Page 1

Atlas Series™

T.M. No. 888-2473-001

© Copyright Harris Corporation 2002, 2003

All rights reserved

TECHNICAL MANUAL

888-2473-001

Atlas Series™

DVB-T UHF Transmitter

Rev C Feb 25, 2003

DVB-T UHF Transmitter

Page 2

Returns And Exchanges

Damaged or undamaged equipment should not be returned unless written approval

and a Return Authorisation is received from HARRIS CORPORATION, Broadcast

Communications Division. Special shipping instructions and coding will be

provided to assure proper handling. Complete details regarding circumstances and

reasons for return are to be included in the request for return. Custom equipment or

special order equipment is not returnable. In those instances where return or

exchange of equipment is at the request of the customer, or convenience of the

customer, a restocking fee will be charged. All returns will be sent freight prepaid

and properly insured by the customer. When communicating with HARRIS

CORPORATION, Broadcast Communications Division, specify the HARRIS

Order Number or Invoice Number.

Unpacking

Carefully unpack the equipment and preform a visual inspection to determine that

no apparent damage was incurred during shipment. Retain the shipping materials

until it has been determined that all received equipment is not damaged. Locate and

retain all PACKING CHECK LISTs. Use the PACKING CHECK LIST to help

locate and identify any components or assemblies which are removed for shipping

and must be reinstalled. Also remove any shipping supports, straps, and packing

materials prior to initial turn on.

Technical Assistance and/or Replaceable Parts Service

Replacement parts are available from the HARRIS Service Parts Department.

Telephone 44 (0) 1223 245115 to contact the service parts department or address

correspondence to Service Parts Department, Broadcast Communications Division,

P.O. Box 41, 515 Coldhams Lane, Cambridge England. The HARRIS factory may

also be contacted through a FAX facility 44 (0) 1223 411370

NOTE:

The # symbol used in the parts list means used with (e.g. #C001 =

used with C001).

Page 3

Manual Revision History

Atlas Series™

REV. DATE ECN Pages Affected

Rev 0 March 04, 2002 All

Rev A May16, 2002 Released. Added installation info for cabinet combiner

reject load flow switch, page 2-7.

Rev B Sept 12, 2002 Add two pages to front pages as stated in ECO 48448:

RTTE Compliance Statement & ATLAS Declaration.

Rev C Feb 25, 2003 14045 Add parts list as seperate Acrobat file to section 7.

Add Note to section 2.13.1 to check rotation of Pump

and Fan motors.

Add paragraph 5.9 Main Controller Battery Check.

888-2473-001

WARNING: Disconnect primary power prior to servicing.

MRH-1

Page 4

888-2473-001

WARNING: Disconnect primary power prior to servicing.

MRH-2

Page 5

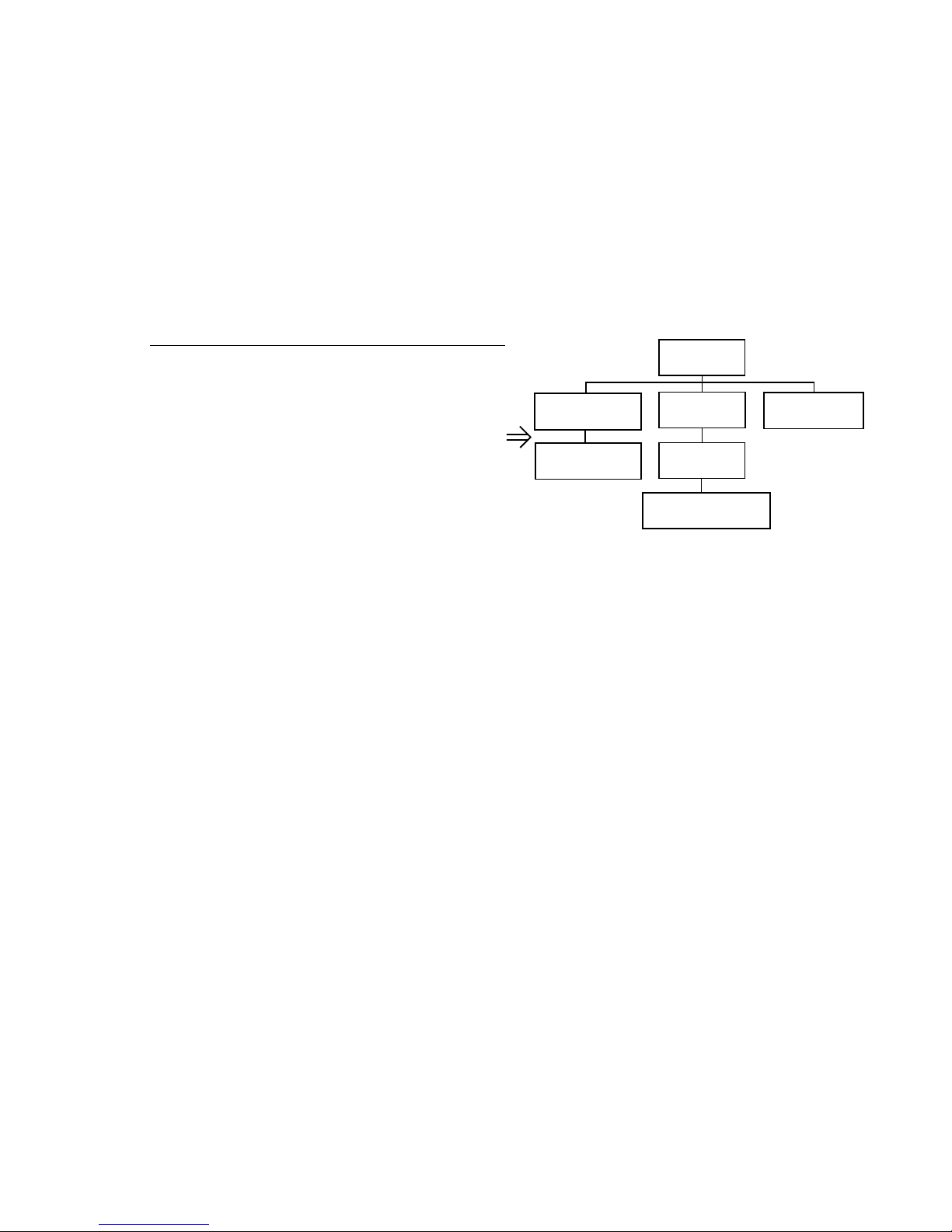

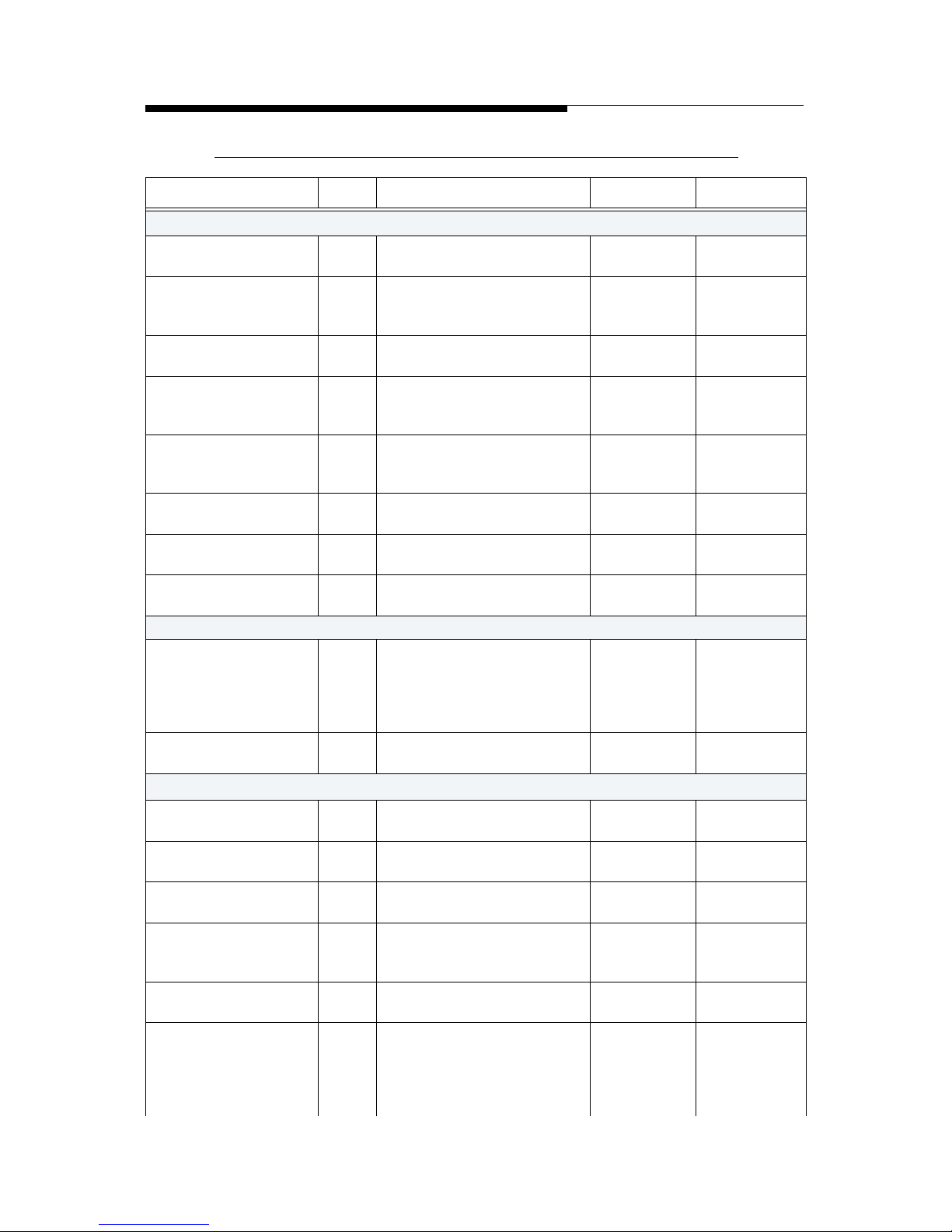

Guide to Using Harris Parts List Information

The Harris Replaceable Parts List Index portrays a tree structure with the major items being leftmost in the index. The

example below shows the Transmitter as the highest item in the tree structure. If you were to look at the bill of

materials table for the Transmitter you would find the Control Cabinet, the PA Cabinet, and the Output Cabinet. In the

Replaceable Parts List Index the Control Cabinet, PA Cabinet, and Output Cabinet show up one indentation level

below the Transmitter and implies that they are used in the Transmitter. The Controller Board is indented one level

below the Control Cabinet so it will show up in the bill of material for the Control Cabinet. The tree structure of this

same index is shown to the right of the table and shows indentation level versus tree structure level.

Example of Replaceable Parts List Index and equivalent tree structure:

Replaceable Parts List Index Part Number Page

Table 7-1. Transmitter 994 9283 001 7-2

Table 7-2. Control Cabinet 992 9244 002 7-3

Table 7-3. Controller Board 992 8344 002 7-6

Table 7-4. PA Cabinet 992 9400 002 7-7

Table 7-5. PA Amplifier 994 7894 002 7-9

Table 7-6. PA Amplifier Board 992 7904 002 7-10

Table 7-7. Output Cabinet 992 9450 001 7-12

The part number of the item is shown to the right of the description as is the page in the manual where the bill for that

part number starts. Inside the actual tables, four main headings are used:

• Table #-#. ITEM NAME - HARRIS PART NUMBER - this line gives the information that corresponds to the

• Replaceable Parts List Index entry;

• HARRIS P/N column gives the ten digit Harris part number (usually in ascending order);

• DESCRIPTION column gives a 25 character or less description of the part number;

• REF. SYMBOLS/EXPLANATIONS column 1) gives the reference designators for the item (i.e., C001, R102, etc.)

that corresponds to the number found in the schematics (C001 in a bill of material is equivalent to C1 on the schematic) or 2) gives added information or further explanation (i.e., “Used for 208V operation only,” or “Used for HT

10LS only,” etc.).

Inside the individual tables some standard conventions are used:

• A # symbol in front of a component such as #C001 under the REF. SYMBOLS/EXPLANATIONS column means

that this item is used on or with C001 and is not the actual part number for C001.

• In the ten digit part numbers, if the last three numbers are 000, the item is a part that Harris has purchased and has

not manufactured or modified. If the last three numbers are other than 000, the item is either manufactured by Harris

or is purchased from a vendor and modified for use in the Harris product.

• The first three digits of the ten digit part number tell which family the part number belongs to - for example, all elec-

trolytic (can) capacitors will be in the same family (524 xxxx 000). If an electrolytic (can) capacitor is found to have

a 9xx xxxx xxx part number (a number outside of the normal family of numbers), it has probably been modified in

some manner at the Harris factory and will therefore show up farther down into the individual parts list (because

each table is normally sorted in ascending order). Most Harris made or modified assemblies will have 9xx xxxx xxx

numbers associated with them.

The term “SEE HIGHER LEVEL BILL” in the description column implies that the reference designated part number

will show up in a bill that is higher in the tree structure. This is often the case for components that may be frequency

determinant or voltage determinant and are called out in a higher level bill structure that is more customer dependent

than the bill at a lower level.

Transmitter

994 9283 001

Control Cabinet

992 9244 002

Controller Board

992 8344 002

PA Cabinet

992 9400 002

PA Amplifier

992 7894 002

PA Amplifier Board

992 7904 002

Output Cabinet

992 9450 001

Page 6

Page 7

!

