Page 1

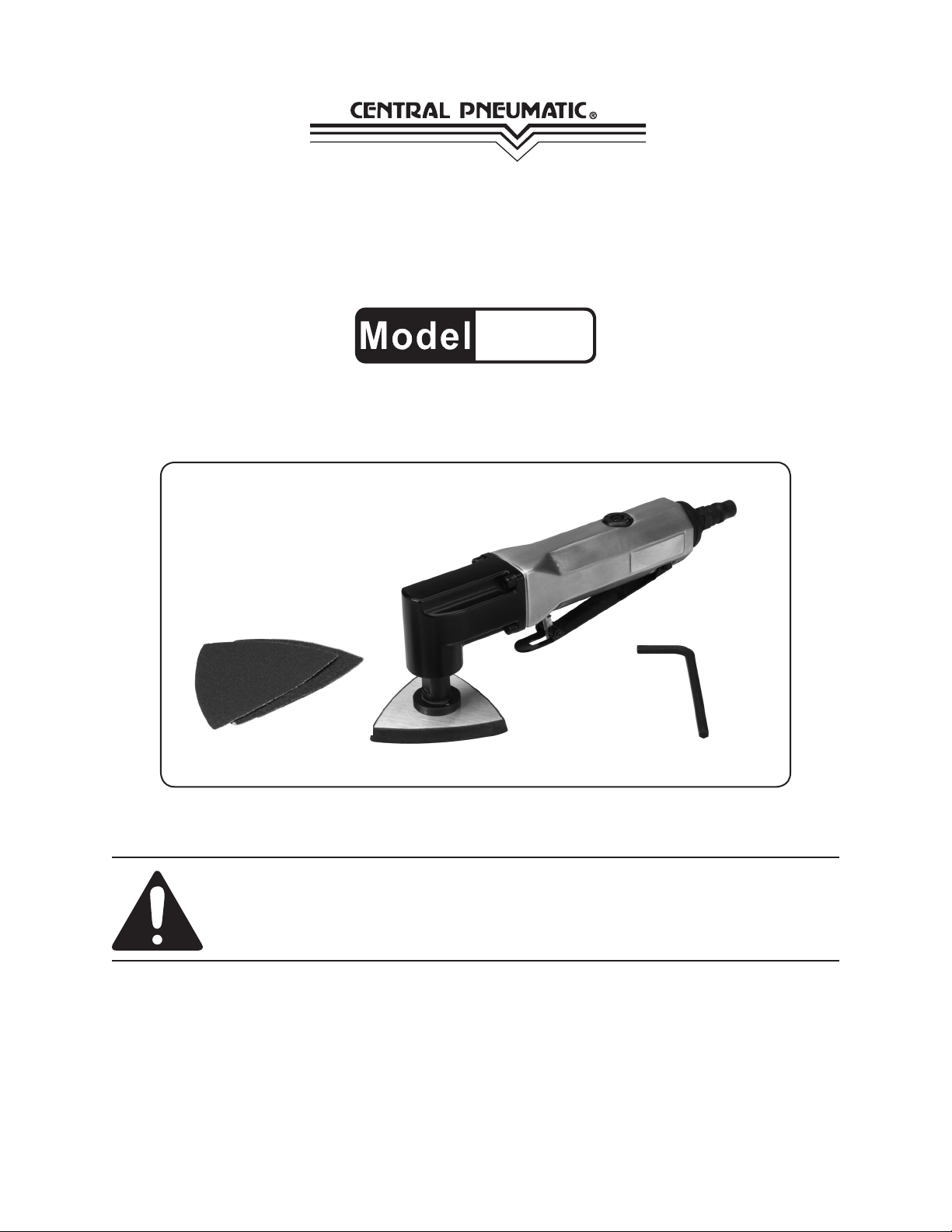

VARIABLE SPEED

MULTI FUNCTION AIR TOOL

67538

SET UP AND OPERATING INSTRUCTIONS

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2009 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of Harbor

Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing improvements,

actual product may differ slightly from the product described herein.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

SAVE THIS MANUAL

Keep this manual for the safety

warnings and precautions, assembly,

operating, inspection, maintenance and

cleaning procedures. Write the product’s

serial number in the back of the manual

near the assembly diagram (or month

and year of purchase if product has no

number). Keep this manual and the

receipt in a safe and dry place for future

reference.

IMPORTANT SAFETY

INFORMATION

In this manual, on the labeling,

and all other information

provided with this product:

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that

follow this symbol to avoid

possible injury or death.

DANGER indicates

a hazardous

situation which, if not

avoided, will result in death or

serious injury.

WARNING

indicates a

hazardous situation which, if

not avoided, could result in

death or serious injury.

