Page 1

Complete Equalization & Loudspeaker Management System

4800/4820

User Manual

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING FOR YOUR PROTECTION READ THESE INSTRUCTIONS:

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

ATTENTION:

WARNING:

SHOCK DO NOT EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE

RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR

TO REDUCE THE RISK OF FIRE OR ELECTRIC

The symbols shown above are internationally

accepted symbols that warn of potential hazards

with electrical products. The lightning flash with

arrowpoint in an equilateral triangle means that

there are dangerous voltages present within the

unit. The exclamation point in an equilateral triangle indicates that it is necessary for the user to

refer to the owner’s manual.

These symbols warn that there are no user serviceable parts inside the unit. Do not open the unit.

Do not attempt to service the unit yourself. Refer

all servicing to qualified personnel. Opening the

chassis for any reason will void the manufacturer’s

warranty. Do not get the unit wet. If liquid is

spilled on the unit, shut it off immediately and take

it to a dealer for service. Disconnect the unit during storms to prevent damage.

SAFETY INSTRUCTIONS

NOTICE FOR CUSTOMERS IF YOUR UNIT IS EQUIPPED

WITH A POWER CORD.

WARNING: THIS APPLIANCE MUST BE EARTHED.

CONNECT ONLY TO A MAINS SOCKET OUTLET WITH

PROTECTIVE EARTHING CONNECTION.

The cores in the mains lead are coloured in accordance with

the following code:

GREEN and YELLOW - Earth BLUE - Neutral BROWN - Live

As colours of the cores in the mains lead of this appliance may

not correspond with the coloured markings identifying the

terminals in your plug, proceed as follows:

• The core which is coloured green and yellow must be connected to the terminal in the plug marked with the letter E, or

with the earth symbol, or coloured green, or green and yellow.

• The core which is coloured blue must be connected to the

terminal marked N or coloured black.

• The core which is coloured brown must be connected to the

terminal marked L or coloured red.

This equipment may require the use of a different line cord,

attachment plug, or both, depending on the available power

source at installation. If the attachment plug needs to be

changed, refer servicing to qualified service personnel who

should refer to the table below. The green/yellow wire shall

be connected directly to the units chassis.

CONDUCTOR

LIVE

L

NEUTRAL

N

E

EARTH GND

WARNING: If the ground is defeated, certain fault conditions

in the unit or in the system to which it is connected can result

in full line voltage between chassis and earth ground. Severe

injury or death can then result if the chassis and earth ground

are touched simultaneously.

WIRE COLOR

Normal Alt

BROWN

BLUE

GREEN/YEL

BLACK

WHITE

GREEN

KEEP THESE INSTRUCTIONS

HEED ALL WARNINGS

FOLLOW ALL INSTRUCTIONS

THE APPARATUS SHALL NOT BE EXPOSED TO DRIPPING OR SPLASHING LIQUID

AND NO OBJECT FILLED WITH LIQUID, SUCH AS VASES, SHALL BE PLACED ON

THE APPARATUS.

CLEAN ONLY WITH A DRY CLOTH.

DO NOT BLOCK ANY OF THE VENTILATION OPENINGS. INSTALL IN ACCORDANCE

WITH THE MANUFACTURER’S INSTRUCTIONS.

DO NOT INSTALL NEAR ANY HEAT SOURCES SUCH AS RADIATORS, HEAT

REGISTERS, STOVES, OR OTHER APPARATUS (INCLUDING AMPLIFIERS) THAT

PRODUCE HEAT.

ONLY USE ATTACHMENTS/ACCESSORIES SPECIFIED BY THE MANUFACTURER.

UNPLUG THIS APPARATUS DURING LIGHTNING STORMS OR WHEN UNUSED

FOR LONG PERIODS OF TIME.

Do not defeat the safety purpose of the polarized or grounding-type

plug. A polarized plug has two blades with one wider than the other. A

grounding type plug has two blades and a third grounding prong. The

wide blade or third prong are provided for your safety. If the provided

plug does not fit your outlet, consult an electrician for replacement of

the obsolete outlet.

Protect the power cord from being walked on or pinched particularly

at plugs, convenience receptacles, and the point where they exit from

the apparatus.

Use only with the cart stand, tripod bracket, or table specified by the

manufacture, or sold with the apparatus. When a cart is used, use

caution when moving the cart/apparatus combination to avoid injury

from tip-over

Refer all servicing to to qualified service personnel. Servicing is

required when the apparatus has been damaged in any way, such as

power-supply cord or plug is damaged, liquid has been spilled or objects

have fallen into the apparatus, the apparatus has been exposed to rain

or moisture, does not operate normally, or has been dropped.

POWER ON/OFF SWITCH: For products provided with a power switch, the

power switch DOES NOT break the connection from the mains.

MAINS DISCONNECT: The plug shall remain readily operable. For rackmount or installation where plug is not accessible, an all-pole mains

switch with a contact separation of at least 3 mm in each pole shall

be incorporated into the electrical installation of the rack or building.

FOR UNITS EQUIPPED WITH EXTERNALLY ACCESSIBLE FUSE RECEPTACLE:

Replace fuse with same type and rating only.

MULTIPLE-INPUT VOLTAGE: This equipment may require the use of a different line cord, attachment plug, or both, depending on the available

power source at installation. Connect this equipment only to the power

source indicated on the equipment rear panel. To reduce the risk of

fire or electric shock, refer servicing to qualified service personnel

or equivalent.

This Equipment is intended for rack mount use only.

If connected to 240V supply, a suitable CSA/UL certified power cord shall

be used for this supply.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

If you want to dispose this product, do not mix it with general household waste. There is a

separate collection syst em fo r used el ectronic products in accordance with legislation tha t

requires proper treatment, recovery and recycling.

Private household in the 25 member states of the EU, in Switzerland and Norway may return their used

electronic products free of charge to designated collection facilities or to a retailer (if you purchase a similar

new one).

For Countries not mentioned above, please contact your local authorities for a correct method of disposal.

By doing so you will ensure that your disposed product undergoes the necessary treatment, recovery and

recycling and thus prevent potential negative effects on the environment and human health.

DECLARATION OF

ELECTROMAGNETIC

COMPATIBILITY

This device complies with part 15 of the

FCC Rules and the Product Specifications

noted on the Declaration of Conformity.

Operation is subject to the following two

conditions:

• this device may not cause harmful

interference, and

• this device must accept any interference received, including interference

that may cause undesired operation.

Operation of this unit within significant

electromagnetic fields should be avoided.

Manufacturer’s Name: dbx Professional Products

Manufacturer’s Address: 8760 S. Sandy Parkway

Sandy, Utah 84070, USA

declares that the product:

Product name: dbx 4800, 4820

Note: Product name may be suffixed by the

EU.

Product option: None

conforms to the following Product Specifications:

Safety: IEC 60065 -01+Amd 1

EMC: EN 55022:2006

EN 55024:1998

FCC Part 15

CONFORMITY

• use only shielded interconnecting

cables.

U.K. MAINS PLUG WARNING

A molded mains plug that has been cut off from the cord

is unsafe. Discard the mains plug at a suitable disposal

facility. NEVER UNDER ANY CIRCUMSTANCES SHOULD YOU

INSERT A DAMAGED OR CUT MAINS PLUG INTO A 13 AMP

POWER SOCKET. Do not use the mains plug without the

fuse cover in place. Replacement fuse covers can be

obtained from your local retailer. Replacement fuses

are 13 amps and MUST be ASTA approved to BS1362.

Supplementary Information:

The product herewith complies with the require

ments of the:

Low Voltage Directive 2006/95/EC

EMC Directive 2004/108/EC.

RoHS Directive 2002/95/EC

WEEE Directive 2002/96/EC

With regard to Directive 2005/32/EC and EC

Regulation 1275/2008 of 17 December 2008,

this product is designed, produced, and classified

as Professional Audio Equipment and thus is

exempt from this Directive.

Roger Johnsen

Director, Engineering

Signal Processing

8760 S. Sandy Parkway

Sandy, Utah 84070, USA

Date: December 8, 2010

European Contact: Your local dbx Sales and Service

Office or

Harman Music Group

8760 South Sandy Parkway

Sandy, Utah

84070 USA

Ph: (801) 566-8800

Fax: (801) 568-7583

Page 4

Table of Contents

®

DriveRack

Introduction

0.1 DriveRack 4800/4820 Features .............................ii

0.2 Service Contact Info ............................................iii

0.3 Warranty .............................................................. iii

Section 1 - Getting Started

1.1 Rear Panel 4800/4820 ..........................................2

1.2 Front Panel (4800) ................................................3

1.3 Front Panel (4820) ...............................................5

1.4 System Architect Control Software .......................6

Section 2 - DriveRack 4800/4820

Philosophy

2.1 DriveRack 4800/4820 Philosophy ...................... 10

Section 3 - Front Panel Operation

3.1 Navigation ..........................................................12

3.2 Modes of Operation ............................................13

Section 4 - Software Operation

4.1 DriveRack Philosophy.........................................20

4.2 System Architect DriveRack 4800/4820

File Storage .........................................................20

4.3 System Architect DriveRack 4800/4820

Philosophy ..........................................................20

4.3.1 Module View .................................................. 20

4.3.2 Device Window ............................................... 21

4.3.3 Venue View .....................................................25

Section 5 - In Use

5.1 Front Panel Operation ........................................ 32

5.2 GUI Operation ................................................... 36

Section 6 - Detailed Parameters

6.1 Input Mixer ........................................................40

6.2 Input Router ....................................................... 41

6.3 Input Graphic EQ ..............................................42

6.4 Input 9-Band Parametric EQ .............................. 43

6.5 Input Delay.........................................................44

6.6 Output Mixer .....................................................45

6.7 Output Router .................................................... 46

6.8 Output Bandpass Filter/Crossover ......................47

6.9 Output 6-Band Parametric EQ ........................... 48

6.10 Output Delay....................................................49

6.11 Advanced Feedback Suppression (AFS®) Insert . 50

6.12 Automatic Gain Control (AGC) Insert ............. 52

6.13 AutoWarmth

6.14 Compressor Insert ............................................. 55

6.15 De-Esser Insert ..................................................57

6.16 Noise Gate ........................................................ 58

6.17 Limiter Insert .................................................... 59

6.18 Notch Filter Insert ............................................ 61

6.19 SubHarmonic Synthesizer Insert ....................... 62

®

Insert ......................................... 54

Section 7 - Utilities

7.1 Miscellaneous ...................................................... 64

7.2 Gains and Trims ................................................. 64

7.3 Sample Rate ........................................................ 64

7.4 Real Time Clock ................................................. 65

7.5 Access Rights.......................................................65

7.6 Users ................................................................... 65

7.7 Preset Range .......................................................65

7.8 Network ..............................................................65

Table of Contents

DriveRack® 4800/4820 User Manual

Page 5

®

DriveRack

Appendix

A.1 Specifications ...................................................... 68

A.2 Block Diagram ...................................................70

A.3 Preset Table ........................................................ 71

A.4 Crossover Table .................................................. 71

A.5 Digital I/O and Clocking ................................... 72

A.6 Word Clock Termination ...................................72

A.7 Zone Controller Wiring and Installation ............ 73

A.8 ZC-4 Wiring Diagram .......................................76

A.9 Factory Reset ...................................................... 77

A.10 Ethernet Networking ........................................ 78

A.10.1 Overview of TCP/IP Address ........................78

A.10.2 Connecting the Computer Directly

to the DriveRack ........................................... 79

A.10.3 Setup of a Simple Isolated Ethernet

Network Using DHCP ................................. 80

A.10.4 Proxy ............................................................. 80

A.10.5 Virtual Private Networks (VPN) ...................81

A.10.6 Network Considerations and Limitations ...... 81

A.10.7 Network Troubleshooting ............................. 82

A.10.8 Copyrights ..................................................... 83

Table of Contents

DriveRack® 4800/4820 User Manual

Table of Contents

Page 6

DriveRack

®

Page 7

DriveRack

®

Introduction

INTRODUCTION

FEATURES

CUSTOMER SERVICE INFO

WARRANTY INFO

Page 8

®

INTRODUCTION

Introduction

Congratulations on your purchase of the dbx® DriveRack® 4800 or 4820 system processor! Designed

to provide “Everything you need between the mixer and the power amps,” the 4800 and 4820 provide

incredible flexibility, sonic excellence, and intuitive control for performance applications. From the powerful 96kHz processing engine and advanced processing algorithms, to the VGA display and direct access

