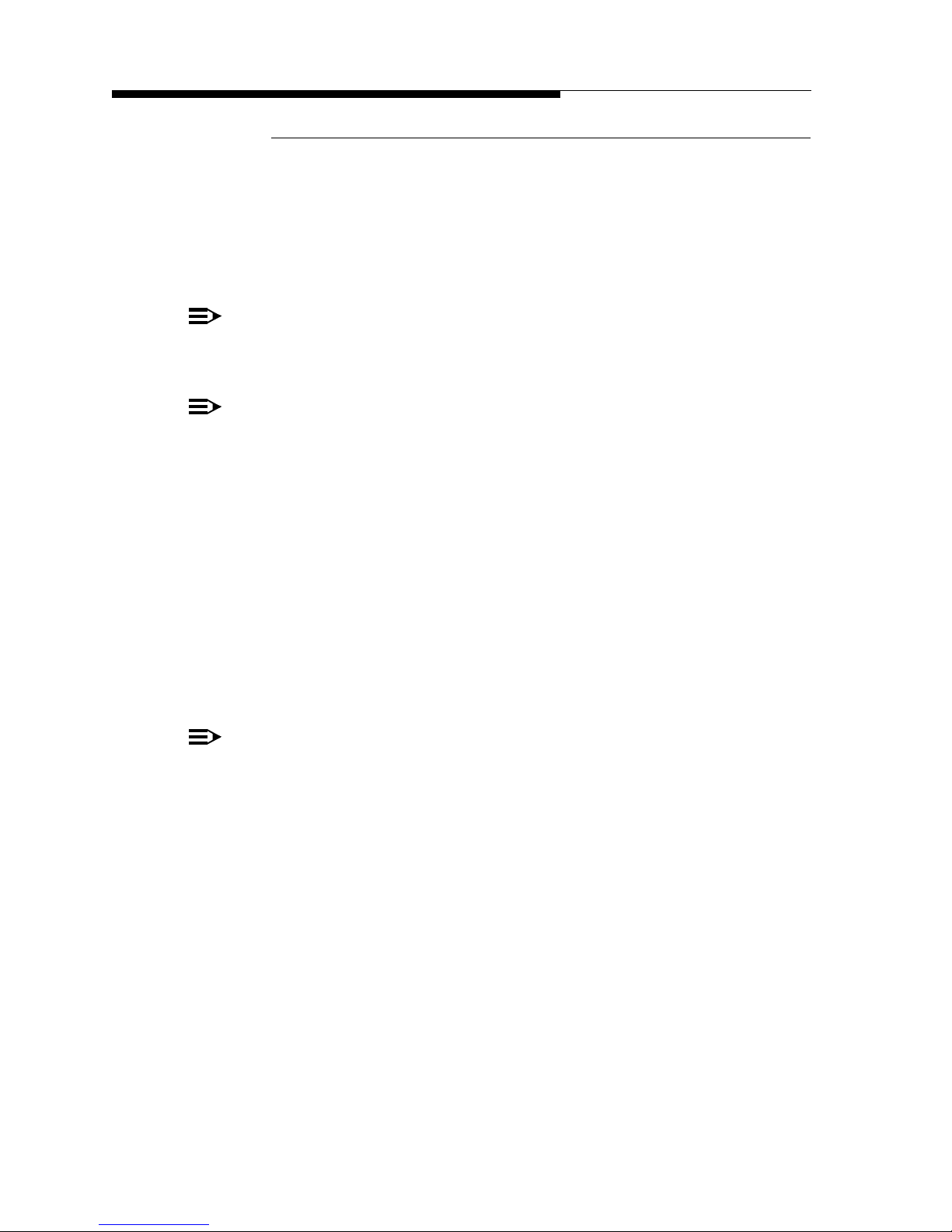

Section 2 Installation & Setup

There are 2 versions of Control Cabinet for the SigmaCD transmitter.

a. In the newer style cabinet the exciter serial

connections are already extended to the Customer I/O panel in the top rear area of the

Control Cabinet. Connect the “Y” splitter

cable to the Exciter A and Exciter B connections (both are male D connectors) on the

