Harris DA-DHR6804+D, DA-DH6804+D, DA-DSR6804+D, DA-DS6804+D, DA-HRO6804+D Installation And Operation Manual

...Page 1

DA-6804+D Series

Single- and Dual-Channel 3 Gb/s-SDI/HD-SDI/

SD-SDI Power Saving Distribution Amplifiers

Installation and Operation Manual

Edition A

175-100192-00

Page 2

Page 3

Preliminary—Contents are proprietary and confidential. Do not photocopy or distribute.

DA-DHR6804+D

Dual 1×4 3-Gb/s HD-SDI Distribution Amplifiers with Reclocking

DA-DH6804+D

Dual 1×4 3-Gb/s HD-SDI Distribution Amplifiers

DA-DSR6804+D

Dual 1×4 SD-SDI Distribution Amplifiers with Reclocking

DA-DS6804+D

Dual 1×4 SD-SDI Distribution Amplifiers

DA-HRO6804+D

3 Gb/s-SDI/HD-SDI/SD-SDI Dual Channel Optical and Electrical

Distribution Amplifiers

DA-DHROE6804+D

3 Gb/s-SDI/HD-SDI/SD-SDI Dual Channel Optical to Electrical

Distribution Amplifiers

DA-DHREO6804+D

3 Gb/s-SDI/HD-SDI/SD-SDI Dual Channel Electrical to Optical

Distribution Amplifiers

DA-DHROO6804+D

3 Gb/s-SDI/HD-SDI/SD-SDI Dual Channel Optical Distribution

Amplifiers with Dual Electrical Output

Installation and Operation Manual

Edition A

February 2010

Page 4

Copyright

Information

Copyright © 2010 Harris Corporation, 1025 West NASA Boulevard, Melbourne,

Florida 32919-0001 U.S.A. All rights reserved. This publication supersedes all

previous releases. Printed in Canada.

This product and related documentation are protected by copyright and are

distributed under licenses restricting their use, copying, distribution, and

decompilation. No part of this product or related documentation may be

reproduced in any form by any means without prior written authorization of Harris

Corporation and its licensors, if any.

This publication could include technical inaccuracies or typographical errors.

Changes are periodically added to the information herein; these changes will be

incorporated into new editions of the publication. Harris Corporation may make

improvements and/or changes in the product(s) and/or the program(s) described in

this publication at any time.

Warranty

Information

The limited warranty policy provides a complete description of your warranty

coverage, limitations, and exclusions, as well as procedures for obtaining warranty

service. To view the complete warranty, visit our website.

This publication is provided “as is” without warranty of any kind, either express or

implied, including, but not limited to, the implied warranties of merchantability,

fitness for a particular purpose, or non-infringement.

Page 5

Contents

About This Manual

Intended Audience ............................................................................................ vii

Finding Specific Information in This Guide ........................................................viii

Manual Information ......................................................................................... viii

Revision History ......................................................................................... viii

Writing Conventions ...................................................................................ix

Obtaining Documents .................................................................................ix

Unpacking/Shipping Information ........................................................................ix

Unpacking a Product ...................................................................................ix

Product Servicing ..........................................................................................x

Returning a Product .....................................................................................x

Safety Standards and Compliances ......................................................................x

Safety Terms and Symbols ............................................................................x

Restriction on Hazardous Substances (RoHS) Directive .................................xi

Waste from Electrical and Electronic Equipment

(WEEE) Directive ..........................................................................................xi

iii

Introduction

Main Features .................................................................................................... 3

DA-DHR6804+D .......................................................................................... 3

DA-DH6804+D ............................................................................................ 4

DA-DSR6804+D .......................................................................................... 5

DA-DS6804+D ............................................................................................ 7

DA-HRO6804+D .......................................................................................... 8

DA-DHROE6804+D ..................................................................................... 9

DA-DHREO6804+D ................................................................................... 10

DA-DHROO6804+D ................................................................................... 12

Product Views .................................................................................................. 14

Front Module ............................................................................................ 14

Back Modules ............................................................................................14

Rear View ..................................................................................................15

Maximum 6800+ Frame Power Ratings ..................................................... 15

Copyright © 2010, Harris Corporation

Page 6

Contents

iv

Installation

Checking the Packing List ................................................................................ 18

Setup Procedures ............................................................................................. 20

Setting Up a Frame .................................................................................... 20

Setting Up Back Connector Modules ......................................................... 21

Setting Up Front Modules .......................................................................... 22

Installing and Removing Modules ..................................................................... 24

Back Module Installation ........................................................................... 24

Front Module Installation ........................................................................... 25

Removing Modules ....................................................................................25

Operation

LED Displays ..................................................................................................... 28

System Status Indicators ............................................................................ 28

Signal Condition Indicators ........................................................................ 28

Alarms ...................................................................................................... 29

Web-Enabled Display and Control .................................................................... 31

CCS Navigator Display and Control .................................................................. 33

Operating Notes .............................................................................................. 34

Setting Locally Controlled Parameters ............................................................... 34

Setting Remotely Controlled Parameters ........................................................... 34

Changing Parameter Settings............................................................................47

Recalling Default Parameter Settings ......................................................... 47

Reading the Software and Hardware Versions ........................................... 47

Copyright © 2010, Harris Corporation

Specifications

Inputs ............................................................................................................... 49

Outputs ........................................................................................................... 51

Temperature..................................................................................................... 52

Power Consumption ......................................................................................... 52

Start-Up Time ................................................................................................... 52

Appendix: Laser Safety Guidelines

General Laser Information ................................................................................54

Lasers and Eye Damage..................................................................................... 54

Classification of Lasers ..................................................................................... 55

Laser Safety Precautions for Optical Fiber Communication Systems ................... 55

Laser Safety ............................................................................................... 55

Precautions for Enclosed Systems .............................................................. 56

Precautions for Unenclosed Systems .......................................................... 56

Specifications.................................................................................................... 57

Page 7

DA-HR/DHR/DH/DSR/DS6804+D

Installation and Operation Manual

Appendix: Inspecting and Cleaning Fiber Optic

Connections

Important Points .............................................................................................. 60

Inspection ........................................................................................................ 61

Dry Cleaning.................................................................................................... 61

Wet Cleaning.................................................................................................... 61

Index

Keywords ......................................................................................................... 63

v

Copyright © 2010, Harris Corporation

Page 8

Contents

vi

Copyright © 2010, Harris Corporation

Page 9

About This Manual

This manual details the features, installation procedures, operational procedures,

and specifications of the following DA-6804+series distribution amplifiers:

DA-DHR6804+D: Dual 1×4 3-Gb/s HD-SDI distribution amplifiers with

reclocking

DA-DH6804+D: Dual 1×4 3-Gb/s HD-SDI distribution amplifiers

DA-DSR6804+D: Dual 1×4 SD-SDI distribution amplifiers with reclocking

DA-DS6804+D: Dual 1×4 SD-SDI distribution amplifiers

DA-HRO6804+D: 3 Gb/s HD-SDI optical and electrical distribution amplifier

DA-DHROE6804+D: 3 Gb/s HD-SDI dual channel optical to electrical

distribution amplifier

DA-DHREO6804+D: 3 Gb/s HD-SDI dual channel electrical to optical

distribution amplifier

DA-DHROO6804+D: 3 Gb/s HD-SDI dual channel optical distribution

amplifier with dual electrical output

vii

Intended

Audience

About This Manual provides an overview of this installation and operation manual,

describes manual conventions, and tells you where to look for specific information.

This section also gives you important information on unpacking and shipping your

product.

This manual is written for engineers, technicians, and operators responsible for the

installation, setup, and/or operation of the DA-6804+ series of distribution

amplifiers.

Copyright © 2010, Harris Corporation

Page 10

viii

About This Manual

Finding

Specific

Information

in This Guide

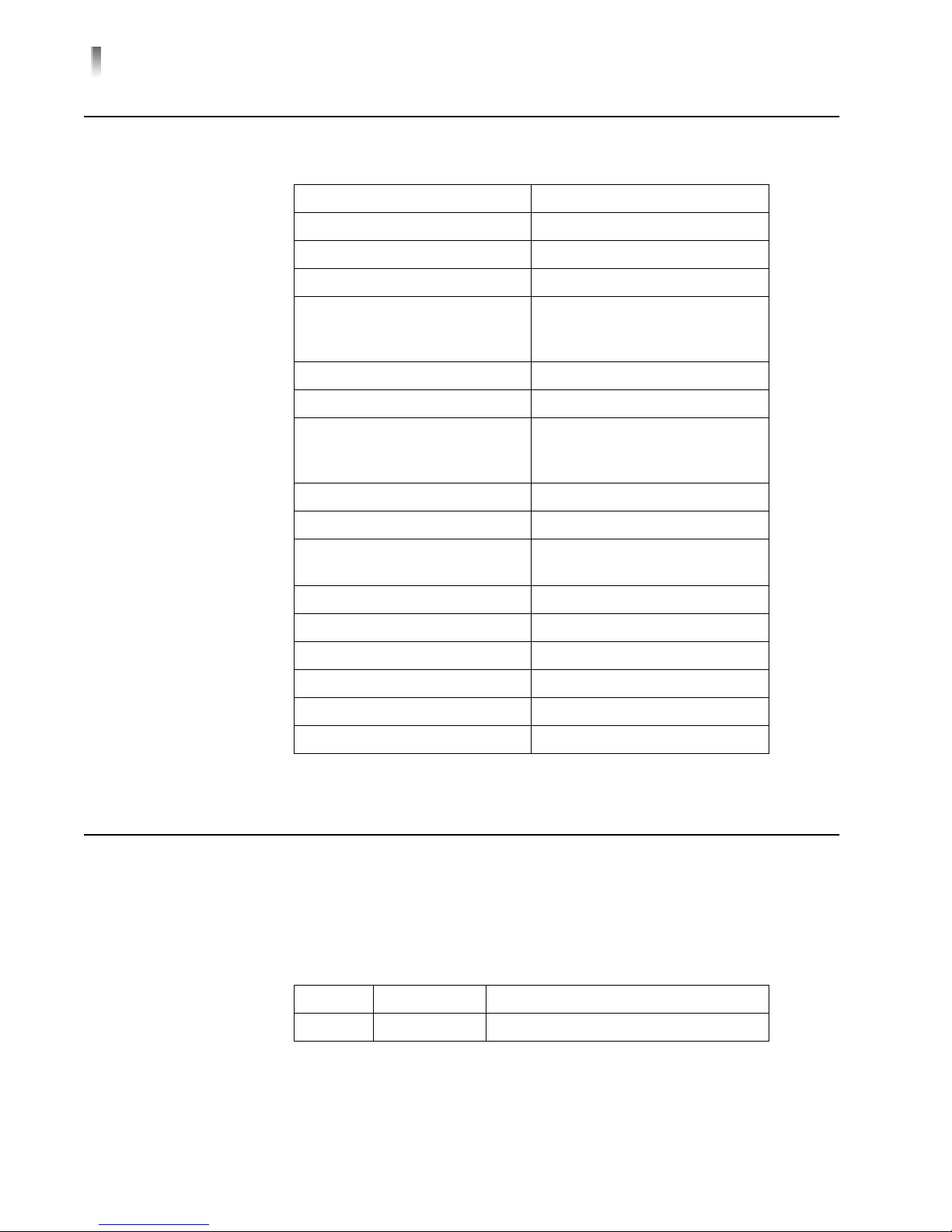

Table P-1 shows the location of specific information in this guide.

