Page 1

Hydraulic Punch

Driver Kit

Item 96718

INSTRUCTIONS AND

PRECAUTIONS

Visit our website at:

http://www.harborfreight.com

Read this material before

using this product.

Failure to do so can result

in serious injury.

SAVE THIS MANUAL.

When unpacking, make sure

that the product is intact and

undamaged.

If any parts are missing or broken,

please call 1-800-444-3353

as soon as possible.

Copyright© 2007 by Harbor Freight Tools®.

All rights reserved. No portion of this document

or any artwork contained herein may be

reproduced in any shape or form without the

express written consent of Harbor Freight

Tools. Diagrams within this document may

not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly

from the product described herein. Tools required

for assembly and service may not be included.

For technical questions or replacement

parts, please call 1-800-444-3353.

Manual Revised 12d

Page 2

Specications

Maximum

Capacity

Punching

Force

11 Gauge (for mild carbon steel)

16 Gauge (for stainless steel)

10 Ton (20,000 lb.)

Important Safety Information

1. Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

2. Keep children and bystanders

away while operating the Punch

Driver Kit. Distractions can

cause you to lose control.

3. Stay alert, watch what you are

doing and use common sense

when operating the Punch Driver

Kit. Do not use the Punch Driver

Kit while you are tired or under

the inuence of drugs, alcohol or

medication. A moment of inattention

while operating hydraulic tools may

result in serious personal injury.

4. Use safety equipment. Always wear

eye protection. Safety equipment

such as dust mask, non-skid safety

shoes, hard hat, or hearing protection

used for appropriate conditions

will reduce personal injuries.

5. Dress properly. Do not wear loose

clothing or jewelry. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewelry or long

hair can be caught in moving parts.

6. Do not force the Hydraulic Punch

Driver Kit. Use the correct tool for

your application. The correct tool

will do the job better and safer at

the rate for which it was designed.

7. Store idle tool out of the reach of

children and do not allow persons

unfamiliar with the Hydraulic Punch

Driver Kit or these instructions

to operate the Hydraulic Punch

Driver Kit. This tool is dangerous

in the hands of untrained users.

8. Maintain tool. Check for misalignment

or binding of moving parts, breakage

of parts and any other condition that

may affect the Hydraulic Punch Driver

Kit’s operation. If damaged, have the

Hydraulic Punch Driver Kit repaired

before use. Many accidents are caused

by poorly maintained power tools.

9. Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely

to bind and are easier to control.

10. Have Hydraulic Punch Driver Kit

serviced by qualied service technician

using only identical replacement parts.

This will ensure the safety of Hydraulic

Punch Driver Kit is maintained.

11. Maintain product labels and

nameplates. These carry important

safety information. If unreadable

or missing, contact Harbor Freight

Tools for a replacement.

12. This product is not a toy.

Keep it out of reach of children.

13. WARNING! Some dust created by

power sanding, sawing, grinding,

drilling, and other construction

activities, contains chemicals

known to the State of California to

cause cancer, birth defects or other

reproductive harm. (California Health

& Safety Code § 25249.5, et seq.)

Page 2 For technical questions, please call 1-800-444-3353. SKU 96718

Page 3

14. The warnings, precautions, and

instructions discussed in this instruction

manual cannot cover all possible

conditions and situations that may

occur. It must be understood by the

operator that common sense and

caution are factors which cannot

be built into this product, but must

be supplied by the operator.

Operating Instructions

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of

this document including all

text under subheadings

therein before set up or use of

this product.

1. Bleed air from Hydraulic System

before rst use. See page 4.

2. When selecting a work piece, please

do not exceed the Maximum Cutting

Capacity of 0.12” for mild carbon

steel and 0.08” for stainless steel.