WARNING:

THE CURRENTS AND VOLTAGES IN THIS EQUIPMENT ARE DANGEROUS.

PERSONNEL MUST AT ALL TIMES OBSERVE SAFETY WARNINGS, INSTRUCTIONS AND REGULATIONS.

This manual is intended as a general guide for trained and qualified personnel who

are aware of the dangers inherent in handling potentially hazardous electrical/

electronic circuits. It is not intended to contain a complete statement of all safety

precautions which should be observed by personnel in using this or other electronic

equipment.

The installation, operation, maintenance and service of this equipment involves

risks both to personnel and equipment, and must be performed only by qualified

personnel exercising due care. HARRIS CORPORATION shall not be responsible

for injury or damage resulting from improper procedures or from the use of

improperly trained or inexperienced personnel performing such tasks. During

installation and operation of this equipment, National and local building codes and

fire protection standards must be observed.

!

WARNING:

ALWAYS DISCONNECT POWER BEFORE OPENING COVERS, DOORS, ENCLOSURES, GATES, PANELS OR SHIELDS. ALWAYS USE GROUNDING STICKS

AND SHORT OUT HIGH VOLTAGE POINTS BEFORE SERVICING. NEVER MAKE

INTERNAL ADJUSTMENTS, PERFORM MAINTENANCE OR SERVICE WHEN

ALONE OR WHEN FATIGUED.

Do not remove, short-circuit or tamper with interlock switches on access covers,

doors, enclosures, gates, panels or shields. Keep away from live circuits, know your

equipment and don’t take chances.

!

WARNING:

IN CASE OF EMERGENCY ENSURE THAT POWER HAS BEEN DISCONNECTED.

!

WARNING:

IF OIL FILLED OR ELECTROLYTIC CAPACITORS ARE UTILISED IN YOUR

EQUIPMENT, AND IF A LEAK OR BULGE IS APPARENT ON THE CAPACITOR

CASE WHEN THE UNIT IS OPENED FOR SERVICE OR MAINTENANCE, ALLOW

THE UNIT TO COOL DOWN BEFORE ATTEMPTING TO REMOVE THE DEFECTIVE CAPACITOR. DO NOT ATTEMPT TO SERVICE A DEFECTIVE CAPACITOR

WHILE IT IS HOT DUE TO THE POSSIBILITY OF A CASE RUPTURE AND SUBSEQUENT INJURY.

Page 8

Page 9

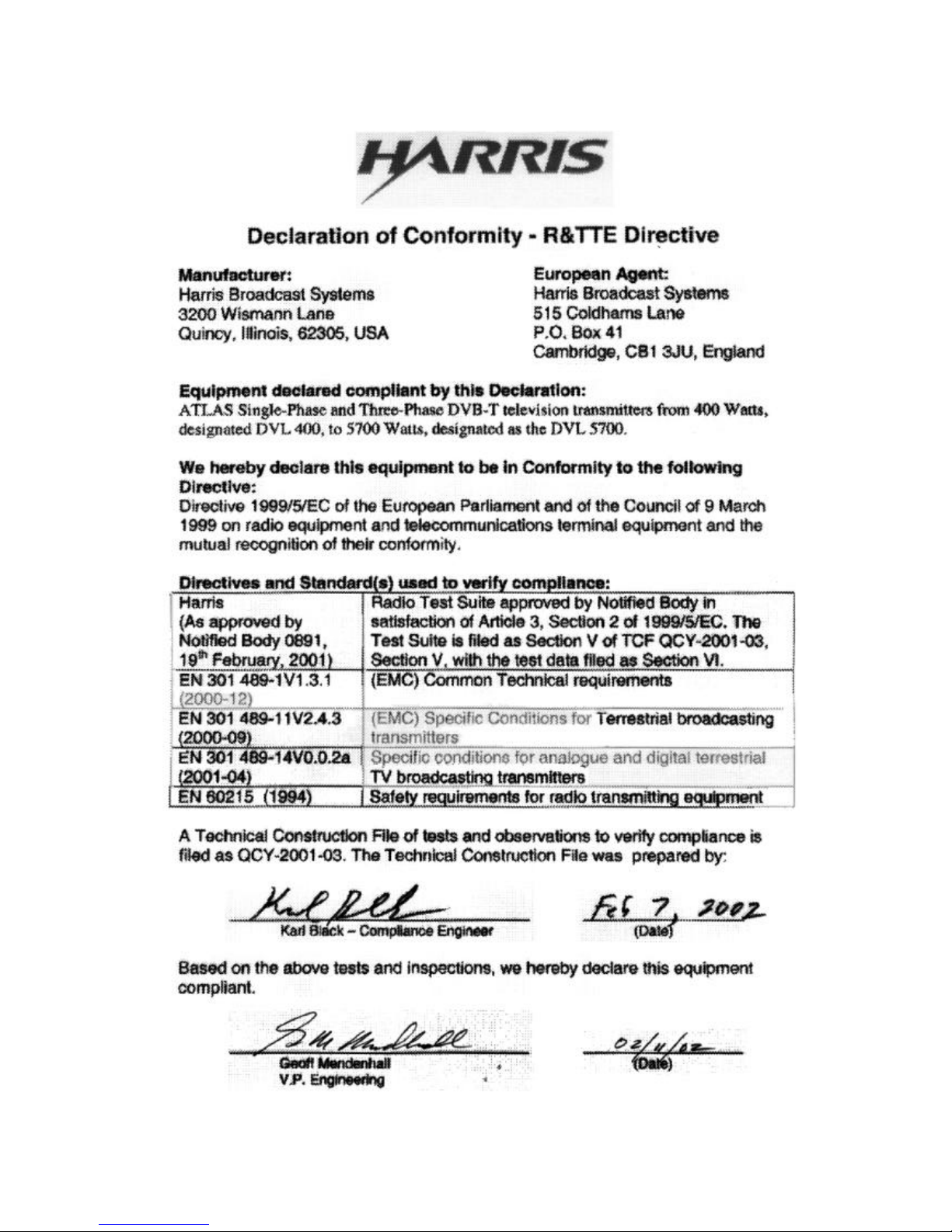

English Hereby, HARRIS Broadcast Communications declares that this

ATLAS SERIES DVB-T Transmitter is in compliance with the

essential requirements and other relevant provisions of Directive

1999/5/EC.

Finnish HARRIS Broadcast Communications vakuuttaa täten että ATLAS

SERIES DVB-T Transmitter tyyppinen laite on direktiivin 1999/5/EY

oleellisten vaatimusten ja sitä koskevien direktiivin muiden ehtojen

mukainen.

Dutch Hierbij verklaart HARRIS Broadcast Communications dat het toestel

ATLAS SERIES DVB-T Transmitter in overeenstemming is met de

essentiële eisen en de andere relevante bepalingen van richtlijn

1999/5/EG

Bij deze verklaart HARRIS Broadcast Communications dat deze

ATLAS SERIES DVB-T Transmitter voldoet aan de essentiële eisen

en aan de overige relevante bepalingen van Richtlijn 1999/5/EC.

French Par la présente HARRIS Broadcast Communications déclare que

l'appareil ATLAS SERIES DVB-T Transmitter est conforme aux

exigences essentielles et aux autres dispositions pertinentes de la

directive 1999/5/CE

Par la présente, HARRIS Broadcast Communications déclare que ce

ATLAS SERIES DVB-T Transmitter est conforme aux exigences

essentielles et aux autres dispositions de la directive 1999/5/CE qui

lui sont applicables

Swedish Härmed intygar HARRIS Broadcast Communications att denna

ATLAS SERIES DVB-T Transmitter står I överensstämmelse med

de väsentliga egenskapskrav och övriga relevanta bestämmelser

som framgår av direktiv 1999/5/EG.

Danish Undertegnede HARRIS Broadcast Communications erklærer herved,

at følgende udstyr ATLAS SERIES DVB-T Transmitter overholder

de væsentlige krav og øvrige relevante krav i direktiv 1999/5/EF

German Hiermit erklärt HARRIS Broadcast Communications, dass sich dieser/

diese/dieses ATLAS SERIES DVB-T Transmitter in

Übereinstimmung mit den grundlegenden Anforderungen und den

anderen relevanten Vorschriften der Richtlinie 1999/5/EG befindet".

(BMWi)

Hiermit erklärt HARRIS Broadcast Communications die

Übereinstimmung des Gerätes ATLAS SERIES DVB-T Transmitter

mit den grundlegenden Anforderungen und den anderen relevanten

Festlegungen der Richtlinie 1999/5/EG. (Wien)

Greek

ΜΕ ΤΗΝ ΠΑΡΟΥ_ HARRIS Broadcast Communications ∆ΗΛ_ΝΕΙ

ΟΤΙ ATLAS SERIES DVB-T Transmitter _ΥΜΜΟΡ__ΝΕΤΑΙ ΠΡΟ ΤΙ

ΟΥ_Ι_∆ΕΙ ΑΠΑΙΤΗ_ΕΙ ΚΑΙ ΤΙ ΛΟΙΠΕ _ΧΕΤΙΚΕ ∆ΙΑΤΑΞΕΙ ΤΗ

Ο∆Η_ΙΑ 1999/5/ΕΚ

Page 10

Italian Con la presente HARRIS Broadcast Communications dichiara che

questo ATLAS SERIES DVB-T Transmitter è conforme ai requisiti

essenziali ed alle altre disposizioni pertinenti stabilite dalla direttiva

1999/5/CE.

Spanish Por medio de la presente HARRIS Broadcast Communications

declara que el ATLAS SERIES DVB-T Transmitter cumple con los

requisitos esenciales y cualesquiera otras disposiciones aplicables o

exigibles de la Directiva 1999/5/CE

PortugueseHARRIS Broadcast Communications declara que este ATLAS

SERIES DVB-T Transmitter está conforme com os requisitos

essenciais e outras disposições da Directiva 1999/5/CE.

Page 11

Page 12

Page 13

Table of Contents

Section 1

Introduction

Purpose of This Manual . . . . . . . . . . . . . . . . . . . 1-1

General Description. . . . . . . . . . . . . . . . . . . . . . . 1-2

Atlas Series™ Transmitter Models . . . . . . . . . 1-3

System Block Diagrams . . . . . . . . . . . . . . . . . . 1-4

Transmitter Control System . . . . . . . . . . . . . . . 1-6

Graphical User Interface . . . . . . . . . . . . . . . . 1-6

Control System Communications . . . . . . . . . 1-7

In-System Programming or ISP. . . . . . . . . . . 1-7

Remote Control . . . . . . . . . . . . . . . . . . . . . . . 1-7

PA Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Module Control . . . . . . . . . . . . . . . . . . . . . . . 1-9

Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Cooling System. . . . . . . . . . . . . . . . . . . . . . . . 1-10

Cooling System Control Panel. . . . . . . . . . . 1-10

Pump Module. . . . . . . . . . . . . . . . . . . . . . . . 1-11

Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . 1-12

Transmitter Cold Plates . . . . . . . . . . . . . . . . 1-12

V-XCAST™ Exciter . . . . . . . . . . . . . . . . . . . 1-13

General Specifications. . . . . . . . . . . . . . . . . . . . 1-14

Section 2

Installation / Initial Turn-On

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation Drawings . . . . . . . . . . . . . . . . . . . . 2-2

Installation Checkboxes . . . . . . . . . . . . . . . . . . . 2-3

Transmitter Cabinet Placement. . . . . . . . . . . . . . 2-3

Cooling System Installation . . . . . . . . . . . . . . . . 2-4

Transmitter AC Connection . . . . . . . . . . . . . . . . 2-7

Second PA Cabinet Interconnections . . . . . . . . 2-10

Signal and Ground Connections . . . . . . . . . . . . 2-11

External Interlock Connections. . . . . . . . . . . . . 2-11

Cabinet Combiner Connections

(DVL 4300 and 5700 only) . . . . . . . . . . . . . . . 2-12

RF Sample Connections . . . . . . . . . . . . . . . . . 2-12

3 Port U-Link Panel Connections . . . . . . . . . . . 2-13

Install PA and PS Modules . . . . . . . . . . . . . . . . 2-14

Initial Turn-On . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Cooling System Turn ON. . . . . . . . . . . . . . . . 2-17

Setting the Transmitter Flow Rate. . . . . . . . 2-18

Setting the Test Load Flow Switch Trip

Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Setting the Heat Exchanger Fan Turn ON

Temperatures . . . . . . . . . . . . . . . . . . . . . . . 2-19

Verifying Pump Switching . . . . . . . . . . . . . 2-19

Local Pump Operation. . . . . . . . . . . . . . . . . 2-20

Setting Exciter Parameters . . . . . . . . . . . . . . . 2-20

RF Initial Turn ON . . . . . . . . . . . . . . . . . . . . .2-22

Cabinet Phasing. . . . . . . . . . . . . . . . . . . . . . . .2-23

Parallel Remote Control Connections . . . . . . . .2-24

Transmitter Control Functions, J13 and J14 . .2-25

Remote Status Outputs, J15 & J16. . . . . . . . . . .2-26

Remote Power Metering, J17 . . . . . . . . . . . . . 2-27

Section 3

Operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Transmitter Control Panel . . . . . . . . . . . . . . . . . .3-1

Main Menu "Quick" Buttons. . . . . . . . . . . . . . .3-2

Graphical User Interface (GUI) . . . . . . . . . . . . . . 3-2

Global Status and Navigation . . . . . . . . . . . . . .3-3

GUI Home Page. . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Drive Chain Main Menu . . . . . . . . . . . . . . . . . . .3-6

