10” DISC SANDER – BENCH TYPE

Model

47404

SET UP AND OPERATING INSTRUCTIONS

Diagrams within this manual may not be drawn proportionally.

Due to continuing improvements, actual product may differ slightly from the product described herein.

Distributed Exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2007 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

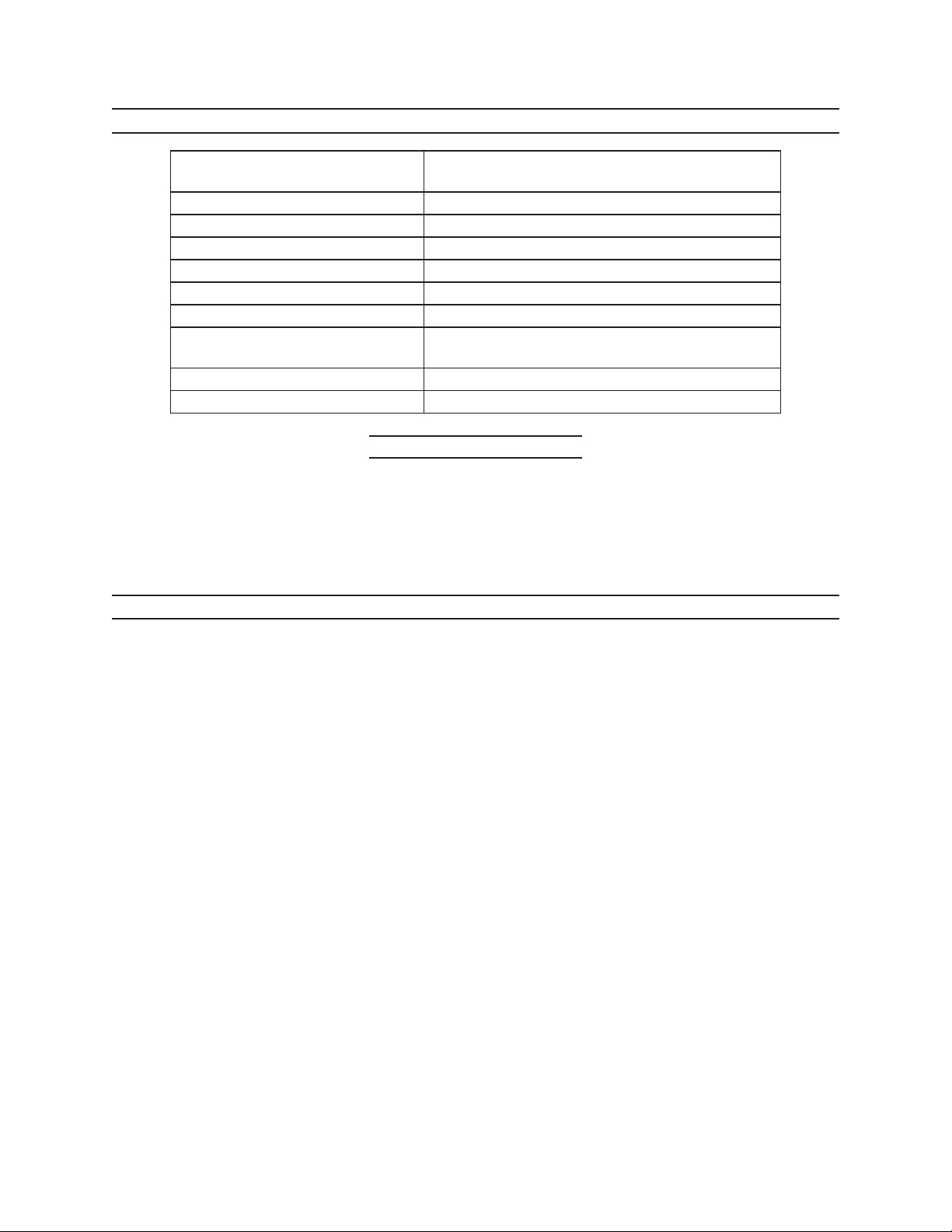

SPECIFICATIONS TABLE

Electrical Requirements 120 V / 60 Hz / 3/4 HP / 13.4 Amps

Single Phase / 1,750 RPM

Sanding Disc Diameter 10”

Sanding Disc Type Pressure Sensitive Adhesive (PSA)

Dust Collection Port 1-3/8” O.D.