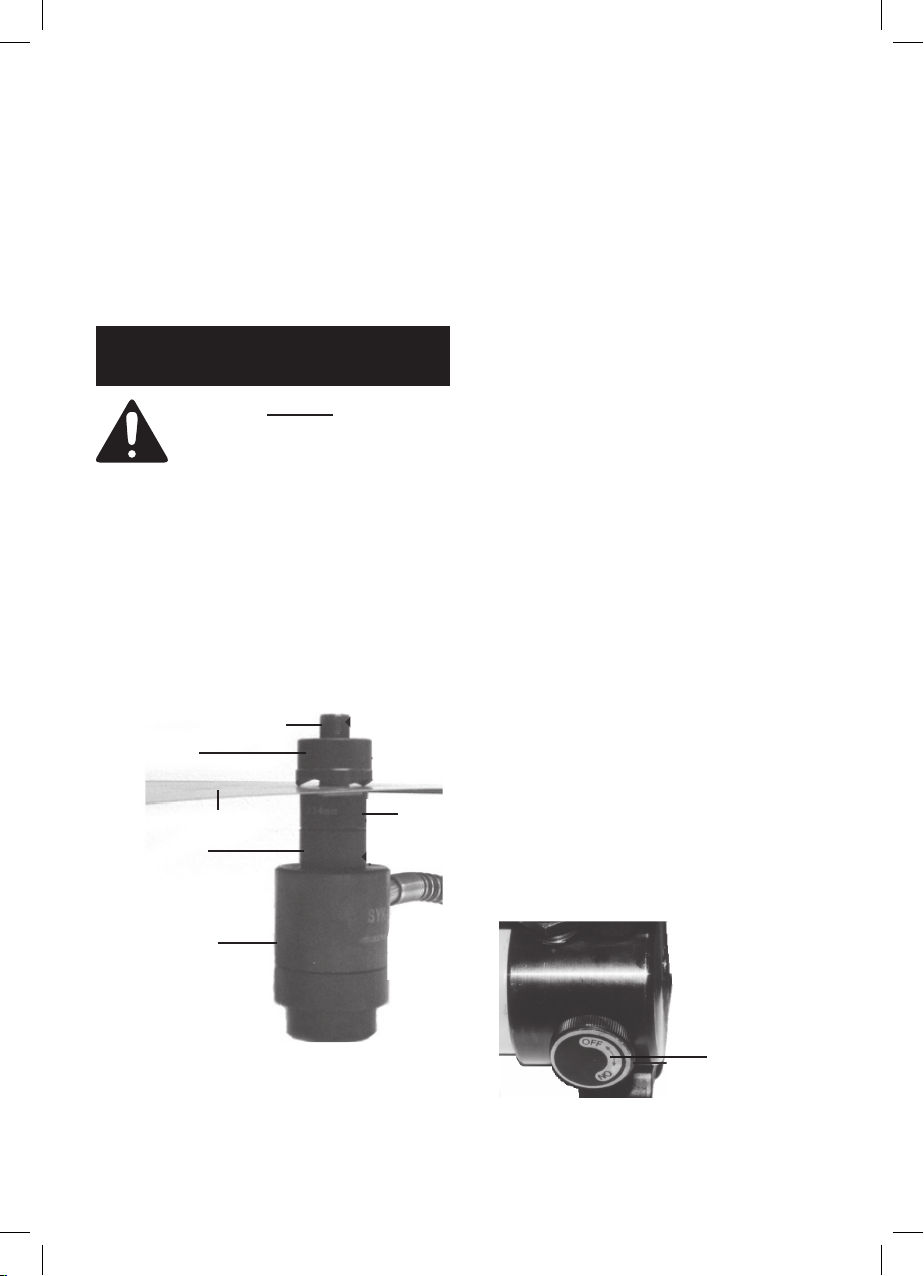

Threaded Stud (13/14)

Punch (2-6)

Work Piece

Adapter (12)

Die

(7-11)

3. Practice with a scrap work piece

before using the actual work piece.

Working with a scrap work piece

will help you familiarize yourself

with the Punch Driver Kit.

4. Select the size of the Threaded Stud

(13, 14) to be used, either 3/4” or 7/16”.

5. Select the size of the Punch and Die

to be used (see Parts List on page 6).

6. Plan and measure the location

of the hole to be punched in the

work piece. This hole must t the

Threaded Stud to be used.

7. Drill a lead hole at the center

point of the hole marked and

measured in step 5.

8. The 7/16” Threaded Stud is to be

used with Punch (2) and Die (7).

9. Thread the Threaded Stud into the

Punch Head (16). Note that the end

with the shorter threads is threaded

into the Punch Head. See Figure 1.

10. The Adapter (12) is to be used with

all Punch and Dies that are used.

11. Slide Adapter and then Die

onto the Threaded Stud.

12. Slide your work piece with

the drilled hole down onto the

Die, as shown in Figure 1.

13. Thread the Punch down onto the

work piece as tightly as possible.

14. Turn the Release Valve (18)

(see Figure 2) to the “ON” position.

Punch Head

(16)

Figure 1

Figure 2

Release

Valve (18)

Page 3For technical questions, please call 1-800-444-3353.SKU 96718

Page 4

15. Grasp the Pump Handle (17) and

pump it up and down until the Punch

has punched through the work piece.

16. Turn the Release Valve (18)

to the “OFF” position.

17. Thread off the Punch, remove

the work piece, the Die and the

Adapter. Remove the Threaded

Stud from the Punch Head.

18. Carefully remove the punched

material and its residue.

19. Clean, then set the Punch Driver Kit

into its Carrying Case and store the

tool indoors out of children’s reach.

Maintenance and Servicing

1. BEFORE EACH USE, inspect the

general condition of the Hydraulic

Punch Driver Kit. Check for loose

attachments, binding of moving parts,

cracked or broken attachments,

and any other condition that may

affect its safe operation. If any

abnormality is found, have the

problem corrected before further use.