Customer I/O Panel and then connect the

eCDi™ serial cable (female to male) to the

“Y” cable as shown in Figure 2-5 (at right).

b. In older style cabinets, the exciter serial port

extension cables connect to the System I/O

Board behind the customer I/O Panel, see Figure 2-6A. In this case, disconnect the 2 serial

cables, labeled 76 and 77 (both are male D

connectors), from the System I/O Board and

connect the “Y” cable directly to the end of

the serial cables. Two (2) standoff kits are provided to allow the exciter cables and the Y

adaptor to be connected together. Then connect the eCDi™ serial cable (female to male)

to the “Y” connector. The completed assembly is shown in Figure 2-6B.

eCDi ™

Figure 2-5 Serial Connection

Y Adaptor with Stand-offs

for Dual CD-1A Exciters

(newer style cabinet)

1. Remove cables from

System I/O Board.

2. Add stand-off kits to

the Y adaptor cable and

connect to the exciter

cables that were just

removed.

3. Connect Y adaptor to

eCDi™ Exciter cable.

(A)

(B)

Figure 2-6 Serial Connection for Dual CD-1A Exciters (older cabinets)

2-8 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 31

eCDi ™

Section 2 Installation & Setup

2.4.2 DiamondCD Series™ Transmitter

2.4.2.1 AC Power

If the eCDi™ is installed in the DiamondCD control cabinet, then it can be plugged into

the already present UPS (Un-interruptible Power Supply) near the bottom front of the

cabinet. Be careful not to un-plug the local transmitter control GUI computer that is

plugged in here.

2.4.2.2 Transmitter Serial Connection

Connect the serial port labeled “XMTR” on the eCDi™ to J6 (Harris Protocol #1) or

J35 (Harris Protocol #2) on the System I/O Board. A 50ft serial cable labeled “XMTR”

is provided in the cable kit. J6 and J35 are both female D connectors.

System I/O Board

Rear View

Figure 2-7 DiamondCD Serial Connections on System I/O Board

Make sure the dipswitches, S4 or S6 (depending on the port being connected) on the

front side of the System I/O Board are set for a direct computer connection, as shown in

Figure 2-4. Only switches 3 and 4 should be ON (in the up position).

S5

S4

S6

TCP/IP port (actually Com 3 from the

local GUI computer). Do not use this port

for eCDi™ connection.

J6 and J35 also called HP1 and HP2 (Harris

Protocol). Either of these ports can be used

for Remote GUI operation. Both ports are

configurable for DTE (Tx and Rx swapped)

or DCE (Tx and Rx thru).

Do not change. Switches set for ISP to Cabinet Controller

ON

J5

S5

J6

J35

These settings assume a pin for pin cable

5 6

1

4

2 3

ON

1

2 3

ON

1

2 3

8

7

Not used for eCDi™

4 5 678

S4

4 8

5 6

7

S6

J5 - TCP\IP

J6 - Harris Protocol #1

J35 - Harris Protocol #2

Figure 2-8 DiamondCD System I/O Board, Serial Port Switch Settings

1/3/05 888-2517-001 2-9

WARNING: Disconnect primary power prior to servicing.

Page 32

Section 2 Installation & Setup

2.4.2.3 DiamondCD Main Controller Setup

2.4.2.3.1 DiamondCD Software Requirements:

The DiamondCD transmitter has four (4) separate pieces of software/firmware which

must be at the following levels or higher before the eCDi™ can be connected:

• GUI Program Software for Windows® - GUI Version 3.0.0 (or higher)

• Main Controller Firmware - Version 3.0 (or higher)

• Cabinet Controller Firmware - Version 3.9 (or higher)

• PA Module Firmware - Version 2.14 (or higher)

NOTE:

The most important one of the above is the Main Controller firmware but the

transmitter software/firmware is a package and all 4 should be updated to the

most current release levels at the same time. Failure to update all 4 to the levels

on the upgrade disk or CD could cause operational conflicts.

eCDi ™

To check the Firmware revision levels on the transmitter see the Introduction section

of the DiamondCD Software manual, 888-2470-001. Complete upgrade procedures are

also located in the software manual. Section 1 explains how to upgrade the GUI

program, while Section 3 explains how to do the ISP (In-System Programming) to

update the Main Controller, Cabinet Controller and PA Modules.