CAUTION, used

with the safety

alert symbol, indicates a

hazardous situation which, if

not avoided, could result in

minor or moderate injury.

NOTICE is used to

address practices

not related to personal injury.

CAUTION, without

the safety alert

symbol, is used to address

practices not related to

personal injury.

IMPORTANT SAFETY

INSTRUCTIONS

INSTRUCTIONS PERTAINING

TO A RISK OF FIRE,

ELECTRIC SHOCK, OR

INJURY TO PERSONS

WARNING – When using tools, basic

precautions should always be

followed, including the following:

General

To reduce the risks of electric shock,

re, and injury to persons, read all the

instructions before using the tool.

Work area

Keep the work area clean and well a.

lighted. Cluttered benches and dark

areas increase the risks of electric

shock, re, and injury to persons.

Do not operate the tool in b.

explosive atmospheres, such as in

the presence of ammable liquids,

gases, or dust. The tool is able to

create sparks resulting in the ignition

of the dust or fumes.

Page 2For technical questions, please call 1-800-444-3353.SKU 67538

Page 3

Keep bystanders, children, and c.

visitors away while operating the

tool. Distractions are able to result in

the loss of control of the tool.

Personal safety

Stay alert. Watch what you are a.

doing and use common sense

when operating the tool. Do not

use the tool while tired or under

the inuence of drugs, alcohol, or

medication. A moment of inattention

while operating the tool increases the

risk of injury to persons.

Dress properly. Do not wear loose b.

clothing or jewelry. Contain long

hair. Keep hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long hair

increases the risk of injury to persons

as a result of being caught in moving

parts.

Avoid unintentional starting. c.

Be sure the switch is off before

connecting to the air supply. Do not

carry the tool with your nger on the

switch or connect the tool to the air

supply with the switch on.

Remove adjusting keys and d.

wrenches before turning the tool

on. A wrench or a key that is left

attached to a rotating part of the tool

increases the risk of personal injury.

Do not overreach. Keep proper e.

footing and balance at all times.

Proper footing and balance

enables better control of the tool in

unexpected situations.

f. Use safety equipment. A

dust mask, non-skid safety

shoes and a hard hat must

be used for the applicable conditions.

Wear heavy-duty work gloves during

use.

g. Always wear eye

protection. Wear ANSIapproved safety goggles.

h. Always wear hearing

protection when using

the tool. Prolonged

exposure to high intensity

noise is able to cause hearing loss.

Risk of Electric Shock. This tool i.

is not provided with an insulated

gripping surface. Contact with a

″live″ wire will also make exposed

metal parts of the tool ″live″ and

shock the operator.

Avoid body contact with grounded j.

surfaces such as pipes, radiators,

ranges and refrigerators. There is

an increased risk of electric shock if

your body is grounded.

Explore the workpiece to avoid k.

contact with hidden wiring.

Thoroughly investigate the workpiece

for possible hidden wiring before

performing work. Contact with live

wiring will shock the operator.

Tool use and care

Use clamps or another practical a.

way to secure and support the

workpiece to a stable platform.

Holding the work by hand or against

the body is unstable and is able to

lead to loss of control.

Do not force the tool.b. Use the

correct tool for the application. The

correct tool will do the job better and

Page 3For technical questions, please call 1-800-444-3353.SKU 67538

Page 4

safer at the rate for which the tool is

designed.

the specic tool model, increases the

risk of injury to persons.

Do not use the tool if the switch c.

does not turn the tool on or off.

Any tool that cannot be controlled

with the switch is dangerous and

must be repaired.

Disconnect the tool from the d.

air source before making

any adjustments, changing

accessories, or storing the tool.

Such preventive safety measures

reduce the risk of starting the tool

unintentionally. Turn off and detach

the air supply, safely discharge any

residual air pressure, and release the

throttle and/or turn the switch to its off

position before leaving the work area.

Store the tool when it is idle, e.

out of reach of children and

other untrained persons. A tool is

dangerous in the hands of untrained

users.

Maintain the tool with care. f. Keep

a cutting tool sharp and clean. A

properly maintained tool, with sharp

cutting edges reduces the risk of

binding and is easier to control.

Service

Tool service must be performed a.

only by qualied repair personnel.

When servicing a tool, use only b.

identical replacement parts. Use

only authorized parts.

Use only the lubricants supplied c.

with the tool or specied by the

manufacturer.

Air source

a. Never connect to an air

source that is capable of

exceeding 90 psi. Over

pressurizing the tool may

cause bursting, abnormal operation,

breakage of the tool or serious injury

to persons. Use only clean, dry,

regulated compressed air at the rated

pressure or within the rated pressure

range as marked on the tool. Always

verify prior to using the tool that the

air source has been adjusted to the

rated air pressure or within the rated

air-pressure range.

