Harbor Freight Tools Gas Engine Clear Water Pump 37 GPM Product manual

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference.

ITEM 69747

79cc GASOLINE POWERED

1" CLEAR WATER PUMP

REV 15a

Using an engine indoors

CAN KILL YOU IN MINUTES.

Engine exhaust contains carbon monoxide.

This is a poison you cannot see or smell.

NEVER use inside

a home or garage,

EVEN IF doors and

windows are open.

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

Copyright© 2012 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

Only use OUTSIDE

and far away from

windows, doors,

and vents.

Visit our website at: http://www.harborfreight.com

Email our technical support at: productsupport@harborfreight.com

or engine technical support at: predator@harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Table of Contents

Specifications ............................................. 2

Safety ......................................................... 3

Setup .......................................................... 6

Operation ................................................... 10

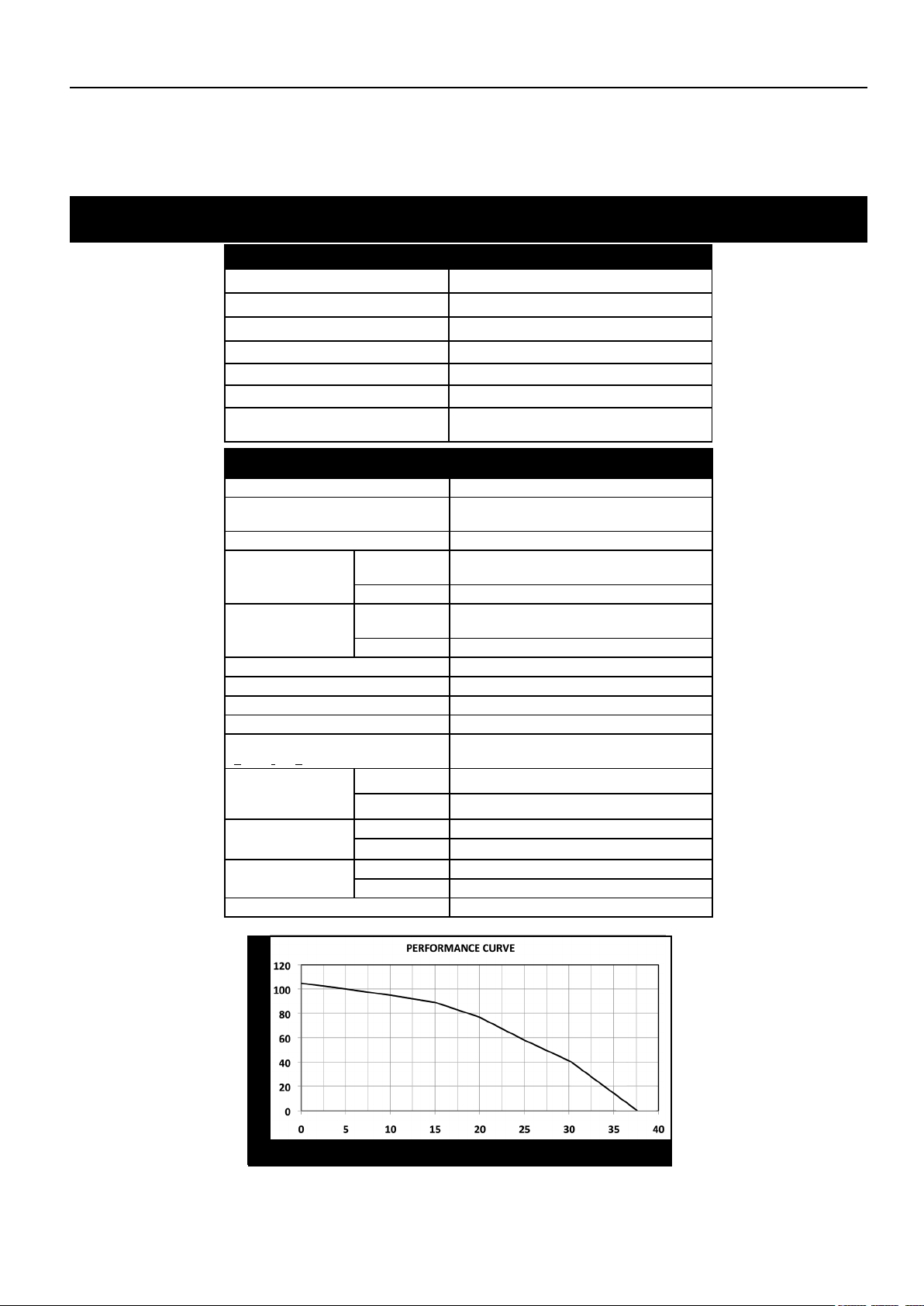

Specifications

Pump

Suction & Discharge Size 1" NPT

Discharge Capacity 37 GPM

Maximum Discharge Head 105 ft.