Table Dimensions 11-3/8” W x 5-1/2” L

Table Tilt Angle 0 to 45 Degrees (Downward)

Table Tilt Scale Increments 15 Degrees

Miter Gauge Scale 0 to 60 Degrees

In 1 Degree Increments – Right and Left

Base Mounting Holes 3/8” (Qty: 2)

Base Dimensions 2 Base Legs at: 2” W x 8-7/8” L

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures, parts list and assembly

diagram. Keep your invoice with this manual. Write the invoice number on the inside of the

front cover. Keep this manual and invoice in a safe and dry place for future reference.

GENERAL SAFETY WARNINGS AND PRECAUTIONS

1. KEEP WORK AREA CLEAN AND DRY. Cluttered, damp, or wet work areas

invite injuries.

2. KEEP CHILDREN AWAY FROM WORK AREA. Do not allow children to handle

this product.

3. STORE IDLE EQUIPMENT. When not in use, tools and equipment should be

stored in a dry location to inhibit rust. Always lock up tools and equipment, and

keep out of reach of children.

4. DO NOT USE THIS PRODUCT IF UNDER THE INFLUENCE OF ALCOHOL OR

DRUGS. Read warning labels on prescriptions to determine if your judgement or

reexes are impaired while taking drugs. If there is any doubt, do not attempt to

use this product.

5. USE EYE AND BREATHING PROTECTION. Wear ANSI approved safety impact

eyeglasses and an ANSI approved dust mask when using this product. ANSI

approved safety impact eyeglasses and dust masks are available from Harbor

Freight Tools.

6. DRESS SAFELY. Do not wear loose clothing or jewelry, as they can become

Page 2SKU 47404 For technical questions, please call 1-800-444-3353.

caught in moving parts. Wear a protective hair covering to prevent long hair from

becoming caught in moving parts. If wearing a long-sleeve shirt, roll sleeves up

above elbows.

7. DO NOT OVERREACH. Keep proper footing and balance at all times to prevent

tripping, falling, back injury, etcetera.

8. INDUSTRIAL APPLICATIONS MUST FOLLOW OSHA REQUIREMENT.

9. STAY ALERT. Watch what you are doing at all times. Use common sense. Do

not use this product when you are tired or distracted from the job at hand.

10. CHECK FOR DAMAGED PARTS. Before using this product, carefully check that

it will operate properly and perform its intended function. Check for damaged

parts and any other conditions that may affect the operation of this product.

Replace or repair damaged or worn parts immediately.

11. REPLACEMENT PARTS AND ACCESSORIES: When servicing, use only

identical replacement parts. Only use accessories intended for use with this

product. Approved accessories are available from Harbor Freight Tools.

12. MAINTAIN THIS PRODUCT WITH CARE. Keep this product clean, dry, and

keep all cutting bits sharp for better and safer performance.

13. MAINTENANCE: For your safety, service and maintenance should be performed

regularly by a qualied technician.

14. USE THE RIGHT TOOL FOR THE JOB. Do not attempt to force a small tool or

attachment to do the work of a larger industrial tool. There are certain

applications for which this tool was designed. It will do the job better and more

safely at the rate for which it was intended. Do not modify this tool, and do not

use this tool for a purpose for which it was not intended.

15. WARNING: The warnings, precautions, and instructions discussed in this manual

cannot cover all possible conditions and situations that may occur. The operator

must understand that common sense and caution are factors, which cannot be

built into this product, but must be supplied by the operator.

