Harris ACO6800+ISD, ACO6800+DSD, ACO6800+ISCST, ACO6800+ASID, ACO6800+IDSD Installation And Operation Manual

Page 1

ACO6800+ISD

Intelligent Single Switchover for SD/HD Sources

Basic Single Switchover for ASI Sources

ACO6800+DSD

Basic Dual Switchover for SD/HD Sources

Basic Dual Switchover for ASI Sources

ACO6800+IDSD

Intelligent Dual Switchover for SD/HD Sources

Basic Dual Switchover for ASI Sources

ACO6800+ASID

Intelligent Single Switchover for ASI Sources

ACO6800+ISCST

Intelligent Single, Clean/Quiet Switchover

for SD/HD Sources

Basic Single Switchover for ASI Sources

Installation and Operation Manual

Edition B

175-100005-01

Page 2

Page 3

ACO6800+ISD

Intelligent Single Switchover for SD/HD Sources

Basic Single Switchover for ASI Sources

ACO6800+DSD

Basic Dual Switchover for SD/HD Sources

Basic Dual Switchover for ASI Sources

ACO6800+IDSD

Intelligent Dual Switchover for SD/HD Sources

Basic Dual Switchover for ASI Sources

ACO6800+ASID

Intelligent Single Switchover for ASI Sources

ACO6800+ISCST

Intelligent Single, Clean/Quiet Switchover

for SD/HD Sources

Basic Single Switchover for ASI Sources

Installation and Operation Manual

Edition B

June 2009

Page 4

Copyright Information

Copyright © 2009 Harris Corporation, 1025 West NASA Boulevard, Melbourne,

Florida 32919-0001 U.S.A.

All rights reserved. This product and related documentation are protected by

copyright and are distributed under licenses restricting their use, copying,

distribution, and decompilation. No part of this product or related documentation

may be reproduced in any form by any means without prior written authorization

of Harris Corporation and its licensors, if any.

This publication could include technical inaccuracies or typographical errors.

Changes are periodically added to the information herein; these changes will be

incorporated into new editions of the publication. Harris Corporation may make

improvements and/or changes in the product(s) and/or the program(s) described in

this publication at any time.

All trademarks are property of their respective owners.

Warranty Information

The Limited Warranty Policy provides a complete description of your warranty

coverage, limitations, and exclusions, as well as procedures for obtaining

warranty service. To view the complete warranty, visit our website.

This publication is provided “as is” without warranty of any kind, either express

or implied, including, but not limited to, the implied warranties of

merchantability, fitness for a particular purpose, or non-infringement.

Page 5

Content s

Preface

Manual Information ...............................................................................................vii

Purpose ........................................................................................................... vii

Audience .........................................................................................................vii

Revision History .............................................................................................vii

Writing Conventions .....................................................................................viii

Unpacking/Shipping Information ........................................................................... ix

Unpacking a Product .......................................................................................ix

Product Servicing ............................................................................................ix

Returning a Product .........................................................................................ix

Restriction on Hazardous Substances (RoHS) Compliance ....................................x

Waste from Electrical and Electronic Equipment (WEEE) Compliance ................x

Safety ..................................................................................................................... xii

Safety Terms and Symbols in this Manual ..................................................... xii

Chapter 1: Introduction

Product Description .................................................................................................1

ACO6800+ Features ........................................................................................1

Applications ..................................................................................................... 4

Front Module ...........................................................................................................4

Back Modules ..........................................................................................................6

GPI Mating Connector .....................................................................................7

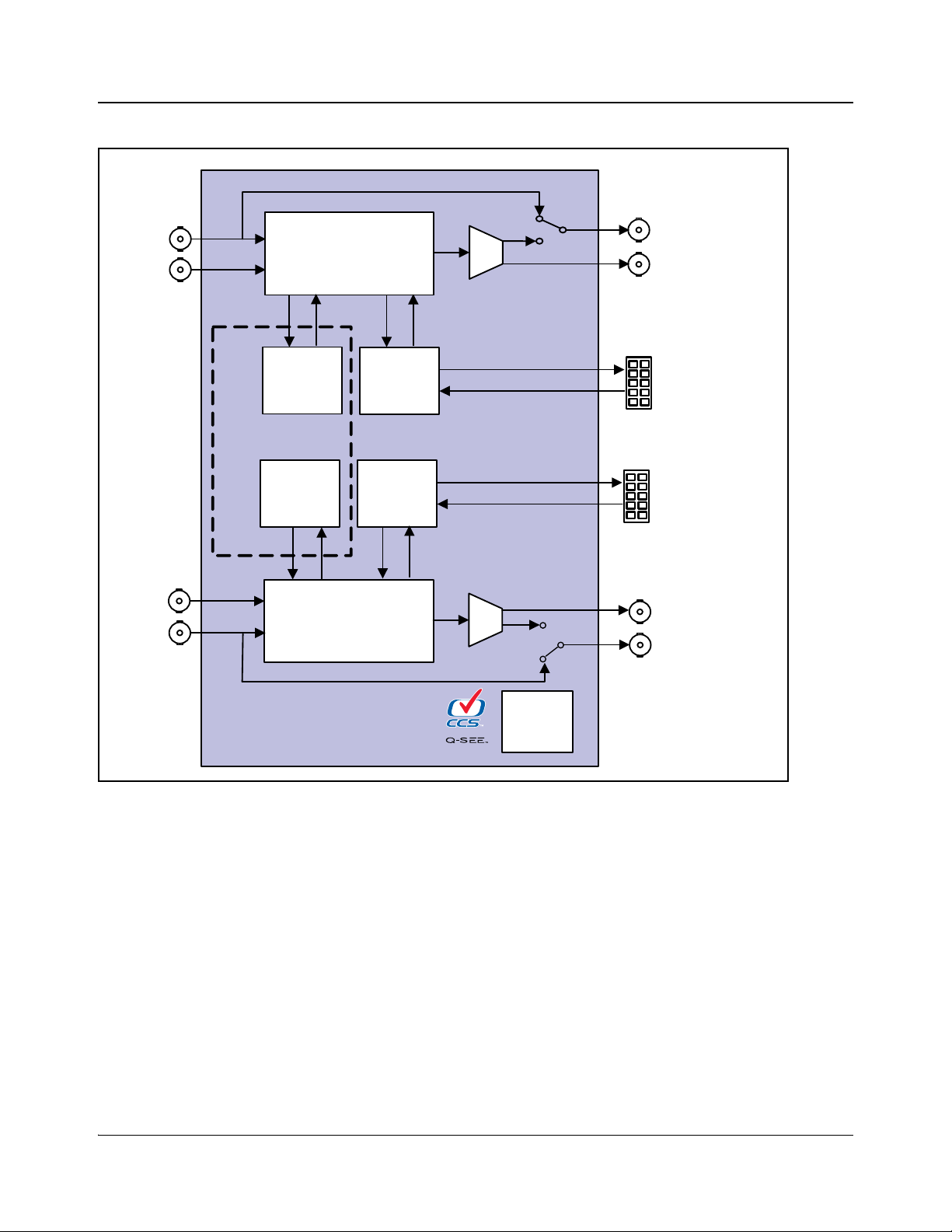

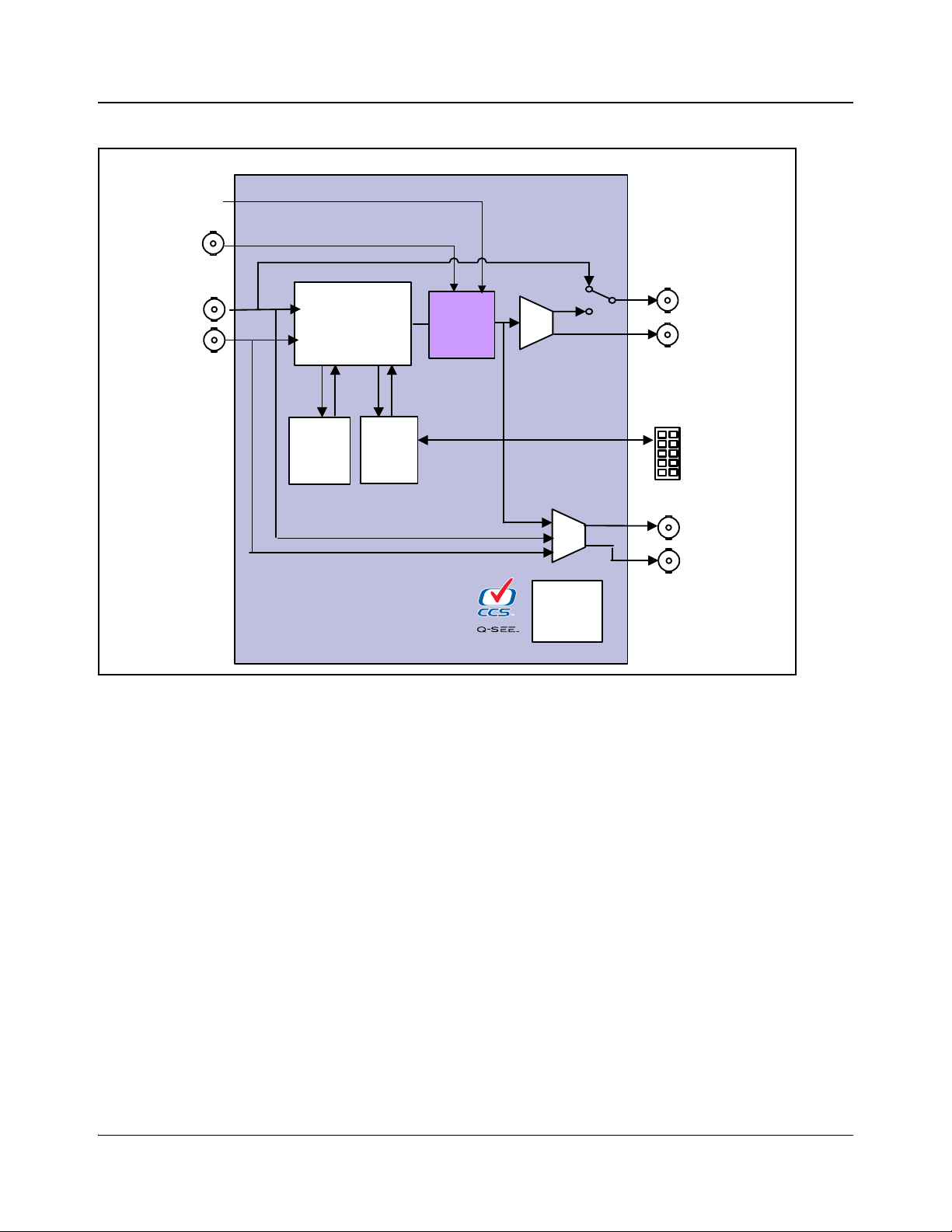

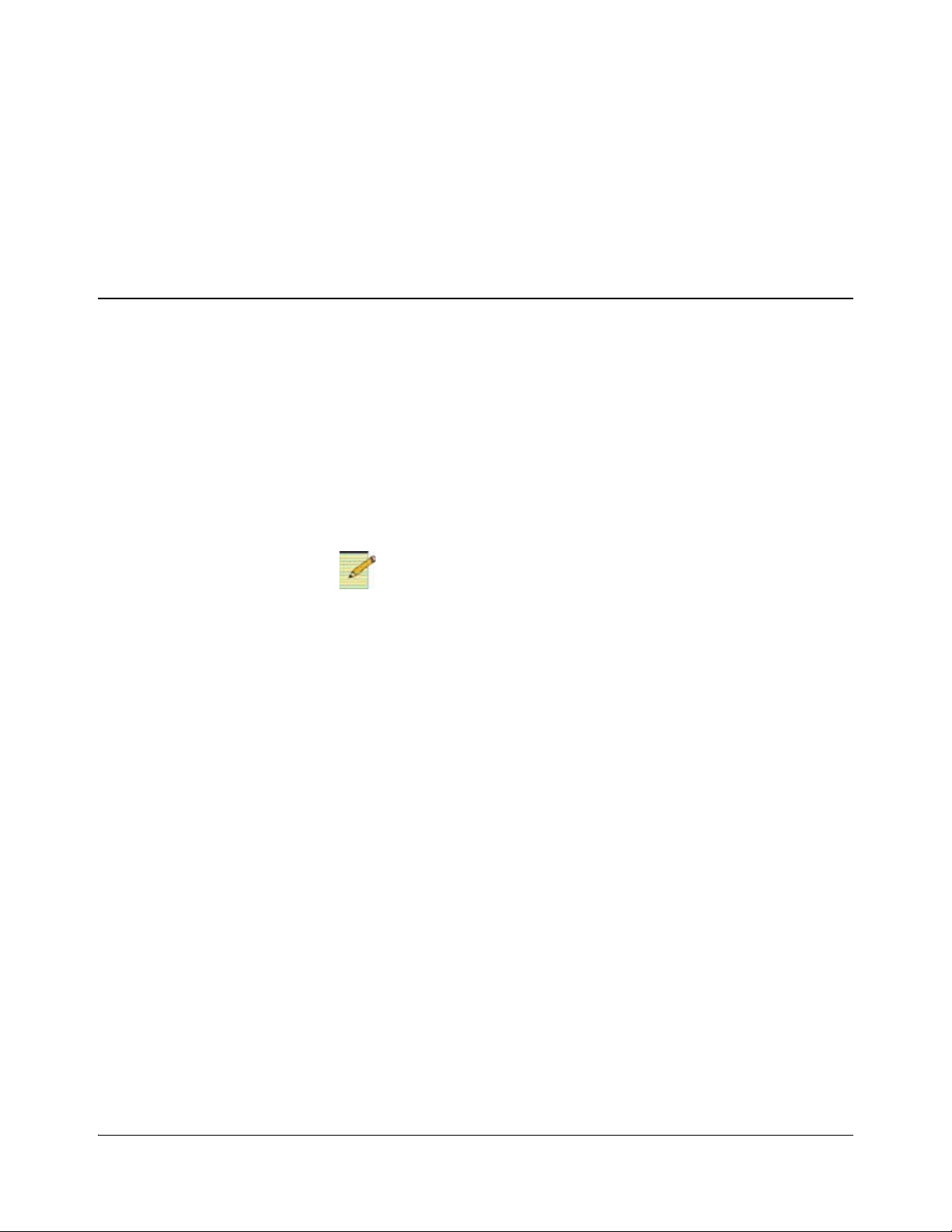

Signal Flow Diagrams ......................................... ....................................................8