2.4.2.3.2 Main Controller Dipswitch Settings

To deactivate the Main Controller password requirement (necessary for eCDi™

connection) set the S2 dipswitch on the transmitter Main Controller Board as follows:

• If eCDi™ is being connected to HP1 (J6), set S2-7 to ON

• If eCDi™ is being connected to HP2 (J35), set S2-8 to ON

NOTE:

If Remote GUI connection is not being used it is also recommended that the

Remote Access password in the Local GUI computer be set to Null (clear the

password and press enter). See the DiamondCD Software Manual for more

information.

2-10 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 33

eCDi ™

Section 2 Installation & Setup

2.4.2.4 Exciter Connections

APEX Exciters

To connect the eCDi™ to an APEX™ exciter requires a standard ethernet cable (not

cross-over) with RJ-45 connectors on each end. Two (2) 50ft ethernet cables labeled

EX1 and EX2 have been provided. Connect the exciter(s) to the RJ-45 ports on the back

of the eCDi™ labeled EX1 and EX2 in Figure 2-2.

IMPORTANT:

The IP address and Subnet mask must also be set up in the APEX exciter. See

"2.5 APEX Exciter Setup" on page 2-22.

NOTE:

When routing the ethernet cable to the back of the exciter, make sure to follow the

cable supports and wiring harness to allow the exciters to be pulled completely

out the front to the extent of the rack slides. Cable ties have been provided to

secure the cables to prevent damage when the exciter is pulled out for service.

CD-1A Exciters

CD-1A exciters connect to the eCDi™ via serial port. Connect the provided 50ft serial

cable labeled “EXCITER” to the serial port labeled “EXCITER” on the eCDi™. Route

the cable into the back of the GUI control cabinet in the transmitter. This cable connects

to the provided Y adaptor in the transmitter control cabinet. The Y adaptor allows 2

exciters to be connected to the eCDi™ on the same serial port. Connection of the Y

adaptor cable depends on the age of the control cabinet. Both types of cabinet are

covered on the next page.

NOTE:

The exciters can both be connected to the same serial cable because they only have

access to the serial port if they are the active or ON-AIR exciter in the transmitter.

1/3/05 888-2517-001 2-11

WARNING: Disconnect primary power prior to servicing.

