Harris DAC-5016, DAC-5012, DAC-5008, DAC-5006, DAC-5005 Installation And Operation Manual

...Page 1

5000 and 5100 Series

Digital Analog Clocks

Installation and Operation Manual

Edition D

5000/5100 MAN

Page 2

Page 3

5000/5100Series

Digital Analog Clocks

Installation and Operation Manual

Edition D

August 2006

Page 4

Trademarks and Copyrights

CCS, CCS CoPilot, CCS Navigator, CCS Pilot, Command Control System,

CineTone, CinePhase, CineSound, DigiBus, DigiPeek, Digital Glue,

DigiWorks, DTV Glue, EventWORKS, EZ HD, Genesis, HDTV Glue,

Image Q, Icon, IconLogo, IconMaster, IconMaster Nav, IconSet, Icon

Station, Inca, Inca Station, InfoCaster, Inscriber, Inscriber CG—FX,

Integrator, LeFont, Leitch, LogoMotion, MediaFile, MIX BOX, NEO, the

NEO design, NEOSCOPE, NewsFlash, Nexio, Opus, Panacea,

PanelMAPPER, Platinum, Portal, PROM-Slide, RouterMAPPER,

RouterWORKS, Signal Quality Manager, SpyderWeb, SuiteView,

TitleMotion, UNIFRAME, Velocity, VelocityHD, VideoCarte, Videotek,

and X75 are trademarks of the Harris Corporation, which may be registered

in the United States, Canada, and/or other countries. All other trademarks

are the property of their respective owners.

Copyright 2006, Harris Corporation. All rights reserved. This publication

supersedes all previous releases. Printed in Canada.

Warranty Information

The Limited Warranty Policy provides a complete description of your

warranty coverage, limitations, and exclusions, as well as procedures

for obtaining warranty service. To view the complete warranty, visit

www.broadcast.harris.com/leitch

.

Page 5

Contents

Preface

Manual Information ............................................................................... iii

Purpose ............................................................................................ iii

Audience ......................................................................................... iii

Revision History ............................................................................. iii

Writing Conventions ....................................................................... iv

Obtaining Documents ..................................................................... iv

Unpacking/Shipping Information ............................................................v

Unpacking a Product .........................................................................v

Product Servicing ..............................................................................v

Returning a Product ..........................................................................v

Restriction on Hazardous Substances (RoHS) Compliance .................. vi

Waste from Electrical and Electronic Equipment (WEEE) Compliance vii

Safety ................................................................................................... viii

Safety Terms and Symbols in this Manual ................................... viii

5000/5100 Series Digital Analog Clocks Installation and Operation Manual i

Chapter 1: DAC-5000 Series Digital Analog Clocks

Overview ..................................................................................................1

Introduction ..............................................................................................2

Installation ................................................................................................3

Wall Mounting ..................................................................................3

Rack Mounting .................................................................................5

Rear Panel .........................................................................................6

Control Modes ..........................................................................................8

Calibration of the Internal Time Base ...............................................8

General Operation ....................................................................................9

Clock Control Modes ........................................................................9

Clock Setting Controls ....................................................................10

Page 6

Contents

Specifications ........................................................................................ 12

Electrical ........................................................................................ 12

Primary Drive Inputs ...................................................................... 12

Secondary Time Bases ................................................................... 12

Mechanical ..................................................................................... 13

Chapter 2: ADC-5100 Series Analog Digital Clocks

Overview ............................................................................................... 15

Introduction ........................................................................................... 16

Installation ............................................................................................. 18

Wall Mounting ............................................................................... 18

Rack Mounting ............................................................................... 20

Desk Mounting ............................................................................... 20

Rear Panel ...................................................................................... 21

Control Modes ....................................................................................... 23

General Operation ................................................................................. 24

Clock Control Modes ..................................................................... 24

Clock Setting .................................................................................. 26

Troubleshooting .................................................................................... 32

Hands are Offset ............................................................................. 32

Specifications ........................................................................................ 34

Electrical ........................................................................................ 34

Inputs and Outputs ......................................................................... 34

Time Base ...................................................................................... 34

Controls .......................................................................................... 35

Mechanical ..................................................................................... 35

ii 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 7

Manual Information

Purpose

This manual details the features, installation, operation, maintenance,

and specifications for 5000/5100 Series Digital Analog Clocks.

Audience

This manual is written for engineers, technicians, and operators

responsible for installation, setup, maintenance, and/or operation of

5000/5100 Series Digital Analog Clocks.

Revision History

Preface

5000/5100 Series Digital Analog Clocks Installation and Operation Manual iii

Table P-1. Revision History of Manual

Edition Date Comments

C December 1998 Full release

D August 2006 Manual reformatted and updated

Page 8

Preface

Writing Conventions

To enhance your understanding, the authors of this manual have

adhered to the following text conventions:

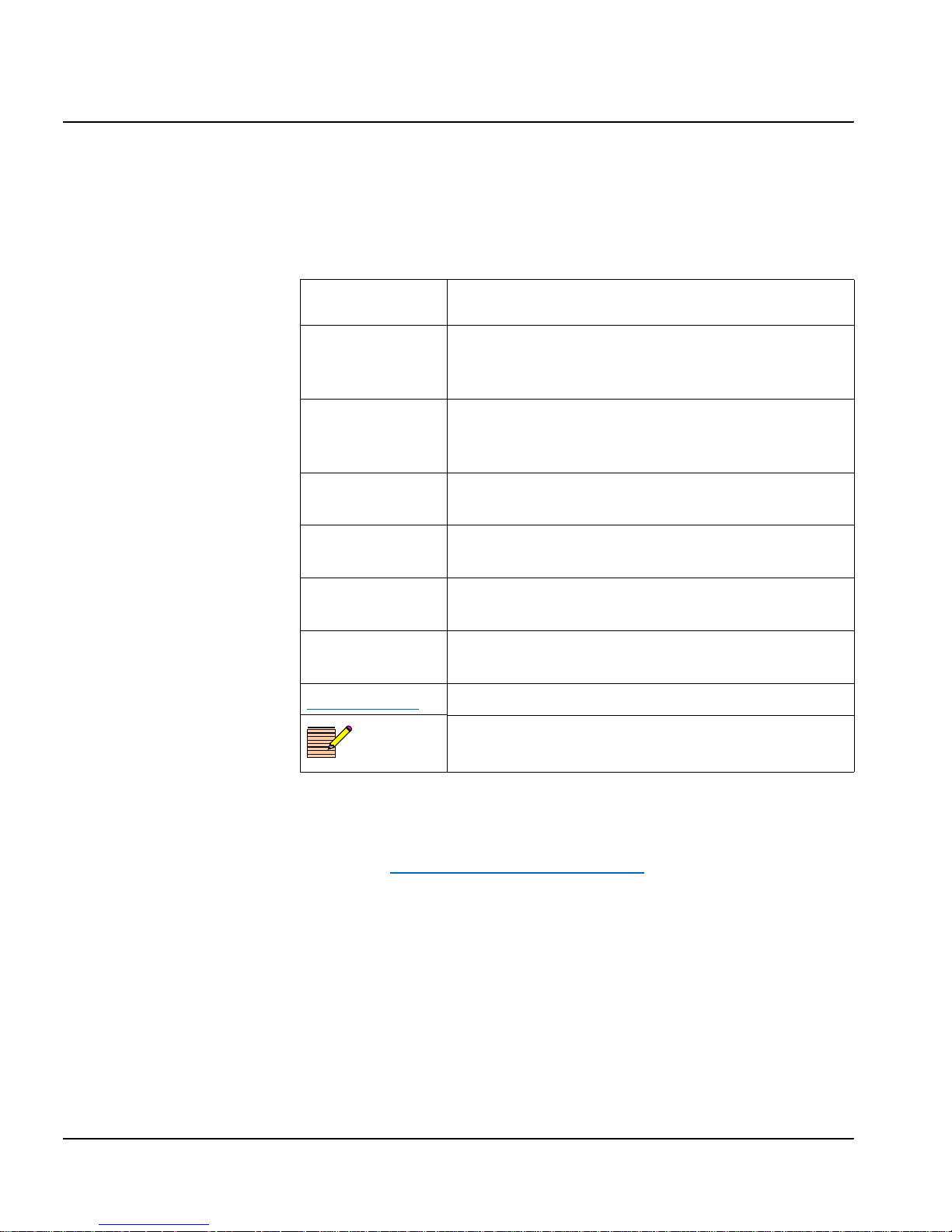

Table P-2. Writing Conventions

Term or

Convention

Bold Indicates dialog boxes, property sheets, fields, buttons,

Italics Indicates E-mail addresses, the names of books or

CAPS Indicates a specific key on the keyboard, such as

Code Indicates variables or command-line entries, such as a

> Indicates the direction of navigation through a hierarchy

hyperlink Indicates a jump to another location within the

Internet address

Note

Description

check boxes, list boxes, combo boxes, menus,

submenus, windows, lists, and selection names

publications, and the first instances of new terms and

specialized words that need emphasis

ENTER, TAB, CTRL, ALT, or DELETE

DOS entry or something you type into a field

of menus and windows

electronic document or elsewhere

Indicates a jump to a Web site or URL

Indicates important information that helps to avoid and

troubleshoot problems

Obtaining Documents

Product support documents can be viewed or downloaded from our

Web site at www.broadcast.harris.com/leitch

Documentation). Alternatively, contact your customer service

representative to request a document.

iv 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

(go to Support>

Page 9

Unpacking/Shipping Information

Unpacking a Product

This product was carefully inspected, tested, and calibrated before

shipment to ensure years of stable and trouble-free service.

1. Check equipment for any visible damage that may have occurred

during transit.

2. Confirm that you have received all items listed on the packing list.

3. Contact your dealer if any item on the packing list is missing.

4. Contact the carrier if any item is damaged.

5. Remove all packaging material from the product and its associated

components before you install the unit.

Keep at least one set of original packaging, in the event that you need to

return a product for servicing.

Preface

Product Servicing

5000/5100 Series Digital Analog Clocks are not designed for field

servicing. All upgrades, modifications, or repairs require you to return

the product to the Customer Service center.

Returning a Product

In the unlikely event that your product fails to operate properly, please

contact Customer Service to obtain a Return Authorization (RA)

number, then send the unit back for servicing.

Keep at least one set of original packaging in the event that a product

needs to be returned for service. If the original package is not available,

you can supply your own packaging as long as it meets the following

criteria:

• The packaging must be able to withstand the product’s weight.

• The product must be held rigid within the packaging.

• There must be at least 2 in. (5 cm) of space between the product and

• The corners of the product must be protected.

the container.

5000/5100 Series Digital Analog Clocks Installation and Operation Manual v

Ship products back to us for servicing prepaid and, if possible, in the

original packaging material. If the product is still within the warranty

period, we will return the product prepaid after servicing.

Page 10

Preface

Restriction on Hazardous Substances (RoHS)

Compliance

Directive 2002/95/EC—commonly known as the European Union (EU)

Restriction on Hazardous Substances (RoHS)—sets limits on the use of

certain substances found in electrical and electronic equipment. The

intent of this legislation is to reduce the amount of hazardous chemicals

that may leach out of landfill sites or otherwise contaminate the

environment during end-of-life recycling. The Directive takes effect on

July 1, 2006, and it refers to the following hazardous substances:

• Lead (Pb)

• Mercury (Hg)

• Cadmium (Cd)

• Hexavalent Chromium (Cr-V1)

• Polybrominated Biphenyls (PBB)

• Polybrominated Diphenyl Ethers (PBDE)

According to this EU Directive, all products sold in the European Union

will be fully RoHS-compliant and “lead-free.” (See our Web site,

www.broadcast.harris.com/leitch

deadlines for compliance.) Spare parts supplied for the repair and

upgrade of equipment sold before July 1, 2006 are exempt from the

legislation. Equipment that complies with the EU directive will be

marked with a RoHS-compliant emblem, as shown in Figure P-1.

Figure P-1. RoHS Compliance Emblem

, for more information on dates and

vi 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 11

Waste from Electrical and Electronic

Equipment (WEEE) Compliance

The European Union (EU) Directive 2002/96/EC on Waste from

Electrical and Electronic Equipment (WEEE) deals with the collection,

treatment, recovery, and recycling of electrical and electronic waste

products. The objective of the WEEE Directive is to assign the

responsibility for the disposal of associated hazardous waste to either

the producers or users of these products. Effective August 13, 2005,

producers or users will be required to recycle electrical and electronic

equipment at end of its useful life, and may not dispose of the

equipment in landfills or by using other unapproved methods. (Some

EU member states may have different deadlines.)

In accordance with this EU Directive, companies selling electric or

electronic devices in the EU will affix labels indicating that such

products must be properly recycled. (See our Web site,

www.broadcast.harris.com/leitch

deadlines for compliance.) Contact your local sales representative for

information on returning these products for recycling. Equipment that

complies with the EU directive will be marked with a WEEE-compliant

emblem, as shown in Figure P-2.

, for more information on dates and

Preface

5000/5100 Series Digital Analog Clocks Installation and Operation Manual vii

Figure P-2. WEEE Compliance Emblem

Page 12

Preface

Safety

Carefully review all safety precautions to avoid injury and prevent

damage to this product or any products connected to it. If this product is

rack-mountable, it should be mounted in an appropriate rack using the

rack-mounting positions and rear support guides provided. It is

recommended that each frame be connected to a separate electrical

circuit for protection against circuit overloading. If this product relies

on forced air cooling, it is recommended that all obstructions to the air

flow be removed prior to mounting the frame in the rack.

If this product has a provision for external earth grounding, it is

recommended that the frame be grounded to earth via the protective

earth ground on the rear panel.

IMPORTANT! Only qualified personnel should perform service

procedures.

Safety Terms and Symbols in this Manual

WARNING

Statements identifying conditions or

practices that may result in personal injury

or loss of life. High voltage is present.

CAUTION

Statements identifying conditions or

practices that can result in damage to the

equipment or other property.

viii 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 13

Chapter 1

DAC-5000 Series Digital Analog Clocks

Overview

This chapter provides installation and operation information about the

DAC-5000 Series digital analog clocks. It includes the following topics:

• “Introduction” on page 2

• “Installation” on page 3

• “Control Modes” on page 8

• “General Operation” on page 9

• “Specifications” on page 12

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 1

Page 14

Chapter 1: DAC-5000 Series Digital Analog Clocks

Introduction

The DAC-5000 Series Digital Analog Clocks feature a quiet, digitally

controlled drive mechanism. Each hand is driven independently by a

separate motor and drive train. The exact position of each hand is

microprocessor controlled and virtually error free.

The standard clock face provides two sets of numerals: 1 to12 are black,

and 13 to 24 are red. A clock face with only black numerals from 1 to

12 is optional.