Processing and Channel buttons, the DriveRack 4800 provides all the processing and control you need

for live use. The 4820 offers all the DSP functionality of the 4800 with a tamper-proof front panel for

installation use. Some of the many features of the 4800 and 4820 include:

DriveRack

0.1 - DriveRack 4800/4820 Features

• 48 and 96 kHz operation

• Color 1/4 VGA (320x240) Display (4800)

• 4 analog and AES/EBU digital inputs

• 8 analog and AES/EBU digital outputs

• Full Bandpass Filter, Crossover and Routing Configurations with

Bessel, Butterworth, and Linkwitz-Riley filters

• 31-Band Graphic and 9-band Parametric EQ on every input

• 6-band Parametric EQ on every output

• Loudspeaker Cluster and Driver Alignment Delays

• Selectable DSP inserts on all inputs and outputs including

Classic dbx Compression, Limiting and Advanced Feedback

Suppression among others

• Ethernet HiQnet networking and control

• Optional dbx ZC wall panel control

• Optional CobraNet I/O

®

• Optional Jensen

I/O Transformers

ii

DriveRack® 4800/4820 User Manual

Page 9

®

DriveRack

Introduction

0.2 - Service Contact Info

If you require technical support, contact dbx Customer Service. Be prepared to accurately describe the

problem. Know the serial number of your unit - this is printed on a sticker attached to the top panel. If you

have not already taken the time to fill out your warranty registration card and send it in, please do so now.

Before you return a product to the factory for service, we recommend you refer to the manual. Make sure

you have correctly followed installation steps and operation procedures. If you are still unable to solve

a problem, contact our Customer Service Department at (801) 568-7660 for consultation. If you need

to return a product to the factory for service, you MUST contact Customer Service to obtain a Return

Authorization Number.

No returned products will be accepted at the factory without a Return Authorization Number. Please refer

to the Warranty information on the following page, which extends to the first end-user. After expiration of

the warranty, a reasonable charge will be made for parts, labor, and packing if you choose to use the factory

service facility. In all cases, you are responsible for transportation charges to the factory. dbx will pay return

shipping if the unit is still under warranty.

Use the original packing material if it is available. Mark the package with the name of the shipper and with

these words in red: DELICATE INSTRUMENT, FRAGILE! Insure the package properly. Ship prepaid,

not collect. Do not ship parcel post.

0.3 - Warranty

This warranty is valid only for the original purchaser and only in the United States.

1. The warranty registration card that accompanies this product must be mailed within 30 days after purchase date to validate this warranty. Proof-of-purchase is considered to be the burden of the consumer.

2. dbx warrants this product, when bought and used solely within the U.S., to be free from defects in

materials and workmanship under normal use and service.

3. dbx liability under this warranty is limited to repairing or, at our discretion, replacing defective

materials that show evidence of defect, provided the product is returned to dbx WITH RETURN

AUTHORIZATION from the factory, where all parts and labor will be covered up to a period of two

years. A Return Authorization number must be obtained from dbx by telephone. The company shall not

be liable for any consequential damage as a result of the product’s use in any circuit or assembly.

4. dbx reserves the right to make changes in design or make additions to or improvements upon this

product without incurring any obligation to install the same additions or improvements on products

previously manufactured.

5. The foregoing is in lieu of all other warranties, expressed or implied, and dbx neither assumes nor authorizes any person to assume on its behalf any obligation or liability in connection with the sale of this

product. In no event shall dbx or its dealers be liable for special or consequential damages or from any

delay in the performance of this warranty due to causes beyond their control.

DriveRack® 4800/4820 User Manual

iii

Page 10

Introduction

®

DriveRack

iv

DriveRack® 4800/4820 User Manual

Page 11

®

DriveRack

Section 1

Getting Started

REAR PANEL

FRONT PANEL

SOFTWARE INSTALLA-

TION

Page 12

Section 1

Getting Started

®

DriveRack

1

7

89

1. IEC Power Cord Receptacle

2. Optional CobraNet™ Connection (RJ-45)

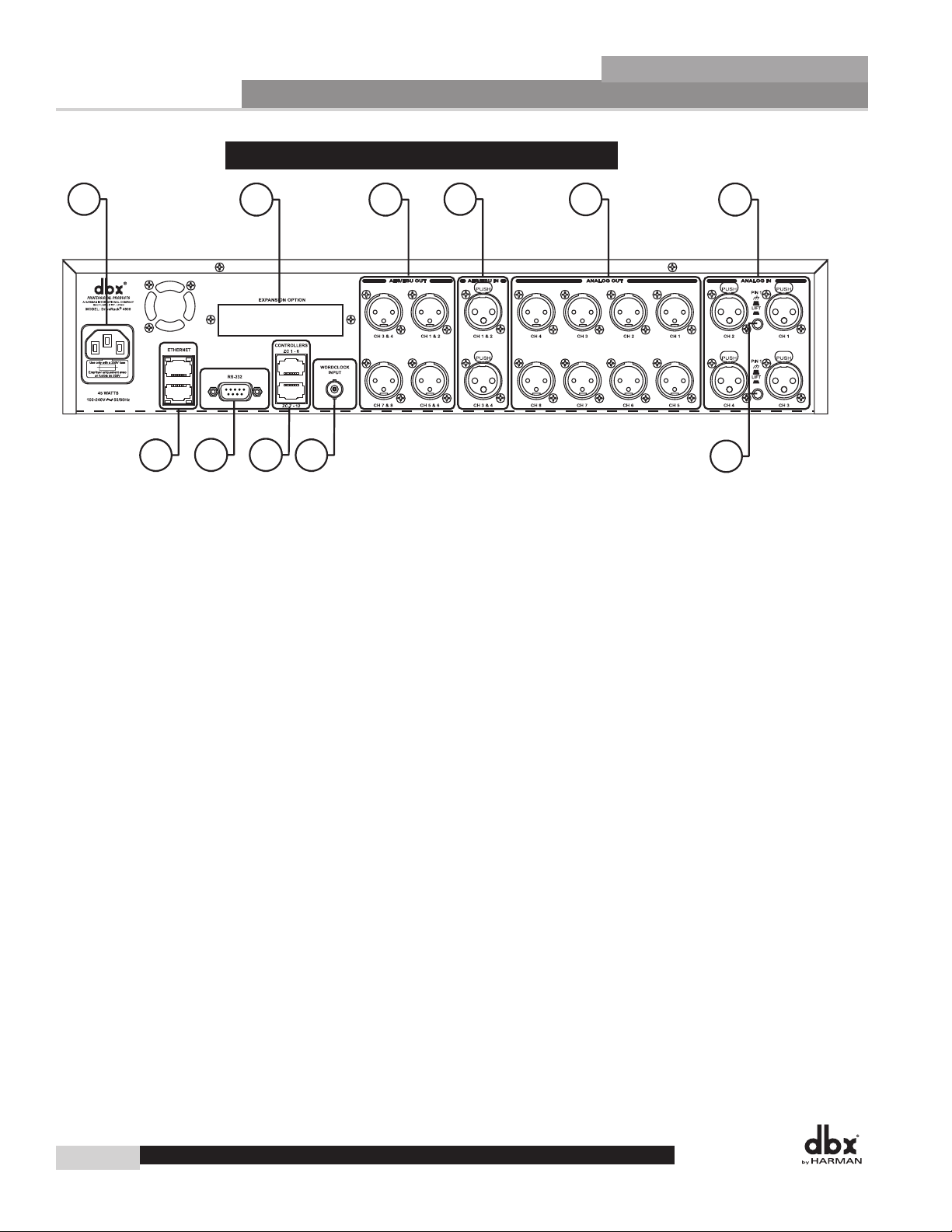

1.1 - Rear Panel 4800/4820

23

4

10

The 4800 and 4820 come with a power supply that will accept voltages ranging from 100V-240V at frequencies from 50Hz-60Hz. An IEC cord is included for both a US and European style AC mains plug.

The Option Slot is for a CobraNet card that provides CobraNet audio and control networking.

5

6

11

3. Digital AES/EBU Output Channels 1-8 (XLR)

The eight AES/EBU output channels (four XLR connectors) are transformer isolated.

4. Digital AES/EBU Input Channels 1-4 (XLR)

The four digital AES/EBU input channels (two XLR connectors) are transformer isolated.

5. Analog Output Channels 1-8 (XLR)

The eight analog outputs of the 4800 and 4820 are electronically balanced and the signals sent to these

outputs are analog copies of the AES/EBU outputs. An optional Input/Output isolation transformer package is available.

6. Analog Input Channels 1-4 (XLR)

The four analog inputs of the 4800 and 4820 are electronically balanced. An optional Input/Output isolation transformer package is available.

7. Ethernet Connection (RJ-45)

These RJ-45 connections are used to network DriveRack devices and control them via Ethernet.

8. PC Connection (DB-9)

This DB-9 connection is used to communicate with the PC GUI and uses RS-232 protocol. This connection requires a Null modem cable (included with the unit).

2

DriveRack

®

4800/4820 User Manual

Page 13

®

DriveRack

9. Zone Control Inputs 1-12 (RJ-45)

These RJ-45 connections are used to receive control information from up to 12 ZC wall panel controllers.

10. Word Clock BNC Connection

This connection allows the DriveRack 4800 or 4820 to lock to a master system clock. It is not terminated. For best results we recommend using “T” connectors when setting up a BNC Word Clock network and terminating the end of of this network with a 75 ohm BNC terminator. (See Appendix 6).

11. Pin Lift Switch

Analog Inputs 1&2, and 3&4 of the DriveRack 4800/4820 share a Ground Lift Switch (Pin 1 lift).

System ground loops can cause hum; this hum can be reduced by pressing the Ground Lift Switch.