Page 34

Section 2 Installation & Setup

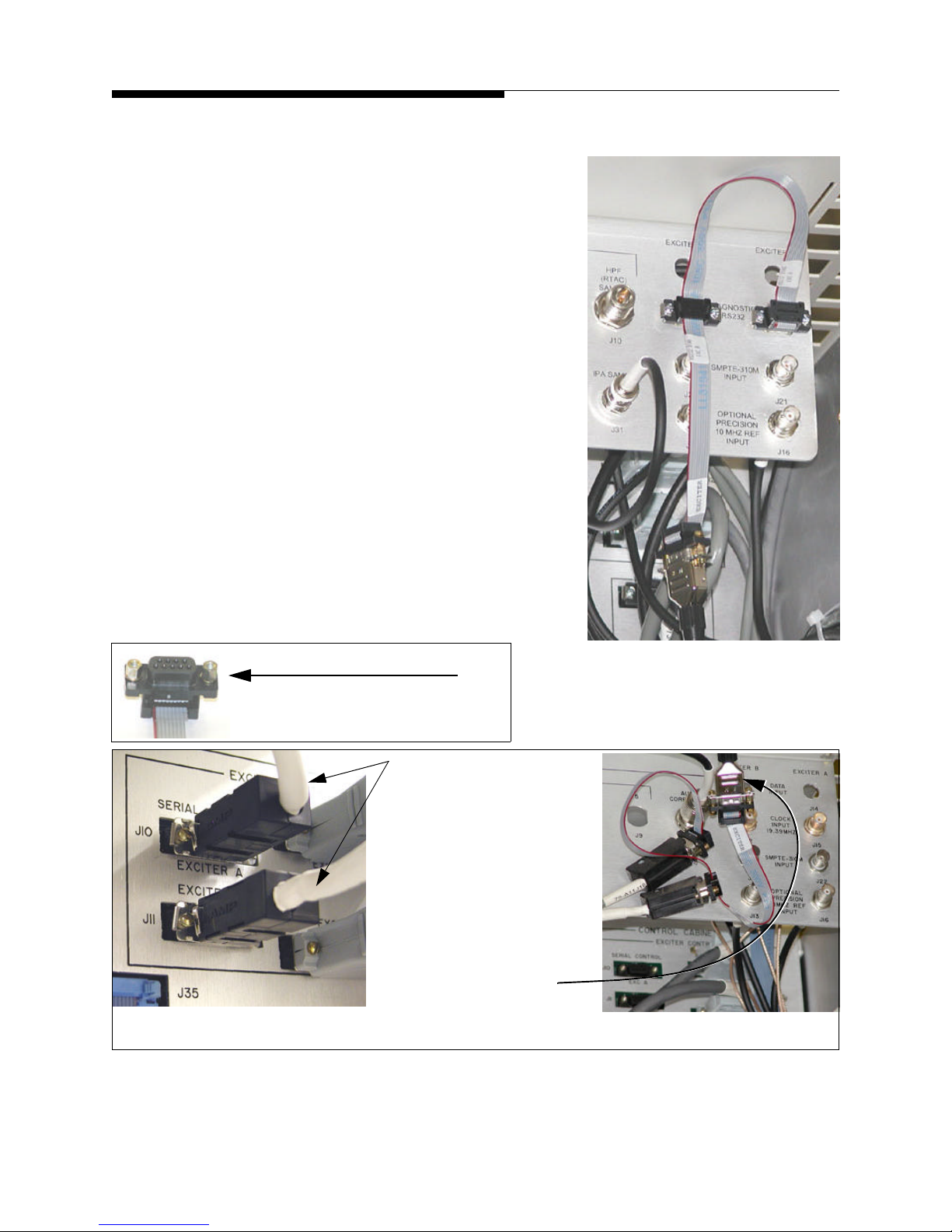

There are 2 versions of Control Cabinet for the DiamondCD transmitter.

a. In the newer style cabinet the exciter serial

connections are already extended to the

Customer I/O panel in the top rear area of

the Control Cabinet. Connect the “Y” splitter cable to the exciter A and Exciter B connections (both are male D connectors) on

the Customer I/O Panel and then connect the

eCDi™ serial cable (female to male) to the

“Y” cable as shown in Figure 2-9.

b. In older style cabinets, the exciter serial port

extension cables connect to the System I/O

Board behind the customer I/O Panel, see

Figure 2-10A. In this case, disconnect the 2

serial cables, labeled 76 and 77 (both are

male D connectors), from the System I/O

Board and connect the “Y” cable directly to

the end of the serial cables. Two (2) standoff

kits are provided to allow the cable and the

Y adaptor to be connected together. Then

connect the eCDi™ serial cable (female to

male) to the “Y” connector. The completed

assembly is shown in Figure 2-10B.

eCDi ™

Figure 2-9 Serial Connection

Y Adaptor with Stand-offs

for Dual CD-1A Exciters

(newer style cabinet)

1. Remove cables from

System I/O Board.

2. Add stand-off kits to

the Y adaptor cable and

connect to the exciter

cables that were just

removed.

3. Connect Y adaptor to

eCDi™ Exciter cable.

(A)

(B)

Figure 2-10 Serial Connection for Dual CD-1A Exciters (older cabinets)

2-12 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 35

eCDi ™

Section 2 Installation & Setup

2.4.3 PlatinumCD and Platinum Analog TV Transmitters

Since the only installation differences between PlatinumCD (DTV transmitter) and the

Platinum Analog transmitter is the exciter, both transmitters will be discussed as one.