Drive Chain Faults . . . . . . . . . . . . . . . . . . . . . . .3-7

Drive Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Drive Service. . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Exciter Setup. . . . . . . . . . . . . . . . . . . . . . . . . .3-9

DCU Setup . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Power Amp Main Menu . . . . . . . . . . . . . . . . . . .3-13

PA Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

PA Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

PA Service. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

PA Module Removal. . . . . . . . . . . . . . . . . . .3-16

PA Module Alignment . . . . . . . . . . . . . . . . .3-17

Output Main Menu. . . . . . . . . . . . . . . . . . . . . . .3-18

Output Faults . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Output Meters . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Output Service. . . . . . . . . . . . . . . . . . . . . . . . .3-20

PA Reject Service. . . . . . . . . . . . . . . . . . . . .3-21

Output Setup . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Power Supply Main Menu . . . . . . . . . . . . . . . . .3-23

PS Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

PS Meters. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

PS Service . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

System Main Menu . . . . . . . . . . . . . . . . . . . . . .3-26

System Control . . . . . . . . . . . . . . . . . . . . . . . .3-27

System Cooling . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Cooling System Control Panel . . . . . . . . . . .3-28

Cooling Faults. . . . . . . . . . . . . . . . . . . . . . . . 3-29

Cooling Meters . . . . . . . . . . . . . . . . . . . . . . .3-29

Cooling Service. . . . . . . . . . . . . . . . . . . . . . . 3-30

System Log . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

System Service . . . . . . . . . . . . . . . . . . . . . . . . 3-32

System Setup. . . . . . . . . . . . . . . . . . . . . . . . .3-33

Software Revisions (SW REVs). . . . . . . . . .3-36

GUI Menu Structures. . . . . . . . . . . . . . . . . . . . .3-37

Page 14

Table of Contents (continued)

Section 4

Theory of Operation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Active Logic Symbols . . . . . . . . . . . . . . . . . . . 4-2

Block Diagram Descriptions. . . . . . . . . . . . . . . . 4-2

Transmitter Control System . . . . . . . . . . . . . . . . 4-3

Micro Module. . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

CPLD, Complex Programmable Logic Device 4-5

I/O Expansion . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Life Support Backup . . . . . . . . . . . . . . . . . . . 4-5

Controller Area Network (CAN) Bus. . . . . . . . 4-6

System Control Bus . . . . . . . . . . . . . . . . . . . . . 4-7

CAN Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Parallel Control Lines . . . . . . . . . . . . . . . . . . 4-7

Main Controller . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Transmitter Control . . . . . . . . . . . . . . . . . . . . 4-9

RS-232 Serial Connections . . . . . . . . . . . . . 4-10

Life Support Mode, Main Controller. . . . . . 4-10

Manual RF MUTE. . . . . . . . . . . . . . . . . . . . 4-11

External I/O Board . . . . . . . . . . . . . . . . . . . . . 4-11

External Interlocks. . . . . . . . . . . . . . . . . . . . 4-13

RF Mute Interlock . . . . . . . . . . . . . . . . . . . . 4-14

Transmitter RF System . . . . . . . . . . . . . . . . . . . 4-15

V-XCAST Exciter(s) . . . . . . . . . . . . . . . . . . . 4-15

Drive Control Unit (DCU) . . . . . . . . . . . . . . . 4-15

Backplane Interface Board. . . . . . . . . . . . . . . 4-16

RF Splitter . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Control Distribution. . . . . . . . . . . . . . . . . . . 4-16

Low Voltage Power Supply Distribution. . . 4-17

PA Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Phase and Gain Board . . . . . . . . . . . . . . . . . 4-18

Automatic Level Control (ALC) . . . . . . . . . 4-19

RF Pallets. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Auto Bias Circuit . . . . . . . . . . . . . . . . . . . . . 4-20

Pallet Splitters and Combiner . . . . . . . . . . . 4-21

DC Distribution Board . . . . . . . . . . . . . . . . . 4-21

Module Controller . . . . . . . . . . . . . . . . . . . . 4-21

PA Module Combiner . . . . . . . . . . . . . . . . . . . 4-22

Combiner Isolation Loads . . . . . . . . . . . . . . 4-25

RF Monitor Board . . . . . . . . . . . . . . . . . . . . . 4-26

RF Detectors . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Reject Load RF Detector (Relative) . . . . . . 4-28

Precision RF Power Detectors . . . . . . . . . . . 4-30

Normal Mode / Life Support Mode . . . . . . . 4-30

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

AC Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

PA Power Supply Modules. . . . . . . . . . . . . . . 4-31

Low Voltage Power Supplies (LVPS) . . . . . . 4-32

Power Supply Monitor Board . . . . . . . . . . . . .4-32

S1, PS Monitor Board Config Switches . . . .4-33

LVPS Interface and Cabinet ID . . . . . . . . . .4-34

PA Power Supply Monitoring and Control. .4-34

AC Line Monitoring . . . . . . . . . . . . . . . . . . .4-35

Cabinet Cooling System Sensors . . . . . . . . . 4-35

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . .4-39

Pump Module . . . . . . . . . . . . . . . . . . . . . . . . .4-39

Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . .4-40

Transmitter Cold Plates. . . . . . . . . . . . . . . . . .4-40

Pump Control Panel. . . . . . . . . . . . . . . . . . . . .4-40

Transmitter Interconnect. . . . . . . . . . . . . . . .4-41

Front Panel Controls. . . . . . . . . . . . . . . . . . .4-41

Control Voltage Power Supply. . . . . . . . . . .4-42

Control Description. . . . . . . . . . . . . . . . . . . .4-42

Section 5

Maintenance and Alignments

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

PA Module Removal and Replacement. . . . . . . .5-1

PA Module Removal. . . . . . . . . . . . . . . . . . . . . 5-2

Installing a PA Module . . . . . . . . . . . . . . . . . . .5-3

PA Module Auto Bias Procedure. . . . . . . . . . . . .5-4

PA Module Phasing . . . . . . . . . . . . . . . . . . . . . . .5-5

Phase Control Voltage. . . . . . . . . . . . . . . . . . . .5-5

Module Phasing Procedure . . . . . . . . . . . . . . . .5-6

Power Calibrations. . . . . . . . . . . . . . . . . . . . . . . . 5-7

Forward Power Calibration . . . . . . . . . . . . . . . .5-8

Reflected Power Calibration . . . . . . . . . . . . . . .5-8

DCU Calibration . . . . . . . . . . . . . . . . . . . . . . . .5-9

LCD Contrast Adjustment . . . . . . . . . . . . . . . . .5-10

Touch Screen Calibration. . . . . . . . . . . . . . . . . .5-11

V-XCAST Exciter adjustments . . . . . . . . . . . . .5-12

Main Controller Battery Check . . . . . . . . . . . . .5-12

Section 6

Diagnostics

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

GUI System Log . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Fault Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Parts List

Parts List Index . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Page 15

2/25/03 888-2473-001 1-1

WARNING: Disconnect primary power prior to servicing.

ATLAS Series™

Section 1

Introduction

1

1.1 Purpose of This Manual

This technical manual contains the information pertaining to the Atlas™ Series

UHF solid-state DTV transmitter. The various sections of this technical manual

provide the following types of information.

• Section 1, Introduction, provides general manual layout, frontispiece, equipment

description, block diagram and general specifications.

• Section 2, Installation/Initial Turn-On, provides physical and electrical installa-

tion procedures for the transmitter, cooling and RF systems and basic remote

control connections.

• Section 3, Operation, provides operation and navigation information for the

Graphical User Interface or GUI as well as identification and functions of all

external panel controls and indicators.

• Section 4, Theory of Operation, provides detailed theory of operation for the

transmitter and sub-assemblies.

• Section 5, Maintenance and Alignments, provides preventative and corrective

maintenance information and all field alignment procedures.

• Section 6, Diagnostics, provides detailed fault information and diagnostic proce-

dures to the board level.

• Section 7, Parts List, provides a parts list for the overall transmitter as well as

individual modules.

Page 16

1-2 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction ATLAS Series™

1.2 General Description

This section contains a general description of the Atlas Series™ series television

transmitters. Included in this section will be descriptions of the Control System,

Power Amplifier, block diagrams of the different models and system specifications.

The Atlas Series™ DTV transmitter consists of one or two cabinets depending on

power level. See Table 1-1 for a listing of the available models and power levels.

Figure 1-1 shows the 2 possible cabinet configurations. The cabinet on the left is for

power levels up to 3kW, with the dual cabinet configuration on the right allowing

for 4.3kW and 5.7kW versions.

Figure 1-1 Transmitter Front View

All Models up to 3kW

DVL 4300 and DVL 5700

(4.3kW and 5.7kW Models)

DVL 400 - DVL 3000

Page 17

2/25/03 888-2473-001 1-3

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction

ATLAS Series™

1.2.1 Atlas Series™ Transmitter Models

The Atlas Series™ UHF transmitter is available in 8 liquid cooled power levels, not

including dual transmitter configurations. The available models are listed below in

Table 1-1.

Table 1-1 Atlas Series™ Transmitter Models

Tx Models Cabinets PA Modules Output Power Primary Cooling

DVL 400 1 1 400W LIQUID

DVL 800 1 2 800W LIQUID

DVL 1100 1 3 1.1kW LIQUID

DVL 1500 1 4 1.5kW LIQUID

DVL 2200 1 6 2.2kW LIQUID

DVL 3000 1 8 3.0kW LIQUID

DVL 4300 2 12 (6 per cabinet) 4.3kW LIQUID

DVL 5700 2 16 (8 per cabinet) 5.7kW LIQUID

NOTE: All power levels given in Average power.