The DAC-5000 Series clocks operate with standard drive signals and

consequently can be easily integrated into new or existing systems.

Selection of the drive signals is made by switches located on the back

panel. The usable drive signals are:

• Serial Timecode (SMPTE or EBU)

• 12 VDC Impulse Clock

• Internal Time Base

• Line Frequency Reference

All clock models accept Serial Timecode are in either the SMPTE or

EBU format.

If reception of the timecode is lost, the error LED located on the clock’s

face will light up and the clock will automatically switch to either the

Internal Time Base or the Line Frequency Reference, as selected on the

back panel switches, without interruption of its operation.

The Internal Time Base is provided by a 4.9 MHz crystal oscillator. The

Line Frequency Reference uses a 50/60 Hz power line. Selection of

either 50 or 60 Hz is made by soldering a jumper on the 5000DL Drive

Logic module.

The following models are available:

• DAC-5016 16 inch illuminated, wall mounting. Rack mounting

kit optional.

• DAC-5012 12 inch illuminated, wall mounting. Rack mounting

kit optional.

• DAC-5008 8 inch illuminated, wall mounting. Rack mounting kit

optional.

• DAC-5006 5 inch non-illuminated, rack mounting.

• DAC-5005 5 inch non-illuminated, desk top.

2 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 15

Installation

Wall Mounting

Chapter 1: DAC-5000 Series Digital Analog Clocks

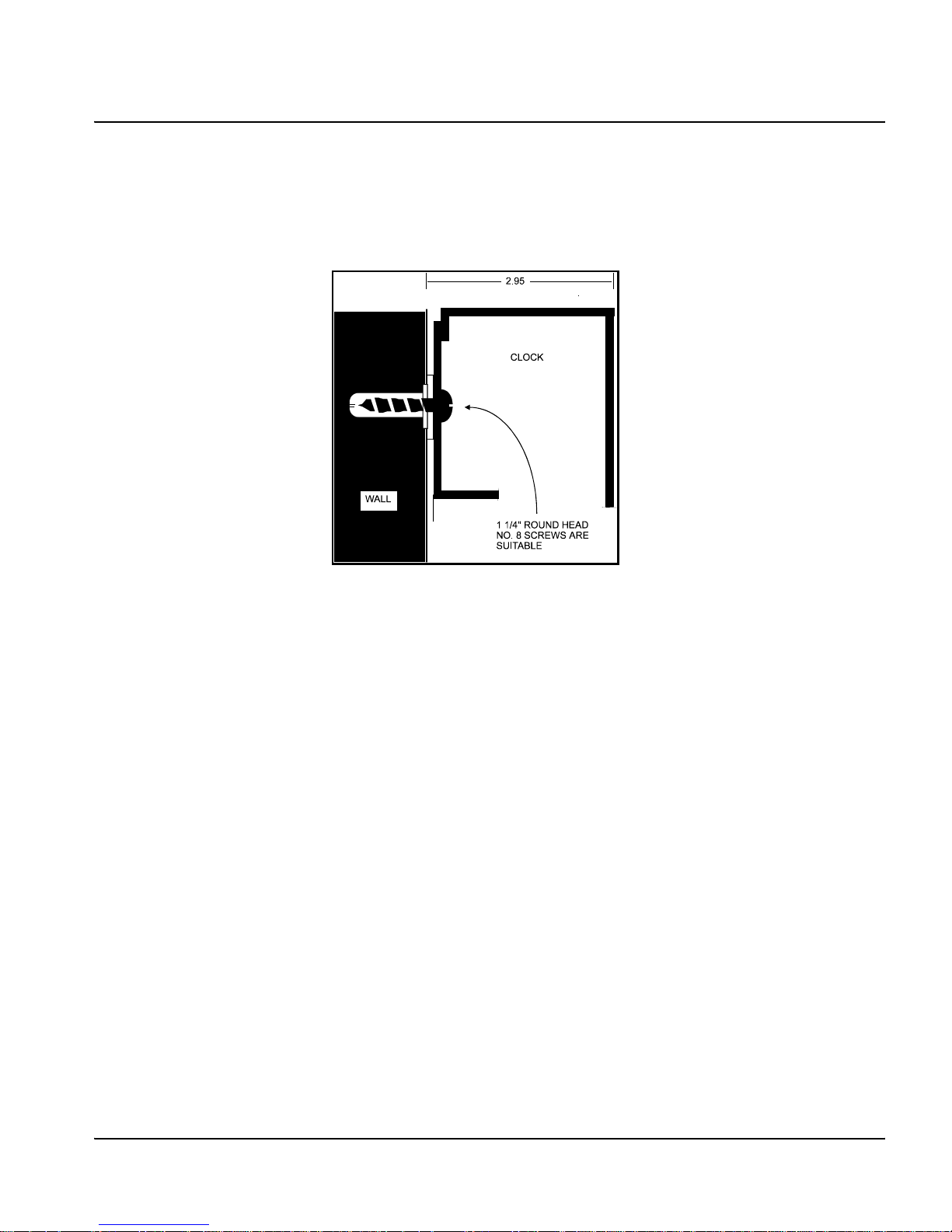

Figure 1-1. Typical Wall Mount

The DAC-5008, DAC-5012 and DAC-5016 Digital Analog Clocks are

designed for wall mounting. Rack mounting kits are optional.

The rear panels of both the DAC-5012 and DAC-5016 clocks are

provided with four rubber feet and four keyholes while the DAC-5008

has only three keyholes. These are dimensioned for #8 screws. The rear

panel also has a large depression to contain the connecting wires and

allow the clock to be placed close to the wall.

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 3

Page 16

Chapter 1: DAC-5000 Series Digital Analog Clocks

Table 1-1 provides information about clock wall mounting

specifications

Table 1-1. Clock Wall Mounting Specifications

Clearances

Clock

DAC-5016 17.45×17.45 in. 16.0×15.5 in.

DAC-5012 13.95×13.95 in. 12.0×10.5 in.

DAC-5008 10.45×10.45 in. 8.0×8.0 in.

Overall

Dimensions

Mounting Keyhole

Centers

(4 keyholes)

(4 keyholes)

(3 keyholes). The bottom

single keyhole is located

Note

A convenient template drawing showing the correct mounting centers

is included with the clock.

Table 1-2 lists the minimum clearances, measured in inches, from the

mounting keyhole centers to the outside edge of each clock:

Table 1-2. Clock Clearances

Clock Clearances (Inches)

DAC-5016

DAC-5012

DAC-5008

4 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

• Top edge 0.8

• Sides 0.725

• Bottom edge 1.275

• Top edge 1.12

• Sides 0.975

• Bottom edge 2.35

• Top edge 0.825

• Sides 1.275

• Bottom edge 1.85

Page 17

Rack Mounting

Chapter 1: DAC-5000 Series Digital Analog Clocks

The DAC-5008, DAC-5012 and DAC-5016 clocks can be rack

mounted with the optional rack mounting kit. The kit is installed by

removing the back panel side screws, placing the rack mount in

position, and reinstalling the screws. The rack mount kits are designated

as 5008RM, 5012RM, and 5016RM, respectively.

The DAC-5006 clock is pre-designed to be rack mounted, and does not

require the optional rack mounting kit. It has an overall dimension of

7×19 inches.

Table 1-3 lists the required rack space for each clock.