Chapter 2: Installation

Unpacking the Module .......................................................................................... 11

Checking the Packing List .............................................................................. 12

Maximum 6800+ Frame Power Ratings ...............................................................13

Installing the Modules ...........................................................................................14

Upgrading Module Firmware ................................................................................14

Chapter 3: Configuration and Operation

Network Control ................ ..................................... ...............................................15

Operating Notes .....................................................................................................16

Adding a License Key ...........................................................................................16

Changing Parameter Settings .................................................................. ..............17

CCS Navigator .............. .................................................................................17

Card-Edge Controls ........................................................................................18

ACO6800+ Installation and Operation Manual iii

Copyright © 2009, Harris Corporation

Page 6

Contents

Recalling Default Parameter Settings ............................................................20

Q-SEE-Compliant Thumbnails .............................................................................20

Relay Bypass .................................................... .....................................................21

Passing Dolby Audio (ACO6800+ISCST Modules Only) ............................ 21

Configuring the Switching Mechanism .................................................................22

GPI Input Control ...........................................................................................22

Manual Control .............................. ................................................................23

Alarm Control ................................................................................................24

Failure of Auto/Manual switchover ...............................................................24

Sample Scenario One .....................................................................................24

Sample Scenario Two ....................................................................... ..............25

Switching to a Still Image (ACO6800+ISCST Modules Only) .................... 26

Creating Trouble Slides .........................................................................................27

Integrated Graphics Storage and Playout .......................................................27

Basic Steps to Installing Logo Files ...............................................................28

Step 1: Install LogoCreator Software ............................................................. 28

Step 2: Convert Files to the .mg2 Format .............................................. ... ..... 29

Step 3: Transfer the Logos to the MicroSD Card ................................... ........31

Using Trouble Slides ...................................................................................... 32

Chapter 4: ACO6800+ISD Parameters, LEDs, and Alarms

On-Screen Display Monitoring .............................................................................35

Parameter Table Notes ..........................................................................................35

ACO6800+ISD Parameters ................................................................................... 36

ACO6800+ISD Subdevice Parameters .................................................................39

LEDs and Alarms ................................................... ............................................... 41

Monitoring LEDs ...........................................................................................42

Module Status LEDs ......................................................................................43

Alarms ............................................................................................................ 43

Chapter 5: ACO6800+DSD Parameters, LEDs, and Alarms

On-Screen Display Monitoring .............................................................................47

Parameter Table Notes ..........................................................................................47

ACO6800+DSD Parameters .................................................................................48

ACO6800+DSD Subdevice Parameters ................................................................51

LEDs and Alarms ................................................... ............................................... 52

Monitoring LEDs ...........................................................................................53

Module Status LEDs ......................................................................................54

Alarms ............................................................................................................ 54

Chapter 6: ACO6800+IDSD Parameters, LEDs, and

Alarms

On-Screen Display Monitoring .............................................................................57

Parameter Table Notes ..........................................................................................57

ACO6800+IDSD Parameters ................................................................................58

ACO6800+IDSD Subdevice Parameters ..............................................................61

LEDs and Alarms ................................................... ............................................... 64

Monitoring LEDs ...........................................................................................65

iv ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 7

Module Status LEDs ......................................................................................66

Alarms ............................................................................................................ 66

Chapter 7: ACO6800+ASID Parameters,

LEDs, and Alarms

Parameter Table Notes ..........................................................................................71

ACO6800+ASID Parameters ................................................................................ 72

ACO6800+ASID Subdevice Parameters .......................................................73

LEDs and Alarms ................................................... ............................................... 78

Monitoring LEDs ...........................................................................................79

Module Status LEDs ......................................................................................79

Alarms ............................................................................................................ 79

Chapter 8: ACO6800+ISCST Parameters, LEDs, and

Alarms

On-Screen Display Monitoring .............................................................................85

Parameter Table Notes ..........................................................................................85

Cross-Functional Parameter Changes ....................................................................85

ACO6800+ISCST Parameters for SDI .................................................................87

ACO6800+ISCST Parameters for ASI .................................................................95

ACO6800+ISCST Subdevice Parameters ....................................... ......................96

LEDs and Alarms ................................................... ............................................... 99

Monitoring LEDs .........................................................................................100

Module Status LEDs .................................................................................... 101

Alarms .......................................................................................................... 101

Contents

Chapter 9: Specifications

Overview ............................................................................................................. 105

Inputs ................................................................................................................... 106

HD/SD-SDI Video .......................................................................................106

ASI Transport Stream ...................................................................................106

Genlock (ACO6800+ISCST Only) ..............................................................107

Outputs ................................................................................................................107

HD/SD-SDI Video .......................................................................................107

ASI Transport Stream Output Specification .................... ............................ 108

Miscellaneous ...................................................................................................... 108

General Purpose Interface ............................................................................108

Propagation Delay ........................................................................................109

Power Consumption .....................................................................................109

Operating Temperature ................................................................................110

Appendix A: Communication and Control

Troubleshooting Tips

Software Communication Problems ....................................................................111

Hardware Communication Problems ..................................................................112

ACO6800+ Installation and Operation Manual v

Copyright © 2009, Harris Corporation

Page 8

Contents

Appendix B: Glossary

Glossary of Terms ...............................................................................................115

Index

Keywords .............................................................................................................119

vi ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 9

Manual Information

Purpose

This manual details the features, installation, operation, maintenance, and

specifications for the following modules:

• ACO6800+ISD Intelligent Single Switchover for SD/HD sources and Basic

Single Switchover for ASI Sources

• ACO6800+DSD Basic Dual Switchover for SD/HD Sources and Basic

Dual Switchover for ASI Sources

• ACO6800+IDSD Intelligent Dual Switchover for SD/HD Sources and

Basic Dual Switchover for ASI Sources

• ACO6800+ASID Intelligent Single Switchover for ASI Sources

• ACO6800+ISCST Intelligent Single, Clean/Quiet Switchover for SD/HD

Sources and Basic Single Switchover for ASI Sources

Preface

Audience

This manual is written for engineers, technicians, and operators responsible for

installation, setup, maintenance, and/or operation of the ACO6800+ISD,

ACO6800+DSD, ACO6800+IDSD, ACO6800+ASID, and ACO6800+ISCST

modules.