SPECIFIC PRODUCT WARNINGS AND PRECAUTIONS

1. MAINTAIN A SAFE WORKING ENVIRONMENT. Keep the work area well lit.

Make sure there is adequate surrounding workspace. Always keep the work

area free of obstructions, grease, oil, trash, and other debris. Do not use the

Disc Sander in areas near ammable chemicals, dusts, and vapors. Do not use

the Disc Sander in a damp or wet location.

Page 3SKU 47404 For technical questions, please call 1-800-444-3353.

2. GROUND THIS PRODUCT. The electrical Power Cord/Plug (part #34) for this

product is equipped with a grounded, 3-prong Plug. Never remove the grounding

prong or modify the Plug in any way. Do not use adapter plugs with this product.

To comply with the National Electric Code, and to provide additional protection

from the risk of electrical shock, this product should only be connected to a 120

Volt, 3-hole electrical outlet that is protected by a Ground Fault Circuit Interrupter

(GFCI). (See Assy. Diagram.)

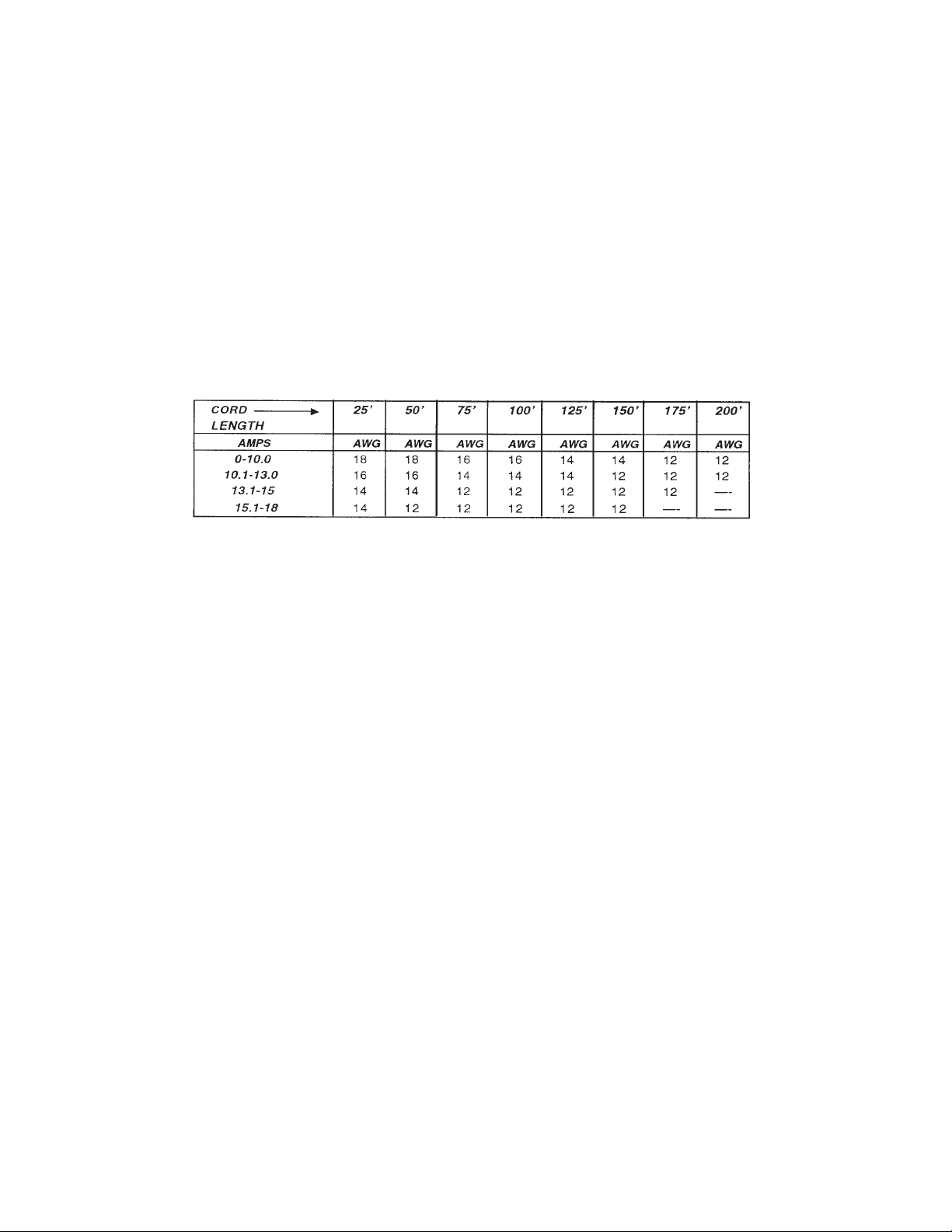

3. IF AN EXTENSION CORD (not provided) IS USED, MAKE SURE TO USE

ONLY UL APPROVED CORDS HAVING THE CORRECT GAUGE AND

LENGTH. (See Figure A.)

AWG RATING CHART - 120 VOLT

FIGURE A

4. PROPERLY ALIGN THE WORK TABLE (part #7). Make sure the distance

between the Work Table and Sanding Disc (part #14) does not exceed 1/16”.

5. REDUCE THE RISK OF ACCIDENTAL STARTING. Make sure the Safety Switch

(part #32) is in the “OFF” position before plugging the Power Cord/Plug (part #34)

into a grounded, 3-hole, 120 Volt, electrical outlet.

(See Figure B, and Assy. Diagram.)

6. PRIOR TO STARTING THE DISC SANDER, MAKE SURE ALL ADJUSTING

KEYS AND WRENCHES ARE REMOVED FROM THE TOOL.

7. ALWAYS FEED THE WORKPIECE INTO AND AGAINST THE DIRECTION OF

THE ROTATING SANDING DISC (part #14).

8. NEVER STAND OR HAVE AN OBSERVER STAND IN LINE WITH THE

SPINNING SANDING DISC (part #14).