Getting Started

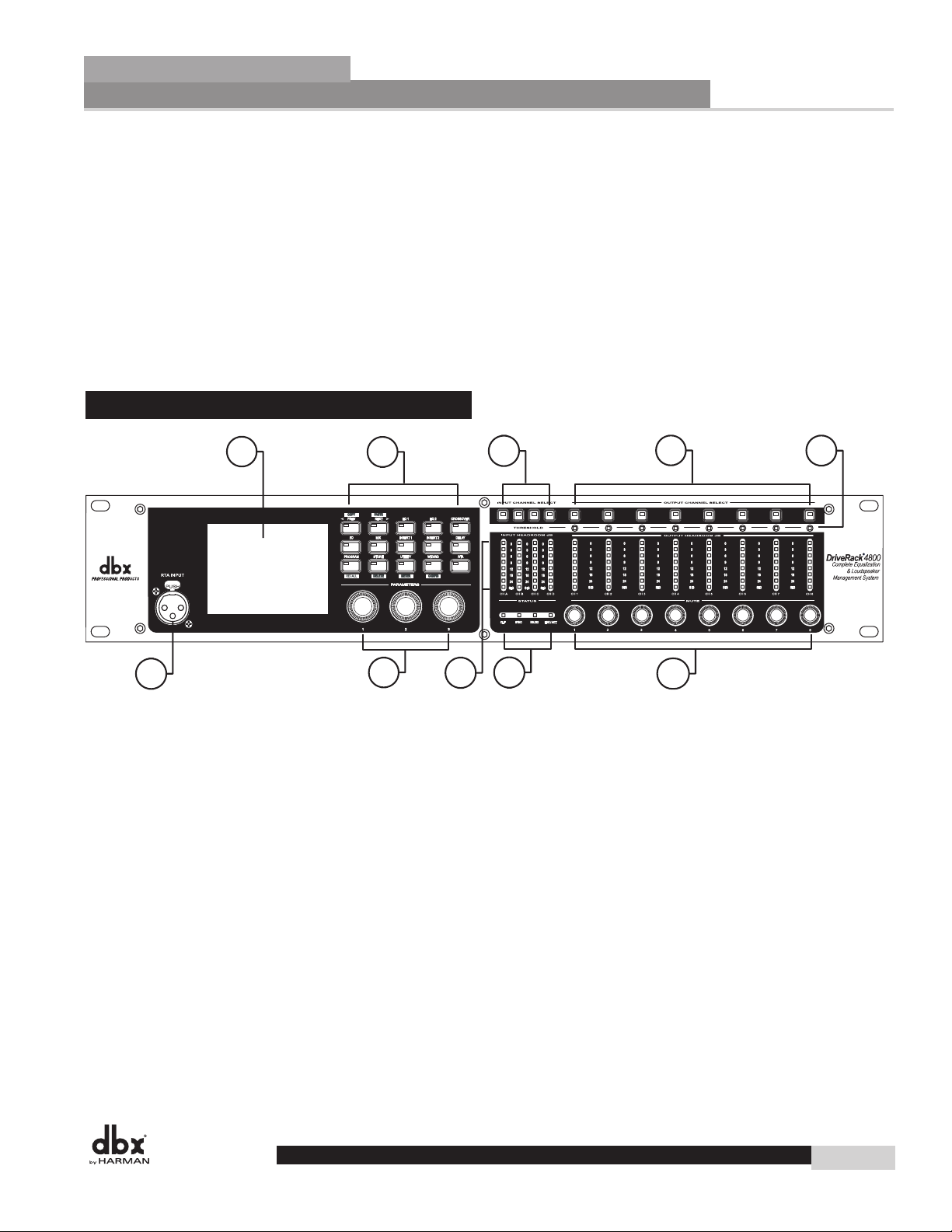

1.2 - Front Panel (4800)

Section 1

1

6

1. LCD Display

The color 1/4 VGA (320x240) display provides viewing of all parameters and attributes of the

DriveRack 4800.

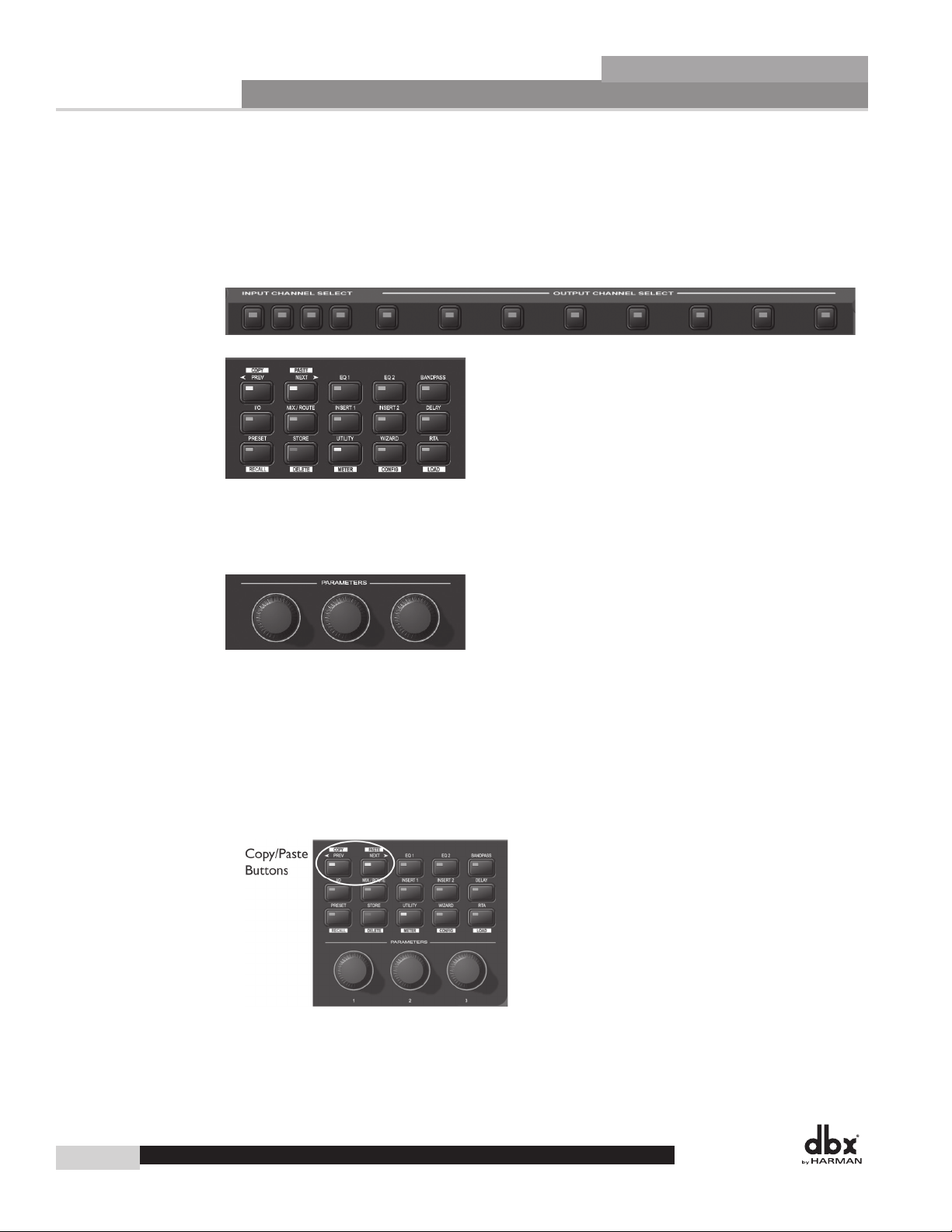

2. Function Buttons

The Function buttons of the DriveRack 4800 allow direct access to all editing and navigating functions

of the DriveRack 4800. The functions of the aforementioned buttons are as follows:

PREV is used to navigate back through the various pages of any module. Pressing and

holding the PREV button allows you to enter Copy/Paste Mode, where subsequent presses

of PREV allow copying all the function DSP parameters.

2

7

3

8

9

4

10

5

NEXT is used to navigate forward through the various pages of any module. Pressing

and holding the NEXT button allows you to enter Copy/Paste Mode, where subsequent

presses of NEXT allow pasting of all the function DSP parameters.

EQ 1 is used to select and/or enter the first Input EQ module or the Output EQ module.

EQ 2 is used to select and/or enter the second Input EQ module or the Output EQ module.

BANDPASS is used to select and/or enter the Bandpass/Crossover function.

DriveRack® 4800/4820 User Manual

3

Page 14

Section 1

Getting Started

OUTPUT is used to select and/or enter the Input and Output setup module.

ROUTE/MIX is used to select and/or enter either the Input or Output Router or Mixer

module.

INSERT 1 is used to select and/or enter the first Insert function in either the Input or

Output.

INSERT 2 is used to select and/or enter the second Insert function in either the

Input or Output.

DELAY is used to select and/or enter either the Input or Output Delay module.

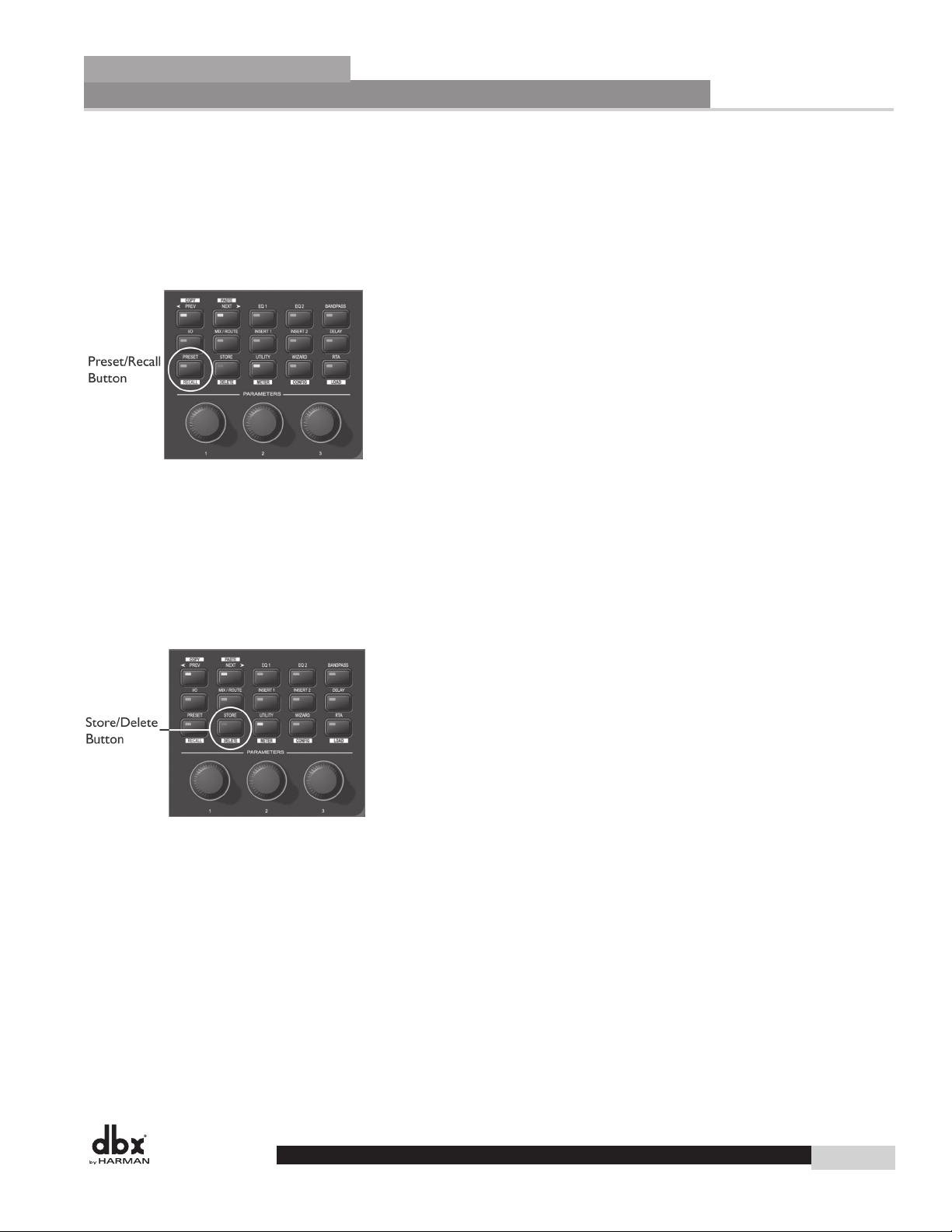

PRESET is used to return to the Preset Screen and exit out of any mode. Pressing and

holding PRESET enters Preset Recall Mode allowing selection of an alternate preset.