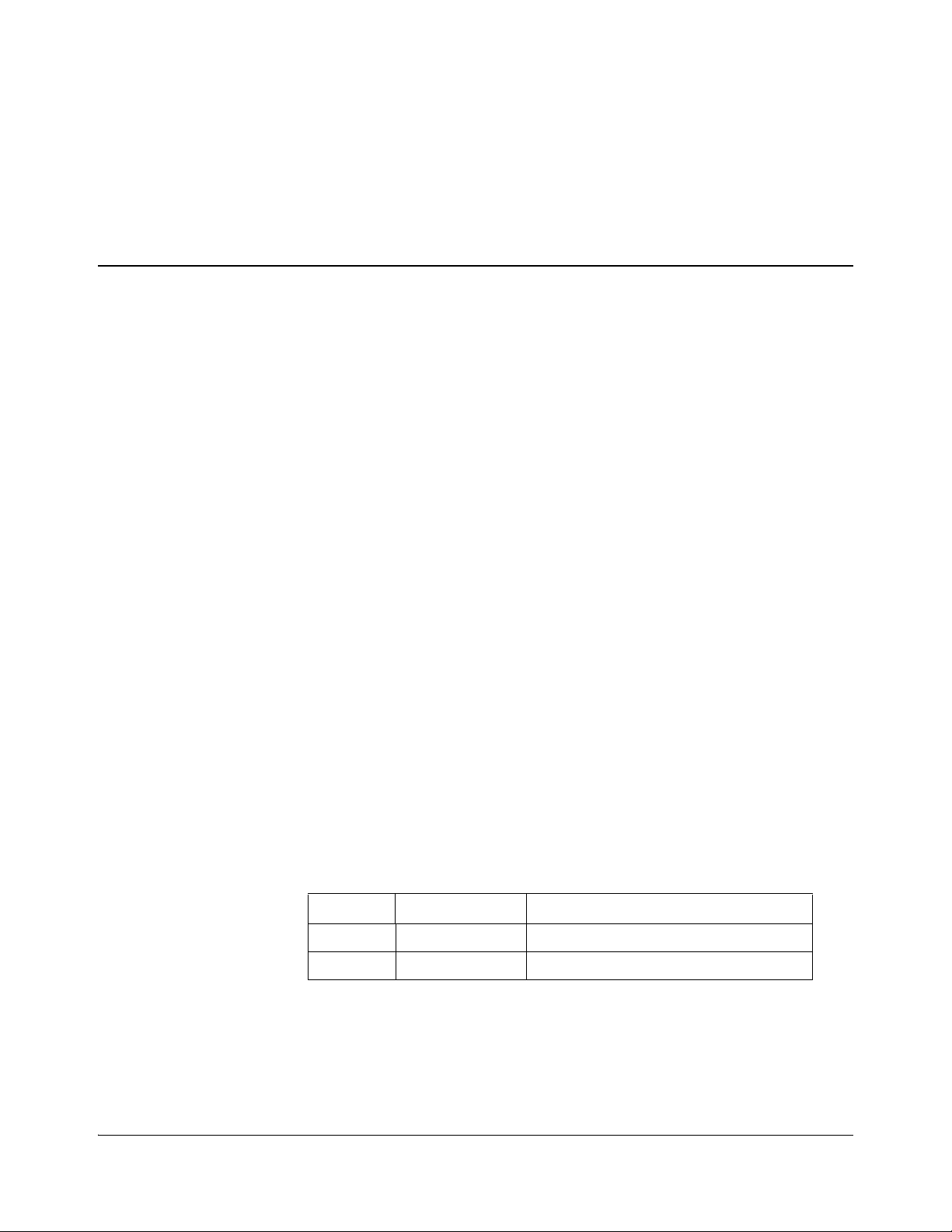

Revision History

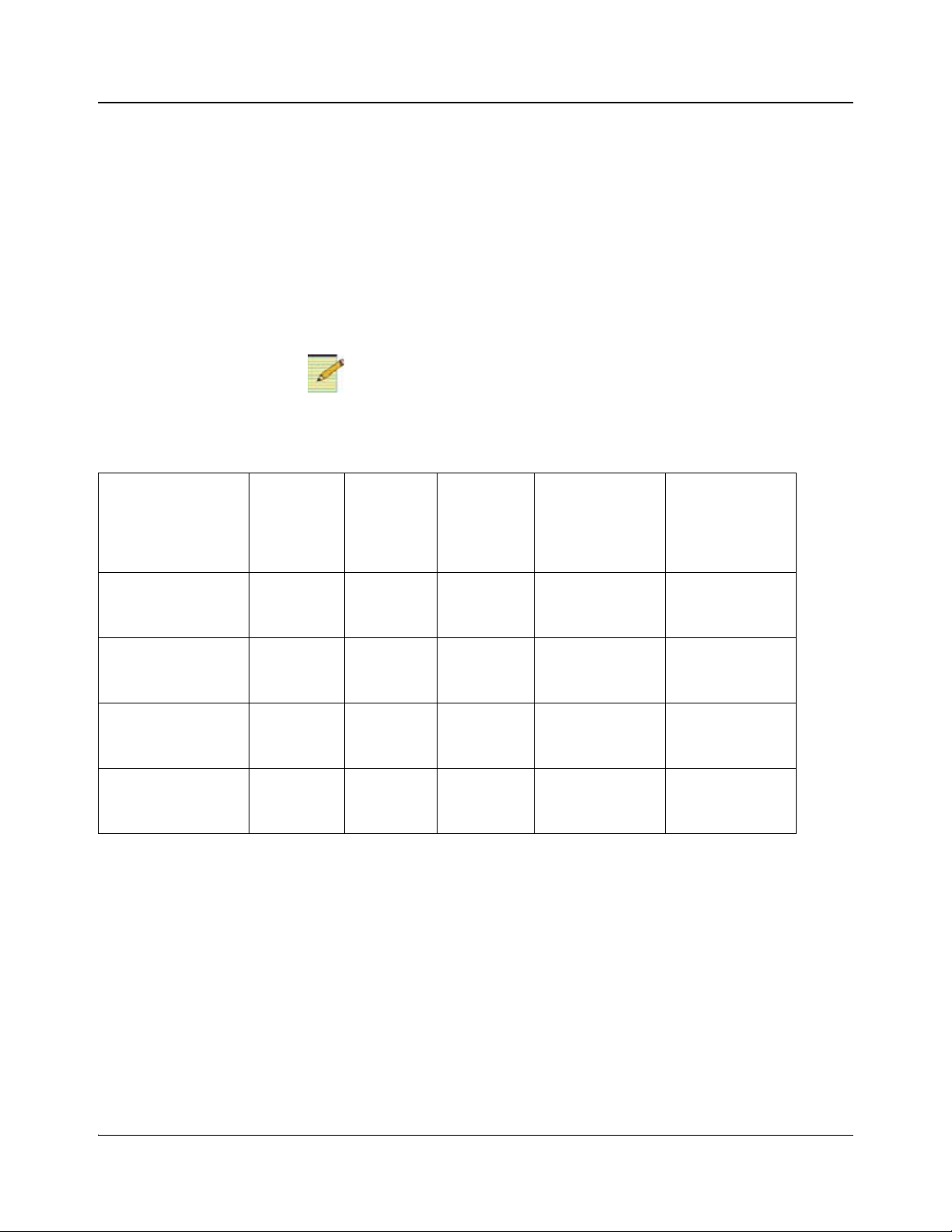

Table P-1. Revision History of Manual

Edition Date Comments

A April 2009 Initial release

B June 2009 Addition of ACO6800+ASID

ACO6800+ Installation and Operation Manual vii

Copyright © 2009, Harris Corporation

Page 10

Preface

Note

Writing Conventions

To enhance your understanding, the authors of this manual have adhered to the

following text conventions:

Table P-2. Writing Conventions

Term or

Convention

Bold Indicates dialog boxes, property sheets, fields, buttons, check

Italics Indicates E-mail addresses, the names of books or publications,

CAPS Indicates a specific key on the keyboard, such as ENTER, TAB,

Code Indicates variables or command-line entries, such as a DOS entry

> Indicates the direction of navigation through a hierarchy of menus

hyperlink Indicates a jump to another location within the electronic document

Internet address

Description

boxes, list boxes, combo boxes, menus, submenus, windows, lists,

and selection names

and the first instances of new terms and specialized words that

need emphasis

CTRL, ALT, or DELETE

or something you type into a field

and windows

or elsewhere

Indicates a jump to a website or URL

Indicates important information that helps to avoid and

troubleshoot problems

viii ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 11

Unpacking/Shipping Information

Unpacking a Product

This product was carefully inspected, tested, and calibrated before shipment to

ensure years of stable and trouble-free service.

1. Check equipment for any visible damage that may have occurred during

transit.

2. Confirm that you have received all items listed on the packing list.

3. Contact your dealer if any item on the packing list is missing.

4. Contact the carrier if any item is damaged.

5. Remove all packaging material from the product and its associated

components before you install the unit.

Keep at least one set of original packaging, in the event that you need to return a

product for servicing.

Product Servicing

Except for firmware upgrades, the modules are not designed for field servicing.

All hardware upgrades, modifications, or repairs require you to return the

modules to the Customer Service center.

Preface

Returning a Product

In the unlikely event that your product fails to operate properly, contact

Customer Service to obtain a Return Authorization (RA) number, and then send

the unit back for servicing.

If the original package is not available, you can supply your own packaging as

long as it meets the following criteria:

• The packaging must be able to withstand the product’s weight.

• The product must be held rigid within the packaging.

• There must be at least 2 in. (5 cm) of space between the product and the

• The corners of the product must be protected.

Ship products back to us for servicing prepaid and, if possible, in the original

packaging material. If the product is still within the warranty period, we will

return the product prepaid after servicing.

container.

ACO6800+ Installation and Operation Manual ix

Copyright © 2009, Harris Corporation

Page 12

Preface

Restriction on Hazardous Substances (RoHS) Compliance

The European Union (EU) Directive 2002/95/EC—commonly known as the

Restriction on Hazardous Substances (RoHS)—sets limits on the use of certain

substances found in electrical and electronic equipment. The intent of this

legislation is to reduce the amount of hazardous chemicals that may leach out of

landfill sites or otherwise contaminate the environment during end-of-life

recycling. The Directive, which took effect on July 1, 2006, refers to the

following hazardous substances:

• Lead (Pb)

• Mercury (Hg)

• Cadmium (Cd)

• Hexavalent Chromium (Cr-V1)

• Polybrominated Biphenyls (PBB)

• Polybrominated Diphenyl Ethers (PBDE)

According to this EU Directive, all products sold in the European Union will be

fully RoHS-compliant and “lead-free.” (See our website for more information.)

Spare parts supplied for the repair and upgrade of equipment sold before

July 1, 2006 are exempt from the legislation. Equipment that complies with the

EU directive will be marked with a RoHS-compliant emblem, as shown in

Figure P-1.

Figure P-1. RoHS Compliance Emblem

Waste from Electrical and Electronic Equipment (WEEE) Compliance

The European Union (EU) Directive 2002/96/EC—commonly known as the

Waste from Electrical and Electronic Equipment (WEEE)—deals with the

collection, treatment, recovery, and recycling of electrical and electronic waste

products. The objective of the WEEE Directive is to assign the responsibility for

the disposal of associated hazardous waste to either the producers or users of

these products. As of August 13, 2005, producers or users will be required to

recycle electrical and electronic equipment at end of its useful life, and may not

dispose of the equipment in landfills or by using other unapproved methods.

(Some EU member states may have different deadlines.)

x ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 13

Preface

In accordance with this EU Directive, companies selling electric or electronic

devices in the EU will affix labels indicating that such products must be

properly recycled. (See our website for more information.) Contact your local

Sales Representative for information on returning these products for recycling.

Equipment that complies with the EU directive will be marked with a

WEEE-compliant emblem, as shown in Figure P-2.

Figure P-2. WEEE Compliance Emblem

ACO6800+ Installation and Operation Manual xi

Copyright © 2009, Harris Corporation

Page 14

Preface

Safety

Carefully review all safety precautions to avoid injury and prevent damage to

this product or any products connected to it. If this product is rack-mountable, it

should be mounted in an appropriate rack using the rack-mounting positions and

rear support guides provided. To protect a frame from circuit overloading,

connect each frame to a separate electrical circuit. If this product relies on

forced air cooling, all obstructions to the air flow should be removed prior to

mounting the frame in the rack.

If this product has a provision for external earth grounding, ground the frame to

the earth using the protective earth ground on the rear panel.

IMPORTANT! Only qualified personnel should perform service procedures.

Safety Terms and Symbols in this Manual

WARNING

Statements identifying conditions or practices that may result in

personal injury or loss of life. High voltage is present.

CAUTION

Statements identifying conditions or practices that can result in

damage to the equipment or other property.

xii ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 15

Product Description

The ACO6800+ISD Single Switch Automatic Switchover

• Provides QSEE-driven 2×1 signal protection

• Switches signals between redundant signals at the point of ingest into a

satellite DTH, mobile TV, or IPTV facility

• Switches signals just prior to arriving at the broadcast transmitter

The ACO6800+DSD Dual Switch Automatic Switchover

• Provides loss of signal 2×1 protection

• Switches the signal between redundant signals at the point of ingest into a

satellite DTH, mobile TV, or IPTV facility

• Switches the signal on redundant paths within a facility

The ACO6800+IDSD Intelligent Dual Switch Automatic Switchover

• Provides QSEE-driven 2×1 signal protection

Chapter 1

Introduction

• Switches signals between redundant signals at the point of ingest into a

satellite DTH, mobile TV, or IPTV facility

• Switches signals just prior to arriving at the broadcast transmitter

The ACO6800+ASID Intelligent Single Switch Automatic Switchover

• Switches the signal between redundant signals at the point of ingest into a

satellite DTH, mobile TV, or IPTV facility

• Switches the signal on redundant paths within a facility

The ACO6800+ISCST Intelligent Single Clean Switch Automatic Switchover

• Provides Q-SEE-driven 2×1 signal protection with clean video switch and

quiet audio fade between sources

• Provides frame sync/audio sync capability

• Switches signals between redundant signals at the point of ingest and ingest

timing into a satellite DTH, mobile TV, or IPTV facility

ACO6800+ Features

All ACO6800+ modules have the following features:

ACO6800+ Installation and Operation Manual 1

Copyright © 2009, Harris Corporation

Page 16

Chapter 1: Introduction

ACO6800+ISD

ACO6800+DSD

ACO6800+IDSD

• Input bypass relay to ensure signal path in the event of power failure or

missing front module

• Three GPI inputs and three GPI outputs for each ACO

• Support for SD-SDI at 270 Mb/s, HD-SDI at 1.5 Gb/s, or ASI at 270 Mb/s.

• Switch-over when user-defined alarm criteria are triggered

• Switch-back to primary signal input when the signal has been restored as

per the user-defined time span

•Single ACO

• Six BNC ports (two inputs and four outputs)

• Independent Q-SEE alarm sets for both inputs

• Support for Q-SEE compliant thumbnails when installed in an

FR6802+QXF or FR6822+QXFE frame

• Dual ACOs

• Four BNC ports for each ACO (two inputs and two outputs)

• Support for Q-SEE compliant thumbnails when installed in an

FR6802+QXF or FR6822+QXFE frame

• Dual ACOs

ACO6800+ASID

ACO6800+ISCST

• Four BNC ports for each ACO (two inputs and two outputs)

• Independent Q-SEE alarm sets for both inputs

• Support for Q-SEE compliant thumbnails when installed in an

FR6802+QXF or FR6822+QXFE frame

• Single ACO

• Six BNC ports (two inputs and four outputs)

• Monitor input 1 (primary) for loss of signal or selected ETR-290 alarms and

switch-over to Input 2 (secondary) with independent alarm setting from

input 1

• Switch-back to primary signal input when the signal has been restored as

per the user-defined time span

• Independent Q-SEE alarm sets for both inputs

• Single ACO

• Seven BNC ports (one genlock in, two inputs and four outputs)