Check for misalignment or binding g.

of moving parts, breakage of

parts, and any other condition

that affects the tool’s operation.

If damaged, have the tool serviced

before using. Many accidents are

caused by poorly maintained tools.

There is a risk of bursting if the tool is

damaged.

Use only accessories that are h.

identied by the manufacturer for

the specic tool model. Use of an

accessory not intended for use with

Never use oxygen, carbon dioxide, b.

combustible gases or any bottled

gas as an air source for the tool.

Such gases are capable of explosion

and serious injury to persons

SAVE THESE

INSTRUCTIONS.

Page 4For technical questions, please call 1-800-444-3353.SKU 67538

Page 5

SYMBOLS AND

Specic Safety Instructions

SPECIFIC SAFETY

INSTRUCTIONS

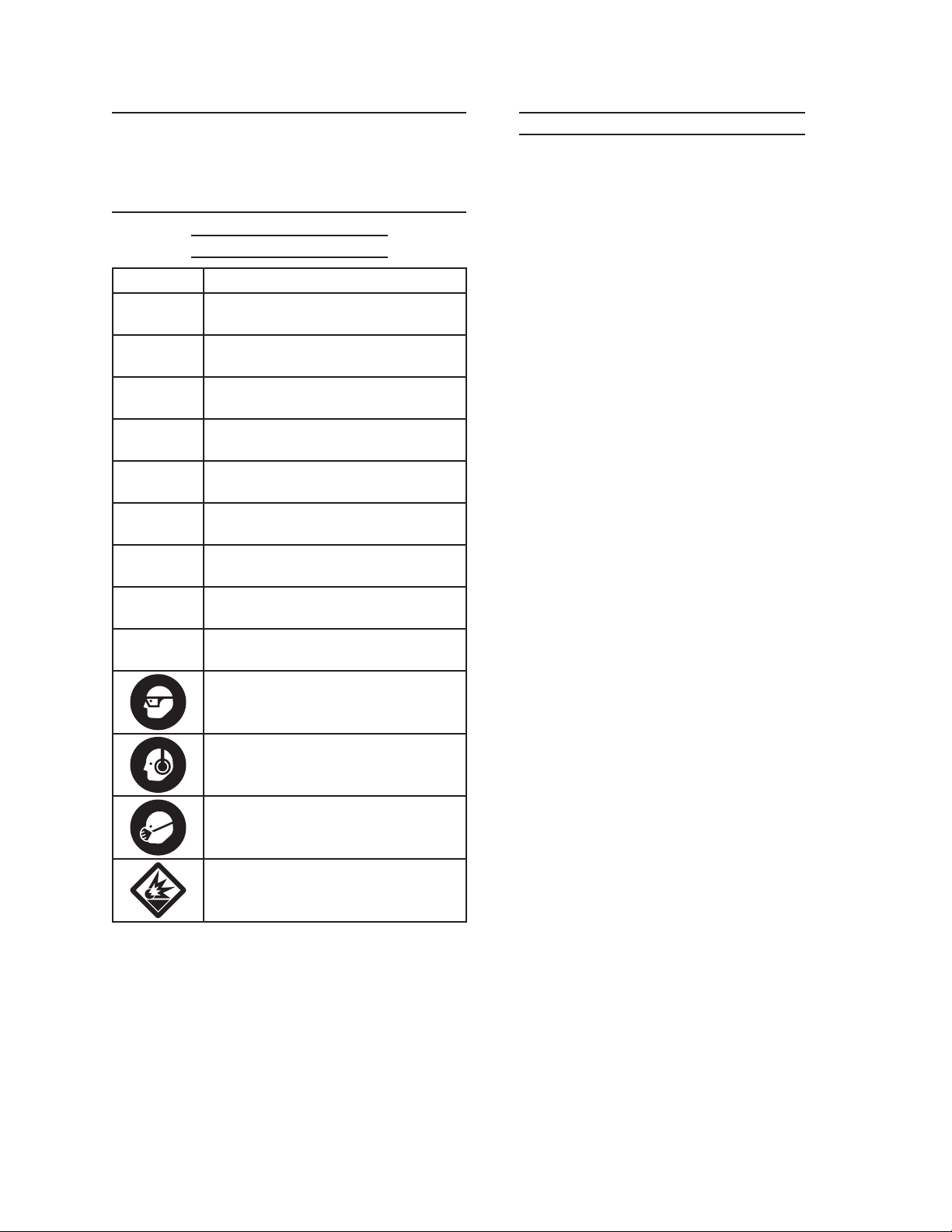

Symbol Denitions

Symbol Property or statement

n

.../min

PSI

ft-lb

BPM

CFM

SCFM

NPT

NPS

o

No-load speed

Revolutions or reciprocation per

minute

Pounds per square inch of pressure

Foot-pounds of torque

Blows per minute

Cubic Feet per Minute ow

Cubic Feet per Minute ow at

standard conditions

National pipe thread, tapered

National pipe thread, straight

WARNING marking concerning Risk

of Eye Injury. Wear ANSI-approved

eye protection.