STORE is used to store any preset changes. Pressing and holding STORE lets you

Delete a preset from the preset table.

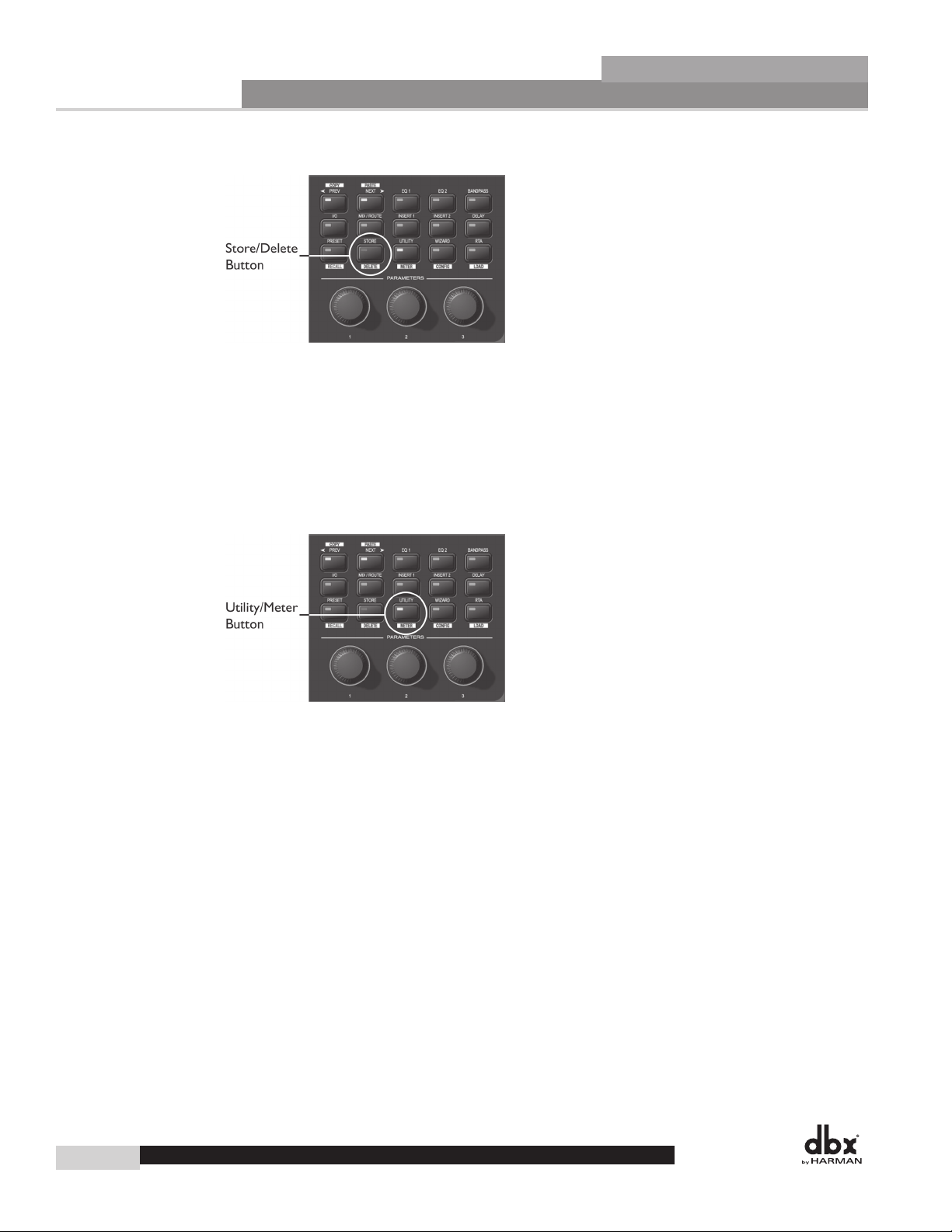

UTILITY is used to access the Utility menu. Pressing and holding UTILITY allows access

to the Meter Mode where additional metering is available.

DriveRack

®

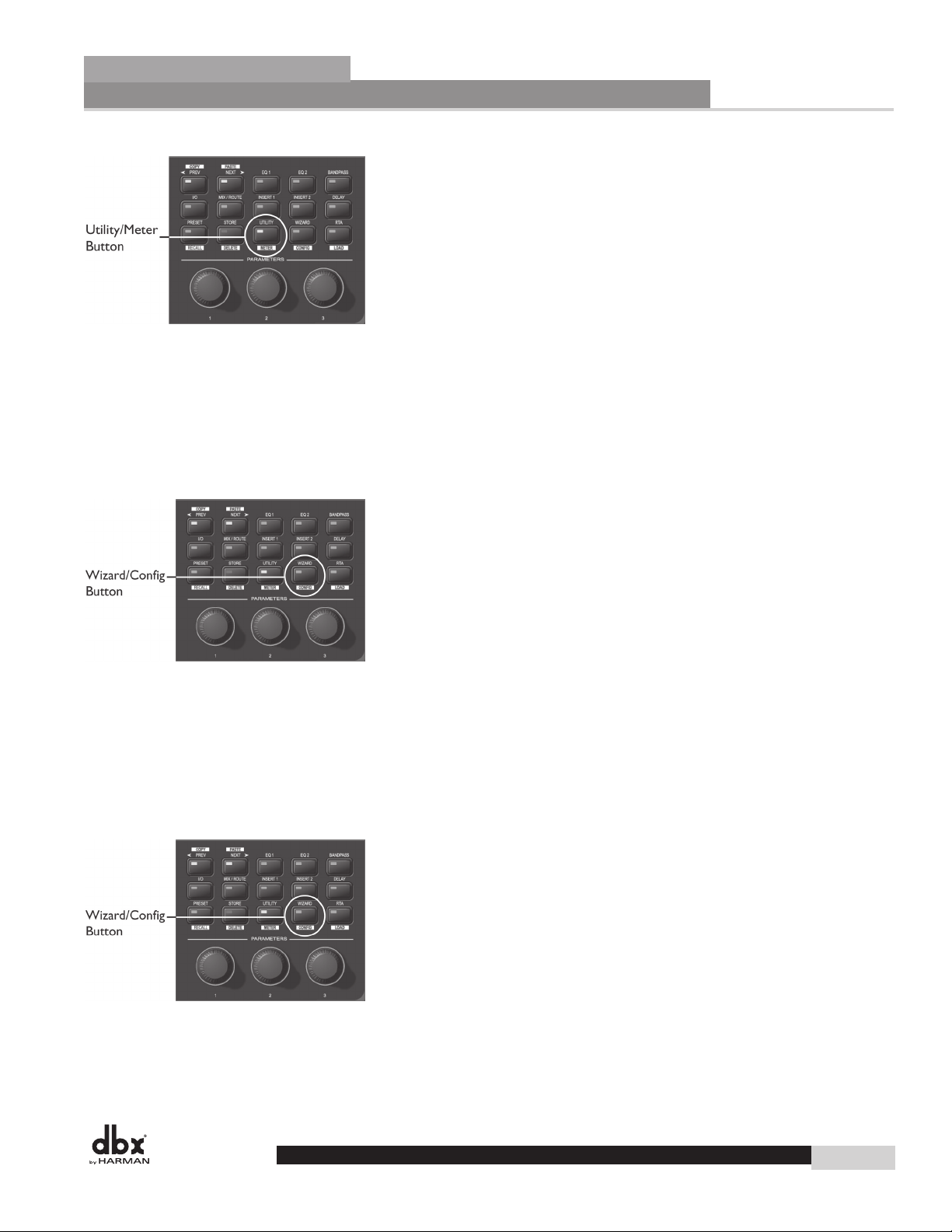

WIZARD is used to enter the Wizard section. Pressing and holding the WIZARD button enters

Configuration Mode where changes to the preset configuration can be made.

RTA is used to view the Real Time Analyzer. In other modes (such as Preset Recall or

Configuration) pressing and holding the RTA button is used to Load those changes.

3. Input Channel Select A-D

These buttons are used to select the desired input channel.

4. Ouput Channel Select 1-8

These buttons are used to select the desired output channel.

5. Threshold Meters

The tri-color Threshold meters indicate that the threshold level has been exceeded in the Output Insert

Limiter, Compressor or Auto Gain Control.

6. RTA Input Jack

This balanced XLR input is used for the connection of an RTA microphone, which may be used with

the Auto EQ Wizard and RTA functions. 48V phantom power is always engaged on this connector.

7. Parameter Control 1-3

These three knobs are used to select and edit parameters.

8. Input Meters

The DriveRack 4800 provides you with four independent eight segment input headroom meters that

range from SIG (-48dB) to 0dB. These meters monitor the signal directly following the input section.

4

DriveRack® 4800/4820 User Manual

Page 15

®

DriveRack

9. Status LEDs

This cluster of four LEDs indicate the following functions:

CLIP - indicates either A/D, D/A, or DSP clipping.

SYNC - indicates DSP syncing to an internal clock, AES/EBU, CobraNet, or Wordclock input.

RS-232 - indicates PC connection via RS-232.

LINK/ACT - indicates connection to and/or activity on an Ethernet network.

10. Output Adjustment/Mute Knobs 1-8

The Output Trim/Mute knobs provide Trim Gain adjustment of each output. Pressing the knob

mutes that output.

11. Output Meters

The DriveRack 4800 provides eight independent eight segment output headroom meters that range from SIG

(-48dB) to 0dB.

