Page 1

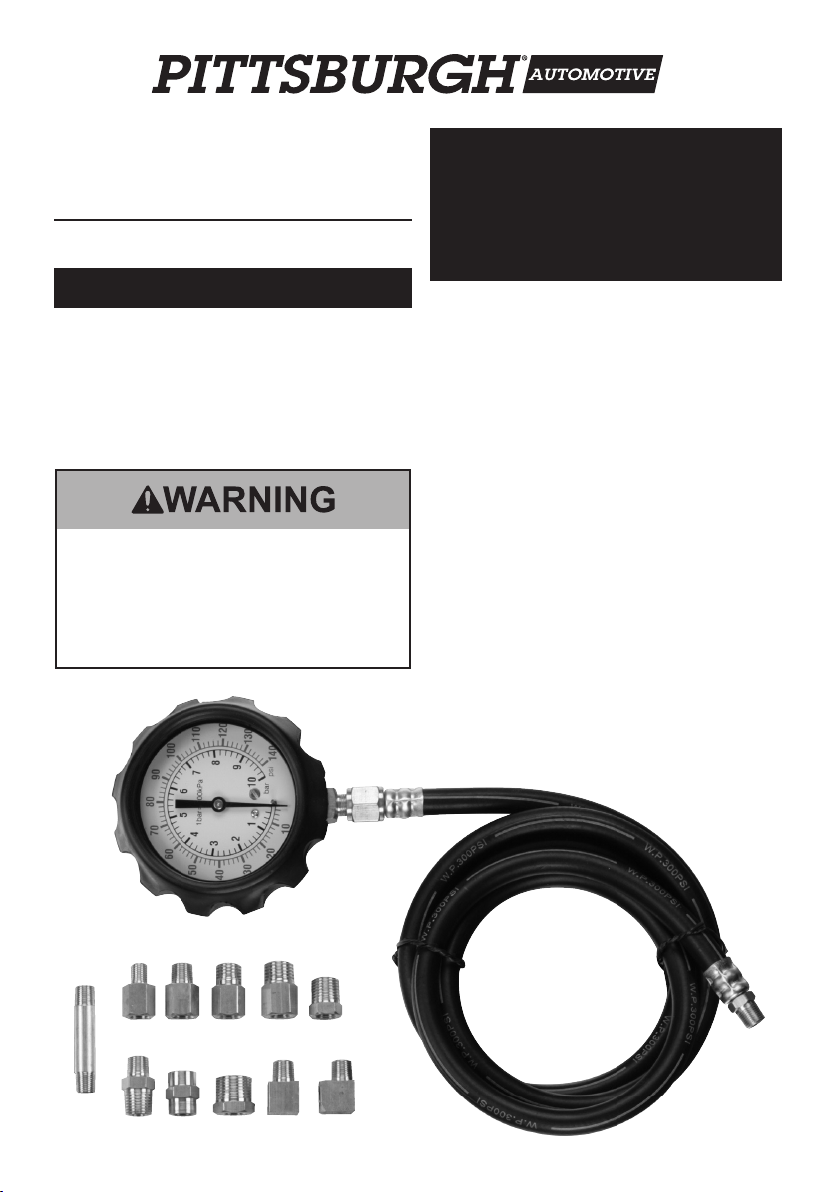

Engine Pressure

Test Kit

When unpacking, make sure that the

product is intact and undamaged.

If any parts are missing or broken,

please call 1‑800‑444‑3353

as soon as possible.

Item 98949

INSTRUCTIONS AND

PRECAUTIONS

Visit our website at:

http://www.harborfreight.com

Read this material before

using this product.

Failure to do so can result

in serious injury.

SAVE THIS MANUAL.

Copyright© 2011 by Harbor Freight Tools®.

All rights reserved. No portion of this document

or any artwork contained herein may be

reproduced in any shape or form without the

express written consent of Harbor Freight

Tools. Diagrams within this document may

not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly

from the product described herein. Tools required

for assembly and service may not be included.

For technical questions or replacement

parts, please call 1‑800‑444‑3353.

Page 2

The warnings, precautions, and

instructions discussed in this instruction

manual cannot cover all possible

conditions and situations that may occur.

It must be understood by the operator that

common sense and caution are factors

which cannot be built into this product,

but must be supplied by the operator.

Important Safety Information

1. Do not allow the Tester to interfere with

the moving parts of a running engine.

2. Maintain labels and nameplates

on the tool. These carry important

safety information. If unreadable or

missing, contact Harbor Freight Tools

for a replacement.

3. This product is not a toy.

Keep it out of reach of children.

4. WARNING: The brass components of

this product contain lead, a chemical

known to the State of California

to cause birth defects (or other

reproductive harm). (California Health

& Safety code § 25249.5, et seq.)

5. People with pacemakers should

consult their physician(s) before use.

Electromagnetic elds in close

proximity to heart pacemaker could

cause pacemaker interference or

pacemaker failure.

Caution is necessary when near coil,

spark plug cables, or distributor of

running engine. Engine should be

off during distributor adjustment.