Maximum Suction Head 26 ft.

Maximum Pressure 45.5 PSI

Mechanical Seal Ceramic

Included Accessories

Engine

Displacement 79cc

Engine Type

Cooling System Forced air cooled

Fuel

Engine Oil

Run Time @ 50% Load with full tank 3 hr.

Sound Level at 22 feet 98 dB

Bore x Stroke 52 mm x 37 mm

Compression Ratio 5.6:1

Rotation viewed from PTO

(power takeoff - the output shaft)

Shaft

Spark Plug

Valve Clearance

No Load Speed 3,800 RPM±100RPM

Type

Capacity 0.4 Gallons / 1.4 Liters

Type SAE

Capacity 0.3 Quarts / 0.3 Liters

Shaft 15mm x 31mm

End Tapped M10 x 1.25-6h outside thread

Type Torch® E5TC

Gap 0.7 - 0.8 mm

Intake 0.10 - 0.20 mm

Exhaust 0.15 - 0.25 mm

Maintenance .............................................. 14

Troubleshooting ......................................... 18

Warranties ................................................. 23

Parts Lists and Diagrams .......................... 20

Intake Strainer, Hose Clamps,

Spark Plug Wrench

Horizontal Single Cylinder 4 stroke OHV

EPA phase III compliant

87+ octane stabilizer-treated

unleaded gasoline

10W-30 above 32° F

5W30 at 32° F or below

Counterclockwise

Discharge Head (ft.)

Flow (Gallons/minute)