Table P-1 Finding Specific Information in this Guide

If you are looking for Go to

Alarms Chapter 3, Operation

Back panel connections Chapter 1, Introduction

Back connector setup Chapter 2, Installation

Cleaning fiber optic connections Appendix B, Inspecting and

Cleaning Fiber Optic

Connections

Frame setup Chapter 2, Installation

Front panel interface Chapter 1, Introduction

Inspecting fiber optic connections Appendix B, Inspecting and

Cleaning Fiber Optic

Connections

Installing and removing modules Chapter 2, Installation

Key features Chapter 1, Introduction

Laser safety guidelines Appendix A, Laser Safety

Guidelines

Manual

Information

Revision History

Power ratings Chapter 2, Installation

Rack mounting instructions Chapter 2, Installation

Setting jumpers Chapter 2, Installation

Setting parameters Chapter 3, Operation

Signal flow Chapter 1, Introduction

Specifications Chapter 4, Specifications

This section provides information about the revision history of the manual, writing

conventions used for ease of understanding as well as for navigation throughout

the document, and information about obtaining

Table P-2 Manual Revision History

Edition Date Revision History

A February 2010 Initial release

Copyright © 2010, Harris Corporation

Page 11

DA-6804+D Series

Installation and Operation Manual

ix

Writing

Conventions

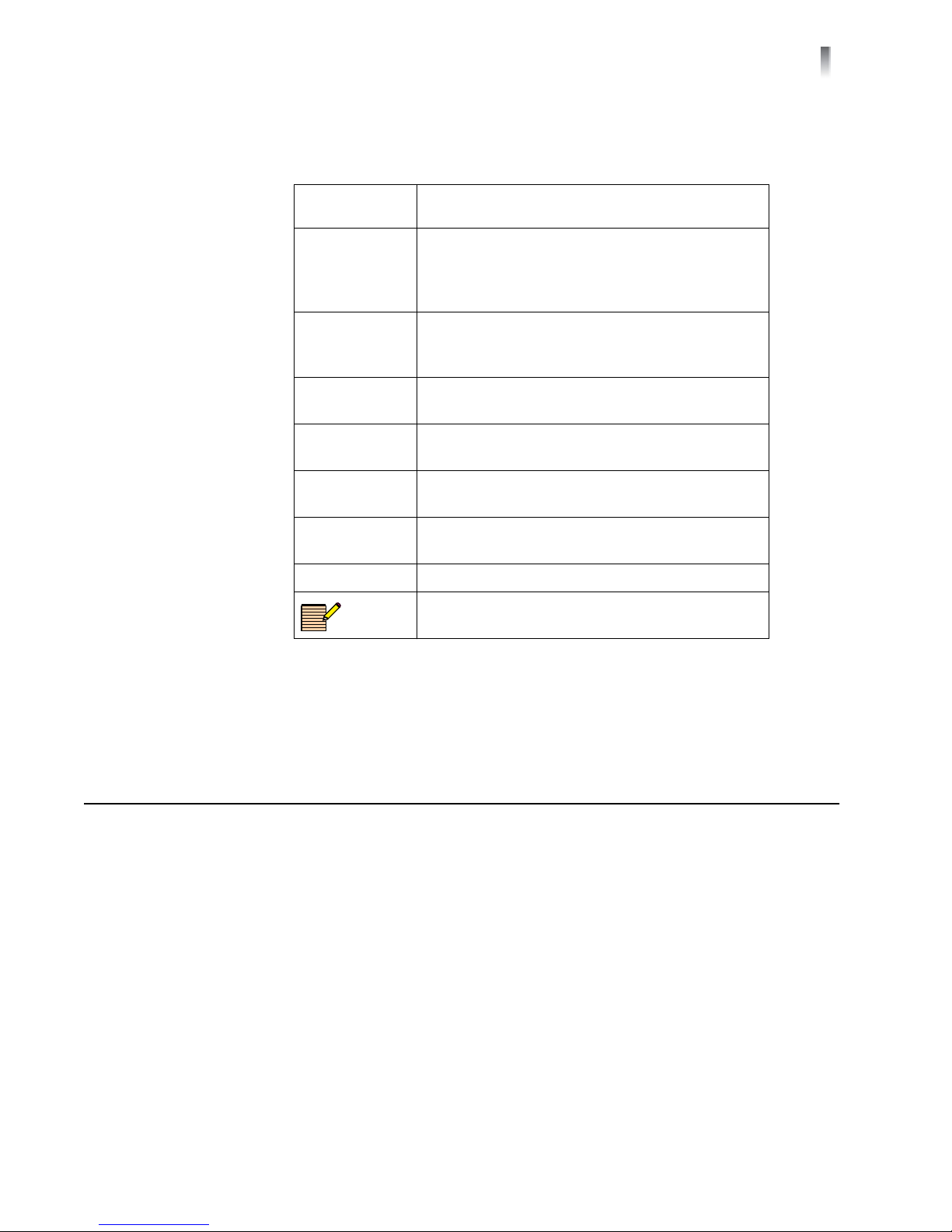

To enhance your understanding, the authors of this manual have adhered to the

following text conventions:

Table P-3 Manual Style and Writing Conventions

Term or

Convention

Bold Indicates dialog boxes, property sheets, fields,

Italics Indicates email addresses, the names of books or

CAPS Indicates a specific key on the keyboard, such as

Code

> Indicates the direction of navigation through a

hyperlink Indicates a jump to another location within the

Description

buttons, check boxes, list boxes, combo boxes,

menus, submenus, windows, lists, and selection

names

publications, and the first instances of new terms

and specialized words that need emphasis

ENTER, TAB, CTRL, ALT, or DELETE

Indicates variables or command-line entries, such as

a DOS entry or something you type into a field

hierarchy of menus and windows

electronic document or elsewhere

Obtaining

Documents

Unpacking/

Shipping

Information

Unpacking a

Product

Internet address Indicates a jump to a website or URL

NOTE:

Technical documents can be viewed or downloaded from our website.

Alternatively, contact your Customer Service representative to request a document.

This product was carefully inspected, tested, and calibrated before shipment to

ensure years of stable and trouble free service.

1 Check equipment for any visible damage that may have occurred during

transit.

2 Confirm that you have received all items listed on the packing list.

3 Contact your dealer if any item on the packing list is missing.

4 Contact the carrier if any item is damaged.

5 Remove all packaging material from the product and its associated

components before you install the unit.

Indicates important information that helps to avoid

and troubleshoot problems

Copyright © 2010, Harris Corporation

Page 12

About This Manual

x

Product Servicing

Returning a

Product

DA-6804+ series modules are not designed for field servicing. All hardware and

firmware upgrades, modifications, or repairs require you to return the modules to

the Customer Service center.

In the unlikely event that your product fails to operate properly, please contact

Customer Service to obtain a Return Authorization (RA) number, and then send

the unit back for servicing.

Keep at least one set of original packaging, in the event that you need to return a

product for servicing. If the original packaging is not available, you can purchase

replacement packaging at a modest cost or supply your own packaging as long as

it meets the following criteria:

Withstands the weight of the product

Holds the product rigid within the packaging

Leaves at least two inches of space between the product and the container

Protects the corners of the product

Ship products back to us for servicing prepaid and, if possible, in the original

packaging material. If the product is still within the warranty period, we will return

the product prepaid after servicing.

Safety

Standards

and

Compliances

Safety Terms and

Symbols

See the 6800+ Safety Instructions and Standards Manual to find the safety

standards and compliances for this 6800+ series product. A safety manual is

shipped with every FR6802+ Frame Installation and Operation Manual and

can be downloaded from our website. Alternatively, contact your Customer Service

representative for a copy of this safety manual.

This product manual uses the following safety terms and symbols to identify

certain conditions or practices. See the 6800+ Safety Instructions and

Standards Manual for more information.

Table P-4 Safety Terms and Symbols

Symbol Description

WARNING: Identifies conditions or practices that can result in

personal injury or loss of life — high voltage is present.

Uninsulated dangerous voltage within the product’s enclosure

may be sufficient to constitute a risk of electric shock to

persons.

CAUTION: Identifies conditions or practices that can result in

damage to the equipment or other property. Important

operating and maintenance (servicing) instructions are

included in the literature accompanying the product.

Copyright © 2010, Harris Corporation

Page 13

DA-6804+D Series

Installation and Operation Manual

xi

Restriction on

Hazardous

Substances

(RoHS) Directive

Directive 2002/95/EC — commonly known as the European Union (EU) Restriction

on Hazardous Substances (RoHS) — sets limits on the use of certain substances

found in electrical and electronic equipment. The intent of this legislation is to

reduce the amount of hazardous chemicals that may leach out of landfill sites or

otherwise contaminate the environment during end-of-life recycling. The Directive,

which took effect on July 1, 2006, refers to the following hazardous substances:

Lead (Pb)

Mercury (Hg)

Cadmium (Cd)

Hexavalent Chromium (Cr-V1)

Polybrominated Biphenyls (PBB)

Polybrominated Diphenyl Ethers (PBDE)

In accordance with this EU Directive, products sold in the European Union will be

fully RoHS-compliant and “lead-free.” Spare parts supplied for the repair and

upgrade of equipment sold before July 1, 2006 are exempt from the legislation.

Equipment that complies with the EU directive will be marked with a

RoHS-compliant symbol, as shown in Figure P-1.

Waste from

Electrical and

Electronic

Equipment

(WEEE) Directive

Figure P-1 RoHS Compliance Symbol

The European Union (EU) Directive 2002/96 /EC on Waste from Electrical and

Electronic Equipment (WEEE) deals with the collection, treatment, recovery, and

recycling of electrical and electronic waste products. The objective of the WEEE

Directive is to assign the responsibility for the disposal of associated hazardous

waste to either the producers or users of these products. As of August 13, 2005,

producers or users are required to recycle electrical and electronic equipment at

end of its useful life, and must not dispose of the equipment in landfills or by using

other unapproved methods. (Some EU member states may have different

deadlines.)

In accordance with this EU Directive, companies selling electric or electronic devices

in the EU will affix labels indicating that such products must be properly recycled.

Contact your local Sales representative for information on returning these products

for recycling. Equipment that complies with the EU directive will be marked with a

WEEE-compliant symbol, as shown in Figure P-2.

Copyright © 2010, Harris Corporation

Page 14

About This Manual

xii

Figure P-2 WEEE Compliance Symbol

Copyright © 2010, Harris Corporation

Page 15

1

1

Introduction

The DA-6804+D series of distribution amplifiers is designed to distribute serial

digital signals according to SMPTE259C, 292M, 424M and DVB-ASI standards.

The individual modules are available as follows:

DA-DHR6804+D is a dual channel 3 Gb/s HD/SD-SDI distribution amplifier

with reclocking. See page 3 for a list of its main features.

DA-DH6804+D is a dual channel 3 Gb/s HD/SD-SDI distribution amplifier. See

page 4 for a list of its main features.

DA-DSR6804+D is a dual channel SD-SDI distribution amplifier with

reclocking. See page 5 for a list of its main features.

DA-DS6804+D is a dual channel SD-SDI distribution amplifier. See page 7 for a

list of its main features.

DA-HRO6804+D is a 3 Gb/s HD/SD-SDI single channel optical to electrical and

electrical to optical converting distribution amplifier. See page 8 for a list of its

main features.

DA-DHROE6804+D is a 3 Gb/s HD/SD-SDI dual channel optical to electrical

converting distribution amplifier. See page 9 for a list of its main features.

DA-DHREO6804+D is a 3 Gb/s HD/SD-SDI dual channel electrical to optical

converting distribution amplifier. See page 10 for a list of its main features.

DA-DHROO6804+D is a 3 Gb/s HD/SD-SDI dual channel optical distribution

amplifier with dual electrical outputs. See page 12 for a list of its main

features.

Each distribution amplifier consists of a front module and a back module, and

operates in FR6802+ series frames.

Each distribution amplifier, with its corresponding back module, occupies two slots

in the frame. Ten distribution amplifiers can be loaded in a frame.

Each distribution amplifier contains two inputs and eight outputs, and can be

configured as a single channel (1×8_ACO or 1×8) or two independent channels

(2_1×4). Each FR6802+ frame can provide up to 20 channels for serial digital

signal distribution.

The DA-6804+D series is featured as “green” (power saving). The power can be

shut down automatically if no input signal is detected. Power consumption should

be reduced if any output BNC is not terminated.

Copyright © 2010, Harris Corporation

Page 16

2

Chapter 1

Introduction

The setup, control, and monitoring can be controlled locally via jumpers on the

front edge of the front module with LED display; or remotely via RS-232 ports or

Ethernet connection using an ICE6800+ and 6800+ETH Ethernet connection and

Harris CCS control software. CCS remote control provides additional control

functions that are not included in local control mode.