Table 1-3. Required Space For Rack Mounting

Clocks Rack Units Inches

DAC-5016 10 17.45

DAC-5012 8 13.95

DAC-5008 6 10.45

DAC-5006 4 7

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 5

Page 18

Chapter 1: DAC-5000 Series Digital Analog Clocks

Rear Panel

AC

Connector

(plug)

Clock Modes

(factory set)

OPERATION MODE

DAC-500 8

DAC-501 2

DAC-501 6

LINE VOLTAGE

115 VAC

230 VAC

LINE F REQUENCY

50 HZ

60 HZ

115/230 VAC 10%250/60Hz

+

25VA Max

Multifunctional Pushbuttons

Full Instructions in Manual

CW

CCW

MANUAL

SET

Time Code

SMPTE

Internal

Normal

Normal

Step Sec onds

OPEN

12 4356

Impulse

EBU

Line

Use Offset

Run On Secondary

Sweep Seconds

Spring Loaded

“Speaker-Type”

Connectors (red

and black)

Push-Buttons:

CW, CCW,

MANUAL SET

DIP Switches

Figure 1-2. DAC-5008/5012/5016 Rear Panel

The rear panels of the DAC-5008/5012/5016 have two spring-loaded

speaker-type connectors (one red, one black) to accept the Primary

Reference input (i.e. SMPTE Serial Timecode or Impulse Drive

signals).

A standard AC connector for the power feed of the unit can be found in

the recessed area running across the middle of the rear panel.

6 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 19

115/230 VAC 0 %

50/60Hz

25VA Max

Chapter 1: DAC-5000 Series Digital Analog Clocks

Below this recessed area are the multifunction clock setting buttons and

the six DIP switches (SW1 to SW6), all of which must be set prior to

installation.

LINE VOLTAGE

115 VAC

230 VAC

LINE FREQUENCY

50 HZ

60 HZ

Run on Second ary

MANUAL

LIN E VOLTAG E

115 VAC

230 VAC

+2

LINE FREQUENCY

50 HZ

60 HZ

SET

CCW

CW

Use Offset

Secondary Ref-Line

Time Code Format-EBU

Not Used

12 4356

OPEN

Normal

Normal

Internal

SMPTE

Primary Ref-Time Code

115/230 VAC 0%

50/60Hz

25VA Max

MANUAL

SET

CCW

+2

CW

Run on Secondary

Use Offset

Secondary Ref-Line

Time Code Format-EBU

Not Used

12 4356

OPEN

Normal

Normal

Internal

SMPTE

Primary Ref-Time Code

Figure 1-3. DAC-5005 (left) and DAC-5006 (right) Rear Panels

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 7

Page 20

Chapter 1: DAC-5000 Series Digital Analog Clocks

Control Modes

Table 1-4 lists the Clock Control mode DIP switch options.

Table 1-4. Clock Control Mode DIP switch options

Dip Switch

SW1 Timecode Impulse

SW2 SMPTE EBU

SW3 Internal Line

SW4 Normal Use offset

SW5 Normal Run on secondary

SW6 (Secondary) NA NA

Switch Options

Open Closed

Calibration of the Internal Time Base

This procedure is used to adjust the frequency of the 4.9152 crystal

oscillator. The accuracy of this adjustment directly affects the accuracy

of the Internal Time Base. The only equipment required is a high

resolution frequency counter.

Connect the frequency counter to the clock test point provided at pin 9

of the CMOS NSC800N Microprocessor IC11. Adjust the 6-25 pF

trimmer capacitor connected to pin 11 of IC11 until the counter

indicates 2.457.600 Hz. It is recommended to use the longest sampling

time possible.

8 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 21

General Operation

Clock Control Modes

Primary Reference Mode

The Primary Reference Mode provides two options, the Timecode and

the Impulse Clock modes. Selection of either mode is done by switch

SW1.

Timecode Mode

No setting of time is required when the timecode mode is selected.

However, selection of either SMPTE or EBU format should be made by

means of switch SW2.

Upon selecting Timecode mode, the microprocessor will start reading

the code and will light the error LED of the clock face (found under the

6) to indicate that the unit is not yet synchronized with the timecode.

Chapter 1: DAC-5000 Series Digital Analog Clocks

Once the timecode is decoded, the clock hands will move in a clockwise

direction towards the 12:00 position where the three hand detectors are

located. The clock hands will then move to their new position via the

shortest route and the error LED will go off to indicate that the unit is

synchronized with the timecode.

If there is a change in the timecode, the error LED will activate again

while the microprocessor verifies the code to ensure that there is a valid

time change and not a transient condition. This verification requires 30

consecutive full code frames or 1 second for SMPTE format operation,

and 1.2 seconds for EBU format, depending on the selection of switch

SW2. Once the verification is completed and if there is a valid change,

the clock hands will move to the new time position as previously

described and the error LED will go off.

If the timecode is lost due to a mechanical failure such as a

disconnected cable or to a malfunction of the master clock, the error

LED will light up again. The clock, however, will continue to operate

and show accurate time since it will automatically switch to the

secondary time base selected by switch SW3 (either the line frequency,

or the internal crystal oscillator). Once the malfunction is eliminated the

clock will automatically switch back to timecode and re-synchronize to

the incoming timecode, and the error LED will go off.

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 9

Page 22

Chapter 1: DAC-5000 Series Digital Analog Clocks

Impulse Clock Mode

The DAC-5000 Series clocks will emulate a standard impulse clock.

Like any impulse clock, it must be manually set to the correct time and

will stop if the impulses from the master clock also stop. The unit will

check the polarity of the pulses so that the positive pulses from the red

input connector on the rear panel will move the second hand to an even

number of the clock face (i.e. 2, 4, 6 etc.), while the black input

connector will handle the odd numbers.

This check will only occur after the position of the second hand is

known by the microprocessor. This takes place when the hand passes

the detector located near the 12:00 position.

Correct hand position will be established automatically by the

microprocessor when the clock hands pass their detection positions.

However, to establish the minute hand, the position of the second hand

must be already established. To establish the hour hand, the position of

both the minute and second hands must also be established.

The error LED will not be on when operating as an impulse clock.

Secondary Reference Mode

The DAC-5000 Series clock will run as a standard wall clock with no

exterior Timecode or Impulse drive when selected by the run on

secondary switch SW5. Selection of either Internal reference or Line

frequency is done by switch SW3. Correct hand position is established

in the same manner as for the Impulse Clock. The time must also be set

manually.

The error LED will not be operational when this mode is selected.

Clock Setting Controls

Manual Setting

The clock is manually set by means of three push-buttons located on the

rear panel.

• MANUAL SET Press this button once to select the hour hand,

twice to select the minute hand, three times to select the second

hand, and four times to set the clock. When selected, the hands will

start shaking briskly to visually indicate their status.

10 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 23

Use Offset

Chapter 1: DAC-5000 Series Digital Analog Clocks

• CCW This button moves the selected hand counter-clockwise

one unit. When the time is set, press the MANUAL SET button (a

fourth time) and release it at the exact time that the clock is to be

set. The clock will now return to normal time keeping with the

second hand advancing one second after the

MANUAL SET button

is released.

• CW Press this button to move the selected hand clockwise one

unit. When the time is set, press the MANUAL SET button (a

fourth time) and release it at the exact time that the clock is to be

set. The clock will now return to normal time keeping with the

second hand advancing one second after the MANUAL SET

button is released.

The

USE OFFSET function allows the addition of a user programmed

constant offset to the user bits of a standard timecode. Therefore, the

availability of a timecode generator capable of programming the user

bits of the timecode is essential.