Getting Started

Getting Started

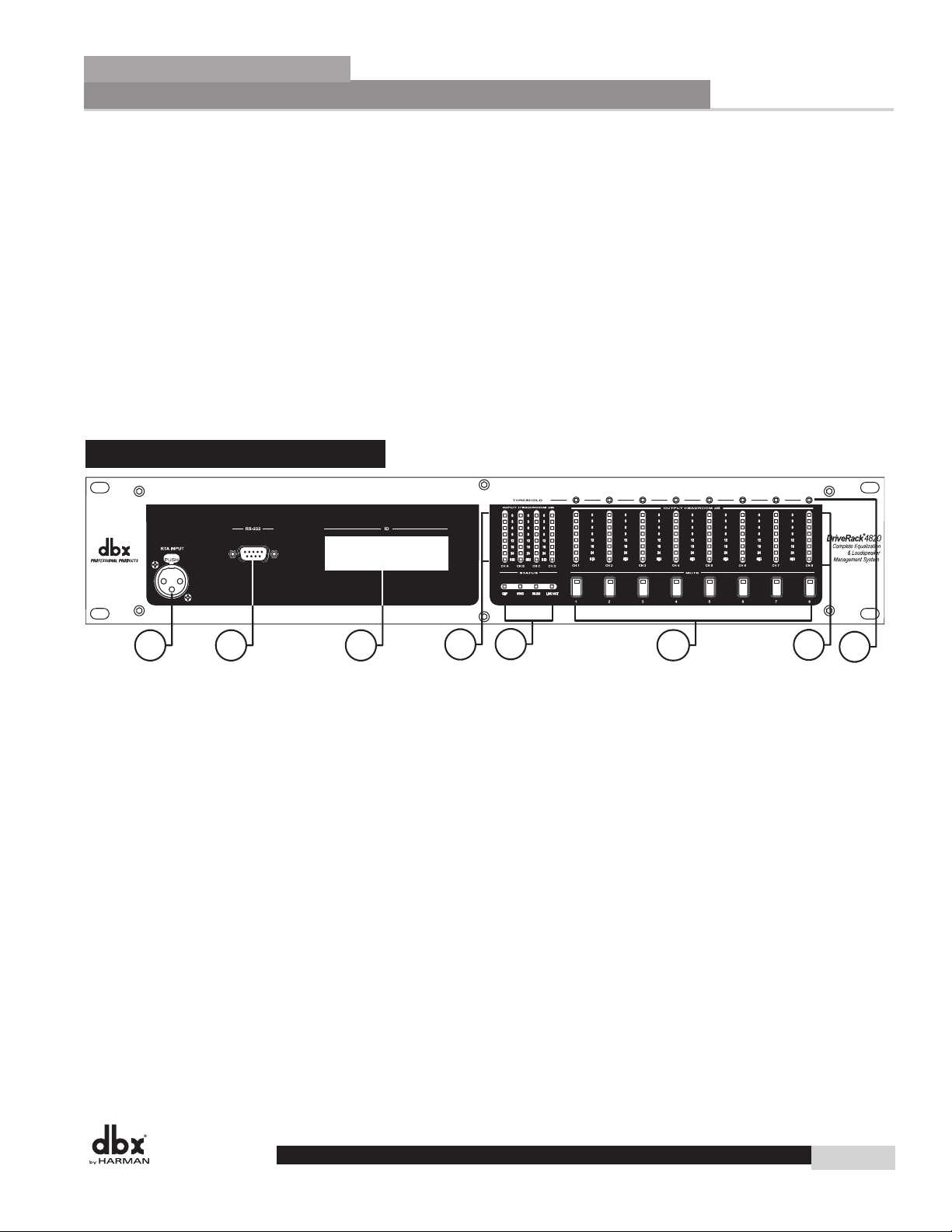

1.3 - Front Panel (4820)

Section 1

1

1. RTA Input Jack

This balanced XLR input is used for the connection of an RTA microphone, which may be used with

the Auto EQ function in the Wizard. 48V phantom power is always engaged on this connector.

2. Serial PC Connection (DB-9)

This DB-9 connection is used to communicate to the System Architect control software and uses

RS-232 protocol. This connection requires a Null Modem cable and one is included with the unit.

3. Alpha Numeric Display

This display shows the ID# of the DriveRack 4820 unit. It can also show various error codes.

4. Input Meters

The DriveRack 4820 provides four independent eight segment input headroom meters that range from

SIG (-48dB) to 0dB. These meters monitor the signal directly following the input section.

5. Status LEDs

This cluster of four LEDs indicate the following functions:

2

3

4

5

6

7

8

DriveRack® 4800/4820 User Manual

5

Page 16

Section 1

®

Getting Started

CLIP - indicates either A/D, D/A, or DSP clipping.

SYNC - indicates DSP syncing to an internal clock, AES/EBU or Wordclock input.

RS-232 - indicates PC connection via RS-232.

LINK/ACT - indicates connection to and/or activity on an Ethernet network.

DriveRack

6. Mute Buttons

The DriveRack 4820 provides a MUTE button for each output.

7. Output Meters

The DriveRack 4800 provides eight independent eight-segment output headroom meters that range from SIG

(-48dB) to 0dB.

8. Threshold Meters

The tri-color Threshold meters indicate that the threshold level has been exceeded in the Output Insert

Gate, Limiter, Compressor or Auto Gain Control.

1. 4 - System Architect Control Software

The System Architect software provides control and monitoring of the DriveRack 4800 and 4820 devices. Multiple units can be networked and controlled together along with other products from Harman

Professional. It is the only software package that allows complete control of all the links in the signal

chain from within a single application. It enables flagship products from best-in-class brands to act as

one collective consciousness, and makes real the benefits only a truly unified system can bring.

Understanding the System Architect software is the key to getting full functionality from the DriveRack

4800 and 4820 products.

System Architect Features

• Supports Ethernet control

• Supports Serial control

• Supports CobraNet audio

• Supports up to 64 channels of streaming audio

• Supports sample rates up to 96kHz

• Supports up to 65,536 HiQnet nodes in a single system

• Wireless 802.11g compatible

• Optimized for tablet PC use

• Optimized for remote access

• Universal Plug and Play compliant

• Multiple computer support

The DriveRack 4800/4820 are compatible with the following products via

System Architect

• AKG WMS 4000 wireless microphone system

• BSS Soundweb London networked audio distribution system

• Crown I-Tech tour sound amplifier range

• Crown amplifier PIP modules - Lite, USP3, USP3/CN

• JBL DP Series intelligent networked amplified speaker

• Studer Vista 8 digital production console

6

DriveRack® 4800/4820 User Manual

Page 17

®

DriveRack

Minimum System Requirements for System Architect are:

1GHz, Pentium III processor

512MB RAM

Windows 2000 or XP service pack 2

Recommended System Requirements:

3GHz, Pentium 4 processor

1GB RAM

Recommended screen resolution: 1024 x 768 pixels or higher

Installation

• Install the System Architect GUI software from either the Harman Professional website at

www.harmanpro.com or from the dbx website at www.dbxpro.com or from the included CD ROM

onto your computer.

• Once the software setup is downloaded, double click on the file named: System Architect setup.

• The application will proceed to prompt you for the installation location.

• Once the software installation has been completed, it is recommended that you restart your computer.

Note

You must disable virus protection software during the installation of the System Architect software.

Getting Started

Section 1

DriveRack® 4800/4820 User Manual

7

Page 18

Section 1

Getting Started

®

DriveRack

8

DriveRack® 4800/4820 User Manual

Page 19

®

DriveRack

Section 2

DriveRack Philosophy

PRESETS

ATTRIBUTES

Page 20

Section 2

®

DriveRack Philosophy

DriveRack

2.1 - DriveRack 4800/4820 Philosophy

The philosophy of the DriveRack 4800 and 4820 revolves around the concept of two elements: Attributes

and Presets.

Attributes

Attributes are parameters that are global like sample rate, analog I/O gain structure, or RTA microphone preamp gain. Most Attributes are found in the Utility menus. Depending on the function, Attributes are

either stored instantly as they are changed or upon exiting the Utility menus, and are stored instantly as they

are changed.

Presets

A Preset is the name given to the audio processing and routing that is occurring in the DriveRack 4800 or

4820. Up to 50 Presets can be stored in the DriveRack 4800 or 4820. The Preset can be further broken

down into two parts: the signal path (or Configuration) and the actual Parameters (listed below) found

in the individual processing functions or modules. Presets are stored manually in the DriveRack unit by

either using the STORE button on the front panel of the 4800 or by using the Preset Tool in the System

Architect software. Presets for the DriveRack 4800 or 4820 can also be saved on the PC as a preset file.

Configuration

The DriveRack 4800 and 4820 units offer two types of processing modules. The first type includes functions like EQ, Bandpass Filters, Mixers, Routers, and Delay; these functions can be linked together but are

fixed in their positions. The second type includes insertable functions that can be selected from a list in four

positions; this list includes Feedback Suppression, Compression, Noise Gate, Limiter, Notch Filter, Auto

Gain Control, AutoWarmth, etc. The process of linking modules and selecting inserts is called Configuring.

The 4800 and 4820 can be configured with hundreds of different signal routing and processing variations.

Parameters

Parameters refers to the processing function parameters. Control of any parameter can be done via the front

panel interface of the DriveRack 4800 with its Function and Channel buttons, or the System Architect

software. Some parameters, such as output gain, can be adjusted from a ZC series wall panel controller.

System Architect Software / DriveRack Plug-In

The HiQnet System Architect Graphic User Interface application (referred to hereafter as System Architect

or GUI) is the control software for the DriveRack 4800 and 4820. In addition to parameter adjustment

and all the same control as the front panel of the 4800, System Architect provides the ability to control

multiple units. The GUI can save and recall Preset files as well as a Device file that includes all the Presets

and Attributes in the unit. Besides these files types, it can also store a venue file with all the units in the

network. It can provide a wealth of additional utility like wireless control, grouping functions, custom

control panels and more; see Software Operation in Section 4.

10

DriveRack® 4800/4820 User Manual

Page 21

®

DriveRack

Section 3

Front Panel Operation

NAVIGATION

MODES

Page 22

Section 3

®

Front Panel Operation

The DriveRack 4800 is modal in its operation with different types of navigation depending on the mode

that the unit is in. For each of the modes, navigation has been optimized to ensure speed and accuracy.

DriveRack

3.1 - Navigation

The DriveRack 4800 uses three types of navigation to access system attributes and parameters, Matrix

navigation, Scroll navigation, and Page navigation. Some functions require the use of more than one type

of navigation; an example of this is the Edit mode, where a combination of Matrix navigation and Page

navigation are used to access individual parameters in the various processing modules.

Matrix Navigation - This refers to moving around the matrix, field, or grid of processing modules that are

shown on the main preset screen. Matrix navigation relies on the use of the channel and Function buttons to find the desired processing module. For example, if you were in Copy/Paste mode (see Copy/Paste

below) and wanted to copy the parameters of the Input Graphic EQ on Input B, you would simply press

the INPUT B button then the EQ1 button, and the Input Graphic EQ on input B would be highlighted.

12

DriveRack® 4800/4820 User Manual

Page 23

®

Front Panel Operation

DriveRack

Scroll Navigation - This navigation is used in the Utility menus, as well as in storing, recalling and deleting

presets. It is very useful for finding menu offerings that are located within another sub-menu. For example,

the RTA mic pre gain is located within the Gain/Trim sub-menu of the Utility.

Page Navigation - This is the easiest and most common type of navigation within the DriveRack 4800.