2.4.3.1

Mounting and AC Power

The eCDi™ unit can be mounted in the Platinum Control cabinet if there is room to

mount it, however there are no rack rails on which to mount the eCDi™ unit. It is

therefore recommended that the eCDi™ unit be mounted in an equipment rack nearby,

or at least within the 50ft maximum limit of the serial cable connection.

NOTE:

If the unit is mounted into the transmitter, ac power may be obtained by

connecting to the same terminals on the 1TB2 terminal strip as the exciters, using

a moulded ac power cord with a pigtailed end. 1TB2 will always have 220/

240Vac present.

!

WARNING:

DISCONNECT PRIMARY POWER FROM THE CONTROL CABINET AT THE MAIN AC

WALL DISCONNECT BEFORE REMOVING SAFETY SHIELDS OR ATTEMPTING TO

MAKE ANY CONNECTIONS.

2.4.3.2

Connect the

Transmitter Serial Connection

9 pin to 25 pin null modem adaptor to J9 (a 25 pin female D connector) on

the rear of the Monitor Board in the Platinum control cabinet. Next connect the provided

9 pin in-line surge protector to the adaptor just installed.

lug on the surge protector to the cabinet.

Finally connect one end of the provided 50ft

Be sure to connect the ground

serial cable labeled “XMTR” to the 9 pin surge protector and the other end to the serial

port on the eCDi™ labeled “XMTR.” Use the provided cable ties to support the cable

and adaptors to prevent stress on the Monitor Board connection.

!

CAUTION:

THE RS232 SERIAL CONNECTION ON THE PLATINUM MONITOR BOARD HAS NO

SURGE PROTECTION. A SURGE PROTECTOR IS PROVIDED WITH THE

INSTALLATION KIT. THE SURGE PROTECTOR SHOULD BE MOUNTED ON THE

TRANSMITTER END OF THE CABLE AND BE GROUNDED TO THE TRANSMITTER

CABINET. FAILURE TO INSTALL THE SURGE PROTECTOR COULD RESULT IN

SERIOUS DAMAGE TO THE PLATINUM MONITOR BOARD.

1/3/05 888-2517-001 2-13

WARNING: Disconnect primary power prior to servicing.

Page 36

Section 2 Installation & Setup

Table 2-1 DB9 to DB25 Null Modem Conversion Cable Connections

Serial Cable - Null Modem Conversion DB9 to DB25

DB9 DTE Device (Computer) Connects To DB25 DTE Device (Transmitter)

eCDi ™

Pin 2 Rx

Pin 3 Tx

Pin 5 Signal GND

When making a cable for this connection, these are the only connections required.

?

?

?

Pin 2 Tx

Pin 3 Rx

Pin 7 Signal GND

2.4.3.3 Exciter Connections

HX-1V Analog Exciters

The eCDi™ does not connect to the HX-1V analog exciters.

APEX Exciters

To connect the eCDi™ to an APEX™ exciter requires a standard ethernet cable (not

cross-over) with RJ-45 connectors on each end. Two (2) 50ft ethernet cables labeled

EX1 and EX2 have been provided. Connect the exciter(s) to the RJ-45 ports on the back

of the eCDi™ labeled EX1 and EX2 in Figure 2-2.

IMPORTANT:

The IP address and Subnet mask must also be set up in the APEX exciter. See

"2.5 APEX Exciter Setup" on page 2-22.

NOTE:

When routing the ethernet cable to the back of the exciter, make sure to follow the

cable supports and wiring harness to allow the exciters to be pulled completely

out the front to the extent of the rack slides. Cable ties have been provided to

secure the cables to prevent damage when the exciter is pulled out for service.

CD-1A Exciters

CD-1A exciters connect to the eCDi™ via serial port. Since the eCDi™ unit will be

mounted external to the control cabinet in most installations the recommended

connection is as follows:

a. Connect the provided, 10ft, 9 pin serial cables labeled RS232 Diag EXC A and

RS232 Diag EXC B to the RS232 ports on the back of each exciter and route the

cables with the exciter wiring harness. See Figure 2-11 for connection drawing.