9. USE THE PROPER SIZE AND TYPE OF SANDING DISC (10”, PRESSURE

SENSITIVE ADHESIVE).

10. HOLD THE WORKPIECE FIRMLY SO THAT IT WILL NOT BE PULLED FROM

YOUR HANDS DURING THE SANDING PROCESS.

11. FEED THE MATERIAL GRADUALLY. Do not force the machine to remove

Page 4SKU 47404 For technical questions, please call 1-800-444-3353.

material faster than it was designed to sand.

12. DO NOT ATTEMPT TO SAND WORKPIECES TOO SMALL TO SAFELY HOLD

BY HAND. Attempting to hold onto a very small workpiece will bring ngers and

hands in dangerous proximity to the spinning sanding disc.

13. WHEN SANDING A LARGE WORKPIECE, MAKE SURE IT IS PROPERLY

SUPPORTED AT THE WORK TABLE (part #7) HEIGHT.

14. NEVER LEAVE THE DISC SANDER UNATTENDED WHEN IT IS RUNNING.

Turn off the machine, and wait until it has completely stopped before leaving.

15. ALWAYS UNPLUG THE DISC SANDER FROM ITS ELECTRICAL SUPPLY

SOURCE BEFORE PERFORMING ANY INSPECTION, MAINTENANCE, OR

CLEANING PROCEDURES.

16. WARNING: Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities, contain chemicals known (to the State of California)

to cause cancer, birth defects or other reproductive harm. Some examples of

these chemicals are: lead from lead-based paints, crystalline silica from bricks

and cement or other masonry products, arsenic and chromium from chemically

treated lumber. Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these chemicals: work in

a well ventilated area, and work with approved safety equipment, such as those

dust masks that are specially designed to lter out microscopic particles.

(California Health & Safety Code 25249.5, et seq.)

18. WARNING: People with pacemakers should consult their physician(s) before

using this product. Operation of electrical equipment in close proximity to a heart

pacemaker could cause interference or failure of the pacemaker.