Page navigation is used when there are several pages of parameters that need to be accessed. An example of

Page navigation is found in the Compressor editor where there are three pages of parameters and the NEXT

and PREV PAGE buttons are used to move between these pages.

Section 3

3.2 - Modes of Operation

The standard mode of operation of the DriveRack 4800 is Edit Preset (or Edit) mode. This mode is the

gateway to all editing and is the only “location” from which all the other modes can be accessed. This

mode can be returned to from any other mode or menu by pressing the PRESET button. Pressing the

PRESET button returns you to the main preset screen that shows the signal path through the unit and all

the current processing functions. Additionally, this main preset screen in Edit mode is the safe or home

page; all changes to the system (editing, recalling, storing, deleting, etc.) require button presses to access

these menus. The DriveRack 4800 defaults to this screen and mode upon startup, and returns to this mode

when exiting from all the other modes and menus including: Recall Preset, Store Preset, Delete Preset,

Copy/Paste, Utility, Meter, Wizard, and Configuration. These other modes and/or menus are indicated

by either a button with normal text (White on Black), or by a button with reversed text (Black on White).

The function in normal text is the standard mode, accessed by pressing the button, while the function in

reversed text is the alternate mode, and is accessed by pressing and holding the button for more than two

seconds. An example of this is the STORE/DELETE button, where Store Preset is the standard mode that

is found by pressing the button, and Delete Preset is the alternate mode that is accessed by pressing and

holding for more than two seconds.

DriveRack® 4800/4820 User Manual

13

Page 24

Section 3

®

Front Panel Operation

Edit Preset Mode - In Edit mode, access to any of the processing functions is no more than two button

presses away.

1. Return to Edit mode by pressing the PRESET button.

2. To select the input or output channel that you would like to edit, press the INPUT or OUTPUT button

that corresponds with that channel.

3. Once you have selected the desired channel, press the desired function button from the processing button field.

4. Now that you have reached the desired processing function, you can use the PREV or NEXT buttons to

navigate through the pages of parameters available and then use the Encoder Knobs below the buttons

to adjust the value.

DriveRack

Copy/Paste Mode - Copy/Paste mode lets you navigate through the processing matrix and select modules

to copy and paste. It is only available from the preset main screen since it is an adjunct to the Edit mode,

but it is very useful when editing presets. Obviously you can only copy and paste between like modules.

(i.e. Graphic EQ to Graphic EQ, etc.)

1. Press the PRESET button to return to the main preset screen (showing the signal path and processing

functions).

2. To enter Copy/Paste mode, press and hold either the PREV/COPY or NEXT/PASTE buttons.

3. Navigate to the processing function that you want to copy by pressing the desired Channel and Function

buttons.

4. Once at the function, press the PREV/COPY button to copy the parameters.

14

DriveRack® 4800/4820 User Manual

Page 25

®

Front Panel Operation

DriveRack

5. Navigate to the location where you want to paste and press the NEXT/PASTE button.

6. To exit Copy/Paste mode and return to Edit mode, press the PRESET button.

Recall Preset Mode - Any preset in the preset list can be recalled, as long as it is within the Preset

Minimum and Maximum range set in the Utility menu. For more information on Preset Min/Max, see

Utilities in Section 7.

1. While in Edit mode press and hold the PRESET/RECALL button for two seconds.

2. Select the preset you would like to recall.

3. Press the RTA/LOAD button to recall the preset.

4. To exit Recall mode and return to Edit mode, without recalling a preset, press the PRESET button.

Section 3

Store Preset Mode - Once a preset has been edited it can be stored by pressing the STORE button. The

DriveRack 4800 can store up to 50 Presets.

1. While in Edit mode press the STORE button.

2. To store the preset with the same name and in the same location press STORE again, and then one more

time to confirm storing of this preset.

3. To change the name, press Encoder Knob #2, then use Encoder Knobs #1 and #2 to change the character

and the cursor position. Once the desired name is created press the STORE button.

4. To store to a new location in the preset table turn Encoder Knob #1.

5. Once the name or location has been changed, press the STORE button to store the preset, then once

more to confirm storing this preset.

6. To exit Store mode and return to Edit mode without storing the preset, press the PRESET button.

Delete Preset Mode - Any preset in the preset list can be deleted.

WARNING: At least one preset must remain stored at all times, or there will be no preset to start with

when creating other presets. DO NOT DELETE ALL PRESETS!

DriveRack® 4800/4820 User Manual

15

Page 26

Section 3

®

Front Panel Operation

1. While in Edit mode, press and hold the STORE/DELETE button for two seconds.

2. Select the preset you would like to delete.

3. Press the STORE/DELETE button to delete the preset, and once more to confirm the deletion.

4. To exit Delete and return to Edit mode without deleting the preset, press the PRESET button.

Utility Menu - Many of the global attributes of the DriveRack 4800 are located in the Utility menus,

including Sample Rate, Analog I/O Gain Structure, etc.

1. While in Edit mode press the UTILITY/METER button.

DriveRack

16

2. Scroll through the various Utility menus using Encoder Knob #1. Press the knob to enter the desired

menu.

3. Once in a Utility menu, use the PREV and NEXT buttons to navigate through the pages within that

menu.

4. To exit the Utility menus and return to Edit mode, press the PRESET button.

Meter Menu - The Meter menu provides you with additional high resolution meters for all the dynamics

functions of the DriveRack 4800.

1. While in Edit mode press and hold the UTILITY/METER button.

DriveRack® 4800/4820 User Manual

Page 27

®

Front Panel Operation

DriveRack

2. Use the PREV and NEXT buttons to navigate through the pages of meters.

3. To exit Meter menus and return to Edit mode, press the PRESET button.

Wizard Mode - The Wizard mode will provide you with setup functions. The Wizard mode is not functional in v1.00.

1. While in Edit mode press the WIZARD/CONFIG button.

Section 3

2. Use the PREV and NEXT buttons to navigate through the Wizard pages.

3. To exit the Wizard and return to Edit mode without making any changes, press the PRESET button.

Configuration Mode - The DriveRack 4800 is configurable from the front panel through the Configuration

mode. This mode lets you create a signal path and a combination of processing functions.

1. While in Edit mode press and hold the WIZARD/CONFIG button for two seconds.

2. Use the CHANNEL and FUNCTION buttons to navigate around the processing matrix.

3. In positions where a change of processing is possible, turning the Encoder #1 knob will accomplish this

change.

4. To link adjacent like functions, turn Encoder #3 knob.

DriveRack® 4800/4820 User Manual

17

Page 28

Section 3

®

Front Panel Operation

5. Once the desired configuration is created, press and hold the RTA/LOAD button to load the configuration.

6. To exit Configuration and return to Edit mode without making any changes to the configuration, press

the PRESET button.

DriveRack

18

DriveRack® 4800/4820 User ManualDriveRack® 4800/4820 User Manual

Page 29

®

DriveRack

Section 4

Software Operation

MODULE VIEW

DEVICE VIEW

VENUE VIEW

Page 30

Section 4

®

Software Operation

DriveRack

4.1 - DriveRack Philosophy

The most basic storage elements of the DriveRack 4800 and 4820 are the Attribute and the Preset.

Attributes are global parameters for that unit, while Presets are snapshots of the current processing functions

or modules, their location in the signal path, and their parameters (see Section 2.1 for more information

about Attributes and Presets).

4.2 - System Architect DriveRack 4800/4820 File Storage

System Architect provides you with the ability to store Presets in the DriveRack unit by using the Preset

Tool in the Device View Window (see next page). Attributes can be directly manipulated in the GUI as

well; most Attributes reside in the Utility menus.

System Architect can also save several file types in the computer including the Preset File, the Device File,

and the Venue File. A Preset File is a copy of the Preset information, all the processing function parameters

and their configuration. Saving a Preset File in the computer allows you to then transfer preset information to other users or create an archive of presets used for various occasions. A Device File is a copy of all

the Presets in the DriveRack device along with all the Attributes of that device. You can “clone” a unit by

saving a Device File from one unit and then opening that file in another unit. A Venue File is a snapshot

of the entire venue including all the units within the venue, their current Preset and their Attributes. The

Preset and Device files can be saved from the Device View Window (see below), and the Venue File can be

saved from the Venue View Window (see below).

4.3 - System Architect DriveRack 4800/4820 Philosophy

The philosophy of the HPro System Architect software is built around the idea of Views or Windows (used

interchangeably). Nearly every function of the DriveRack 4800 and/or 4820 can be accessed from one

of three windows: the Venue View, the Device Window, and the Module Window. These views all have

some common features including the standard Microsoft Windows Minimize and Close icons in the upper

right hand corner.

System Architect also provides a “Recycle” icon that is used to either recycle the window or spawn new

windows. If the Recycle icon is white, every new window that is opened will open in the same location and

take the place of the previous. If the Recycle icon is red, every new view that is opened will be in addition to

the others that are still on the screen. Clicking on the icon changes it from white to red. Window recycling

allows you to keep your screen manageable by automatically replacing windows instead of constantly opening up new windows. Recycling works for module views, device windows, and custom control panels. For

more information on window recycling see the Help File in System Architect. Additionally, right-clicking

on the Device View and the Module Window will bring up the “Right-Click” Menu that also includes

the standard Microsoft Move, Minimize, and Close, as well as provide a way to Dock the Window in the

Venue View or open the Help File.

4.3.1 - Module View

The Module Window (shown at the top of the next page) provides a view of the processing module and

all its parameters. The Module Window is accessed by double-clicking the processing icons in the Device

View. These icons are designed to look like the processing function they represent; for example, a Graphic

EQ icon looks like this:

20

DriveRack® 4800/4820 User Manual

Page 31

®

Software Operation

DriveRack

Module View Features

While changes to the parameters within the module are instantaneous, every Module View includes the OK

and Cancel buttons to either accept or reject these changes before closing the window. The Module View

also provides the Recycle Icon in the upper right hand corner, allowing the window location to be reused

upon opening a new module.

Section 4

4.3.2 - Device Window

The DriveRack Device View (seen below) is accessed by double-clicking the device icons in System

Architect’s Venue View, and provides access to the processing modules and other features of the DriveRack

4800 or 4820 devices. Like the processing icons, the device icons look like the devices they represent.

DriveRack® 4800/4820 User Manual

21

Page 32

Section 4

®

Software Operation

Device View Features

Besides access to the processing functions, the Device View offers many other features, some of which can

be found as pull-downs in the Windows Menu. Items in the Windows Menu include the File Menu, Edit

Menu, Tools Menu, View Menu, and Help Menu. Additional features of the Device View include the

Preset Tool, Meters, Mutes and Solos, and the RTA.

Device File Menu

The Device File Menu provides the ability to Open and Save Device and Preset Files to the computer as

well as Print Parameter Values.

DriveRack

Device Edit Menu

In the Device Edit Menu you can Copy and Paste processing module parameters as well as the Preset.

Device Tools Menu

In the Device Tools Menu you can access the Configuration Wizard, Zone Controller Wizard, Utilities,

and Manage Roles. The Configuration Wizard is central in the operation of the DriveRack 4800 because

it is through the Configuration Wizard that the DriveRack 4800 or 4820 is configured with the desired

signal path and processing elements. The Zone Controller Wizard is also important if you wish to use the

DriveRack 4800 or 4820 with ZC wall panel controllers. The Utility Menu holds several of the attributes

of the DriveRack 4800 including the Sample Rate, Analog I/O Gain Structure, Real Time Clock, the Preset

Range, and LCD Intensity. Manage Roles lets you select the access rights (View, Modify) that the four

System Architect roles will have for each processing function.