Copyright © 2010, Harris Corporation

Page 17

DA-6804+D Series

Installation and Operation Manual

3

Main

Features

DA-DHR6804+D

This section provides the main features for each of the DA-6804+D series of

distribution amplifiers.

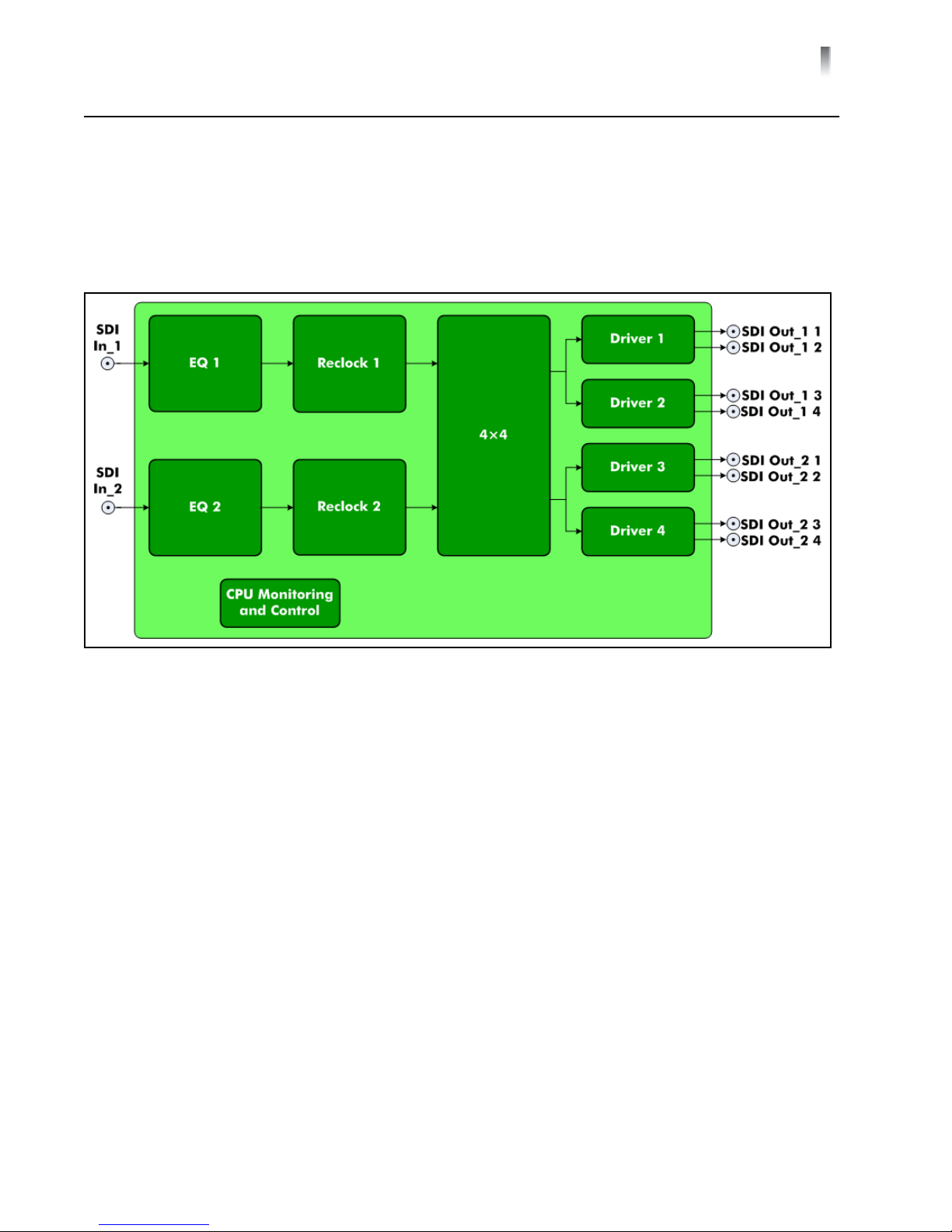

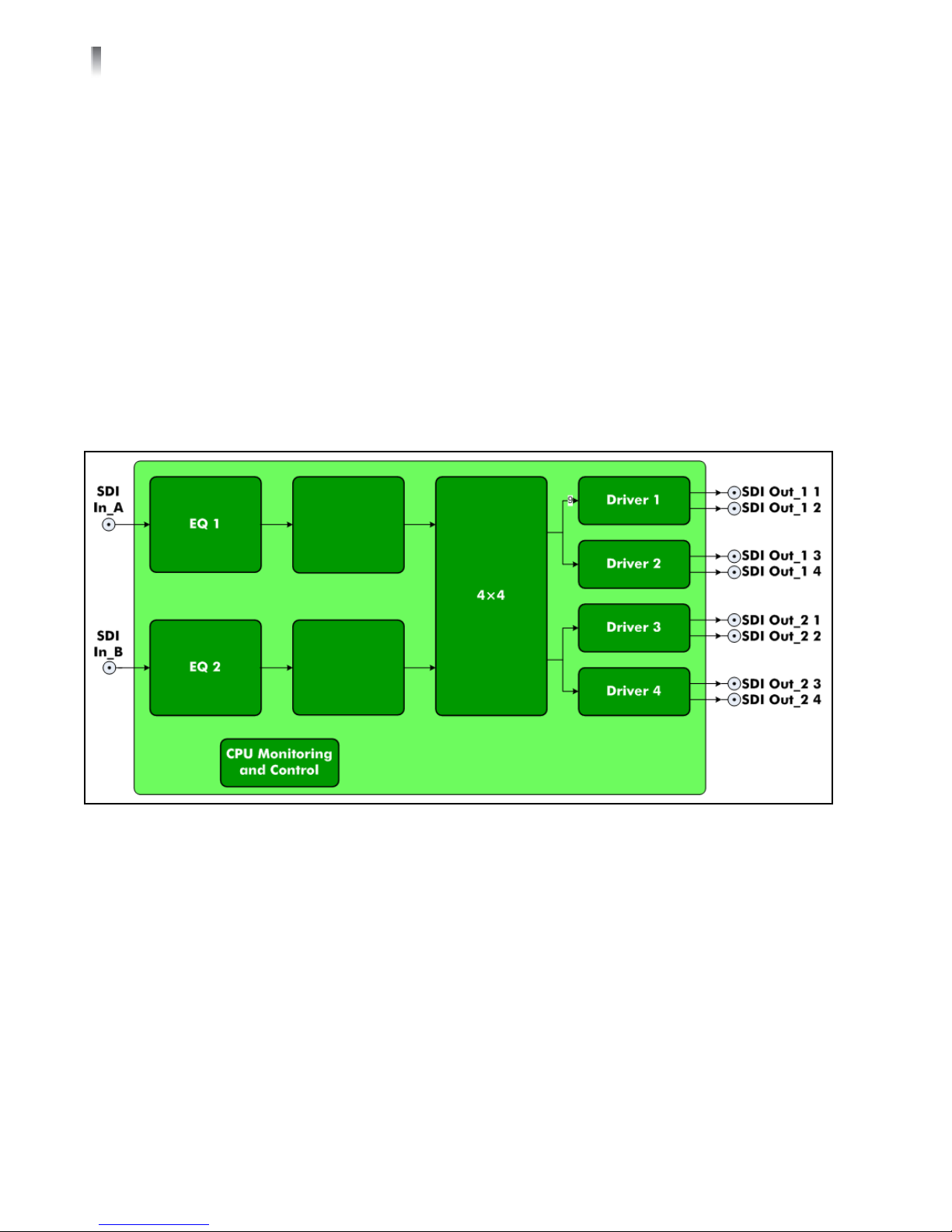

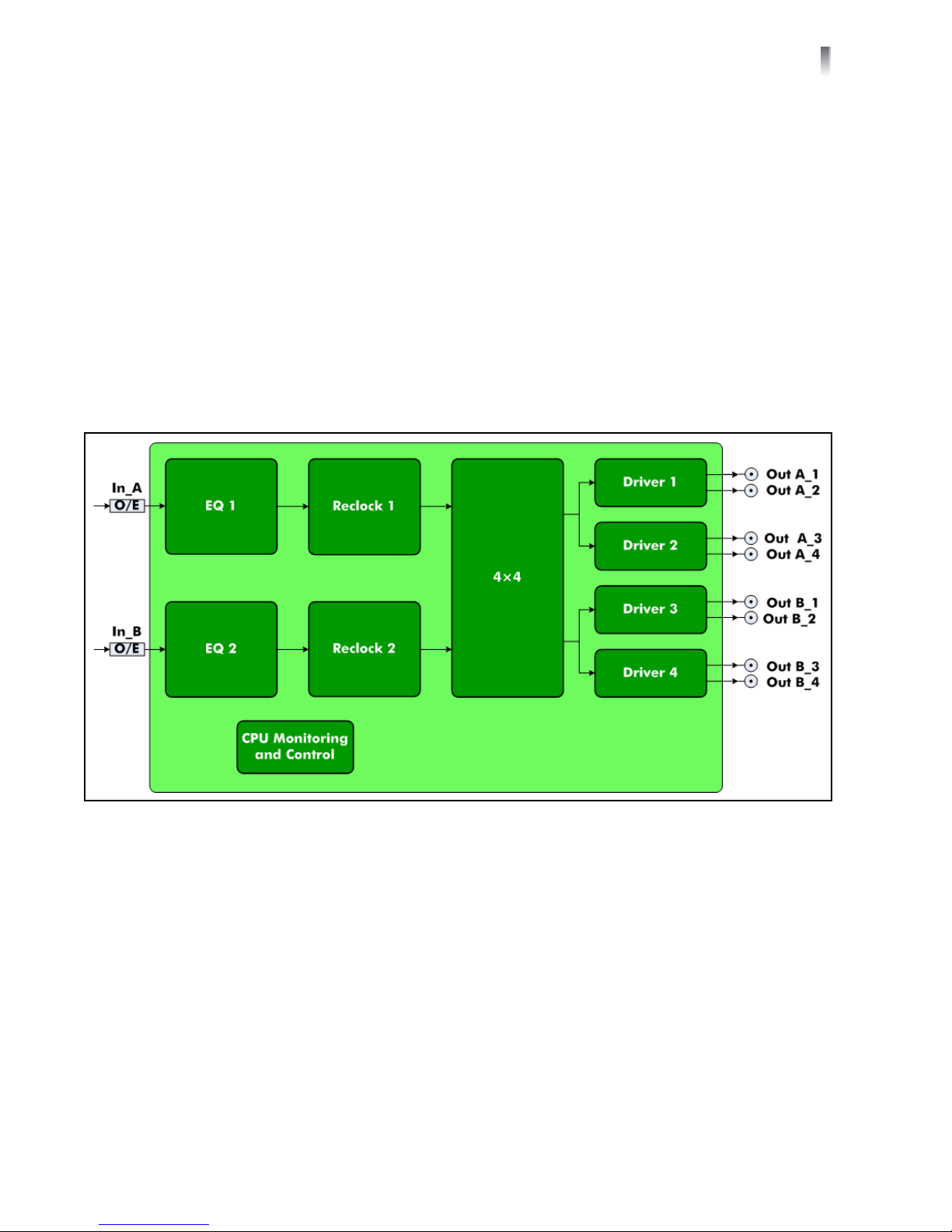

The main features for the DA-DHR6804+D are listed below. Figure 1-1 shows a

basic signal flow diagram for this distribution amplifier module.

Figure 1-1 DA-DHR6804+D Signal Flow Diagram

Operates with standard dual slot distribution amplifier back module (see

page 14)

Passes signals at data rates from 5 Mb/s to 3 Gb/s

Four selectable channel configurations:

1×8_ACO: 1 input to 8 outputs with auto changeover

The signal on SDI In_1 is distributed to 8 outputs. If the signal at SDI In_1

disappears, the outputs are switched to SDI In_2 (if a signal at SDI In_2 is

detected).