Page 18

1-4 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction ATLAS Series™

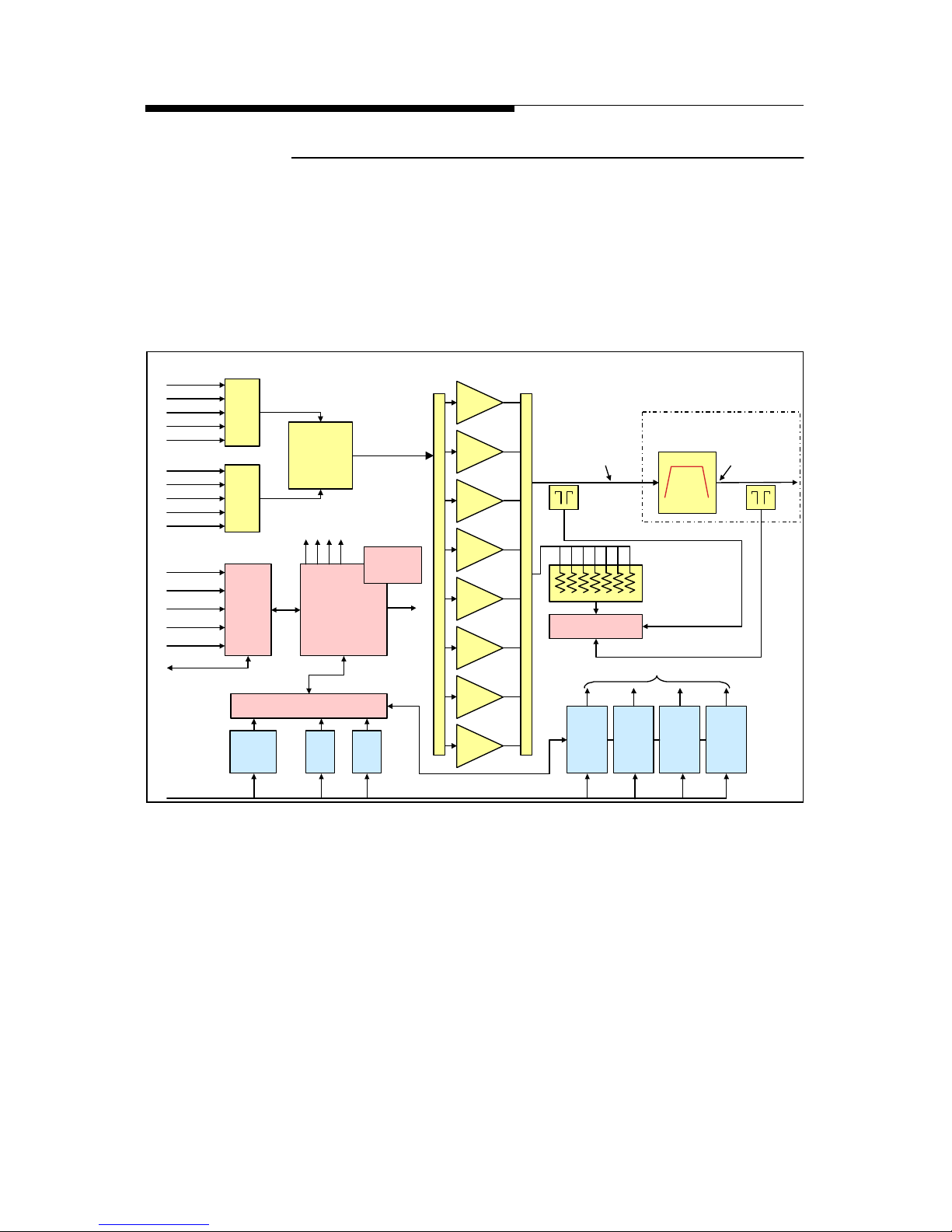

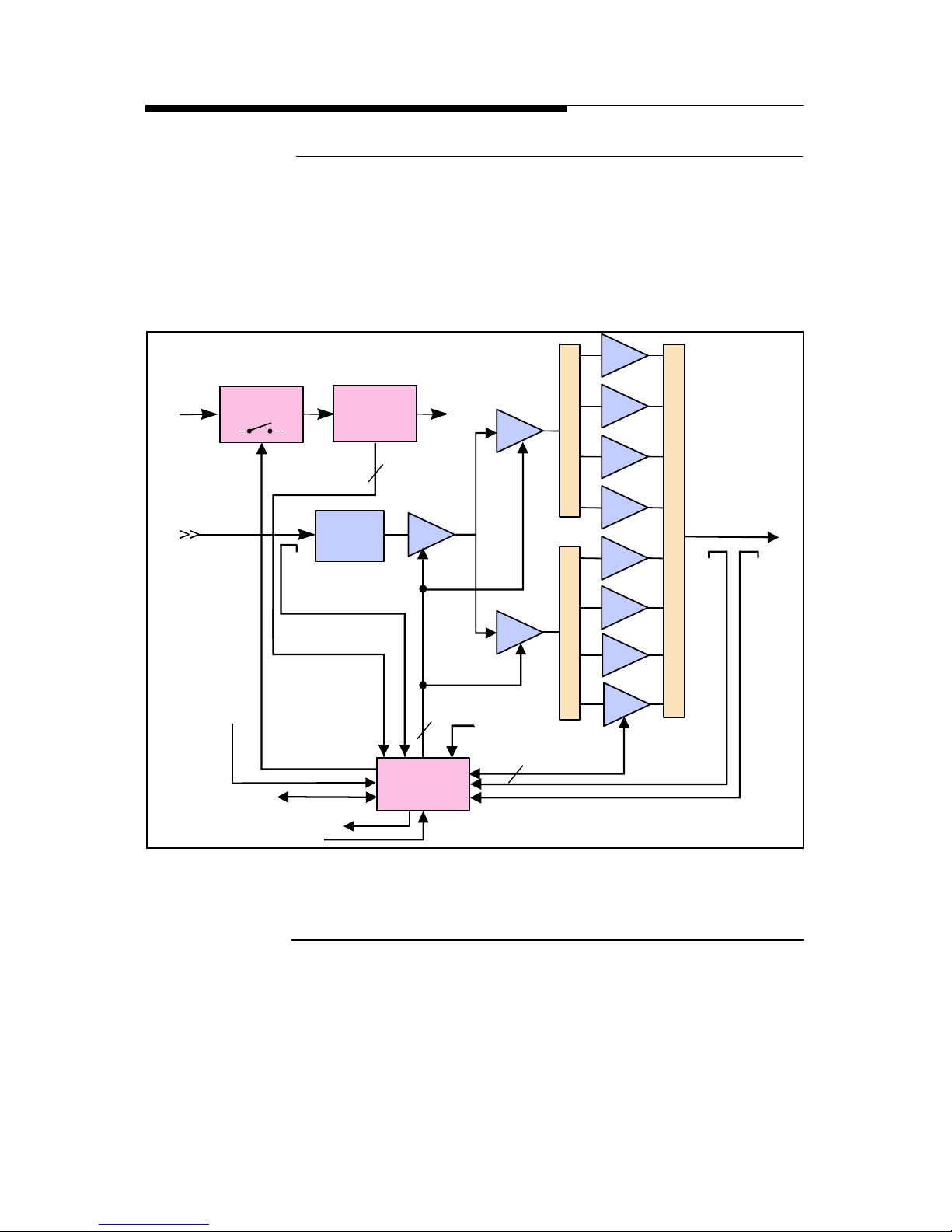

1.2.2 System Block Diagrams

The following figures contain System block diagrams showing the basic signal flow

and configuration for each Atlas Series™ Transmitter Model. Figure 1-2 shows the

Medium Power single cabinet system with up to 8 PA modules. Note that a driver is

not needed, as the exciter power is sufficient to drive up to 8 PA modules. Figure 13 shows the High Power configuration which is simply the addition of a second

cabinet and a cabinet combiner for outputs of 4.3Kw and 5.7kW.

Figure 1-2 Atlas Series™ Medium Power System Block Diagram

400W up to 3kW (DVL 3000 shown)

Exciter AExciter B

Drive

Control

Unit

RF Monitor

DVB

Filter

Reject

Loads

PA 1

PA 2

PA 3

PA 4

PA 5

PA 6

PA 7

PA 8

PS 1

32V

PS 2

32V

PS 3

32V

PS 4

32V

Ext

I/O

Board

Main

Controller

&

Life Support

MOV

Board

LVPS

LVPS

AC Power

380/400/415

VAC 3-Phase

or

220/240

Single Phase

To PA Modules

Bus to 2nd PA

TCP/IP

RS-232

Parallel

Ext Interlocks

Pump Control

ASI-1

ASI-2

10MHz

GPS

1 PPS

ASI-1

ASI-2

10MHz

GPS

1 PPS

1-5/8” Line

Model: DVL 3000

3.4kW 3.0kW

460W

460W

460W

460W

460W

460W

460W

460W

Power Supply Monitor

PS Control and Monitoring

Graphical

User

Interface

RF Samples

Note: This represents Cabinet #1

for the DVL 4300 and 5700

RF Splitter

RF Combiner

PA Cabinet FWD and RFLD

Total System FWD and RFLD

These Components are outside

the Transmitter Cabinet

Page 19

2/25/03 888-2473-001 1-5

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction

ATLAS Series™

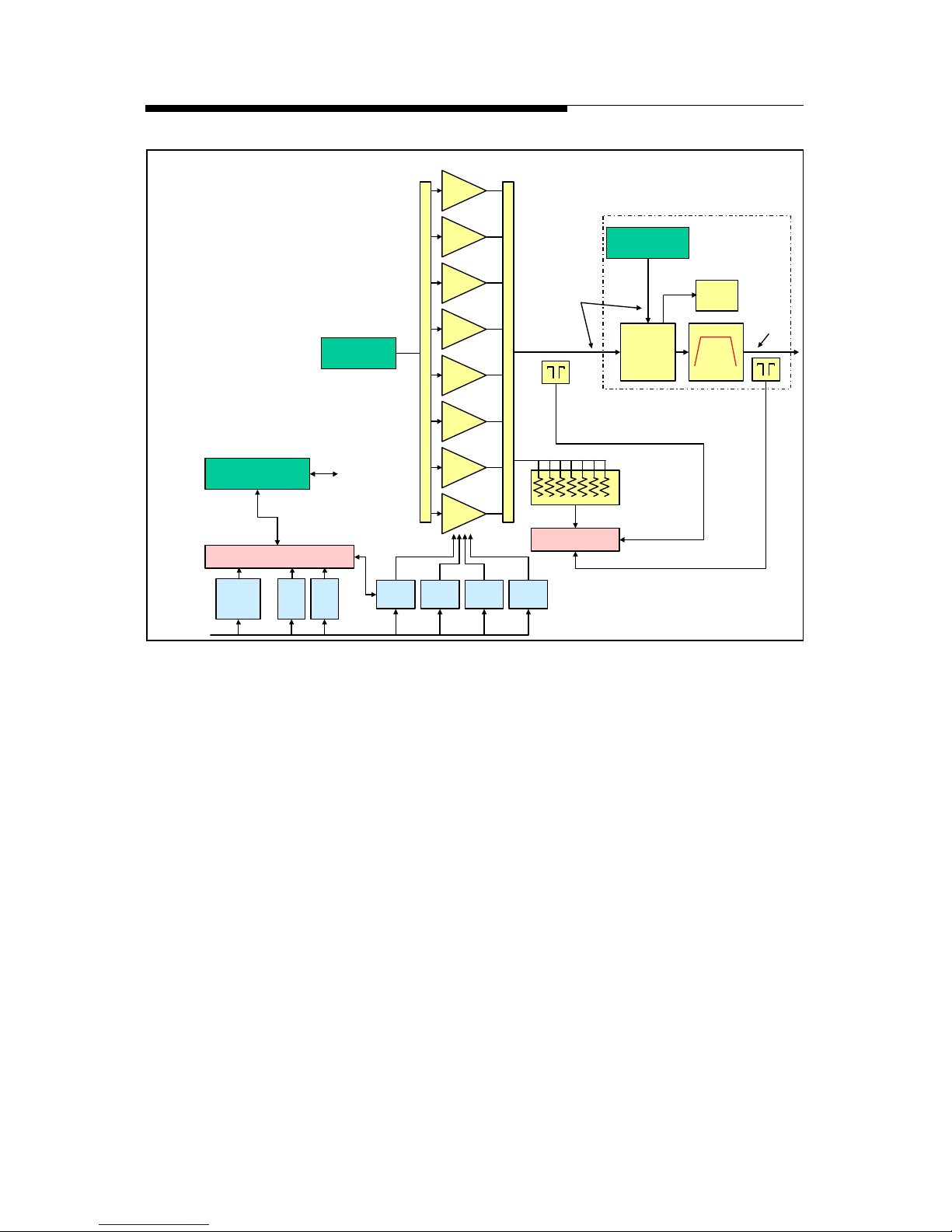

Figure 1-3 Atlas Series™ High Power System Block Diagram

DVL 4300 or DVL 5700 (shown)

RF Monitor

Cabinet

Combiner

Reject

Loads

PS 1

32V

PS 2

32V

PS 3

32V

PS 4

32V

MOV

Board

LVPS

LVPS

AC Power

380/400/415

VAC 3-Phase

5.7kW

RF Samples

Power Supply Monitor

Model: DVL 5700

Cabinet #2

RF Drive from

Cabinet #1

RF Output from

Cabinet #1

3.4kW

DVB

Filter

Control PS Bus from

Cabinet #1

Note: For DVL 4300

Omit PAs 7 & 8 and PS #4

To PA Modules

and RF Monitor

These

Components are

outside the

transmitter cabinet

PA Cabinet FWD and RFLD

Total System FWD and RFLD

PA 1

PA 2

PA 3

PA 4

PA 5

PA 6

PA 7

PA 8

460W

460W

460W

460W

460W

460W

460W

460W

RF Splitter

RF Combiner

Reject

Load

Page 20

1-6 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction ATLAS Series™

1.2.3 Transmitter Control System

The transmitter uses a distributed architecture control system. This means that each

transmitter sub-system is responsible for its own monitoring and protection and

simply reports back to the Main Controller for display on the GUI (Graphical User

Interface) or to a remote interface. The heart of the system is the 376 Micro Module

which is used in all of the transmitter systems for control, monitoring and

protection. The Micro Module is used on each of the following controllers and subsystems:

a. Main Controller Board - This board is responsible for transmitter control and

monitoring. However, with the distributed control architecture, it is not

directly responsible for protection of the individual transmitter components. It

merely gathers all status and fault data from the individual sub-systems and

reports that information to the operator. The Main Controller is responsible

for system level control (issues which effect multiple systems) since it is the

only part of the control system which can monitor the entire transmitter.

b. Module Controllers (1 in each module) - Responsible for protection and con-

trol of the PA Module. Report directly to the Main Controller Board.

c. RF Monitor Board - Responsible for cabinet VSWR protection and monitor-

ing of combiner reject loads. Reports directly to the Main Controller.

d. Power Supply Monitor Board - Responsible for control and monitoring of the

PA power supplies and distribution of the low voltage. Also responsible for

monitoring the cooling system including temperature, flow and leaks. Reports

directly to the Main Controller.

e. External I/O Board - Provides all customer interface connections including

parallel remote control and serial remote control. Reports directly to the Main

Controller.

1.2.3.1 Graphical User Interface

The front panel user interface is a 1/4 VGA, LCD touchscreen display. The

touchscreen display uses software buttons to monitor the transmitter. Hardware

buttons for the primary transmitter functions such as ON, OFF, RAISE and

LOWER are provided on the overlay panel next to the display.

Page 21

2/25/03 888-2473-001 1-7

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction

ATLAS Series™

1.2.3.2 Control System Communications

The control system uses a serial communications system called a CAN bus. CAN

stands for Controller Area Network. The CAN bus is a closed loop serial network

operated by the Main Controller Board. Each circuit board and module connected to

the CAN bus is considered a node and therefore has a specific address. This allows

the Main Controller to gather information from all parts of the transmitter and

display it on the GUI. One big advantage of the CAN bus is that it requires only 2

wires of the system control ribbon cable, eliminating a large amount of discrete

wiring which would otherwise be required.

For redundancy, the CAN bus is backed up by parallel, hardwired, control lines that

allow the transmitter to stay on the air even if the CAN bus fails. The parallel

control lines also provide the instantaneous OFF and RF MUTE commands

necessary for transmitter protection.

1.2.3.3 In-System Programming or ISP

The use of the CAN bus for communication between the various Micro Modules in

the transmitter also allows for easy updating of the software used in each transmitter

sub-system via a serial port connection to an external computer. This is referred to

as In-System Programming or ISP.

The real benefit of In-System Programming is that it allows any or all of the

transmitter software to be updated without removing or replacing any firmware ICs.

The Harris ISP program is provided on the CD-ROM accompanying this manual

along with all of the transmitter software as it shipped from the factory. The Harris

ISP program is easy to use and it only takes a few minutes to load or update

software.

NOTE:

Software does not need to be loaded into the transmitter unless new components are installed or an update is sent from Harris. The transmitter, as

shipped from the factory, is preloaded and ready to run.

1.2.3.4 Remote Control

The Atlas Series™ transmitter has the basic Discrete wired parallel remote control

with the standard connections for control, status and analogue monitoring. A

network interface will be available by mid year 2002, but this will be an optional

add-on deivce.