• Clean/quiet switch between selected sources

• Selectable switch to TSG or trouble slide when both inputs are loss

• Provide video and audio processing

2 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 17

• Frame/audio synchronizer

• Frame or external reference input to drive frame synchronization

• Independent Q-SEE alarm sets for both inputs

• Support for Q-SEE compliant thumbnails when installed in an

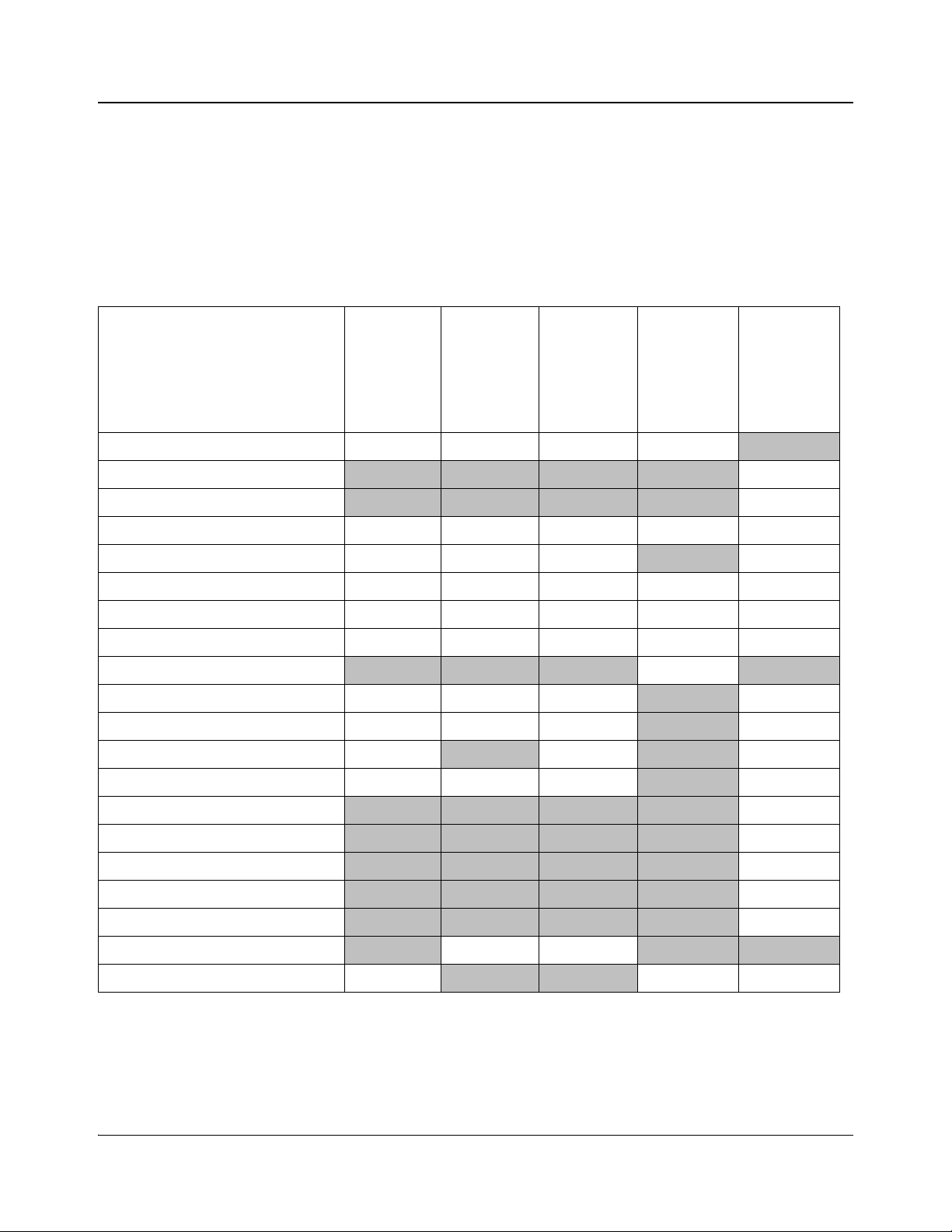

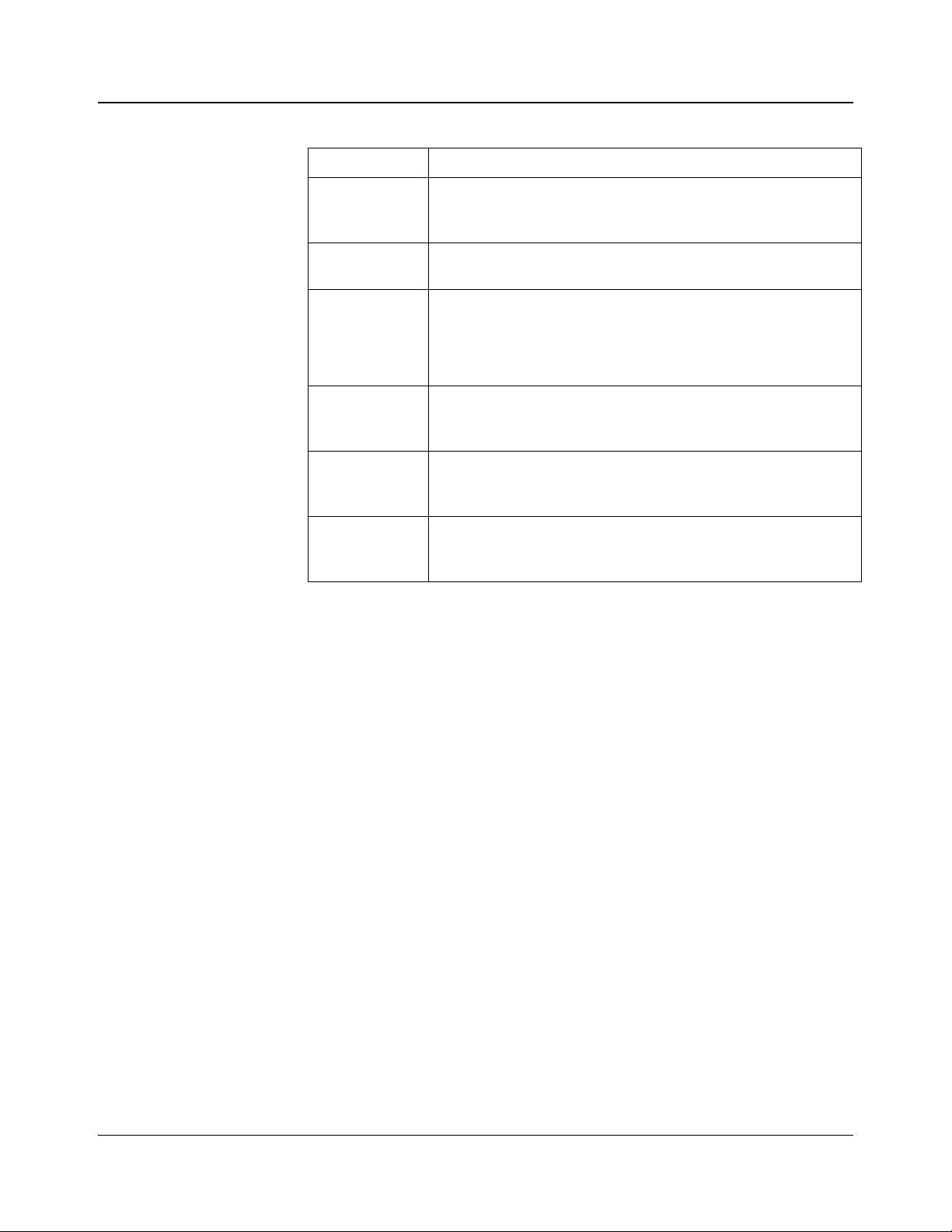

Table 1-1 provides a quick view of the main features for each module.

Table 1-1. ACO6800+ Features

Feature

Chapter 1: Introduction

FR6802+QXF or FR6822+QXFE frame

ACO6800+ISD

ACO6800+DSD

ACO6800+IDSD

ACO6800+ASID

Two-slot module Yes Yes Yes Yes No

Three-slot module

Sub-module needed

No No No No Yes

No No No No Yes

CCS Navigator support Yes Yes Yes Yes Yes

Card-edge control Yes Yes Yes

No Yes

Bypass relay Yes Yes Yes Yes Yes

GPIs Yes Yes Yes Yes Yes

Basic ASI support Yes Yes Yes Yes Yes

Intelligent ASI support

270 Mps Yes Yes Yes

1.5 Gbps Yes Yes Yes

Q-SEE switching Yes

Thumbnail support Yes Yes Yes

Frame/Audio synchronizer

Clean/Quiet switch

Reference input

No No No Yes No

No Yes

No Yes

No Yes No Yes

No Yes

No No No No Yes

No No No No Yes

No No No No Yes

ACO6800+ISCST

Supports TSG or Trouble Slide

Video and audio processing

Dual channel

Single channel Yes

ACO6800+ Installation and Operation Manual 3

Copyright © 2009, Harris Corporation

No No No No Yes

No No No No Yes

No Yes Yes No No

No No Yes Yes

Page 18

Chapter 1: Introduction

Module status LED

Mode select

rotary switch

Navigation

toggle switch

Monitoring

LEDs

Control

LEDs

Extractor

handle

Applications

Front Module

ACO6800+ modules allow broadcasters who must turn aro und large numbers of

signals (such as satellite direct-to home operations, cable head-ends, mobile

television operations, and IPTV operations) to provide two signal sources with

the ability to switch between the signals to play one on air.

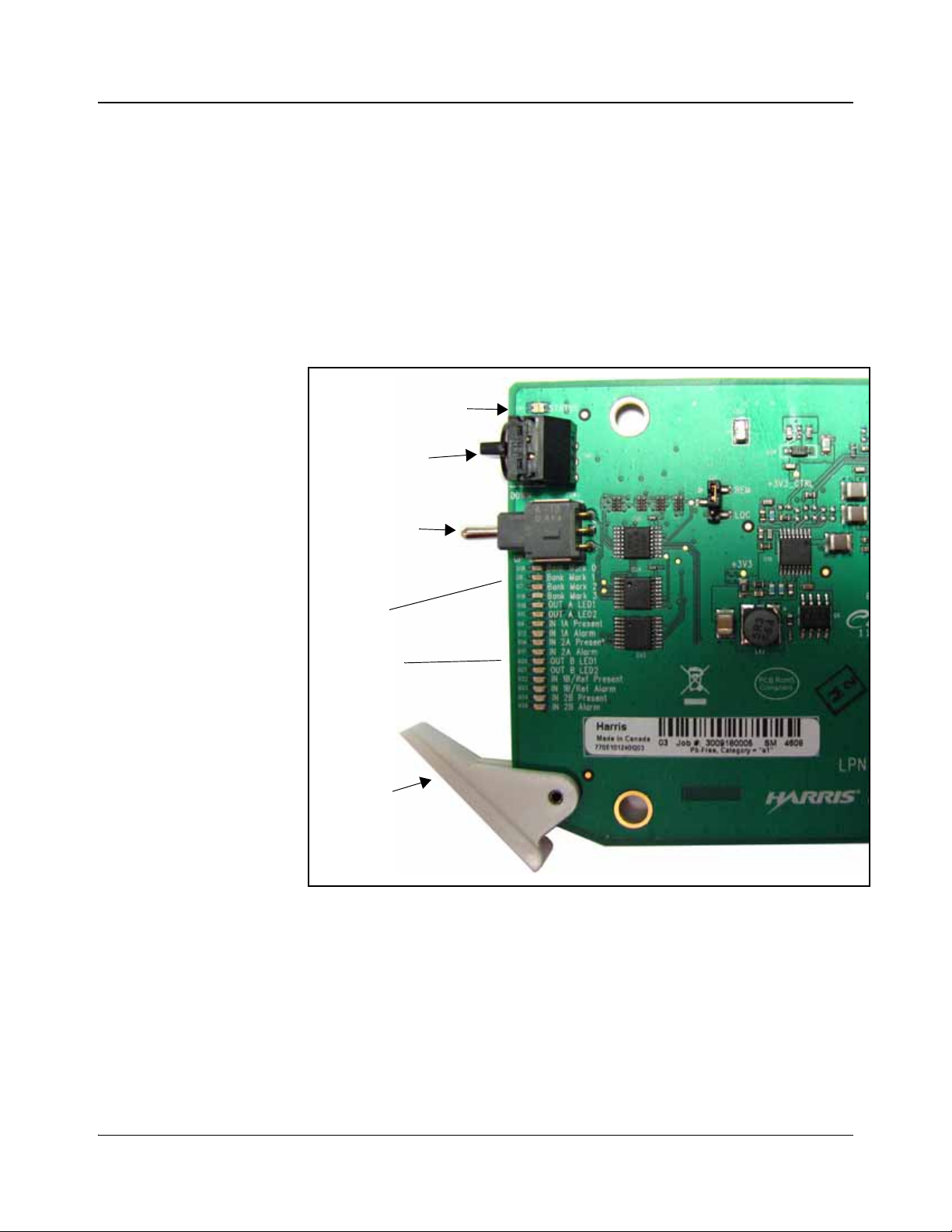

Figure 1-1 shows the position of the LEDs and module controls on the front of

the modules.

4 ACO6800+ Installation and Operation Manual

Figure 1-1. Typical Module

Table 1-2 on page 5 briefly describes the LEDs, switches, and jumpers.

Copyright © 2009, Harris Corporation

Page 19

Table 1-2. Generic 6800+ Module Features

Feature Description

Chapter 1: Introduction

Module status

LEDs

Various color and lighting combinations of these LEDs indicate the

module state. See page 41, page 52, page 64, and page 99 for more

information.

Mode select

rotary switch

Navigation

toggle switch

This switch selects between various control and feedback

parameters.