When the signal reappears at SDI In_1, the outputs are switched back to

SDI In_1 from SDI In_2 automatically.

1×8_ In_1: SDI In_1 to 8 outputs

1×8_ In_2: SDI In_2 to 8 outputs

2_1×4: 2 independent 1×4

SDI In_1 to SDI Out_1, 1-4

SDI In_2 to SDI Out_2, 1-4

Input signal presence detect and report

Automatic input cable equalization

Selectable + 6dB gain to use external passive 75 2×1 splitter (via CCS only)

Copyright © 2010, Harris Corporation

Page 18

4

Chapter 1

Introduction

Selectable input EQ bypass

Reclockable for 270 Mb/s, 1.485 Gb/s, or 2.97 Gb/s SMPTE and DVB-ASI

signals

Three selectable reclocking modes (automatic, manual, enforce bypass)

Automatic bypassing reclock stage if not relockable

Reclock status and data rate report

Automatic slew rate control for output signal

Automatic power saving if no input signal or no termination on the output

BNC

Local and remote control

Module hot swappable

DA-DH6804+D

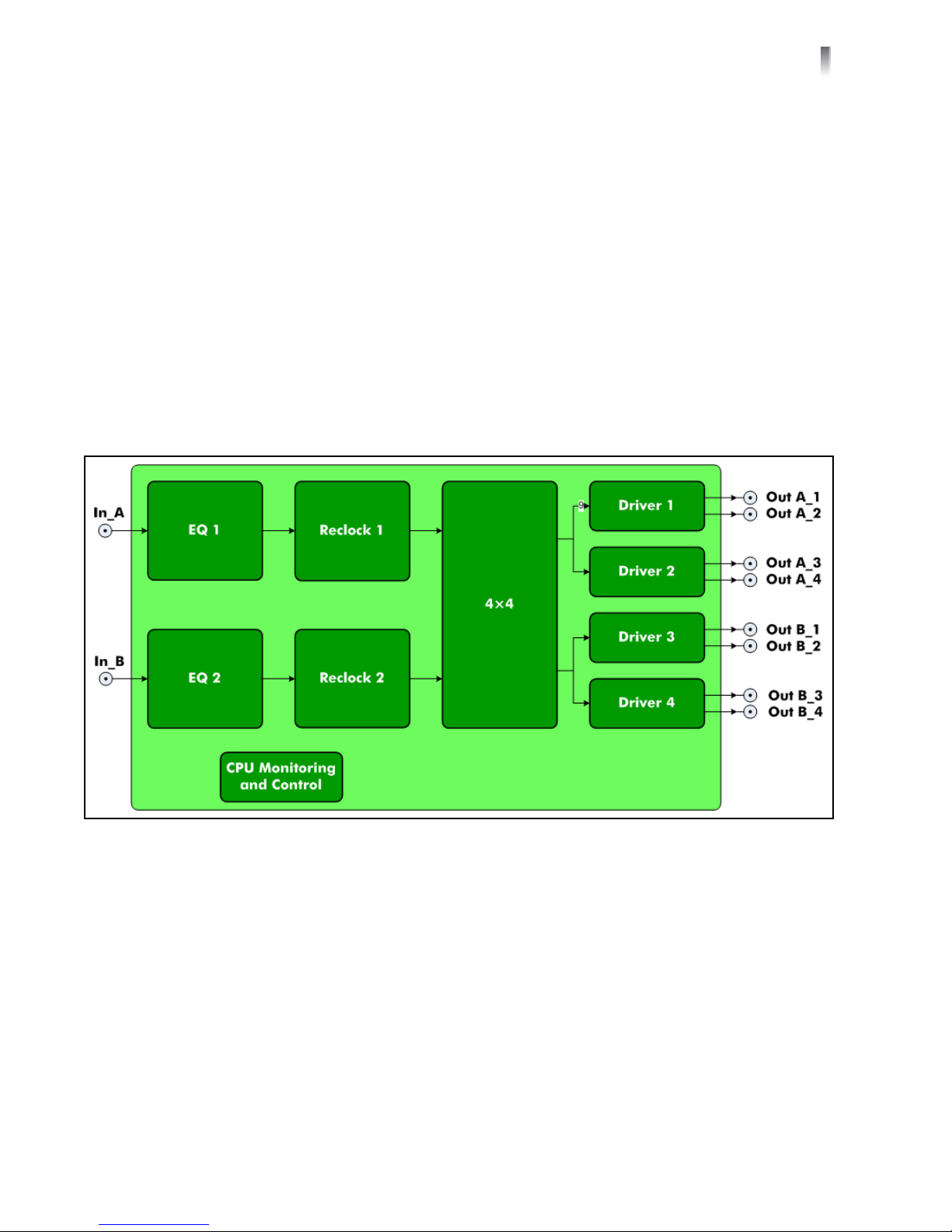

The main features for the DA-DH6804+D are listed below. Figure 1-2 shows a

basic signal flow diagram for this distribution amplifier module.

Figure 1-2 DA-DH6804+D Signal Flow Diagram

Operates with standard dual slot distribution amplifier back module (see

Passes signals at data rates from 5 Mb/s to 3 Gb/s

Four selectable channel configurations:

Copyright © 2010, Harris Corporation

page 14)

1×8_ACO: 1 input to 8 outputs with auto changeover

The signal on SDI In_1 is distributed to 8 outputs. If the signal at SDI In_1

disappears, the distribution amplifier outputs are switched to SDI In_2 (if a

signal at SDI In_2 is detected).

When the signal reappears SDI In_1, the outputs are switched back to SDI

In_1 from SDI In_2 automatically.

1×8_ In_1: SDI In_1 to 8 outputs

1×8_ In_2: SDI In_2 to 8 outputs

Page 19

DA-6804+D Series

Installation and Operation Manual

2_1×4: 2 independent 1×4

SDI In_1 to SDI Out_1, 1-4

SDI In_2 to SDI Out_2, 1-4

Input signal presence detect and report

Automatic input cable equalization

Selectable +6 dB gain to use external passive 75 2×1 splitter (via CCS only)

Selectable input EQ bypass

Automatic power saving if not input signal or no termination on the output

BNC

Local and remote control

Module hot swappable

5

DA-DSR6804+D

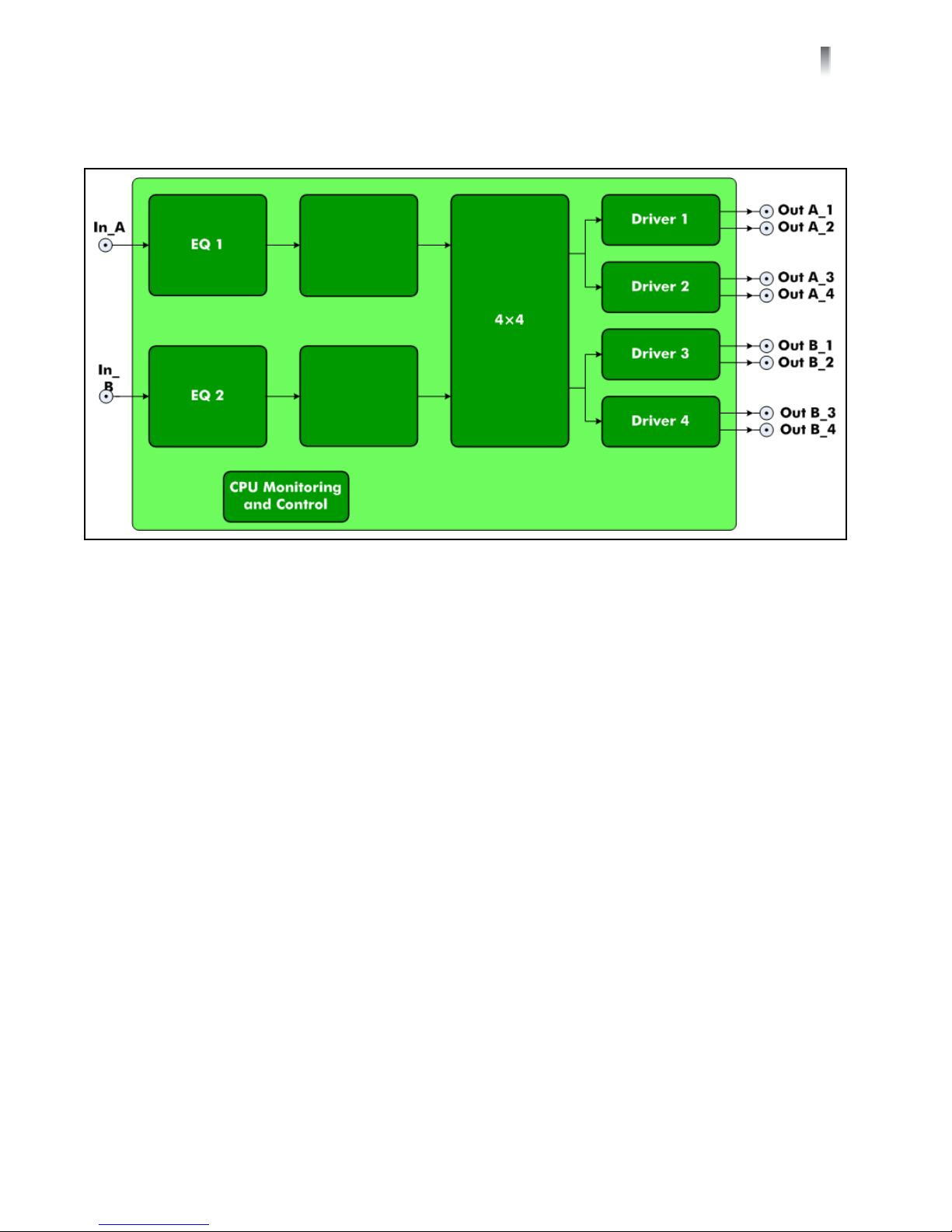

The main features for the DA-DSR6804+D are listed below. Figure 1-3 shows a

basic signal flow diagram for this distribution amplifier module.

Figure 1-3 DA-DSR6804+D Signal Flow Diagram

Operates with standard dual slot distribution amplifier back module (see

Passes signals at data rates from 5 Mb/s to 540 Mb/s

Four selectable channel configurations:

page 14)

1×8_ACO: 1 input to 8 outputs with auto changeover

The signal on SDI In_1 is distributed to 8 outputs. If the signal at SDI In_1

disappears, the outputs are switched to SDI In_2 (if a signal at SDI In_2 is

detected).

When the signal reappears SDI In_1, the outputs are automatically

switched back to SDI In_1 from SDI In_2.

1×8_ In_1: SDI In_1 to 8 outputs

Copyright © 2010, Harris Corporation

Page 20

6

Chapter 1

Introduction

1×8_ In_2: SDI In_2 to 8 outputs

2_1×4: 2 independent 1×4

SDI In_1 to SDI Out_1, 1-4

SDI In_2 to SDI Out_2, 1-4

Input signal presence detect and report

Automatic input cable equalization

Selectable +6 dB gain to use external passive 75 2×1 splitter (via CCS only)

Selectable input EQ bypass

Reclockable for 270 Mb/s SMPTE and DVB-ASI signals

Three selectable reclocking modes (automatic, manual, enforce bypass)

Automatic bypassing reclock stage if not relockable

Reclock status and data rate report

Automatic slew rate control for output signal

Automatic power saving if not input signal or no termination on the output

BNC

Local and remote control

Module hot swappable

Copyright © 2010, Harris Corporation

Page 21

DA-6804+D Series

Installation and Operation Manual

7

DA-DS6804+D

The main features for the DA-DS6804+D are listed below. Figure 1-4 shows a

basic signal flow diagram for this distribution amplifier module.

Figure 1-4 DA-DS6804+D Signal Flow Diagram

Operates with standard dual slot distribution amplifier back module (see

page 14)

Passes signals at data rates from 5 Mb/s to 540 Mb/s

Four selectable channel configurations:

1×8_ACO: 1 input to 8 outputs with auto changeover

The signal on SDI In_1 is distributed to 8 outputs. If the signal at SDI In_1

disappears, the outputs are switched to SDI In_2 (if a signal at SDI In_2 is

detected).