WARNING marking concerning Risk

of Hearing Loss. Wear hearing

protection.

WARNING marking concerning Risk

of Respiratory Injury. Wear NIOSH-

approved dust mask/respirator.

WARNING marking concerning Risk

of Explosion.

The warnings and precautions 1.

discussed in this manual cannot

cover all possible conditions and

situations that may occur. It must

be understood by the operator that

common sense and caution are

factors which cannot be built into this

product, but must be supplied by the

operator.

WARNING: Some dust created by 2.

power sanding, sawing, grinding,

drilling, and other construction

activities, contains chemicals

known [to the State of California] to

cause cancer, birth defects or other

reproductive harm. Some examples

of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and

cement or other masonry products

• Arsenic and chromium from

chemically treated lumber

Your risk from these exposures

varies, depending on how often you

do this type of work. To reduce your

exposure to these chemicals: work in

a well ventilated area, and work with

approved safety equipment, such as

those dust masks that are specially

designed to lter out microscopic

particles. (California Health & Safety

Code § 25249.5, et seq.)

WARNING: The brass components

of this product contain lead, a

chemical known to the State of

California to cause birth defects (or

other reproductive harm). (California

Health & Safety code § 25249.5, et

seq.)

Only use with accessories rated to 3.

handle the forces exerted by this tool

during operation. Other accessories

Page 5For technical questions, please call 1-800-444-3353.SKU 67538

Page 6

not designed for the forces generated

may break and forcefully launch

pieces.

Avoid accidental injury. Keep hands 4.

and ngers safely away from the

oscillating Scraper, Blades, Sanding

Pad and Sandpaper when operating

the Tool.

Before each use make sure the 5.

Retainer (2) and Cap Screw (1) are

tightly secured for safe and efcient

operation.

Attach all accessories properly to the 6.

tool before connecting the air supply.

A loose accessory may detach or

break during operation.

Obey the manual for the air 7.

compressor used to power this tool.

Install an in-line shutoff valve to allow 8.

immediate control over the air supply

in an emergency, even if a hose is

ruptured.

Replace bent or damaged blades.9.

Use this tool with both hands only. 10.

Using tools with only one hand can

result in loss of control.

Do not lay the tool down until it has 11.

come to a complete stop. Moving

parts can grab the surface and pull

the tool out of your control.

the hands, arms and shoulders. To reduce

the risk of vibration-related injury:

Anyone using vibrating tools regularly 1.

or for an extended period should

rst be examined by a doctor and

then have regular medical checkups to ensure medical problems are

not being caused or worsened from

use. Pregnant women or people

who have impaired blood circulation

to the hand, past hand injuries,

nervous system disorders, diabetes,

or Raynaud’s Disease should not use

this tool. If you feel any symptoms

related to vibration (such as tingling,

numbness, and white or blue ngers),

seek medical advice as soon as

possible.

Do not smoke during use. Nicotine 2.

reduces the blood supply to the

hands and ngers, increasing the risk

of vibration-related injury.

Wear suitable gloves to reduce the 3.

vibration effects on the user.

Use tools with the lowest vibration 4.

when there is a choice.

Include vibration-free periods each 5.

day of work.

Grip tool as lightly as possible (while 6.

still keeping safe control of it). Let

the tool do the work.

This product is not a toy. Keep it out 12.

of reach of children.

Vibration Precautions

This tool vibrates during use.

Repeated or long-term exposure to

vibration may cause temporary or

permanent physical injury, particularly to

To reduce vibration, maintain tool as 7.

explained in this manual. If abnormal

vibration occurs, stop immediately.

SAVE THESE

INSTRUCTIONS.

Page 6For technical questions, please call 1-800-444-3353.SKU 67538

Page 7

SPECIFICATIONS

INITIAL TOOL SET UP/

Operating Air

Pressure

Air Inlet 1/4” -18 NPT

Maximum

Speed*

Average Air

Consumption

Blade

Attachment

Recommended

Air Hose

Accessories

Optional

Accessories

Sold Separately

* Maximum speed at stated maximum air pressure.

Excess air pressure is hazardous and may cause the

tool to exceed stated maximum speed.