Page 2 For technical questions, please call 1-888-866-5797. ITEM 69747

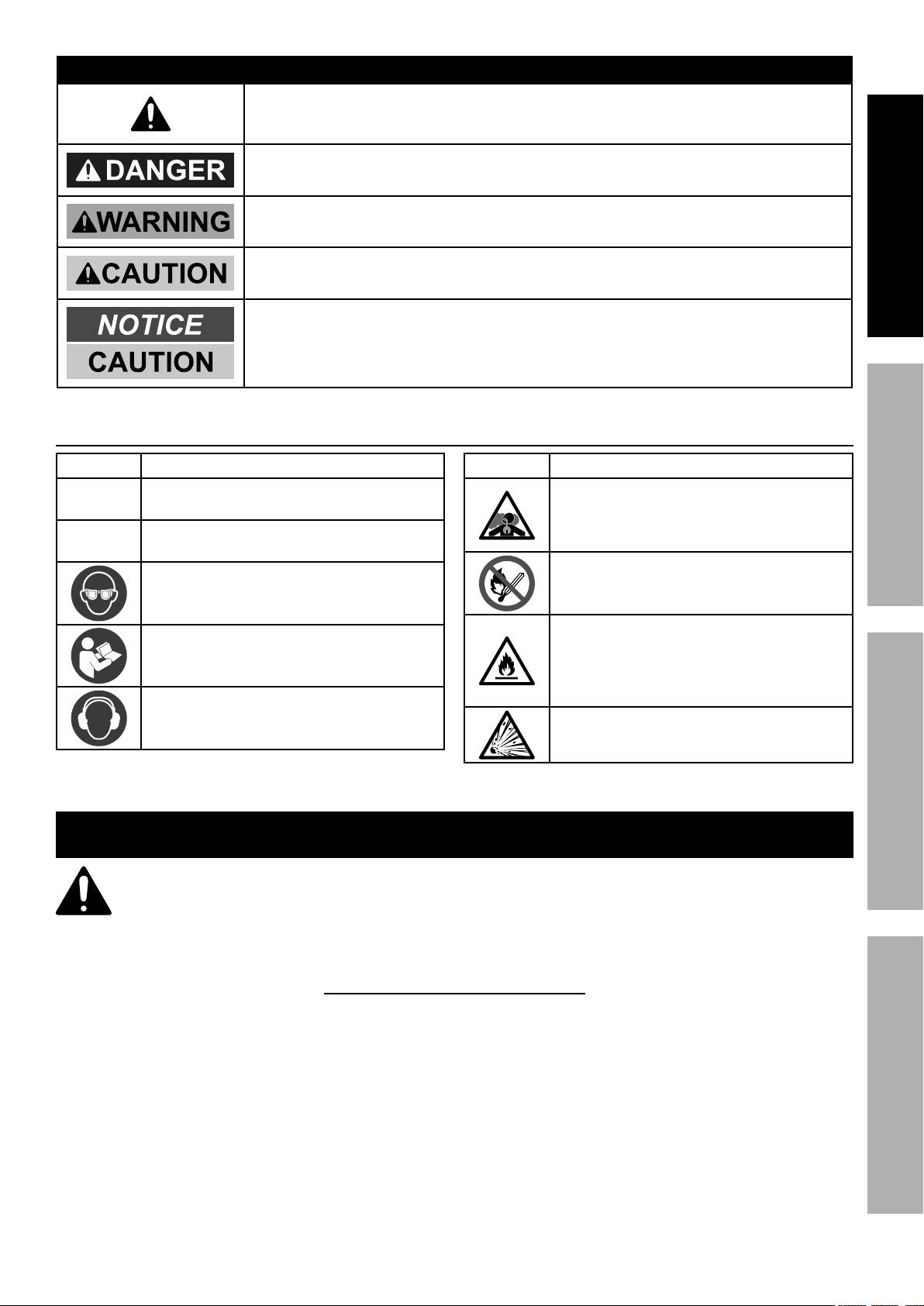

Symbol Definitions

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

SAFETYOPERATIONMAINTENANCE SETUP

Symbol Property or Statement

RPM

HP

Revolutions Per Minute

Horsepower

WARNING marking concerning

Risk of Eye Injury. Wear ANSI-approved

safety goggles with side shields.

Read the manual before

set-up and/or use.

WARNING marking concerning

Risk of Hearing Loss.

Wear hearing protection.

Safety Warnings

WARNING! Read all instructions.

Failure to follow all instructions may result in fire, serious injury and/or DEATH.

The warnings and precautions discussed in this manual cannot cover all possible conditions and

situations that may occur. It must be understood by the operator that common sense and caution

are factors which cannot be built into this product, but must be supplied by the operator.

Symbol Property or Statement

WARNING marking concerning

Risk of Respiratory Injury.

Operate engine OUTSIDE and far away

from windows, doors, and vents.

WARNING marking concerning

Risk of Fire while handling fuel.

Do not smoke while handling fuel.

WARNING marking concerning

Risk of Fire.

Do not refuel while operating.

Keep flammable objects

away from engine.

WARNING marking concerning

Risk of Explosion.

SAVE THESE INSTRUCTIONS

Page 3For technical questions, please call 1-888-866-5797.ITEM 69747

Set Up Precautions

1. Gasoline fuel and fumes are flammable, and

potentially explosive. Use proper fuel storage

and handling procedures. Do not store fuel

SAFETY OPERATION MAINTENANCESETUP

or other flammable materials nearby.

2. Have multiple ABC class fire extinguishers nearby.

3. Operation of this equipment may create sparks

that can start fires around dry vegetation. A spark

arrestor may be required. The operator should

contact local fire agencies for laws or regulations

relating to fire prevention requirements.

Operating Precautions

1. CARBON MONOXIDE HAZARD

Using an engine indoors CAN KILL

YOU IN MINUTES.

Engine exhaust contains carbon

monoxide. This is a poison you cannot see or smell.

NEVER use inside a home or garage,

EVEN IF doors and windows are open.

Only use OUTSIDE and far away from windows,

doors, and vents.

2. Keep children away from the equipment,

especially while it is operating.

3. Keep all spectators at least six feet

from the Engine during operation.

4. Fire Hazard! Do not fill gas tank while engine is

running. Do not operate if gasoline has been spilled.

Clean spilled gasoline before starting engine.

Do not operate near pilot light or open flame.

5. Do not touch engine during use.

Let engine cool down after use.

6. Never store fuel or other flammable

materials near the engine.

7. Only use a suitable means of transport and

lifting devices with sufficient weight bearing

capacity when transporting the Engine.

8. Secure the Engine on transport vehicles to

prevent the tool from rolling, slipping, and tilting.

9. Industrial applications must follow

OSHA requirements.