This switch navigates up and down through the available control

parameters:

• Down: Moves down through the parameters

• Up: Moves up through the parameters

Control LEDs Various lighting combinations of these Control LEDs (sometimes

referred to as “Bank Select LEDs”) indicate the currently selected

bank. See “Bank Select LEDs” on page 19 for more information.

Monitoring

LEDs

Each 6800+ module has a number of LEDs assigned to indicate

varying states/functions. See page 42, page 53, page 65, and

page 100 for descriptions of these LEDs.

Jumpers This module has Remote/Local jumper, for selecting either local or

remote control of the module (default is Remote). The

BSCAN/Normal jumper must be left in the Normal position.

ACO6800+ Installation and Operation Manual 5

Copyright © 2009, Harris Corporation

Page 20

Chapter 1: Introduction

IN 2IN 1

OUT 2

OUT 1

AUX 2AUX 1

GENLOC K

GPI

BYPASS

IN 2

IN 1

OUT 2

OUT 1

IN 2IN 1

OUT 2

OUT 1

GPI A GPI B

A

B

BYPASS

BYPASS

IN 2IN 1

OUT 2

OUT 1

NOT USEDNOT USED

OUT 2

OUT 1

GPI A NOT USED

A

B

BYPASS

ACO6800+DSD/IDSD

ACO6800+ISCST

ACO6800+ISD/ASID

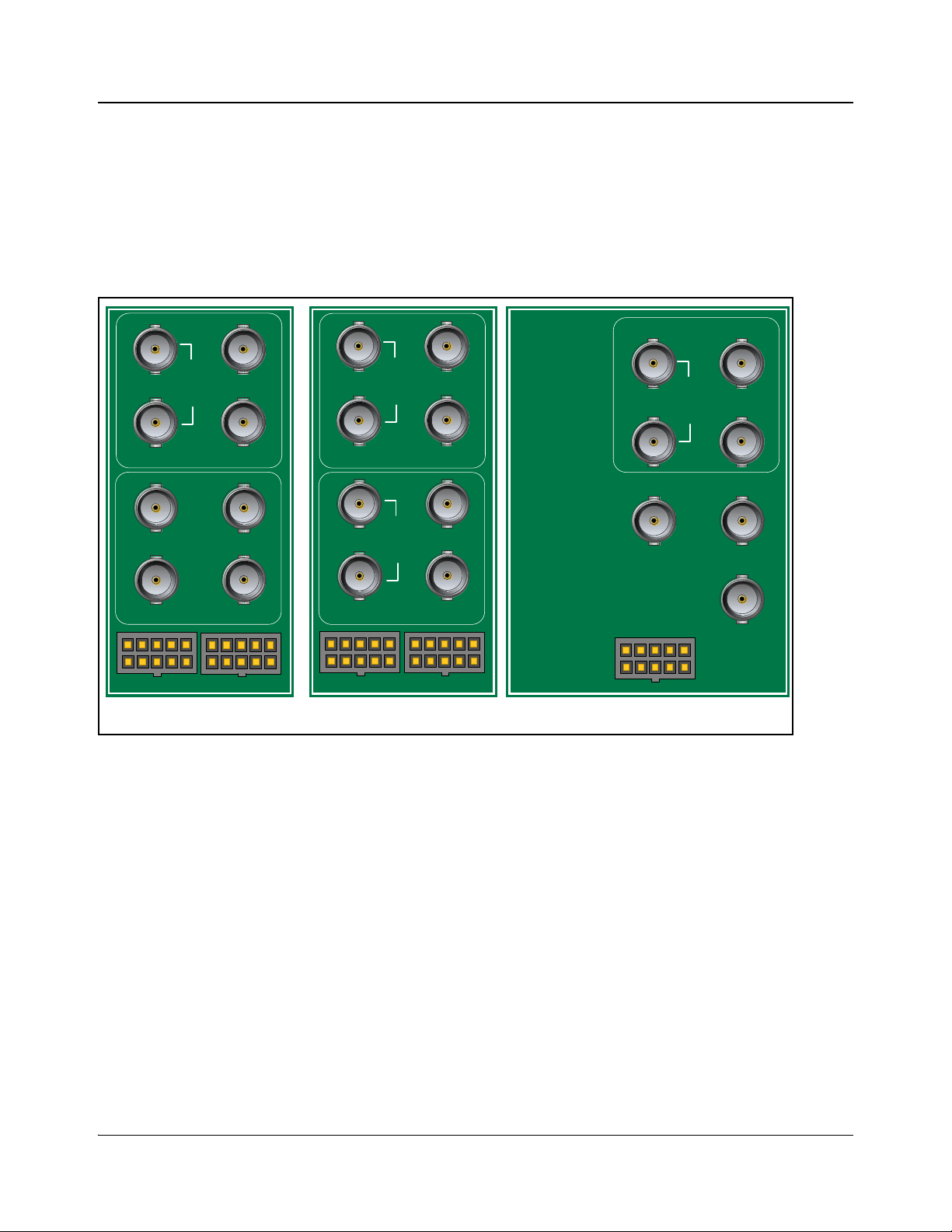

Back Modules

Figure 1-2 shows the double-slot back modules used by the ACO6800+ISD,

ACO6800+DSD, ACO6800+ASID, and ACO6800+IDSD modules, and the

triple-slot back module used by the ACO6800+ISCST module.

The back and front modules cannot be installed in frames witho ut fans, or in

FR6802+DM and 6800/7000 series frames.

Figure 1-2. ACO6800+ Back Modules

6 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 21

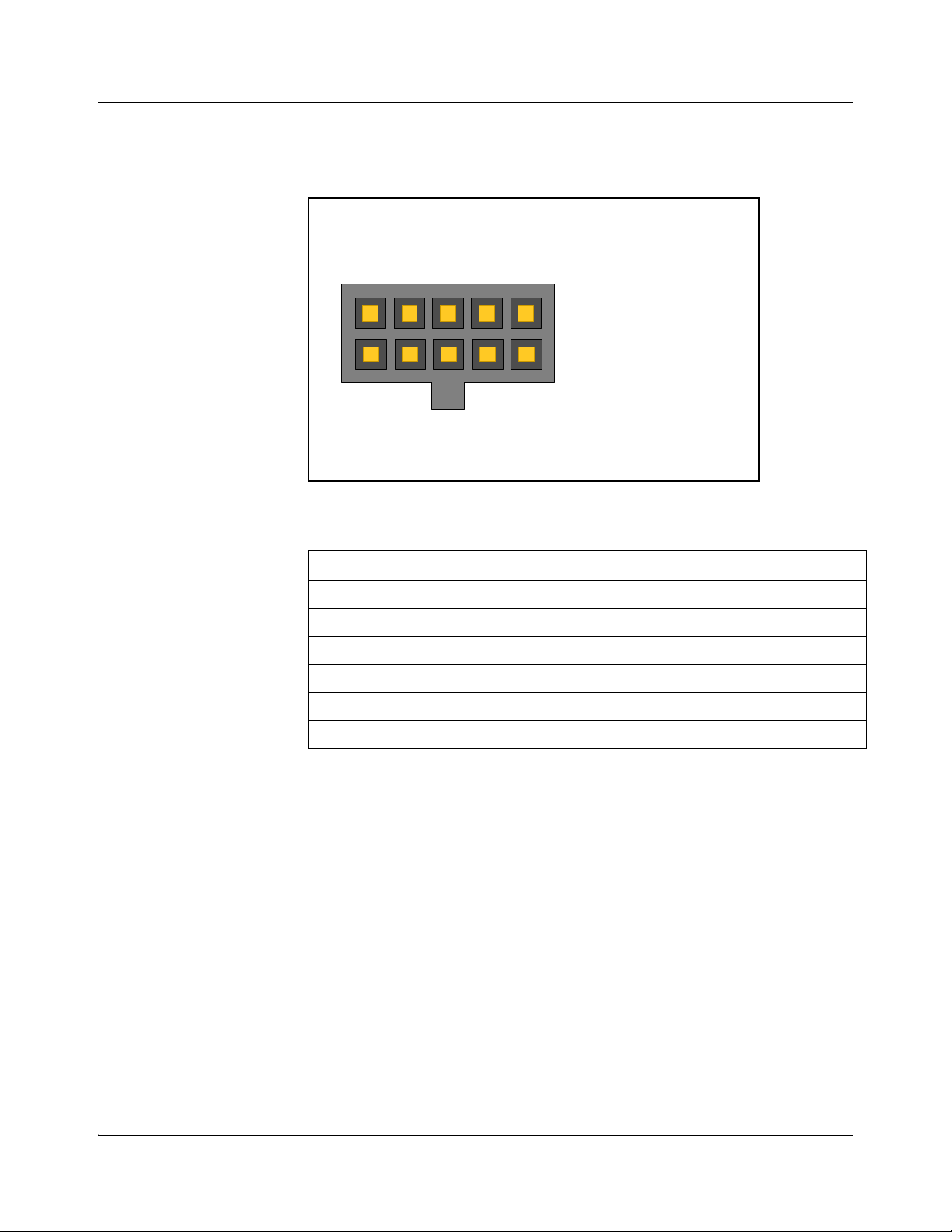

GPI Mating Connector

15

610

1. GPI In 1

2. Ground

3. GPI In 2

4. Ground

5. GPI In 3

6. GPI Out 1

7. Ground

8. GPI Out 2

9. Ground

10. GPI Out 3

The GPI Connector cable (provided) has the following connections:

Figure 1-3. GPI Connector Pinouts

Table 1-3. GPI Functions

Chapter 1: Introduction

ACO6800+ Installation and Operation Manual 7

Copyright © 2009, Harris Corporation

GPI Function

GPI In 1 Switch to IN 1

GPI In 2 Switch to IN 2

GPI In 3 Force relay to bypass signal IN 1

GPI Out 1 Indicate IN 1 is selected as output source

GPI Out 2 Indicate IN 2 is selected as output source

GPI Out 3 Indicate signal IN 1 is bypassed

Page 22

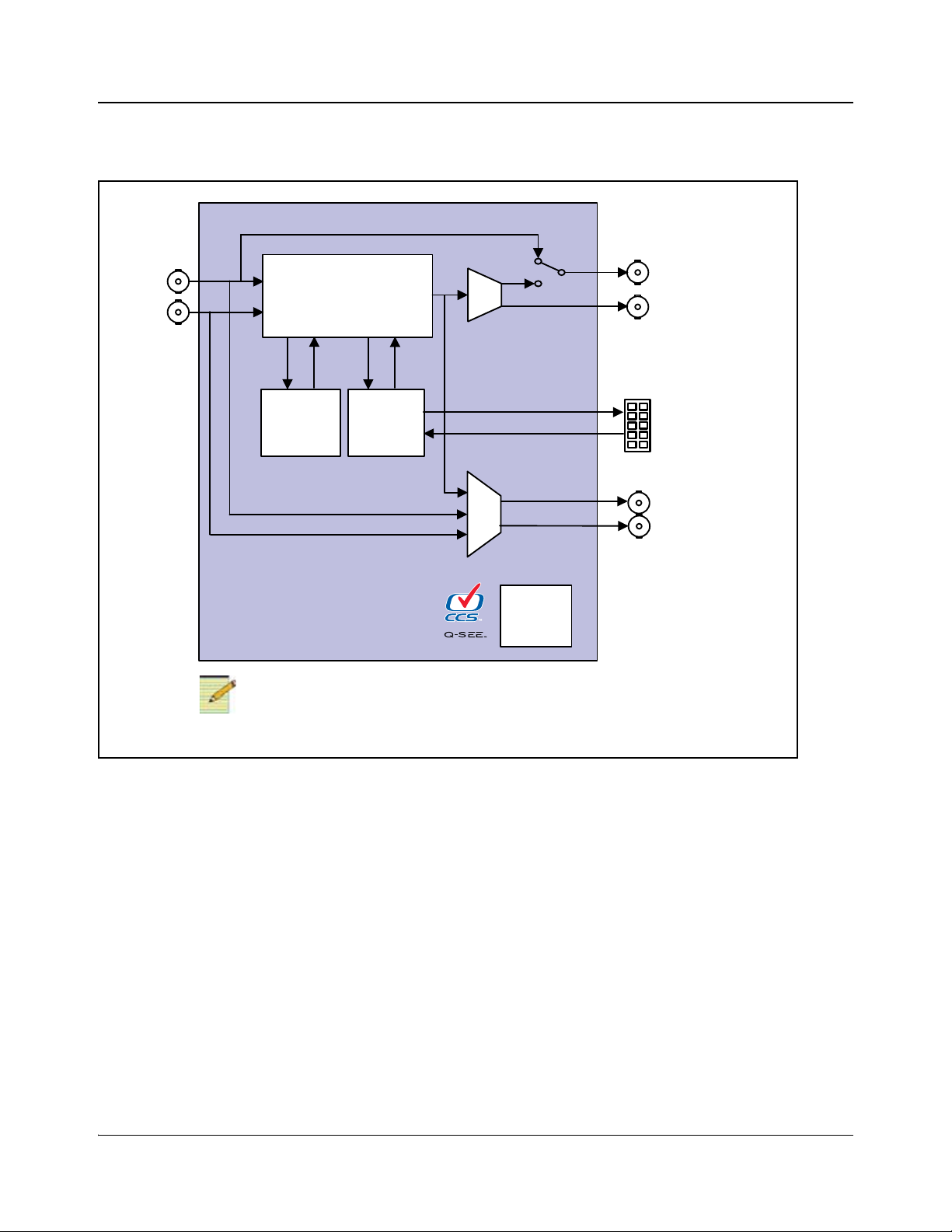

Chapter 1: Introduction

Switch

In 1A

Switch

logic

Q-SEE

logic

Out 1 B

Out 2B

CPU

Monitoring

and

Control

Out 1A bypass

Out 2A

In 2A

GPI in/out A

Note

ACO6800+ASID does not support thumbnails in the Q-SEE logic.