90 PSI

17,000 OPM (Oscillations per

minute)

- 8 SCFM @ 90 PSI for

scraping and cutting

- 16 SCFM @ 90 PSI for

sanding

Circular Flange

Mounts in 7 different positions

at 30° increments

3/8”

3” Triangular Sanding Pad (45)

Sandpaper (46) two sheets

5 mm Hex Wrench (43)

- Diamond Cutter Blade

(SKU 67264)

- 3 Blade Set

1 Angled Cutter, 2 Scrapers

(SKU 67261)

- Half-Moon Cutter Blade

(SKU 67279)

- Sanding Sheets, pack of 6

2 ne, 2 medium, 2 course

(SKU 65985)

Uses

This multi-functional tool is suitable

for a variety of uses including

household remodeling and repair

jobs, automotive repairs, and

hobbies. Cut plastic material such

as cable and air ducts, downspouts,

plasterboard and pipes. Sand down

cement, concrete, stone, plaster, tile

adhesive, paint and wood. Saw up to

3-3/8” deep into wood.

ASSEMBLY

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

Note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

Unpacking

When unpacking, check to make sure

that the item is intact and undamaged. If

any parts are missing or broken, please

call Harbor Freight Tools at 1-800-4443353 as soon as possible.

This air tool may be shipped with a •

protective plug covering the air inlet.

Remove this plug before set up.

Air Supply

TO PREVENT

EXPLOSION:

Use only clean, dry, regulated,

compressed air to power this

tool. Do not use oxygen,

carbon dioxide, combustible

gases, or any other bottled

gas as a power source for this

tool.

Page 7For technical questions, please call 1-800-444-3353.SKU 67538

Page 8

Tool

Coupler

Plug

Quick

Coupler

Coupler

Plug

Air Hose

on Reel

OPERATION:

Do not install a female quick

coupler on the tool. Such a coupler

contains an air valve that will allow

the air tool to retain pressure and

operate accidentally after the air

supply is disconnected.

Valve FilterOiler

Air

Compressor

Quick

Coupler

Regulator with

Pressure Gauge

Recommended Air Line Components

Incorporate a lter, regulator with 1.

pressure gauge, oiler, in-line shutoff

valve, and quick coupler for best

service, as shown in the diagram

above. An in-line shutoff ball

valve is an important safety device

because it controls the air supply

even if the air hose is ruptured.

The shutoff valve should be a ball

valve because it can be closed

quickly.

Note: If an automatic oiler system is not

used, add a few drops of Pneumatic

Tool Oil to the airline connection

before operation. Add a few more

drops after each hour of continual

use.

Note: Air ow, and therefore tool

performance, can be hindered by

undersized air supply components.

The air hose must be long enough 3.

to reach the work area with enough

extra length to allow free movement

while working.

Turn the tool’s throttle or switch to the 4.

off position; refer to Operation section

for description of controls.

Close the in-line safety valve between 5.

the compressor and the tool.

Turn on the air compressor according 6.

to the manufacturer’s directions and

allow it to build up pressure until it

cycles off.

Adjust the air compressor’s output 7.

regulator so that the air output is

enough to properly power the tool,

but the output will not exceed the

tool’s maximum air pressure at any

time. Adjust the pressure gradually,

while checking the air output gauge

to set the right pressure range.

Attach an air hose to the 2.

compressor’s air outlet. Connect the

air hose to the air inlet of the tool.

Other components, such as a coupler

plug and quick coupler, will make

operation more efcient, but are not

required.

WARNING! TO PREVENT SERIOUS

INJURY FROM ACCIDENTAL

Inspect the air connections for leaks. 8.

Repair any leaks found.

If the tool will not be used at this 9.

time, turn off and detach the air

supply, safely discharge any

residual air pressure, and release

the throttle and/or turn the switch to

its off position to prevent accidental

operation.

Page 8For technical questions, please call 1-800-444-3353.SKU 67538

Page 9

Note: Residual air pressure should not be

present after the tool is disconnected

from the air supply. However, it is a

good safety measure to attempt to

discharge the tool in a safe fashion

after disconnecting to ensure that the

tool is unpowered.

Turn the tool off, detach the

air supply, safely discharge

any residual air pressure in

the tool, and release the

throttle and/or turn the switch

to its off position before

assembling or making any

adjustments to the tool.

INSTRUCTIONS FOR

PUTTING INTO USE

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

Inspect tool before use, looking

for damaged, loose or missing

parts. If any problems are

found, do not use tool until

repaired.

Components & Controls

Air Inlet

3” Triangular

Sanding Pad (45)

Trigger

Lever

(41)

Note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

Work Piece and Work Area Set Up

Designate a work area that is clean 1.

and well-lit. The work area must not

allow access by children or pets to

prevent distraction and injury.

