Page 1

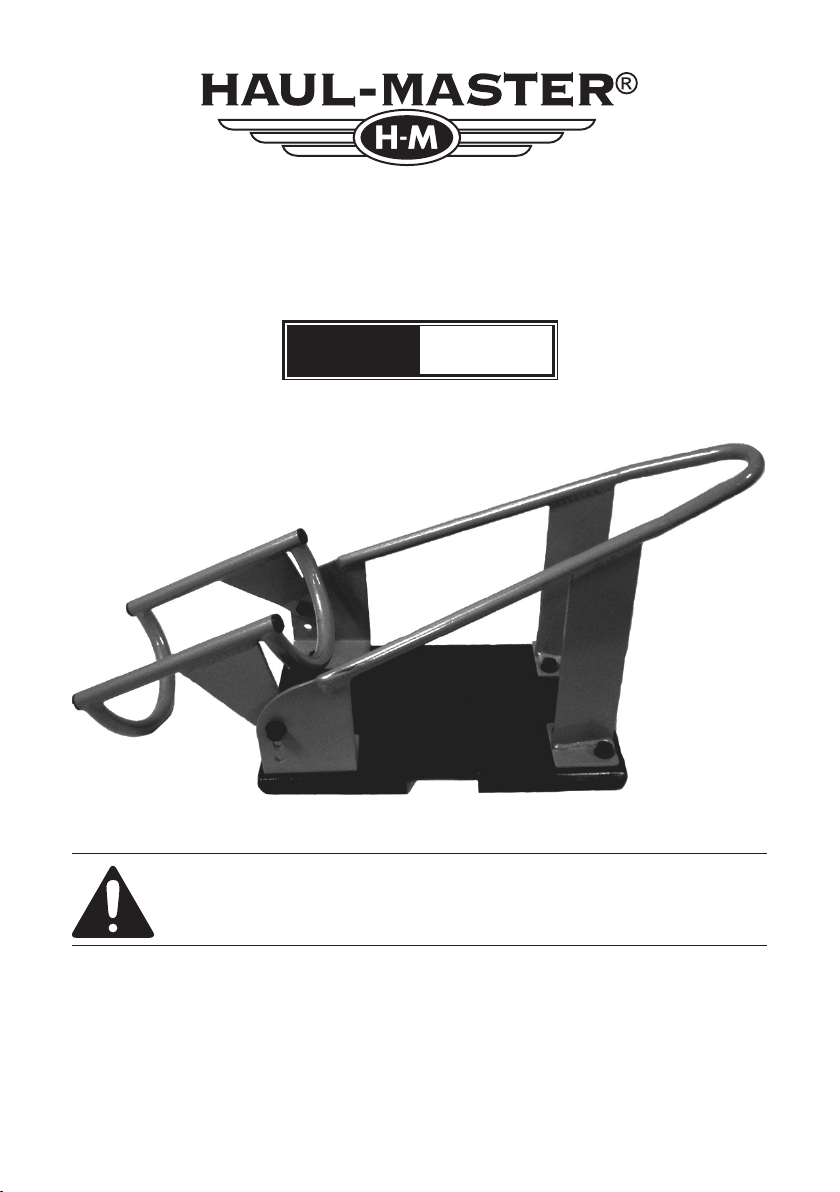

MOTORCYCLE WHEEL

CHOCK

Model

96349

SET UP AND OPERATING INSTRUCTIONS

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2009 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any

artwork contained herein may be reproduced in any shape or form without the express written

consent of Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally.

Due to continuing improvements, actual product may differ slightly from the product described

herein. Tools required for assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Manual revised 09j

Page 2

SPECIFICATIONS

Construction Formed Steel w/ Carbon

Overall Dimensions 15-9/16” L X 10-3/8” W X

Weight 16 Pounds

Moveable Chock

Length

Note: The Wheel Chock will t most

standard motorcycles currently on the

market. However, some models with

especially wide tires or custom low-

prole front fenders will not t into the

Wheel Chock.

