Page 1

How to choose a

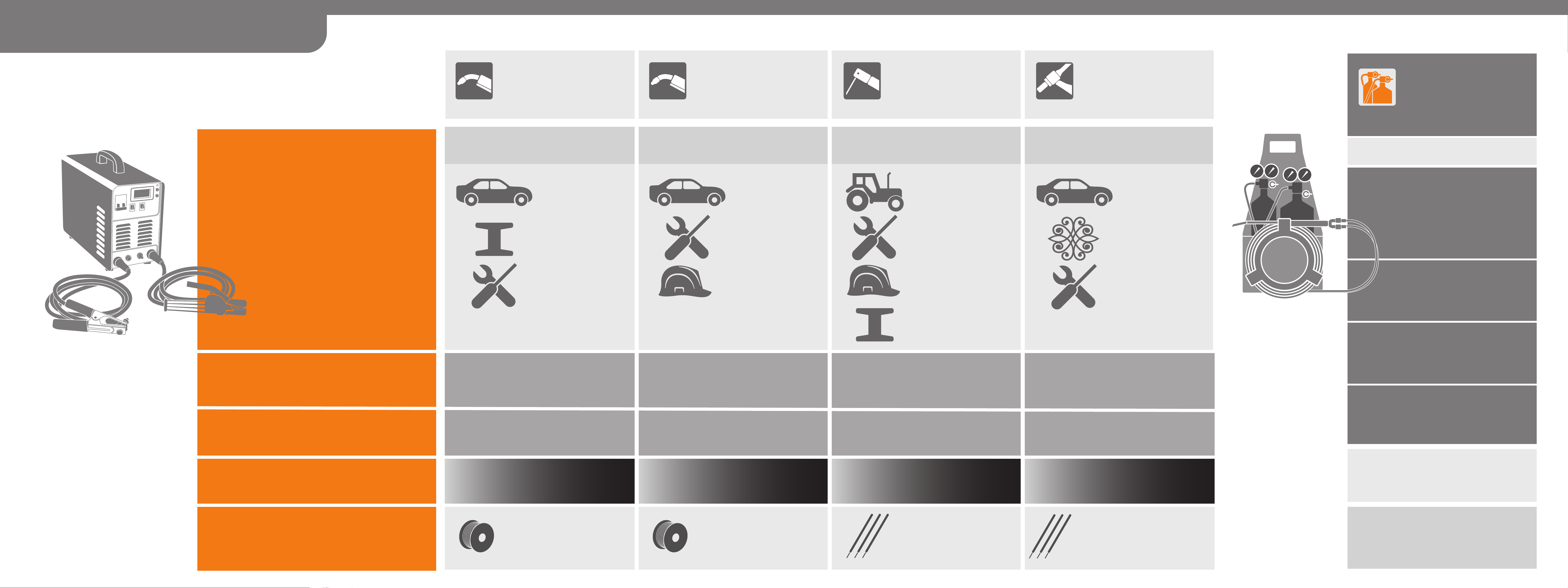

* Check your items and materials for exact requirements. The chart should be used as a general guide.

WELDER

Cómo elegir un soldador

WHERE are you welding?

1

• GAS for Indoors

• NO-GAS for Outdoors

FLUX

WELDING

SOLDADURA FLUX

NO GAS / OUTDOOR

SIN GAS PARA EXTERIORES

Vehicle

Repairs

MIG

WELDING

SOLDADURA MIG

GAS / INDOOR

GAS PARA INTERIORES

Vehicle

Repair

ARC

WELDING

SOLDADURA POR ARCO

NO GAS / OUTDOOR

SIN GAS PARA EXTERIORES

Farm, Ranch

Repairs

TIG

WELDING

SOLDADURA TIG

GAS / INDOOR

GAS PARA INTERIORES

Vehicle

Repair

GAS/

OXYGEN

ACETYLENE

WELDING

INDOOR • OUTDOOR

PARA INTERIORES • EXTERIORES

WELDING

¿DÓNDE está soldado?

• GAS para interiores

• SIN GAS para exteriores

Structural

Components

Maintenance

& Repair

Maintenance

& Repair

Construction

Maintenance

& Repair

Construction

Structural

Components

Metal

Artwork

Maintenance

& Repair

Steel

Cast Iron

BRAZING

IMPORTANT!

Identify your

VOLTAGE CAPABILITIES.

Are you using 120 Volt

or 240 Volt?

2

3

4

Identify the TYPE OF MATERIAL

you will be welding

Identique el TIPO DE MATERIAL que soldará

Identify the THICKNESS OF

MATERIAL you will be welding

Identique el GROSOR DEL MATERIAL que soldará

Thickness determines the AMPS

you will require

Stainless Steel

Steel

Thickness:

18 Gauge to 5/16"

Stainless Steel

Steel

Thickness:

22 Gauge to 5/16"

30-180 Amp

Stainless Steel

Cast Iron

Steel

Thickness:

1/16" & UP

10-225 Amp 10-165 Amp60-120 Amp

CUTTING

Stainless Steel

Copper • Titanium

Brass •Steel

HEATING

Thickness:

22 Gauge to 3/16"

NO ELECTRICITY

NEEDED

5

El grosor determina los AMPERIOS que requerirá

Type of WELDING MATERIAL

you will use

Tipo del MATERIAL DE SOLDAR usará

SOLID MIG WIREFLUX-CORED WIRE ELECTRODES

STICK AND TUNGSTEN

ELECTRODES

& FILLER MATERIALS

FILLER MATERIALS

Loading...

Loading...