Route the air hose along a safe 2.

path to reach the work area without

creating a tripping hazard or exposing

the power cord to possible damage.

The power cord must reach the work

area with enough extra length to

allow free movement while working.

There must not be hazardous 3.

objects, such as utility lines or foreign

objects, nearby that will present a

hazard while working.

Sandpaper (46)

Figure 1

TO PREVENT

FROM ACCIDENTAL

OPERATION:

Safety Catch (38)

Tool Set Up

SERIOUS INJURY

Hex

Wrench

(43)

You must use personal safety 4.

equipment including, but not limited

to, ANSI-approved eye and hearing

protection, as well as heavy work

gloves.

Before beginning work, provide for 5.

sparks and debris that will y off the

work surface.

Remove the Plug (28) from the Air 6.

Inlet and thread the Coupler Plug

(44) onto the tool, using three to four

Page 9For technical questions, please call 1-800-444-3353.SKU 67538

Page 10

wraps of thread sealing tape (sold

separately).

over the four pins on the Output

Shaft (3).

General Operating Instructions

If an automatic oiler is not used, 1. add

a few drops of Pneumatic Tool Oil

to the airline connection before use.

Add a few drops more after each

hour of continual use.

Accessory -

Angled Cutting

Blade

(sold separately

SKU 67261)

Pins

Pins

Output Shaft (3)

Note: When attaching the Angled

Cutting Blade Accessory, orient the

accessory as shown at left so the

Cap Screw (1) will be out of the way

when working.

Replace the Retainer and Cap c.

Screw while holding the blade. Hold

the Output Shaft with the wrench,

then tighten securely using the Hex

Wrench.

Note: For sanding, rst attach the Sanding

Pad to the tool, then align a sheet of

sand paper over the pad and press

into place.

Attach the air hose from the air d.

source. While holding the air

tool rmly in one hand and the

other safely out of the way of the

accessory, turn the air source on.

Output Shaft (3)

Accessory -

Angled Cutting

Blade

(sold separately

SKU 67261)

Cap Screw (1)

Figure 3

2. To install an accessory:

While the air hose is disconnected a.

from the tool, hold the Output Shaft

(3) with a 13mm wrench (sold

separately), and unthread the Cap

Screw (1) using the Hex Wrench

(43). Remove the Cap Screw and

Retainer (2).

Install the desired accessory in any b.

one of seven orientations by aligning

four of the holes in the accessory

To begin use, push the Safety Catch 3.

(38) forward while squeezing the

Trigger Lever (41). A stable twohanded grip on this tool is best.

Adjust pressure on the Trigger Lever 4.

to change the speed of the tool.

Retainer (2)

Address the material with a smooth 5.

steady stroke of the tool.

Note: Do not force the tool. Let the tool do

the work.

If the tool requires more force to 6.

accomplish the task, verify that the

tool receives sufcient, unobstructed

airow (CFM) and increase the

pressure (PSI) output of the regulator

up to the maximum air pressure

rating for this tool.

CAUTION! TO PREVENT TOOL

AND ACCESSORY FAILURE,

Page 10For technical questions, please call 1-800-444-3353.SKU 67538

Page 11

RESULTING IN INJURY:

Do not exceed the tool’s maximum

air pressure rating of 90 PSI.

If the tool still does not have sufcient

force at maximum pressure and

sufcient airow, then a larger tool

may be required.

USER-MAINTENANCE

INSTRUCTIONS

Procedures not specically

explained in this manual

must be performed only by a

qualied technician.

To prevent accidents, turn off the tool 7.

by releasing the Trigger Lever (41),

detaching the air supply, and safely

discharging any residual air pressure

in the tool after use. Clean external

surfaces of the tool with a clean, dry

cloth. Store the tool indoors out of

children’s reach.

Do not remove the Safety Catch. It 8.

has been included for your safety.

Without it, the tool could activate

when it is bumped against something,

set down on its Trigger Lever, or

picked up while accidently pressing

on the Trigger Lever, activating the

tool.

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL

OPERATION:

Turn off the tool, detach the

air supply, safely discharge

any residual air pressure in

the tool, and release the

throttle before performing any

inspection, maintenance, or

cleaning procedures.

TO PREVENT SERIOUS

INJURY FROM TOOL

FAILURE:

Do not use damaged

equipment. If abnormal

noise, vibration, or leaking

air occurs, have the problem

corrected before further use.

TO PREVENT EXPLOSION:

Lubricate the tool only

with specied lubricants.

Lubricate the air inlet using

only pneumatic tool oil. Other

lubricants may damage the

mechanism and may be

highly ammable, causing an

explosion.