Signal Flow Diagrams

Figure 1-4. Signal Flow Diagram for ACO6800+ISD and ACO6800+ASID

8 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 23

Chapter 1: Introduction

Switch

In 1A

Switch

logic

Q-SEE

logic

Out 1B bypass

Switch

In 1B

Out 2 B

CPU

Monitoring

and

Control

Out 1A by pas s

Out 2A

In 2A

In 2B

GPI in/out A

Switch

logic

Q-SEE

logic

ACO6800+IDSD only

GPI in/out B

Figure 1-5. Signal Flow Diagram for ACO6800+DSD and ACO6800+IDSD

ACO6800+ Installation and Operation Manual 9

Copyright © 2009, Harris Corporation

Page 24

Chapter 1: Introduction

Switch

In 1

Switch

logic

Q-SEE

logic

AUX 2

AUX 1

CPU

Monitoring

and

Control

Out 1 bypass

Out 2

In 2

GPI in/out

Frame

and audio

sync

Trouble

slide/TSG

Genlock

Figure 1-6. Signal Flow Diagram for ACO6800+ISCST

10 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 25

Unpacking the Module

Note

Before you install the module, do the following:

• Check the equipment for any visible damage that may have occurred during

transit.

• Confirm receipt of all items on the packing list. See “Checking the Packing

List” on page 12 below for more information.

Contact your Customer Service representative if parts are missing or

damaged.

• Remove the anti-static shipping pouch, if present, and all other packaging

material.

Chapter 2

Installation

• Retain the original packaging materials for possible re-use.

See “Unpacking/Shipping Information” on page ix for information about

returning a product for servicing.

ACO6800+ Installation and Operation Manual 11

Copyright © 2009, Harris Corporation

Page 26

Chapter 2: Installation

Checking the Packing List

Table 2-1. Available Product Packages

Ordered Product Content Description

ACO6800+ISD

ACO6800+DSD

ACO6800+IDSD

ACO6800+ASID

ACO6800+ISCST

• One ACO6800+ front module

• One two-slot back module

• One ACO6800+ISD back module overlay

• One license key

• One GPIO cable

• One ACO6800+ISD/ACO6800+DSD/ACO6800+IDSD/

ACO6800+ASID/ACO6800+ISCST Installation and Operation Manual

• One ACO6800+

• One two-slot back module

• One ACO6800+DS/ACO6800+IDS back module overlay

• Two GPIO cables

• One license key

• One ACO6800+ISD/ACO6800+DSD/ACO6800+IDSD/

ACO6800+ASID/ACO6800+ISCST Installation and Operation Manual

• One ACO6800+

• One two-slot back module

• One ACO6800+DS/ACO6800+IDS back module overlay

• Two GPIO cables

• One license key

• One ACO6800+ISD/ACO6800+DSD/ACO6800+IDSD/

ACO6800+ASID/ACO6800+ISCST Installation and Operation Manual

• One ACO6800+ front module

• One two-slot back module

• One ACO6800+ASID back module overlay

• One GPIO cable

• One ACO6800+ISD/ACO6800+DSD/ACO6800+IDSD/

ACO6800+ASID/ACO6800+ISCST Installation and Operation Manual

• One ACO6800+ front module

• One three-slot back module

• One submodule

• One GPIO cable

• One license key

• One Icon SoftTools CD (wi th LogoCreator)

• One ACO6800+ISD/ACO6800+DSD/ACO6800+IDSD/

ACO6800+ASID/ACO6800+ISCST Installation and Operation Manual

front module

front module

12 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 27

Maximum 6800+ Frame Power Ratings

Note

Note

The power consumption for the ACO6800+ISD, ACO6800+DSD,

ACO6800+ASID, and ACO6800+IDSD 2-slot modules is less than 12 W. The

power consumption for the three-slot ACO6800+ISCST module is less than 13

W. Table 2-2 shows the maximum allowable power ratings for 6800+ frames.

Note the given maximums before installing any 6800+ modules in your frame.

Due to high levels of heat dissipation, the modules should not be installed in

frames without fans. The modules cannot be installed in FR6802+DM and

6800/7000 series frames.

To maintain proper temperatures, ensure that the front panel is closed at all

times, and that the fan module is fully operational.

Table 2-2. Maximum Power Ratings for 6800+ Frames

Chapter 2: Installation

6800+ Frame

Type

FR6802+QXF

Max. Number of

Max. Frame

Power

Dissipation

Max Power

Dissipation

for Two

Slots

Max Power

Dissipation

for Three

Slots

ACO6800

ACO6800+DSD/

ACO6800+ASID/

ACO6800+IDSD

Modules

120 W 12 W 18 W 10 6

+ISD/

*

Max. Number of

ACO6800

Modules

(frame with AC or

DC power supply)

FR6802+XF

120 W 12 W 18 W 10 6

(frame with AC

power supply)

FR6802+XF-48

105 W 10.5 W 15.25 W 9 6

(frame with DC

power supply)

FR6822+

120 W 12 W 18 W 10 6

(frame with AC or

DC power supply)

* The power consumption of

ACO6800+ISD, ACO6800+DSD, ACO6800+ASID, and

ACO6800+IDSD, listed as <12 W, is measured at around 11.5 W.

† The power consumption of ACO6800+ISCST, listed as <13 W, is measured at around 12.5 W.

+ISCST

†

ACO6800+ Installation and Operation Manual 13

Copyright © 2009, Harris Corporation

Page 28

Chapter 2: Installation

Caution

Caution

Note

Note

Installing the Modules

Due to high levels of heat dissipation, the modules must not be installed in

frames without fans. The modules cannot be installed in FR6802+DM or

6800/7000 series frames.

These modules require no specialized installation or removal procedures.

However, if you are installing b oth front module and back connector , ensure that

the back connector is installed first before plugging in the front module.

Likewise, ensure that the front module is unplugged from the frame before

removing the back connector. See the installation and operation manual for your

frame for information about installing and operating the frame and its

components.

Use the FR6802+RM (Rear Support Extension Rails for 6800+ series frames)

for the modules. See the installation and operation manual for your frame for

installation instructions.

Before installing this product, read the 6800+ Series Safety Instructions and

Standards Manual shipped with every frame installation and operation

manual. This information is also available on our website. The safety

manual contains important information about the safe installation and

operation of 6800+ series products.

Upgrading Module Firmware

Firmware upgrading is a routine procedure that you must perform to install

newer versions of software on 6800+ modules. Navigator software version 4.4

or later is required to perform this procedure on ACO6800+ modules. The

frame must contain or be connected to another frame that contains an ICE6800+

or a 6800+ETH module, version 4.1 or higher.

You can upgrade your 6800+ module’s firmware using the Software Upgrade

tool in CCS Navigator 4.4 or higher. See your frame manual for more

information.

The File Transfer tab is not meant to be used for firmware upgrades. Use

the Software Upgrade tool to upgrade module firmware.

If you do not use the correct firmware version, your module may display

incorrect menu structures, thumbnail failures, and software upgrade failures.

The module uses high-speed upgrading in ASI mode, and normal field

upgrading in SDI mode.

14 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 29

Network Control

For detailed information on how to operate this product remotely, see the

Navigator, NUCLEUS Network Control Pan el, or LCP-3901-1 U/RCP-CCS-1U

manual for Ethernet interface.

ACO6800+ modules do not support + Pilot Lite software; however , you can use

HTTP or SNMP monitoring and control. For detailed information, see the

installation and operation manual for your frame.

Chapter 3

Configuration and Operation

ACO6800+ Installation and Operation Manual 15

Copyright © 2009, Harris Corporation

Page 30

Chapter 3: Configuration and Operation

Note

Operating Notes

When you set the control parameters on the ACO6800+, observe the following:

• If you make changes to certain parameters, other related parameters may

also be affected.

• When you change a parameter, the effect is immediate. However, the

module requires up to 20 seconds to save the latest change. After 20

seconds, the new settings are saved and will be restored if the module loses

power and must be restarted.

• For best results, terminate any unused coaxial output connectors with a 75Ω

connector.

Adding a License Key

ACO6800+ISD, ACO6800+DSD, and ACO6800+IDSD modules can be

converted to one another through use of a license key. It is not possible to

upgrade to an ACO6800+ISCST or ACO6800+ASID module.

For assistance with a license key , or to purchase a license key, contact your

Sales representative. See “Checking the Packing List” on page 12.

To enter a license key, your CCS software must be in Control mode. Follow

these steps:

1. Select the ACO6800+ module in the Navigation pane.

2. Right-click, and then select Control to open the module’ s Control window.

3. If it is not already selected, click on the Parameters tab.

4. Select General in the tree view, and then type your license key in the

License Key field.

If your license key is valid, the Installed Options field displays the features that

are activated on the module.

16 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 31

Changing Parameter Settings

Note

You can control the ACO6800+ modules at the card edge, or by using

CCS-enabled hardware and software applications.

ACO6800+ASID does not use card-edge controls.

CCS Navigator

Before using CCS Navigator to change your module’s parameter settings, you

must discover the module. Discovery is the process by which your software

finds, and then connects to your module.

Discovering a Module

T o discover your mod ule, your CCS Navigator software must be in Build mode.

Follow these steps:

1. If the Discovery pane is not open, select Tools > Discovery in the main

menu.

A Discovery pane opens, most likely in the bottom left corner of the screen.

2. Click Options, and then click Add.

Chapter 3: Configuration and Operation

3. Enter the IP address of the frame that contains your module, the frame that

contains your ICE6800

module that provides access to your module.

4. Click OK, and then OK again to close the Discovery Options dialog box.

5. Click Start.

This causes Navigator to run a discovery.

6. When your discovery is complete, Discovery Completed is displayed in

the Discovery pane. To continue, click Save, to save the contents of your

discovery to the Discovery folder of the Navigation pane.

+ module, or the frame that contains a 6800+ETH

ACO6800+ Installation and Operation Manual 17

Copyright © 2009, Harris Corporation

Page 32

Chapter 3: Configuration and Operation

Note

Note

ACO6800+ISD,

ACO6800+ASID, or

ACO6800+ISCST

ACO6800+DSD or

You can now switch to Control mode by selecting Operational Mode >

Control from the main menu. Double-click ACO6800+ in the Navigation pane.

The Control dialog box opens displaying the module’s controls.

Confirm that the four sub-devices (for ACO6800+DSD, ACO6800+ASID, or

ACO6800+IDSD) or two sub-devices (for ACO6800+ISD and

ACO6800+ISCST) are also discovered, as in Figure 3-1. If the sub-devices

are not discovered, re-discover the module.

Figure 3-1. Discovery of ACO6800+ Modules in CCS Navigator

Card-Edge Controls

Using the module’ s rotary and navigation switches, you can change ACO6800 +

parameter settings at the card edge. You can view and confirm your changes

using the On-screen display feature (see “Activating On-Screen Display” on

page 19).

Card-edge controls are not available for ACO6800+ASID modules.

1. Rotate the mode select rotary switch (hex switch) to “0.”

2. Once the hex switch is set to “0,” toggle the navigation switch up or down

to select a bank.

View the four control LEDs next to the navigation toggle switch to see

which bank is currently selected.