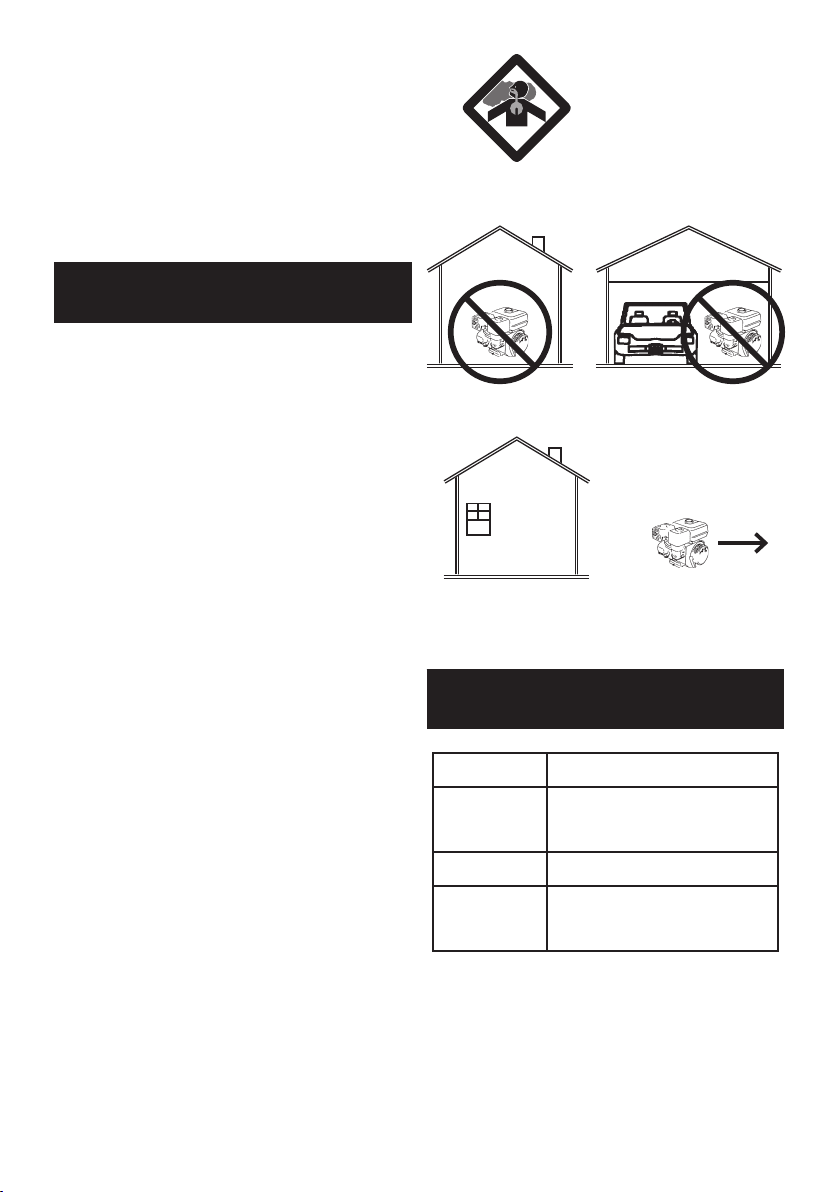

6. CARBON MONOXIDE

HAZARD

Using an engine

indoors CAN KILL YOU

IN MINUTES.

Engine exhaust contains

carbon monoxide. This is a poison you

cannot see or smell.

NEVER use inside a home or garage,

EVEN IF doors and windows are open.

Only use OUTSIDE and far away from

windows, doors, and vents.

Specications

Accuracy ±2% of Reading

Pressure

Scale

Gauge Fitting 1/8″ 27 NPT

Applications

0~100 PSI (2 PSI Divisions);

0~10 Bar (2 Bar Divisions);

310° Pointer Sweep

Works on many domestic

and imported cars, trucks,

tractors, and starting engines.

Page 2 For technical questions, please call 1‑800‑444‑3353. SKU 98949

Page 3

Operating Instructions

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of

this document including

all text under subheadings

therein before set up or

use of this product.

1. Read the service manual of the engine

that the gauge will be testing.

2. If testing the engine in a vehicle;

the vehicle should be parked on a level

surface, the transmission should be

set in neutral with the parking brake

engaged and the wheels chocked.

3. The oil pressure/temperature sensor is

usually located on or near the oil pan

at the lower part of the engine. Clean

the area thoroughly before proceeding.

4. Only connect the Gauge when

the engine is off and cool.

5. Place a pan underneath the sensor

to catch oil, remove the sensor, and

thread the Gauge into the opening.

6. Attach the appropriate

tting to the Gauge.

7. Check the oil level and rell as needed.

8. Start the vehicle and allow it to come

to normal running temperature.

If necessary, have an assistant maintain

the proper RPM indicated by the chart.

9. Compare the reading on the Gauge

to the numbers on the chart.

If the actual reading is lower or

higher than the numbers indicated

on the chart have the engine

serviced by a qualied technician.