4. Set up and use only on a flat, level,

well-ventilated surface.

5. Wear ANSI-approved safety goggles, heavy-duty

work gloves, and dust mask/respirator during set up.

6. Use only lubricants and fuel recommended

in the Specifications chart of this manual.

10. Do not leave the equipment unattended when it is

running. Turn off the equipment (and remove safety

keys, if available) before leaving the work area.

11. Engine can produce high noise levels.

Prolonged exposure to noise levels

above 85 dBA is hazardous to hearing.

Always wear ear protection when operating or

working around the gas engine while it is operating.

12. Wear ANSI-approved safety glasses, hearing

protection, and NIOSH-approved dust mask/

respirator under a full face shield along

with steel-toed work boots during use.

13. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields in

close proximity to a heart pacemaker could cause

pacemaker interference or pacemaker failure.

Caution is necessary when near the

engine’s magneto or recoil starter.

14. Use only accessories that are recommended

by Harbor Freight Tools for your model.

Accessories that may be suitable for one

piece of equipment may become hazardous

when used on another piece of equipment.

15. Do not operate in explosive atmospheres,

such as in the presence of flammable

liquids, gases, or dust. Gasoline-powered

engines may ignite the dust or fumes.

16. Stay alert, watch what you are doing and

use common sense when operating this

piece of equipment. Do not use this piece

of equipment while tired or under the

influence of drugs, alcohol or medication.

17. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the equipment in unexpected situations.

18. Dress properly. Do not wear loose clothing or

jewelry. Keep hair, clothing and gloves away

from moving parts. Loose clothes, jewelry or

long hair can be caught in moving parts.

19. Parts, especially exhaust system components,

get very hot during use. Stay clear of hot parts.

Page 4 For technical questions, please call 1-888-866-5797. ITEM 69747

Operating Precautions (cont.)

20. Do not cover the engine or

equipment during operation.

21. Keep the equipment, engine, and

surrounding area clean at all times.

22. Use the equipment, accessories, etc., in

accordance with these instructions and in the

manner intended for the particular type of

equipment, taking into account the working

conditions and the work to be performed. Use of

the equipment for operations different from those

intended could result in a hazardous situation.

23. Do not operate the equipment with known

leaks in the engine’s fuel system.

24. This product contains or, when used, produces a

chemical known to the State of California to cause

cancer and birth defects or other reproductive harm.

(California Health & Safety Code § 25249.5, et seq.)

Service Precautions

1. Before service, maintenance, or cleaning:

a. Turn the engine switch to its “OFF” position.

b. Allow the engine to completely cool.

c. Then, remove the spark plug

cap from the spark plug.

2. Keep all safety guards in place and in

proper working order. Safety guards include

muffler, air cleaner, mechanical guards,

and heat shields, among other guards.

3. Do not alter or adjust any part of the

equipment or its engine that is sealed by the

manufacturer or distributor. Only a qualified

service technician may adjust parts that may

increase or decrease governed engine speed.

4. Wear ANSI-approved safety goggles,

heavy-duty work gloves, and dust

mask/respirator during service.

5. Maintain labels and nameplates on the equipment.

These carry important information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

25. When spills of fuel or oil occur, they must be

cleaned up immediately. Dispose of fluids and

cleaning materials as per any local, state, or

federal codes and regulations. Store oil rags in

a bottom-ventilated, covered, metal container.

26. Keep hands and feet away from moving parts. Do

not reach over or across equipment while operating.

27. Before use, check for misalignment or binding of

moving parts, breakage of parts, and any other

condition that may affect the equipment’s operation.

If damaged, have the equipment serviced

before using. Many accidents are caused

by poorly maintained equipment.

28. Use the correct equipment for the application.

Do not modify the equipment and do not use the

equipment for a purpose for which it is not intended.

6. Have the equipment serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the equipment

is maintained. Do not attempt any service or

maintenance procedures not explained in this

manual or any procedures that you are uncertain

about your ability to perform safely or correctly.

7. Store equipment out of the reach of children.

8. Follow scheduled engine and

equipment maintenance.

Refueling:

1. Do not smoke, or allow sparks, flames,

or other sources of ignition around the

equipment, especially when refuelling.

2. Do not refill the fuel tank while the

engine is running or hot.

3. Do not fill fuel tank to the top. Leave a little

room for the fuel to expand as needed.

