Page 1

TECHNICAL MANUAL

GATES ONE - 994 9202 002

GATES TWO - 994 9203 002

GATES FIVE (1-PHASE) - 994 9204 002

GATES Series™

AM TRANSMITTERS

GATES FIVE (3-PHASE) - 994 9205 002

T.M. No. 888-2314-001

© Copyright 1990, 1991, 1992, 1994, 1995, 1996, 1998, 1999,

2000, 2001, 2002

Harris Corporation

All rights reserved

Printed: 1990

Rev. AF: 06-21-02

Page 2

Returns And Exchanges

Damaged or undamaged equipment should not be returned unless written approval and a

Return Authorization is received from HARRIS CORPORATION, Broadcast Systems Division. Special shipping instructions and coding will be provided to assure proper handling.

Complete details regarding circumstances and reasons for return are to be included in the

request for return. Custom equipment or special order equipment is not returnable. In those

instances where return or exchange of equipment is at the request of the customer, or

convenience of the customer, a res tocking fee will be charged. All returns will be sent

freight prepaid and properly insured by the customer. When communicating with HARRIS

CORPORATION, Broadcast Systems Div ision, specify the HARRIS Order Number or Invoice Number.

Unpacking

Carefully unpack the equipment and preform a visual inspection to determine that no apparent damage was incurred during shipment. Retain the shipping materials until it has been

determined that all received equipment is not damaged. Locate and retain all PACKING

CHECK LISTs. Use the PACKING CHECK LIST to help locate and identify any components

or assemblies which are removed for shipping and must be reinstalled. Also remove any

shipping supports, straps, and packing materials prior to initial turn on.

Technical Assistance

HARRIS Technical and Troubleshooting assistance is available from HARRIS Field Service

during normal business hours (8:00 AM - 5:00 PM Central Time). Emergency service is

available 24 hours a day. Telephone 217/222-8200 to contact the Field Service Department

or address correspondence to Field Service Department, HARRIS CORPORATION, Broadcast Systems Division, P.O. Box 4290, Quincy, Illinois 62305-4290, USA. Technical Support

by e-mail: tsupport@harris.com. The HARRIS factory may also be contacted through a FAX

facility (217/221-7096).

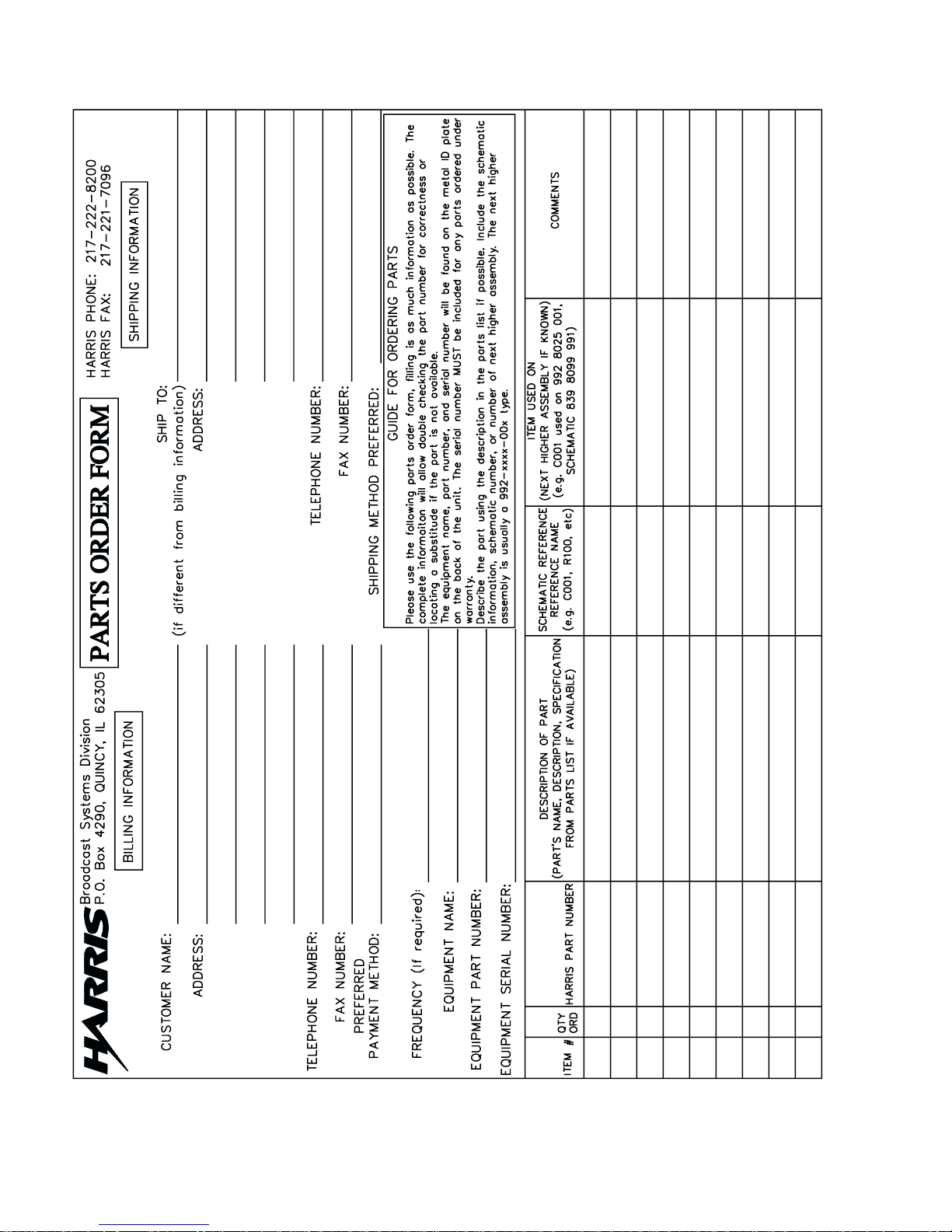

Replaceable Parts Service

Replacement parts are available 24 hours a day, seven days a week from the HARRIS

Service Parts Department. Telephone 217/222-8200 to contact the service parts department

or address correspondence to Service Parts Department, HARRIS CORPORATION, Broadcast Systems Division, P.O. Box 4290, Quincy, Illinois 62305-4290, USA. The HARRIS factory may also be contacted through a FAX facility (217/221-7096).

NOTE

The # symbol used in the parts list means used with (e.g. #C001 = used with C001).

Page 3

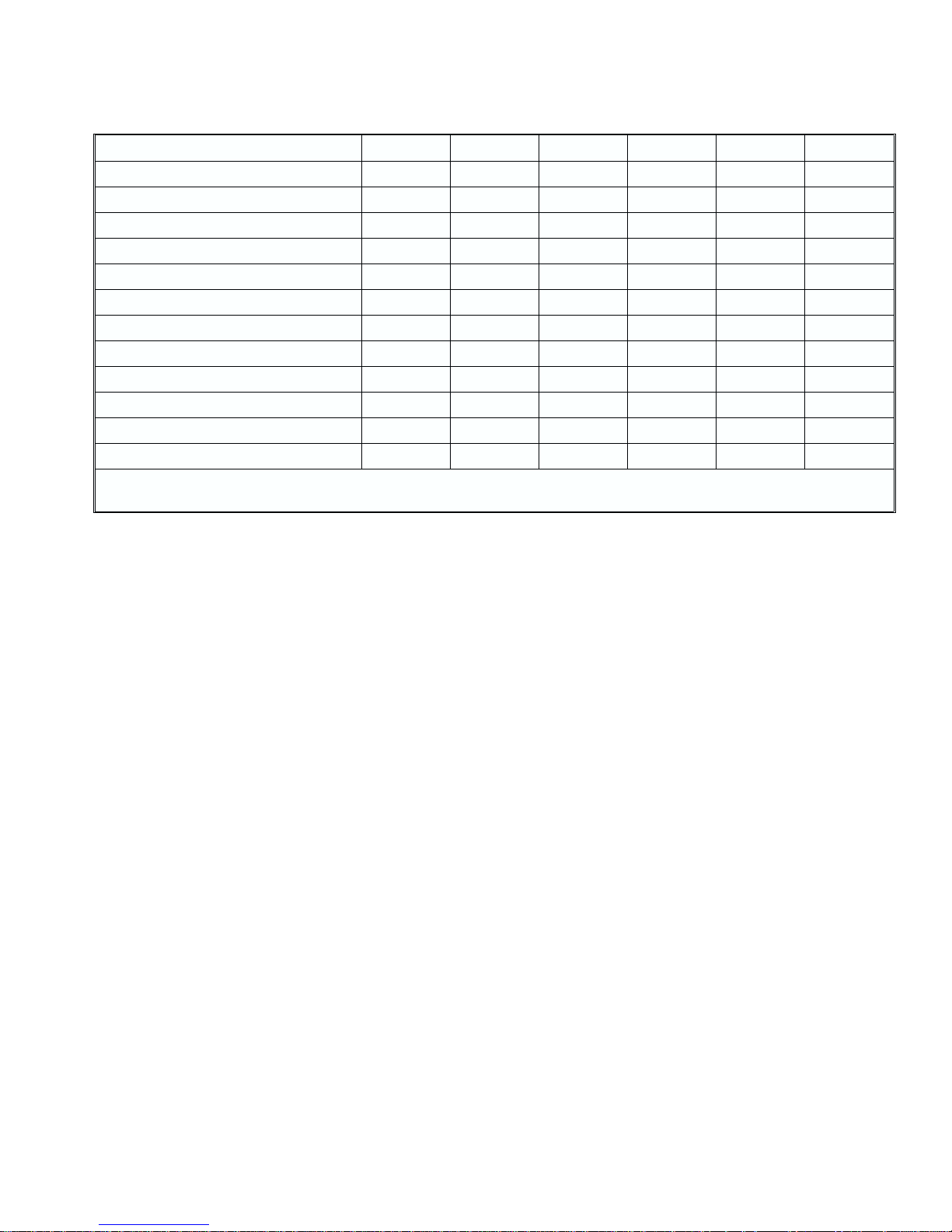

MANUAL REVISION HISTORY

GATES Series™ AM Transmitters

888-2314-xxx

Rev.

A April 1990 None Replaced the following pages: Title Page, v, vii, 2-1 thru 2-6, 3-3, 3-4, 4-3, 4-4, 5-1 thru 5-6, J-3, & J-4

B Aug. 1990 None Replaced the following pages: Title Page, v, 3-5, 3-6, 4-1 thru 4-4, A-1, B-1, B-2, C-2, E-3, F-1 thru F-3,

C Aug. 1990 35969 Replaced the following pages: Title Page, MRH-1/MRH-2, C-4, & C-5

D Aug. 1990 Field

E Sept. 1990 36322 Replace the following pages: Title Page, MRH-1/MRH-2, & all of Section VI

F Oct. 1990 36415 Replace the following pages: Title Page, MRH-1/MRH-2, & all of Section A

G Jan. 1991 Errata

H June 1991 FS

I July 1991 36962 Replace the following pages: Title Page, MRH-1/MRH-2, and K-3

J Aug. 1991 36963 Replace the following pages: Title Page, MRH-1/MRH-2, 6-9 to 6-12, & J-9 TO J-11

K Jan. 1992 37611 &

L June 1992 37442 Replaced Title Page, MRH-1/MRH-2 and pages 6-14 to 6-17

M Jan. 1994 38809 Replaced Title Page, MRH-1/MRH-2, page K-3, and all of section VI

N Feb. 1994 38895 Replaced Title Page, MRH-1/MRH-2, and pages F-4 & F-5

P July 1994 39302 Replaced Title Page, MRH-1/MRH-2, and all of section VI

R Dec. 1994 39223 Replaced Title Page, MRH-1/MRH-2, and pages F-4 & F-5

S July 1995 39125 Replaced Title Page, MRH-1/MRH-2, and all of section VI

T Jan. 1996 41051R Replaced Title Page, MRH-1/MRH-2, Table of Contents, 1-2 to 1-4, all of sections 2, 4, & 5

U Jan. 1996 41051R Replaced Tit le Page, MRH-1/MRH-2, and pages 6-15 to 6-19

V Mar. 1996 TBD Replaced Title Page, MRH-1/MRH-2, and page 2-9

X Dec. 1996 41575 Replaced Title Page, MRH-1/MRH-2, iv thru vi, and all of Section C

Y May 1998 42198 Replaced Title Page, MRH-1/MRH-2, and page 2-4

Y1 10-02-98 42359 Replaced Title Page, MRH-1/MRH-2, page G-6 and all of Section VI

Z 12-22-98 38895A Replaced Title Page, MRH-1/MRH-2, and all of Section F

Z1 2-15-99 42544 Replaced Title Page, MRH-1/MRH-2, and pages C-4 & C-5.