10. Turn the vehicle off and allow it to

cool before removing the Gauge.

11. Replace the oil pressure/temperature

sensor, rell oil as necessary and

recycle spilled oil according to local,

state, and federal laws and regulations.

12. Clean, then store the tool indoors

out of children’s reach.

Maintenance and Servicing

Proceduresnotspecically

explained in this manual

must be performed only by

aqualiedtechnician.

TO PREVENT SERIOUS INJURY FROM

ACCIDENTAL OPERATION:

Detach the tool from the vehicle being

tested before performing any inspection,

maintenance, or cleaning procedures.

TO PREVENT SERIOUS INJURY FROM

TOOL FAILURE:

Do not use damaged equipment.

If abnormal noise or vibration

occurs, have the problem

corrected before further use.

1. BEFORE EACH USE, inspect

the general condition of the tool.

Check for loose ttings, misalignment

or binding of moving parts, cracked or

broken parts and any other condition

that may affect its safe operation.

2. AFTER USE, clean external surfaces

of the tool with clean cloth.

Page 3For technical questions, please call 1‑800‑444‑3353.SKU 98949

Page 4

Normal

Make Year Engine

Chrysler® 1983‑86 1.6 40‑90 2.8‑6.3 3,000

Chrysler 1983 1.7 28 1.97 2,000

Chrysler 1983‑85 2.2 50 3.5 2,000

Chrysler 1986‑89 2.2 & 2.8 50 3.5 3,000

Chrysler 1983‑85 2.6 50‑64 3.5‑4.5 2,000

Chrysler 1989 2.5 (2459) 37 2.6 1,600

Chrysler 1989‑90 2.2 30‑80 2.1‑5.6 3,000

Chrysler 1989‑93 1.5 & 1.6 54 3.8 2,000

Chrysler 1989‑93 1.8 & 2.0 41 2.9 2,000

Chrysler 1993 2.4 11.4 .8 Idle

Chrysler 1994 Talon® & Laser® 11.4 .8 Idle

Chrysler 1995-97 Talon (F) 11.4 .8 Idle

Chrysler 1995-97 Talon (Y) 4 .28 Idle

Chrysler 1993‑95

Chrysler 1995-97 2.0 (except Talon & Laser) and all 2.4 25‑80 1.8‑5.6 3,000

Chrysler 1995-97 2.5 Cirrus®, Stratus®, Sebring®, Avenger® 35-75 2.5‑5.3 3,000

Chrysler 1993 2.5 (2507) 35‑65 2.5‑4.6 2,000

Chrysler 1994‑95 2.5 (2507 & 2458) 25‑80 1.8‑5.6 3,000

Chrysler 1988 3.0 100 7.0 3,000

Chrysler 1983 3.7 30-70 2.1‑4.9 2,000

Chrysler 1991‑92 3.0 (2967) 30‑80 2.1‑5.6 2,000

Chrysler 1989‑92 3.0 (2950) 60 4.2 4,000

Chrysler 1993-97 3.0 (2972), 3.3, 3.8, 3.9 (3916), 5.2, 5.9 (5899) 30‑80 2.1‑5.6 3,000