This function is generally used when it is desired to simultaneously

provide GMT and local time with two clocks being fed the same

timecode.

The

USE OFFSET function is selected by closing the control mode

switch SW4 of the rear panel. Six bits of data are used to specify the

offset. The six bits are divided into two three bit sections. The first three

bits follow the unit minutes at bits 36, 37 and 38 of the timecode. The

second three bits follow the unit hours data at bits 52, 53 and 54. The

minimum offset allowed is 30 minutes. This can be incremented in 30

minute periods until reaching 23 hours and 30 minutes which is the

maximum offset allowed.

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 11

Page 24

Chapter 1: DAC-5000 Series Digital Analog Clocks

Specifications

Specifications and designs are subject to change without notice.

Electrical

Table 1-5. Electrical

Item Specification

Electrical voltage 115/230 VAC ±20%

Frequency 50 or 60 Hz, selectable

Power 25 VA max.

Primary Drive Inputs

Table 1-6. Primary Drive Inputs

Input Item Specification

Serial timecode

SMPTE/EBU

Impulse drive

12 VDC±6 dB,

bipolar

Secondary Time Bases

Table 1-7. Secondary Time Bases

Item Specification

Internal Derived from processor clock 2.4576

Impedance Hi-Z, balanced

Maximum voltage 100 Vp-p

Common mode rejection 55 dB

Level 4 Vp-p ±12 dB

Impedance Hi-Z, balanced

Maximum voltage 100 Vp-p

Common mode rejection 55 dB

Level 4 Vp-p ±12 dB

MHz, crystal oscillator

Power line 50 or 60 Hz, jumper selectable

12 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 25

Chapter 1: DAC-5000 Series Digital Analog Clocks

Mechanical

Table 1-8. Mechanical Specifications

Clock Item Specification

DAC-5016 Style Wall-mount

Face diameter 16 in. (406 mm)

Overall dimensions 17.45×17.45×2.8 in.

(443×443×71 mm)

Weight 9.1 lbs (4.1 kg)

DAC-5012 Style Wall-mount

Face diameter 11.75 in. (298 mm)

Overall dimensions 13.95×13.95×2.8 in.

(354×354×71 mm)

Weight 7.3 lbs (3.3 kg)

DAC-5008 Style Wall-mount

Face diameter 8 in. (203 mm)

Overall dimensions 10.45×10.45×2.8 in. (265×265×71 mm)

Weight 5 lbs (2.3 kg)

DAC-5006 Style Rack-mount

Face diameter 5 in. (127 mm)

Overall dimensions 7×19×2.8 in. (177×482×71 mm)

Weight 4.5 lbs (2 Kg)

DAC-5005 Style Desk-mount

Face diameter 5 in. (127 mm)

Overall dimensions 8.25×6×7.25 in. (209×152×184 mm)

Weight 3.8 lbs (1.75 Kg)

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 13

Page 26

Chapter 1: DAC-5000 Series Digital Analog Clocks

14 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 27

Chapter 2

ADC-5100 Series Analog Digital Clocks

Overview

This chapter provides installation and operation information about the

ADC-5100 Series digital analog clocks. It includes the following topics:

• “Introduction” on page 16

• “Installation” on page 18

• “Control Modes” on page 23

• “General Operation” on page 24

• “Troubleshooting” on page 32

• “Specifications” on page 34

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 15

Page 28

Chapter 2: ADC-5100 Series Analog Digital Clocks

Introduction

The ADC-5100 Series Analog Digital Clocks are a group of quiet,

digitally controlled, self-setting analog face clocks. These may operate

either stand-alone via power line frequency or internal crystal, or with a

SMPTE or EBU serial timecode input.

When provided with a SMPTE or EBU timecode source, the ADC

Series Clocks are self-setting. If the timecode is valid, the ADC Series

Clocks will advance or reverse their hand positions to the correct time.

In the event of a power failure, the ADC Series Clocks maintain the

correct time internally via a battery-backed timekeeping memory. If

power should be restored without timecode, the ADC Series Clocks will

self-set to the correct time as maintained by the battery backup, and

then continue to operate on internal crystal or power line timebase.

The ADC clocks may operate with either a sweep or step second hand,

and will automatically decode either SMPTE or EBU timecode inputs.

Additionally, the ADC may function as a timecode generator when

operated from its internal crystal. Either SMPTE or EBU timecode may

be generated and used to drive other clocks (in Master Mode).

Note

Internal connector ‘P1’ must be reversed for Master Operation.

The ADC Series clocks are compatible with a user-defined auxiliary

offset when driven from the following clock system drivers;

• MTG-3901 Master Timing Generator

• CSD-3901/3902 Master Clock System Driver

• CSD-5300 Master Clock System Driver.

A local offset can also be provided by electronically re-positioning the

clock hands.

In the event of a timecode input failure, an error LED (located on the

clock face under the 6) will flash at the rate of twice per second. The

ADC clock will then automatically switch to the user-selected

secondary timebase, either power line frequency or internal crystal. The

power line frequency is automatically determined during power-up. The

error LED will illuminate during power-up to indicate 50 Hz power line

frequency detection.

16 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 29

Chapter 2: ADC-5100 Series Analog Digital Clocks

If timecode operation is not required, the ADC clock may be set to use

the secondary timebase permanently, and the error LED will be

extinguished.

The following models are available:

• ADC-5116 16 inch, wall mounting. Rack mounting and light kit

optional.

• ADC-5112 12 inch, wall mounting. Rack mounting and light kit

optional.

• ADC-5108 8 inch, wall mounting. Rack mounting and light kit

optional.

• ADC-5106 5 inch, rack mounting. Light optional.

• ADC-5105 5 inch, desk top mounting. Light optional.

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 17

Page 30

Chapter 2: ADC-5100 Series Analog Digital Clocks

Installation

Wall Mounting

Figure 2-4. Typical Wall Mounting

The ADC-5108, ADC-5112, and ADC-5116 Analog Digital Clocks are

designed for wall mounting. Rack mounting kits are optional.

The rear panels of both the ADC-5112 and ADC-5116 clocks are

provided with four rubber feet and four keyholes, while the ADC-5108

has only three keyholes. These are dimensioned for #8 screws. The rear

panel of all three clocks is recessed for connectors, and to allow the

clock to be placed close to the wall.

18 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 31

Chapter 2: ADC-5100 Series Analog Digital Clocks

Table 2-9 provides information about clock wall mounting

specifications

Table 2-9. Clock Wall Mounting Specifications

Clearances

Clock

ADC-5116 17.5×17.5 in. 16.0×15.5 in.

ADC-5112 14.0×14.0 in. 12.0×10.5 in.

ADC-5108 10.5×10.5 in. 8.0×7.75 in.

Overall

Dimensions

Mounting Keyhole

Centers

(4 keyholes)

(4 keyholes)

(3 keyholes).

The bottom single

keyhole is located 0.35

in. to the right of the

center line.

Note

A convenient template drawing showing the correct mounting centers

is included with the clock.

Table 2-10 lists the minimum clearances, measured in inches, from the

mounting keyhole centers to the outside edge of each clock:

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 19

Table 2-10. Clock Clearances

Clock Clearances (Inches)

ADC-5116

ADC-5112

ADC-5108

• Top edge 0.813

• Sides 0.75

• Bottom edge 1.187

• Top edge 1.125

•Sides 1.0

• Bottom edge 2.375

• Top edge 0.875

• Sides 1.250

• Bottom edge 1.875

Page 32

Chapter 2: ADC-5100 Series Analog Digital Clocks

Rack Mounting

The ADC-5116, ADC-5112 and ADC-5108 clocks can be rack mounted

with the optional rack mounting kit. The kit is installed by removing the

back panel side screws, placing the rack mount in position, and

reinstalling the screws. The rack mount kits are designated as RM-5116,

RM-5112, and RM-5108, respectively.