Page 22

1-8 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction ATLAS Series™

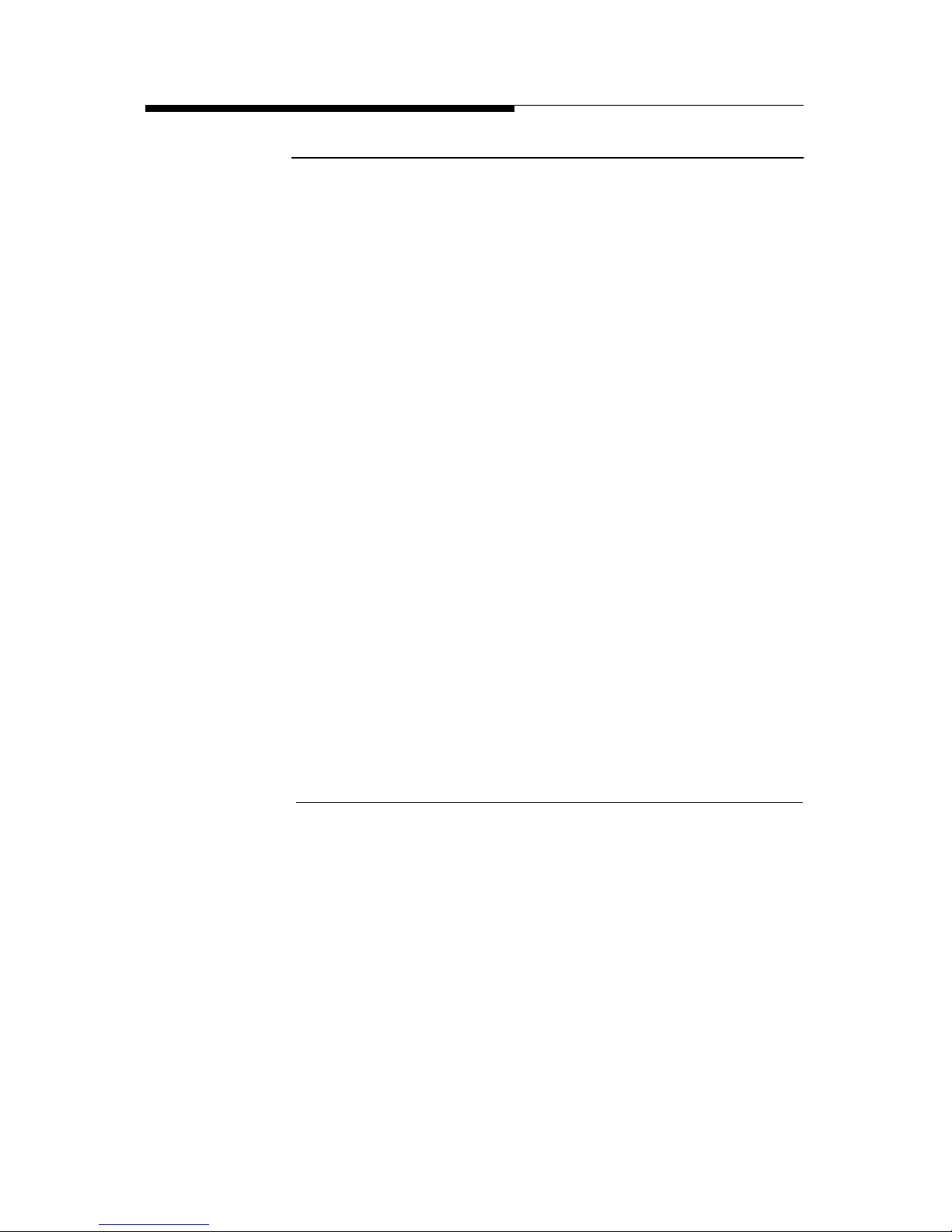

1.2.4 PA Module

The Atlas Series™ PA Module utilises LDMOS amplifiers to produce up to 460W

average power output. Each module weighs approximately 20.5kg and can be unplugged while the transmitter is running. A single cabinet Atlas Series™ transmitter

can have 1, 2, 3, 4, 6 or 8 PA modules to achieve the various power levels shown in

Table 1-1. The 2 cabinet version will have either 6 or 8 modules per cabinet. A

block diagram of the PA module is shown in Figure 1-4.

Each PA module consists of the following components:

a. PA Module Controller Board - Responsible for all monitoring and protection

of the module. Reports to the transmitter Main Controller via the CAN bus

but is also connected to the parallel control lines in case the CAN bus is not

operational.

b. Phase and Gain Board - Provides for module phase and gain adjustments to

minimise module combiner reject power. Also provides for cabinet phasing

for the 2 cabinet transmitters to minimise cabinet combiner reject power.

c. DC Distribution Board - Provides FET switching of the +32Vdc and sensing

of driver and pallet currents.

d. Pre-driver Pallet - Provides enough power to drive the 2 way splitter and the 2

driver pallets.

e. Two (2) LDMOS Driver Pallets - Provide enough power to drive the 4 way

splitters and the inputs to the power amplifier pallets.

f. Pallet Splitter and Combiner - Actually two 4-way splitters and one 8-way

combiner.

g. Eight (8) LDMOS Amplifier Pallets - When combined, they provide up to

460 watts of average power at the output of the module.

h. Liquid Cooled Cold Plate - Mounted directly to the 8 LDMOS power ampli-

fier pallets for cooling.

i. RF Output Directional Coupler - Samples both Forward and Reflected power

for metering, module ALC and module VSWR protection.

Each Atlas Series™ PA Module is a self-contained 460W transmitter (except for the

power supply) with its own internal control, monitoring and protection. The

modules only receive basic On/Off, Mute, Restart, Phase and Gain commands from

the transmitter control system. This means that each module will protect itself

without relying on the system controller.

Page 23

2/25/03 888-2473-001 1-9

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction

ATLAS Series™

1.2.4.1 Module Control

The primary method for control and monitoring of the PA Modules is by the serial

CAN (Controller Area Network) Bus. It is used for control, status and monitoring of

all PA Module parameters and for the reporting of Module faults. As a backup to

this serial control network, each PA Module has dedicated hardware control lines

for functions such as On, Off, Restart and RF Mute.

Figure 1-4 PA Module Block Diagram

1.2.5 Power Supplies

Up to four +32 Vdc power supplies are used to provide the DC voltage to the PA

modules within each PA cabinet. Each power supply provides power to two PA

modules. Module power supplies are designed to allow removal and insertion of one

unit while the remaining power supplies are operating. The control system in the PA

Cabinet is powered by a single low voltage power. A second (redundant) low

voltage power supply is optional.

AB

PHASE

&

GAIN

CONTROL

BOARD

SS RELAY

AB

AB

AB

AB

AB

AB

A

FWD

TEMP

Pin

+32V

BIAS

RF IN

TO MAIN CONTROLLER

SWITCHED

+32V

ON/OFF

MODULE ENABLE/DISABLE

32V

MON

RF

OUT

AB

AB

AB

Auto Biasing

Pre-driver

Driver A

Driver B

8

CURRENT

SENSING

Pallets

Pallet Combiner

SplitterSplitter

BIAS

BIAS

3

12

RFL

CAN Bus

Page 24

1-10 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction ATLAS Series™

1.2.6 Cooling System

The Atlas Series™ transmitter uses a 50/50 glycol liquid cooling system to remove

the majority of the heat away from the transmitter but also has cabinet flushing fans

to remove residual cabinet heat. A simplified block diagram of the liquid cooling

system is shown in Figure 1-6. A simplified diagram of the liquid cooling system

inside the transmitter cabinet is shown in Figure 1-7. The cooling system basically

consists of:

a. Cooling System Control Panel

b. Pump Module

c. Heat Exchanger

d. Transmitter Cold Plates

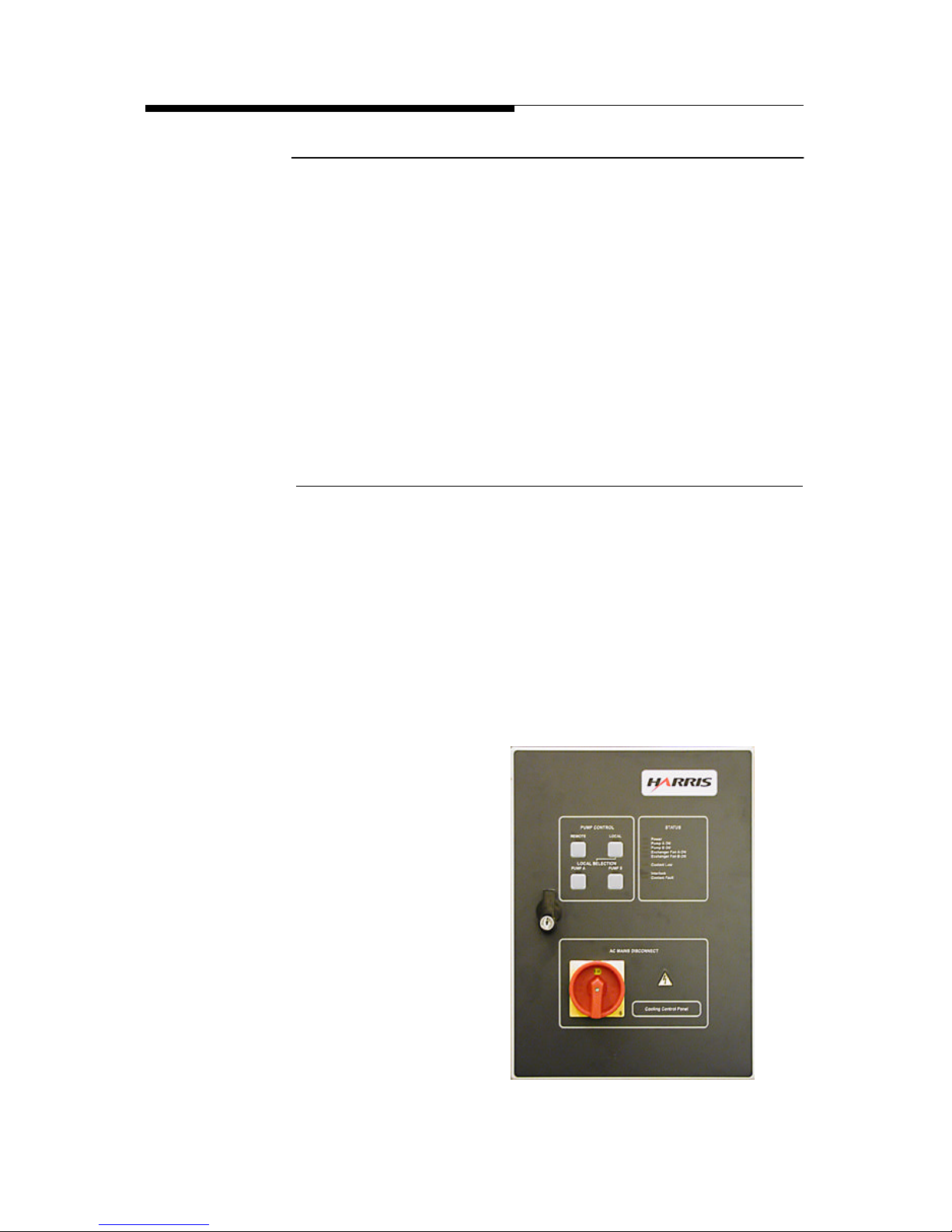

1.2.6.1 Cooling System Control Panel

The cooling system control panel controls the pump module and the heat exchanger

and is the interface to the transmitter control system. It uses very basic relay logic

for reliable operation. The cooling system control panel is connected to the External

I/O board in the Atlas Transmitter for monitoring and control. It also supplies ac

power to the pump module and the heat exchanger and interfaces the fault and status

information from these units to the transmitter.

The cooling system control panel, shown in Figure 1-5 below, has local controls on

the front which allow manual selection of pump A or optional pump B and selection

of Remote/Local control. It also has the following status indicators:

• Remote

• Local

• Interlock

• Fan A ON

• Fan B ON

• *Pump A ON

• *Pump B ON

• Pump A Preset

• Pump B Preset

• *Coolant Fault

• *Coolant Low

• Power

Figure 1-5 Cooling System Control Panel

Page 25

2/25/03 888-2473-001 1-11

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction

ATLAS Series™

* Each of these status indications is also sent to the transmitter for display on the

GUI and via remote control.

When in Remote mode, the transmitter is responsible for control of the cooling

system, including ON/OFF, manual pump selection and automatic pump switching

in the case of a failure. Placing the control panel in Local mode allows manual

switching of the pumps using the pump select buttons on the cooling control panel.

The lower half of the control panel contains the ac isolation switch which

disconnects ac power from the pump module and heat exchanger as well as the

control circuitry in the control panel itself.