Chrysler 1993 3.0 (except Stealth® & 2972) 28.5 2.0 3,000

Chrysler 1994‑95 3.0 (except Stealth & 2972) 35-75 2.5‑5.3 3,000

Chrysler 1993-97 Stealth 35‑100 2.5-7.0 2000

Chrysler 1993 3.5 25-70 1.8‑4.9 3,000

Chrysler 1994, 96, 97 3.5 25‑80 1.8‑5.6 3,000

Chrysler 1983‑89 5.2 30‑80 2.1‑5.6 2,000

Chrysler 1993-97 5.9 (5882) 30 2.1 2,500

Chrysler 1989‑93 A, C, E, G, H, J, K, P, Y Body 30‑80 2.1‑5.6 3,000

Chrysler 1989 Rear Wheel Drive 80 5.6 3,000

Chrysler 1989‑90 Front Wheel Drive 30‑80 2.1‑5.6 3,000

Ford® 1983‑85 1.6 30‑50 2.1‑3.5 2,000

Ford 1989‑91 1.6 50‑64 3.5‑4.5 3,000

Ford 1992‑94 1.6 45 3.2 3,000

Ford 1994-97 Aspire® 50‑64 3.5‑4.5 3,000

Ford 1986-97 1.9 35‑65 2.5‑4.6 2,000

Ford 1991‑92 1.8 43-57 3.0‑4.0 3,000

2.3, 2.5, Lebaron®, Daytona®, Shadow®,

Spirit®, Acclaim®, Sundance®

25‑80 1.8‑5.6 3,000

2

@RPMPSI KG/CM

Page 4 For technical questions, please call 1‑800‑444‑3353. SKU 98949

Page 5

Normal

Make Year Engine

Ford 1993‑95 1.8 35‑65 2.5‑4.6 2,000

Ford 1996-97 1.8 28‑43 2.0‑3.0 1,000

Ford 1985-87 2.0 43 3.0 3,000

Ford 1993-97 2.0 (1993) 57-71 4.0‑5.0 2,000

Ford 1995-97 2.0 (1999) & 2.5 (2507) 20‑45 1.4‑3.2 1,500

Ford 1989‑92 2.2 43-57 3.0‑4.0 3,000

Ford 1984‑93 2.3 (2326 OHV) & 2.5 (2524) 55-70 3.9‑4.9 2,000

Ford 1983‑93 2.3 (2295 OHC) & 2.3 (2300 M) 40‑60 2.8‑4.2 2,000

Ford 1993-97 2.3 (2294), 4.0 & 4.9 40‑60 2.8‑4.2 2,000

Ford 1993‑94 Villager® 40‑60 2.8‑4.2 2,000

Ford 1995-97 Windstar® & Villager 40‑60 2.8‑4.2 2,500

Ford 1993-97 2.5 (2501) 49-71 3.4‑5.0 3,000

Ford 1986‑92 3.0 (2971) & 3.8 40‑60 2.8‑4.2 2,000

Ford 1993‑94 3.0 (2971 Y) 40‑65 2.8‑4.6 2,000

Ford 1988‑92 3.0 (2980 SHO) 12.8 .9 800

Ford 1993‑95 3.0 (2980 Y) 40‑65 2.8‑4.6 2,000

Ford 1993-97

Ford 1993‑95 3.2 40‑60 2.8‑4.2 2,000

Ford 1983 3.3 30‑50 2.1‑3.5 2,000

Ford 1993-97 3.0 Aerostar®, Ranger® & all 3.8 40‑60 2.8‑4.2 2,500

Ford 1996-97 4.2 50 3.5 2,000

Ford 1991‑92 4.6 40‑60 2.8‑4.2 1,500

Ford 1993-97 4.6 (4593 V) 33 2.3 1,500

Ford 1993-97 406 (4593 W) 20‑45 1.4‑3.2 2,000

Ford 1996-97 3.0 (2998 S) & 4.6 (4588) 20‑45 1.4‑3.2 1,500

Ford 1983-97 5.0 & 5.8 40‑65 2.8‑4.6 2,000

Ford 1993 7.3 40-70 2.8‑4.9 2,000

Ford 1994-97 7.3 VIN F 40-70 2.8‑4.9 3,000

Ford 1994‑95 7.3 VIN K & VIN M 40-70 2.8‑4.9 2,000

Ford 1993 7.5 40‑65 2.8‑4.6 2,000

Ford 1994-97 7.5 40‑88 2.8‑6.2 2,000

GM® 1984-87 1.6 50‑65 3.5‑4.6 1,200

GM 1985‑88 Sprint® 42.7-54 3.0‑3.8 3,000

GM 1985‑90 Spectrum® 49 3.4 5,200

GM 1985‑88 Nova® (1600) 34 2.4 2,000

GM 1988 Nova (1600 EFI) 56 3.9 3,000

GM 1988 1.6 35 2.5 2,000

GM 1989‑92 Metro® 39 2.7 4,000

GM 1993 Metro 1.0 50 3.5 3,000

3.0 (2971 U), 2.3 (2300 X), 3.0

(2980 U) 3.0 (2982)