The ADC-5106 clock is pre-designed to be rack mounted, and does not

require the optional rack mounting kit. It has an overall dimension of

7×19 inches.

Table 2-11 lists the required rack space for each clock.

Table 2-11. Required Space For Rack Mounting

Clocks Rack Units Inches

ADC-5116 10 17.5

ADC-5112 8 14.0

Desk Mounting

ADC-5108 6 10.5

ADC-5106 4 7

The ADC-5105 clock can simply be set or mounted on any desk

surface. Its overall dimensions are 8.25 x 5.85 in.

20 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 33

Rear Panel

AC

Connector

(plug)

Clock Modes

(factory set)

OPERATION MODE

SLAVE

MASTER

ADC-510 8

ADC-5108-L

ADC-5112

ADC-5112- L

ADC-5116

ADC-5116- L

Line Vol tage

115VAC

230VAC

Chapter 2: ADC-5100 Series Analog Digital Clocks

Mult ifunct ional Pus hbuttons

Full Instructions in Manual

CW

CCW

Time Code

Step Sec onds

MANUAL

SET

SMPTE

Internal

Normal

Normal

115/230 VAC 10 %

OPEN

50/60Hz

15VA Max

12 4356

Impulse

EBU

Line

Use Offset

Run On Secondary

Sweep Seconds

+

Spring Loaded

“Speaker-Type”

Connectors (red

and black)

Push-Buttons:

CW, CCW,

MANUAL SET

DIP Switches

Figure 2-5. ADC-5108/5112/5116 Rear Panel

The rear panels of the ADC-5108/5112/5116 have two spring-loaded

speaker-type connectors (one red, one black) to accept the Primary

Reference input (i.e. SMPTE Serial Timecode or Impulse Drive

signals). Note that the correct polarity (i.e. red-to-red) is not required.

There is an indicator along the left side of the clock rear panel noting

whether the clock is in “MASTER” or “SLAVE” configuration. All

clocks are shipped configured for timecode input (slave) operation,

unless otherwise specified when ordering. The clock type and operating

voltage are also indicated on the rear panel.

A standard AC connector for the power feed of the unit can be found in

the recessed area running across the middle of the rear panel.

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 21

Page 34

Chapter 2: ADC-5100 Series Analog Digital Clocks

Below this recessed area are the multifunction clock setting buttons and

the six DIP switches (SW1 to SW6), all of which must be set prior to

installation.

OPERATION MODE

115/230 VAC 10%

50/60Hz

15VA Max

SLAVE

MASTER

ADC-5105

ADC-5105-L

Line Voltage

115VAC

230VAC

+

MANUAL

SET

CCW

CW

Run on Secondary

Use Offset

Secondary Ref-Line

Time Code Format-EBU

Not Used

12 4356

OPEN

Step Seconds

Normal

Normal

Internal

SMPTE

Primary Ref-Time Code

OPERATION MODE

SLAVE

MASTER

ADC-5106

ADC-5106-L

Line Voltage

115VAC

230VAC

115/230 VAC 10%

50/60Hz

15VA Max

Run on Secondary

Use Offset

Secondary Ref-Line

Time Code Format-EBU

MANUAL

SET

CCW

CW

+

Not Used

12 4356

OPEN

Step Seconds

Normal

Normal

Internal

SMPTE

Primary Ref-Time Code

Figure 2-6. ADC-5105 (left) and ADC-5106 (right) Rear Panels

22 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 35

Control Modes

Chapter 2: ADC-5100 Series Analog Digital Clocks

Selection of the clock control modes is achieved with the rear panel DIP

switches. Table 2-12 lists the Clock Control mode DIP switch options.

Table 2-12. Clock Control Mode DIP switch options

Switch Options

Dip Switch

Open Closed

SW1 Timecode Impulse

SW2 SMPTE EBU

SW3 Internal Line

SW4 Normal Use offset

SW5 Normal Run on secondary

SW6 (Secondary) Step seconds Sweep seconds

Note

Changes to the DIP Switch settings (other than SW3) made during

clock self-setting will NOT be recognized until the clock has finished

setting.

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 23

Page 36

Chapter 2: ADC-5100 Series Analog Digital Clocks

General Operation

Clock Control Modes

Primary Reference (timecode) Mode

No setting of time is required when input timecode is provided to the

ADC Series clock. Once valid timecode is detected, either SMPTE or

EBU, the clock will begin to self-set. The self-setting procedure moves

the hands at a rapid rate in either the clockwise or counter-clockwise

direction until the correct position is obtained. If the hands and the

correct time are the maximum distance apart (6 hours), the self-setting

process may require up to 15 minutes to complete.

Once the clock hands match the correct time, as indicated by the input

timecode, the error LED on the clock face will extinguish to indicate

that the clock is synchronized with the timecode.

The clock may require up to 2 additional minutes of normal operation

(following self-set) for the second hand to completely re-synchronize.

This is due to accumulated gear slippage during counter-clockwise

movements.

If there is a failure of the input timecode, the clock will switch to the

Secondary Reference as selected by DIP switch SW4 on the rear panel.

Either the clock’s own internal crystal or the power line frequency may

be selected as the secondary reference. Both will provide the clock with

a timebase during the absence of input timecode. (Note that either a 50

Hz or 60 Hz power line frequency is suitable for the timebase, since the

clock automatically selects the correct frequency available.)

To signal the failure of the input timecode, the error LED on the clock

face will flash at a rate of twice per second. When correct timecode is

re-established, the clock will again self-set to the new time, and the

error LED will extinguish.

Similarly, if there is an error in the input timecode, the clock will

automatically switch to the secondary reference, and the error LED will

flash.

Note

Impulse input is not currently recognized by the ADC-5100 Series

clocks.

24 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 37

Secondary Reference Mode

The ADC-5100 Series clocks will run as standard wall clocks when no

input timecode is provided. Rear panel DIP switch SW4 selects the

timebase to be used, either the clock’s internal crystal, or the power line

frequency (50/60Hz).

Chapter 2: ADC-5100 Series Analog Digital Clocks

Auxiliary Offset

Rear panel DIP switch SW2 should be switched to the

SECONDARY

position when the clock is used in this mode. When in

RUN ON

this position, the error LED on the clock face will extinguish. Note that

the clock will still function without selecting

RUN ON SECONDARY.

However, the error LED will flash at the rate of twice per second to

indicate the absence of input timecode.

When operating in this mode, the time must be set manually using the

rear panel set switches,

MANUAL SET, CW, and CCW. Once set,

however, the correct time is maintained even in the event of a power

failure. Upon the return of external power, the clock will automatically

self-set to the correct time. The internal battery-backed timekeeping

function will maintain time for up to two years in the absence of

external power.

DIP switch SW3 allows access to a user-programmed auxiliary offset

from the input timecode’s user bits. The timecode source, however,

must have the ability to generate the correct information in the user bits.

The MTG-3901, CSD-3901/3902, and CSD-5300 Clock System

Drivers are real time timecode sources which can program such an

offset into the timecode’s user bits. The offset is programmed in 30

minute intervals up to 23 hours and 30 minutes, using 6 bits of the

timecode’s user bit space.