Steel Hardware &

Thermoplastic End Caps

13-5/16” H

10”

WORK AREA

Keep your work area clean and well 1.

lit. Cluttered benches and dark areas

invite accidents.

Keep children and visitors away 2.

while installing. Distractions can

cause you to lose control. Protect

others in the work area from debris

such as chips and sparks. Provide

barriers or shields as needed.

Store idle products out of reach 3.

of children and other untrained

persons. Never allow children to play

with or around the Wheel Chock.

Save This Manual

You will need this manual for

the safety warnings and precautions,

assembly, operating, inspection,

maintenance and cleaning procedures,

parts list and assembly diagram. Keep

your invoice with this manual. Write the

invoice number on the inside of the front

cover. Write the product’s serial number in

the back of the manual near the assembly

diagram, or write month and year of

purchase if product has no number. Keep

this manual and invoice in a safe and dry

place for future reference.

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL

PERSONAL SAFETY

Stay alert. Watch what you are 1.

doing, and use common sense

when using the Wheel Chock. Do

not use this product while tired

or under the inuence of drugs,

alcohol, or medication. A moment

of inattention while operating may

result in serious personal injury.

Dress properly. Do not wear loose 2.

clothing or jewelry. Contain long

hair. Keep your hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long hair

can be caught in moving parts.

Do not overreach. Keep proper 3.

footing and balance at all times.

Proper footing and balance enables

better control of the motorcycle in

unexpected situations.

INSTRUCTIONS

Failure to follow all instructions

listed below may cause injury.

SAVE THESE INSTRUCTIONS

Page 2 For technical questions, please call 1-800-444-3353. SKU 96349

Use safety equipment. Always 4.

wear eye protection. Dust

mask, nonskid safety shoes, hard

hat, heavy-duty work gloves, or

hearing protection must be used for

appropriate conditions. Always wear

ANSI-approved safety goggles and a

dust mask/respirator when installing

Rev 08a

Page 3

or performing maintenance on this

tool.

Maintain labels and nameplates 5.

on the tool. These carry important

information. If unreadable or missing,

contact Harbor Freight Tools for a

replacement.

Maintain a safe working 6.

environment. Make sure there is

adequate surrounding workspace. Do

not use this product in a damp or wet

location.

Use the correct product for 7.

your motorcycle. Make sure the

motorcycle’s wheel ts into the Wheel

Chock prior to rst use.

UNPACKING

When unpacking, check to

make sure that the item is intact and

undamaged. If any parts are missing or

broken, please call Harbor Freight Tools

at the number shown on the cover of this

manual as soon as possible.

ASSEMBLY AND

INSTALLATION

INSTRUCTIONS

Note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram at the

end of the manual.

The Wheel Chock comes fully assembled,

however it must be mounted onto a solid

surface to secure it. It is designed to

be mounted on the bed of a truck, or a

motorcycle lift, or onto a concrete oor.

Concrete Floor Mounting

Choose a location to install the Wheel 1.

Chock that is at, level, and capable

of bearing the combined weight of

the Wheel Chock and the motorcycle

being secured. Be certain that the

location will not obstruct walkways

and will still provide enough room

to retrieve the motorcycle after it

is mounted. The surface of the

location should be one suitable for the

mounting of heavy equipment.

Use the mounting holes in the Base 2.

(7) of the Wheel Chock as a template.

Arrange the Base (7) in the chosen

location and, using a pencil, mark

where the holes are to be drilled.

You will need concrete anchors (not

included) to secure the Base (7) to

the concrete oor. Using the correct

size concrete drill bit (not included),

drill the mounting holes to secure

the Base (7). Attache the concrete

anchors to the oor. Secure the Base

(7) to the oor utilizing the concrete

anchors.

Truck Bed or Motorcycle Lift

Mounting

Place the Base (7) in the desired 1.

location of the truck bed or motorcycle

lift that you want to mount it at. Use

the of the Base (7) as a pattern to

mark where you will drill the holes

that accept the hardware to mount the

Wheel Chock. Use a power drill (not

included) and a steel cutting drill bit

(not included) to drill holes in the truck

bed or motorcycle lift.