55-70 3.9‑4.9 2,000

2

@RPMPSI KG/CM

Page 5For technical questions, please call 1‑800‑444‑3353.SKU 98949

Page 6

Normal

Make Year Engine

GM 1994-97 Metro 1.0 54 3.8 3,000

GM 1989‑92 Prizm® & Storm® 56 3.9 3,000

GM 1993‑94 Prizm 1.6 54 3.8 3,000

GM 1993 Prizm 1.8 54 3.8 3,000

GM 1994 Prizm 1.8 71 5.0 3,000

GM 1993 Storm 1.6 58 4.1 3,000

GM 1993 Storm 1.8 71 5.0 3,000

GM 1995-97 Prizm 1.6 & Prizm 1.8 36-71 2.5‑5.0 3,000

GM 1993 Tracker® 51‑62 3.6‑4.4 3,000

GM 1994 Tracker 47-61 3.3‑4.3 3,000

GM 1995-97 Tracker 47-61 3.3‑4.3 4,000

GM 1993-97 Saturn® 1.9 (7) 29 2.0 2,000

GM 1993-97 Saturn 1.9 (8 & 9) 36 2.5 2,000

GM 1984‑89 1.8 & 2.0 (1983 OHC Turbo) 65 4.6 2,500

GM 1991‑93 1.9 36 2.5 2,000

GM 1989 2.0 (1983 TBI) 45 3.2 2,000

GM 1983‑89 2.0 (1983 OHV TBI‑HO) 63-77 4.4‑5.4 1,200

GM 1993‑94 2.0 (1993) H 30 2.1 2,000

GM 1990-97 2.2 (2189, 2195, 2196) 56 3.9 3,000

GM 1990‑95 2.2 (2180) 63-77 4.4‑5.4 1,200

GM 1996-97 2.2 (2180) 56 3.9 3,000

GM 1988 2.3 25 1.8 2,000

GM 1989‑93 2.3 (DOHC 2262 & 2300) 30 2.1 2,000

GM 1989 2.3 (2262 DOHC‑HO) 37 2.6 2,000

GM 1993‑95 2.3 30 2.1 2,000

GM 1996-97 2.4 30 2.1 3,000

GM 1983-87 2.5 36‑41 2.5‑2.9 2,000

GM 1988 2.5 50 3.5 2,000

GM 1989 2.5 26 1.8 800

GM 1991‑93 2.5 (2475 & 2500) 26 1.8 800

GM 1989‑90 2.5 (2475) 37.5 2.6 2,000

GM 1993 2.5 (2474) 41 2.9 2,000

GM 1985 2.8 30‑55 2.1‑3.9 2,000

GM 1989 2.8 PFI “A” Body & 2.8 Beretta/Corsica® 50‑65 3.5‑4.6 1,200

GM 1989 2.8 (2835 PFIJ Body) 50 3.5 2,400

GM 1989 2.8 (MPFI 2835 W Body 15 1.1 1,100

GM 1989 2.8 (2837) 55 3.9 2,000

GM 1993 2.8 (2835) 50 3.5 2,000

GM 1991 All 11.5 .8 750

GM 1992‑3 Colt® 1.5 & Summit® 1.5 50‑64 3.5‑4.5 700

2

@RPMPSI KG/CM

Page 6 For technical questions, please call 1‑800‑444‑3353. SKU 98949

Page 7

Normal

Make Year Engine

GM 1994‑96 Colt 1.5 & Summit 1.5 54 3.8 2,000

GM 1992‑96 Colt Vista 2.4 & Summit® Wagon 2.4 42.7 3.0 2,000

GM 1992‑96 Colt Vista, Summit, Summit Wagon & Colt (AL) 56.9 4.0 3,000

Daihatsu® 1989‑92 All 36-71 3.5 2,000

Honda® 1983‑85 Accord® 50 3.5 2,000

Honda 1986‑88 Accord 55 3.9 2,000

Honda 1989 Accord 55‑65 3.9‑4.6 3,000

Honda 1983‑88 Civic® 50‑55 3.5‑3.9 2,000

Honda 1989 Civic 74 5.2 3,000

Honda 1983‑84 Prelude® 60 4.2 1,500

Honda 1985 Prelude 55 3.9 2,000

Honda 1986‑88 Prelude 50 3.5 2,000

Honda 1989 Prelude 75-87 5.3‑6.1 3,000

Honda 1995 Passport® 2.6 57-71 4.0‑5.0 4,000

Honda 1995 Passport 3.2 57-80 4.0‑5.6 3,000

Honda 1996-97 Passport 57-80 4.0‑5.6 3,000

Honda 1990-97 All Others 50 3.5 3,000

Hyundai® 1986‑89 All 45 3.2 2,000

Hyundai 1990‑92 Excel® (VIN M) & Sonata® 45 3.2 2,000

Hyundai 1990‑92 Elantra®, Sonata® 2.0 & S Coupe 12 .8 750

Hyundai 1990‑92 Excel (VIN J) 12 .8 750

Hyundai 1990‑96 Sonata 3.0 L 30‑80 2.1‑5.6 2,000

Hyundai 1993‑96 Excel, Elantra, Sonata 2.0 12 .8 750

Hyundai 1993‑96 S Coupe 21 1.5 800

Hyundai 1995‑96 Accent® 21 1.5 Idle

Inniti® 1990‑96 Q45 4.5 L 67-81 4.7-5.7 3,000

Inniti 1990‑92 M30 3.0 L 53‑65 3.7-4.6 3,200

Inniti 1990‑96 G20 2.0 L 46-57 3.2‑4.0 3,200

Inniti 1990‑96 J30 3.0 L 51‑65 3.6‑4.6 3,000

Isuzu 1983‑89 Impulse® I‑mark 1816 57 4.0 1,400

Isuzu 1985‑91 I-mark 1588 & 1471 49 3.4 3,000