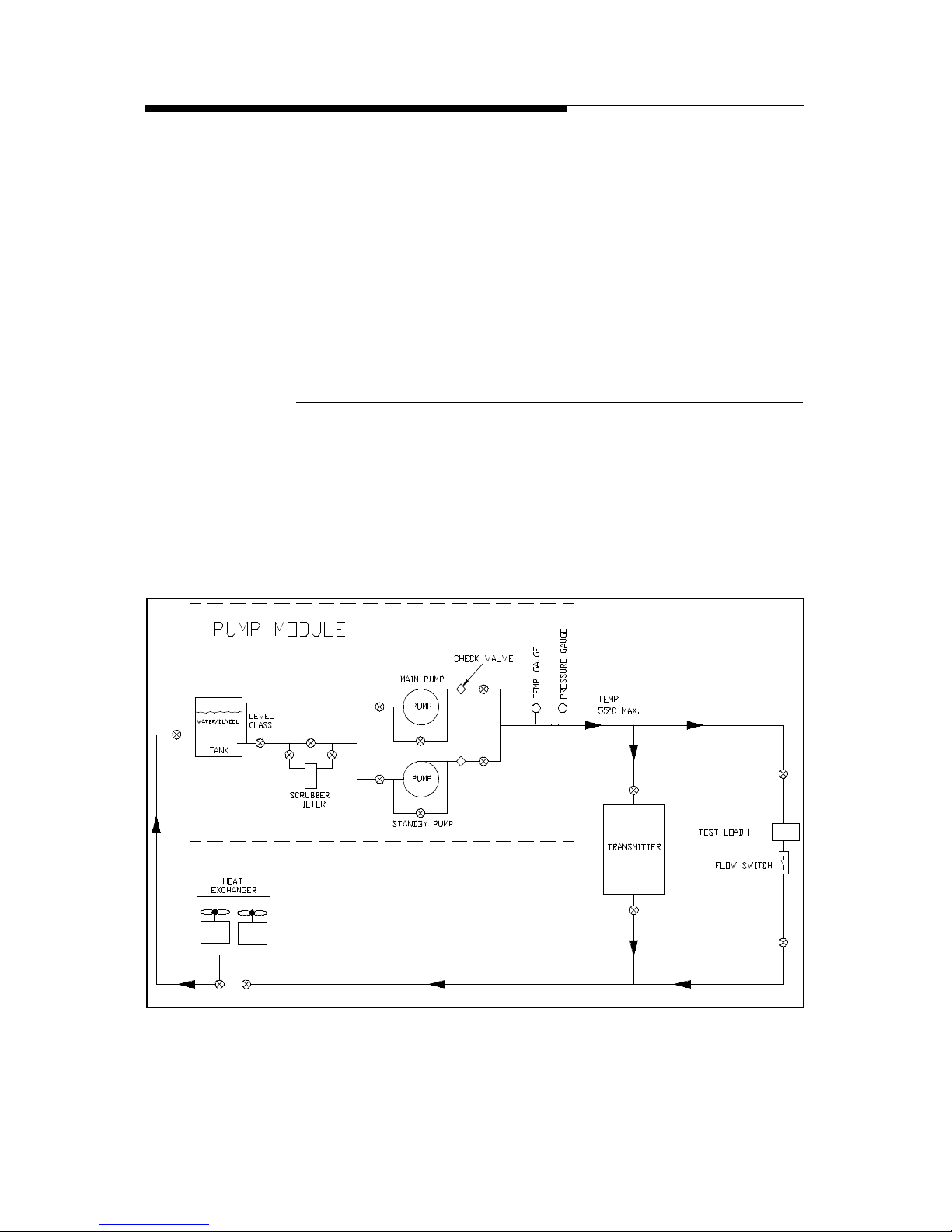

1.2.6.2 Pump Module

The pump module is a self-contained unit with a storage tank, pressure and

temperature gauges, a strainer filter and one pump or the optional dual pumps

operating in main/standby mode. The pump module is an open frame unit and is

meant to be installed inside the building (with a special option for outside

mounting). The control panel is separate from the pump module and should be

mounted near the transmitter (usually next to the transmitter disconnect panel).

Figure 1-6 Simplified Liquid Cooling System Block Diagram

Medium Power (up to DVL 3000)

Page 26

1-12 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction ATLAS Series™

1.2.6.3 Heat Exchanger

The heat exchanger, which is usually installed outside, has 2 fans. The fans are

enabled whenever the pump module is activated, but temperature sensors determine

when the fans will actually start. The first one turns on when the coolant

temperature reaches 32oC with the second one turning on at 38oC.

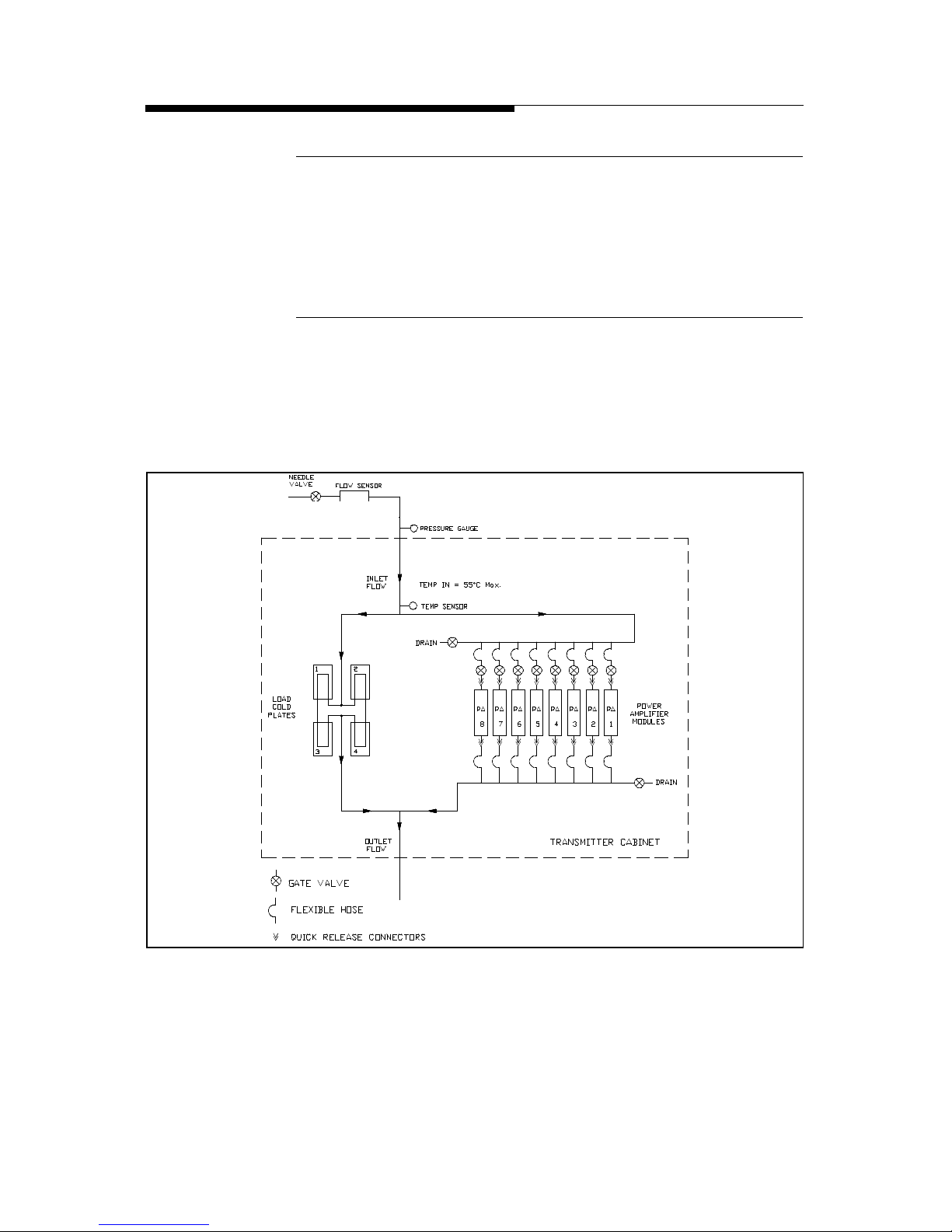

1.2.6.4 Transmitter Cold Plates

Each PA Module has an attached liquid cooled cold plate which connects to the

cooling system with flexible hoses and quick release connectors. There is also a

separate cold plate mounted inside the transmitter cabinet to which all of the

combiner reject loads are attached. See Figure 1-7.

Figure 1-7 Internal Transmitter Liquid Cooling System

Page 27

2/25/03 888-2473-001 1-13

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction

ATLAS Series™

1.2.7 V-XCAST™ Exciter

The ITIS V-XCAST™ COFDM (Coded Orthogonal Frequency Division Multiplex)

exciter is used with the Atlas Series™ transmitter. This exciter is described in a

separate instruction book. A second hot standby exciter/driver and drive chain

switcher is available as an option. The exciter is controlled and configured using an

RS-232 serial connection. Software is provided with the exciter. A serial diagnostic

and monitoring port is also provided.

The COFDM exciter V-XCAST is a fully compliant DVB-T (Digital Video

Broadcast - Terrestrial) exciter and up-converter supporting both 2K and 8K

operations, specifically designed for commercial networks. This device performs

channel coding and OFDM modulation of a MPEG2 transport stream. One single

unit drives the Atlas Series™ transmitter with a fully modulated RF DVB-T

channel. The excellent quality and stability of analogue UHF signal output

maximises the TV transmitter efficiency, decreasing global cost. Thanks to its ASI

(Asynchronous Serial Interface) standardised interface, the V-XCAST exciter can

be used with any DVB compliant source equipment.

A flexible Bit Rate Adaptation mechanism, with PCR (Program Clock Reference)

restamping, is provided, giving an independence between the multiplexer rate and

the DVB-T rate.

Test generators are included, which allow easier BER (Bit Error Rate) measurement

with the optional V-TER, professional test receiver.

The V-XCAST COFDM exciter accepts a SFN (Single Frequency Network) option

which allows to set up single frequency networks with use of a SFN adapter at the

DVB multiplexer site. In SFN mode, the COFDM modulation and RF up-converter

are locked on a stable 10 MHz external reference coming from GPS (Global

Positioning System). With the optional internal GPS receiver, the V-XCAST offers

a compact and reliable SFN modulation solution.

The full device remote control can be performed via the MIP channel (remote

control from network head-end), or via an RS232 port and the PC software (local

control or remote control via modem) or via a standard SNMP (Simple Network

Management Protocol) manager, allowing a very fast integration with most Control

Systems.

The same PC software can be used for easy logging and maintenance, thanks to an

accessible rear panel RS-232 connector. It will be used to adjust digital

precorrection curves.

Alarms are monitored on front panel leds and on a rear side connector as relay

contacts. Alarms are optionally controlled and monitored by standard SNMP

managers.

Page 28

1-14 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction ATLAS Series™

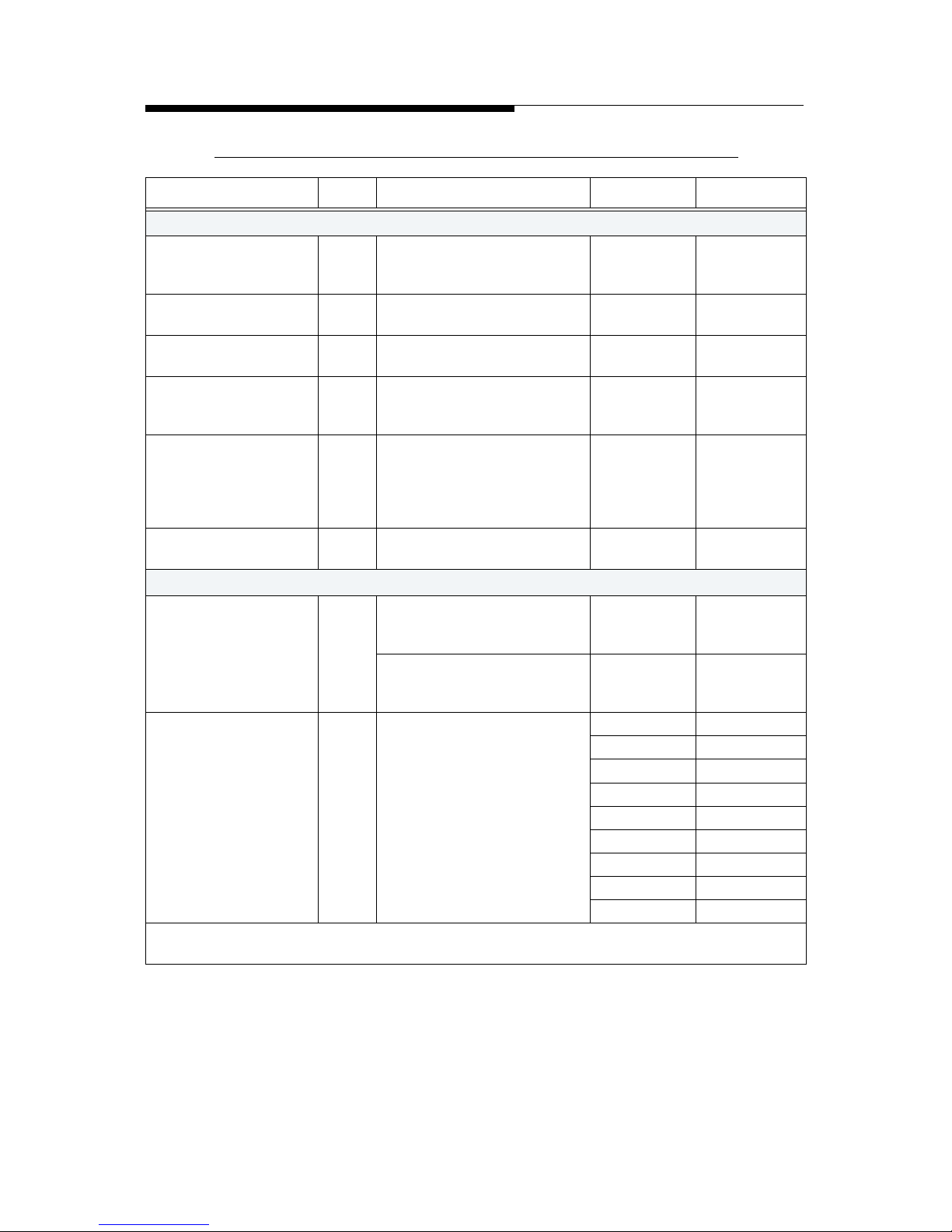

1.3 General Specifications

The following table lists the specifications the Atlas Series™ UHF transmitter.