Z2 2-25-99 42636 Replaced Title Page, MRH-1/MRH-2, and all of Section VI

AA 08-18-99 45024 Replaced Title Page, MRH-1/MRH-2, and all of Section H

AB 12-10-99 45544 Replaced Title Page, MRH-1/MRH-2 and pages 2-4 and 2-5

AC 02-20-00 45748 Replaced Title Page, MRH-1/MRH-2 and all of Section II

AD 10-04-01 47730 Replaced Title Page, MRH-1/MRH-2 and page 3-6

AD1 01-15-02 47924 Replaced Title Page, MRH-1/MRH-2, and all of Section VI

AE 03-05-02 48100 Replace Title Page, MRH1/MRH2, all parts lists and chapter B.

AF 06-21-02 48426 Replace Title Page, MRH1/MRH2, and page C-3

Date ECN

Service

Request

FS

Request

Request

Misc

Pages Affected

Added MRH-1/MRH-2

G-1 thru G-4, J-1, J-2, J-3, J-4, J-9 thru J-11, & K-3

Replace the following pages: Title Page, MRH-1/MRH-2, & 2-5

Replace the following pages: Title Page, MRH-1/MRH-2, & all of Section VI

Replace the following pages: Title Page, MRH-1/MRH-2, 2-6, G-2, & J-3

Replaced Title Page, MRH-1/MRH-2 and all part lists in manual

888-2314-001 MRH-1/MRH-2

Page 4

Page 5

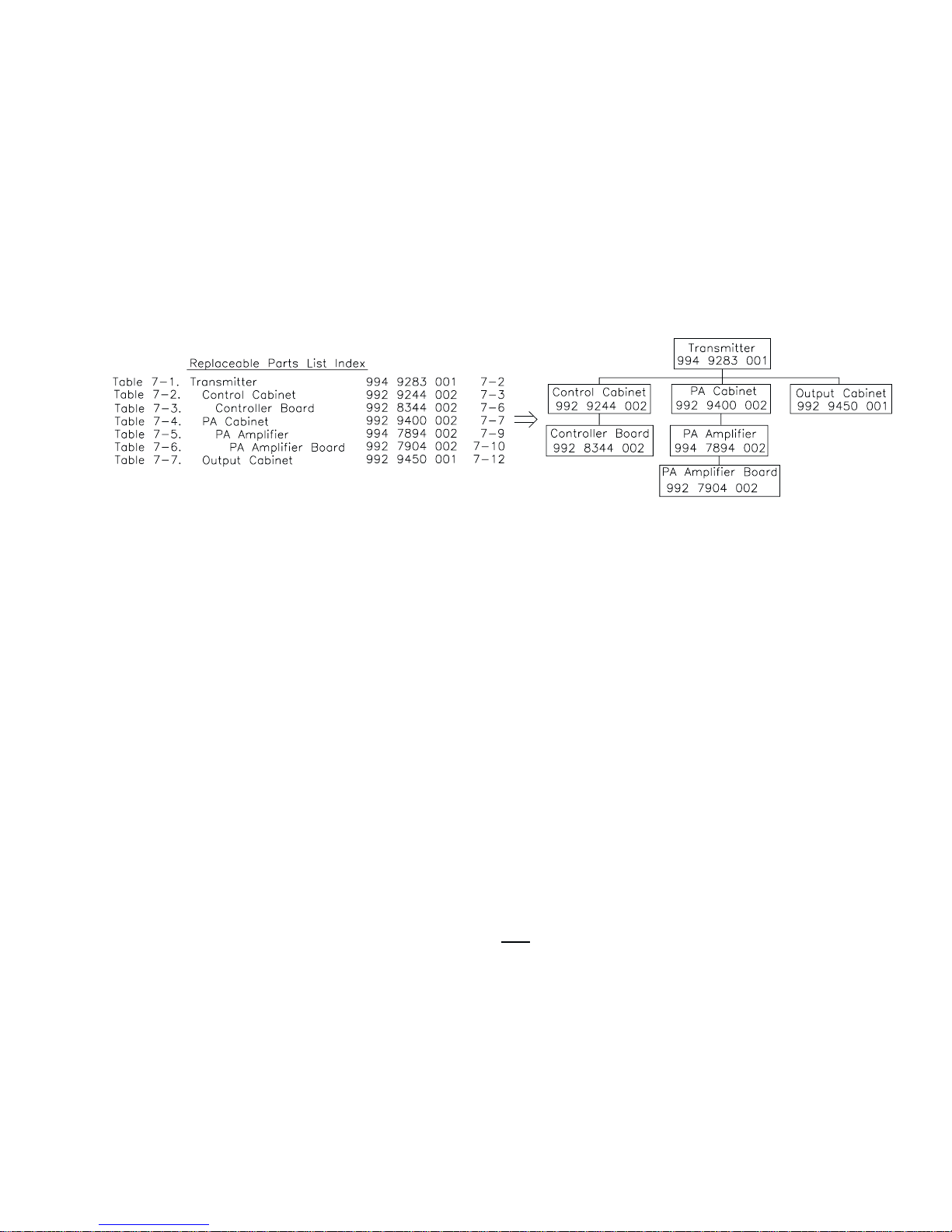

Guide to Using Harris Parts List Information

The Harris Replaceable Parts List Index portrays a tree structure with the major items being leftmost in the index. The

example below shows the Transmitter as the highest item in the tree structure. If you were to look at the bill of materials

table for the Transmitter you would find the Control Cabinet, the PA Cabinet, and the Output Cabinet. In the Replaceable

Parts List Index the Control Cabinet, PA Cabinet, and Output Cabinet show up one indentation level below the Transmitter

and implies that they are used in the Transmitter. The Controller Board is indented one level below the Control Cabinet so

it will show up in the bill of material for the Control Cabinet. The tree structure of this same index is shown to the right of

the table and shows indentation level versus tree structure level.

Example of Replaceable Parts List Index and equivalent tree structure:

The part number of the item is shown to the right of the description as is the page in the manual where the bill for that part

number starts.

Inside the actual tables, four main headings are used:

Table #-#. ITEM NAME - HARRIS PART NUMBER -this line gives the information that corresponds to the Replaceable Parts List Index entry;

HARRIS P/N column gives the ten digit Harris part number (usually in ascending order);

DESCRIPTION column gives a 25 character or less description of the part number;

REF. SYMBOLS/EXPLANATIONS column 1) gives the reference designators for the item (i.e., C001, R102, etc.) that

corresponds to the number found in the schematics (C001 in a bill of material is equivalent to C1 on the schematic) or

2) gives added information or further explanation (i.e., “Used for 208V operation only,” or “Used for HT 10LS only,”

etc.).

Inside the individual tables some standard conventions are used:

A # symbol in front of a component such as #C001 under the REF. SYMBOLS/EXPLANATIONS column means that

this item is used on or with C001 and is not the actual part number for C001.

In the ten digit part numbers, if the last three numbers are 000, the item is a part that Harris has purchased and has not

manufactured or modified. If the last three numbers are other than 000, the item is either manufactured by Harris or is

purchased from a vendor and modified for use in the Harris product.

The first three digits of the ten digit part number tell which family the part number belongs to - for example, all

electrolytic (can) capacitors will be in the same family

have a 9xx xxxx xxx part number (a number outside of the normal family of numbers), it has probably been modified

in some manner at the Harris factory and will therefore show up farther down into the individual parts list (because

each table is normally sorted in ascending order). Most Harris made or modified assemblies will have 9xx xxxx xxx

numbers associated with them.

The term “SEE HIGHER LEVEL BILL” in the description column implies that the reference designated part number

will show up in a bill that is higher in the tree structure. This is often the case for components that may be frequency

determinant or voltage determinant and are called out in a higher level bill structure that is more customer dependent

than the bill at a lower level.

(524 xxxx 000). If an electrolytic (can) capacitor is found to

Rev. X 888-2314-001 iii

WARNING: Disconnect primary power prior to servicing.

Page 6

iv 888-2314-001 Rev. X

WARNING: Disconnect primary power prior to servicing.

Page 7

WARNING

THE CURRENTS AND VOLTAGES IN THIS EQUIPMENT ARE DANGEROUS. PERSONNEL MUST

AT ALL TIMES OBSERVE SAFETY WARNINGS, INSTRUCTIONS AND REGULATIONS.

This manual is intended as a general guide for trained and qualified personnel who are aware of the dangers inherent in

handling potentially hazardous electrical/electronic circuits. It is not intended to contain a complete statement of all safety

precautions which should be observed by personnel in using this or other electronic equipment.

The installation, operation, maintenance and service of this equipment involves risks both to personnel and equipment, and

must be performed only by qualified personnel exercising due care. HARRIS CORPORATION shall not be responsible for

injury or damage resulting from improper procedures or from the use of improperly trained or inexperienced personnel

performing such tasks.

During installation and operation of this equipment, local building codes and fire protection standards must be observed.

The following National Fire Protection Association (NFPA) standards are recommended as reference:

- Automatic Fire Detectors, No. 72E

- Installation, Maintenance, and Use of Portable Fire Extinguishers, No. 10

- Halogenated Fire Extinguishing Agent Systems, No. 12A

WARNING

ALWAYS DISCONNECT POWER BEFORE OPENING COVERS, DOORS, ENCLOSURES, GATES,

PANELS OR SHIELDS. ALWAYS USE GROUNDING STICKS AND SHORT OUT HIGH VOLTAGE

POINTS BEFORE SERVICING. NEVER MAKE INTERNAL ADJUSTMENTS, PERFORM MAINTENANCE OR SERVICE WHEN ALONE OR WHEN FATIGUED.

Do not remove, short-circuit or tamper with interlock switches on access covers, doors, enclosures, gates, panels or shields.

Keep away from live circuits, know your equipment and don’t take chances.

WARNING

IN CASE OF EMERGENCY ENSURE THAT POWER HAS BEEN DISCONNECTED.

WARNING

IF OIL FILLED OR ELECTROLYTIC CAPACITORS ARE UTILIZED IN YOUR EQUIPMENT, AND IF

A LEAK OR BULGE IS APPARENT ON THE CAPACITOR CASE WHEN THE UNIT IS OPENED FOR

SERVICE OR MAINTENANCE, ALLOW THE UNIT TO COOL DOWN BEFORE ATTEMPTING TO

REMOVE THE DEFECTIVE CAPACITOR. DO NOT ATTEMPT TO SERVICE A DEFECTIVE CAPACITOR WHILE IT IS HOT DUE TO THE POSSIBILITY OF A CASE RUPTURE AND SUBSEQUENT

INJURY.

Rev. X 888-2314-001 v

WARNING: Disconnect primary power prior to servicing.

Page 8

vi 888-2314-001 Rev. X

WARNING: Disconnect primary power prior to servicing.

