Page 1

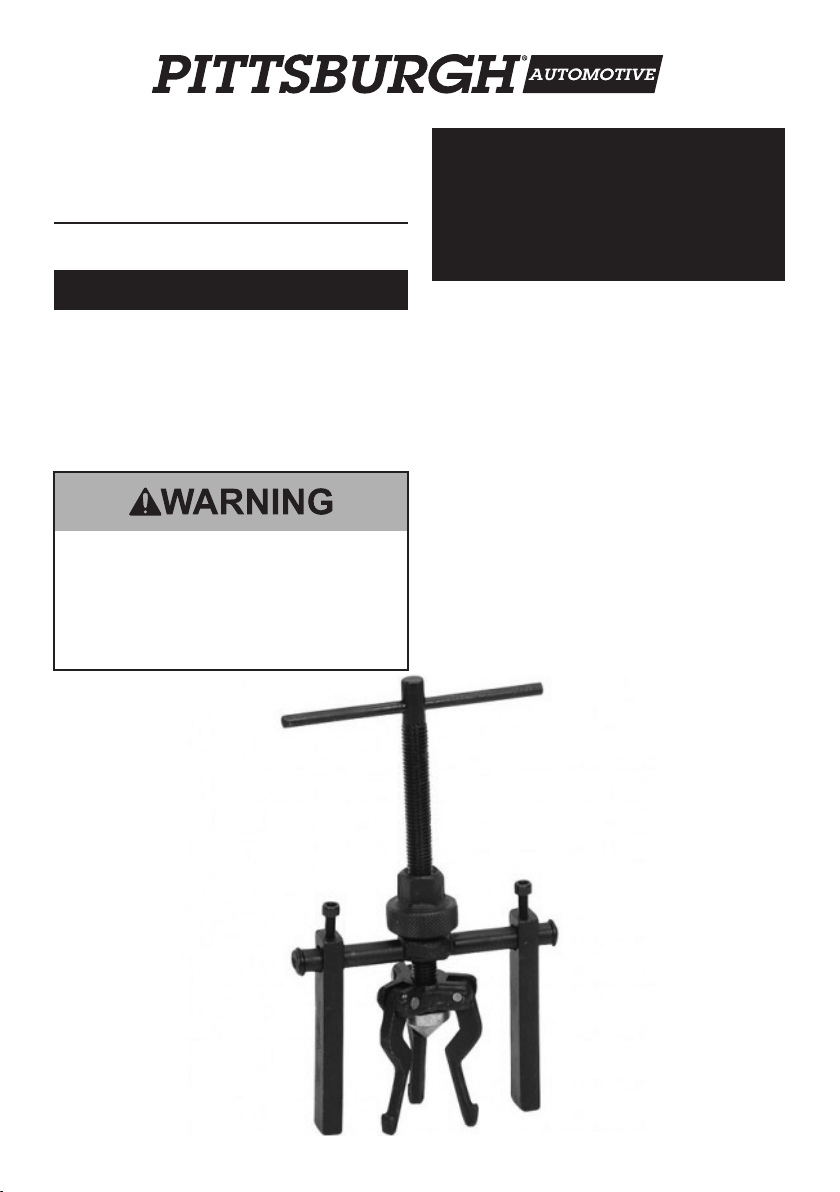

3-Jaw Pilot

Bearing Puller

04876 Bearing Puller

INSTRUCTIONS AND

PRECAUTIONS

Visit our website at:

http://www.harborfreight.com

Read this material before

using this product.

Failure to do so can result

in serious injury.

SAVE THIS MANUAL.

When unpacking, make sure

that the product is intact and

undamaged.

If any parts are missing or broken,

please call 1‑800‑444‑3353

as soon as possible.

Copyright© 1997 by Harbor Freight Tools®.

All rights reserved. No portion of this document

or any artwork contained herein may be

reproduced in any shape or form without the

express written consent of Harbor Freight

Tools. Diagrams within this document may

not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly

from the product described herein. Tools required

for assembly and service may not be included.

For technical questions or replacement

parts, please call 1-800-444-3353.