2-14 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 37

eCDi ™

with Stand-offs

Section 2 Installation & Setup

NOTE:

When routing the serial cable to the back of the exciters, make sure to follow the

cable supports and wiring harness to allow the exciters to be pulled completely

out the front to the extent of the rack slides. Cable ties should be used to secure

the serial cable to prevent damage when the exciter is pulled out for service.

b. Connect the provided Y adaptor to the ends of

both 10ft. cables. Two (2) stand-off kits are

provided and should be attached to the Y adap-

Y Adaptor

tor cable as shown here.

c. Connect the supplied 50ft. cable labeled

“Exciter” from the Y adaptor “Exciter” port to the serial port labeled “Exciter” on

the eCDi™ unit.

NOTE:

The exciters can both be connected to the same serial cable because they only

have access to the serial port if they are the active or ON-AIR exciter in the

transmitter.

IMPORTANT:

If there is only one (1) CD-1A exciter to be connected, then simply omit the “Y”

splitter cable in the previous instructions and connect the 50ft. eCDi™ serial

cable labeled “Exciter” directly from the eCDi™ unit to the exciter.

CD-1A

RS232

10ft. Serial Cable

Exciter A

CD-1A

RS232

10ft. Serial Cable

Exciter B

NOTE: Be sure to route these cables

along the existing wiring harness

to the exciters

NOTE: attach the standoff kits to the Y

adaptor cable. This allows the serial cables to

be secured directly to the Y adaptor.

Y Adaptor Cable

eCDi™

Exciter Port

50ft. Serial Cable

Figure 2-11 Connection Drawing for Dual CD-1A Exciters

1/3/05 888-2517-001 2-15

WARNING: Disconnect primary power prior to servicing.

Page 38

Section 2 Installation & Setup

?

2.4.3.4 Platinum TV Transmitter Settings

There are 2 settings in the Platinum TV transmitter which must be setup before the

eCDi™ will connect:

• Baud Rate - 9600 Baud

• Control and System Passwords - Null (no passwords set)

These controls are accessed via the Platinum Control Panel (plasma display) by

selecting:

SETUP ? SENTRY

This will bring up the display shown below in Figure 2-12. Once the baud rate is set and

any passwords cleared, select SAVE.

INFO:

eCDi ™

If the SENTRY™ option is not available under the setup menu, the Platinum

Monitor board will require a software and memory upgrade. These components

are included in the eCDi™ installation kit for the Platinum Analog TV

transmitters. See " Appendix G Platinum TV Monitor Board Upgrade" to decide

if the upgrade is necessary and for detailed instructions on performing the

upgrade. This upgrade may also be required for some Platinum CD Digital TV

transmitters.

NOTE:

Set Baud Rate to 9600 and

make sure that no passwords are

set.

Figure 2-12 Platinum Control Panel

2-16 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 39

eCDi ™

Section 2 Installation & Setup

2.4.4 Ranger Transmitter

2.4.4.1

If the eCDi™ unit is mounted in the Ranger cabinet, it should be mounted near the top

of the cabinet and can be plugged into the power strip in the rear of the transmitter.

Alternately, the eCDi™ can also be mounted in a nearby equipment rack.

2.4.4.2

Connect the serial port labeled “XMTR” on the eCDi™ to

Board uing the provided

used depending on where the eCDi™ is mounted).

Mounting and AC Power

Transmitter Serial Connection

J7 on the Main Controller

10ft or 50ft serial cable labeled “XMTR” (either cable can be

2.4.4.3 Exciter Connections

CD-1A Exciter

Connect the provided 10ft or 50ft, 9 pin, serial cable labeled “Exciter” to the serial port

on the eCDi™ labeled “Exciter.” Connect the other end to the RS232 serial port on the

back of the CD-1A exciter (it is the only 9 pin D connector and is labeled Diagnostic

Port on some exciters).

NOTE:

When routing the serial cable to the back of the exciter, make sure to follow the

cable supports and wiring harness to allow the exciters to be pulled completely

out the front to the extent of the rack slides. Cable ties should be used to secure

the serial cable to prevent damage when the exciter is pulled out for service.