Page 9

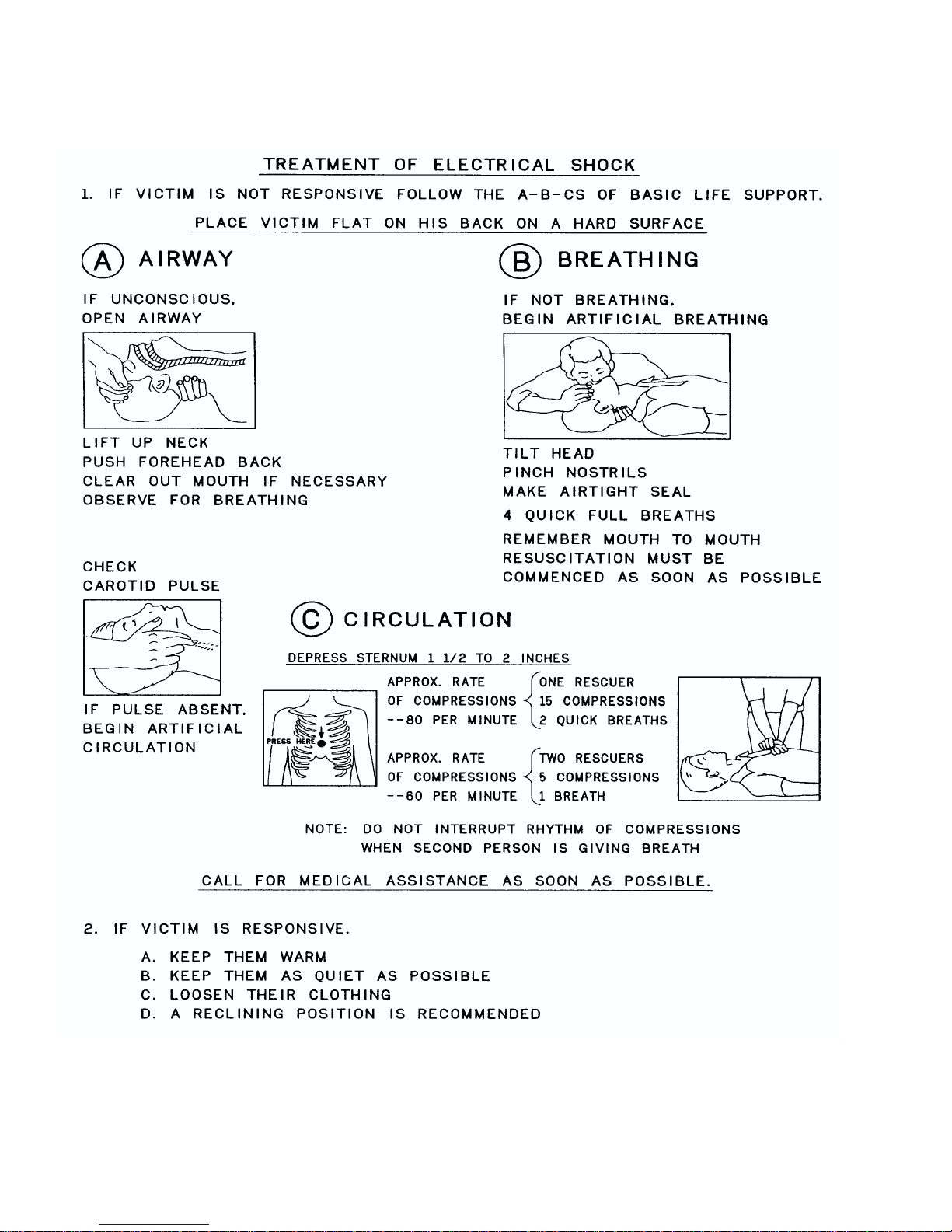

FIRST-AID

Personnel engaged in the installation, operation, maintenance or servicing of this equipment are urged to become familiar

with first-aid theory and practices. The following information is not intended to be complete first-aid procedures, it is a

brief and is only to be used as a reference. It is the duty of all personnel using the equipment to be prepared to give

adequate Emergency First Aid and thereby prevent avoidable loss of life.

Treatment of Electrical Burns

1. Extensive burned and broken skin

a. Cover area with clean sheet or cloth. (Cleanest available cloth article.)

b. Do not break blisters, remove tissue, remove adhered particles of clothing, or apply any salve or ointment.

c. Treat victim for shock as required.

d. Arrange transportation to a hospital as quickly as possible.

e. If arms or legs are affected keep them elevated.

NOTE

If medical help will not be available within an hour and the victim is

conscious and not vomiting, give him a weak solution of salt and

soda: 1 level teaspoonful of salt and 1/2 level teaspoonful of baking

soda to each quart of water (neither hot or cold). Allow victim to sip

slowly about 4 ounces (a half of glass) over a period of 15 minutes.

Discontinue fluid if vomiting occurs. (Do not give alcohol.)

REFERENCE:

2. Less severe burns - (1st & 2nd degree)

a. Apply cool (not ice cold) compresses using the cleanest available cloth article.

b. Do not break blisters, remove tissue, remove adhered particles of clothing, or apply salve or ointment.

c. Apply clean dry dressing if necessary.

d. Treat victim for shock as required.

e. Arrange transportation to a hospital as quickly as possible.

f. If arms or legs are affected keep them elevated.

ILLINOIS HEART ASSOCIATION

AMERICAN RED CROSS STANDARD FIRST AID AND PERSONAL SAFETY MANUAL (SECOND EDITION)

Rev. X 888-2314-001 vii

WARNING: Disconnect primary power prior to servicing.

Page 10

TABLE OF CONTENTS

SECTION I

GENERAL INFORMATION

Introduction......................................1-1

ScopeAndPurpose..............................1-1

Specifications....................................1-1

SECTION II

INSTALLATION/OPERATION

Introduction......................................2-1

Unpacking.......................................2-1

ReturnsandExchanges.............................2-1

GeneralInstallationInformation .....................2-1

Power Distribution for Optimum Transmitter Perform-

ance .........................................2-1

OverheatingfromLineUnbalance..............2-1

TransmitterNoisePerformance ................2-1

TheCausesofLineUnbalance.................2-1

ThreePhaseDeltaDistributionTransformers..... 2-2

ThreePhaseWyeDistributionTransformers...... 2-2

General Installation

Requirements ...................................2-2

EquipmentPlacement............................2-2

Pre-InstallationInspection ........................2-2

EquipmentPositioning...........................2-3

Ground Strap Installation ......................... 2-3

ElectricalInstallation ..............................2-3

PowerRequirements.............................2-3

Procedure. .................................2-3

RFOutputConnection........................... 2-4

BatteryInstallation.............................. 2-4

Audio Input .................................... 2-4

RemoteControl.................................2-4

AirflowSensorStatus............................ 2-5

FailsafeConnection..............................2-5

Modulation Monitor Sample ......................2-5

InitialTurnOnProcedure...........................2-5

InitialTurnOn .................................2-5

Modulation Monitor Carrier Level.................. 2-6

ApplicationofAudio ............................2-7

RemoteMeterCalibration ........................2-7

SECTION III

MAINTENANCE

Introduction......................................3-1

StationRecords...................................3-1

Maintenance Logbook ........................... 3-1

PreventiveMaintenance............................3-1

Maintenance Of Components ...................... 3-1

AirSystem.....................................3-2

GATES Series™ Top Removal

Procedure ....................................3-2

LowVoltageSupplyAdjustment...................3-2

High Voltage Supply Adjustment ..................3-4

RFDriveMeasurement........................... 3-4

IPATuning.................................... 3-5

PAVoltageElectricalZero ....................... 3-5

PAVoltMeterCalibration........................3-5

PACurrentCalibration........................... 3-5

Power Supply Current Calibration .................. 3-5

viii 888-2314-001 Rev. X

WARNING: Disconnect primary power prior to servicing.

PowerOutputCalibration........................ 3-5

OverloadAdjustmentProcedures.................. 3-6

Power Supply Current Overload ............... 3-6

UnderdriveFault............................ 3-6

VSWRDetector............................ 3-6

Replacing Boards and

ReplacingBoardComponents ..................... 3-6

SECTION IV

TROUBLESHOOTING

Introduction ..................................... 4-1

Definition of

FrontPanelIndicators ............................ 4-1

Symptom: Transmitter Will Not Turn On - None of

the Green LED’s on the Power Level Switches are Il-

luminated....................................... 4-1

PossibleCauses................................ 4-1

LossofACPower .......................... 4-1

ControlSupplyFailure....................... 4-1

Symptom: Green Power Level Status LED’s Illumi-

nate, but the Primary Contactors Do Not Energize and

NoOverloadLED’sIlluminate..................... 4-1

PossibleCauses................................ 4-1

Phase Monitor (3∅ FIVEonly)................ 4-1

Blownfuse................................ 4-1

OpenInterlock............................. 4-1

FailsafeInterlockOpen ...................... 4-1

InterfaceboardOutput....................... 4-1

OpenContactorCircuit ...................... 4-1

ContactorControlSignal..................... 4-1

Symptom: One or Both Primary Contactors Energize,

ButThereIsNoPowerOutput ..................... 4-1

HighVoltageSupplyFailure...................... 4-1

Symptom: High Voltage Is Present, But There Is No

PowerOutput ................................... 4-2

PDMKillCondition ............................ 4-2

PDMLevel.................................... 4-2

PossibleCausesForOverloads...................... 4-2

Supply Voltage Overload ........................ 4-2

Supply Voltage Too High .................... 4-2

Power Supply Current Overloads- At Turn On ....... 4-2

Supply Short ............................... 4-2

Power Supply Current Overloads, Continuous Cycling

andAutomaticCutback......................... 4-2

PDMSystemProblem....................... 4-2

PDMGeneratorOutputsHigh................. 4-2

PDMAmplifierShorts....................... 4-2

Supply Current Calibration ................... 4-2

Random Supply Current Overloads With Modulation. . 4-2

Sub-audibleSignals......................... 4-2

UnderdriveFault ............................... 4-2

Low/NoDrive.............................. 4-2

IPAandPATransistors...................... 4-2

VSWR Overload- Continuous VSWR Cycling ....... 4-2

BadLoadImpedance........................ 4-2

AntennaProblem........................... 4-3

OutputNetwork............................ 4-3

Page 11

VSWR Trips With High Levels Of Modulation and

HighPower................................... 4-3

ImproperTuningandLoading................. 4-3

Antenna .................................. 4-3

OutputNetwork............................ 4-3

Symptom:RemoteControlFunctionsDoNotWork .... 4-3

PossibleCauses................................ 4-3

Remote/LocalSwitch........................ 4-3

RemoteControlImproperlyWired............. 4-3

RemoteControlUnitNotFunctioning.......... 4-3

RibbonConnectorsLoose.................... 4-3

CausesforaPAVolts/PAAmpsRatioChange ........ 4-3

No+20VoltstoPDMAmplifier.................. 4-3

ImpedanceChange ............................. 4-3

PAFailure.................................... 4-3

Troubleshooting AM Noise......................... 4-4

50/60Hz...................................... 4-4

AudioLinesareNormallyBalanced ............... 4-4

100/120Hz.................................... 4-4

300/360Hz.................................... 4-4

60kHz....................................... 4-4

RFINoiseonAudio ............................ 4-4

SECTION V

TRANSMITTER OVERALL

Introduction..................................... 5-1

Personnel Protection .............................. 5-1

PrinciplesOfOperation............................ 5-1

FET’SintheGATESSeries™.................... 5-1

PDMTheoryInBrief ........................... 5-1

PolyphaseTheory .............................. 5-1

Audio/PDMSignalFlow......................... 5-1

PDMLoop.................................... 5-3

RFPowerFlow................................ 5-3

Failsafe....................................... 5-3

ACPowerFlow................................ 5-3

High Voltage Power Supply ...................... 5-3

Introduction ............................... 5-3

Description................................ 5-3

Low Voltage Power Supply and IPA Power Supply. . . 5-6

Introduction ............................... 5-6

Description................................ 5-6

AirflowSensor................................. 5-6

Introduction ............................... 5-6

Description................................ 5-6

Section VI

Parts List

Introduction..................................... 6-1

SECTION A

OSCILLATOR (A16)

PrinciplesOfOperation............................ A-1

Replacement/Alignment ........................... A-1

FrequencyAdjustment........................... A-1

Troubleshooting the

RFOscillator ................................... A-1

Symptom:NoOutput ........................... A-1

OpenFuse/Lossof+20V..................... A-1

RFKILL.................................. A-1

Q1,Q2,CR1................................ A-1

U1,CR4...................................A-1

U2.......................................A-1

U3.......................................A-1

SECTION B

IPA (A5)