Isuzu 1996-97 2.2 (2156) 50 3.5 3,000

Isuzu 1996-97 2.2 (2189) 56 3.9 3,000

Isuzu 1993‑95 2.3 (2243 & 2254) 57 4.0 3,000

Isuzu 1993‑95 2.6 (2559) 57-71 4.0‑5.0 4,000

Isuzu 1996-97 2.6 (2559) 57-80 4.0‑5.6 3,000

Isuzu 1993‑94 3.1 (3098) 30‑55 2.1‑3.9 2,000

Isuzu 1993-97 3.2 (3165) 57-80 4.0‑5.6 3,000

Isuzu 1992‑93 All others 51‑80 3.6‑5.6 3,000

Jaguar® 1989‑93 All 70 4.9 4,000

2

@RPMPSI KG/CM

Page 7For technical questions, please call 1‑800‑444‑3353.SKU 98949

Page 8

Normal

Make Year Engine

Lexus® 1990‑96 EX 300, SC 300, ES 250 & GS 300 43-78 3.0‑5.5 3,000

Lexus 1990‑96 LS 400, SC 40 & LX 450 36-71 2.5‑5.0 3,000

Mazda® 1983‑85 GLC® 50‑64 3.5‑4.5 3,000

Mazda 1986-87 323 43-57 3.0‑4.0 3,000

Mazda 1988‑91 323 50‑64 3.5‑4.5 3,000

Mazda 1992‑96 323 & MX3 (1.6) 43-57 3.0‑4.0 3,000

Mazda 1992‑96 MS3 (1.8) 48-71 3.4‑5.0 3,000

Mazda 1983‑92 626, MX6 (both 2184) 43-57 3.0‑4.0 3,000

Mazda 1993‑96 626, MX6 (both 1991) 57-71 4.0‑5.0 3,000

Mazda 1993‑96 626 (2.5), MX6 (2.5) & Millenia (2.5) 49-71 3.4‑5.0 3,000

Mazda 1993 MX6 LS (2496) 49-71 3.4‑5.0 3,000

Mazda 1988 929 50‑64 3.5‑4.5 3,000

Mazda 1989 929 47-61 3.2‑5.0 3,000

Mazda 1990‑92 929 46-71 3.2‑5.0 3,000

Mazda 1993-97 929 & MPV 3.0 53-75 3.7-5.3 3,000

Mazda 1983‑91 RX7 64-78 4.5‑5.5 3,000

Mazda 1992‑93 RX7 50 3.5 3,000

Mazda 1990‑96 Protege® & Miata® 43-57 3.0‑4.0 3,000

Mazda 1995‑96 Millenia® S (2.3) 44‑66 3.1‑4.6 3,000

Mazda 1993 B2200 43-57 3.0‑4.0 3,000

Mazda 1993‑94 B2600 & MPV 2.6 45‑58 3.2‑4.1 3,000

Mazda 1993‑94 Navajo® 40‑60 2.8‑4.2 2,000

Mazda 1994, 96, 97 B2300 & B3000 40‑60 2.8‑4.2 2,000

Mazda 1995 B3000, B2300, B4000 36-71 2.5‑5.0 3,000

Mazda 1996-97 B4000 40‑60 2.8‑4.2 2,000

Mercedes

Benz®

Mercedes

Benz

Mercedes

Benz

Mercedes

Benz

Mercedes

Benz

Mercedes

Benz

Mercedes

Benz

Mercedes

Benz

Mercedes

Benz

1983‑91 All 55 3.9 2,000

1992‑93 400E, 400SE, 400SEL, 500E, 500SEL, 500SEC

1992 All others 43.5 3.1 Idle

1993 500SL

1993 300E (2.8), 300CE (3.2), 300TE (3.2) 69.6 4.9 2,000

1993 All others 43.5 3.1 Idle

1994‑96 C220 43.5‑58 3.1‑4.1 2,000

1994‑96 S350, S600, SL600 43.5 3.1 @ Idle

1994‑96 S420, E500, E420, S500, SL500

23.2 ‑

72.5

23.2 ‑

72.5

23.2 ‑

72.5

1.6‑5.1 2,000

1.6‑5.1 2,000

1.6‑5.1 2,000

2

@RPMPSI KG/CM

Page 8 For technical questions, please call 1‑800‑444‑3353. SKU 98949

Page 9

Normal

Make Year Engine

Merkur® 1983‑90 All 50 3.5 2,000

Mitsubishi® 1983‑88 All 11‑15 0.8‑1.1 Idle

Mitsubishi 1989‑96 Starion®, Sigma®, Precis®, Mirage® (1.5) 54 3.8 2,000

Mitsubishi 1989‑96 Eclipse®, Mirage (1.6 & 1.8) 41 2.9 2,000

Mitsubishi 1991‑96 3000GT & Diamanté® 30‑80 2.1‑5.6 2,000

Mitsubishi 1989‑93 Galant® 41 2.9 2,000

Mitsubishi 1993-97 Galant 30‑80 2.1‑5.6 2,000

Mitsubishi 1993-97 Pickup 2.4 41 2.9 2,000

Mitsubishi 1993-97 Pickup 3.0 & Montero® 30‑80 2.1‑5.6 2,000

Nissan® 1983-87 300ZX, 810, 200SX, 280ZX, Stanza®, Maxima® 43 3.0 2,000

Nissan 1983-87 Pulsar® & Sentra® (1597 & 1488) 43 3.0 1,700

Nissan 1988‑96 Pulsar (1598 & 1809) 67 4.7 2,000

Nissan 1988‑96 Sentra 1.6 & Pulsar 1597 50 3.5 3,000

Nissan 1988‑89 200SX, 300ZX & Maxima® 60 4.2 3,200