When the signal reappears on SDI In_1, the outputs are automatically

switched back to SDI In_1 from SDI In_2.

1×8_ In_1: SDI_ In_1 to 8 outputs

1×8_ In_2: SDI_ In_2 to 8 outputs

2_1×4: 2 independent 1x4

SDI In_1 to SDI Out_1, 1-4

SDI In_2 to SDI Out_2, 1-4

Input signal presence detect and report

Automatic input cable equalization

Selectable +6 dB gain to use external passive 75 2×1 splitter (via CCS only)

Selectable input EQ bypass

Automatic power saving if not input signal or no termination on the output

BNC

Local and remote control

Module hot swappable

Copyright © 2010, Harris Corporation

Page 22

8

Chapter 1

Introduction

DA-HRO6804+D

The main features for the DA-HRO6804+D are listed below. Figure 1-5 shows a

basic signal flow diagram for this distribution amplifier module.

Figure 1-5 DA-HRO6804+D Signal Flow Diagram

Operates with dual slot, RT optical distribution amplifier back module (see

page 14)

Passes signals at data rates from 5 Mb/s to 3 Gb/s

Three selectable channel configurations:

1×8_ACO: 1 electrical input to 1 optical output and 7 electrical outputs

with auto changeover

The Electrical signal on SDI In_1 is distributed to 1 optical output and 7

electrical outputs. If the electrical signal at SDI In_1 disappears, the

outputs are switched to Optical input at SDI In_2 (if an Optical signal at

SDI In_2 is detected). When the Electrical signal reappears on SDI In_1, the

outputs are automatically switched back to SDI In_1 from SDI In_2.

1×8_ In_1: 1 electrical input (In_A) to 1 optical output and 7 electrical

outputs

1×8_ In_2: 1 optical input (In_B) to 1 optical output and 7 electrical

outputs

Input signal presence detect and report

Optical input status for optical input (by CCS)

Automatic input cable equalization for electrical input

Selectable +6 dB gain to use external passive 75 2×1 splitter (via CCS only)

for electrical input

Selectable input EQ bypass for electrical input

Reclockable for 270 Mb/s, 1.485 Gb/s, or 2.97 Gb/s SMPTE and DVB-ASI

signals

Three selectable reclocking modes (automatic, manual, enforce bypass)

Copyright © 2010, Harris Corporation

Page 23

DA-6804+D Series

Installation and Operation Manual

Automatic bypassing reclock stage if not relockable

Reclock status and data rate report

Automatic slew rate control for electrical output signal

Optical output protection enable

Output output loss alarm

Optical status for optical output (by CCS)

Automatic power saving if not input signal or no termination on the output

BNC

Local and remote control

Module hot swappable

9

DA-DHROE6804+D

The main features for the DA-DHROE6804+D are listed below. Figure 1-6 shows a

basic signal flow diagram for this distribution amplifier module.

Figure 1-6 DA-DHROE6804+D Signal Flow Diagram

Operates with dual slot, RR optical distribution amplifier back module (see

Passes signals at data rates from 5 Mb/s to 3 Gb/s

Four selectable channel configurations:

page 14)

1×8_ACO: 1 optical input (In_A) to 8 electrical outputs with auto

changeover

The optical signal on In_A is converted and distributed to 8 electrical

outputs. If the signal at In_A disappears, the outputs are switched to In_B

(if a signal at In_B is detected).

When the signal reappears on In_A, the outputs are automatically

switched back to In_A from In_B.

1×8_ In_1: optical In_A to 8 electrical outputs

Copyright © 2010, Harris Corporation

Page 24

10

Chapter 1

Introduction

1×8_ In_2: optical In_B to 8 electrical outputs

2_1×4: 2 independent 1×4

Optical In_A to electrical Out_A, 1-4

Optical In_B to electrical Out_B, 1-4

Input signal presence detect and report

Optical input status for optical input (by CCS)

Reclockable for 270 Mb/s, 1.485 Gb/s, or 2.97 Gb/s SMPTE and DVB-ASI

signals

Three selectable reclocking modes (automatic, manual, enforce bypass)

Automatic bypassing reclock stage if not relockable

Reclock status and data rate report

Automatic slew rate control for electrical output signal

Automatic power saving if not input signal or no termination on the output

BNC

Local and remote control

Module hot swappable

DA-DHREO6804+D

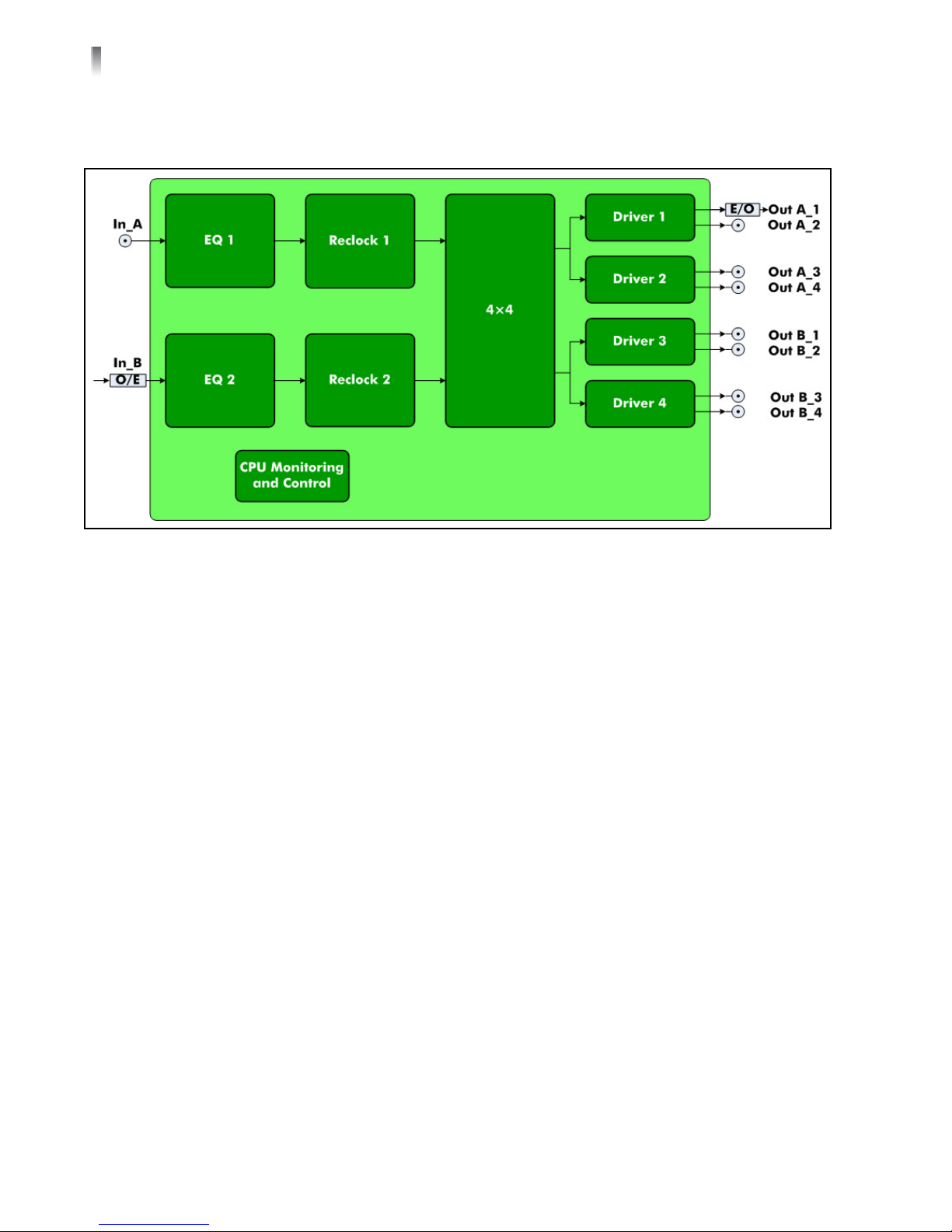

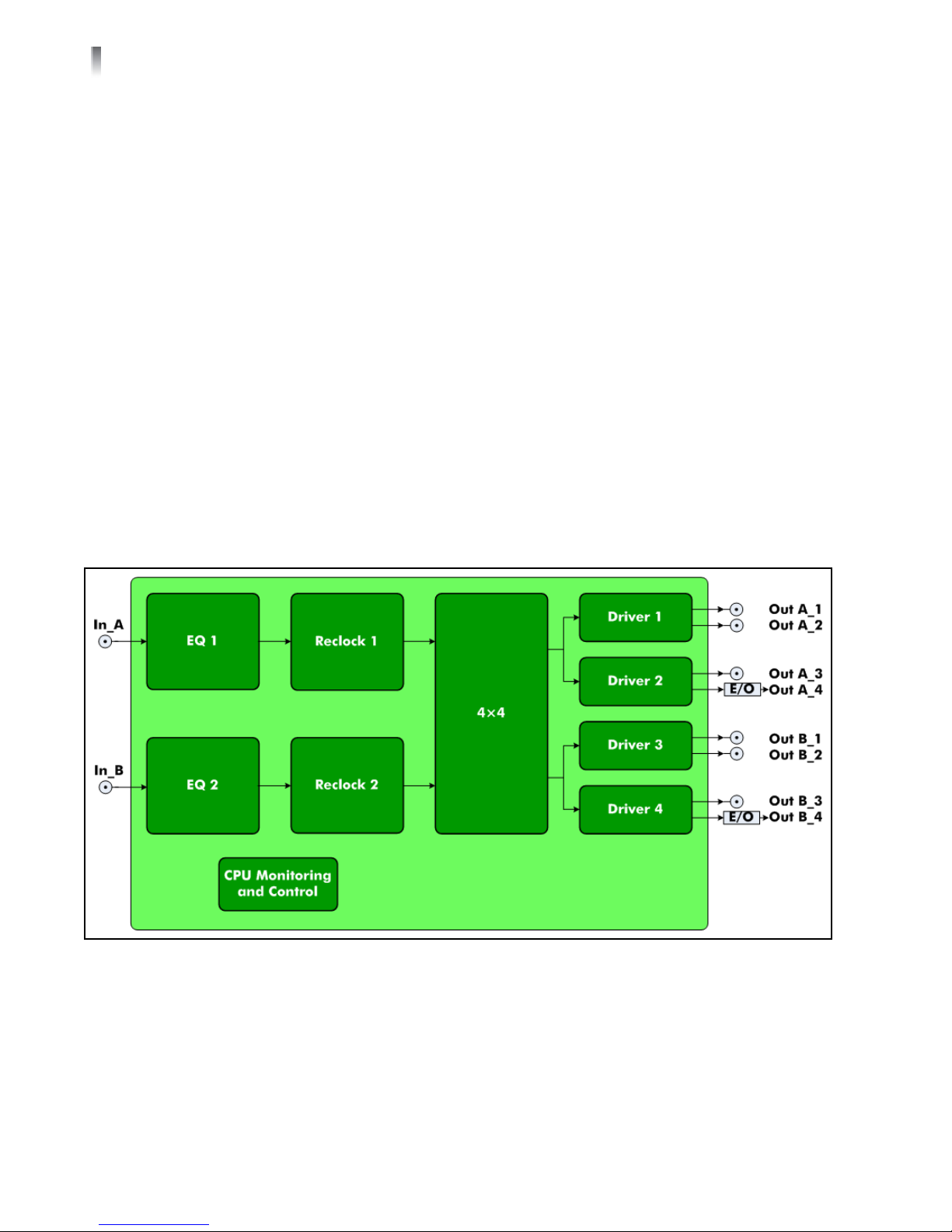

The main features for the DA-DHREO6804+D are listed below. Figure 1-7 shows a

basic signal flow diagram for this distribution amplifier module.