Warning: Verify that the installation

surface has no hidden wires, brake

lines, etc. before drilling.

Attach the Base (7) to the truck 2.

bed utilizing the Mounting Bolts (6),

Nylon Sleeves (8), Large Washers

(9), Spring Washers (3), and secure

with Hex Nuts (10). See page 6,

assembly diagram.

Page 3For technical questions, please call 1-800-444-3353.SKU 96349

Page 4

OPERATING INSTRUCTIONS

Select the correct mounting hole for 1.

the motorcycle being loaded into the

Wheel Chock, and use the Pivot Bolts

(5) to secure the Pivoting Bracket in

place.

Note: Do not sit on the motorcycle when it

is loaded in the Wheel Chock.

To load a motorcycle, lower the 2.

Pivoting Bracket (13) to the horizontal

position and simply push the

motorcycle into the Wheel Chock.

The Pivoting Bracket will close on the 3.

motorcycle tire, securing the bike in

an upright position.

For long-term storage, or if the 4.

Wheel Chock is mounted to a mobile

platform, the motorcycle should be

secured with belts or straps (not

included).

INSPECTION,

MAINTENANCE, AND

CLEANING

BEFORE EACH USE, inspect the 1.

general condition of the tool. Check

for loose screws, misalignment or

binding of moving parts, cracked or

broken parts, and any other condition

that may affect its safe operation. Do

not use damaged equipment.

Occasionally, wipe the Wheel Chock 2.

down with a soft cloth and mild

detergent.

LIMITED 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to

assure that its products meet high quality and

durability standards, and warrants to the original

purchaser that this product is free from defects in

materials and workmanship for the period of 90

days from the date of purchase. This warranty

does not apply to damage due directly or indirectly,

to misuse, abuse, negligence or accidents, repairs

or alterations outside our facilities, criminal

activity, improper installation, normal wear and

tear, or to lack of maintenance. We shall in no

event be liable for death, injuries to persons or

property, or for incidental, contingent, special or

consequential damages arising from the use of our

product. Some states do not allow the exclusion or

limitation of incidental or consequential damages,

so the above limitation of exclusion may not apply

to you. This warranty is expressly in lieu of all

other warranties, express or implied, including the

warranties of merchantability and tness.

To take advantage of this warranty, the product

or part must be returned to us with transportation

charges prepaid. Proof of purchase date and an

explanation of the complaint must accompany the

merchandise. If our inspection veries the defect,

we will either repair or replace the product at our

election or we may elect to refund the purchase

price if we cannot readily and quickly provide

you with a replacement. We will return repaired

products at our expense, but if we determine

there is no defect, or that the defect resulted from

causes not within the scope of our warranty, then

you must bear the cost of returning the product.

This warranty gives you specic legal rights and

you may also have other rights which vary from

state to state.

3491 Mission Oaks Blvd. • PO Box 6009 •

Camarillo, CA 93011 • (800) 444-3353

Page 4 For technical questions, please call 1-800-444-3353. SKU 96349

Page 5

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND

ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND

TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR

THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE

MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS

REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS,

AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF

HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO,

OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

PARTS LIST

Part Description Qty

1 Main Frame 1

2 Hex Bolt M10x20 4

3 Spring Washer 8

4 Flat Washer 4

5 Pivot Bolt M10x30 2

6 Bolt M10x70 4

7 Base 1

8 Nylon Sleeve 4

9 Large Washer 4

10 Hex Nut M10 6

11 Nylon Washer 2

12 Rubber Cap 4

13 Pivoting Bracket 1

PLEASE READ THE FOLLOWING CAREFULLY

Page 5For technical questions, please call 1-800-444-3353.SKU 96349

Page 6

ASSEMBLY DIAGRAM

10

3

Page 6 For technical questions, please call 1-800-444-3353. SKU 96349

Loading...

Loading...