UNPACKING

When unpacking, check to make sure all the parts shown on the Parts List on page 11

are included. If any parts are missing or broken, please call Harbor Freight Tools at the

number shown on the cover of this manual as soon as possible.

Page 5SKU 47404 For technical questions, please call 1-800-444-3353.

ASSEMBLY INSTRUCTIONS

KNOB (#1)

MITER GAUGE (#3)

KNOB BOLT (#11)

SPRING (#12)

SPRING ADJUSTING

SCREW (#13)

10” PRESSURE SENSITIVE

ADHESIVE SANDING DISC (#14)

DISC (#15)

WORK TABLE (#7)

KNOB BOLT (#11)

SPRING (#12)

SPRING ADJUSTING

SCREW (#13)

BASE (#23)

DUST COVER (#18)

FIGURE B

ALWAYS FEED WORKPIECE INTO AND AGAINST

THE ROTATION DIRECTION OF THE SANDING DISC.

WORKPIECE

ROTATION DIRECTION

NOTE: For additional references to the parts listed below, refer to the Assembly

Diagram on page 12.

To Assemble The Disc Sander:

1. CAUTION: Prior to performing this procedure, make sure the Safety Switch (part

#32) of the Disc Sander is in its “OFF” position and the Power Cord/Plug (part

#34) is unplugged from its electrical outlet.

(See Figures C, D, and Assy. Diagram.)

2. Assembly of the Disc Sander requires the attachment of one Knob Bolt (part #11)

on the front end and back end of the Work Table (part #7).

(See Figure B, and Assy. Diagram.)

3. Insert one Knob Bolt (part #11) onto each of the two Table Lock Assemblies (part

#10). Insert one Spring (part #12) into each of the two Knob Bolts. Then, screw

one Spring Adjusting Screw (part #13) into each of the two Knob Bolts to secure

the Knob Bolts in place. (See Figure B, and Assy. Diagram.)

Page 6SKU 47404 For technical questions, please call 1-800-444-3353.

MACHINE ADJUSTMENT INSTRUCTIONS

NOTE: For additional references to the parts listed below, refer to the Assembly

Diagram on page 12.

To Adjust The Table Angle:

1. CAUTION: Prior to performing this procedure, make sure the Safety Switch (part

#32) of the Disc Sander is in its “OFF” position and the Power Cord/Plug (part

#34) is unplugged from its electrical outlet.

(See Figures C, D, and Assy. Diagram.)

2. The Work Table (part #7) may be angled downward from 0 to 45 degrees. To

do so, slightly loosen the two Knob Bolts (part #11). Move the Work Table

downward until the Angle Scale indicates the desired angle. Then, rmly

retighten the two Knob Bolts. (See Figures B, C, and Assy. Diagram.)

FRONT VIEW

SAFETY SWITCH (#32)

DISC (#15)

WORK TABLE (#7)

ANGLE SCALE

KNOB BOLT (#11)

KNOB BOLT (#11)

SAFETY SWITCH (#32)

DISC (#15)

ANGLE SCALE WORK TABLE (#7)

FIGURE C

To Adjust The Miter Angle:

1. CAUTION: Prior to performing this procedure, make sure the Safety Switch (part

#32) of the Disc Sander is in its “OFF” position and the Power Cord/Plug (part

#34) is unplugged from its electrical outlet.

(See Figures C, D, and Assy. Diagram.)

Page 7SKU 47404 For technical questions, please call 1-800-444-3353.

2. The Miter Gauge (part #3) may be angled from 0 to 60 degrees, right or left. To

MITER GAUGE (#3)

MITER GAUGE (#3)

KNOB (#1)

KNOB

(#1)

POINTER (#5)

POINTER (#5)

SAFETY SWITCH

(#32)

SAFETY SWITCH

(#32)

FIGURE D

FRONT VIEW

do so, slightly loosen the Knob (part #1). Move the Miter Gauge horizontally to

the right or left until the Pointer (part #5) indicates the desired angle. Then, rmly

retighten the Knob Bolt. (See Figures B, D, and Assy. Diagram.)