Cleaning, Maintenance, and

Lubrication

Note: These procedures are in addition to

the regular checks and maintenance

explained as part of the regular

operation of the air-operated tool.

Page 11For technical questions, please call 1-800-444-3353.SKU 67538

Page 12

Changing Accessories: 1.

Remove the Cap Screw (1), Washer

(47) and Retainer (2) using the Hex

Wrench (43). The accessories can

be mounted in 7 different positions

at 30° increments. Mount the blades

facing forward. Replace Cap Screw,

Washer and Retainer.

CAUTION: The Blades are sharp. Use

care when handling the Blades.

Daily - Air Supply Maintenance: 2.

Every day, perform maintenance

on the air supply according to

the component manufacturers’

instructions. The lubricator’s oil

level needs to be maintained and

the moisture lter must be regularly

drained. Performing routine

maintenance on the air supply will

allow the tool to operate more safely

and will also reduce wear on the tool.

Before every use, add a few drops

of Air Tool Oil (sold separately, SKU

46080) to the Air Inlet (26).

Quarterly (every 3 months) - Tool 3.

Disassembly, Cleaning, and

Inspection:

Have the internal mechanism

cleaned, inspected, and lubricated by

a qualied technician.

Replace accessories when they 4.

become worn or damaged.

Page 12For technical questions, please call 1-800-444-3353.SKU 67538

Page 13

Troubleshooting

Problem Possible Causes Likely Solutions

Decreased output. Not enough air pressure and/1.

Housing heats

during use.

Severe air

leakage.

(Slight air leakage

is normal,

especially on older

tools.)

or air ow.

Obstructed Lever. 2.

Incorrect lubrication or not 3.

enough lubrication.

Dull or damaged accessory.4.

Blocked Air Inlet (27) screen.5.

Air leaking from loose housing. 6.

Mechanism contaminated. 7.

Incorrect lubrication or not 1.

enough lubrication.

Worn parts.2.

Cross-threaded housing 1.

components.

Loose housing. 2.

Damaged valve or housing.3.

Dirty, worn or damaged valve. 4.

Check for loose connections and make sure 1.

that air supply is providing enough air ow

(CFM) at required pressure (PSI) to the

tool’s air inlet. Do not exceed maximum air

pressure.

Clean around Lever to ensure free 2.

movement.

Lubricate using air tool oil according to 3.

directions.

Replace accessory.4.

Clean air inlet screen of buildup.5.

Make sure housing is properly assembled 6.

and tight.

Have qualied technician clean and lubricate 7.

mechanism. Install in-line lter in air supply

as stated in Initial Set Up: Air Supply.

Lubricate using air tool oil according to 1.

directions.

Have qualied technician inspect internal 2.

mechanism and replace parts as needed.

Check for incorrect alignment and uneven 1.

gaps. If cross-threaded, disassemble and

replace damaged parts before use.

Tighten housing assembly. If housing cannot 2.

tighten properly, internal parts may be

misaligned.

Replace damaged components.3.

Clean or replace valve assembly.4.

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect air supply before service.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/

OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 13For technical questions, please call 1-800-444-3353.SKU 67538