Do not use damaged equipment.

2. AFTER EACH USE, wipe off Punch

Driver Kit with clean, moist cloth.

3. Service to the Punch Driver

Kit should only be done by a

qualied Service Technician.

Bleeding Instructions

1. NOTE: During shipment and handling,

air may get trapped in the hydraulic

system-Hydraulic Pump with Pressure

Hose. This can interfere with the

performance of the Punch Driver Kit.

Bleed air from the hydraulic system

according to the following instructions.

2. Open the Release Valve, making sure

the Punch Head is fully extended, and

unscrew the coupler to disconnect the

Hose from the Punch Head. Close

the Release Valve, press down the

core rod in the Hose Coupler.

3. Pump the Pump Handle.

Release the Hose Coupler until

oil ows out of the Hose.

4. Attach the Hose to the Punch Head.

5. Open Release Valve, and Pump Handle

several times in rapid succession.

Repeat this procedure until the Punch

Driver Kit is working properly.

Troubleshooting

PROBLEM POSSIBLE CAUSES PROBABLE SOLUTIONS

Handle stroke only

partly effective.

Handle raises on its own. Sticking or leaking

Handle snaps back. Sticking Delivery Valve. Open Release Valve.

Page 4 For technical questions, please call 1-800-444-3353. SKU 96718

Air in pump chamber. Follow the Bleeding

Instructions above.

Remove and clean

Release Valve.

the Release Valve.

Pump rapidly several

times. Close Valve.

Page 5

Punch Sizes/Pipe, Conduit, Metal Tubing

Outside Diameter Specications Chart

Punch Pipe / O.D. Conduit O.D.

Intermediate

1.115” 3/4” / 1.505” 1.029” 0.922” 0.922”

1.362” 1” / 1.315” 1.29" 1.163" 1.163"

1-11/16” (1.687”) 1-1/4” / 1.660” 1.638" 1.51" 1.570"

1-15/16” (1.937”) 1-1/2” / 1.900” 1.883" 1.74" 1.74"

2-3/8” (2.375”) 2” / 2.375” 2.360” 2.197” 2.197”

Pipe Tube

1.115” 3/4” 3/4”

Thin Wall O.D. Electrical Metal

Tubing O.D.

Page 5For technical questions, please call 1-800-444-3353.SKU 96718

Page 6

Parts List

Part Description Qty

1

Hydraulic Pump with

1

Pressure Hose

2

Punch 1.115” for 3/4” Pipe

3

Punch 1.362” for 1” Pipe

4

Punch 1-11/16”

1

1

1

for 1-1/4” Pipe

5

Punch 1-15/16”

1

for 1-1/2” Pipe

6

Punch 2-3/8” for 2” Pipe

7

Die for 1.115” Punch

8

Die for 1.362” Punch

1

1

1

Part Description Qty

9

Die for 1-11/16” Punch

10

Die for 1.15/16” Punch

11

Die for 2-3/8” Punch

12

Adapter

13

Threaded Stud 3/4”

14

Threaded Stud 7/16”

15

Carrying Case (not shown)

16

Punch Head

17

Pump Handle

18

Release Valve

1

1

1

1

1

1

1

1

1

1

Record Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

PLEASE READ THE FOLLOWING CAREFULLY

NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY

KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE

OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR

DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN

BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND

LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 6 For technical questions, please call 1-800-444-3353. SKU 96718

Page 7

Parts Diagram

6

11

10

12

17

16

1

5

9

4

3

2

8

7

13

18

14

Page 7For technical questions, please call 1-800-444-3353.SKU 96718

Page 8

90 Day Warranty

Harbor Freight Tools Co. makes every effort to assure that its products meet

high quality and durability standards, and warrants to the original purchaser that

this product is free from defects in materials and workmanship for the period

of 90 days from the date of purchase. This warranty does not apply to damage

due directly or indirectly, to misuse, abuse, negligence or accidents, repairs or

alterations outside our facilities, criminal activity, improper installation, normal

wear and tear, or to lack of maintenance. We shall in no event be liable for

death, injuries to persons or property, or for incidental, contingent, special or

consequential damages arising from the use of our product. Some states do

not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation of exclusion may not apply to you. THIS WARRANTY IS

EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us

with transportation charges prepaid. Proof of purchase date and an explanation

of the complaint must accompany the merchandise. If our inspection veries

the defect, we will either repair or replace the product at our election or we may

elect to refund the purchase price if we cannot readily and quickly provide you

with a replacement. We will return repaired products at our expense, but if we

determine there is no defect, or that the defect resulted from causes not within

the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state. ghghghghhhhhhhghhhhhhhhhghhhhhhgh

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Loading...

Loading...