To Attach A Sanding Disc To The Disc Sander:

1. CAUTION: Prior to performing this procedure, make sure the Safety Switch (part

#32) of the Disc Sander is in its “OFF” position and the Power Cord/Plug (part

#34) is unplugged from its electrical outlet.

(See Figures C, D, and Assy. Diagram.)

2. The Disc Sander requires the use of a 10”, Pressure Sensitive Adhesive,

Sanding Disc (part #14). Additional replacement Sanding Discs are available

from Harbor Freight Tools. (See Figure B, and Assy. Diagram.)

3. To attach the Sanding Disc (part #14) to the Disc (part #15) of the Disc Sander,

peel off the protective backing of the Sanding Disc and rmly and evenly stick the

Sanding Disc onto the Disc. (See Figure B, and Assy. Diagram.)

Page 8SKU 47404 For technical questions, please call 1-800-444-3353.

OPERATING INSTRUCTIONS

NOTE: For additional references to the parts listed below, refer to the Assembly

Diagram on page 12.

1. CAUTION: Prior to beginning to use, make sure the Safety Switch (part #32) is

in its “OFF” position and the Power Cord/Plug (part #34) is unplugged from its

electrical outlet. (See Figures C, D, and Assy. Diagram.)

2. Make all necessary adjustments to the Disc Sander as previously discussed.

Make sure the distance between the Work Table (part #7) and Sanding Disc and

Sanding Disc (part #14) does not exceed 1/16”.

3. Plug the Power Cord/Plug (part #34) into the nearest 120 volt, grounded, 3-

prong, electrical outlet. (See Figure B, and Assy. Diagram.)

4. Turn the Safety Switch (part #32) to its “ON” position, and allow sufcient time

for the Sanding Disc (part #14) to spin at full speed for 2 to 3 minutes. Check for

proper sanding disc alignment. (See Figure B, and Assy. Diagram.)

5. With both hands, slowly and carefully place the workpiece on the Work Table

(part #7) and against the at edge of the Miter Gauge (part #3), taking care not to

allow the workpiece to immediately touch the spinning Sanding Disc (part #14).

(See Figure B, and Assy. Diagram.)

6. With both hands, rmly hold the workpiece down on the Work Table (part #7) and

against the Miter Gauge (part #3). While holding the workpiece with one hand,

use the other hand to grasp the Miter Gauge and slowly push the workpiece into

the spinning Sanding Disc. CAUTION: ALWAYS KEEP HANDS AND FINGERS

AWAY FROM THE SANDING DISC. (See Figures B, D, and Assy. Diagram.)

7. NOTE: Make sure to feed the workpiece gradually into the spinning Sanding

Disc. Do not force the machine to remove material faster than it was designed

to sand. If necessary, use the Miter Gauge (part #3) to back the workpiece away

from the spinning Sanding Disc (part #14) and repeat Step #6 until the desired

amount of material has been sanded off the workpiece.

(See Figures B, D, and Assy. Diagram.)

8. Once the sanding job is completed, back the workpiece slightly away from the

spinning Sanding Disc (part #14). Keep a rm grip on the workpiece with one

hand, and with the other hand turn the Safety Switch (part #32) to its “OFF”

position. Wait until the Sanding Disc has completely stopped spinning. Then,

remove the workpiece from the machine and unplug the Power Cord/Plug (part

#34) from its electrical outlet. (See Figures B, C, D, and Assy. Diagram.)

Page 9SKU 47404 For technical questions, please call 1-800-444-3353.

INSPECTION, MAINTENANCE, AND CLEANING

NOTE: For additional references to the parts listed below, refer to the Assembly

Diagram on page 12.

1. CAUTION: Always turn the Safety Switch (part #32) to its “OFF” position, unplug

the Power Cord/Plug (part #34) from its electrical outlet, and wait until the

Sanding Disc (part #14) has completely stopped spinning before performing any

inspection, maintenance, or cleaning.