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 25

The offset is encoded using timecode bits 36, 37, 38, 52, 53, and 54. Bit

36 is the least significant bit (LSB), while bit 54 is the most significant

bit (MSB).

When DIP switch SW3 on the ADC-5100 Series clock is in the

OFFSET

position, the auxiliary offset found in the input timecode’s

USE

user bits is added to the input timecode. The clock hands then display

the total. If no input timecode is available, then DIP switch SW3 has no

effect. If the user bits are incorrectly programmed, then the offset is

disregarded.

Page 38

Chapter 2: ADC-5100 Series Analog Digital Clocks

Local offsets (hand position offsets) are still in effect while using the

auxiliary offset. The hand positioning local offsets are totally

transparent to the input timecode’s user bit offset.

If input timecode is removed while

will retain the time with the offset added, not the original time.

Timecode Generator Mode (Master Clock)

The ADC Series Clocks can also function as real time timecode

generators, essentially operating as master clocks. In this mode, the

clock will be accurate to within +

MTG-3901, CSD-3901/3902, and CSD-5300 master clocks are

accurate to within +

To configure the ADC as a timecode generator, an internal connector

must be transposed so that the rear panel speaker-type connectors

become the timecode output terminals.

To do this, remove the 10 screws along the outside edge of the clock.

Carefully lift the rear panel from the chassis taking care not to disturb

the cables connected to the motor assembly. (If the cables become

disconnected, the time shown on the hands may become offset from the

real time, in which case, see “Clock Setting” on page 26.)

Follow the two wires from the speaker-type terminals to their connector

on the PC board. The connector, attached at point P1, must be removed

and reversed. Normally, the wires on the connector are located near the

corner of the board at pin 1. Reversing this will relocate the wires on the

connector to pin 10. When completed, return the rear panel chassis and

re-fasten the 10 screws.

USE OFFSET is selected, the clock

4 seconds per month. (The

1 second per year.)

After completing this process, the rear speaker-type connectors will

output real time timecode when DIP switch SW4 is set to the

INTERNAL position.

To set the time, see “Clock Setting”.

Clock Setting

When shipped from the factory, the hands are set to 12:00. The clock’s

internal microprocessor has been re-set to memorize this hand position,

and the internal battery has been electronically disabled to preserve

battery life during storage and shipping.

26 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 39

Manual Setting

Chapter 2: ADC-5100 Series Analog Digital Clocks

When first powered up, the clock will start from 12:00:00. Or, if the

external timecode is present, the clock will automatically reset to the

correct time. This may take up to 15 minutes.

The battery is enabled when power is first applied. Henceforth, the

clock will continue to retain time information for the lifetime of the

battery, even if the power is disconnected.

The ADC Series clocks may be manually set using the three

push-button switches located on the rear panel. These push-buttons,

labelled

MANUAL SET, CW, and CCW may be used to reposition the

hands of the clock for any of the following reasons:

• The clock will be used as a Stand Alone Clock, locked to its own

internal crystal or AC line frequency. In this case the hands must be

initially set to the correct time.

• The clock will be used as a master timecode generating clock.

• The clock hands must be offset for a different time zone.

• The offset must be removed. (For example, an offset of hours,

minutes, or seconds may have been inadvertently applied if the rear

buttons were actuated without following the correct procedure. In

this case, the hands and the internal microprocessor must both be

set to the same time. The clock will then display the correct time

when timecode is applied).

•

MANUAL SET This rear panel button stops hands and

enters/exits Manual Set Mode. (LED is on continuously when

entering Manual Set Mode, LED flashes when exiting Manual Set

Mode.)

•

CW This rear panel button moves hands one second clockwise

while in Manual Set Mode.

Advances time one hour if held for 10 seconds during normal

operation (non-Manual Set Mode), without timecode input.

•

CCW This rear panel button moves hands 50 seconds

counter-clockwise while in Manual Set Mode.

Changes time by minus one hour if held for 10 seconds during

normal operation (non-Manual Set Mode), without timecode input.

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 27

•

CW + MANUAL SET Pressed together, these buttons advance

second hand position for precise tracking during normal operation

(non-Manual Set Mode).

Page 40

Chapter 2: ADC-5100 Series Analog Digital Clocks

• CCW + MANUAL SET Pressed together, these buttons move

second hand position in counter-clockwise direction for precise

tracking during normal operation (non-Manual Set Mode).

Repositioning the Hands

To reposition the clock hands, follow these steps:

1. Enter the Manual Set Mode by pressing and holding the

SET

button until the hands come to a complete stop and the error

LED at the bottom of the clock face is illuminated.

2. The

CW button advances the hands clockwise by one second each

time it is pressed. If the

CW button is held down, the hands

accelerate until full speed is reached (after about 30 seconds). To

stop the hands, re-press the

3. The

CCW button causes the hands to move counter-clockwise.

CW button.

When pressed once, the hands move backwards 50 seconds. If the

CCW button is held down, the hands accelerate until full speed is

reached. To stop the hands, re-press the

Setting the Time in Master Clock or Stand Alone Modes

To set the time in Master Clock or Stand Alone modes, follow these

steps:

1. Follow the steps described in “Repositioning the Hands”.

2. Stop the hands a little after the real time and wait for the precise

moment to start the clock.

MANUAL

CCW button.

3. Press and hold the

MANUAL SET button. Release MANUAL SET

one second before the correct time to ensure proper synchronization

with the time of day. The clock will start normally.

Local Time Offsets

The clock hands may be electronically repositioned to provide a local

offset from the input timecode. This is particularly useful for displaying

multiple time zones from the same timecode source. There are a number

of methods to achieve this and the simplest is described below.

28 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 41

Chapter 2: ADC-5100 Series Analog Digital Clocks

This method assumes that the local time reference is 12:00:00. The

hands are manually set to the required offset time (according to

Table 2-13 on page 29) and the microprocessor is then reset. This tells

the microprocessor that the hands are at the 12:00 position, whereas in

fact they are set to the offset time. When timecode is applied, the clock

will set itself to the correct offset time. To set an offset, follow these

steps:

1. Disconnect the timecode input.

2. Enter the Manual Set Mode by pressing and holding the

SET

button until the hands come to a complete stop and the error

MANUAL

LED at the bottom of the clock face is illuminated.

3. Set the hands to the offset time using the

CW and CCW buttons as

described in “Repositioning the Hands” on page 28. (For example,

to apply a + 4 hour offset, set the hands to 4:00. If the hands are a

long way off, the process may take up to 15 minutes. A short cut

method is described in “Hands are Offset” on page 32.)

4. Once the hands are positioned at the appropriate time, press and

hold the

still holding the

MANUAL SET button until the error LED flashes. While

MANUAL SET button, press and hold the CCW

button to reset the microprocessor. Once the LED extinguishes,

release the

CCW button and then the MANUAL SET button.

5. Re-connect the timecode. The hands should move to the correct

offset time.