NOTE:

Specifications subject to change without notice.

Table 1-2 Atlas Performance Specifications

Item Units Conditions Notes Value

General

Frequency Range Mhz Any UHF TV

Channel

470-860

DTV Channel

Bandwidth

Mhz "8, 7 or 6

Mhz"

Cabinet Output Power

(before mask filter)

kW At 37 dB shoulders (measured

+/-4.2 MHz from center of

channel for a 8 Mhz DTV

channel)

Model Power

DVL400 450W

DVL800 850W

DVL1100 1.25kW

DVL1500 1.7kW

DVL2200 2.5kW

DVL3000 3.4kW

DVL4300 4.7kW

DVL5700 6.2kW

System Output Power

(after mask filter)

kW At 37 dB shoulders (measured

+/-4.2 MHz from center of

channel for a 8 Mhz DTV

channel)

Model Power

DVL400 410W

DVL800 800W

DVL1100 1.1kW

DVL1500 1.5kW

DVL2200 2.2kW

DVL3000 3.0kW

DVL4300 4.3kW

DVL5700 5.7kW

Variation in Output

Power

% At rated Power (RMS) within

AC mains variation spec and

+/- 5 Degree C from Nominal

Operating Temperature

+/-2

RF Load Impedance Ohms 50

RF Load VSWR Measured on any 8 Mhz

channel

1.1:1

Output Connector

Medium Power

"1-5/8"" EIA

Flanged"

Output Connector High

Power

"3-1/8"" EIA

Flanged"

Page 29

2/25/03 888-2473-001 1-15

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction

ATLAS Series™

Performance

Equivalent Noise

Degradation (END)

dB Measured per ETR 290 < 0.5

Modulation Error Ratio

(MER)

dB At rated Power and -37 dB

shoulders (using HP89440)

Within the

performance

temp window

> 33 dB

Phase Noise dBc/HzAfter warm up time -95@10Khz

Frequency stability

(without external

reference)

+/- HzStand alone transmitter < 17

Frequency stability

(with external

reference)

+/- HzRequires external 10 Mhz < 0.1

Coarse Frequency

Offset Range

+/Mhz

In steps of 166 KHz 4

Fine Frequency Offset

Range

+/KHz

In steps of 1Hz 166

Transmitter Processing

Delay

msec From TS input to RF output Used in SFN

operation

programmabl

e to 1 sec max

Spurious Radiation

Harmonics and

spurious emissions

dBc "After Mask Filter,

referenced to average

transmitter power"

Depends on

DTV Mask

requirement

of individual

countries

< -60

Harmonics before

Mask Filter

dBc Transmitter output before

mask filter

< -40

AC Line

AC Line Voltage (3phase models)

VAC 3-phase 50/60 Hz select one "380, 400,

415"

AC Line Voltage (1phase models)

VAC 1-phase 50/60 Hz "220,230,240

"

AC Line Voltage

Variation

% "+10, -15"

Power Factor (3-phase

models)

"DVL1500, DVL2200,

DVL3000, DVL4300,

DVL5700"

> 0.94

Power Factor (1-phase

models)

"DVL

400,DVL800,DVL1100"

> 0.97

Overall Efficiency

(typical)

% AC power to RF average

power

18% Typical

Table 1-2 Atlas Performance Specifications

Item Units Conditions Notes Value

Page 30

1-16 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction ATLAS Series™

Environmental

Operational

Temperature Range

°C Derate 2

degree C per

300m AMSL

0-45

Operational Relative

Humidity

% non-condensing 0 - 90

Altitude metersAMSL 0-4000

Cooling Method

(primary)

% Liquid cooling Propylene

Glycol/

Water

50/50

Acoustic Noise dBA Measured 1m from front of

cabinet and 1m up from the

floor (does not include

cooling pump module and

heat exchanger)

<65

Residual Heat

transferred to room

kW Maximum per transmitter

cabinet with 8PAs

< 3.9

Physical

Dimensions mm Single Cabinet Transmitter DVL400 thru

DVL3000

700W x

1980H x

1040D

Dual Cabinet Transmitter DVL4300 &

DVL5700

1400W x

1980H x

1040D

Weight Kg Weight includes all options Model Weight

DVL400 303

DVL800 330

DVL1100 365

DVL1500 399

DVL2200 463

DVL3000 526

DVL4300 894

DVL5700 1020

"Note: Unless otherwise noted, these specifications apply at the output of a Harris supplied mask

filter."

Table 1-2 Atlas Performance Specifications

Item Units Conditions Notes Value

Page 31

2/25/03 888-2473-001 2-1

WARNING: Disconnect primary power prior to servicing.

ATLAS Series™

Section 2

Installation /

Initial Turn-On

2

2.1 Introduction

This section includes the information necessary for installation and initial turn on of

an Atlas Series DVB-T, solid state, UHF transmitter. Information is included for

single and multiple cabinet configurations. Due to the modular nature of the Atlas,

all models have the same basic cabinet level installation and testing procedures,

with additional information given for multiple cabinet connections and testing.

2.2 Documentation

The following is a list of documentation that ships with the transmitter (in addition

to this manual):

a. Drawing Package with a complete set of prints for the transmitter. This

should have your transmitter model number printed on the front.

b. CD-ROM - There should be a CD-ROM accompanying this manual. It

contains:

1. An Acrobat (pdf) version of this manual. This is convenient as it allows

full search capability, color pictures and allows extra copies to be made

at any time.

2. An Acrobat (pdf) version of the Drawing Package with a linked index

for quick access. This also allows printing of extra copies or

replacements.

3. A copy of the transmitter control software of the same revision as

loaded into the transmitter at the factory.

4. Harris ISP (In-System Programming) software which is used to install

software upgrades into the transmitter controllers.

Page 32

2-2 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation / Initial Turn-On ATLAS Series™

2.2.1 Installation Drawings

It is recommended that you look through the drawing package to familiarize

yourself with the information available. Although drawings are provided for all

assemblies in the transmitter, most of the installation and planning information is

given in the following drawings (in the supplied drawing package):

a. Transmitter Outline Drawing - 843-5550-136 (843-5550-173 for DVL 4300

and 5700) Shows connections points for AC, control, coolant lines and rf output. Also gives cabinet dimensions, required cabinet clearances and a table of

basic requirements for all models.

b. AC Power Flow Diagram - Shows overall ac wiring and has information on

proper wire, fuse and breaker sizes as well as location of disconnects.

1. 843-5550-188 (sht 1) - DVL400 - DVL1100, 220/240Vac single phase

2. 843-5550-188 (sht 2) - DVL1500 - DVL3000, 380 - 415Vac 3 phase.

3. 843-5550-217 for DVL 4300 and 5700

c. RF Equipment Layout - Shows one possible placement of the transmitter RF

components based on minimum required clearances.

1. 843-5550-169, DVL400 - DVL2200 - Sheet 1 gives dimensions using

the Teracom filter while sheet 2 shows the Spinner filter.

2. 843-5550-171, DVL3000 - Sheet 1 gives dimensions using the

Teracom filter while sheet 2 shows the Spinner filter.

3. 843-5550-172 for DVL 4300 and 5700

d. Cooling System Layout - 843-5550-170 (843-5550-217 for DVL 4300 and

5700) Shows basic plumbing component locations and connections, flow rate

and pressure information as well as simplified cooling diagrams.

e. Electrical Installation Diagram - 843-5550-189 (843-5550-218 for DVL 4300

and 5700) Shows interconnect wiring between transmitter and all external

systems, including AC connections.

f. Cooling System Electrical Diagram - 843-5396-865 (3phase) and 843-5396-

880 (single phase) - Shows the internal workings of the Cooling Control

Panel and all interconnects with transmitter, pump module and heat

exchanger, including AC connections.

g. Transmitter Wiring Diagram - Interconnection wiring diagram for all

assemblies inside the transmitter cabinet. The wiring diagrams are model

dependent:

• 843-5550-102, DVL 400 up to DVL 1100 - Single Cabinet with 1 to 3 PA

Modules.

• 843-5550-154, DVL 1500, single cabinet with 4 PA modules

• 843-5550-004, DVL 2200 and DVL 3000 - Single Cabinet with 6 or 8 PA

Modules.

Page 33

2/25/03 888-2473-001 2-3

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation / Initial Turn-On

ATLAS Series™

• 843-5550-100, DVL 4300 and DVL 5700 - Additional PA Cabinet

Wiring Diagram. Only used with dual cabinet transmitters, this

schematic is used in addition to the 843-5550-004.

h. Pump Module Outline Drawing - 843-5550-175

i. Heat Exchanger Outline Drawing- 843-5550-176

2.3 Installation Checkboxes

Located to the left of each important step in the installation procedure is a checkbox

like the one to the left of this paragraph. As each step in the procedure is completed,

the box should be checked. This provides a quick confidence check at the end of the

procedure that no steps were skipped. The primary goal of each step is also in

bold letters, with the rest of the paragraph being support information toward that

goal.

NOTE:

In case of discrepancy between the connections listed in the schematics versus the information given in this installation section, the wiring information in

the schematics should be considered the most accurate. All connections listed

in this section should be verified with the schematics before initial turn on.

2.4 Transmitter Cabinet Placement

The transmitter cabinet should be placed where it will have approximately 1 meter

clearance on each side and in the back. The front of the transmitter should have a

clearance of at least 1.5 meters to allow access for removal and installation of the

PA and power supply modules. There are several equipment layout drawings

included in the drawing package to help plan the cabinet placement:

• 843-5550-136 (843-5550-173 for DVL 4300 and 5700) Transmitter

Outline Drawing

• 843-5550-169 171 (843-5550-172 for DVL 4300 and 5700) Rf

Equipment Layouts

• 843-5550-170 (843-5550-213 for DVL 4300 and 5700) - Cooling System

Layout

Remove the bolts holding the transmitter to the wooden pallet and carefully

slide the cabinet off the pallet.

Remove the front door from each cabinet and set it aside in a safe place for the

rest of the installation process.

Use shims or flat washers to make sure the transmitter is level and solid (not

rocking). For 2 cabinet systems, PA Cabinet 2 (the one without the control panel)

Page 34

2-4 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation / Initial Turn-On ATLAS Series™

should be placed on the right side of Cabinet 1 (looking from the front of the

transmitter). There are holes in the sides of the cabinets which should line up to

allow for interconnect wiring between the cabinets. One hole is approximately in

the middle and the other near the bottom (rear) of the cabinets.

NOTE:

Do not install the PA modules or the power supplies at this time. These will

be installed just before the initial turn on procedure.

2.5 Cooling System Installation

The major components of the Atlas cooling system include the pump module,

cooling control panel and heat exchanger. The following procedure will rely heavily

on the following schematics.

DVL 400 - DVL 3000:

a. Electrical Installation Diagram - 843-5550-189.

b. AC Power Flow Diagram- 843-5550-188.

c. Cooling System Electrical Diagram- 843-5396-865.

d. Cooling System Layout - 843-5550-170.

DVL 4300 &DVL 5700:

a. Electrical Installation Diagram - 843-5550-218.

b. AC Power Flow Diagram - 843-5550-217.

c. Cooling System Electrical Diagram - 843-5396-865.

d. Cooling System Layout - 843-5550-213.

When planning the installation, keep the following restrictions in mind:

a. The pump module cannot be placed more than 8 meters away from the trans-

mitter cabinet.

b. The pump module must be less than 8 meters away from the heat exchanger.

c. The cooling control panel should also be mounted relatively close to the

pump module, and no more than 3 meters away.

d. It would also be a good idea to have the front of the cooling control panel

visible while standing in front of the transmitter (this is not a requirement).

!

WARNING:

DISABLE AND LOCK OUT STATION PRIMARY POWER BEFORE PRIMARY

POWER CABLES ARE CONNECTED TO THE EQUIPMENT.

Page 35

2/25/03 888-2473-001 2-5

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation / Initial Turn-On

ATLAS Series™

Set the pump module in place and mount the cooling control panel. Use shims

or flat washers to make sure the pump module is level and solid (not rocking). The

cooling control panel should be mounted to a solid surface, or structure, able to

withstand the minor vibration of the contactors without coming loose.

Connect one conduit from the control panel to the pump module and one to the

heat exchanger for AC wiring. Depending on local wiring codes and personal

preference, another set of conduit runs may be installed for the control and status

wires to the pump module and the heat exchanger. The small signal wires and the

AC wiring should never be run in the same conduit.

Open the Isolator switches on the cooling control panel, pump module and heat

exchanger. This will allow them to be closed one at a time later to check for wiring

problems.

Connect the AC wiring between the cooling control panel and the pump

module and heat exchanger. Follow the AC Power Flow Diagrams and Electrical

Installation Diagrams mentioned at the beginning of this section. All AC

connections are connected to terminals labeled X1.

Connect the control and status wires between the cooling control panel and the

pump module with the supplied 16-2-12C (screened) multi-conductor cable.