PrinciplesofOperation.............................B-1

IPATuningNetwork............................B-1

Replacement/Alignment............................B-1

IPA Tuning and Testing

Procedure......................................B-1

IPATuning................................B-1

OhmmeterTestingtheIPA .......................B-1

HandlingMOSFET’s..............................B-1

TestingMOSFET’s ...............................B-2

SECTION C

POWER AMPLIFIER A1 through A4

PrinciplesofOperation.............................C-1

PAToroids......................................C-1

Replacing a PA Module............................C-1

TroubleshootingthePABoards......................C-1

OhmmeterTesting..............................C-1

HandlingMOSFET’s..............................C-2

TestingMOSFET’s ...............................C-2

ReplacingPATransistors.........................C-2

ScopingtheRFDrive..............................C-2

RFDrivePhasingMeasurement .....................C-2

SECTION D

OUTPUT NETWORK

PrinciplesofOperation.............................D-1

AdjustmentProcedures.............................D-1

TuningAndLoadingControls.....................D-1

OutputNetworkColdTuning .....................D-1

ThirdHarmonicTrapL7-C4 ..................D-1

Bandpass Filter L2-C2 .......................D-1

TEENetwork-LoadandTune................D-1

L2SlidingTap .............................D-1

L1Tap....................................D-2

SECTION E

OUTPUT MONITOR (A18)

PrinciplesofOperation.............................E-1

Replacement/Alignment............................E-1

Troubleshooting..................................E-1

Symptom: Detector Null Reading Is High and Cannot

BeAdjustedToZero............................E-1

BadLoadImpedance ........................E-1

SampleSignalMissing.......................E-1

SECTION F

PDM GENERATOR (A15)

PrinciplesOfOperation............................ F-1

Replacement/Alignment............................F-1

TroubleshootingPDMGenerator..................... F-1

Symptom: No Pulses At J4, Causing Zero Power Out-

putfromtheTransmitter......................... F-1

PowerSetting ..............................F-1

LossofPlusandMinus15Volts............... F-1

PDMInterrupt.............................. F-1

DC/AudioFailure........................... F-1

Rev. X 888-2314-001 ix

WARNING: Disconnect primary power prior to servicing.

Page 12

Symptom:ImbalanceInOutputPulseWidths ........F-2

AudioImbalance............................F-2

TriangleWaveImbalance.....................F-2

Symptom: Output(s) At J2 Always In A High State,

Causing One or More Pdm Amplifiers to Conduct

FullTime.....................................F-2

Symptom:OnlyOneOutputHigh..................F-3

Symptom:TwoOutputsAreHigh..................F-3

Symptom:AllFourOutputsAreHigh ..............F-3

SECTION G

PDM AMPLIFIER/PULL-UP (A6-A9)

PrinciplesofOperation............................ G-1

PDMAmplifier................................ G-1

PDMPull-UpBoard............................ G-1

Maintenance .................................... G-1

PDMAmplifiers............................... G-1

GateDriveChecks............................. G-1

In-Circuit Ohmmetering the PDM Amp Module (A6

thruA9)MOSFET’s........................... G-2

CheckingGateDrive........................ G-4

HandlingMOSFET’s............................. G-4

TestingMOSFET’s............................... G-4

SECTION H

PDM FILTER (A10 and A11)

PrinciplesofOperation............................ H-1

SECTION J

CONTROLLER BOARD (A12)

PrinciplesofOperation............................. J-1

CoarsePowerLevelControl ...................... J-1

ContactorControl............................... J-1

FinePowerControl.............................. J-1

Metering ...................................... J-1

OverloadCircuitry .............................. J-1

OtherFaultDetection............................ J-2

ControllerSupplyVoltages........................J-2

Replacement/AlignmentProcedures...................J-2

PAVoltageElectricalZero........................J-2

PAVoltMeterCalibration ........................J-2

Power Supply Current Calibration ..................J-2

PowerOutputCalibration.........................J-3

OverloadAdjustmentProcedures.....................J-3

Power Supply Current Overload ....................J-3

UnderdriveFault ................................J-3

VSWRDetector.................................J-3

Troubleshooting the Controller .......................J-3

Symptom: Will Not Respond To An On Command ....J-3

Controller Supply Failure ......................J-3

Failedflipflopcircuitry.......................J-3

Symptom: PDM Power Level Signal Cannot Be Con-

trolled ........................................J-3

Symptom:MultimeterIsPinnedFarLeftorRight .....J-3

Symptom: Some Remote Control Functions Do Not

Work.........................................J-3

SECTION K

INTERFACE BOARD (A24)

PrinciplesofOperation............................ K-1

Replacement/Alignment............................ K-1

Troubleshooting .................................. K-1

Symptom: Green Power Level Status LED’s Light On

Controller,ButTheContactorsDoNotEnergize.....K-1

OpenInterlock............................. K-1

24VACMissing............................ K-1

ONCommandMissing ...................... K-1

BadTriacorOpticalIsolator..................K-1

APPENDIX L

TEST EQUIPMENT

Introduction ..................................... L-1

x 888-2314-001 Rev. X

WARNING: Disconnect primary power prior to servicing.

Page 13

SECTION I

GENERAL INFORMATION

1.1. Introduction

1.1.1. Scope And Purpose

This technical manual contains the information necessary to install and maintainthe

GATES Series™ AM Transmitters. The

various sections of this technical manual

provide the following types of information.

Section I, General Information, provides introduction to technical manual contents.

Section II, Installation/operation, provides detailed installation and operation procedures.

Section III, Maintenance, provides

preventive and corrective maintenance as well as tuning procedures

(alignment procedures).

Section IV, Troubleshooting, provides a listing of the protection devices in the transmitter as well as

troubleshooting procedures.

Section V, Transmitter Overall, provides theory of operation of the various sections of the transmitter not

covered in later sections.

Section VI, Parts List, provides parts

list for the transmitter.

The following sections provideprinciples

of operation, maintenance information,

troubleshooting,and parts lists forboardsin

GATES Series™ transmitter:

Section A, Oscillator

Section B, IPA

Section C, Power Amplifier

Section D, Output Network

Section E, Output Monitor

Section F, PDM Generator

Section G, PDM Amplifier/Pull-Up

Section H, PDM Filter

Section J, Controller

Section K, Interface Board

Appendix L, Test Equipment, provides a list of the test equipment provided and recommended to perform

maintenance on the transmitter.

1.2. Specifications

Table 1-1, 1-2, and 1-3 list the specifica-

tions of the GATES Series™ transmitters.

NOTE

Specifications subject to change without

notice.

Rev. T: Jan. 1996 888-2314-001 1-1

WARNING: Disconnect primary power prior to servicing.

Page 14

Table 1-1. GATES ONE Specifications

POWER OUTPUT: 1000 watts (Rated). Six power levels adjustable between 100-1100 watts. Capable

of lower power PSA/PSSA operation.

RF FREQUENCY RANGE: 531 kHz through 1705 kHz. Supplied to one frequency as ordered.

CARRIER FREQUENCY STABILITY: Crystal control oscillator meets FCC specifications. +/-4 Hz in typical operating

environment.

RF OUTPUT IMPEDANCE: 50 ohms unbalanced.

RF OUTPUT TUNING: Integral network will match a VSWR of 1.5:1 to 1.0:1 at carrier.

RF OUTPUT TERMINAL: Type N female connector.

CARRIER SHIFT: Less than 1% at 100% modulation at 1000 Hz.

RF HARMONICS AND SPURIOUS EMISSIONS: Exceeds FCC and CCIR specifications.

OTHER EMISSIONS: Meets FCC NRSC 2 when presented with audio signal conforming to NRSC 1

standard.

TYPE OF MODULATOR: Patented Polyphase PDM.

AUDIO FREQUENCY RESPONSE: +/-0.5 dB, from 20 to 10,000 Hz (with Bessel filter out).

AUDIO HARMONIC DISTORTION: Less than 1.0% at 1 kW, 20 to 10,000 Hz @ 95% modulation.

AUDIO INTERMODULATION DISTORTION: Less than 1.0%, 60/7000 Hz 1:1. Less than 1.5%, 60/7000 Hz 4:1, SMPTE

standards at 1 kW operation at 95% modulation.

SQUAREWAVE OVERSHOOT: Less than 3.5% at 400 Hz.

SQUAREWAVE TILT: Less than 3% at 20 Hz, 90% modulation.

Less than 1.5% at 40 Hz, 90% modulation.

NOISE (UNWEIGHTED) Better t han 60 dB below 100% modulation, 1000 Hz at 1kW.

POSITIVE PEAK CAPABILITY: Greater than 130% positive peak program modulation capability at 1100 watts.

INCIDENTAL QUADRATURE MODULATION

30 dB typical below 95% modulation of L+R channel at 1 kHz.

(IQM):

AUDIO INPUT: Continuously adjustable from -10 to +10 dBm, transformer-less active 600 ohms

input.

ACVOLTAGE INPUT: 197-251 VAC, 50/60 Hz, single phase.

OVERALL EFFICIENCY: Better than 65% at 1000W.

POWER CONSUMPTION: At 1000 watts carrier, 1538 watts or less at 0% modulation, 2307 watts or less at

100% sine wave modulation, 1923 watts during typical programming.

MONITOR PROVISIONS: Adjustable to 5 volts nominal RMS modulated output sample at 50 ohms for six

power levels from 100 watts to 1100 watts.

REMOTE CONTROL/MONITORING: Self-contained interface for most remote control systems TTL compatible.

AMBIENT TEMPERATURERANGE: -10°Cto+50°C AMSL (derate upper limit 2°C per 1000 feet altitude).

AMBIENT HUMIDITY RANGE: To 95%, non condensing.

AIR FLOW: 500 CFM

HEAT GENERATED: 2756 BTU per hour at 1 KW 100% tone modulation.

ALTITUDE: Up to 13,000 feet (4000 meters).

SIZE: 72"H X 28"W X 30"D (1830mm X 712 mm X 762 mm).

WEIGHT: (Unpacked) 400 lbs. (181 kg) - approximate. Domestic packed, 600 lbs. (275 kg)

- approximate. Export packed, 700 lbs. (320 kg) - approximate.

CUBAGE: 68.7 cubic feet (2 cubic meters) packed.

NOTE: ALL SPECIFICATIONS TAKEN WITH TRANSMITTER CONNECTED TO TEST LOAD. SPECIFICATIONS SUBJECT

TO CHANGE WITHOUT NOTICE.

1-2 888-2314-001 Rev. T: Jan. 1996

WARNING: Disconnect primary power prior to servicing.

Page 15

Table 1-2. GATES TWO Specifications

POWER OUTPUT: 2500 watts (Rated). Six power levels adjustable between 250-2750 watts. Capable of

lower power PSA/PSSA operation.

RF FREQUENCY RANGE: 531 kHz through 1705 kHz. Supplied to one frequency as ordered.

CARRIER FREQUENCY STABILITY: Crystal control oscillator meets FCC specifications. +/-4 Hz in typical operating

environment.

RF OUTPUT IMPEDANCE: 50 ohms unbalanced.

RF OUTPUT TUNING: Integral network will match a VSWR of 1.5:1 to 1.0:1 at carrier.

RF OUTPUT TERMINAL: 7/8" EIA male/female flange connector.

CARRIER SHIFT: Less than 1% at 100% modulation at 1000 Hz.

RF HARMONICS AND SPURIOUS EMIS-

Exceeds FCC and CCIR specifications.

SIONS:

OTHER EMISSIONS: MeetsFCCNRSC2whenpresentedwithaudiosignalconformingtoNRSC1standard.

TYPE OF MODULATOR: Patented Polyphase PDM.

AUDIO FREQUENCY RESPONSE: +/-0.5 dB, from 20 to 10,000 Hz (with Bessel filter out).

AUDIO HARMONIC DISTORTION: Less than 1.0% at 2500 watts, 20 to 10,000 Hz @ 95% modulation.

AUDIO INTERMODULATION DISTORTION: Less than 1.0%, 60/7000 Hz 1:1. Less than 1.5%, 60/7000 Hz 4:1, SMPTE standards

at 2500 watts operation at 95% modulation.

SQUAREWAVE OVERSHOOT: Less than 3.5% at 400 Hz.

SQUAREWAVE TILT: Less than 3% at 20 Hz, 90% modulation.

Less than 1.5% at 40 Hz, 90% modulation.

NOISE (UNWEIGHTED): Better than 60 dB below 100% modulation, 1000 Hz at 2500 watts.