Table 2-13 lists local offset programming settings:

Table 2-13. Table 3.1 Local Offset Programming

Offset Desired (hrs) Move Hands To Offset Desired (hrs) Move Hands To

None 12:00:00 +1/2 12:30:00

+1 1:00:00 +1 1/2 1:30:00

+2 2:00:00 +2 1/2 2:30:00

+3 3:00:00 +3 1/2 3:30:00

+4 4:00:00 +4 1/2 4:30:00

+5 5:00:00 +5 1/2 5:30:00

+

6 6:00:00 +6 1/2 or -5 1/2 6:30:00

-5 7:00:00 -4 1/2 7:30:00

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 29

Page 42

Chapter 2: ADC-5100 Series Analog Digital Clocks

Table 2-13. Table 3.1 Local Offset Programming (Continued)

Offset Desired (hrs) Move Hands To Offset Desired (hrs) Move Hands To

-4 8:00:00 -3 1/2 8:30:00

-3 9:00:00 -2 1/2 9:30:00

-2 10:00:00 -1 1/2 10:30:00

-1 11:00:00 -1/2 11:30:00

Note

The offset range is only ±6 hours due to the

12-hour representation of 24-hour time. For example, offsets of -8 or

+16 hours can both be represented by a move of +4 hours.

Daylight Saving Time Adjustment (Free Running Clocks)

Second Hand Tracking

To advance the time by one hour, press and hold the

seconds. Release the

CW button when the clock hands begin to move

CW button for 10

rapidly. The clock will automatically set to the new time.

To revert the time by one hour, press and hold the

seconds. Release the

CCW button when the block hands begin to move

CCW button for 10

rapidly. The clock will automatically set to the new time.

Note

When operating from external timecode, daylight saving time is applied

to the master clock, not the ADC.

If the second hand is not falling on the second marks, the following

calibration procedure should be used while the clock is operating

normally. (Be careful not to enter the Manual Set Mode).

Note

Before moving the seconds hands, place the hands in Step Mode using

DIP switch SW1 (closed position).

• To advance the second hand clockwise slightly, press and hold the

30 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

CW and MANUAL SET buttons together in the following manner:

press and hold the

CW button first, followed by the MANUAL SET

button. For every second that the buttons are held, the hands will

move three extra motor points forward. There are 150 motor points

per second; therefore a one second error requires that the

CW and

Page 43

Chapter 2: ADC-5100 Series Analog Digital Clocks

MANUAL SET buttons be held for 50 seconds. When adjustments

are complete and the second hand is on the marker, be sure to

release the

CW button after the MANUAL SET button in order to

avoid accidentally entering the Manual Set Mode.

• To move the second hand counter-clockwise, press and hold the

CCW and MANUAL SET buttons together in the following manner:

press and hold the

SET

button. For every second that the buttons are held, the hands

CCW button first, followed by the MANUAL

will move three extra motor points backward. There are 150 motor

points per second; therefore a one second error requires that the

CCW and MANUAL SET buttons be held for 50 seconds. When

adjustments are complete and the second hand is on the marker, be

sure to release the

CCW button after the MANUAL SET button in

order to avoid accidentally entering the Manual Set Mode.

•

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 31

Page 44

Chapter 2: ADC-5100 Series Analog Digital Clocks

Troubleshooting

Hands are Offset

Sometimes the hands are offset by any number of hours, minutes, or

seconds. This generally occurs when the microprocessor loses track of

where the clock hands are positioned. This problem may occur if the

rear push buttons have been pressed in the wrong sequence.

The hands can be re-aligned (see t“Repositioning the Hands” on

page 28). This involves setting the hands to 12:00:00, which may take

up to 15 minutes. A short cut method is provided below.

Note

You cannot use the short cut method for the

24-hour model ADC-5124.

In the shortcut method, the hands are re-positioned to the top of the

closest hour and then the microprocessor is advised of the new hand

position. To re-calibrate the hands using this method follow these steps:

1. Disconnect the timecode. The front LED will flash twice per

second.

2. Press and hold the

MANUAL SET button until the LED stays

illuminated.

3. Using the

CW and/or CCW buttons (as described in the section

“Repositioning the Hands” on page 28), position the hands to the

top of the nearest hour.

4. Press and hold

5. While holding

MANUAL SET. The error LED will start to flash.

MANUAL SET, press and hold the CCW button until

the error LED extinguishes.

6. While continuing to hold the

momentarily press the

CW button once for every hour indicated on

MANUAL SET and CCW buttons,

the hour hand. For example, if the hands are set to 7:00, press the

CW button seven times. The LED will flash once every time the

CW button is pressed. Doing this will tell the microprocessor what

time the hands are showing. To apply offset times, add or subtract

the number of hours offset to the number of times the

pressed. For example, for -3 hours offset, press the

CW button is

CW button 4

times (7 - 3). In case of difficulties, please see t“Local Time

Offsets” on page 28.

32 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 45

Chapter 2: ADC-5100 Series Analog Digital Clocks

7. Release the CCW button, and then release the MANUAL SET

button.

8. Re-connect timecode.

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 33

Page 46

Chapter 2: ADC-5100 Series Analog Digital Clocks

Specifications

Specifications and designs are subject to change without notice.

Electrical

Table 2-14. Electrical

Item Specification

Electrical voltage 115/230 VAC ±20%, selectable

Frequency 50 or 60 Hz, automatic selection

Inputs and Outputs

Table 2-15. Inputs

Item Specification

Time Base

Serial timecode SMPTE/EBU

Impedance Hi-Z, balanced

Level 4 Vp-p ±8 dB

Table 2-16. Outputs

Item Specification

Serial timecode SMPTE/EBU non-drop frame

Impedance Lo-Z, balanced

Level +10 dB nominal unloaded -3dB

into 180 Ohms

Table 2-17. Time Base

Item Specification

Timecode SMPTE/EBU, automatic selection

Internal Crystal, ± 4 sec/month, 0°—50°C

Power line 50 or 60 Hz, automatic selection

Battery backup Crystal, ± 10 sec/month, 0°—50°C

34 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 47

Controls

Mechanical

Chapter 2: ADC-5100 Series Analog Digital Clocks

Table 2-18. Controls

Item Specification

Output timecode format SMPTE/EBU

Secondary reference Internal or power line

Second hand movement Step or continuous sweep

Aux. offset Requires one of the following system

clock drivers:

• MTG-3901

• CSD-3901/3902

•CSD-5300

Table 2-19. Mechanical Specifications

Clock Item Specification

ADC-5116 Style Wall-mount

Face diameter 16 in. (406 mm)

Overall dimensions 17.5×17.5×3.375 in. (445×445×86 mm)

ADC-5112 Style Wall-mount

Face diameter 11.5 in. (292 mm)

Overall dimensions 14.0×14.0×3.375 in. (356×356×86 mm)

ADC-5108 Style Wall-mount

Face diameter 8 in. (203 mm)

Overall dimensions 10.5×10.5×3.375 in. (267×267×71 mm)

ADC-5106 Style Rack-mount

Face diameter 5.4 in. (137 mm)

Overall dimensions 8.25×19×6.6 in. (178×483×168 mm)

ADC-5105 Style Desk-mount

5000/5100 Series Digital Analog Clocks Installation and Operation Manual 35

Face diameter 5 in. (127 mm)

Overall dimensions 8.25×5.85×7.25 in. (209×145×184 mm)

Page 48

Chapter 2: ADC-5100 Series Analog Digital Clocks

36 5000/5100 Series Digital Analog Clocks Installation and Operation Manual

Page 49

Page 50

Broadcast Communications Division

4393 Digital Way | Mason, OH USA 45040 | Tel: 1 (513) 459 3400

www.broadcast.harris.com

©2006 Harris Corporation

Harris and Leitch are registered trademarks of Harris Corporation. Trademarks and tradenames are the property of their respective companies.

A brand of Harris Corporation

Loading...

Loading...