Figure 1-7 DA-DHREO6804+D Signal Flow Diagram

Operates with dual slot, TT optical distribution amplifier back module (see

Passes signals at data rates from 5 Mb/s to 3 Gb/s

Four selectable channel configurations:

Copyright © 2010, Harris Corporation

page 14)

Page 25

DA-6804+D Series

Installation and Operation Manual

1×8_ACO: 1 electrical input (In_A) to 6 electrical outputs and 2 optical

outputs with auto changeover

The signal on In_A is distributed to 6 electrical outputs and 2 optical

outputs. If the signal at In_A disappears, the outputs are switched to In_B

(if a signal at In_B is detected).

When the signal reappears on In_A, the outputs are automatically

switched back to In_A from In_B.

1×8_ In_1: Electrical In_A to 6 electrical outputs and 2 optical outputs

1×8_ In_2: Electrical In_B to 6 electrical outputs and 2 optical outputs

2_1×4: 2 independent 1×4

Electrical In_A to Out_A, 1 optical output and 3 electrical outputs

Electrical In_B to Out_B, 1 optical output and 3 electrical outputs

Input signal presence detect and report

Automatic input cable equalization for electrical input

Selectable +6 dB gain to use external passive 75 2×1 splitter (via CCS only)

for electrical input

Selectable input EQ bypass for electrical input

Reclockable for 270 Mb/s, 1.485 Gb/s, or 2.97 Gb/s SMPTE and DVB-ASI

signals

Three selectable reclocking modes (automatic, manual, enforce bypass)

Automatic bypassing reclock stage if not relockable

Reclock status and data rate report automatic slew rate control for electrical

outputs

Optical output protection enable

Optical output loss alarm

Optical status for optical output (by CCS)

Automatic power saving if not input signal or no termination on the output

BNC

Local and remote control

Module hot swappable

11

Copyright © 2010, Harris Corporation

Page 26

12

Chapter 1

Introduction

DA-DHROO6804+D

The main features for the DA-DHROO6804+D are listed below. Figure 1-8 shows

a basic signal flow diagram for this distribution amplifier module.

Figure 1-8 DA-DHROO6804+D Signal Flow Diagram

Operates with dual slot, 3SFP optical distribution amplifier back module (see

page 14)

Passes signals at data rates from 5 Mb/s to 3 Gb/s

Four selectable channel configurations:

1×8_ACO: 1 optical input (In_A) to 4 electrical outputs and 4 optical

outputs with auto changeover

The optical signal on In_A is distributed to 4 electrical outputs and 4

optical outputs. If the signal at In_A disappears, the outputs are switched

to In_B (if an optical signal at In_B is detected).

When the signal is reappears In_A, the outputs are automatically switched

back to In_A from In_B.

1×8_ In_1: optical In_A to four electrical outputs and four optical outputs

1×8_ In_2: optical In_B to four electrical outputs and four optical outputs

2_1×4: 2 independent 1×4

Optical In_A to OUT_A1/A2 (optical outputs) and A3/A4 (electrical

outputs)

Optical In_B to OUT_B1/B2 (optical outputs) and B3/B4 (electrical

outputs)

Input signal presence detect and report

Optical input status for optical input (by CCS)

Reclockable for 270 Mb/s, 1.485 Gb/s, or 2.97 Gb/s SMPTE and DVB-ASI

signals

Three selectable reclocking modes (automatic, manual, enforce bypass)

Automatic bypassing reclock stage if not relockable

Copyright © 2010, Harris Corporation

Page 27

DA-6804+D Series

Installation and Operation Manual

Reclock status and data rate report

Automatic slew rate control for electrical output signal

Optical output protection enable

Optical output loss alarm

Optical status for optical output (by CCS)

Automatic power saving if not input signal or no termination on the output

BNC

Local and remote control

Module hot swappable

13

Copyright © 2010, Harris Corporation

Page 28

14

Chapter 1

Introduction

Product

Views

Front Module

Back Modules

This section includes information about the front and back modules, as well as a

view of the rear of a frame with various DA-6804+D series back connector

modules installed.

Figure 1-9 DA-6804+D Series Front Module

DA-6804+D series modules can be installed with double-width back modules in

their respective host frames. (These modules cannot be installed in 6800 /7000

series frames.)

Table 1-1 Back Modules

DA-DS6804+D

DA-DSR6804+D

DA-DH6804+D

DA-DHR6804+D

Table 1-1 show the back connector modules used with corresponding front

modules when installed in the host frame.

DA-HRO6804+D DA-DHROE6804+D DA-DHREO6804+D DA-DHROO6804+D

Copyright © 2010, Harris Corporation

Page 29

DA-6804+D Series

Installation and Operation Manual

15

Rear View

Maximum 6800+

Frame Power

Ratings

Figure 1-10 shows a rear view of the DA-6804+D Series fully-filled frame. The

frame holds 10 modules (each front module and its corresponding back module

occupies 2 slots in a frame).

Figure 1-10 Frame Rear View

Power consumption information is listed in Chapter 4, Specifications on page 52.

Table 1-2 describes the maximum allowable power ratings for 6800+ frames.

Note the given maximums before installing any 6800+ modules in your frame.

DA-6804+D series modules cannot be installed in 6800 / 7000 series frames.

Table 1-2 Maximum Power Ratings for 6800+ Frames

6800+ Frame Type

FR6802+XF

(frame with AC power

supply)

FR6802+XF48

(frame with DC power

supply)

FR6802+QXF

(frame with AC or DC

power supply)

FR6822+

(frame with AC or DC

power supply)

Max. Frame

Power

Dissipation

120 W 20 6 W

105 W 20 5.25 W

120 W 20 6 W

120 W 20 6 W

Number of

Usable Slots

Max. Power

Dissipation

Per Slot

Copyright © 2010, Harris Corporation

Page 30

16

Chapter 1

Introduction

Copyright © 2010, Harris Corporation

Page 31

2

17

Installation

CAUTION: Before installing this product, read the 6800+ Series

Safety Instructions and Standards manual shipped with every frame

installation and operation manual, or downloadable from our

website. This safety manual contains important information about

the safe installation and operation of 6800+ series products.

Before you install DA-6804+D series modules, perform the following:

Remove the anti-static shipping pouch, if present, and all other packaging

material.

Retain the original packaging materials for possible re-use.

Confirm receipt of all items on the packing list. See Checking the Packing

List on page 18.

Check the equipment for any visible damage that may have occurred during

transit.

Contact your Customer Service representative if parts are missing or damaged.

See Unpacking/Shipping Information on page ix for information about

returning a product for servicing.

Copyright © 2010, Harris Corporation

Page 32

18

Chapter 2

Installation

Checking the

Packing List

Table 2-1 shows the items that are part of your DA-6804+D series module

package. If any of these items are missing from your shipment, contact your

Customer Service representative.

Table 2-1 DA-6804+D Series Packing List

Ordered Product Content Description

DA-DHR6804+D: 3G/HD/SD/ASI Dual Channel Distribution Amplifier

with Reclocking

DA-DHR6804+ One DA-DHR6804+ front module

One DA-6804+ Series Installation and Operation

Manual

DA-DHR6804+D One DA-DHR6804+ front module

One standard double-slot BNC back connector

module

One DA-6804+ Series Installation and Operation

Manual

DA-DH6804+D 3G/HD/SD/ASI Dual Channel Distribution Amplifier

DA-DH6804+ One DA-DH6804+ front module

One DA-6804+ Series Installation and Operation

Manual

DA-DH6804+D One DA-DH6804+ front module

One standard double-slot BNC back connector

module

One DA-6804+ Series Installation and Operation

Manual

DA-DSR6804+D SD/ASI Dual Channel Distribution Amplifier with

Reclocking

DA-DSR6804+ One DA-DSR6804+ front module

One DA-6804+ Series Installation and Operation

Manual

DA-DSR6804+D One DA-DSR6804+ front module

One standard double-slot BNC back connector

module

One DA-6804+ Series Installation and Operation

Manual

DA-DS6804+D SD/ASI Dual Channel Distribution Amplifier with

Reclocking

DA-DS6804+ One DA-DS6804+ front module

One DA-6804+ Series Installation and Operation

Manual

DA-DS6804+D One DA-DS6804+ front module

One standard double-slot BNC back connector

module

One DA-6804+ Series

Manual

Installation and Operation

Copyright © 2010, Harris Corporation

Page 33

DA-6804+D Series

Installation and Operation Manual

Table 2-1 DA-6804+D Series Packing List (Continued)

Ordered Product Content Description

DA-HRO6804+D 3G/HD/SD Optical and Electrical Distribution

Amplifier

DA-HRO6804+D One DA-DHR6804+ front module

One RT optical distribution amplifier back

connector module

One DA-6804+ Series Installation and Operation

Manual

DA-DHROE6804+D 3G/HD/SD/ASI Dual Channel Optical to Electrical

Distribution Amplifier

DA-DHROE6804+D One DA-DHR6804+ front module

One RR optical distribution amplifier back

connector module

One DA-6804+ Series Installation and Operation

Manual

DA-DHREO6804+D 3G/HD/SD/ASI Dual Channel Electrical to Optical

Distribution Amplifier

19

DA-DHREO6804+D One DA-DHR6804+ front module

One TT optical distribution amplifier back

connector module

One DA-6804+ Series Installation and Operation

Manual

DA-DHROO6804+D 3G/HD/SD/ASI Dual Channel Electrical to Optical

Distribution Amplifier

DA-DHROO6804+D

One DA-DHR6804+ front module

One 3SFP optical distribution amplifier back

connector module

One DA-6804+ Series Installation and Operation

Manual

Copyright © 2010, Harris Corporation

Page 34

20

Chapter 2

Installation

Setup

Procedures

Setting Up a

Frame

DA-6804+D series frames, back connectors, and front modules require different

setup procedures before the modules can be installed in the frame.

Frame setup consists of installing a frame into its rack, and then connecting to a

power and/or Ethernet source. See the appropriate frame installation and

operation manual for details on installing and operating the frame and its

components.

If the frame does not have CCS control, plug a power cord (A) to the back of the

frame as shown in Figure 2-1. Plug the other end of the power cord into an

electrical outlet.

Figure 2-1 Connection for Non-CCS Control

Copyright © 2010, Harris Corporation

Page 35

DA-6804+D Series

Installation and Operation Manual

If the frame uses CCS control, plug the power cord (A) and the Ethernet connector

cable (B) to the back of the frame, as shown in Figure 2-2. Plug the other end of

the power cord into an electrical outlet. Plug the other end of the Ethernet

connector to a PC that has Harris CCS software installed.

21

Setting Up Back

Connector

Modules

Figure 2-2 Connection for CCS Control

Back module setup consists of plugging in coaxial cables (A) and fiber optical

cables (B), as shown in Figure 2-3. Apply a 75 coaxial cable to the BNC jacks and

LC single mode fiber optical cables, as appropriate, to installed back modules. The

other ends of the cables should be connected to a system’s other devices.

Figure 2-3 Plugging in Coaxial and Fiber Optical Cables

CAUTION: Take special care when attaching fiber optical cables. See

page 21 for more information.

Copyright © 2010, Harris Corporation

Page 36

22

Chapter 2

Installation

Setting Up Front

Modules

Setting Up J1 and J2

Jumpers

Front module setup consists of setting the jumpers for the DA-6804+D series

modules. Three jumpers that need to be set: J1 and J2 are used for reclockers, and

J3 is designed for channel configuration and enabling remote control.

Figure 2-4 shows the location of the J1, J2, and J3 jumpers.

Figure 2-4 Jumper Locations

J1 and J2 are used to locally set the reclocker working mode. J1 is used for

channel 1 and J2 for is used for channel 2. The reclocker remains in AUTO mode if

no shunt is on any position of the jumper.