POSITIVE PEAK CAPABILITY: Greater than 130% positive peak program modulation capability at 2750 watts.

INCIDENTAL QUADRATURE MODULA-

30 dB typical below 95% modulation of L+R channel at 1 kHz.

TION (IQM):

AUDIOINPUT: Continuouslyadjustablefrom-10to+10dBm,transformer-lessactive600ohmsinput.

AC VOLTAGE INPUT: 197-251 VAC, 50/60 Hz, single phase.

OVERALL EFFICIENCY: Better than 65% at 2500W.

POWER CONSUMPTION: At 2500 watts carrier,3846 watts or less at 0%modulation, 5769 watts or less at 100%

sine wave modulation, 4807 watts during typical programming.

MONITOR PROVISIONS: Adjustable to5 volts nominal RMSmodulated output sample at50 ohms for sixpower

levels from 250 watts to 2750 watts.

REMOTE CONTROL/MONITORING: Self-contained interface for most remote control systems TTL compatible.

AMBIENT TEMPERATURERANGE: -10°Cto+50°C AMSL (derate upper limit 2°C per 1000 feet altitude).

AMBIENT HUMIDITY RANGE: To 95%, non condensing.

AIR FLOW: 500 CFM

HEAT GENERATED: 6895 BTU per hour at 2500 watts, 100% tone modulation.

ALTITUDE: Up to 13,000 feet (4000 meters).

SIZE: 72"H X 28"W X 30"D (1830 mm X 712 mm X 762 mm).

WEIGHT: (Unpacked) 450 lbs. (204 kg) - approximate. Domestic packed, 650 lbs. (298 kg) -

approximate. Export packed, 750 lbs. (343 kg) - approximate.

CUBAGE: 68.7 cubic feet (2 cubic meters) packed.

NOTE: ALL SPECIFICATIONS TAKEN WITH TRANSMITTER CONNECTED TO TEST LOAD. S PECIFICATIONS SUBJECT

TO CHANGE WITHOUT NOTICE.

Rev. T: Jan. 1996 888-2314-001 1-3

WARNING: Disconnect primary power prior to servicing.

Page 16

Table 1-3. GATES FIVE Specifications

POWER OUTPUT: 5000 watts (Rated). Six power levels adjustable between 500-5600 watts. Capable of

lower power PSA/PSSA operation.

RF FREQUENCY RANGE: 531 kHz through 1705 kHz. Supplied to one frequency as ordered.

CARRIER FREQUENCY STABILITY: Crystal control oscillator meets FCC specifications. +/-4 Hz in typical operating

environment.

RF OUTPUT IMPEDANCE: 50 ohms unbalanced.

RF OUTPUT TUNING: Integral network will match a VSWR of 1.5:1 to 1.0:1 at carrier.

RF OUTPUT TERMINAL: 7/8" EIA male/female flange connector.

CARRIER SHIFT: Less than 1% at 100% modulation at 1000 Hz.

RF HAR MONICS AND SPURIOUS EMIS-

Exceeds FCC and CCIR specifications.

SIONS:

OTHER EMISSIONS: Meets FCC NRSC 2 when presented with audio signal c onforming to NRSC 1

standard.

TYPE OF MODULATOR: Patented Polyphase PDM.

AUDIO FREQUENCY RESPONSE: +/-0.5 dB, from 20 to 10,000 Hz (with Bessel filter out).

AUDIOHARMONIC DISTORTION: Less than 0.8% at 5000 watts, typically less than 1.5% at 1 kW, 20 to 10,000 Hz @

95% modulation.

AUDIO INTERMODULATION DISTORTION: Less than 1.0%, 60/7000 Hz 1:1. Less than 1.5%, 60/7000 Hz 4:1, SMPTE standards

at 5000 watts operation at 95% modulation.

SQUAREWAVE OVERSHOOT: Less than 3.5% at 400 Hz.

SQUAREWAVE TILT: Less than 3% at 20 Hz, 90% modulation.

Less than 1.5% at 40 Hz, 90% modulation.

NOISE (UNWEIGHTED): Better than 60 dB below 100% modulation, 1000 Hz at 2500 watts to 5000 watts.

POSITIVE PEAK CAPABILITY: Greater than 130% positive peak program modulation capability at 5600 watts.

INCIDENTAL QUADRATURE MODULA-

30 dB typical below 95% modulation of L+R channel at 1 kHz.

TION (IQM):

AUDIO INPUT: Continuouslyadjustable from -10 to+10dBm,transformer-lessactive600 ohms input.

ACVOLTAGE INPUT: 197-251 VAC, 50/60 Hz, three phase or international 341 to 434 VAC. Compatible

with WYE or closed delta power sources. AC voltage variation: +5, -10% for full

performance. Single phase version accepts 197 to 251 VAC 50/60 Hz.

OVERALL EFFICIENCY: Better than 65% at 5000W.

POWER CONSUMPTION: At 5000 watts carrier, 7692 watts or less at 0% modulation, 11538 watts or less at

100% sine wave modulation, 9615 watts during typical programming.

MONITOR PROVISIONS: Adjustableto 5 volts nominal RMS modulated output sample at50ohms for six power

levels from 500 watts to 5600 watts.

REMOTE CONTROL/MONITORING: Self-contained interface for most remote control systems TTL compatible.

AMBIENT TEMPERATURERANGE: -10°Cto+50°C AMSL (derate upper limit 2°C per 1000 feet altitude).

AMBIENT HUMIDITY RANGE: To 95%, non condensing.

AIR FLOW: 500 CFM, (14.16 CMM).

HEAT GENERATED: 13790 BTU per hour at 5000 watts, 100% tone modulation.

ALTITUDE: Up to 13,000 feet (4000 meters).

SIZE: 72"H X 28"W X 30"D (1830 mm X 712 mm X 762 mm).

WEIGHT: (Unpacked) 500 lbs. (230 kg) - approximate. Domestic packed, 700 lbs. (320 kg) -

approximate. Export packed, 800 lbs. (370 kg) - approximate.

CUBAGE: 68.7 cubic feet (2 cubic meters) packed.

NOTE: ALL SPECIFICATIONS TAKEN WITH TRANSMITTER CONNECTED TO TEST LOAD. SPECIFICATIONS SUBJECT

TO CHANGE WITHOUT NOTICE.

1-4 888-2314-001 Rev. T: Jan. 1996

WARNING: Disconnect primary power prior to servicing.

Page 17

SECTION II

INSTALLATION/OPERATION

2.1. Introduction

This section of the technical manual provides detailed installation procedures and

setup instructions for the GATES Series™

AM transmitters.

Under normal conditions, the GATES Series™ T ransmitters are shipped completely

assembled and ready for installation. However ,if adverseshipping conditions are anticipated, certain components may be removed

for transport in which case these components

will be properly identified with appropriate

instructions for reinstalling the components

and making wiring connections.

2.2. Unpacking

Carefully unpack the transmitter and perform a visual inspection to determine that no

apparent damage was incurred during shipment.Retain theshippingmaterialsuntil ithas

been determined that the unit isnot damaged.

The contents of the shipment should be as

indicatedonthePackingCheckListwhich

accompanies each shipment. If the contents

are incomplete or if the unit is damaged electricallyormechanically ,notifytheCARRIER

and HARRIS CORPORATION.

2.3. Returns and Exchanges

Damaged or undamaged equipment should

not be returned unless written approval and a

ReturnAuthorizationisreceivedfrom HARRIS

CORPORATION, Broadcast TransmissionDivision.Special shipping instructions and coding

will be provided to assure proper handling.

Complete details re garding circumstances and

reasonsforreturnaretobeincludedinthe

requestforreturn.Customequipmentorspecial

order equipment is not returnable. In those instances where return or exchange of equipment

isat the request of the customer ,or conv enience

ofthe customer,arestockingfeewillbe charged.

Allreturnswill be sent freightprepaidandproperly insured by the customer .When communicating with HARRIS CORPORATION,

Broadcast Transmission Division, specify the

Factory Order Number or InvoiceNumber.

2.4. General Installation Information

The GATES Series™ Transmitters have

been designed for rapid installation. In addition to the 28 inch width by 30 inchdepth

of the equipment, a minimum of 24 inches

should be allowed for maintenance access

from both the front and rear of the cabinet.

Signal and power wires can be connected

through several different entries or any desired c ombination thereof.

The holes for cable entrance are 2 inches

in diameter, and are located at the front and

rear bottom of each side panel. These entriesprovidea means to entertheequipment

with wires that are then routed into the base

of the equipment.

Input powerwiresshouldrun to the terminal board installed in the base of the transmitter. Access to this terminal board is

gainedby removing the coverplate overthe

face of the contactor chassis. The screws

holding the chassis must then be removed

and the chassis pulled forward.

The normal air flow through the transmitter is taken in through the back of the unit

(at the bottom of the cabinet). Maximum

temperature at the base of the transmitter

should not be more than 50°C. The air

moves from the base of the cabinet into the

side panels and into themain enclosure. Air

passes over the heat sink fins in the side

panelsand exits through the holes inthetop

ofthe cabinet. This providesefficientchimney action cooling of all the Power Amplifier and Modulator transistors.

The air that enters the main enclosure

passes directly over the components dissipating heat and exhauststhroughtheoutput

coils and out the top of the transmitter. The

circuit cards and their heat sinks have been

designed to provide a chimney action to the

maximum extent practical.

NOTE

Note that the two blowers have separate

air intakes. One is filtered and the other

is not. The unfiltered side is dedicated to

the PA side wall. No filter is needed be-

cause most of the air passes through the

heat sink fins. A small amount of air is

channeled in the cabinet to flush the PA

Toroids. At approximately one year in-

tervals, the PA heat sink fins should be

inspected and cleaned. They may be re-

moved by removing the 10/32 mounting

screws.

2.4.1. Power Distribution for Optimum

Transmitter Performance

(This section is applicable to the three

phase GATES FIVE only, as well as other

three phase equipment.)

For many years HARRIS engineers have

recommended that the three phase power

distribution system should be either a

closed delta or W YE configuration to provide better radio and television transmitter

performanceby helping preventlineunbalance. Operation with substantial voltage

unbalance from line toline results in higher

than normal signal-to-noise ratio in the

transmitter output signal, increased three

phase transformer heating, and hot three

phase motors.

2.4.1.1. Overheating from Line Unbalance

Evenadeviceassimpleasathreephase

motor should be operated from a power line

in which the voltage is balanced within 1%. It

takes only a 3.5% line unbalance to produce

a 25% increase above normal temperature. A

5%unbalancewillcausedestructivetemperature rises of 50% greater than normal!

Similar characteristics can be expected in

the windings of a three phase power transformer down inside the cabinet of your transmitter. Transformers and motors can be

designedwithextrasafetyfeatureswherethermal rise is limited to acceptable levels; however ,in this case, other transmitter parameters

cannot be made acceptable at a reasonable

cost.

2.4.1.2. Transmitter Noise Performance

The most difficultparameter to meet with

power line unbalance is transmitter noise

performance. Most large transmitters use

six-phase or twelve-phase high voltage

power supplies. The energy storage capacitors are expensiveto install and largestored

energiesmake destructive faults inevitable.

A good design will have sufficient energy

storage capacitors to meet thespecifiedsignal-to-noise but not much more. When the

equipment is then operated from an unbalanced line, the power supply ripple frequency will be twice the line frequency

instead of six to twelve times. It becomes

obvious that it would take three times as

much energy storage to achieve the original

performance goal.

2.4.1.3. The Causes of Line Unbalance

How does a line unbalance occur? It is a

rare case in w hich a large commercial

powerproducer would generateunbalanced

voltage, so we must look elsewhere in the

system. When you have large single phase

power u sers on a power line this can cause

uneven distribution of the line currents in

the system. Uneven currents through balanced impedances will result in line-to-line

voltage unbalance.

Another likely source of this problem can

come from unbalanced impedances in the

power distribution system. Unbalanced impedance will always be seen when an

“open” delta three phase distribution system is used. Transformer design textbooks

Rev. AC: 2/29/00 888-2314-001 2-1

WARNING: Disconnect primary power prior to servicing.