22

DriveRack® 4800/4820 User Manual

Page 33

®

®

Software Operation

DriveRack

DriveRack

Device View Menu

In the View Menu, you can select to Dock the window in the Venue View or leave it floating.

Device Help Menu

GUI Software Overview

Section 4

In the Help Menu, you can select from Contents, Index, or Search as ways to search for topics in the Help

File. There is also a link to the Device information; this can be helpful when troubleshooting with technical support because it gives a list of many of the attributes of the unit including Sample Rate, Critical

Error Count, IP address, etc. The Device Locate On/Off is a handy feature for finding devices in a larger

system. The Locate function flashes the front panel display. The About DriveRack menu item provides

more information about the unit as well as information about the DriveRack .dll driver in System Architect.

Preset Tool

The Preset Tool lets you store and recall Presets on the DriveRack device when online. It is important to

note that the Preset Tool is used to store Presets on the DriveRack Device while the File Menu/Save Preset

is used to save a Preset File on the computer.

DriveRack® 4800/4820 User Manual

23

Page 34

Section 4

®

Software Operation

Meters

The Meters in the lower left hand corner of the Device View are real time meters, and they show the current input and output levels if the unit is online. The meters can be turned off to reduce the amount of

network traffic if so desired.

Mutes and Solos

DriveRack

The Mutes and Solos are also in the bottom left hand corner of the Device Window, directly below the

Meters. Mutes provide a quick way of muting DriveRack 4800 outputs. The Solos employ the Mutes for

soloing of a single channel during setup.

RTA

Outside of the “normal” DriveRack 4800/4820 signal path, the RTA provides an additional utility that lets

you analyze incoming signals. Clicking on the RTA icon opens the RTA viewer.

24

DriveRack® 4800/4820 User Manual

Page 35

®

®

®

GUI Software Overview

Software Operation

DriveRack

DriveRack

DriveRack

4.3.3 - Venue View

GUI Software Overview

Section 4

Section 4

The Venue View is the most encompassing perspective, providing a “global” view of the entire venue or

system. The Venue View provides many features that make System Architect superior in the way that it

provides control of an audio system. Many of these features can be found as elements within pull-down

menus on the Windows Menu of the Venue View. Other features can be found by right-clicking on the

units within the Venue View. For more information about any of these features refer to the Help menu,

found on the Windows Menu of the Venue View.

Venue File Menu

Beginning with the File Menu, the Venue View lets you save and open Venue Files that are complete copies

of the entire system, including every single unit in the venue, their current presets and parameters, as well as

their attributes. Besides saving and opening Venue files, System Architect can also print a list of the devices

in the system and even the parameters within those units. If Manage Roles is set up, the File Menu can log

users out or switch users, providing varying amounts of control for these users.

DriveRack® 4800/4820 User Manual

25

Page 36

Section 4Section 4

®

GUI Software Overview

Software Operation

Venue Edit Menu

In the Edit menu, System Architect provides the ability to Undo or Redo commands as well as Cut, Copy,

Paste and Delete selected units in the Venue. The Find… command lets you find a specific unit in the

system either by name or ID#.

Venue View Menu

DriveRack

26

The View Menu (seen above) provides quick access to various menus, panels and toolbars.

The Device Panel lets you add various Harman Professional devices to the Venue.

System Explorer provides access to various parameters within each of the units in the venue.

The HiQnet Explorer shows all physical connections that are accessible to the system. If a HiQnet device

is available but is not currently part of the venue, it can be selected and dragged over into the venue view.

The Event Log shows system activity that has occurred within System Architect and on any HiQnet device,

including error messages. The log may be utilized by individual devices to perform certain operations. You

can also use the logs for troubleshooting.

The Controls Toolbox gives you the tools you need to construct a custom control panel.

Custom Control Panels are user-designed screens that can be totally customized to your specifications.

Custom Control Panels offer total versatility in designing and controlling a venue. They enable you to

manage venues more easily by simplifying common editing tasks and restricting access to audio systems by

other users.

DriveRack® 4800/4820 User Manual

Page 37

®

®

®

®

®

®

®

GUI Software Overview

GUI Software Overview

GUI Software Overview

GUI Software Overview

GUI Software Overview

Software Operation

DriveRack

DriveRack

DriveRack

DriveRack

DriveRack

DriveRack

DriveRack

Properties are all of the user-defined display options for any venue view, device, custom control panel, or

controls in System Architect. Different items provide different editable properties, such as changing the

name, background color, or background image.

The Navigator window gives you the ability to view the entire venue and locate a unit’s current position,

since not all units may be viewable in the current window.

Toolbars are also available from the View Menu including the Alignment toolbar, the Window Sets toolbar, and the Zoom toolbar. The Alignment toolbar provides tools that can be used in aligning the various

units in the venue view. The Windows Sets toolbar lets you have different device panels, control panels

and customer control panels available at the touch of a button, simplifying moving between these different

panels. The Zoom toolbar lets you zoom in or out in a venue.

Venue Insert Menu

GUI Software Overview

Section 4

Section 4

Section 4

Section 4

Section 4

Section 4

The Insert Menu provides the ability to insert devices into a venue.

DriveRack® 4800/4820 User Manual

27

Page 38

Section 4

®

Software Operation

Venue Panel Menu

The Panel Menu option lets you create and manage Custom Control Panels, with functions including add,

remove, import, export and activate a control panel.

Venue Tools Menu

DriveRack

28

The Tools Menu lets you manage and control the way System Architect functions.

Network Wizard locates all HiQnet devices physically connected to the network and

provides the ability to change their HiQnet and communications address.

Re-populate Venue automatically searches for devices and adds them to your venue.

Grouping Wizard creates a custom control panel with channels from multiple devices

linked together.

Venue Recall loads presets for multiple devices.

Event Log Archive displays a repository of old Event Log information.

Access Control allows the administrator to restrict or allow access to different parts of

System Architect for multiple users.

Options accesses settings related to the way System Architect functions and displays information.

DriveRack® 4800/4820 User Manual

Page 39

®

Software Operation

DriveRack

Venue Window Menu

The Window Menu manages the main Venue View window. It provides you with the following options:

New adds a new Venue View to the main window.

New Horizontal Group tiles the tab groups horizontally.

New Vertical Group tiles the tab groups vertically.

Section 4

Close Current closes the selected window tab.

Close All closes all window tabs except the primary Venue View.

Venue Help Menu

The Help Menu provides links to the Help File with different ways to find information; it also provides

information about System Architect and the various .dll files that are compiled within it.

DriveRack® 4800/4820 User Manual

29

Page 40

Section 4

Software Operation

®

DriveRack

30

DriveRack® 4800/4820 User Manual

Page 41

®

DriveRack

Section 5

In Use

FRONT PANEL

OPERATION

SOFTWARE

OPERATION

31

Page 42

Section 5

®

In Use

Under normal operation the most common modes are Configuration, Edit, Store and Recall Preset. The

simplest way to illustrate these modes in use is by example; this will be done for both the Front Panel

Navigation as well as the GUI.

In our example we’ll create a Stereo Tri-Amped System with a Mono Sub, a mono send to Delayed House

speakers, and Side Fill sends.

DriveRack

5.1 - Front Panel Operation

The example begins with recalling a preset from the Preset Table:

1. Press the PRESET/RECALL button to return to the main preset screen.

2. Press and hold the PRESET/RECALL button to enter Preset Recall mode.

3. Select Preset 8 Stereo 2-Way with Sub from the preset table by turning the Encoder #1 knob until Preset

8 appears on the display.

4. Press and hold the RTA/LOAD button to load the preset.

This 2x5 preset is a good starting point, but we want to make some modifications to it. We want to link

the Input Graphic EQs and change the Inserts on the main stereo feed from Notch Filters to Compressors.

We also want to rename the Inputs, put a Mixer in the Mid position, and lengthen the Delay that feeds

Output 6, our Delayed speaker send. To do all this we must make a Configuration change.

To make a Configuration change:

1. Since the preset was just recalled, we’re already in Edit Preset mode and can press and hold the

WIZARD/CONFIG button for two seconds to enter Configuration mode.

32

DriveRack® 4800/4820 User Manual

Page 43

®

In Use

DriveRack

2. Press the INPUT A button and the EQ 1 button to move to the Input Graphic EQ.

Section 5

3. Turn Encoder knob #3 to link the Graphic EQs on Inputs 1 and 2.

4. Press the INSERT 2 button and turn the Encoder #1 knob to select the Compressor.

5. Turn Encoder knob #3 to link the Compressors on Inputs 1 and 2.

6. Select the Input Router on Input A by pressing the MIX/ROUTE button and INPUT A button.

DriveRack® 4800/4820 User Manual

33

Page 44

Section 5

®

In Use

7. Rename the Input by pressing Encoder #2 and using Encoder #1 and Encoder #2 to select characters

and advance the cursor.

8. Store the name by pressing the STORE/DELETE button.

9. To change the Mid Router to a Mixer, press the Output 6 button and then the MIX/ROUTE button,

then turn Encoder #1 to select Mixer.

10. While on Output 6, press the DELAY button to allocate enough Delay for these speakers.

11. Load this configuration by pressing the RTA/LOAD button, and one more time to confirm this

configuration change. You’re returned to Edit mode and the main preset screen.

DriveRack

Once the configuration loads, the change is now active and audio can be passed through this new configuration. Now we’ll edit the processing function parameters in the Bandpass filter, Compressor and Graphic

EQ, and create the correct mono mix for our Delayed speakers. To do this we take the following steps:

1. Press the OUTPUT CHANNEL 1 button and the BANDPASS button to navigate to the Bandpass

filter on Output 1.

2. Edit the parameters found on page 1 of that menu (Lowpass Filter Frequency and Slope). The name of

the output that is being edited is shown in the upper right corner; the total number of pages is shown

in the upper left corner.

3. Press NEXT to access the next page of parameters. Continue until all desired pages of parameters have

been edited.

34

DriveRack® 4800/4820 User Manual

Page 45

®

In Use

DriveRack

With three pages per Bandpass filter set, it should be noted that there will be nine total pages in this

function; these pages can either be accessed by continuing to press NEXT PAGE or by pressing the next

OUTPUT CHANNEL button. Since in a 2x5 Bandpass the first two and the next two outputs are

“linked” together, both outputs 1 and 2 will be controlled together in the first three pages of the Bandpass.

Likewise, outputs 3 and 4 will be linked together, and controlled in pages 4 through 6. Output 5 is the

mono summed output designed to be the Subwoofer output, and it is controlled on pages 7 through 9.

4. Navigate to the linked Graphic EQ module on Inputs 1 and 2 by pressing the INPUT CHANNEL A

button and the EQ 1 button.

Section 5

5. Edit the Graphic EQ parameters using the NEXT and PREV buttons to move between the pages. Once

again, Input Channels A and B are linked so adjusting one actually adjusts them both.