Table 2-2 J1 and J2 Jumper Settings

Jumper

Selection

Pin

Setting

Label Description

J1/J2 1/2 AUTO_1/2 Input signal locked at one of these

data rates:

2.97 Gb/s

1.485 Gb/s

270 Mb/s

If not relockable, signal automatically

bypasses reclocker

J1/J2 3/4 3.0G_1/2 Input signal locked at 2.97 Gb/s*;if

not relockable, signal automatically

bypasses reclocker

J1/J2 5/6 HD_1/2 Input signal locked at 1.485 Gb/s*;if

not relockable, signal automatically

bypasses reclocker

J1/J2 7/8 SD_1/2 Input locked at 270 Mb/s; if not

relockable, signal automatically

bypasses reclocker

J1/J2 9/10 BYPASS_1/2 Enforces signal bypass reclocker

*

Not used with DA-DSR6804+

Copyright © 2010, Harris Corporation

Page 37

DA-6804+D Series

Installation and Operation Manual

23

Setting Up J3

Jumpers

The J3 jumper controls the control modes available for DA-6804+D series modules.

Local control for channel configuration

Remote control enable

Table 2-3 J3 Jumper Settings

Jumper

Selection

Pin

Setting

Label Description

J3 1/2 1×8_ACO Locally configures distribution

amplifier as single channel (1×8) with

ACO

J3 3/4 1×8_IN1 Locally configures distribution

amplifier as single channel (1×8);

input is from IN1

J3 5/6 1×8_IN2 Locally configures distribution

amplifier as single channel (1×8);

input is from IN2

J3 7/8 2_1×4 Locally configures distribution

amplifier as dual channel (2-1×4)

J3 11/12 REMOTE Enables remote control via CCS; J3

pins 1-8 are not functional

Copyright © 2010, Harris Corporation

Page 38

24

Chapter 2

Installation

Installing and

Removing

Modules

Back Module

Installation

The DA-6804+D series front modules have corresponding back modules that are

installed in the host frame. See page 24 for details on installing back modules.

These modules cannot be installed in 6800/7000 series frames.

The DA-6804+D series back modules have specialized installation procedures. If

installing both front and back modules, ensure that the back module is installed

first before plugging in the front module.

When removing both the front and back modules, ensure that the front

module is unplugged from the frame first, before removing the back module.

See the appropriate frame installation and operation manual for details on

installing and operating the frame and its components.

See the 6800+ Safety Instructions and Standards Manual for important

information about safely installing your module.

Once you have installed the modules, you can connect them to the appropriate

input and outputs.

SFPs on DA-6804+D series back modules have plastic caps that protect the fragile

laser connections from dust (see Figure 2-5 on page 25). You must remove these

protective covers before you attach the fiber cables.

Figure 2-5 on page 25 shows a typical fiber optical back module. Your module’s

appearance may differ slightly from the one shown; however, the protective covers

are positioned identically and must be removed according to the instructions

provided. The installation instructions that follow will prompt you as to when you

should remove the protective covers.

In addition, all of the LC connections of the fiber optical cables must be inspected

and cleaned before they are assembled. Carefully follow the inspection and

cleaning steps described in the next pages. Additional safety information begins on

Laser Safety Guidelines on page 53.

Copyright © 2010, Harris Corporation

Page 39

DA-6804+D Series

Installation and Operation Manual

25

Front Module

Installation

Figure 2-5 Protective Covers for Laser Connectors

1 Remove a blank back plate from the frame. Do not discard the blank back

plates. They may be needed for future configurations.

CAUTION: Microscopic dust or other contaminants can seriously

impair or disable a fiber optic network. Observe strict cleaning

procedures. Do not touch the end of the fiber.

2 If it is already installed, remove the front module from the slot.

3 Install the new back module by inserting the bottom lip into the required

frame slot, and then screwing it into place.

4 Follow the fiber cable inspection and cleaning procedure that begins on

page 59.

5 Insert the front module into the slot holding the corresponding back module.

6 Attach the fiber cable and/or electrical cables to the back module (see Setting

Up Back Connector Modules on page 21).

Front modules require no specialized installation procedures other than those

described in Setting Up Front Modules on page 22. If installing both front and

back modules, ensure that the back module is installed first before plugging in the

front module.

Removing Modules

These modules require no specialized removal procedures. If installing both front

and back modules, ensure that the front module is removed first.

Copyright © 2010, Harris Corporation

Page 40

26

Chapter 2

Installation

Copyright © 2010, Harris Corporation

Page 41

3

27

Operation

When a frame, back modules, and the front module are set up, plug the front

module into the frame; connect the input and output cables to BNCs on back

module and/or LC fiber optional cables to SFPs; and turn on the power supply of

the frame. After approximately three seconds, the distribution amplifier should

operate properly. Usually there is no need for other operational changes.

Without a CCS remote control system, DA-6804+D series distribution amplifiers

are fully functional in FR6802+ frames. With an installed CCS system (including

6800+ETH module in the FR6802+ frame), distribution amplifier operation can be

monitored and configured on the remote computer display. The J3 jumper must be

set to REMOTE (see Table 2-3 on page 23). If the J3 jumper is not set to this

setting, the distribution amplifier can be remotely monitored only, and remote

configuration is not possible.

Copyright © 2010, Harris Corporation

Page 42

28

Chapter 3

Operation

LED Displays

LEDs on the front edge of the front module report the operating status when

power is ON and signal is applied. The location of the system status (A) and signal

condition (B) LEDs are shown in Figure 3-1. The meaning of the system status LED

color sequence is described in Table 3-1. The meanings for the signal condition

LEDs are described in Table 3-2.

Figure 3-1 LED Locations

System Status

Indicators

Signal Condition

Indicators

Table 3-1 System Status Indicator LED Descriptions

LED Color Sequence Meaning

Off There is no power to the module; the module is not

operational

Red There is an alarm condition

Green There is power to the module; the module is

operating properly

Each 6800+ module has a number of LEDs assigned to indicate varying states /

functions. These functions are listed in Table 3-2.

Table 3-2 Signal Condition LED Descriptions

Name Color Function

PRES Green Input signal is present

Off Input signal is absent

LOCK Green Input signal is locked

Off Input signal is unlocked and appears on the

outputs

Copyright © 2010, Harris Corporation

Page 43

DA-6804+D Series

Installation and Operation Manual

Table 3-2 Signal Condition LED Descriptions (Continued)

Name Color Function

270 Green Input signal is reclocked at 270 Mb/s

Off Input signal is not reclocked

1.5G Green Input signal is reclocked at 1.485 Gb/s

Off Input signal is not reclocked

3.0G Green Input signal is reclocked at 2.97 Gb/s

Off Input signal is not reclocked

29

Alarms

If an alarm is triggered within a module, the module status LED turns red and the

alarm light on the front of the frame lights red.

Figure 3-2 Alarm Indicator, System Status LED

Figure 3-3 Alarm Indicator, Frame Front

Copyright © 2010, Harris Corporation

Page 44

30

Chapter 3

Operation

Alarms are usually logged and monitored within the available software control

applications. See the appropriate software control user manual or online help for

more information.

Table 3-3 Alarm Definitions

Alarm Name Alarm Description Alarm Level

Ch. 1 loss of input Indicates input signal for channel 1 is lost

or absent

Ch. 2 loss of input Indicates input signal for channel 2 is lost

or absent

Ch. 1 loss of lock Indicates signal for channel 1 is not

locked

Ch. 2 loss of lock Indicates signal for channel 2 is not

locked

Ch.1a Tx Fault Indicates SFP transmitter fault on

channel 1a

Ch.1b Tx Fault Indicates SFP transmitter fault on

channel 1b

Ch.2a Tx Fault Indicates SFP transmitter fault on

channel 2a

Ch.2b Tx Fault Indicates SFP transmitter fault on

channel 2b

Major

Major

Major

Major

Major

Major

Major

Major

Copyright © 2010, Harris Corporation

Page 45

DA-6804+D Series

Installation and Operation Manual

31

Web-Enabled

Display and

Control

NOTE: To enable web-based display and control, make sure that you have

set up the frame for CCS control, as described in Setting Up a Frame on

page 20. You must also have an 6800+ETH Ethernet connection module

installed.

To access the web-enabled display, open a web browser and enter the IP address of

the frame in the Address field, and then click Enter at the 6800+ Control

Interface display. A view of the frame modules components is displayed on

screen.

Figure 3-4 Web-Enabled Control Display

A tree view of the frame and its contents is displayed at the left of the screen. Click

the + button (or click on the component name) to expand the tree view.

Information corresponding to the selection is displayed in the control pane to the

right of the tree view.

Click the - button to collapse the tree view.

When you select the frame and slot for a distribution amplifier module location,

the software displays the item list in the tree view and the item values on the

control pane, as shown in Figure 3-5. Some parameters are adjustable if the J3

jumper is set to REMOTE.

Copyright © 2010, Harris Corporation

Page 46

32

Chapter 3

Operation

Figure 3-5 Parameter View for Web-Enabled Display

In the value display boxes on the pane, the value of read-only parameter is

displayed as grey ground with black characters and you cannot change it. The

adjustable parameter value is displayed as white ground with black characters. The

adjustable parameter boxes should be turned to grey if the J3 jumper is not set on

the REMOTE pins.

Copyright © 2010, Harris Corporation

Page 47

DA-6804+D Series

Installation and Operation Manual

33

CCS Naviga-

tor Display

and Control

NOTE: This section presupposes that you have a working knowledge of

CCS Navigator and have used the software’s other capabilities. If not,

please refer to the pertinent software application user manual to

familiarize yourself with its functions before you continue.

When viewing the DA-6804+D series in Navigator control mode, a control pane is

displayed on screen of the computer monitor. When you select the frame and slot

for a distribution amplifier module location, the software displays the item values

on the control pane, as shown in Figure 3-6. Some parameters are adjustable if

the J3 jumper is set to REMOTE.

Figure 3-6 CCS Navigator Control Display

In the value display boxes on the pane, the value of read-only parameter is

displayed as black ground with green characters. The adjustable parameter value is

displayed as white ground with black characters. The adjustable parameter boxes

should be turned to grey if the J3 jumper is not set to REMOTE.

Copyright © 2010, Harris Corporation

Page 48

34

Chapter 3

Operation

Operating

Notes

Setting

Locally

Controlled

Parameters

When you set the control parameters on DA-6804+D series distribution amplifiers,

observe the following:

If you make changes to certain parameters, other related parameters may also

be affected.

When you change a parameter, the effect is immediate. However, the module

requires up to 30 seconds to save the latest change. After 30 seconds, the new

settings are saved and will be restored if the module loses power and must be

restarted.

In the local control operation mode, all of the settings’ data status information

appears on the CCS control software application control screen; however, you

cannot change any setting in this mode via the CCS control software application.

(To control the operation mode via the CCS control software application, set the J3

jumper to the REMOTE.)

Reclocking mode and control mode parameters are available for local control.

The J1 and J2 jumpers are used to determine reclocking mode. Table 2-2 on

page 22 describes parameters that are accessible locally.

The J3 jumper is used to determine control mode. Table 2-3 on page 23 describes

parameters that are accessible locally.

Setting

Remotely

Controlled

Parameters

Copyright © 2010, Harris Corporation

In the remote control operation mode, all of the settings’ data status information

appears on the CCS control software application control screen, and you can

change settings in this mode via the CCS control software application. (To control

the operation mode via the CCS control software application, set the J3 jumper to

the REMOTE.) Figure 3-4 on page 31 shows a web-enabled control pane and

Figure 3-6 on page 33 shows a Navigator control pane displaying the parameters

for a DA-DHROO6804+D module. Table 3-8 describes parameters that are

accessible remotely.

See your CCS control software application manual or online help for more

information on setting and monitoring these parameters remotely.

Page 49

DA-6804+D Series

Installation and Operation Manual

Table 3-4 DA-DHR6804+D/DA-DH6804+D/DA-DSR6804+D/DA-DS6804+D

Remotely Controlled Parameters

Bold text = Default setting [RO] = Read only/feedback

Path Parameter Range Description

Processing Serial Number [RO] String Serial number for the module

License Key String License key number for the module

Other Output Config.

Ch.1 Signal Present [RO]

Ch.2 Signal Present [RO]

Ch.1 Loss of Input Alarm

Ch.2 Loss of Input Alarm

Current Input [RO]

NOTE: Only valid in 1×8

Ch.1 1×8 with ACO

Ch.1 1×8

Ch.2 1×8

2×4

No

Yes

No

Yes

Disabled

Enabled

Disabled

Enabled

N/A

Ch. 1

Ch. 2

Selects module output configuration

as dual 1×4 or 1×8, 1 input routed to

all outputs; or 1×8 with input 2 routed

to all outputs

Indicates if the input signal for

channel 1 is present or not

Indicates if the input signal for

channel 2 is present or not

Enables or disables the Loss of Input

alarm for channel 1

Enables or disables the Loss of Input

alarm for channel 2

Indicates if the input signal is channel

1 or channel 2

with ACO mode output

configuration

Ch. 1 Slew Rate

SD

HD

Auto

Controls output/rise fall time for

channel 1

SD – Output Rise Fall time complies

with SMPTE 259M

HD – Output Rise Fall time complies

with SMPTE 424M /292M

Auto – Automatically selects proper

rise fall time based on incoming

signal

Ch. 2 Slew Rate

SD

HD

Auto

Controls output/rise fall time for

channel 2

SD – Output Rise Fall time complies

with SMPTE 259M

HD – Output Rise Fall time complies

with SMPTE 424M /292M

Auto – Automatically selects proper

rise fall time based on incoming

signal

35

Parameter Hysteresis 0.1 to 0.5 seconds Value used to determine how long a

condition (that is, signal presence)

must be asserted before it is reported

to the control system

Copyright © 2010, Harris Corporation

Page 50

Chapter 3

36

Operation

Table 3-4 DA-DHR6804+D/DA-DH6804+D/DA-DSR6804+D/DA-DS6804+D

Remotely Controlled Parameters (Continued)

Bold text = Default setting [RO] = Read only/feedback

Path Parameter Range Description

Green Mode

Out 1A Cable Fault [RO]

Out 1B Cable Fault [RO]

Out 1C Cable Fault [RO]

Out 1D Cable Fault [RO]

Out 2A Cable Fault [RO]

Out 2B Cable Fault [RO]

Out 2C Cable Fault [RO]

Out 2D Cable Fault [RO]

Ch.1 Data Rate [RO]

Ch.2 Data Rate [RO]

Ch. 1 Re-Clocking Mode

NOTE: Only valid with

DA-DHRO6804+ and

DA-DSR6804+D modules

Ch. 2 Re-Clocking Mode

NOTE: Only valid with

DA-DHRO6804+ and

DA-DSR6804+D modules

Ch1 Loss of Lock Alarm

Enabled

Disabled

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Unknown

270 Mb/s

Bypass

HD

3G

Unknown

270 Mb/s

Bypass

HD

3G

Auto

270 Mb/s

Bypass

HD

3G

Auto

270 Mb/s

Bypass

HD

3G

Disabled

Enabled

Enables or disables the use of the

power-saving (“green”) mode

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Displays locked data rate for channel 1

Displays locked data rate for channel 2

Selects the reclock rate for channel 1

input

Selects the reclock rate for channel 2

input

Enables or disables Loss of Lock alarm

on channel 1 (Loss of Lock alarm

indicates the signal is not locked)

Copyright © 2010, Harris Corporation

Page 51

DA-6804+D Series

Installation and Operation Manual

Table 3-4 DA-DHR6804+D/DA-DH6804+D/DA-DSR6804+D/DA-DS6804+D

Remotely Controlled Parameters (Continued)

Bold text = Default setting [RO] = Read only/feedback

Path Parameter Range Description

Ch2 Loss of Lock Alarm

Disabled

Enabled

Enables or disables Loss of Lock alarm

on channel 2 (Loss of Lock alarm

indicates the signal is not locked)

Table 3-5 DA-HRO6804+ Remotely Controlled Parameters

Bold text = Default setting [RO] = Read only/feedback

Path Parameter Range Description

Processing Serial Number [RO] String Serial number for the module

License Key String License key number for the module

Other Output Config.

Ch.1 Signal Present [RO]

Ch.2 Signal Present [RO]

Ch.1 Loss of Input Alarm

Ch.2 Loss of Input Alarm

Current Input [RO]

NOTE: Only valid in 1×8

Ch.1 1×8 with ACO

Ch.1 1×8

Ch.2 1×8

2×4

No

Yes

No

Yes

Disabled

Enabled

Disabled

Enabled

N/A

Ch. 1

Ch. 2

Selects module output configuration

as dual 1×4 or 1×8, 1 input routed to

all outputs; or 1×8 with input 2 routed

to all outputs

Indicates if the input signal for

channel 1 is present or not

Indicates if the input signal for

channel 2 is present or not

Enables or disables the Loss of Input

alarm for channel 1

Enables or disables the Loss of Input

alarm for channel 2

Indicates if the input signal is channel

1 or channel 2

with ACO mode output

configuration

Ch. 1 Slew Rate

SD

HD

Auto

Controls output/rise fall time for

channel 1

SD – Output Rise Fall time complies

with SMPTE 259M

HD – Output Rise Fall time complies

with SMPTE 424M /292M

Auto – Automatically selects proper

rise fall time based on incoming

signal

37

Copyright © 2010, Harris Corporation

Page 52

Chapter 3

38

Operation

Table 3-5 DA-HRO6804+ Remotely Controlled Parameters (Continued)

Bold text = Default setting [RO] = Read only/feedback

Path Parameter Range Description

Ch. 2 Slew Rate

SD

HD

Auto

Controls output/rise fall time for

channel 2

SD – Output Rise Fall time complies

with SMPTE 259M

HD – Output Rise Fall time complies

with SMPTE 424M /292M

Auto – Automatically selects proper

rise fall time based on incoming

signal

Parameter Hysteresis 0.1 second to 0.5 seconds Value used to determine how long a

condition (that is, signal presence)

must be asserted before it is reported

to the control system

Green Mode

Out 1A Cable Fault [RO]

Out 1B Cable Fault [RO]

Out 1C Cable Fault [RO]

Out 1D Cable Fault [RO]

Out 2A Cable Fault [RO]

Out 2B Cable Fault [RO]

Out 2C Cable Fault [RO]

Out 2D Cable Fault [RO]

Ch.1 Data Rate [RO]

Ch.2 Data Rate [RO]

Enabled

Disabled

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Unknown

270 Mb/s

Bypass

HD

3G

Unknown

270 Mb/s

Bypass

HD

3G

Enables or disables the use of the

power-saving (“green”) mode

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Displays locked data rate for channel 1

Displays locked data rate for channel 2

Copyright © 2010, Harris Corporation

Page 53

Installation and Operation Manual

Table 3-5 DA-HRO6804+ Remotely Controlled Parameters (Continued)

Bold text = Default setting [RO] = Read only/feedback

Path Parameter Range Description

Ch. 1 Re-Clocking Mode

Ch. 2 Re-Clocking Mode

Ch1 Loss of Lock Alarm

Auto

270 Mb/s

Bypass

HD

3G

Auto

270 Mb/s

Bypass

HD

3G

Disabled

Enabled

Selects the reclock rate for channel 1

input

Selects the reclock rate for channel 2

input

Enables or disables the Loss of Lock

alarm on channel 1 (the Loss of Lock

alarm indicates the signal is not

locked)

Ch2 Loss of Lock Alarm

Disabled

Enabled

Enables or disables the Loss of Lock

alarm on channel 2 (the Loss of Lock

alarm indicates the signal is not

locked)

SFP 1 Type [RO]

Transceiver 1A

Dual Receiver 1A

Dual Transmitter 1A

Unknown

Transceiver 2A

Dual Receiver 2A

Dual Transmitter 2A

Displays the SFP type present in SFP

slot 1

DA-6804+D Series

39

Ch. 1 Rx Power [RO] 0.000 mW to 6.535 mW Internally measured receiver power on

optical channel 1

Table 3-6 DA-DHROE6804+ Remotely Controlled Parameters

Bold text = Default setting [RO] = Read only/feedback

Path Parameter Range Description

Processing Serial Number [RO] String Serial number for the module

License Key String License key number for the module

Other Output Config.

Ch.1 Signal Present [RO]

Ch.2 Signal Present [RO]

Ch.1 Loss of Input Alarm

Ch.1 1×8 with ACO

Ch.1 1×8

Ch.2 1×8

2×4

No

Yes

No

Yes

Disabled

Enabled

Selects module output configuration

as dual 1×4 or 1×8, 1 input routed to

all outputs; or 1×8 with input 2 routed

to all outputs

Indicates if the input signal for

channel 1 is present or not

Indicates if the input signal for

channel 2 is present or not

Enables or disables the Loss of Input

alarm for channel 1

Copyright © 2010, Harris Corporation

Page 54

Chapter 3

40

Operation

Table 3-6 DA-DHROE6804+ Remotely Controlled Parameters (Continued)

Bold text = Default setting [RO] = Read only/feedback

Path Parameter Range Description

Ch.2 Loss of Input Alarm

Current Input [RO]

NOTE: Only valid in 1×8

Disabled

Enabled

N/A

Ch. 1

Ch. 2

Enables or disables the Loss of Input

alarm for channel 2

Indicates if the input signal is channel

1 or channel 2

with ACO mode output

configuration

Ch. 1 Slew Rate

SD

HD

Auto

Controls output/rise fall time for

channel 1

SD – Output Rise Fall time complies

with SMPTE 259M

HD – Output Rise Fall time complies

with SMPTE 424M /292M

Auto – Automatically selects proper

rise fall time based on incoming

signal

Ch. 2 Slew Rate

SD

HD

Auto

Controls output/rise fall time for

channel 2

SD – Output Rise Fall time complies

with SMPTE 259M

HD – Output Rise Fall time complies

with SMPTE 424M /292M

Auto – Automatically selects proper

rise fall time based on incoming

signal

Parameter Hysteresis 0.1 second to 0.5 seconds Value used to determine how long a

Green Mode

Out 1A Cable Fault [RO]

Out 1B Cable Fault [RO]

Out 1C Cable Fault [RO]

Out 1D Cable Fault [RO]

Out 2A Cable Fault [RO]

Out 2B Cable Fault [RO]

Copyright © 2010, Harris Corporation

Enabled

Disabled

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

condition (that is, signal presence)

must be asserted before it is reported

to the control system

Enables or disables the use of the

power-saving (“green”) mode

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Page 55

Installation and Operation Manual

Table 3-6 DA-DHROE6804+ Remotely Controlled Parameters (Continued)

Bold text = Default setting [RO] = Read only/feedback

Path Parameter Range Description

Out 2C Cable Fault [RO]

Out 2D Cable Fault [RO]

Ch.1 Data Rate [RO]

Ch.2 Data Rate [RO]

Ch. 1 Re-Clocking Mode

Ch. 2 Re-Clocking Mode

Ch1 Loss of Lock Alarm

Yes

No

Yes

No

Unknown

270 Mb/s

Bypass

HD

3G

Unknown

270 Mb/s

Bypass

HD

3G

Auto

270 Mb/s

Bypass

HD

3G

Auto

270 Mb/s

Bypass

HD

3G

Disabled

Enabled

Reports loss of signal or termination

fault for the corresponding output

Reports loss of signal or termination

fault for the corresponding output

Displays locked data rate for channel 1

Displays locked data rate for channel 2

Selects the reclock rate for channel 1

input

Selects the reclock rate for channel 2

input

Enables or disables the Loss of Lock

alarm on channel 1 (the Loss of Lock

alarm indicates the signal is not

locked)

Ch2 Loss of Lock Alarm

Disabled

Enabled

Enables or disables the Loss of Lock

alarm on channel 2 (the Loss of Lock

alarm indicates the signal is not

locked)

SFP 1 Type [RO]

Transceiver 1A

Dual Receiver 1A

Dual Transmitter 1A

Unknown

Transceiver 2A

Dual Receiver 2A

Dual Transmitter 2A

Displays the SFP type present in SFP

slot 1

DA-6804+D Series

41

Ch. 1 Rx Power [RO] 0.000 mW to 6.535 mW Internally measured receiver power on

Ch. 2 Rx Power [RO] 0.000 mW to 6.535 mW Internally measured receiver power on

optical channel 1

optical channel 2