Page 18

clearly show that the voltage regulation of

an unbalanced system is poor.

2.4.1.4. Three Phase Delta Distribution

Transformers

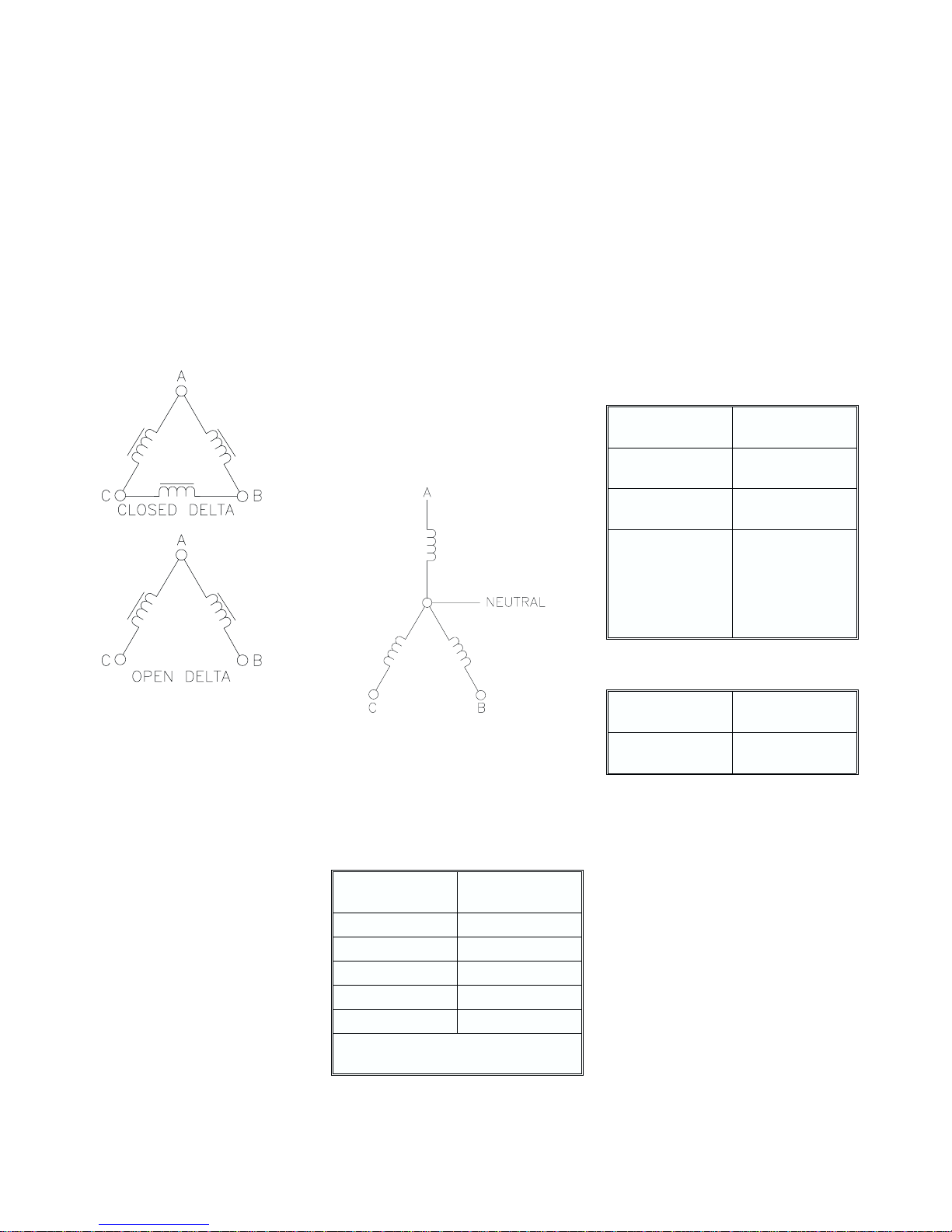

Figure 2-1 shows open and closed delta

systems. The closed delta impedance looking into each terminal (A, B & C) is exactly

thesame;butthisisnotthecaseintheopen

delta configuration. Depending on the impedances of the transformers in the open

delta circuit, line voltage unbalance sufficient to impair satisfactory operation of the

overall transmitter may result. For this reason, along with their inherent susceptibility

to transients, Harris does not recommend

the use of open delta systems.

over voltage spikes. These units are limited

in the amount of energy that can be dissipated, but will handle, if designed properly,

very large currents. You can’t take a direct

lightning hit and still operate, but not many

things will. It has been reported by engineers that installation of a thirdtransformer

and trans ient protection devices, have

eliminated the difficulty.

2.4.1.5. Three Phase Wye Distribution

Transformers

The WYE connected system is also considered a symmetrical form of three phase

power distribution. All impedances are balanced as seen from each terminal (see Figure 2-2). It is important when using a WYE

connected system that the fourth wire (neutral) is connected to the mid-point of the

system as shown in the diagram. When this

connectionismadeit providesa path for the

zerosequencecurrentsaswellasanyharmonic currents which are generated due to

the rectificationof the secondary voltages.

In summary, both symmetrical power distribution systems are satisfactory because

of their balanced impedances. Use either a

closed delta or a four wire WYE system for

maximum transmitter performance. Never

use an open delta system just to cut costs it could cost dearly in the long run.

2.5. General Installation

Requirements

The key to a rapid and successful setup is

careful planning prior to delivery of the

system. HARRIS offers, as an option, engineering services to reviewand comment on

proposedinstallations. InadditionHARRIS

offers,as anoption,design,fabrication,and

installation services to any required level

for total integration of the system into a

facility.

Lifting Equipment

(Fork Lift, etc)

Hand Tools For opening wooden

Shims (2" by 2") Aluminum,assorted

Hand Operated

Hole Punch

900 lbs (408 kg)

capacity

crates

thicknesses

For adding 0.25"

hardware holes to

0.020" thick copper

ground strap at

transmitter ground

connection.

Figure 2-1. Three Phase Delta

Distribution Transformers

The only advantage of the open delta is

lower initial cost, and this is partiallyoffset

by the fact that when only two transformers

are used, they must be larger than the three

transformers in a closed delta system.

Difficulties have often been experienced

with open delta systems; but when a third

transformerwasaddedtoclose thedelta,the

problems disappeared.

Thereisanother problem which can occur

with an open delta system, and that i s

caused by lightning and switching transients. When lightning strikes or heavy

loads are switched on a power distribution

system, high voltage transients are propagated throughout the system. Unbalanced

impedances will enhance these transients

and can cause transmitter damage, particularly to solid state rectifiers.

Many transmitters are located at the end

of a long transmission line which is highly

susceptible to transient phenomena. Devices such as Metal Oxide Varistors are

inexpensive and very effective in reducing

Figure 2-2. Three Phase WYE

Distribution Transformers

Today, many transformers are supplied

with all of the primary terminals available

sothateitheradeltaor WYEconnectioncan

be made. Table2-1 shows the different lineto-line voltages that are available with this

configuration.

Delta connected

transformer

WYE connected

transformer

210 364

220* 380*

230 400

240* 415*

250 433

* Typical voltages in some areas of the

world.

Table 2-1. Typical Line Voltages

Delta or WYE

Table 2-2. Special Installation

Tools and Equipment

Tra ns forme r, Low

472 1678 000 (1)

Level,A20T01

Transformer,

Power,A19T01

Table 2-3. Equipment Supplied with

Transmitter and Listed on Packing

Check List Supplied with Transmitter

2.5.1. Equipment Placement

See packing list for

part number

The transmitter should be located to permit adequate maintenance access and sufficient ventilation. Primary AC power cables

can enter the transmitter at a variety of

locations and the specific location of entry

will need to be determined on site. The

grounding strap between the transmitter

and the station earth ground must be properly connected before AC power wiring is

attached to transmitter.

2.5.2. Pre-Installation Inspection

Prior to performing the installation of the

GATES Series™ transmitter, it should be

thoroughly inspected for any connections

which may have loosenedduring shipment.

2-2 888-2314-001 Rev. AC: 2/29/00

WARNING: Disconnect primary power prior to servicing.

Page 19

This is important due to numerous high

current connections in the transmitter.

Also check that all ribbon cablesare properly locked into their respective printed circuit board connectors.

The mechanical interconnecting integrity

of the above mentioneditems is essential to

the attaining of proper transmitter operation. Although appropriate packaging and

shipping precautions are taken prior to the

equipment leaving the factory, hardware

may, in isolated cases, work loose in transit

and result in a failure.

Check for debris or loose hardware, especiallyaroundthe high current power supply

connections.

2.5.3. Equipment Positioning

Following removal of the shipping material, move the cabinet on its skid as near as

possible to its permanent position. If shipping bolts have been used, they will be

locatedateachcorneroftheskid.Remove

the bolts from the underside of the skid.

NOTE

Positioning of the cabinet is to be per-

formed by experienced personnel to pre-

vent damage to the equipment or injury

to personnel.

With a suitable lifting device, raise one

end of the transmitter cabinet sufficientlyto

permit the placing of three lengthsof circular bar stock under the cabinet. In this manner the cabinet can be efficiently and

carefully rolled off the skid.

2.5.4. Ground Strap Installation

The importance of a good groundingsystem and lightning protection can hardly be

overemphasized for reasons of personnel

safety, p rotection of the equipment, and

equipment performance. The following is

only a brief overview.

Lightning and transient energy via the

powerline or towerconnectionscanimpose

serious threats to your personal safety as

well as damage the equipment. For these

reasons you should have a good protective

earthing system to divert these forms of

energyto earth ground.Propergrounding of

theequipmentalso guards against electrical

shock hazards that would exist if the equipment failed in a way which put a hazardous

voltage on the chassis.

A good grounding system should include

substantial grounding at the tower base usingcopper ground rods and/or a buriedcopper ground screen, with copper strap used

to connect the tower base to earth ground.

A low impedance will help carry lightning

current directly into the ground instead of

into your building. Additionally, coax

shield(s)should be electricallyconnectedto

and exit the tower as near to the bottom as

practical to minimize the lightning voltage

potential carried by the coax into your

building.

For coaxes, a singlepoint of entry into the

building is best, with all connected to a

common grounding plate (or bulkhead

panel) having a low impedance connection

tothebuildingperimeter ground.Widecopper straps should be used for making the

connection from the common grounding

plate to earth ground.

Acommongroundingplate is alsothebest

locationfor coaxialsurgeprotectorsforsensitive equipment such as an STL receiver.

Ideally, this plate should also be the entry

point for all signal lines, and serve as a

single point ground for AC power surge

protection.

A good ground system should include perimeter grounding of the transmitter building using copper ground rods and copper

strap. There should also be a copper strap

running from tower ground to the building

perimeter ground.

Good grounding and shielding will help

keep stray RF current to a minimum. RF

interference usually shows up in one of

several ways, intermittent problems with

digital or remote control circuits, audio

feedback or high pitched noise. Even a

smallamountofnon-shieldedwiremakesa

very efficient antenna for RF and transient

energy. If RF is allowed into the audio

equipment,itcanberectifiedand may show

up as noise or feedback. Wire and cable

shields should normally be connected at

both ends to the equipment chassis.

Agroundstrapattachment point islocated

on the bottom, right rear, of the cabinet

behind the dust cover (uses a 10-32 brass

screw with brass washer). Use this connectionwhenutilizingasinglepointgrounding

system, attaching your ground strap to the

common grounding plate. See 839-7920044 Gates series Outline drawing.

A groundingstud is also providednearthe

AC input connections in the lower portion

of the transmitter. Use this connection for

the power line ground. It is located under

the low voltage power supply board.

2.6. Electrical Installation

NOTE

All GATES Series™ transmitters are

shipped with A19T1 and A20T1 con-

nected for 251 VAC operation. It is ad-

vised that the end user determine the ap-

propriate tap settings during the initial

turn-on. In this procedure, the trans-

former tapping is determined by the re-

sulting DC supply voltage. This ensures

that the DC supplies are operated in the

desired range.

2.6.1. Power Requirements

The GATES Series™ GATES FIVE (3

phase version) is designed to operate from

a3phase,208/240 VAC,50to60 Hz source.