4. Refuel in a well-ventilated area only.

5. Wipe up any spilled fuel and allow excess

to evaporate before starting engine.

To prevent FIRE, do not start the engine

while the smell of fuel hangs in the air.

SAFETYOPERATIONMAINTENANCE SETUP

SAVE THESE INSTRUCTIONS.

Page 5For technical questions, please call 1-888-866-5797.ITEM 69747

Setup

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual

including all text under subheadings therein before set up or use of this product.

SAFETY OPERATION MAINTENANCESETUP

TO PREVENT SERIOUS INJURY:

Operate only with proper spark arrestor installed.

Operation of this equipment may create sparks that can start fires around dry vegetation.

A spark arrestor may be required. The operator should contact local fire agencies

for laws or regulations relating to fire prevention requirements.

High Altitude Operation Above 3000 feet

WARNING! To prevent serious injury from fire:

Follow instructions in a well-ventilated area away from ignition sources.

If the engine is hot from use, shut the engine off and wait for it to cool before proceeding. Do not smoke.

NOTICE: Warranty void if necessary adjustments are not made for high altitude use.

At high altitudes, the engine’s carburetor, governor (if so equipped), and any other parts that control the fuel-air

ratio will need to be adjusted by a qualified mechanic to allow efficient high-altitude use and to prevent damage

to the engine and any other devices used with this product. The fuel system on this engine may be influenced by

operation at higher altitudes. Proper operation can be ensured by installing an altitude kit at altitudes higher than

3000 ft. above sea level. At elevations above 8000 ft, the engine may experience decreased performance, even

with the proper main jet. Operating this engine without the proper altitude kit installed may increase the engine’s

emissions and decrease fuel economy and performance. The kit should be installed by a qualified mechanic.

1. Turn off the engine.

2. Close the fuel valve.

3. Place a bowl under the fuel cup to catch any spilled fuel.

CAUTION! Carburetor bowl may have gas in it which will leak upon removing the bolt.

4. Unthread the bolt holding the fuel cup.

5. Remove the bolt, Bolt Seal, fuel cup, Fuel Cup Seal and Main Jet from the body of the carburetor assembly.

A carburetor screwdriver (not included) is needed to remove and install the Main Jet.

Note: The mixing tube is held in place by the Main Jet and might fall out when it is removed. If it falls out,

replace it in the same orientation before replacing the Main Jet.

6. Replace the Main Jet with the replacement Main Jet

needed for your altitude range (part 1a or 2a).

Note: The Fuel Cup Seal and Bolt Seal may be damaged during

removal and should be replaced with the new ones from the kit.

7. Replace the Fuel Cup Seal (4a), fuel cup,

Bolt Seal (3a), and bolt. Tighten in place.

CAUTION: Do not cross thread bolt when tightening.

Finger tighten first and then use a wrench to

make sure the bolt is properly threaded.

8. Wipe up any spilled fuel and allow excess to evaporate

before starting engine. To prevent FIRE, do not start the

engine while the smell of fuel hangs in the air.

Carburetor

Assembly

Fuel Cup Seal

Mixing Tube

(might remain

inside carburetor)