APEX Exciters

To connect the eCDi™ to an APEX™ exciter requires a standard ethernet cable (not

cross-over) with RJ-45 connectors on each end. Use the provided 10ft or 50ft ethernet

cable labeled EX1 to connect the exciter ethernet port to the ethernet port on the back of

the eCDi™ labeled EX1 in Figure 2-2.

IMPORTANT:

The IP address and Subnet mask must also be set up in the APEX exciter. See

"2.5 APEX Exciter Setup" on page 2-22.

NOTE:

When routing the ethernet cable to the back of the exciter, make sure to follow the

cable supports and wiring harness to allow the exciters to be pulled completely

out the front to the extent of the rack slides. Cable ties have been provided to

secure the cables to prevent damage when the exciter is pulled out for service.

1/3/05 888-2517-001 2-17

WARNING: Disconnect primary power prior to servicing.

Page 40

Section 2 Installation & Setup

2.4.5 Platinum Z FM and IBOC Transmitters

Since the only difference between the Platinum Z FM analog and the Platinum Z IBOC

transmitter is the exciter (at least as far as the eCDi™ installation is concerned) these

transmitters will be discussed as one.

eCDi ™

2.4.5.1

The eCDi™ unit can only be mounted in the transmitter if it has a single exciter. This

would also require bringing an external source of 110/220Vac into the transmitter.

2.4.5.2

Connect the provided 9 pin to 25 pin null modem adaptor to J21 on the Display/

Backplane Board in the transmitter control unit. J21 is on the left side of the Display/

Backplane board right next to the Master Controller, see Figure 2-13 for location of the

connector.

Connect one end of the provided 10ft or 50ft serial cable labeled “XMTR” (either cable

can be used depending on where the eCDi™ is mounted) to the serial port on the

eCDi™ labeled “XMTR”. Connect the other end to the 9 pin to 25 pin null modem

adaptor previously connected to J21 on the Display/Backplane Board. See Table 2-2 for

DB9 (DTE) to DB25 (DCE) conversion pinouts.

Mounting and AC Power

IMPORTANT:

Do not plug the eCDi™ into the spare ac cord that is already wired in all Z FM

Transmitters for the second exciter. This cord is 220/240Vac, which is okay, but is

switched with the transmitter on/off switch, which is unacceptable.

Transmitter Serial Connection

See Close-up at right

Figure 2-13 Platinum Z Controller Serial Connection

2-18 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

J21

Page 41

eCDi ™

Section 2 Installation & Setup

Table 2-2 DB9 to DB25 Null Modem Cable Connections

Serial Cable - Straight Conversion DB9 to DB25

DB9 DTE Device (Computer) Connects To DB25 DCE Device (Transmitter)

Pin 1 DCE

*Pin 2 Rx

*Pin 3 Tx

Pin 4 DTE (DTR)

*Pin 5 Signal GND

Pin 6 DSR

Pin 7 RTS

Pin 8 CTS

Soldered to DB9 metal - Shield

*The connections in the shaded rows are the only required connections.

?

?

?

?

?

?

?

?

?

Pin 8

*Pin 3 Rx

*Pin 2 Tx

Pin 20 DTE (DTR)

*Pin 7 Signal GND

Pin 6 DSR

Pin 4 RTS

Pin 5 CTS

Pin 1 Shield to Frame GND

2.4.5.3 Exciter Connections

No exciter connection required. Exciter information is gathered via the transmitter

controller. This applies for all Platinum Z exciters:

• Dexstar™ IBOC Exciter

• Digit™

• SuperCiter Analog Exciter

1/3/05 888-2517-001 2-19

WARNING: Disconnect primary power prior to servicing.

Page 42

Section 2 Installation & Setup

2.4.6 Atlas Transmitter

The following applies to either the Atlas Digital DVB-T transmitter or the Atlas Analog

(NTSC or PAL) transmitter as they both have the same Main Controller hardware.