These connections are on Electrical Installation Drawing, 843-5550-189 or 8435550-218. These low level signals connect from terminals X1-8 thru X1-15 in the

pump module to X2-21 thru X2-28 in the cooling control panel. Table 2-1 is a

connection reference chart.

Connect the control and status wires between the cooling control panel and the

heat exchanger with the supplied 16-2-12C (screened) multi-conductor cable.

These connections are on the Electrical Installation Drawing. These low level

Table 2-1 Pump Module Control and Status Connections

Cooling Control Panel Pump Module

X2-21 X1-8

X2-22 X1-9

X2-23 X1-10

X2-24 X1-11

X2-25 X1-12

X2-26 X1-13

X2-27 X1-14

X2-28 X1-15

These connections should be verified using Schematic

#843-5550-189 or 843-5550-218

Page 36

2-6 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation / Initial Turn-On ATLAS Series™

signals connect from terminals X1-8 thru X1-15 in the heat exchanger to X2-13 thru

X2-20 in the cooling control panel. Table 2-2 is a connection reference chart.

NOTE:

Condensation can occur in the conduit leading to the outside heat exchanger

from the control panel. This conduit should be caulked or sealed after the system is tested and operational.

Connect the control and status wires between the cooling control panel and the

transmitter with the supplied 16-2-12C (screened) multi-conductor cable.

These low level signals connect from terminals X2-1 thru X2-12 in the cooling

control panel to J12-1 thru J12-12 on the External I/O board in the transmitter (pin

for pin connection).

Connect the test load flow switch to J18-9 and J18-10 on the External I/O

board in the transmitter. This will mute the transmitter rf output if there is no

coolant flow through the test load (provided the U-Link is in position 2, transmitter

to test load). Specified wire is 7-2-4C, 4 conductor cable. A closed contact is

required to operate the transmitter. Some switches may also use +15V and ground.

The connections are as follows:

• J18-9 to flow switch terminal 1 (common)

• J18-10 to flow switch terminal 3 (N.O.)

Depending on the switch the following may also be required:

• J11-1 (+15Vdc) to flow switch terminal 2 (+DC)

• J11-6 (ground) to flow switch terminal 4 (-DC)

Table 2-2 Heat Exchanger Control and Status Connections

Cooling Control Panel Heat Exchanger

X2-13 X1-8

X2-14 X1-9

X2-15 X1-10

X2-16 X1-11

X2-17 (2 conductors) X1-13 (2 conductors)

X2-18 (2 conductors) X1-14 (2 conductors)

X2-19 (2 conductors) X1-15 (2 conductors)

X2-20 X1-12(GND)

These connections should be verified using Schematic

#843-5550-189 or 843-5550-218

The Gray rows require

2 conductors be used

on each terminal for

current capacity.

NOTE:

Page 37

2/25/03 888-2473-001 2-7

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation / Initial Turn-On

ATLAS Series™

If there is a temperature overload switch on the test load, (as would be the case

for an air cooled load) it should be connected to J18-11 and J18-12. This will

mute the transmitter rf output if the test load temperature threshold is exceeded. A

closed contact is required to operate the transmitter. A jumper is installed at the

factory which must be removed to use this input.

For the DVL 4300 and DVL 5700only, connect the cabinet combiner reject

load coolant flow switch. The DVL 4300 and DVL 5700 use a liquid cooled reject

load for the cabinet combiner. The flow switch connection, as shown on drawing

#843-5550-218, will mute the transmitter rf output if there is no coolant flow

through the reject load. Specified wire is 7-2-4C, 4 conductor cable. A closed

contact is required to operate the transmitter. Some switches may also use +15V and

ground. The connections are as follows:

• J18-11 to flow switch terminal 1 (common)

• J18-12 to flow switch terminal 3 (N.O.)

Depending on the switch the following may also be required:

• J11-1 (+15Vdc) to flow switch terminal 2 (+DC)

• J11-6 (ground) to flow switch terminal 4 (-DC)

2.6 Transmitter AC Connection

For Conduit connections to the transmitter refer to Figure 2-1 or the Transmitter

Outline Drawing 843-5550-136 (or 843-5550-173 for DVL 4300 & DVL 5700),

Top View.

!

WARNING:

DISABLE AND LOCK OUT STATION PRIMARY POWER BEFORE PRIMARY

POWER CABLES ARE CONNECTED TO THE EQUIPMENT.

NOTE:

The 3 phase version of the Atlas transmitter uses a stepdown transformer for

all single phase loads in the transmitter, therefore no neutral connection is

required in the cabinet. DO NOT run a neutral connection to the transmit-

ter as there is no connection point and the neutral should not be connected to the cabinet ground. A safety ground wire is required and connects

to E10 which is shown in Figure 2-2 on page 2-9.

Page 38

2-8 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation / Initial Turn-On ATLAS Series™

The DVL1500 -DVL5700 models are 3 phase 380/400/415Vac at 50/60Hz delta or

wye. The DVL400 - DVL1100 models are equipped for single phase 220/240Vac at

50/60Hz. If voltage variations in excess of +10/-15% are anticipated, the transmitter

power input must be equipped with automatic voltage regulators (optional

equipment) capable of correcting the mains voltage.

NOTE:

It is important that the correct voltage be specified as the MOV protection

components are different for delta, wye or single phase configurations.

Connect the Primary AC conduit to the top of the transmitter cabinet.

The top of the transmitter cabinet has pre-cut holes for conduit connections as

shown in the outline drawing. The AC input is routed down through the hollow

space on the left side of the transmitter cabinet and out through a hole near the base

of the cabinet and up to the front of the cabinet behind the breaker panel.

Figure 2-1 Conduit Connections and AC Wiring

Connect the AC wires to the primary AC disconnect switch S3.

For 3 phase or single phase, the AC input wires will connect to the AC disconnect

switch S3, located on the front of the transmitter in the lower left-hand corner. It

will be necessary to unscrew the breaker panel to make the connection to AC

disconnect switch S3 as shown in Figure 2-2.

Connect the safety ground wire to terminal E10, shown in Figure 2-2. Replace

the breaker panel when finished.

Coolant Supply

Coolant Return

Ext I/O

AC IN

1 5/8 EIA RF Output

Exhaust

Air

Page 39

2/25/03 888-2473-001 2-9

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation / Initial Turn-On

ATLAS Series™

Figure 2-2 AC Connection to AC Disconnect Switch, S3

Verify that the Primary AC line voltage is correct for the installed MOV

board. Measure the primary AC line voltage from phase to phase and write it in the

blank below. The transmitter was setup in the factory with a 380/400/415Vac Delta

or WYE 3 phase, or 220/240Vac single phase configured MOV board. Make sure

that the transmitter is setup for the same power configuration used at the site by

checking the factory test data sheet.

VAC

NOTE:

There must be less than a 5% imbalance between the phases to allow the

transmitter to operate.

Verify that the single phase step-down transformer is tapped correctly. This

step is not required on single phase transmitters. Step-down transformer T1

reduces the 380/400/415Vac down to 220Vac for the transmitter low voltage power

supplies, fans and exciters. Using the voltage measured above, check the primary

tapping of T1. TB4 is used to re-tap the transformer if necessary, by moving wire

#58. Figure 2-3 shows a chart of the 3 possible tap positions. The transformer is

located in the bottom rear section of the PA cabinet.

Figure 2-3 Tapping Stepdown Transformer, T1, using TB4

Safety Ground Connection

E10

Primary Line

Voltage

380Vac

400Vac

415Vac

Wire #58 TAP

on TB4

Terminal 5

Terminal 4

Terminal 3

Also shown on

843-5550-004

Wiring Diagram

Page 40

2-10 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation / Initial Turn-On ATLAS Series™

2.7 Second PA Cabinet Interconnections

NOTE:

The following only applies to the DVL 4300 and the DVL 5700 transmitters

which have an additional PA Cabinet (Cabinet 2).

The following interconnects will have to be made between from the Main PA/

Control cabinet (called Cabinet 1) to the Additional PA Cabinet (called Cabinet 2).

This information is found on schematics 843-5550-004 and 843-5550-100. The

following cables are labeled and already have one end connected to Cabinet 1 where

they were bundled for shipping. The cables should be routed through the

appropriate hole between the cabinets for connection to Cabinet 2.

Connect the 220VAC from the stepdown transformer in Cabinet 1, to TB2 in

Cabinet 2 for the low voltage supplies. The connections are as follows:

• Wire W61 connects from TB2 terminal #3 in Cabinet 1 to TB2 terminal #1 in

Cabinet 2.

• Wire W62 connects from TB2 terminal #6 in Cabinet 1 to TB2 terminal #4 in

Cabinet 2.

Connect the 3 phase ac wiring from TB1 in Cabinet 1 to TB1 in Cabinet 2. The

connections are as follows:

• Wire #21 connects from TB1-3 in Cabinet 1 to TB1-3 in Cabinet 2.

• Wire #22 connects from TB1-7 in Cabinet 1 to TB1-8 in Cabinet 2.

• Wire #23 connects from TB1-11 in Cabinet 1 to TB1-13 in Cabinet 2.

Route the ground strap between the 2 cabinets and secure under the brass

blocks provided.

Connect coaxial cable W57 from DCU connector J8 in Cabinet 1, to J1 on the

Backplane Interface board in Cabinet 2.

Connect the Control Bus (ribbon cable) W56 from Backplane Interface J17 in

Cabinet 1 to the Backplane Interface J17 in Cabinet 2. This connects the CAN

bus and parallel control lines to the PA Modules, RF Monitor and PS Monitor

boards.

Page 41

2/25/03 888-2473-001 2-11

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation / Initial Turn-On

ATLAS Series™

2.8 Signal and Ground Connections

NOTE:

Control and signal wires should never be run in the same conduit with any

AC wiring. A separate conduit should be used for control and signal cables.

Connect an MPEG Transport Stream DVB ASI input to each exciter.

Depending on purchased options, each exciter also has inputs for a GPS Aerial, 1

PPS input, 10MHz Reference and Demodulator A. For more information refer to

the V-XCAST exciter manual.

Connect the sample cables from the Forward and

Reflected directional couplers at the system output

(after the filter). These samples connect to a small

Customer I/O panel, with 2 "N" style connectors,

mounted to the ceiling of the cabinet. J1 is for Total

Forward and J2 is for Total Reflected. If necessary, these

samples will be calibrated using the GUI after initial

turn-on. These cables are not supplied since the required

length is determined at each site. For 2 cabinet systems

see 2.10.1 RF Sample Connections.

Connect a ground strap from the transmitter cabinet

E7 to the station ground. There is a brass ground block

located in the center of the cabinet. Remove the block,

punch holes in the copper ground strap and then mount

the strap under the block. The copper strap must be at

least 5cm wide and 0.5mm thick.

2.9 External Interlock Connections

The transmitter has inputs for up to four external interlocks on the External I/O

Board. More may be used by placing 2 or more interlocks in series. The transmitter

is shipped from the factory with jumpers in the External Interlock positions which

will allow the transmitter to operate with no external interlock connections. The

electrical installation drawing (843-5550-189 or 843-5550-218) shows that

Interlock #1, J18-1 to J18-2, is used by the 3 Port U-Link Panel or possibly a

motorized switch. The other three are to be used at the customers discretion. The

External Interlock circuit requires a closed connection between all of the following

terminals on the External I/O Board to turn the transmitter on:

• J18 pins 1-2 (connected to 3 Port U-Link Panel or switch)

• J18 pins 3-4

• J18 pins 5-6

• J18 pins 7-8

Page 42

2-12 888-2473-001 2/25/03

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation / Initial Turn-On ATLAS Series™

2.10 Cabinet Combiner Connections

(DVL 4300 and 5700 only)

Drawing #843-5550-172 shows one possible layout of the rf equipment for the high

power systems. This includes the connections and locations of the hybrid combiner,

reject load, filter and patch panel.

Each PA cabinet has a 1 5/8" rf output line which connects to the hybrid combiner.

The hybrid is marked for Cabinet1, Cabinet 2, Output and Reject Load connections.

NOTE:

It is very important that the cabinets be connected to the correct hybrid port.

If they are reversed then all of the power will end up in the reject load port. If

this happens, the drive cables (W57 and 73) at the output of the DCU should

be reversed as well.

Precision directional couplers for measuring forward and reflected power should be

installed both before the filter and at the system output for measuring and

calibrating power. If the precision couplers are supplied by Harris, they will come

with a coupling chart which can be used for calbration purposes.

2.10.1 RF Sample Connections

Connect the RF Sample from the cabinet combiner reject load to J17 of the RF

monitor board in Cabinet 1. The hybrid combiner reject load is a water cooled

load which should also have an rf sample port between it and the hybrid. This

sample coupler is labeled DC4 on the 843-5550-100 Additional Cabinet Wiring

Diagram. This sample is used for Cabinet Phasing. This cable is not included since

the required length is determined at each site.

Connect the System Forward and Reflected directional coupler to the

transmitter. These samples connect to a small Customer I/O panel, with 2 "N" style

connectors, mounted to the ceiling of the cabinet. J1 is for Total Forward and J2 is

for Total Reflected. If necessary, these samples will be calibrated using the GUI

after initial turn-on. These cables are not supplied since the required length is

determined at each site.

NOTE:

For 2 cabinet systems these samples can be taken at DC3 (directional coupler

3) which is after the cabinet combiner but before the filter or can be connected to the directional coupler after the filter. The choice of which sample

to use is to be decided by the customer or by site requirements.

Page 43

2/25/03 888-2473-001 2-13

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation / Initial Turn-On

ATLAS Series™