Sixty ampere service is required. Use 6

gauge wire for this connection.

The single phase GATESFIVE requires a

100 amp 208/240 VAC, 50 to 60 Hz source.

Use 4 gauge wire for this connection.

The GATES TWO requires a 60 amp

208/240 VAC, 50 to 60 Hz source. Use 6

gauge wire for this connection.

The GATES ONE requires a 30 amp

208/240 VAC, 50 to 60 Hz source. Use 8

gauge wire for this connection.

There is no requirement for 120 VAC in

any case.

As an option, the low voltage circuits can

be powered from a separate circuit breaker.

Although not a requirement, thissetup sometimes is advantageous for maintenance and

troubleshooting. If you choose to wire your

transmitter this way,you will need to provide

a separate 10 amp circuit breaker.

NOTE

If service voltage is less than 208 VAC,

a higher current service may be needed.

Refer to the Outline drawing for mechanical dimensions and wire feed locations.

WARNING

ENSURE THAT ALL AC POWER IS OFF

PRIOR TO STARTING THE FOLLOWING

INSTALLATION

2.6.1.1. Procedure.

For a three phase GATES FIVE, connect 3

phaseACinput powerfromafuseddisconnect

box or circuit breaker to transmitter cabinet

terminal board TB1 terminals 1, 2 and 3. The

powersourcecan be either a closeddelta(usually 230 to 240 volts) or aWYE (usually 208).

For a four wire WYE system (341 to 434

volts), connect the neutral wire to terminal

board TB1 terminal 4. Also for a WYE

system ensure that the high voltage transformer has been tapped correctly for the

configuration (see the Wiring Diagram for

the three phase GATESFIVE transmitter).

For the GATES ONE, GATES TWO, or

single phase GATESFIVE, connect ACinput

power(197 to 251 VAC)from afused disconnect box orcircuit breaker to transmitter cabinet terminal board TB1 terminals 1 and 2.

NOTE

Terminal board TB1 is accessed by remov-

ing the four screws which hold the circuit

breaker panel to the front of the transmit-

Rev. AC: 2/29/00 888-2314-001 2-3

WARNING: Disconnect primary power prior to servicing.

Page 20

ter and then sliding the circuit breaker

panel forward. Terminal board TB1 is

located on the floor of the transmitter directly below the AC Power panel. Terminals are numbered left to right.

Ifyou choose towireyourtransmitterwith

separatelow voltageandhigh voltagefeeds,

you will need to remove the factory installedjumperwiresfrom TB1, and connect

a10ampservicetoTB1terminals5and6.

For the 3 phase GATESFIVE, ensure that

the Phase Monitor relay A19K3 is installed

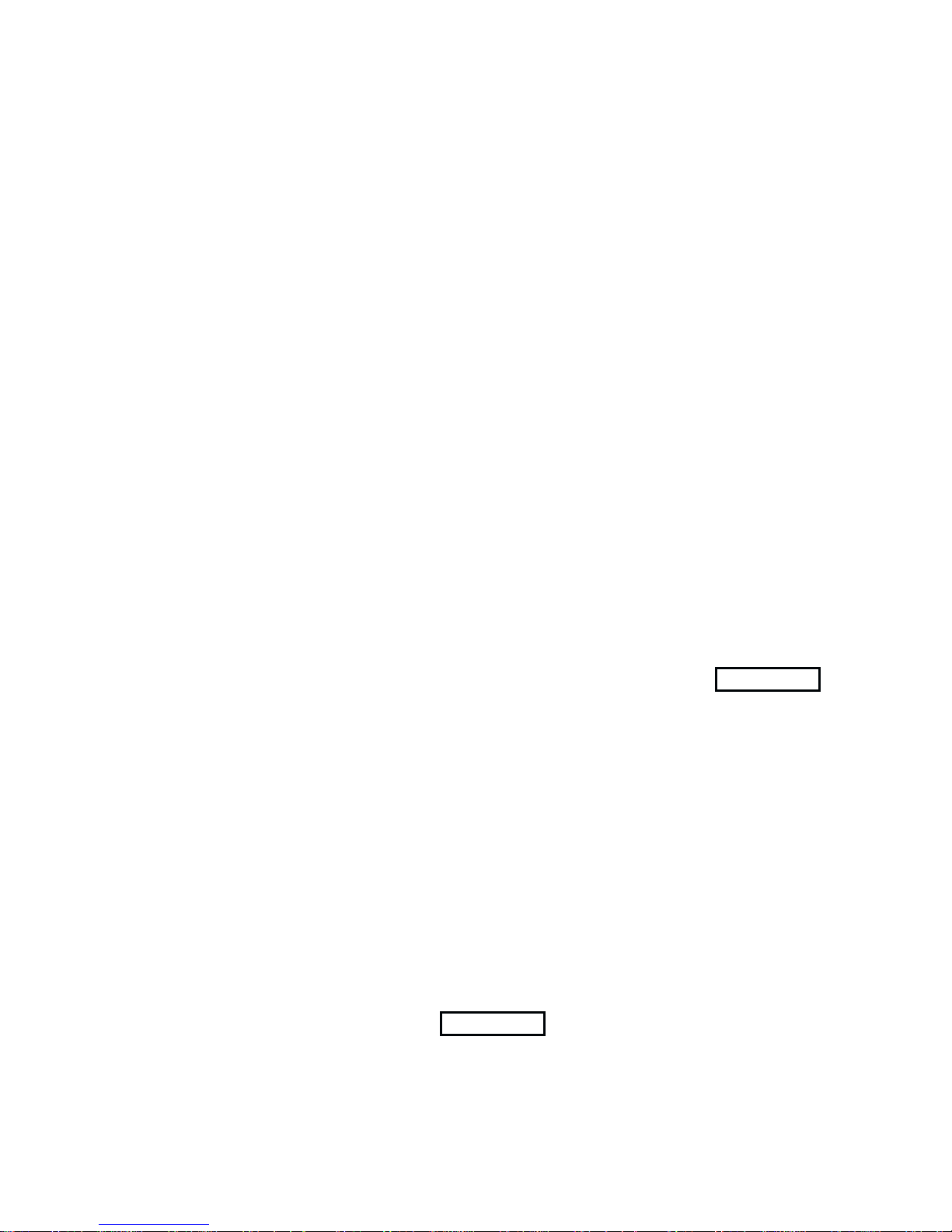

Table 2-4. Interface Board Connections

CONTROL

INPUTS TERMINAL

Low TB2-1

Two TB2-2

Three TB2-3

Four TB2-4

Five TB2-5

High TB2-6

Off TB2-7

Raise TB2-8

Lower TB2-9

Ext Kill (RF mute) TB2-10

FAILSAFE TB1-1 and TB1-2

METERING

OUTPUTS TERMINAL

PA Voltage TB2-11

PS Current TB2-12

Power Output TB2-13

STATUS TERMINAL

Low TB2-15

Two TB2-16

Three TB2-17

Four TB2-18

Five TB2-19

High TB2-20

OVERLOAD

STATUS TERMINAL

Overload Ind Reset TB2-14

Auto Cutback TB2-21

Supply Voltage TB2-22

Supply Current TB2-23

Underdrive TB2-24

VSWR TB2-25

Audio TB2-26

Audio TB2-27

Ground TB2-28

in the AC Power panel and is adjusted to

MIN.SeeNotebelow.

NOTE

To adjust the Phase Monitor, remove all

power from transmitter and rotate the voltage

adjustment screw to your approximate AC

line voltage. The actual setting will have to be

determined by trial and error. Refer to paragraph 2.7.1.g for adjustment information.

2.6.2. RF Output Connection

Connect the output transmission line from

theantennato theRFOUTPUTconnectorjack

J1 located on top of the transmitter cabinet.

A GATES ONE requires a male type N

connector. Specific type N connectors are

availablefor various types of coax.

TheGATESTWOandGATESFIVErequire

a 7/8 EIA flange. Specific connectors of this

type are available for various kinds of coax.

2.6.3. Battery Installation

The purpose of the battery on the Controller

board (on the swing out panel) is to maintain

transmitter operational status during a power

interruption. It is not important to install it until

you are nearly ready to put the transmitter

into regular operation. The transmitter will

operate properly without the battery, however , po wer interruptions lasting more than

a few seconds will result in an OFF condition, and all overload lights lit.

A standard 9 volt battery will last about 2

weeks of continuous running with no AC

powerapplied.Alkalinebatterieswillgivethe

longest shelf life. It is a good idea to change

the battery after a long outage or yearly.

2.6.4. Audio Input

Route the audio cable up from the base of

the transmitter to the Interface board. The

Interface board is located in the lower left

portion of the transmitter in the front. Connecttheaudioinputwiresto terminals TB226 and TB2-27 on the Interface Board.

TB2-28is ground for the audiocable.Refer

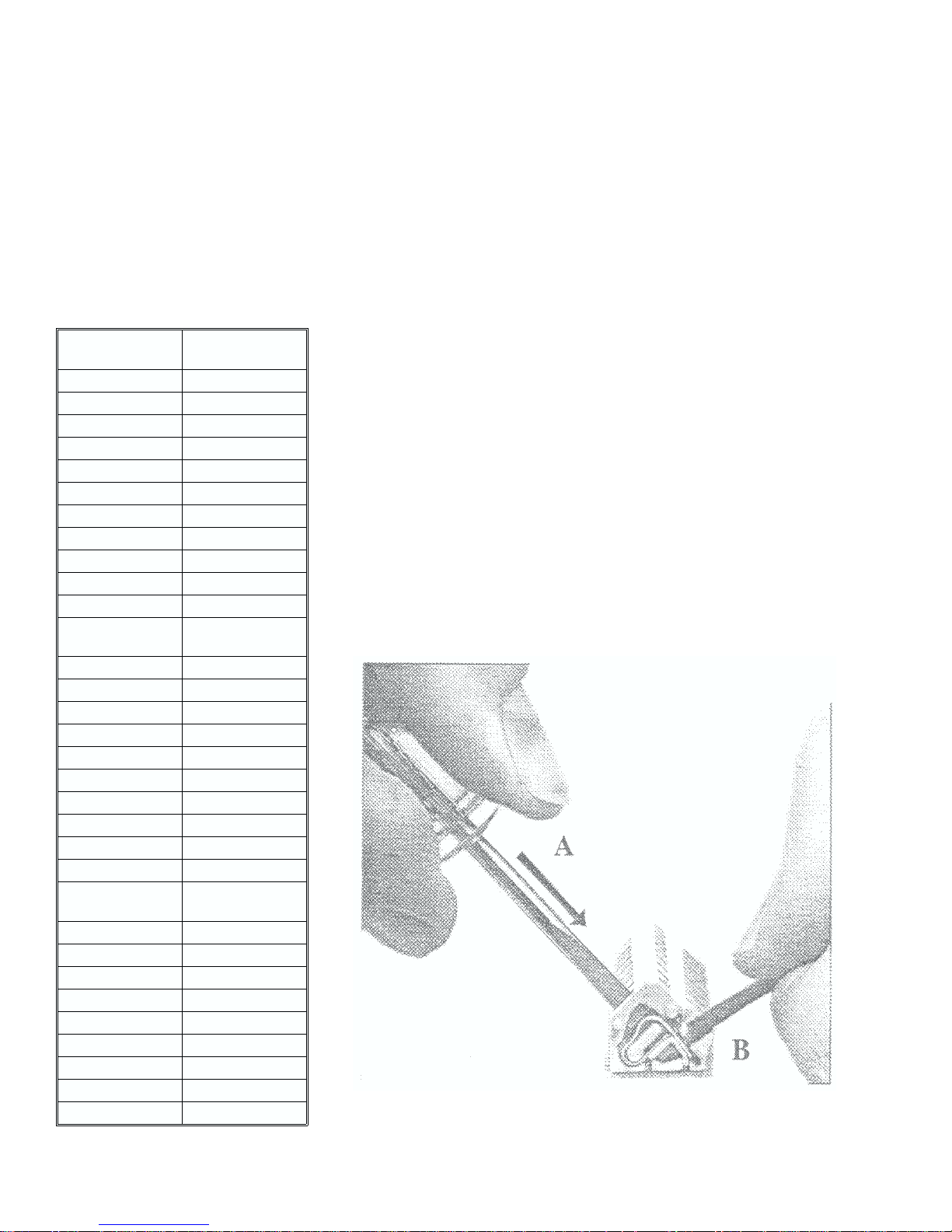

to Table 2-4 and Figure 2-3.