Main Jet

Fuel Cup

High Altitude Kit Parts List - A

Bolt Seal

Part Description Qty

1a Main Jet 3000-6000 ft. 1

2a Main Jet 6000-8000 ft. 1

3a Bolt Seal 1

4a Fuel Cup Seal 1

Page 6 For technical questions, please call 1-888-866-5797. ITEM 69747

Bolt

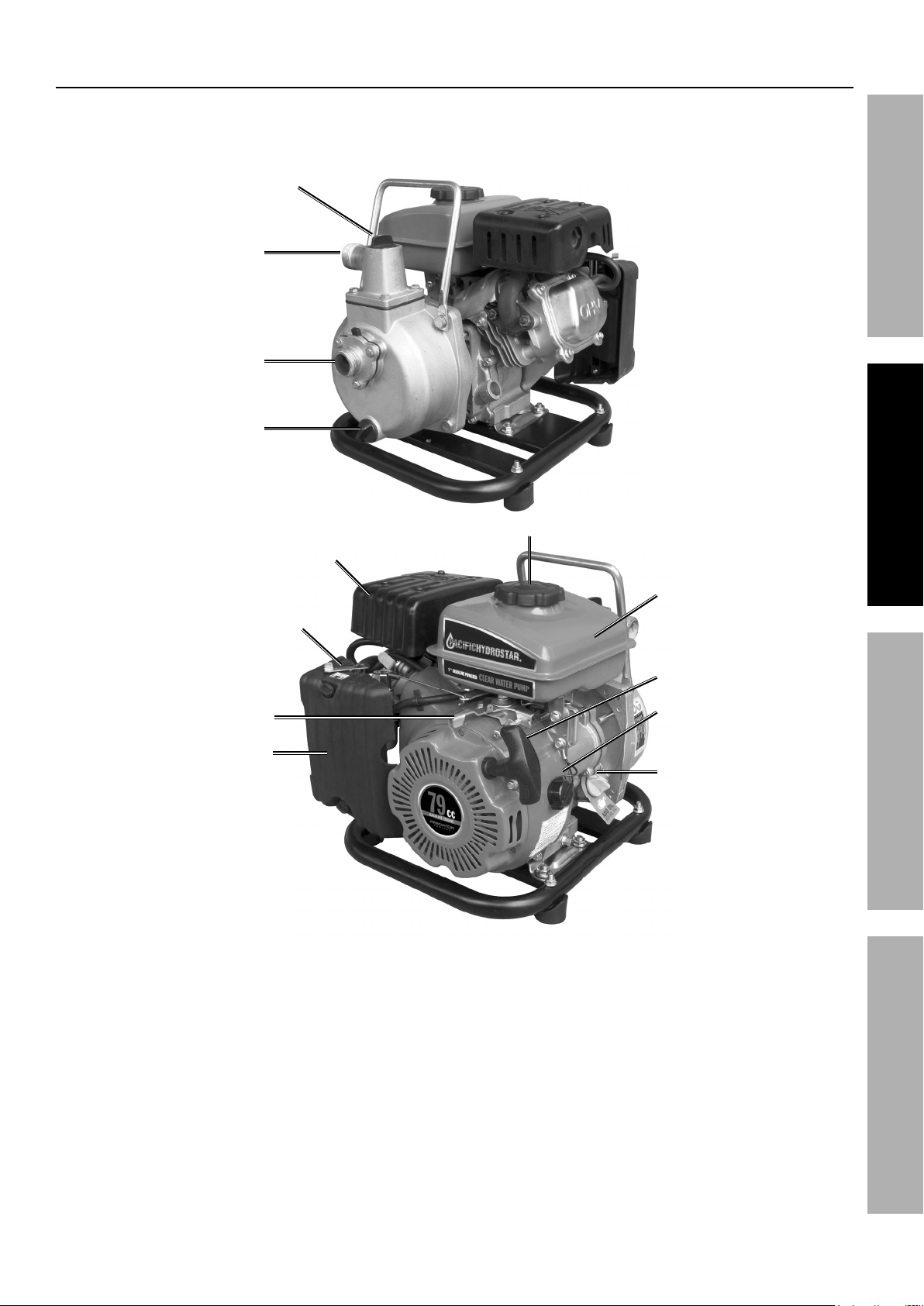

Controls

Priming

Cap

Discharge Port

Intake

Port

Water Drain

Plug

SAFETYOPERATIONMAINTENANCE SETUP

Fuel Tank Cap

Muffler

Fuel Tank

Choke

Starter Handle

Throttle

Air Filter

Engine Switch

Oil Dipstick

Page 7For technical questions, please call 1-888-866-5797.ITEM 69747

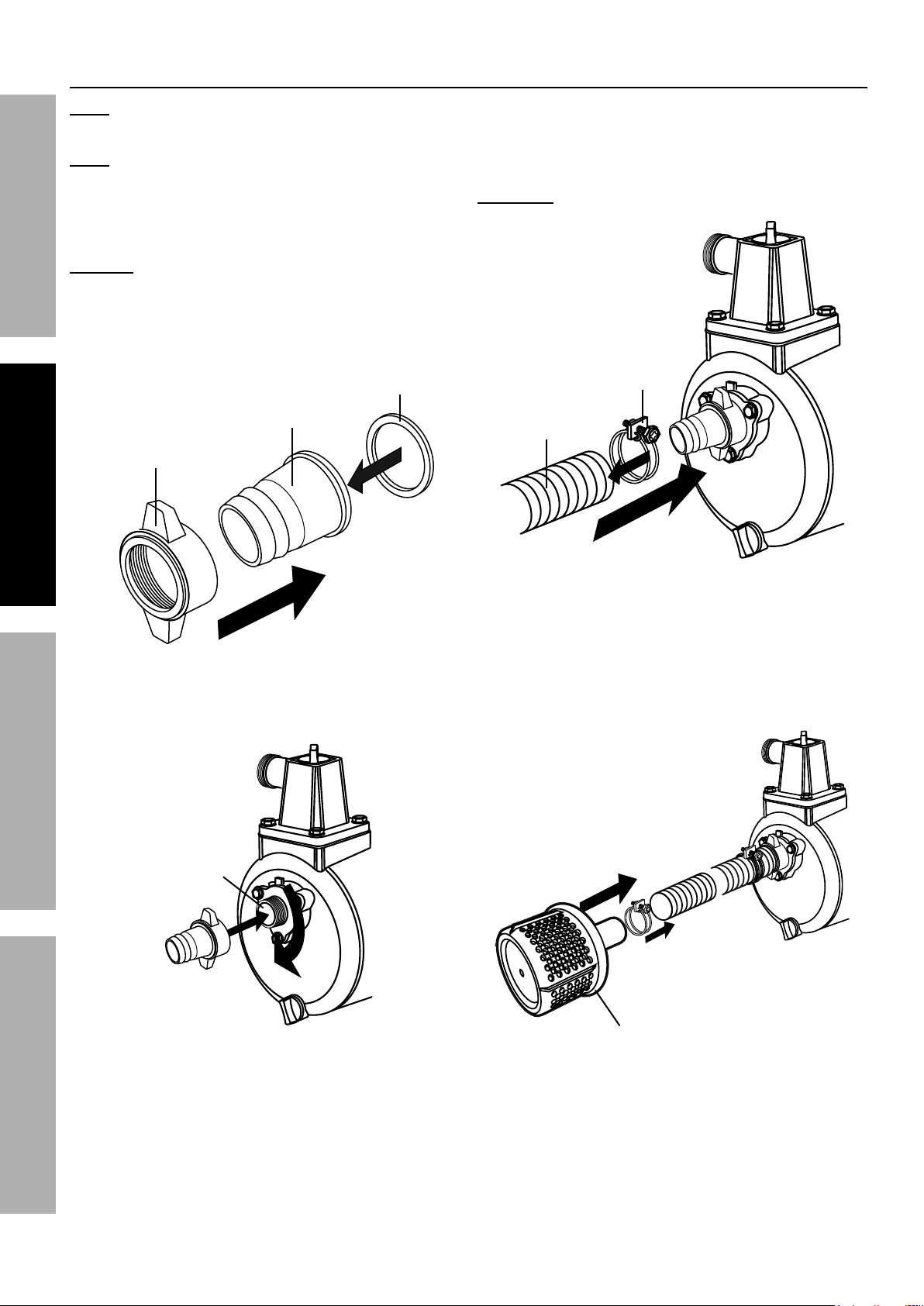

Connecting Hoses

Note: Hose coupling components

and hoses not included.

Note: The Suction Hose (not included)

SAFETY OPERATION MAINTENANCESETUP

MUST be reinforced with braided material or

have non-collapsible construction. Do not use

a hose with an inside diameter smaller than 1"

(pump’s intake and discharge port diameters).

NOTICE: Do not over-tighten Hose Clamps as the

clamp may damage the hose or other components.

1. Slide one of the Hose Coupling Rings over

one of the Hose Couplers (a), then place a

Gasket on the end of the Hose Coupler (b).

Hose Coupler

Hose Coupling Ring

Gasket

b

3. Slide one of the Hose Clamps over the end of the

suction hose (a). Slide the Hose onto the Hose

Coupler (b). Use a screwdriver (not included)

to tighten the Hose Clamp until secure.

CAUTION: Use only a non-collapsible intake hose.

Hose Clamp

Suction Hose

a

b

a

2.

Thread the Hose Coupling Ring onto

the Intake Port (a), and turn clockwise

until fastened securely (b).

Intake Port

a

4. Slide the threaded Hose Coupler onto the Intake

Strainer and thread it securely in place, turning

clockwise (a and b). Slide a Hose Clamp over

the end of the suction hose (c). Slide the Intake

Strainer into the end of the suction hose (d). Use a

screwdriver to tighten the Hose Clamp until secure.

b

b

Intake Strainer

a

Page 8 For technical questions, please call 1-888-866-5797. ITEM 69747

Loading...

Loading...