Page 14

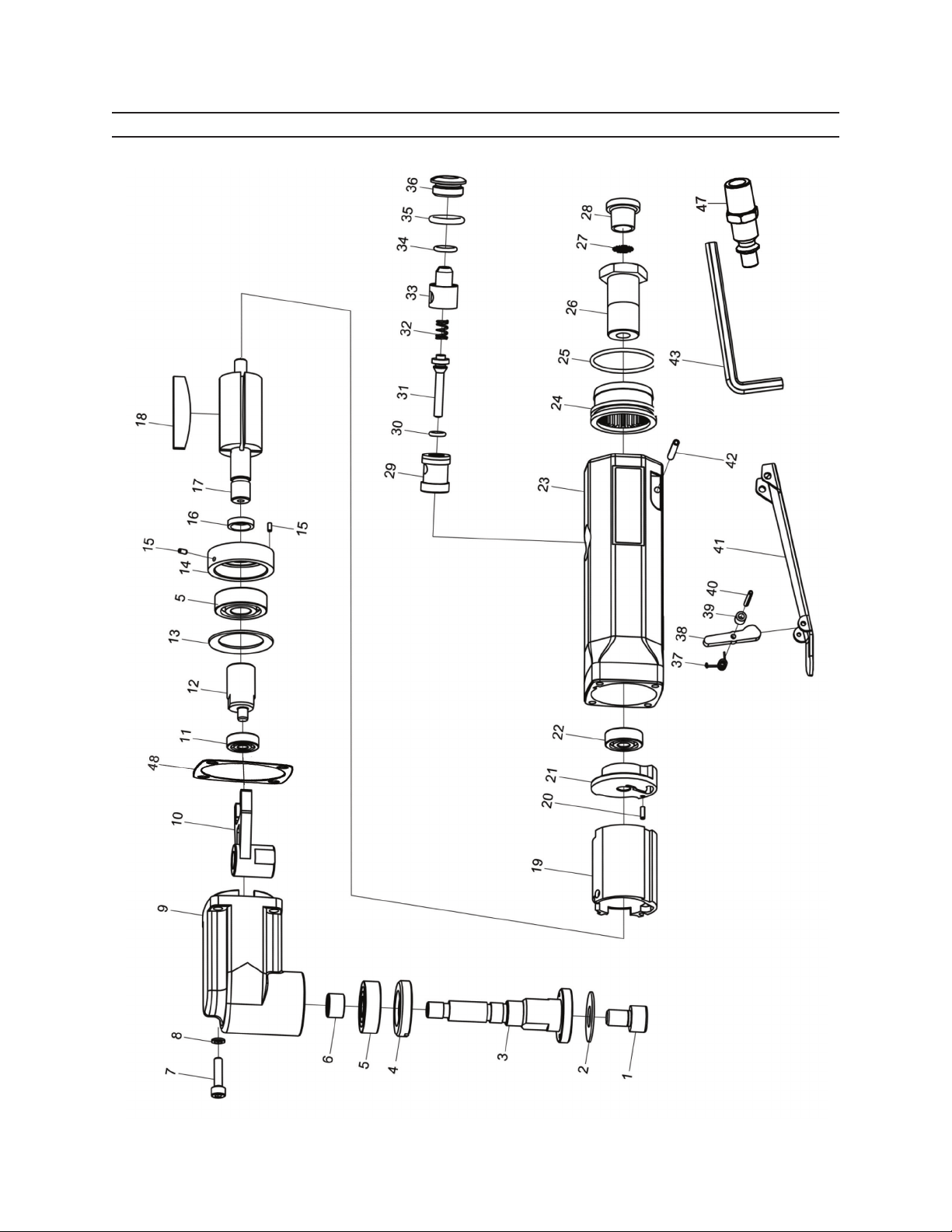

PARTS LIST & ASSEMBLY DIAGRAM

Part Description Qty

1 Cap Screw M8 x 1.25 x 12mm 1

2 Retainer 1

3 Output Shaft 1

4 Locking Knob 1

5 Bearing 2

6 Oil Bearing 1

7 Screw 4

8 Spring Washer 4

9 Head Casing 1

10 Oscillating Bar 1

11 Bearing 1

12 Adapter Sleeve 1

13 Disc Spring 1

14 Front-End Board 1

15 Pin 2

16 Check Ring 1

17 Rotor 1

18 Blade 4

19 Air Cylinder 1

20 Pin 1

21 Back 1

22 Bearing 1

23 Main Housing 1

24 Sound Proof Housing 1

Part Description Qty

25 O-Ring 1

26 Air Inlet 1

27 Filter Netting 1

28 Rubber Plug 1

29 Switch Valve Sleeve 1

30 O-Ring 1

31 Lock 1

32 Spring Washer 1

33 Speed Control Valve 1

34 O-Ring 1

35 O-Ring 1

36 Fixed Cap 1

37 Torsion Spring 1

38 Safety Catch 1

39 Stop Collar 1

40 Pin 1

41 Trigger Lever 1

42 Pin 1

43 Hex Wrench 1

44 Coupler Plug (not shown) 1

45 3” Triangular Sanding Pad 1

46 Sandpaper 2

47 Inlet Connector 1

48 Gasket 1

Page 14For technical questions, please call 1-800-444-3353.SKU 67538

Page 15

ASSEMBLY DIAGRAM

Page 15For technical questions, please call 1-800-444-3353.SKU 67538

Page 16

LIMITED 1 YEAR WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that this product is

free from defects in materials and workmanship for the period of one year from the date

of purchase (90 days if used by a professional contractor or if used as rental equipment).

This warranty does not apply to damage due directly or indirectly, to misuse, abuse,

negligence or accidents, repairs or alterations outside our facilities, normal wear and tear,

or to lack of maintenance. We shall in no event be liable for death, injuries to persons or

property, or for incidental, contingent, special or consequential damages arising from the

use of our product. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation of exclusion may not apply to you. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection veries the defect, we will either

repair or replace the product at our election or we may elect to refund the purchase price

if we cannot readily and quickly provide you with a replacement. We will return repaired

products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning

the product.

This warranty gives you specic legal rights and you may also have other rights which

vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

Page 16For technical questions, please call 1-800-444-3353.SKU 67538

Loading...

Loading...