18 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 33

Note

Note

Table 3-1. Bank Select LEDs

Chapter 3: Configuration and Operation

Bank Number

0 Off Off Off Off

1 On Off Off Off

2 Off On Off Off

3On OnOffOff

4OffOffOnOff

5OnOffOnOff

6 Off On On Off

7On OnOnOff

8 Off Off Off On

Bank 0 LED

(first top LED)

3. Rotate the hex switch to the parameter number (1 to 9) or letter (A to F) of

4. Toggle the navigation switch to select and set the value of the chosen

5. Do either of the following:

Bank 1 LED

(second top LED)

Bank 2 LED

(third top LED)

Bank 3 LED

(fourth top LED)

the option you want to set.

parameter.

• Rotate the hex switch to another parameter number/letter in the current

bank, and then repeat step 4.

Throughout this chapter, in the Parameter Navigation sections, the bank and hex

switch positions for each configuration setting are listed in square brackets (for

example, [0, 2]) beside or below the parameter name.

Activating On-Screen Display

You can use the On-Screen Display (OSD) Monitoring feature to view the

current parameter selections on your output display. This feature makes

configuring the ACO6800+ using the card-edge controls much easier.

• Rotate the hex switch to “0” again to select a different bank, and then

repeat steps 3 and 4.

The manufacturer recommends that you use the available 6800+ software

control options (serial/local or Ethernet/remote) to aid in viewing, setting,

and confirming parameter values.

In ACO6800+ISD, ACO6800+DSD, and ACO6800+IDSD modules, OSD is

only displayed on Out A. In ACO6800+ISCST, OSD can be displayed on

any one of the four outputs. OSD is not available in ASI mode. OSD is not

available on ACO6800+ASID modules.

ACO6800+ Installation and Operation Manual 19

Copyright © 2009, Harris Corporation

Page 34

Chapter 3: Configuration and Operation

Note

Note

OSD will only appear when the option is enabled. The module must be in SDI

mode for OSD to appear correctly. On ACO6800+DSD and ACO6800+IDSD

modules, the Output Source must be from Group A.

Table 3-2 lists the parameters to set to activate OSD.

Table 3-2. Activating OSD

Parameter Name

Function Options

Bank,

Switch

ACO6800+ISD, ACO6800+DSD, and ACO6800+IDSD

ACO Group A > MISC Settings

OutA OSD Enable 1, 4 Activates the on-screen display on Out A outputs

ACO6800+ISCST

Video > Out 1_2 Settings

OSD Enable 5 C Activates the on-screen display on PGM outputs

Video > AUX Settings

AUX OSD Enable 5, E Activates the on-screen display on AUX outputs

Recalling Default Parameter Settings

You can use the module’s Factory Recall parameter under System Config to

return all of the module’s parameters to factory default settings. In the

ACO6800+ control parameter list (see page 35, page 47, page 57, and page 85),

each factory default setting appears in bold.

To return this module to its default settings, set the Factory Recall parameter

(0, F) to Enable.

• Enable

• Disable

• Enable

• Disable

• Enable

• Disable

There are two independent sets of d efault values, one for SDI mode and the

other for ASI mode. Factory Recall in SDI mode will not affect the

parameters in ASI mode; nor will Factory Recall in ASI mode affect the

parameters in SDI mode. This does not apply to ACO6800+ASID.

Q-SEE-Compliant Thumbnails

The ACO6800+ASID does not support Q-SEE compliant thumbnails.

20 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 35

Chapter 3: Configuration and Operation

Note

ACO6800+ modules support Q-SEE compliant thumbnails. To use Q-SEE

compliant features, the following conditions must be met:

• The modules must be installed in an FR6802+QXF frame that also contains

a 6800+ETH module (firmware version 4.0 or higher) or an

FR6822

• You must use CCS Navigator version 4.4 or later.

When you open a Control window in CCS Navigator for the 6800+ETH

module, all Q-SEE compliant modules provide thumbnails on a Video

Streaming tab. In addition, the ACO6800+ module Control dialog box has a

Streaming tab where a thumbnail is displayed and updated at up to three frames

per second.

Q-SEE-compliant thumbnails are available for all inputs and outputs, but only

one can be viewed at a time.

If thumbnails do not appear correctly, refresh the tab. To ensure that thumbnails

are operating correctly on your system, view the thumbnail in the 6800

module’s Control dialog bo x.

For more information on Q-SEE compliant thumbnails, see the installation and

operation manual for your frame.

+QXFE frame.

+ETH

Relay Bypass

When Group A or Group B Relay Bypass is activated, Out 2 goes blank, and

the thumbnail and OSD are not available.

Group A or Group B Relay Bypass can be triggered in the following

situations:

• Power failure

•The Group A or Group B GPI In Trigger Level parameter is set to Active

High while nothing is connected to the connector (the Relay Bypass is

triggered because of the internal pull-up on this port)

•The Group A or Gr oup B GPI In Trigger Level parameter is set to Active

Low while the external GPI Input 3 is low

•The Group A or Group B Relay Bypass parameter is set to On.

As soon as the command is accepted (by GPI Input or by Group A or Group B

Relay Bypass parameter), the signal IN 1 is bypassed regardless of switching

mechanism.

If the Group A or Group B Relay Status parameter is shown to be Off

while the relay is actually working, the relay on the card may be damaged.

Passing Dolby Audio (ACO6800+ISCST Modules Only)

To properly process Dolby audio embedded in the video signal, the following

requirements must be met:

ACO6800+ Installation and Operation Manual 21

Copyright © 2009, Harris Corporation

Page 36

Chapter 3: Configuration and Operation

Note

•The Sync Mode Set parameter must be set to Genlock.

• Genlock must be available, with a frame rate that matches the operation

standard.

• Input video must be synced to Genlock.

•The SRC (1-8) Bypass parameter must be set to Yes.

If the SRC Bypass Mode parameter is set to Auto, ACO6800+ will enable

SRC bypass automatically when Dolby data is detected.

Configuring the Switching Mechanism

Three factors control the output channels on the ACO6800+:

•GPI control

• Alarm severity levels for each input channel

• Parameters that can be manually switched in CCS Navigator or at the card

edge

Use the following parameters in the Switch Settings group of parameters to

define the switch priority levels:

• Group A or Group B Switch High Priority (the default setting is GPI Input)

GPI Input Control

• Group A or Group B Switch Medium Priority (the default setting is

Manual)

• Group A or Group B Switch Low Priority (the default setting is Alarms)

A high priority event overrides a medium priority event, which overrides a low

priority event. The three options are mutually exclusive.

As an example, the current settings might start out in these default values:

• Group A Switch High Priority: GPI Input

• Group A Switch Medium Priority: Manual

• Group A Switch Low Priority: Alarms

By changing the Group A Switch Low Priority setting to GPI Input, the

module automatically changes the Group A Switch High Priority setting to

Alarms. This new setting is exclusive, and will not conflict with the Medium

and Low settings.

Table 3-3 indicates what happens when a GPI Input is activated—for example,

pressing a button on a panel—when the switching is not triggered by other

higher priority events than GPI Input.

22 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 37

Table 3-3. GPI Input Control

GPI Action/Result

GPI 1 Switches output source to IN 1

GPI 2 Switches output source to IN 2

Manual Control

When the switching is not triggered by other higher priority events, you can use

the parameters described in Table 3-4 to manually switch the source using either

CCS Navigator or the card-edge controls.

Table 3-4. Manual Switch Parameters

Chapter 3: Configuration and Operation

Parameter Name

ACO6800+ISD

Group A Manual Switch 1, E Sets the output source when a channel is

ACO6800+DSD and ACO6800+IDSD

Group A Manual Switch 1, E Sets the output source when a channel is

Group B Manual Switch 4, E Sets the output source when a channel is

ACO6800+ASID

Manual Switch n/a Sets the output source when a channel is

ACO6800+ISCST

Manual Switch 1, E Sets the output source when a channel is

Function Options

Bank,

Switch

switched manually

switched manually

switched manually

switched manually

switched manually

• Disable

• Switch to A1

• Switch to A2

• Disable

• Switch to A1

• Switch to A2

• Disable

• Switch to B1

• Switch to B2

• Disable

• Switch to 1

• Switch to 2

• Disable

• Switch to A1

• Switch to A2

ACO6800+ Installation and Operation Manual 23

Copyright © 2009, Harris Corporation

Page 38

Chapter 3: Configuration and Operation

Note

Alarm Control

The combination of the switch priority parameter settings, adjustable alarm

switch levels, and SQM smart alarms on the subdevice of the ACO6800+

module provides flexible automatic and manual switch control. In the case of

the SQM smart alarms, you can individually adjust the severity and trigger/clear

duration for each alarm type (for more information, see page 43, page 54,

page 66, and page 101). The following tables offer two sample scenarios.

By default, all alarms are set to a disabled state. To configure a device to

switch using alarms as a trigger, first enable alarms in the sub-device.

Failure of Auto/Manual switchover

If your auto/manual switchover does not work as expected, confirm that the

following parameters have been configured correctly:

• Group (A/B) GPI Input_(1-3) should confirm the GPI Input condition.

• Group A or Group B Manual Switch should confirm the expected setting.

• Group A or Group B Switch (High/Medium/Low) Priority should

display the sort of logic seen in Table 3-6 and Table 3-8.

• Group A or Group B Alarm Switch Level should confirm the triggered

level.

Confirm that the configurable portions of sub-device alarms match your

expectations. (This includes Enable/Disable, Alarm Priority, Trigger Time, and

Clear Time.)

For ACO6800+ISCST modules, ensure that the Video Standard and

Operation Standard parameters have the same setting. The Still Image Mode

parameter must be set to Auto, and the Force Free z e an d For ce Black

parameters must be set to Off.

Sample Scenario One

The initial settings for sample scenario one are outlined in Table 3-5.

Table 3-5. Sample Scenario One: Parameter Settings

Parameter Setting

Group A Switch High Priority GPI Input

Group A Switch Medium Priority Manual

Group A Switch Low Priority Alarms

Group A Alarm Switch Level 6

Group A Manual Switch Disable

24 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 39

Chapter 3: Configuration and Operation

Table 3-5. Sample Scenario One: Parameter Settings

Parameter Setting

A1 SDI Loss of Video: Priority 6

A1 SDI Loss of Video: Trigger 2 s

A1 SDI Loss of Video: Clear 10 s

Table 3-6. Sample Scenario One: Chain of Events

Event Result

1. At the start, A1 and A2 are both present.

Output A is A1 (A1 is the primary channel).

2. A1 is lost.

3. Two seconds pass.

4. A user sets the Manual Switch to A1.

5. A user activates GPI Input 2.

6. A user sets the Manual switch to

Disable.

7. A1 is present.

8. Five seconds after A1 is present, GPI

Input 2 is deactivated.

9. Five seconds pass.

Sample Scenario Two

The initial settings for sample scenario two are outlined in Table 3-7. For this

scenario, the trigger time and clear time of all alarms is presumed to be 0

seconds.

Table 3-7. Sample Scenario Two: Parameter Settings

Output A is A1 (alarm is not yet triggered;

waiting for two second trigger condition).

Output A is A2 (alarm is triggered).

Output A is A1 (Manual has higher priority

than Alarm).

Output A is A2 (GPI Input has higher priority

than Manual).

Output A is A2.

Output A is A2 (GPI Input command is still

active).

Output A is A2 (alarm for A1 is not cleared

yet; waiting for 10 seconds clear condition).

Output A is A1 (alarm is cleared).

Parameter Setting

Group A Switch High Priority GPI Input

Group A Switch Medium Priority Alarms

Group A Switch Low Priority Manual

Group A Alarm Switch Level 6

Group A Manual Switch Disable

A1 SDI Loss of Video: Priority 6

A1 SDI Video Standard Mismatch: Priority 1

ACO6800+ Installation and Operation Manual 25

Copyright © 2009, Harris Corporation

Page 40

Chapter 3: Configuration and Operation

Table 3-7. Sample Scenario Two: Parameter Settings (Continued)

Parameter Setting

A1 SDI Expected Standard 525

A2 SDI Video Standard Mismatch: Priority 6

A2 SDI Expected Standard 525

Table 3-8. Sample Scenario Two: Chain of Events

Event Result

1. At the start, A1 and A2 are both

2. A1 is lost.

3. A user sets the Manual Switch to

present and 625 format.

A2.

Output A is A1 (A1 Standard Mismatch alarm is

on, but has not met switching condition, level 6).

Output A is A1 (A1 and A2 inputs are bad, but A2

Standard Mismatch alarm level is 6, so the

ACO6800+ selects primary input as output).

Output A is A1 (A2 is still bad, and Alarm has

higher priority than Manual).

4. A user activates GPI Input 2.

5. A user deactivates GPI Input 2.

6. A1 is present, 625 format.

Output A is A2 (GPI Input has higher priority than

Alarm).

Output A is A1.

Output A is A1 (Alarm is still on, but it has not

met switching condition).