Nissan 1989‑96 240SX & Altima® 60 4.2 3,000

Nissan 1988 Stanza® 58 4.1 3,000

Nissan 1989 Stanza 61 4.3 3,200

Nissan 1990‑92 Stanza 60 4.2 3,000

Nissan 1990‑96 300ZX & Maxima VE30DE 51 3.6 3,000

Nissan 1991‑96 Sentra 2.0 (1998) 46 3.2 3,200

Nissan 1992‑96 Maxima VG30E 53 3.7 3,200

Nissan 1993-97 Pickup 2.4 60 4.2 3,200

Nissan 1993-97 Pickup 3.0, Quest® & Pathnder® 53 3.7 3,200

Porsche® 1983‑88 911® 50 3.5 5,000

Porsche 1989 9 11 66 4.6 5,000

Porsche 1986‑88 911 Turbo 60 4.2 5,500

Porsche 1983‑88 928, 928S, 928S4 70 4.9 5,500

Porsche 1983‑88 924S, 944, 944S, 944 Turbo 50-70 3.5‑4.9 5,500

Porsche 1989‑93 911 Carrera® A4 & 2 73 5.1 5,000

Porsche 1989‑93 911 Turbo 66 4.6 5,500

Porsche 1989‑93 928S4, 928 GT, 928 GTS 74 5.2 4,000

Porsche 1989 944, 944 Turbo, 944S2 52 3.7 6,000

Porsche 1989‑91 944S2 58 401 5,000

Porsche 1992‑93 968 44 3.1 3,000

Saab® 1983‑85 All 64-71 4.5‑5.0 2,000

Saab 1986‑90 900 & 9000 51-74 3.6‑5.2 2,000

Saab 1987-90 900 Turbo & 9000 Turbo 64-71 4.5‑5.0 2,000

Saab 1991 All 52-75 3.7-5.3 2,000

Saab 1992‑96 All 39 2.7 2,000

Sterling® 1987-91 All 71-82 5.0‑5.8 3,000

2

@RPMPSI KG/CM

Page 9For technical questions, please call 1‑800‑444‑3353.SKU 98949

Page 10

Normal

Make Year Engine

Subaru® 1983‑84 1600 71-82 2.5‑4.0 2,000

Subaru 1983‑84 1800 50‑64 3.5‑4.5 2,000

Subaru 1985‑88 All except 3 cylinder 57-74 4.0‑4.5 2,000

Subaru 1986‑88 3 Cylinder 35‑40 2.5‑2.8 2,000

Subaru 1989 2 DR 57 4.0 2,500

Subaru 1989‑91 Justy® 47 3.3 3,000

Subaru 1989‑91 All others 43 3.0 5,000

Subaru 1992‑96 Justy 30 2.1 1,500

Subaru 1992‑96 Loyale® 14 1.0 550

Subaru 1992‑96 Legacy®, SVX, Impreza® 14 1.0 600

Suzuki® 1993‑95 Samurai® 43‑60 3.0‑4.2 3,000

Suzuki 1993‑95 Sidekick® EFI & TEI 51‑63 3.6‑4.4 3,000

Suzuki 1993‑95 Sidekick 16 Valve 47-61 3.3‑4.3 3,000

Suzuki 1996-97 X90 & Sidekick 1.6 47-61 3.3‑4.3 3,000

Suzuki 1996-97 Sidekick 1.8 55-67 3.9-4.7 4,000

Toyota® 1983‑91 All 36-71 2.5‑5.0 3,000

Toyota 1994‑96 Supra® 36-71 2.5‑5.0 3,000

Toyota 1993-97

Toyota 1992‑96 All others 4.3 0.3 Idle

VW® 1983‑96 All (except Eurovan®) 28 1.97 2,000

VW 1993-97 Eurovan 29 2.0 2,000

Volvo® 1983‑96 All Except Those Listed Below 35‑85 2.5‑6.0 2,000

Volvo 1983‑86 760 GLE 60 4.2 3,000

Volvo 1987-90 760, 780 (both 2849) 57 4.0 3,000

Volvo 1992‑96 960 36 2.5 2,000

Volvo 1993‑96 850 49.8 3.5 4,000

Land Cruiser®, Pickup, Previa®,

Rav4®, T100, Tacoma®, 4Runner

36-71 2.5‑5.0 3,000

2

@RPMPSI KG/CM

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST

AND ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY.

NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION

OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED

TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED

TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS

REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED

TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK

AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL

PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF

HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 10 For technical questions, please call 1‑800‑444‑3353. SKU 98949

