Page 1

®

UNIVERSAL - QUICK/DISCONNECT

®

COMPRESSION GAUGE SET

Model 95187

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY, READ

AND UNDERSTAND ALL WARNINGS

AND INSTRUCTIONS BEFORE USE.

Copyright© 2006 by Harbor Freight Tools®. All rights reserved. No portion of this instruction sheet or any artwork contained

herein may be reproduced in any shape or form without the express written consent of Harbor Freight Tools.

For technical questions, please call 1-800-444-3353.

SPECIFICATIONS

Pressure Gauge 3” Diameter x 1-1/8” Deep with Push Button Air Release Valve

Pressure Gauge

Scale

Pressure Gauge

Hose

Hose Adapters Long Reach: 10-1/2” Long x M12 x 1.25 / 500 PSI Working Pressure

Net Weight 2.8 Pounds

0<->300 PSI (In 10 PSI Increments)

0<->2000 kPa (In 100 kPa Increments)

26” L x 3/16” I.D. x 15/32” O.D.

Maximum working pressure 500 PSI

Standard Reach: 10-1/2” Long x M14 x 1.25 / 500 PSI Working Pressure

Standard Reach: 10-1/2” Long x M10 x 1.00 / 500 PSI Working Pressure

SAVE THIS INSTRUCTION SHEET

You will need this instruction sheet for the safety warnings and precautions, assembly, operating, parts list and assembly diagram. Keep your invoice with this instruction sheet. Write the

invoice number on the front cover. Keep this instruction sheet and invoice in a safe and dry

place for future reference.

UNPACKING

When unpacking, check to make sure all the parts shown on the Assembly Diagram are

included. If any parts are missing or broken, please call Harbor Freight Tools at the number

shown on the front cover of this instruction sheet as soon as possible.

SAFETY WARNINGS AND PRECAUTIONS

1.

Use the Compression Kit only in well ventilated areas. A running engine

produces carbon monoxide. Carbon monoxide is a colorless, odorless

gas that, when inhaled, can cause serious injury or death.

Rev 11/06

Page 2

When warming up an engine in preparation for compression testing, make sure the

2.

vehicle’s transmission is placed in “Park” (or “Neutral” for a manual transmission)

and the emergency brake is applied.

Prior to using this product, read and adhere to all instructions and safety precau-

3.

tions as outlined in the vehicle manufacturer’s manual and engine diagnostic

manual.

Use extreme care when working around hot or moving engine parts.

4.

Do not exceed the maximum pressure capacity for this tool (300 PSI). Exceeding

5.

the maximum pressure capacity could cause serious personal injury and/or property

damage. Use only for intended purpose.

Use eye protection. Always wear ANSI-approved safety impact goggles during use.

6.

WARNING! The brass components of this product contain lead, a chemical known to the

7.

State of California to cause cancer and birth defects (or other reproductive harm).

(California Health & Safety Code § 25249.5, et seq.)