2. BEFORE EACH USE, inspect the general condition of the Disc Sander. Check

for loose screws, misalignment or binding of moving parts, cracked or broken

parts, damaged electrical wiring, and any other condition that may affect its safe

operation. If abnormal noise or vibration occurs, have the problem corrected

before further use. Do not use damaged equipment.

3. DAILY: Sanding Discs (part #14) must be sharp and clean to perform properly.

Depending on materials sanded and frequency of machine use, Sanding Discs

become clogged with wood, metal particles, and become dull. Dull Sanding

Discs rub the workpiece rather than cut, which results in increased friction, higher

temperatures, and a burned workpiece. As often as possible, check the condition

of the Sanding Disc and, if necessary, replace a worn Sanding Disc with a new,

10” Pressure Sensitive Adhesive disc. (See “To Attach A Sanding Disc To The

Disc Sander” section in this manual for further information.)

4. DAILY: With a soft brush, cloth, or vacuum, remove all debris from the Disc

Sander. Then, use a premium quality, lightweight machine oil to lubricate all

moving parts.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR

DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE

UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER

ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL

PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION

OF REPLACEMENT PARTS THERETO.

Page 10SKU 47404 For technical questions, please call 1-800-444-3353.

PARTS LIST

Part Description Qty.

1 Knob 1

2 Screw (M5 x 6) 1

3 Miter Gauge 1

4 Washer 19

5 Pointer 1

6 Gauge Sliding Bar 1

7 Work Table 1

8 Round Body Threaded Rod 2

9 Washer 2

10 Table Lock Assembly 2

11 Knob Bolt 2

12 Spring 2

13 Spring Adjusting Screw 2

14 Sanding Disc 1

15 Disc 1

16 Washer 1

17 Screw (M6 x 12) 1

18 Dust Cover 1

19 Screw (M5 x 8) 7

20 Spring Washer 7

21 Big Pointer 1

22 Screw (M5 x 16) 4

23 Base 1

24 Screw (M5 x 12) 4

25 Rubber Pad 4

26 Screw (M5 x 20) 1

27 Motor Housing 1

Part Description Qty.

28* Rubber Ring 1

29* Terminal Box 1

30* Screw (ST3.5 x 14) 4

31* Switch Plate 1

32* Safety Switch 1

33* Swivel Clamp 1

34* Cord/Plug 1

35* Capacitor Clip 1

36* Capacitor (6uF/8uF) 1

37** Wavy Washer 1

38** Stator 1

39** Bearing (6004) 1

40** Key (C5 x 12) 1

41** Rotor 1

42** Screw (M4 x 35) 1

43** Bearing (6203) 1

44** Washer 4

45** Nut (M4) 1

46** End Bell 1

47** Plastic Washer 3

48** Nut (M5) 4

49** Fan 1

50** Fan Cover 1

51** Spring Washer 3

52** Screw (M4 x 16) 3

53* Switch Assembly 1

54** Motor Assembly 1

* Available only as a complete Switch Assembly (see Part #53).

** Available only as a complete Motor Assembly (see Part #54).

Page 11SKU 47404 For technical questions, please call 1-800-444-3353.

NOTE: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

Page 12SKU 47404 For technical questions, please call 1-800-444-3353.

LIMITED 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that this product

is free from defects in materials and workmanship for the period of 90 days from the date

of purchase. This warranty does not apply to damage due directly or indirectly, to misuse,

abuse, negligence or accidents, repairs or alterations outside our facilities, criminal activity,

improper installation, normal wear and tear, or to lack of maintenance. We shall in no event

be liable for death, injuries to persons or property, or for incidental, contingent, special

or consequential damages arising from the use of our product. Some states do not allow

the exclusion or limitation of incidental or consequential damages, so the above limitation

of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection veries the defect, we will either

repair or replace the product at our election or we may elect to refund the purchase price

if we cannot readily and quickly provide you with a replacement. We will return repaired

products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning

the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

REV 07j

Page 13SKU 47404 For technical questions, please call 1-800-444-3353.

Loading...

Loading...