Page 11

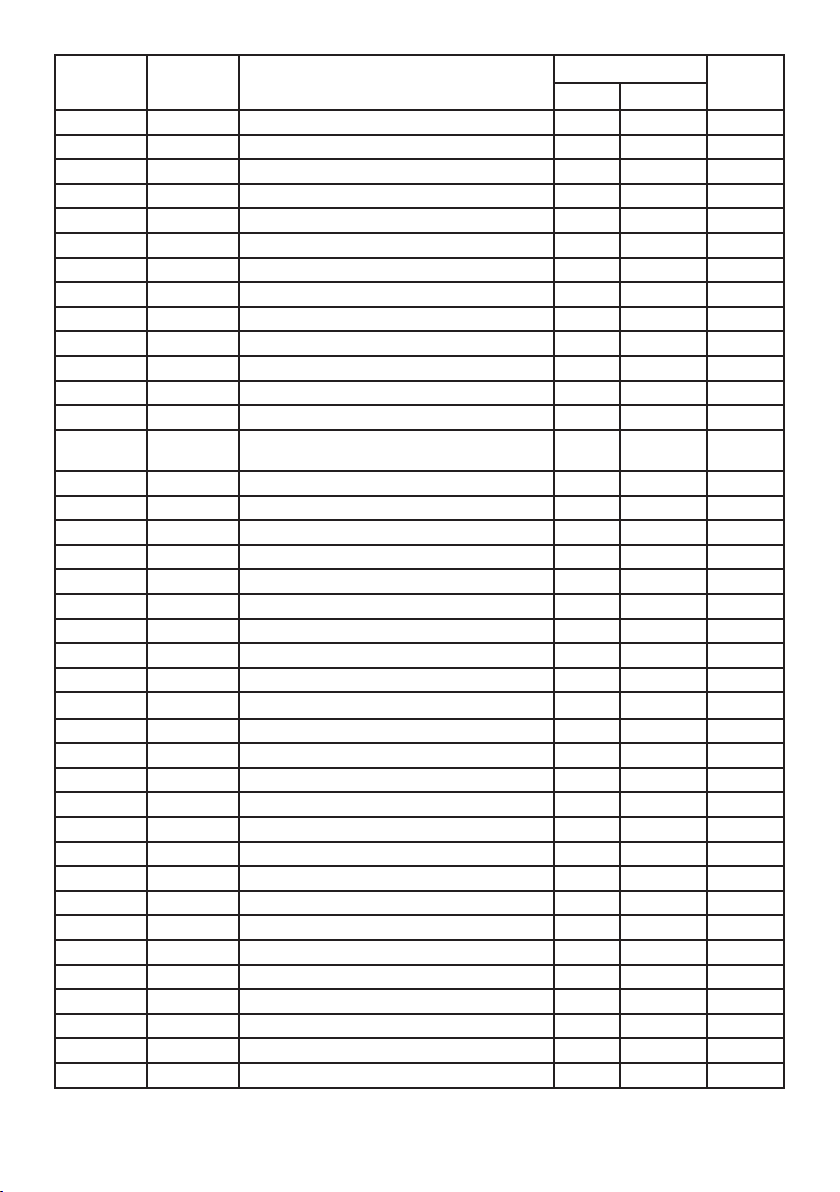

Parts List and Assembly Diagram

Part Description Qty

1 1/4″-18 NPT F x 1/8″-27 NPT M 1

2 1/8″-27 NPT M x 1/8″-27 NPT F – 90º Elbow 1

3 1/8″-28 BSPT M x 1/8″-27 NPT F – 90º Elbow 1

4 M8x1 M x 1/8″-27 NPT F 1

5 M10x1 M x 1/8″-27 NPT F 1

6 M12x1.5 M x 1/8″-27 NPT F 1

7 M14x1.5 M x 1/8″-27 NPT F 1

8 1/4″-18 NPT M x 1/8″-27 NPT F 1

9 1/8″-27 NPT M x 1/8″-27 NPT M 1

10 1/8″-27 NPT F x 1/8″-27 NPT F 1

11 3/8″-18 NPT M x 1/8″-27 NPT F 1

12 Hose 1

13 Gauge 1

14 Case (not shown) 1

13

1

5 6 7 8

9

10 11

Record Product’s Serial Number Here:

Note: If product has no serial number,

record month and year of purchase instead.

2 34

12

Note: Some parts are listed and shown

for illustration purposes only, and are not

available individually as replacement parts.

Page 11For technical questions, please call 1‑800‑444‑3353.SKU 98949

Page 12

Limited 90 Day Warranty

Harbor Freight Tools Co. makes every effort

to assure that its products meet high quality

and durability standards, and warrants to the

original purchaser that this product is free

from defects in materials and workmanship

for the period of 90 days from the date of

purchase. This warranty does not apply to

damage due directly or indirectly, to misuse,

abuse, negligence or accidents, repairs or

alterations outside our facilities, criminal

activity, improper installation, normal wear

and tear, or to lack of maintenance. We

shall in no event be liable for death, injuries

to persons or property, or for incidental,

contingent, special or consequential

damages arising from the use of our product.

Some states do not allow the exclusion

or limitation of incidental or consequential

damages, so the above limitation of

exclusion may not apply to you. THIS

WARRANTY IS EXPRESSLY IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING THE WARRANTIES

OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the

product or part must be returned to us

with transportation charges prepaid. Proof

of purchase date and an explanation

of the complaint must accompany the

merchandise. If our inspection veries

the defect, we will either repair or replace

the product at our election or we may

elect to refund the purchase price if

we cannot readily and quickly provide

you with a replacement. We will return

repaired products at our expense, but if

we determine there is no defect, or that

the defect resulted from causes not within

the scope of our warranty, then you must

bear the cost of returning the product.

This warranty gives you specic legal

rights and you may also have other

rights which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Loading...

Loading...