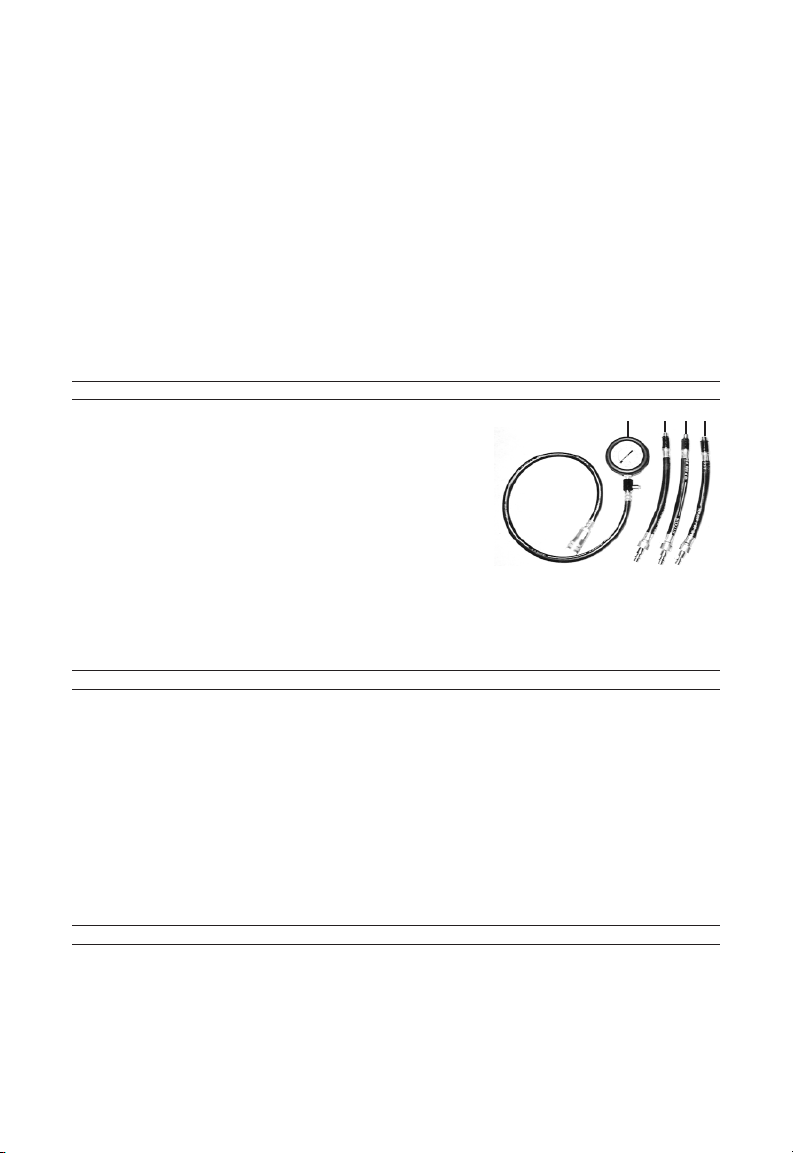

COMPONENTS

Compression Gauge (1): Displays cylinder pressure

1.

at cranking speed for an individual cylinder. When the

Gauge is not pressurized, the Gauge Needle may be

anywhere in the zero box without affecting the accuracy

of the Gauge.

M14 x 1.25 Standard Reach Adapter (2): Connects

2.

the Compression Gauge (1) to a cylinder that has

14mm standard length spark plug threads.

M12 x 1.25 Long Reach Adapter (3): Connects the

3.

Compression Gauge (1) to a cylinder that has 12mm extra length spark plug threads.

M10 x 1.00 Standard Reach Adapter (4): Connects the Compression Gauge (1) to a

4.

cylinder that has 10mm standard length spark plug threads.

1 4321 432

OPERATION

Attach the proper size Adapter (2, 3, 4) to the Compression Gauge (1) Hose.

1.

Remove the spark plug from one cylinder of the engine, and screw the Adapter into the

2.

spark plug hole. Disable coil to prevent engine from starting.

Crank the engine several times until the highest reading appears on the Compression

3.

Gauge (1). Make note of the reading, then press the Air Release Button on the Compression Gauge to release all compressed air in the tool.

Remove the Adapter from the spark plug hole and re-install the spark plug.

4.

NOTE: Some parts are listed and shown for illustration purposes only, and are not available individually as

replacement parts.

Due to continuing improvements, actual product may differ slightly from the product described herein.

PLEASE READ THE FOLLOWING

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR

WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE

PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND

PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY

THE BUYER. THE BUYER ASSUMES ALL RISKS AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF

REPLACEMENT PARTS THERETO.

SKU 95187 For technical questions, please call 1-800-444-3353 PAGE 2

Page 3

WARRANTY

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards,

and warrants to the original purchaser that this product is free from defects in materials and workmanship for

the period of ninety days from the date of purchase. This warranty does not apply to damage due directly or

indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities, or to lack of

maintenance. We shall in no event be liable for death, injuries to persons or property, or for incidental, contingent,

special or consequential damages arising from the use of our product. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation of exclusion may not apply to you. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with transportation charges prepaid.

Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection

verifies the defect, we will either repair or replace the product at our election or we may elect to refund the purchase

price if we cannot readily and quickly provide you with a replacement. We will return repaired products at our

expense, but if we determine there is no defect, or that the defect resulted from causes not within the scope of

our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

Limited 90 day

warranty

®

SKU 95187 For technical questions, please call 1-800-444-3353 PAGE 3

Loading...

Loading...