2.6.5. Remote Control

Allremote controlconnectionsaremadeatthe

Interfaceboard. Cabling forremotecontrolmay

be routed up from the base of the transmitter.

To prepare wire, strip insulation back approximately 1/4" and twist strands back into

their natural position.

A small flat blade screwdriveris an appropriate tool to use to make the connection.

To make connection, align wire in side opening “B” and depress clamp down from

opening “A”with tool. Insert wire or component in opening “B” andsecurebywithdrawing tool.

Figure 2-3. Making Connections to WAGO Block

2-4 888-2314-001 Rev. AC: 2/29/00

WARNING: Disconnect primary power prior to servicing.

Page 21

Note:Allremotecontrol inputs areactivated

by applying a momentary ground connection

to each desired input. This makes the transmitterdirectlycompatiblewithopencollector

type remote control units as well as dry contact systems. With a dry contact (relay) system, you will simply need to momentarily

switch each of the desired control inputs to

ground in order to cause a function to occur.

The status outputs for power levels and

overloads are open collector outputs. These

are directly compatible with TTL type inputs,or may be usedto drivesmallrelays or

other indicating devices as long as the current requirements are 100 ma or less.

To use a status output to drive a small

relay, you will need to connect the relay

from the status output toa DC power source

with a positive voltage between 5 volts and

24volts.As with anyDCpoweredrelay,you

should connect a diode across the coil, with

the cathode toward the positive supply.

2.6.6. Airflow Sensor Status

In addition to the status outputs described

above, transmitters manufactured December 1995 and later are equipped with an

Airflow Sensor circuit which includes a

status output. A relay contact closure is

providedonTB1onthemainAirflowSensor circuit board, located in the air inlet for

A20B1.

All metering samples are positive with

respect to ground and are less than 5 volts

into a 10k ohm input resistance.

2.6.7. Failsafe Connection

24VAC contactor coil current passes

through the Failsafe Interlock t ermi nals.

Therefore, high voltage power supply activationrequires the presence of a continuous

closure across the Failsafe Interlock terminals. Opening of the contacts results in deenergizing the HV contactors.

A connection is required at the Failsafe

terminals even if the transmitter will be

locally controlled. Switching the transmitter to Local control does not bypass the

Failsafe interlock.

Contacts and wiring connected to these

terminalsshouldberatedfor atleast24 VAC

@ 1 amp. Refer to the listing of Interface

Board connections in the Table 2-4.

The shield connection forthe remote controlcablingshouldbe connected to a nearby

ground stud or one of the Interface board

mounting screws.

2.6.8. Modulation Monitor Sample

An adjustable, 1 to 5 Volt RMS signal

source is provided on the Output Monitor

board.The Output Monitor board is located

behind an access door on the front. Route

the cable for the modulation monitor from

the base of the transmitter up to thelocation

of the Output Monitor board. The coax will

slip into the gap between the transmitter

wallandtheenclosurefortheOutputMonitor, RF Oscillator, and PDM Generator.

Connect modulation monitor to the BNC

jackon theOutputMonitorboardA18.Besure

topositionthecoaxsafelyawayfromany

components which may generate enough heat

to melt the insulation on the coaxial cable.

2.7. Initial Turn On Procedure

Before initial t urn on, ensure that the following items are checked:

a. Ground strap is properly connected be-

tween tran smitter and station earth

ground.

b. Check for debris/hardware in base of

transmitter and in AC Panel.

c. Make sure all hardware connections are

tight.

d. AC input wiring is properly connected.

e. Transmitter output is properly termi-

nated into a suitable load capable of

handling rated output power (antenna or

dummy load).

f. Audio input is properly connected.

g. Monitoring equipment is properly con-

nected.

h. The REMOTE/LOCAL switch on the

Controller board (on the swing out

panel) should be in the local mode.

i. Be sure the front and rear covers are in

place.

2.7.1. Initial Turn On

Important

Temporarily remove F1 from the Interface

board. This will disable the contactor circuit

for the first part of the turn-on procedure.

Fasten the bottom frontpanel in place with at

least two screws.

WARNING

THE NORMAL PROCEDURE FOR

TRANSMITTER TURN OFF SHOULD BE

FOLLOWEDINORDERTOPROPERLY

DISCHARGE THE HIGH VOLTAGE COMPONENTS. TURN OFF THE HIGH VOLTAGEBYDEPRESSING THEOFF BUTTON.

IFYOUMUSTENTERTHETRANSMITTER,

SET THE REMOTE/LOCAL SWITCH TO

LOCAL AND ALLOW THE POWER SUPPLY TO DISCHARGE AS INDICATED BY

THEFRONTPANEL METERS. LOWVOLTAGE MAY THEN BE REMOVED BY SETTING THE LOW VOLTAGE CIRCUIT

BREAKER TO OFF. DISCONNECT ALL

PRIMARY POWER SERVICE. REMOVE

THE REAR LIFT OFF PANEL SLOWLY TO

ALLOW THE RESISTOR DISCHARGE

MECHANISMTOFUNCTION.AGROUNDING STICK IS PROVIDEDIN THE TRANS-

MITTER AND SHOULD BE USED TO ASSURE THAT ALL HIGH VOLTAGE HAS

BEEN REMOVED UNDER FAULT CONDITIONS. BE CAREFUL NOT TO GROUND

ANY CONNECTIONS WHICH ARE STILL

ENERGIZED.THISWOULDINCLUDE ALL

LOW VOLTAGE CIRCUITS IF THE LOW

VOLTAGE CIRCUIT BREAKER HAS NOT

BEEN SET TO OFF POSITION.

CAUTION

IF ANY ABNORMALITIES ARE ENCOUNTERED IN THE FOLLOWING STEPS, STOP

THE PROCEDURE, REMOVE ALL POWER,

AND PROCEED TO TROUBLESHOOTING

SECTION OF MANUAL.

a. Using a small blade screwdriver or ad-

justing tool, rotate the LOWpowerlevel

control pot (located below the LOW

powerON switch)severalturns counterclockwise. The other pots may be left at

the factory settings for now.

b. Apply AC power to transmitter.

c. Set the LOW VOLTAGE circuit breaker

A20CB1 to ON position.

d. Verify the +/- 12 volt supply LED’sillu-

minate on the control panel.

e. If you havea3 phase GA TESFIVE,verify

red LED on Phase Monitor (inthe contac-

tordrawer) isilluminated.Ifthe LEDisnot

illuminated, either the Phase Monitor is

not adjusted for the correct line voltage or

thephasesequenceis backwards.Remove

all po wer and adjust the volta ge selector

on the Phase Monitor to the lowest setting

and re-apply power.

f. If the LED is still not illuminated, re-

move all power and reverse any two

leads in the main disconnect box and

re-apply power and verify that the LED

is illuminated. Adjust the voltage selec-

tor so that the red LED on the Phase

Monitor relay illu minates when AC

power is applied. In this adjustment, al-

low for a reasonable sag in line voltage,

butdo not desensitize it so far that itwill

be ineffective.

Note: The Phase Monitor relay adjustment is affected only by the particular line

voltage.Itisnot affectedbythe changing of

transformer taps which may be done later.

g. Install screws holding AC Power panel

in place.

WARNING

ENSURE ALL VOLTAGE IS REMOVED

FROM TRANSMITTER AND ALL POINTS

WHERE VOLTAGE HAS BEEN APPLIED

ARE GROUNDED BEFORE CHANGING

ANY TAPSIN THE FOLLOWING STEP.

h. Use a suitable voltmeter to measure the

+/-20voltsupply. A convenientpointfor

checking these voltages is on the PDM

Rev. AC: 2/29/00 888-2314-001 2-5

WARNING: Disconnect primary power prior to servicing.

Page 22

Generator, A15 at the fuses. Measure

each voltage with respect to ground. If

the voltages are under 19 Vdc, disconnect AC power and re-tap A20T1 to the

nextlowerprimary voltage(taps240,0).

It is desired thatthe low voltage supply be

between 19 and 23 Vdc both plus and minus. Use a procedure of removing AC

power, grounding transformer taps, moving

the primary wiring to the next lower increment, then measuring +/-20 volt supplies,

to achieve the desired supply voltages.

Note: The transformer tap connections

are provided on TB3, terminals 15 through

19. Refer to Figure 2-3 for instructions on

using the Wago block terminals. Move the

AC connection as deemed appropriate to

achieve the desired output voltage.

i. Verify that all overloadand fault indica-

tors can be extinguished by pressing the

Reset button.

j. Check theRFDrivereadingontheMul-

timeter. It should be close to the values

recorded on the factory test data sheet. If

it is not, re-check the low voltage transformer tapping. If needed, check the actual RF Drive on the PA module(s) per

the procedure in Section C.

k. Confirm that when any of the power ON

pushbuttonsaredepressed theyilluminate.

The AC contactors in the pull out drawer

should not be heard energizing at this time

sinceF1isnotinthe Interfaceboard.Also,

thePDMKILLandPDMFAULTLED’s

will light in this condition.

l. Verifythat depressing the OFFpushbut-

ton clears all power ON pushbuttons.

m.Disconnect all primary power, and in-

stall F1 in place on the Interface board.

n. Reapply primary power.

o. Rotate the multimeter switchto theSup-

ply Voltage position. Depress the LOW

power pushbutton. The contactors

should close and apply main ACvoltage

tothehigh voltagesupply.Themultime-

ter should show a voltagein the rangeof

220 to 270 on the 300 scale.

WARNING

IF CONTACTORS DO NOT CLOSE IN THE

PRECEDING STEP, REMOVE ALL

POWER FROM TRANSMITTER AND ENSURE FAILSAFE INTERLOCK CONTACTS ARE JUMPERED OR EXTERNAL

FAILSAFE HIGH VOLTAGE INTERLOCK

CIRCUIT IS PROPERLY CONNECTED.

ALSO BE SURE THE REAR PANEL IS

SECURELY FASTENED.

p. Switch the multimeter to read Detector

Nullandverifythatthereadingiszero.

q. Rotate the LowPowercontrol potclock-

wise and observe the PA Voltage, PA

Amps, and FWD Power meters, and

raise the power until the power level is

as stated on the factory Final Test Data

Sheets for the Low Power setting.

r. If the Detector Null reading increases

from zero, adjust the TUNING and

LOADING controls to minimize the

reading. This will match the PA to the

load impedance you are using.

Duringtheinitial tune-up, the null should be

found to be well withinthe range of the TUNING and LOADING controls. If these controlsrequire considerable adjustment,theload

impedance on the transmitter is probably not

very close to 50 ohms. Ifconsiderable adjustment is required, the impedance presented to

the transmitter output terminal should be

measured and corrected as necessary.

Although the transmitter is designed to

match up to a 1.5:1 VSWR, the optimum

condition is to terminate it into 50 ohms.

s. Depress Power Level number 2. The

power level should increase to near the

factory setting for this power level. It

probably will not be exactly the same

since the Fine Power adjustment has not

been made.

t. AdjusttheTuningand Loading controls

as necessary to null the Detector Null

readingtozero.

u. Compare the present readings against

thefactorydataforanymajordiscrepancies. If any exist, it should be investigated at this time.

v. Progressively step the power level up-

ward by selecting each higher level,

check the readings against the Final Test

Data Sheets. Adjust the TUNING and

LOADINGcontrols to minimize the Detector Null reading to zero.

w.Compare all readings against the Test

Data. Since the High Voltage transformer is tapped at 240 +11 from the

factory, it will probably be necessary to

changethetransformertapsaccordingly.

The need to do this or not is determined

by the Supply Voltage reading on the

Multimeter.Itshouldbe250to265 volts

at full power.

A change from one transformer tap setting

to the next will produce about a 5% change in

DC Supply voltage. For example, moving

from 240, +11 to a setting of 240, 0 would

result in a DC Supply increase of about 5%.

NOTE

The smaller gauge wiring on the trans-