Switching to a Still Image (ACO6800+ISCST Modules Only)

In ACO6800+ISCST modules, the Still Image Source parameter determines

whether the output is to TSG or trouble slide.

When the Still Image Mode parameter is set to Force, the output is to a

pre-defined still image, except when relay bypass is enabled.

When the Still Image Mode parameter is set to Auto, the still image is treated

as the module’s third input, which is always in good quality. The switching

mechanism includes the still image in its priority list. The order of priority, from

highest to lowest, is IN 1, IN 2, and still image.

Table 3-9 shows the relationship between switch mechanism and still image

output when the Still Image Mode parameter is set to Auto.

Table 3-9. Still Image Priority and Image Output When Still Image Mode is set to Auto

Switch High

Priority

Switch Medium

Priority

Switch Low

Priority

Output

Source

Note

GPI Input Select

IN1

GPI Input =

Inactive

26 ACO6800+ Installation and Operation Manual

N/A N/A Input 1 GPI forces IN 1 as output

source even when IN1 is

lost.

Manual Switch =

IN_2

N/A Input 2 Manual switch forces IN 2

as output source, even

when IN 2 is lost.

Copyright © 2009, Harris Corporation

Page 41

Chapter 3: Configuration and Operation

Table 3-9. Still Image Priority and Image Output When Still Image Mode is set to Auto

Switch High

Priority

GPI Input =

Inactive

GPI Input =

Inactive

Switch Medium

Priority

Manual Switch =

Disable

Manual Switch =

Disable

Switch Low

Priority

Alarm = Enable and

Alarm switch

condition met for

both inputs

Alarm = Disable Input 1 Switch Mechanism is

Output

Source

Still Image Switch Mechanism selects

Note

Still Image as output

source.

disabled.

Table 3-10 shows what happens when both inputs are lost and the SDI Loss of

Video alarm of both IN 1 and IN2 are considered as fatal alarms and triggered

(supposing GPI Input and Manual Switch are both not active).

Table 3-10. Still Image Output on ACO6800+ISCST Modules

Still Image

Mode

*

Auto

Auto TSG/Trouble Slide Black The output turns black, and then switches over

Auto TSG/Trouble Slide Freeze The output freezes the last good frame or field,

Auto Non e Pass The output passes some noise.

Still Image

Source

TSG/Trouble Slide Pass The output temporarily passes some video

LOV Mode Result

noise, and then switches over to the still image.

to the still image.

and then switches over to the still image.

†

Auto Non e Black The output switches to black signal.

Auto Non e Freeze The output freezes the last good frame or field.

* If the Still Image Mode parameter is set to Force, TSG/Trouble Slide is always on-line regardless of

signal quality of inputs.

† ACO6800+ cannot pass video with a different standard than the operation standard.

Creating Trouble Slides

Integrated Graphics Storage and Playout

The ACO6800+ISCST provides on-demand insertion of pre-defined static

SD-SDI and HD-SDI logo images.

ACO6800+ Installation and Operation Manual 27

Copyright © 2009, Harris Corporation

Page 42

Chapter 3: Configuration and Operation

Logo Insertion on the ACO6800+ISCST

Existing logo

graphic with

alpha channel

Conversion to

.mg2 format using

LogoCreator

Storage of logo file

on a microSD card

via the USB port on

a PC

Loading of file into

ACO6800+ISCST

module for on-air use

Logos used by the ACO6800+ISCST must be created or saved in the .mg2 file

format, and initially stored on a micro-SD card that is inserted into the slot

located at the card edge of the module. The ACO6800+ISCST supports

SanDisk, LEXAR, and Kingston 1G and 2G microSD cards.The files must be

loaded onto the card directly at your PC workstation. (LogoCreator software is

provided as a utility to convert existing files to .mg2).

Figure 3-2. Progression of Logo to On-Air Signal

The files that you use as logos must be selected according to the video output

standard set on the ACO6800+ISCST (System > Operation Standard). When

the output standard changes on the module, the ACO6800+ISCST

automatically loads files that use the selected output standard.

Basic Steps to Installing Logo Files

If you are starting with existing graphics files, these basic steps are as follows:

1. Install the LogoCreator conversion software from the IconSoft Tools

CD-ROM.

2. Convert the logos to an .mg2 format.

3. Transfer the files to the microSD card directly from the PC.

Step 1: Install LogoCreator Software

All logos used by the ACO6800+ISCST must either be generated as .mg2 files

or converted to that format. A version of LogoCreator (located on the IconSoft

Tools CD-ROM) is provided with the manual for this purpose.

For best results, LogoCreator requires a PC with the following system

specifications:

• Intel Pentium III processor at 500 MHz or faster

• 512 MB or more of physical memory (RAM)

• Microsoft

If a version of LogoCreator already exists on the PC, ensure that you first

uninstall the program and restart the computer. Then, proceed with the steps

below:

®

Windows® XP or Windows 2000

1. Close all other software applications running on the PC and then insert the

IconTools CD-ROM into the computer’s CD-ROM tray.

28 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 43

2. Using Windows Explorer, browse to the CD-ROM contents, and then

Note

double-click the LogoCreator folder.

3. Double-click Setup.exe.

4. When the IconTools 3 Setup box appears, click Next, and then follow the

on-screen installation instructions.

Step 2: Convert Files to the .mg2 Format

When using LogoCreator, you need a source image file for the fill portion of

your logo, and a source image file for the key portion. The fill is the picture or

image you want to overlay onto the program output. The key is the cutout or

shape of the desired logo, which may or may not be the same shape as the fill.

Use LogoCreator to set the fill and key images to the same size (resolution) as

the standard of the ACO6800+ISCST output. LogoCreator infers the key from

the alpha channel in a targa (.tga) file.

After you save the logo, the logo displays in your LogoCreator workspace. To

save your logo files using LogoCreator, follow these steps:

1. In LogoCreator, open the Logo Set-Up dialog box (Figure 3-3 below).

When you first open LogoCreator, the Logo Set-Up dialog box opens

automatically . If the Logo Set-Up dialog box is closed, select File > New to

open the dialog box.

Chapter 3: Configuration and Operation

Figure 3-3. LogoCreator Setup Dialog Box

If you click the Open button directly in the Logo Set-Up box, the

program will only launch files with a .mg2 prefix. If you attempt to open

a file with any other prefix, the program will generate error messages.

2. Click the Logo button to open the Static Logo dialog box.

3. Use the Logo ID box to assign the logo to a specific slot on your IconLogo

system.

4. Enter a name for the logo in the Name box.

ACO6800+ Installation and Operation Manual 29

Copyright © 2009, Harris Corporation

Page 44

Chapter 3: Configuration and Operation

Note

5. Click the Open button below the Logo Image Preview windo w.

6. Select your existing logo file and click the Open button to open the logo in

The Open dialog box displays.

the Static Logo dialog box.

Figure 3-4. Static Logo Dialog Box

• A preview of the composited logo displays in the Logo Image Preview

area.

• A preview of the image alpha displays in the Logo Alpha Preview area

if the file contains alpha.

7. Select a file to use as the alpha channel for your logo.

You must select a file before you can save the logo.

• T o use the original image’s alpha channel, select the Use the alpha key

found with image checkbox.

• To use a different image for the alpha channel, clear the Use the alpha

key found with image checkbox, and then click the Open button to

select a new file for your alpha channel.

An alpha channel is an 8-bit layer in a graphics file format that expresses

transparency. Typically, you define the alpha channel on a per-object basis.

Different parts of an object will have different levels of transparency

depending on how much background you want to show through.

8. Click the Save button in the Static Logo dialog box.

The Save Logo File dialog box opens. In this dialog box, you can save your

logo as a .mg2 file. Once you save the logo as a .mg2 file, the logo displays

in the LogoCreator workspace.

30 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 45

Figure 3-5. LogoCreator Work Space

Chapter 3: Configuration and Operation

Once you create an .mg2 logo, you can

• Open the file in LogoCreator

• Set the logo position

• Modify specific logo attributes

LogoCreator also makes it possible to adjust the noise and strength of the

key signal and apply fade on/off transitions to the logo.

Step 3: Transfer the Logos to the MicroSD Card

When your logos have been created or converted to the .mg2 format, they can

be saved on the microSD card. The ACO6800+ISCST references files on the

MicroSD card using the DOS 8.3 short filename convention. Longer filenames

may be accessed by entering the alternate 8.3 filename. To avoid any confusion,

it is preferable to limit all filenames to the 8.3 format, with a maximum of 8

characters before the .mg2 extension.

ACO6800+ Installation and Operation Manual 31

Copyright © 2009, Harris Corporation

Page 46

Chapter 3: Configuration and Operation

MicroSD card

in socket

In addition, all files must be located within the logos folder on the microSD

card. Figure 3-6 shows the location of the microSD socket.

Figure 3-6. Inserting the MicroSD Card

Using Trouble Slides

The Trouble Slide Source parameter has four options. The Trouble Slide

(1/2/3) options are only available when there are compatible trouble slides

(MG2 format) stored in the microSD card.

The trouble slide can have two sources:

• Default trouble slides are stored within the firmware of the ACO6800+.

• Up to three user trouble slides can be stored in a microSD card (located at

Trouble slides must meet the following criteria:

You can only change the background portion of default trouble slides (using

parameter Trouble Slide Background)

the sub-module)

32 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 47

Chapter 3: Configuration and Operation

• The SD card must be microSD, formatted as FAT/FAT16 (FAT32 is not

supported). Suppliers SANDISK, LEXAR and Kingston, memory size 1G

and 2G have been verified. Figure 3-7 shows a valid SD card in a PC

browser window.

Figure 3-7. Valid SD Card in Browser Window

• The image file must be put in folder named “logos” in the root directory

(regardless of uppercase or lowercase).

• The image file must be MG2 format with extended name “mg2” or “MG2”.

• The width and height of mg2 file must be smaller than the supported size of

current operation standard (for example, if the current operation standard is

720p, and the video size is 1280*720, if the image size is 720*576, it is

acceptable. If it is 1920*1280, it would be refused).

• For best results, the length of file name should be less or equal to 8 letters.

(If the length of mg2 file name is larger than 8 characters, a shortened name

will display on Navigator.)

• Only the first three valid MG2 files sorted by access time are displayed on

Navigator.

• For best results, the original image (before converting to MG2 format)

should consist of an even number of pixels and an even number of lines.

• Every time the operation standard or trouble slide background changes, the

system reloads the trouble slide.

Generally, larger or more complicated images take longer for the system to

load. A complicated image with size of 1920*1280 (the maximum supported

size) takes about 7 minutes to finish loading. The trouble slide will not be

displayed until loading is finished (it is masked as black during that time).

ACO6800+ Installation and Operation Manual 33

Copyright © 2009, Harris Corporation

Page 48

Chapter 3: Configuration and Operation

34 ACO6800+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 49

ACO6800+ISD Parameters, LEDs, and

On-Screen Display Monitoring

If you are using card-edge controls to configure your ACO6800+ISD module,

you can use the on-screen display (OSD) monitoring feature to view the current

parameter selections. When the OSD monitoring is activated, the current

parameter selections are displayed on module’s monitoring outputs. For

information on enabling OSD monitoring, see “Activating On-Screen Display”

on page 19.

Parameter Table Notes

When you look at the control parameter tables, note the following:

• Shaded table rows and [RO] after the parameter name indicate read-only

(feedback) parameters.

• Bolded parameter options indicate the default settings for the parameter.

• The bank selection and rotary switch combinations for each parameter and

parameter option are listed in the tables under the Bank, Switch heading.

For more information about using the card-edge controls, see “Card-Edge

Controls” on page 18.

Chapter 4

Alarms

• The parameters are listed in the order that they appear in CCS Navigator.

ACO6800+ Installation and Operation Manual 35

Copyright © 2009, Harris Corporation

Page 50

Chapter 4: ACO6800+ISD Parameters, LEDs, and Alarms

ACO6800+ISD Parameters

Table 4-1. ACO6800+ISD Parameters

Group Parameter Name

General

Serial Number [RO] Displays the serial number of the

License Key Provides a location for entering

Enabled Options [RO] Displays the current license option <string>

Factory Recall 0, F Sets the module back to factory

Soft Reboot 0, E Activates a soft reboot of the module

Operation Mode 0, 1 Sets the ACO work mode to SDI or

Thumbnail Source 0, 2 Selects the thumbnail source

Submodule Type [RO] Displays whether or not there is a

Backmodule Type [RO} Displays which back module is

Function Options

Bank,

Switch

module

license key numbers

default settings

Note There are two independent sets

of default values for SDI mode and ASI

mode. Factory Recall in SDI mode

does not affect the parameters in ASI