Manual Revised 11c

Page 2

Specications

Operating Instructions

Attachment

Type

Capability 3/4’ to 1‑1/2”

Material Carbon Steel

Threaded

Important Safety Information

1. Use only according to these

instructions. Improper assembly

and usage can create hazards.

2. Wear ANSI‑approved safety

goggles and heavy‑duty work

gloves during usage.

3. Keep area clean and well lit.

4. Keep children and other

bystanders out of the area.

5. Do not use when tired or when under

the inuence of drugs or medication.

6. Use as intended only.

7. Inspect before every use; do not

use if parts are loose or damaged.

8. Maintain product labels and

nameplates. These carry important

safety information. If unreadable or

missing, contact Harbor Freight Tools

for a replacement.

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of

this document including all

text under subheadings therein

before set up or use of

this product.

Insert Three-Pronged Jaws

1. Brace the Pilot Bearing Puller

directly over the Bearing Seat

using the Stand Legs (8), Stand

Crossbar (9) and Fixing Screws

(4). See photo on opposite page.

2. Insert the Three‑Pronged Jaws (7) into

the inner hole of the bearing case.

3. Turn the Yoke (5) by hand so that

the Tapered Tip (6) expands the jaws

outward until they are snug against the

bearing.

NOTE: Make sure the hooked tip

of each jaw is afxed underneath

the rim of the bearing case.

Extract the Bearing Case

1. Tighten the Extracting Nut (3)

until it is snug against the Stand

Crossbar. A crescent wrench (not

included) may be needed to further

tighten the Extracting Nut.

2. Turn the Handle (1) until the bearing

case is removed evenly from the

bearing seat.

Page 2For technical questions, please call 1-800-444-3353.SKU 04876

Page 3

Parts List and Diagram

Part Description Qty

1 Handle 1

2 Threaded Shaft 1

3 Extracting Nut 1

4 Fixing Screw 2

5 Yoke 1

6 Tapered Tip 1

7 Three‑Pronged Jaw 1

8 Stand Legs 2

9 Stand Crossbar 1

10 O‑Ring 1

Maintenance and Servicing

1. Before each use, inspect general

condition of tool. Check for

misalignment or binding of moving

parts, cracked or broken parts,

and any other condition that may

affect its safe operation. Do not

use damaged equipment.

2. After use, clean external

surfaces. Do not use solvents.

3. When storing, keep Pilot Bearing

Puller in a clean, dry, safe location

that is out of reach of children.

1

2

3

4

5

8

Record Serial Number Here:

Note: If product has no serial number, record

month and year of purchase instead.

PLEASE READ THE FOLLOWING CAREFULLY

NEITHER THE MANUFACTURER OR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY

OF ANY KIND TO THE BUYER THAT HE OR

SHE IS QUALIFIED TO MAKE ANY REPAIRS

TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE

PRODUCT. IN FACT, THE MANUFACTURER AND/

OR DISTRIBUTOR EXPRESSLY STATES THAT ALL

REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED

TECHNICIANS, AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING

OUT OF HIS OR HER REPAIRS TO THE ORIGINAL

PRODUCT OR REPLACEMENT PARTS THERETO,

OR ARISING OUT OF HIS OR HER INSTALLATION

OF REPLACEMENT PARTS THERETO.

9

10

7

6

Page 3For technical questions, please call 1-800-444-3353.SKU 04876

Page 4

LIMITED 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet

high quality and durability standards, and warrants to the original purchaser that this

product is free from defects in materials and workmanship for the period of 90 days

from the date of purchase. This warranty does not apply to damage due directly or

indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside

our facilities, criminal activity, improper installation, normal wear and tear, or to lack of

maintenance. We shall in no event be liable for death, injuries to persons or property,

or for incidental, contingent, special or consequential damages arising from the use

of our product. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation of exclusion may not apply to you. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to

us with transportation charges prepaid. Proof of purchase date and an explanation

of the complaint must accompany the merchandise. If our inspection veries

the defect, we will either repair or replace the product at our election or we may

elect to refund the purchase price if we cannot readily and quickly provide you

with a replacement. We will return repaired products at our expense, but if we

determine there is no defect, or that the defect resulted from causes not within the

scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state. also have other rights which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Page 4For technical questions, please call 1-800-444-3353.SKU 04876

Loading...

Loading...