2.4.6.1 Atlas Digital Mounting and AC Power

The eCDi™ can be mounted inside the transmitter cabinet if there is sufficient room. In

this case the ac power may be obtained from TB6 pins 1, 2 and 3 using a standard

moulded ac plug with a pigtail at the opposite end for connection to the terminal strip.

TB6-1 and 2 come from a step down transformer and are therefore interchangeable.

The ac connections to the transmitter are as follows:

• TB6 - 1 Line/N

eCDi ™

• TB6 - 2 Line/N

eCDi™ Power supply connector

• TB6 - 3 GND

2.4.6.2 Atlas Analog Mounting and AC Power

The eCDi™ can be mounted inside the transmitter cabinet and is actually shown in the

Atlas Analogue Overall Wiring Diagrams which came with the transmitter. The AC

cord for the eCDi™ is prewired into the Atlas Analogue cabinet along with the serial

cable to the controller (W9).

2.4.6.3

For the Atlas Digital, connect the serial port labeled “XMTR” on the eCDi™ to

the Main Controller Board using the provided

(either cable can be used depending on where the eCDi™ is mounted).

For the Atlas Analogue, cable W9 is prewired into the cabinet and simply needs to be

connected to the eCDi™ “XMTR” port. See the Atlas Analogue Wiring Diagram.

Transmitter Serial Connection

J7 on

10ft or 50ft serial cable labeled “XMTR”

2.4.6.4 Exciter Connections

No exciter connection required. Exciter information is gathered via the transmitter

controller.

2-20 888-2517-001 1/3/05

WARNING: Disconnect primary power prior to servicing.

Page 43

eCDi ™

Section 2 Installation & Setup

2.4.7 PowerCD™ Digital UHF Transmitter

The “Display Unit” in the PowerCD transmitter is actually a modified eCDi™ which

has a local touchscreen interface attached to its front panel.

For information about operating the local touchscreen interface see the “PowerCD

Transmitter Operators Manual” 888-2475-001.

The eCDi™ (aka the PowerCD Display Unit) comes pre-installed and configured in the

powerCD. However, you will still need to go through the configuration screens to

customize the unit for your site. This includes making sure the time and date are correct,

adding users and setting passwords, setting Email alert addresses, fault log filters etc...

If you are going to use an SNMP Network Manager program like Recon™ or the Harris

Broadcast Manager, you will want to pay close attention to the SNMP configuration

screens.

See "2.8 eCDi™ Configuration" on page 2-26 to check and set your configuration. It is

important that you check the information in all of the configuration screens to see if it

applies to your site.

It is also important to note that the PowerCD transmitter uses one eCDi™ in the Driver

cabinet and one in each PA Cabinet. A router, with a 4 port switch, is installed in the

Driver cabinet and is factory configured to provide access to all of the eCDi’s in the

transmitter using a single internet IP address (using port forwarding). While each

eCDi™ could actually be placed directly on a network with its own IP address, the

router also provides a firewall at the transmitter site to protect the transmitter. For more

information on setting up the router, see the “PowerCD Transmitter Operators Manual”

888-2475-001.

1/3/05 888-2517-001 2-21

WARNING: Disconnect primary power prior to servicing.

Page 44

Section 2 Installation & Setup

?

2.5 APEX Exciter Setup

IMPORTANT:

The APEX exciter software must be 4.0 or later to activate the Ethernet port for

use with eCDi™. This software (along with the Harris ISP program and programming instructions) can be obtained via download from the Harris Premier web

site or by contacting Harris Technical support. To check the software revision of

your APEX press the “System Control” button on the APEX front panel. This

will bring up the screen shown in Figure 2-14. If the software revision is not 4.0

or later, it must be upgraded using the Harris ISP (In-System Programming) software, and the files downloaded from the web site, before it will communicate

with the eCDi™.

eCDi ™

Control Software

revision

NOTE:

For more information regarding APEX upgrades, see the APEX technical

manual, 888-2491-001.

INFO:

The Harris ISP (In-System Programming)2.0 software, provided at no cost, is

used to update the firmware memory in the APEX exciter via the serial port on