6. Since the we’re already in the Input Channel A Graphic EQ, moving to the Stereo linked Compressor

on these same channels requires just a single button press on the INSERT 2 button.

7. Use the NEXT and/or PREV PAGE buttons to navigate to the various desired parameters.

8. Press the OUTPUT CHANNEL 6 button and the MIX/ROUTE button to move to the Output Mixer

on Output 6.

9. Make the changes by finding the Input channels A and B and adjusting their relative amounts using the

Encoders.

10. Press the PRESET/RECALL button to return to the main preset screen.

DriveRack® 4800/4820 User Manual

35

Page 46

Section 5

In Use

Now that the preset has had its configuration changed and has been edited, we can Store it:

1. Press the STORE/DELETE button to enter Store mode.

DriveRack

®

2. Select a location for this new preset in the preset table by turning Encoder Knob #1. (A preset can either

be stored over an existing preset or stored in an empty location.)

3. To name the preset, press Encoder Knob #2, then use the Encoder Knobs #1 and #2 to change the character and move the cursor through the name. (To accept the name change press the STORE/DELETE

button; to reject the name change press Encoder Knob #3.)

4. Once the name and location have been selected, press the STORE/DELETE button to store the preset,

and again to confirm storing the preset.

5. If you want to store an altered preset over the previous preset in the same location, you can press the

STORE/DELETE button three times in succession.

6. Once the preset is stored, you’re returned to the main preset screen and Edit mode.

5.2 - GUI Operation

The example begins with recalling a preset from the Preset Table:

1. Open the Device Window by double clicking on the DriveRack 4800 or 4820 icon in System architect.

2. Click the RECALL button on the Preset Tool. The Preset Recall dialog appears, where you can select a

preset and View it, Recall it, or Cancel the Recall operation.

3. Select Preset 8 Stereo 2-Way with Sub from the list and click on the Recall button.

As before, this 2x5 preset is a good starting point, but we still need to make a Configuration change. To

change the configuration, do the following:

1. Click on the Tools menu in the DriveRack Device window.

36

DriveRack® 4800/4820 User Manual

Page 47

®

In Use

DriveRack

2. Select the Configuration Wizard.

3. Use the links on the left side of the page to quickly jump to the desired locations.

4. Select the EQs link in the Input Section, and click the check box to link the Input Channel A and B

Graphic EQs.

5. Select the DSP Inserts and Delay link in the Input Section, and in Insert 2 on Channels A and B select

Compressor from the pull down menu. Now check the link button that is between them and to the

right.

6. To select between output Mixers and Routers, select the Output Mixers and router link. Use the Radio

buttons to select a Mixer on Output 6.

7. If you forget to rename the Inputs, you can quickly jump back to the Input Channels (by selecting the

Input Channels link) and rename the inputs there.

8. The final Configuration change is allocating Output Delay. Click on the PEQ and Delay link for the

Output Section and select the desired Delay length from the pull down menu in the Delays. Notice

that the GUI keeps a running total of the allocated Delay and provides a warning when the maximum

Delay has been exceeded.

9. Once all the configuration changes have been made, click the Finish button at the bottom of the page.

Now that our configuration is complete, we can Edit the parameters in the Bandpass filter, Compressor and

Graphic EQ, as well as create the correct mono mix for our Delayed speakers:

Section 5

1. Double click the linked Input Graphic EQ icon. The Graphic EQ function opens.

2. Select the frequency faders and adjust them to the desired location. If you make a mistake, you can select

the Flat or Restore button. The Cancel button at the bottom of the editor also can be used to cancel

any changes; the OK button accepts any changes that were made.

3. Double click on the stereo linked Compressor icon to open the Compressor editor and provide access

to all the Compressor parameters.

4. Double click the 2x5 Bandpass icon to open the Bandpass/Crossover filters and allow access to those

parameters.

5. Double click the Output Mixer on Output Channel 6 to open the Mixer and provide access to those

parameters.

The final operation we want to perform is to Store this as a preset in the DriveRack unit. Note that in the

GUI you can also save this as a preset or device file to the Computer. To store the preset:

1. Click on the Store button on the Preset Tool. The Store dialog opens.

2. Select the location in the Preset Table where you want to store the preset.

3. Select the preset’s name.

4. Click the Store button to store the preset.

DriveRack® 4800/4820 User Manual

37

Page 48

Section 5

In Use

®

DriveRack

38

DriveRack® 4800/4820 User Manual

Page 49

®

DriveRack

Section 6

Detailed Parameters

DETAILED

PARAMETERS

Page 50

Section 6

®

Detailed Parameters

The DriveRack 4800 and 4820 provide a wealth of processing capabilities. This processing can be broken

into two distinct sections: Input Processing and Output Processing. Both the Input and Output sections

offer two types of processing functions, Fixed and Insert. Fixed processing modules can be linked and/or

switched with a similar type of function, but they are fixed in their location in the DSP path. An example

of a Fixed processing function is the Input Graphic EQ or EQ1. The Input Graphic EQ can be linked

between adjacent channels. Insert processing functions have fixed locations in the DSP chain, but they

differ from Fixed processing functions because there are several different types of processing that can be put

into these locations. An example of Insert Processing is the second Output Insert. This Insert gives you a

selection of Compressor, Limiter, Noise Gate, or Automatic Gain Control. Like the Fixed functions, they

too can be linked between adjacent channels if there is the same type of function in the other channels.

The following section outlines each of the Fixed processing functions available in both the Input and

Output sections (Sections 6.1-6.10). Following the Input and Output Fixed functions, the Insert

Processing functions is also outlined (Sections 6.11-6.19). These outlines provide GUI images for each of

these functions and describe the various parameters associated with each function.

DriveRack

6.1 - Input Mixer

Each input DSP channel can be configured with either an Input Mixer or Router. The Input Mixer lets

you mix between the input signals. Master Gain is also available, along with Pink Noise On/Off and Pink

Noise Gain.

40

Analog, AES/EBU, and CobraNet faders

Provides gain control for each of the input sources (–inf to +20dB).

Pink Noise Gain fader

Provides Gain control of the internal Pink Noise source (-20 to +20 dB).

Pink Noise On/Off switch

Turns the pink noise on or off.

Master Gain fader

Provides Gain control for the Mixer module (–inf to +20dB).

DriveRack® 4800/4820 User Manual

Page 51

DriveRack

®

Detailed Parameters

Section 6

6.2 - Input Router

The Input Router lets you select from any of the input sources and adjust the Master Gain. Pink Noise

On/Off and Gain are also available in this module.

Selected Source Switch

Allows selection between the input Sources (Analog 1-4, AES/EBU 1-4, CobraNet 1-4).

Pink Noise Gain fader

Provides Gain control of the internal Pink Noise source (-20 to +20 dB).

Pink Noise On/Off switch

Turns the pink noise on or off

Master Gain fader

Provides Gain control for the Router module (–inf to +20dB).

DriveRack® 4800/4820 User Manual

41

Page 52

Section 6

Detailed Parameters

®

DriveRack

6.3 - Input Graphic EQ

The DriveRack 4800/4820 provides a 31 band Graphic EQ on each input channel. This EQ offers up to

+/-15dB of gain at each of the 31 ISO frequency centers.

EQ On/Off switch

This turns the Graphic EQ on and off.

Flat/Restore switch

This either flattens the EQ or restores it to its previous settings.

Frequency switch

This lets you select any one the 31 frequencies and is adjustable between 20Hz to 20kHz on ISO frequency

centers.

Gain fader

This lets you cut or boost the selected frequency by up to 15dB.

42

DriveRack® 4800/4820 User Manual

Page 53

®

DriveRack

Detailed Parameters

6.4 - Input 9-Band Parametric EQ

The DriveRack 4800 and 4820 offer a second EQ (EQ2), after the input Graphic EQ, that can be configured as either a Graphic or 9-Band Parametric EQ. The 9-Band Parametric EQ provides Frequency, Gain

and Q control for each EQ band.

Section 6

EQ On/Off switch

This turns the Parametric EQ on and off.

Flat/Restore switch

These buttons either flatten all bands (Flat) or restore (Restore) all bands to their previous settings.

Type Bell and Shelf switch

Filter 1 and 9 are selectable between Bell and Shelf.

Filter Select switch

This allows selection of the Parametric EQ filter to be adjusted.

Filter On/Off switch

This turns the Selected (1-9) parametric EQ on and off.

Frequency (Fc) fader

This sets the frequency of the selected Parametric EQ and is adjustable between 20Hz to 20kHz.

Gain fader

This sets the amount of boost or cut of the selected Parametric EQ, and is adjustable between +/-15 dB.

Q fader

This sets the Q (or bandwidth) of the selected Parametric EQ and is adjustable between 0.13 to 16.0.

DriveRack® 4800/4820 User Manual

43

Page 54

Section 6

Detailed Parameters

6.5 - Input Delay

Each input channel of the DriveRack 4800 and 4820 provide up to 680 mSec of Input Delay.

DriveRack

®

Delay On/Off switch

This turns the input channel Delay module on and off.

Delay fader

This sets the amount of delay time and is adjustable in either 10 or 20 µSec steps (one sample at either 96

or 48 kHz). The Input Delay maximum is 680 mSec.

Units switch

This selects what the Delay is expressed in, Seconds, Feet or Meters. The GUI shows all three simultaneously.

44

DriveRack® 4800/4820 User Manual

Page 55

®

DriveRack

6.6 - Output Mixer

Each output DSP channel can be configured with either a Mixer or Router. The Output Mixer lets you

mix between signals coming from the input DSP channels. Master Gain and Muting of this Mixer is also

available.

Detailed Parameters

Section 6

Channels A-D

Provides gain control for each of the input channels (–inf to +20dB).

Master Gain fader

Provides Gain control for the Mixer module (–inf to +20dB).

Master Mute switch

Allows output muting of the Mixer module.

DriveRack® 4800/4820 User Manual

45

Page 56

Section 6

®

Detailed Parameters

6.7 - Output Router

The Output Router lets you select from any of the input channels, adjust the Master Gain and Mute the

output.

DriveRack

Selected Source Switch

Allows selection between the input channels (Channels A-D).

Master Gain fader

Provides Gain control for the Router module (–inf to +20dB).

Master Mute switch

Provides Mute control for the Router module.

46

DriveRack® 4800/4820 User Manual

Page 57

DriveRack

®

Detailed Parameters

Section 6

6.8 - Output Bandpass Filter/Crossover

The DriveRack 4800/4820 provides a Bandpass Filter on each output channel. These filters can be configured as Crossovers so you can adjust the frequency content of the adjacent output channels.

Band Select switch

This selects the specific band or channel to be adjusted.

Highpass (HiPass) fader

This adjusts the lowest frequency that the output channel will be able to achieve. The range of this control

is between “Out” to 20kHz, where “Out” denotes that the filter is not in the signal path and is not active.

Lowpass (LoPass) fader

This adjusts the highest frequency that the output channel will be able to achieve. The range of this control

is between 20 Hz and “Out”, where “Out” denotes that the filter is not in the signal path and is not active.

Gain fader

This sets the gain of the Crossover output and is adjustable between -Inf and 20dB.

Lowpass and Highpass Slope switch

This selects the desired slope and filter topology. It offers the following filter topologies and slopes: