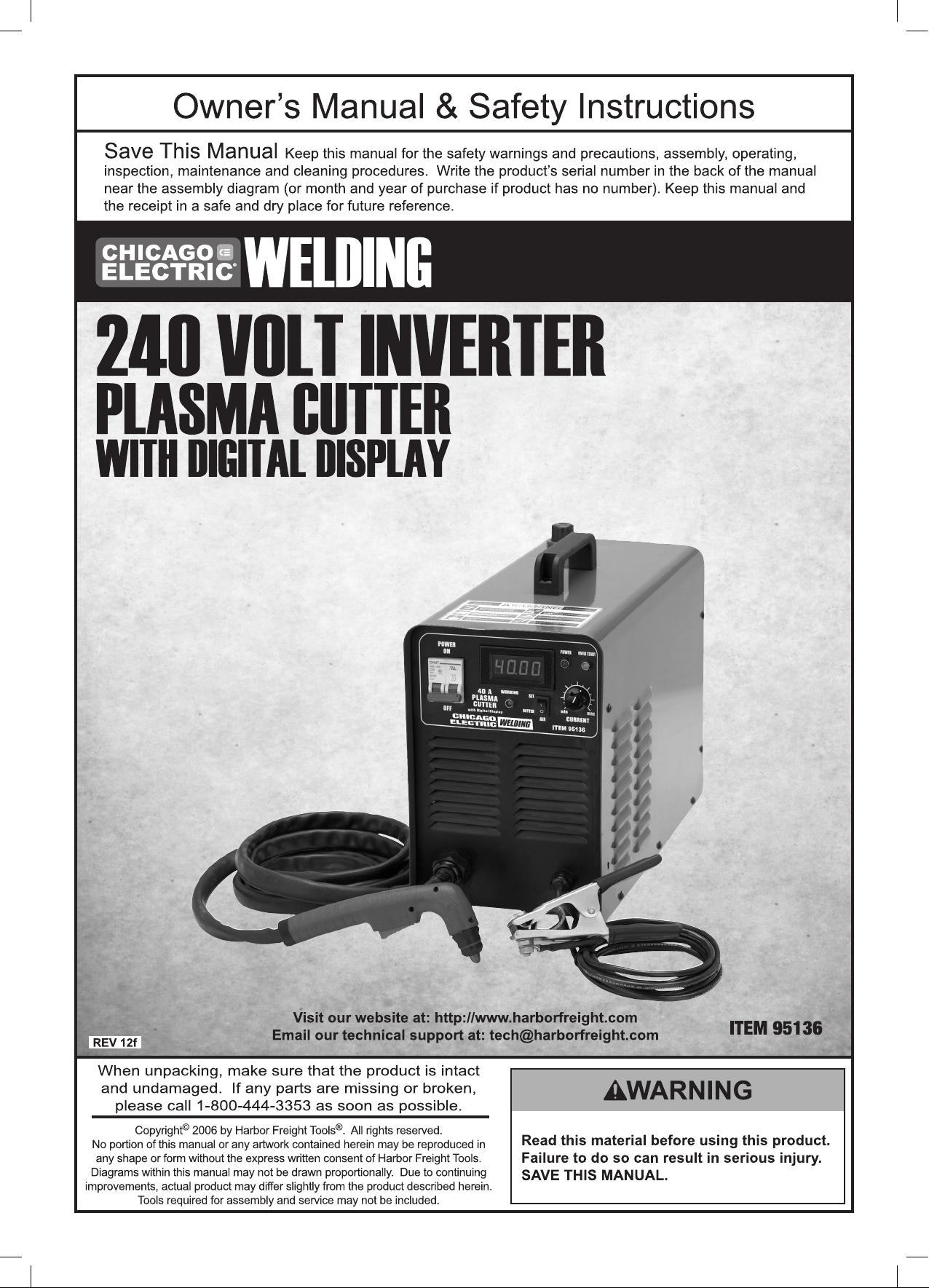

Page 1

Page 2

Table of Contents

Safety ......................................................... 2

Setup .......................................................... 5

SAFETY SERVICEOPERATION TECHNIQUESSETUP

Specications ............................................. 5

Operation ................................................... 10

Techniques ................................................ 12

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Maintenance .............................................. 13

Troubleshooting ......................................... 14

Parts List and Diagrams ............................ 18

Warranty .................................................... 22

WARNING SYMBOLS AND DEFINITIONS

Obey all safety messages that follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

IMPORTANT SAFETY INSTRUCTIONS

General Tool Safety Warnings

Read all safety warnings and instructions.

Failure to follow the warnings and instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference.

1. Maintain labels and nameplates on the tool.

These carry important information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

2. Maintain a safe working environment.

Keep the work area well lit. Make sure

there is adequate surrounding workspace.

Keep the work area free of obstructions, grease,

oil, trash, and other debris. Do not use in areas

near ammable chemicals, dusts, and vapors.

Do not use in a damp or wet location.

3. Avoid unintentional starting. Make sure

switch is in off position before plugging in.

Make sure you are prepared to begin

work before turning on the tool.

4. Never leave the tool unattended when

it is plugged into an electrical outlet.

Turn off the tool, and unplug it from its electrical

outlet before leaving. Unplug the tool from

its electrical outlet before performing

any inspection, maintenance, or cleaning

procedures, including changing accessories.

5. Prevent eye injury and burns. Wearing personal

protective equipment reduces the risk for injury.

• Wear an ANSI-approved welding helmet featuring

at least a number 10 shade lens rating.

• Leather leggings, re resistant shoes or

boots should be worn when using this

product. Do not wear pants with cuffs, shirts

with open pockets, or any clothing that can

catch and hold molten metal or sparks.

• Keep clothing free of grease, oil, solvents,

or any ammable substances. Wear dry,

insulating gloves and protective clothing.

Page 2 For technical questions, please call 1-800-444-3353. SKU 95136

Page 3

General Tool Safety Warnings (cont.)

• Wear an approved head covering to protect

the head and neck. Use aprons, cape, sleeves,

shoulder covers, and bibs designed and

approved for welding and cutting procedures.

• When welding/cutting overhead or in conned

spaces, wear ame resistant ear plugs or

ear muffs to keep sparks out of ears.

8. Prevent accidental res. Remove any

combustible material from the work area.

• When possible, move the work to a location well

away from combustible materials. If relocation

is not possible, protect the combustibles with

a cover made of re resistant material.

• Remove or make safe all combustible

materials for a radius of 35 feet (10 meters)

around the work area. Use a re resistant

material to cover or block all open doorways,

windows, cracks, and other openings.

• Enclose the work area with portable re

resistant screens. Protect combustible

walls, ceilings, oors, etc., from sparks

and heat with re resistant covers.

• If working on a metal wall, ceiling, etc.,

prevent ignition of combustibles on the other

side by moving the combustibles to a safe

location. If relocation of combustibles is not

possible, designate someone to serve as a

re watch, equipped with a re extinguisher,

during the cutting process and for at least

one half hour after the cutting is completed.

• Do not weld or cut on materials having a

combustible coating or combustible internal

structure, as in walls or ceilings, without an

approved method for eliminating the hazard.

• Do not dispose of hot slag in containers

holding combustible materials. Keep a re

extinguisher nearby and know how to use it.

• After welding or cutting, make a thorough

examination for evidence of re. Be aware

that easily visible smoke or ame may not

be present for some time after the re has

started. Do not weld or cut in atmospheres

containing dangerously reactive or ammable

gases, vapors, liquids, and dust.

• Provide adequate ventilation in work areas

to prevent accumulation of ammable gases,

vapors, and dust. Do not apply heat to a

container that has held an unknown substance

or a combustible material whose contents, when

heated, can produce ammable or explosive

vapors. Clean and purge containers before

applying heat. Vent closed containers, including

castings, before preheating, welding, or cutting.

• Only use compressed air to operate

the Plasma Welder/Cutter. Never use

other compressed gases. Don’t exceed

maximum PSI for this product as stated

on the specication table on page 6.

9. INHALATION HAZARD:

Welding and Cutting Produce

TOXIC FUMES.

Exposure to welding or cutting

exhaust fumes can increase

the risk of developing certain cancers,

such as cancer of the larynx and lung cancer.

Also, some diseases that may be linked to

exposure to welding or cutting exhaust fumes are:

• Early onset of Parkinson’s Disease

• Heart disease • Ulcers

• Damage to the reproductive organs

• Inammation of the small intestine or

stomach • Kidney damage

• Respiratory diseases such as

emphysema, bronchitis, or pneumonia

Use natural or forced air ventilation

and wear a respirator approved by

NIOSH to protect against the fumes

produced to reduce the risk of

developing the above illnesses.

10. Avoid overexposure to fumes and gases.

Always keep your head out of the fumes.

Do not breathe the fumes. Use enough ventilation

or exhaust, or both, to keep fumes and gases

from your breathing zone and general area.

• Where ventilation is questionable, have a

qualied technician take an air sampling to

determine the need for corrective measures.

Use mechanical ventilation to improve

air quality. If engineering controls are not

feasible, use an approved respirator.

• Work in a conned area only if it is well ventilated,

or while wearing an air-supplied respirator.

• Follow OSHA guidelines for

Permissible Exposure Limits (PEL’s)

for various fumes and gases.

• Follow the American Conference of

Governmental Industrial Hygienists

recommendations for Threshold Limit

Values (TLV’s) for fumes and gases.

• Have a recognized specialist in Industrial

Hygiene or Environmental Services

check the operation and air quality

and make recommendations for the

specic welding or cutting situation.

11. Keep hoses away from welding/cutting area.

Examine all hoses and cables for cuts, burns, or

worn areas before each use. If any damaged areas

are found, replace the hoses or cables immediately.

SAFETYSERVICE OPERATIONTECHNIQUES SETUP

Page 3For technical questions, please call 1-800-444-3353.SKU 95136

Page 4

General Tool Safety Warnings (cont.)

12. Proper cylinder care. Secure cylinders to a

cart, wall, or post, to prevent them from falling.

SAFETY SERVICEOPERATION TECHNIQUESSETUP

All cylinders should be used and stored in an

upright position. Never drop or strike a cylinder.

Do not use cylinders that have been dented.

Cylinder caps should be used when moving or

storing cylinders. Empty cylinders should be kept

in specied areas and clearly marked “empty.”

13. Never use oil or grease on any inlet connector,

outlet connector, or cylinder valves.

14. Use only supplied Torch on this Inverter

Air Plasma Cutter. Using components

from other systems may cause personal

injury and damage components within.

15. This product, when used for cutting and

similar applications, contains or produces

a chemical known to the State of California

to cause cancer and birth defects (or other

reproductive harm). (California Health

& Safety Code § 25249.5, et seq.)

16. People with pacemakers should consult

their physician(s) before using this product.

Electromagnetic elds in close proximity to

a heart pacemaker could cause interference

to, or failure of the pacemaker.

17. USE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. When

using an extension cord, be sure to use one heavy

enough to carry the current your product will draw.

An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating.

A 50 foot extension cord must be at least

12 gauge in diameter, and an 100 foot extension

cord must be at least 10 gauge in diameter.

If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

18. This product requires a 3-prong, 240 V~,

twist-lock plug (not included). This plug must

be installed by a qualied electrician.

19. KEEP CHILDREN AWAY. All visitors should

be kept safe distance from work area.

20. MAKE WORKSHOP KID PROOF with padlocks,

master switches, or by removing starter keys.

21. USE RIGHT TOOL. Don’t force tool or attachment

to do a job for which it was not designed.

22. SECURE WORK. Use clamps or a vise to

hold work. It’s safer than using your hand

and it frees both hands to operate tool.

23. MAINTAIN TOOLS WITH CARE.

Keep tools clean for best and safest performance.

Follow instructions for changing accessories.

Symbology

24. Inspect before every use;

do not use if parts loose or damaged.

Double Insulated

Canadian Standards Association

Underwriters Laboratories, Inc.

V~

A

n0 xxxx/min. No Load Revolutions per Minute (RPM)

Volts Alternating Current

Amperes

Page 4 For technical questions, please call 1-800-444-3353. SKU 95136

Page 5

Specications

Rated Input 240V~, 50/60Hz, 19.2A

60%

@

40 A

Rated Duty Cycle

Air Requirements 3.5 CFM @ 60-80 PSI

Power Switch Rocker Type

Weight 49.6 lb.

Cutting Current 15-40 A

Cutting Thickness 1/2″ Mild Steel Maximum

Arc Striking System Pilot Arc

Unit Size 20″ L x 8-1/8″ W x 14-3/8″ H

Air Inlet 1/4″ - 18 NPT

Duty Cycle

Duty Cycle is the equipment specication which denes the number of minutes

within a 10 minute period that a piece of equipment can safely operate.

This plasma cutter has a 60% duty cycle at 40 Amps, which means that it may be used only

6 minutes at 40 Amps out of any 10 minute period, and must be rested the remaining 4 minutes.

80%

100%

@

@

34.6 A

31 A

SAFETYSERVICE OPERATIONTECHNIQUES SETUP

CAUTION: Failure to observe the duty cycle limitations of this Plasma Cutter

can easily damage this equipment, and will void the warranty.

Page 5For technical questions, please call 1-800-444-3353.SKU 95136

Page 6

Setup

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this

SAFETY SERVICEOPERATION TECHNIQUESSETUP

Note: For additional information regarding the parts listed in the following pages,

refer to the Assembly Diagram near the end of this manual.

Note: This air tool may be shipped with a protective plug covering the air inlet. Remove this plug before set up.

manual including all text under subheadings therein before set up or use of this product.

Grounding

1. Attach a ground wire of at least 14 Ga.

thickness (not supplied) to the screw on the

lower left of the back of the tool case.

2. Connect the other end of the wire to an

appropriate ground, such as a steel workbench,

steel building member or grounding stake.

Page 6 For technical questions, please call 1-800-444-3353. SKU 95136

Page 7

Air Supply

TO PREVENT SERIOUS INJURY FROM EXPLOSION:

Use only clean, dry, regulated, compressed air with this tool.

Do not use oxygen, acetylene, carbon dioxide, combustible gases,

or any other bottled gas as a power source for this tool.

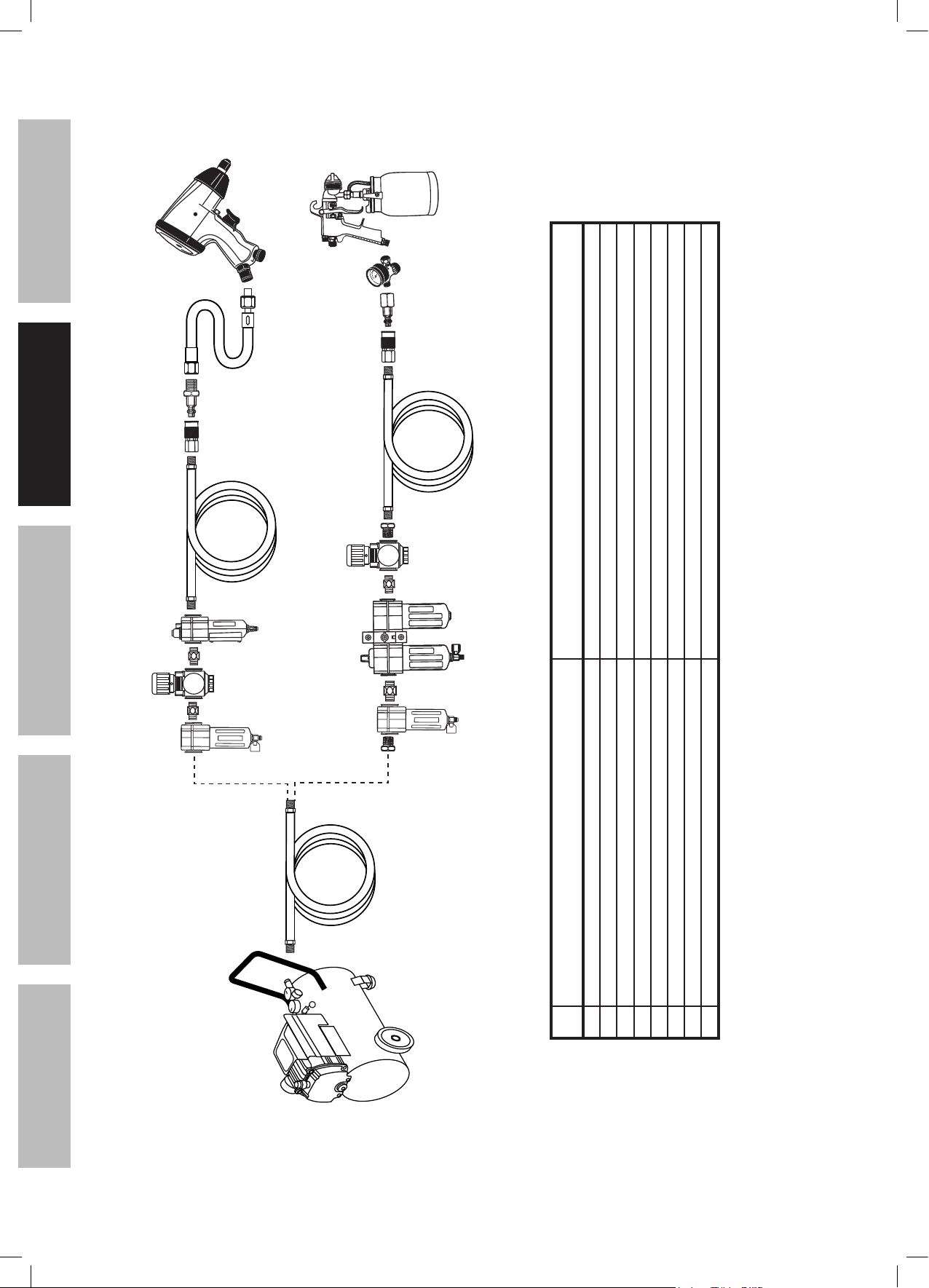

1. Incorporate a lter, regulator with pressure gauge,

dryer, in-line shutoff valve, and quick coupler for

best service, as shown on Figure A on page 8

and Figure B on page 9. An in-line shutoff

ball valve is an important safety device because

it controls the air supply even if the air hose

is ruptured. The shutoff valve should be a

ball valve because it can be closed quickly.

Note: An oiler system should not be used with

this tool. The oil will mix with the material

being propelled, causing poor results.

2. Attach an air hose to the compressor’s air outlet.

Connect the air hose to the air inlet on the back

of the Plasma Cutter. Other components, such

as a coupler plug and quick coupler, will make

operation more efcient, but are not required.

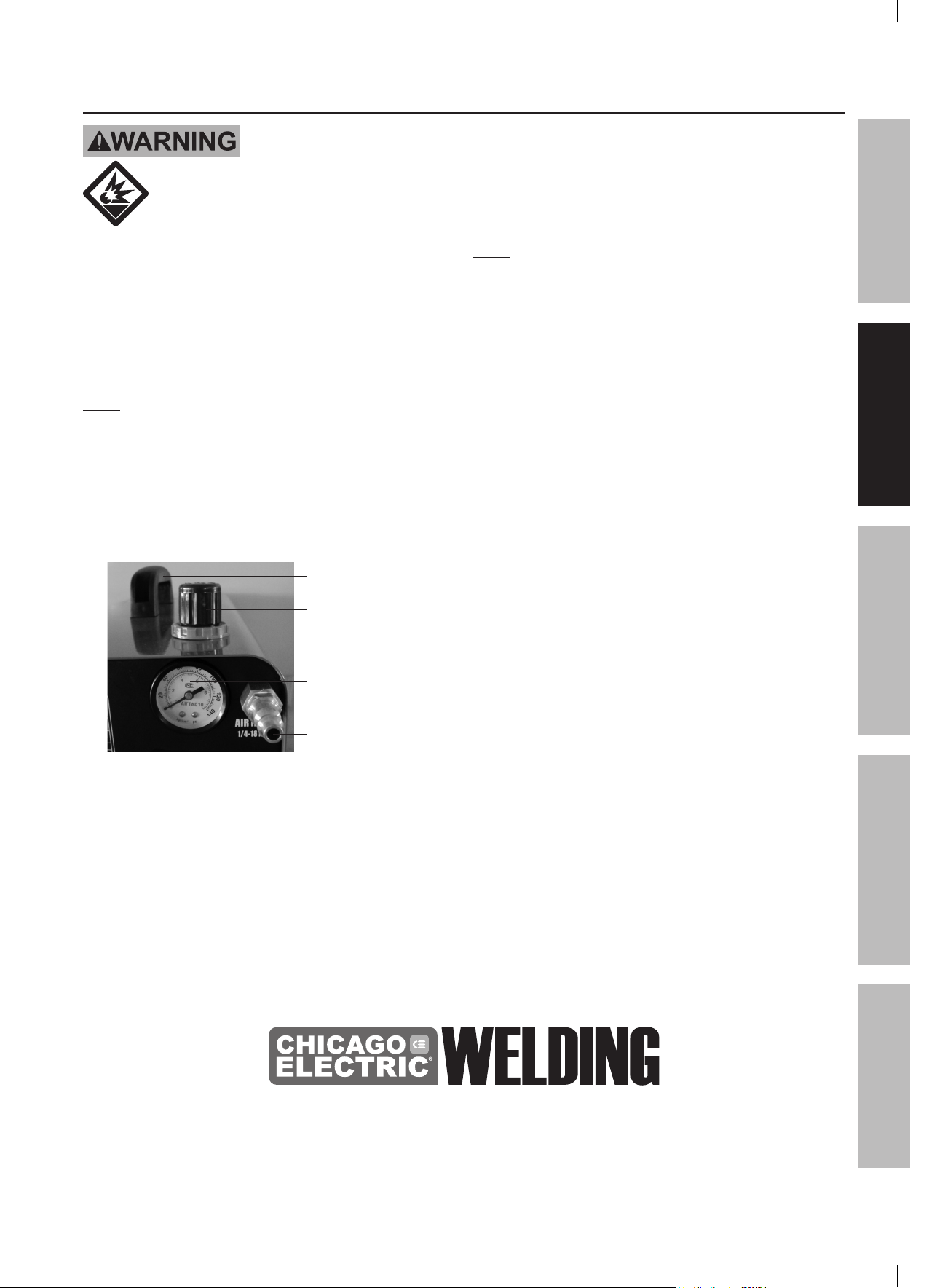

Handle

Air pressure

regulator knob

Note: Air ow, and therefore tool performance, can

be hindered by undersized air supply components.

The air hose must be long enough to reach

the work area with enough extra length to

allow free movement while working.

3. Turn the tool’s switch to the off position; refer to

Operation section for description of controls.

4. Close the in-line shutoff valve between

the compressor and the tool.

5. Turn on the air compressor according to

the manufacturer’s directions and allow it

to build up pressure until it cycles off.

6. Adjust the air compressor’s output regulator so

that the air output is enough to properly power

the tool, but the output will not exceed the tool’s

maximum air pressure at any time (60-80 PSI).

Adjust the pressure gradually, while checking the

air output gauge to set the right pressure range.

7. Inspect the air connections for leaks.

Repair any leaks found.

SAFETYSERVICE OPERATIONTECHNIQUES SETUP

Air pressure gauge

Air inlet

8. If the tool will not be used at this time, turn off

and detach the air supply, safely discharge

any residual air pressure, and release

the throttle and/or turn the switch to its off

position to prevent accidental operation.

Page 7For technical questions, please call 1-800-444-3353.SKU 95136

Page 8

SAFETY SERVICEOPERATION TECHNIQUESSETUP

C

F

E H

E

A

A

C

D

Figure A: Portable Air Supply Setup

B

Lubricated

Tools

A

G

B

Non-lubricated

Tools

Description Function

A Air Hose Connects air to tool

B Filter Prevents dirt and condensation from damaging tool or work piece

C Regulator Adjusts air pressure to tool

F Leader Hose (optional) Increases coupler life

E Coupler and Plug Provides quick connection and release

D Lubricator (optional) For air tool lubrication

H Air Adjusting Valve (optional) For ne tuning airow at tool

G Air Cleaner / Dryer (optional) Prevents water vapor from damaging work piece

Page 8 For technical questions, please call 1-800-444-3353. SKU 95136

Page 9

F

M

L

SAFETYSERVICE OPERATIONTECHNIQUES SETUP

L O

H

Slope

Lubricated

Figure B: Stationary Air Supply Setup

J

Tools

G

H

K

C

E

D

J

N

I

I

C

Non-lubricated

Tools

F

F

Description Function

C

B B

A A

I Filter Prevents dirt and condensation from damaging tool or work piece

J Regulator Adjusts air pressure to tool

A Vibration Pads For noise and vibration reduction

B Anchor Bolts Secures air compressor in place

C Ball Valve Isolates sections of system for maintenance

F Ball Valve To drain moisture from system

E Main Air Line - 3/4″ minimum recommended Distributes air to branch lines

D Isolation Hose For vibration reduction

H Air Hose Connects air to tool

G Branch Air Line -1/2″ minimum recommended Brings air to point of use

L Coupler and Plug Provides quick connection and release

K Lubricator (optional) For air tool lubrication

N Air Cleaner / Dryer (optional) Prevents water vapor from damaging work piece

O Air Adjusting Valve (optional) For ne tuning airow at tool

M Leader Hose (optional) Increases coupler life

Page 9For technical questions, please call 1-800-444-3353.SKU 95136

Page 10

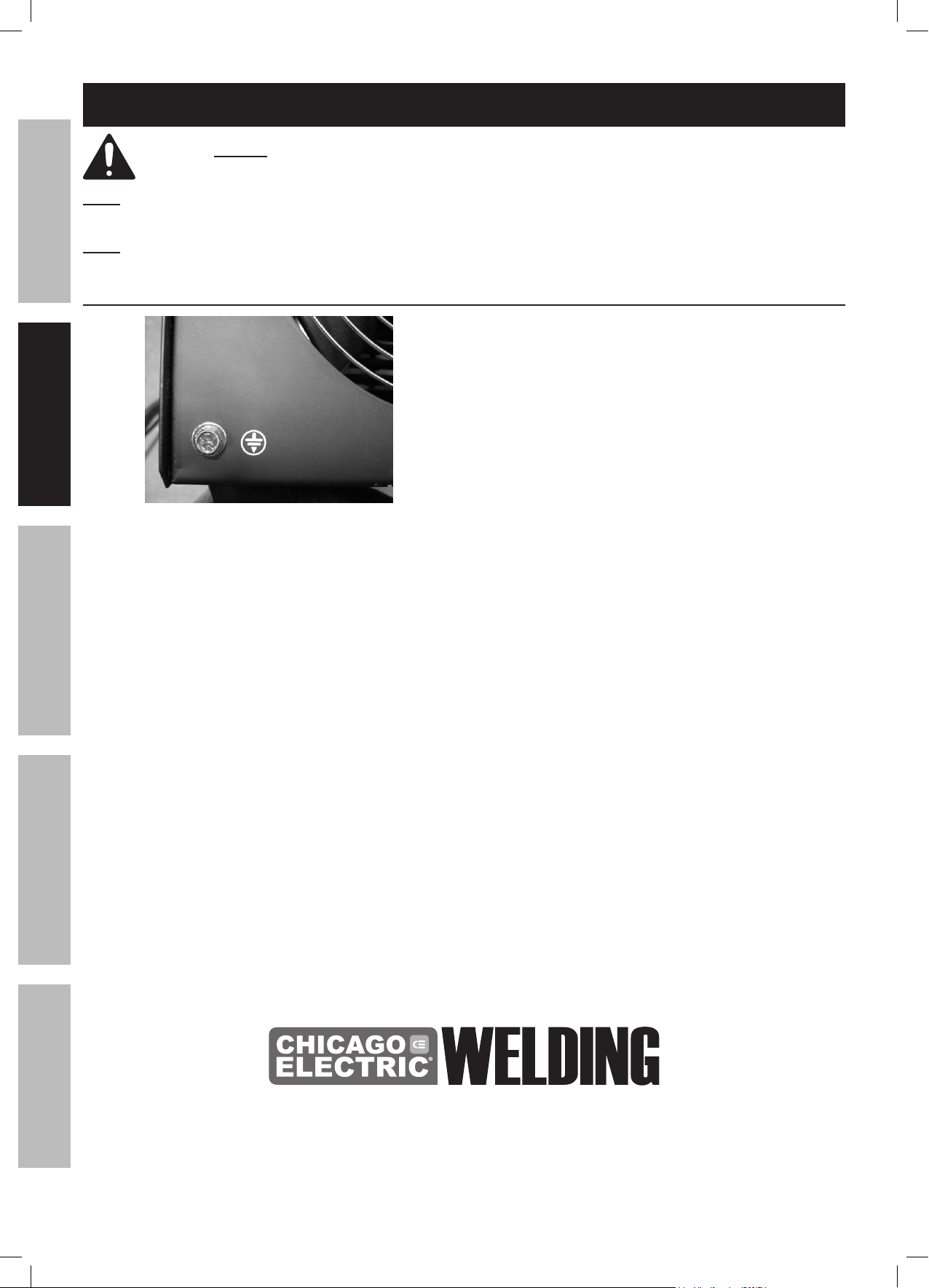

Operating Instructions

POWER

ON

POWER

WORKING

AIR

CURRENT

MIN MAX

SET

CUTTER

OVERHEAT

OFF

240 VOLT INVERTER PLASMA CUTTER

with Digital Display

ITEM 95136

GROUND

TORCH

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual

SAFETY SERVICEOPERATION TECHNIQUESSETUP

including all text under subheadings therein before set up or use of this product.

Controls and Indicators

4

2

1

7

3

5

6

1. Power Switch.

Up is ON, down is OFF.

2. Digital Amp Meter.

Shows actual cutting current,

which will vary during operation.

3. Thermal Overload Indicator Lamp.

This light will come on, and the device will

shut down if the tool becomes overheated.

Stop trying to use the cutter while leaving the

power switch ON to allow the cooling fan to

Torch

Connector

operate, and the lamp will turn off automatically

when the machine cools down.

Pay attention to Duty Cycle discussed on page 6.

Ground

4. Power ON Light.

Connector

5. Power Supply Controller.

6. Mode Selector.

Turns the air supply ON prior to cutting.

7. Working Indicator Light.

Will be on during cutting operation.

Preparing Your Work Area

1. You must have a sturdy work table that is

open below the area you are cutting. Molten

slag will be blown through the work metal,

and must be able to fall away freely.

2. Your work table must allow the work metal to be rmly

clamped to prevent it accidentally falling or moving.

3. The oor and surrounding area of your work site

must not be ammable. A clean cement oor is

recommended. The cutting process will eject

molten metal slag onto the oor, and it will scatter

for 8-10 feet or more in any direction. Have an

adequate re extinguisher available if needed.

Page 10 For technical questions, please call 1-800-444-3353. SKU 95136

Page 11

Basic Operation

1. Mount the metal to be cut to the metal

welding-cutting table. It should be mounted so

that the cutting debris falls to the cement oor.

2. Place the Air Plasma Cutter unit no closer

than six feet from the workpiece to be cut.

3. Connect an air hose and coupling (not supplied)

from the air supply tank to the Air Input Coupling at

the rear of the unit. See photo on page 6, bottom.

The air supply must be regulated to between 60

and 80 PSI as read on the Air Pressure Gauge.

The air supply must be dry. It is recommended

to install a moisture lter (not included) on

the compressor. Do not use an air oiler.

4. Connect the Torch Cable plug into the twist-lock

connector on the lower left unit front. Twist to lock.

5. Plug in the Grounding Cable into the

Ground Connector on the lower right

of the unit front. Twist to lock.

6. Securely place the clamping end of the Grounding

Cable Clamp to a part of the workpiece or

metal table that is clean of paint, oil, or dirt.

Clamp as close as possible to the workpiece

without damaging the cable during cutting.

7. Verify that the Power Switch is in the Off

(O) position, then plug the 240 V~ line cord

plug into an appropriate 240 V~ outlet.

8. Turn the Power Supply Controller to the

desired current (15 to 40 amps).

9. Adjust air pressure by turning the Pressure

Regulator Knob on top of the unit (see photo on

page 6). Read pressure on Pressure Gauge.

10. When everything is in place for cutting, press

the Power Switch UP to the ON position.

The green Power On Light will illuminate,

but the Torch is not yet energized.

11. Orient yourself to one side of the area to be cut,

and move the Welding Helmet Face Shield (not

included, see page 4 item 7) over your eyes.

12. BE CAREFUL! PILOT PLASMA ARC CAN

SEVERELY INJURE. Once the trigger

is squeezed, the arc will ignite. This

unit provides a pilot arc, so the torch

does not need to contact the workpiece

before the cutting arc ignites.

2A

1A

Part Description

1A Handle

2A Trigger

3A Body

4A Electrode

5A

6A Nozzle

7A Nozzle Holder

Insulating

Diffuser

3A

4A

5A

6A

7A

13.

Direct torch away from people and ammables

while you squeeze (and hold) the Torch Handle

Trigger (2A) to energize the Torch Electrode (4A).

The air output is delayed a few seconds to enable a

proper arc to begin.

Caution: The Torch handle is now energized.

Be careful not to touch anything else with the

Torch except the workpiece to be cut.

WARNING! Never look at the ignited arc without

ANSI-approved, arc shaded, eye protection in a full

face shield. Permanent eye damage or blindness can

occur. Skin burns can occur. Never breathe arc fumes.

14. Bring the Electrode (4A) of the Torch

close to the starting point of the cut. The

Working Indicator Light will come on.

15. Slowly move the Torch at a slight angle along the

cutting line with the Torch tip trailing.

The air causes the molten metal to fall away

from the workpiece being cut. If proper cutting

is not achieved, adjust the Power Supply

Controller to a higher level, and/ or increase

air ow. To increase air ow, press the Power

Switch to the Off (O) position, then adjust the air

pressure at the Air Pressure Regulator. The air

will continue to come out of the Torch Handle

for a few seconds once the trigger is released.

Note: If too much current is drawn from the Plasma

Cutter (i.e., short circuit), the Thermal Switch, an overload

protector, will activate and the red Thermal Overload

Indicator Light will light. The Plasma Cutter will turn off

until it cools down. To reset you must turn the power OFF

then back ON. Press the Trigger to begin cutting again.

16. When nished cutting:

a. Release the Torch handle trigger and lift

the Torch handle from the workpiece,

b. Press the Power Switch to the Off (O) position,

c. Set the Torch handle down on

the metal workbench,

d. Turn the air supply off,

e. Unplug the line cord from the electrical outlet.

SAFETYSERVICE OPERATIONTECHNIQUES SETUP

Page 11For technical questions, please call 1-800-444-3353.SKU 95136

Page 12

Technique

Using a plasma cutter is a skill that requires time and

effort to do well. Practice striking and maintaining

SAFETY SERVICEOPERATION TECHNIQUESSETUP

an arc on scrap work pieces before beginning

work. This will help you gauge the best settings

for the plasma cutter for the material at hand.

1. You can cut any metal that will conduct

electricity up to approximately ½″ thick mild

steel or equivalent. Very thin or very thick

metals are more difcult to cut cleanly.

2. Generally set the air pressure between 60 and

80 psi. Increased air pressure will increase

plasma speed and cutting pressure. Air pressure

and amperage should be adjusted in tandem.

3. Generally start with a mid-range amperage

setting (32-33 amps) and adjust up or down

from there. Increased amperage will increase

cutting heat. This is needed with heavier and

harder metals. However, increased amperage

will reduce Duty Cycle time. (See page 6.)

4. Move the cutting head more slowly for thicker and

harder metals, and more quickly for thin or soft

metals. Keep the cutting head moving while cutting.

What is Plasma?

Materials in Nature exist in one of four different

states: Solid, Liquid, Gas or Plasma. Plasma is very

rare on Earth because of its very high temperature,

however most of the matter in the universe is plasma.

The Sun, stars and galaxies are made of plasma.

On Earth, you will nd plasma in lightning and a

few other places. Neon tubes and orescent lights

contain low-temperature plasma when lighted.

The difference between water ice, liquid water and

water vapor is temperature. In each of these states,

temperature energy pushes the molecules of water

away from each other to change the state the water

is in. At very high temperature and pressure the water

molecules themselves break apart, and the atoms

begin to ionize. Normal atoms are made up of protons

and neutrons in the nucleus, surrounded by a cloud of

electrons. In plasma, the electrons separate from the

nucleus. The electrons are negatively charged, and

they leave behind their positively charged nuclei which

are known as ions. When the fast-moving electrons

collide with other electrons and ions, they release

vast amounts of energy. This energy is what gives

plasma its unusual status and great cutting power.

How Plasma Cutters Work

Plasma cutters work by feeding an inert gas (air)

through an electric arc. The air is then heated to

an extremely high temperature which converts

the gas to plasma which cuts the metal.

High temperature and pressure are required to create

a plasma. The electric arc provides the temperature,

and by exhausting the air through a very small

orice, the pressure is increased far beyond the

60-80 PSI operating pressure of the air supply.

Page 12 For technical questions, please call 1-800-444-3353. SKU 95136

Page 13

Service

Procedures not specically explained in this

manual

must be performed only by a

qualied technician.

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL OPERATION OR ELECTRIC SHOCK:

Make sure the Power Switch of the Plasma Cutter is in its "OFF" position and that the tool is unplugged

from the electrical outlet before performing any inspection, maintenance, or cleaning procedures..

TO PREVENT SERIOUS INJURY FROM TOOL FAILURE: Do not use damaged equipment.

If abnormal noise or vibration occurs, have the problem corrected before further use.

SAFETYSERVICE OPERATIONTECHNIQUES SETUP

1. Before each use, inspect the general condition

of the Air Plasma Cutter. Check for loose cable

connections, misalignment or binding of the fan,

cracked or broken parts, damaged electrical

wiring, and any other condition that may affect

its safe operation. If abnormal noise or vibration

occurs, have the problem corrected before

further use. Do not use damaged equipment.

2. Periodically recheck all nuts, bolts,

and screws for tightness.

3. Periodically blow the dust from the

cooling vents with compressed air.

4. Verify that the cooling fan is

operational before cutting.

5. If the unit repeatedly shuts down from

thermal overload, stop all use. Have the

Air Plasma Cutter inspected and repaired

by a qualied service technician.

6. Store the welder and accessories

in a clean and dry location.

7. Periodically disassemble and clean the Torch Head

components with steel wool. Replace burnt,

cracked, distorted, or coated components.

Refer to the assembly drawing on page 19.

8. To gain access to the internal components

of the unit, remove screws from Main Body

Cover. The home user is strongly advised not

to remove the tool covers and not to attempt

any electronic repairs. Any repairs must be

completed by a qualied technician. Opening

the tool will void any warranties, and may

result in damage to equipment or possible

personal injury. Do not open the housing.

9. On a daily basis check for any of the

following problems: if any are found, take

the tool to a qualied repair technician.

a. Abnormal vibration, sound or smell.

b. Abnormal heating at any cable connection.

c. The fan does not work properly.

d. Any switch or control does not work properly.

e. Any damage to cables.

Page 13For technical questions, please call 1-800-444-3353.SKU 95136

Page 14

Troubleshooting

IMPORTANT!

Be CERTAIN to shut off the Plasma Cutter, and disconnect it from power and air before adjusting, cleaning, or

SAFETY SERVICEOPERATION TECHNIQUESSETUP

repairing the unit. A technician should discharge all capacitors before performing any internal procedures.

FAN RUNS WHEN SWITCHED ON BUT ARC WILL NOT IGNITE

Air pressure too high or too low.

Check the Air Pressure setting

on the regulator’s gauge.

AIR PRESSURE

TOO HIGH

Adjust the Air Regulator

to deliver only 60-80 PSI

to the Cutter.

LOOSE

CONNECTIONS

Shut off switch, if not off already,

and tighten connections.

If connections do not tighten properly,

contact a qualied technician.

Check that all air and electrical

connections are tight.

AIR PRESSURE

CORRECT

AIR PRESSURE

TOO LOW

a. Verify that the compressor

is delivering at least

3.5 CFM @ 60 PSI.

b. Set Regulator on the

unit to at least 60 PSI.

TIGHT

CONNECTIONS

Disconnect the

Torch Cables.

Disassemble the torch

assembly and inspect all

internal components.

Replace any damaged

or missing components

and reassemble

carefully, following the

directions on page 11.

If the steps above do not solve the problem or if the repairs involved are too complex,

contact a qualied technician.

Page 14 For technical questions, please call 1-800-444-3353. SKU 95136

Page 15

Troubleshooting (cont.)

IMPORTANT!

Be CERTAIN to shut off the Plasma Cutter, and disconnect it from power and air before adjusting, cleaning, or

repairing the unit. A technician should discharge all capacitors before performing any internal procedures.

ARC IGNITES FOR SEVERAL SECONDS BUT THEN GOES OUT

Air pressure too high or too low.

Check the Air Pressure setting

on the regulator’s gauge.

SAFETYSERVICE OPERATIONTECHNIQUES SETUP

AIR PRESSURE

TOO HIGH

Adjust the Air Regulator

to deliver only 60-80 PSI

to the Cutter.

DIRTY OR

COATED METAL

Use a wire wheel brush or sander

(not included) to thoroughly

clean both the grounding point

and the area that will be cut.

If any cleaners are used, allow them

to dry thoroughly before continuing.

Check that the grounding point and

the metal being cut are both clean, dry,

and free from all coatings and paint.

These sections need to be able to

conduct electricity efciently.

AIR PRESSURE

CORRECT

AIR PRESSURE

TOO LOW

a. Verify that the compressor

is delivering at least

3.5 CFM @ 80 PSI.

b. Set Regulator on the

unit to at least 60 PSI.

METAL IS CLEAN IN

BOTH AREAS

Check that all air and electrical

connections are tight.

LOOSE

CONNECTIONS

Shut off switch,

if not off already, and

tighten connections.

If connections do not

tighten properly, contact

a qualied technician.

If the steps above do not solve the problem or if the repairs involved are too complex,

TIGHT

CONNECTIONS

Torch isn’t maintaining contact with the workpiece.

a. Be careful to not lose workpiece

contact after an arc is struck.

b. Disconnect the Torch Cables.

Disassemble the torch assembly and

inspect all internal components.

Replace any damaged or missing

components and reassemble carefully,

following the steps on page 11.

DO NOT OVERTIGHTEN.

c. Nozzle is moving too slowly across

the metal and cutting the material from

underneath, breaking contact.

contact a qualied technician.

Page 15For technical questions, please call 1-800-444-3353.SKU 95136

Page 16

Troubleshooting (cont.)

IMPORTANT!

Be CERTAIN to shut off the Plasma Cutter, and disconnect it from power and air before adjusting, cleaning, or

SAFETY SERVICEOPERATION TECHNIQUESSETUP

repairing the unit. A technician should discharge all capacitors before performing any internal procedures.

CUT GOES ONLY PARTIALLY THROUGH THE WORKPIECE

Material being cut is too thick.

Maximum thickness for steel is 1/2″.

WITHIN THICKNESS

RANGE

Turn up the current

adjustment knob

and try again.

PROBLEM

CORRECTED

Take note of the

setting required for

this metal thickness.

AIR PRESSURE

CORRECT

Disconnect the Torch Cables.

Disassemble the torch assembly

and inspect all internal components,

as explained on page 11.

MATERIAL

TOO THICK

Cut the object along one side

and then cut along the other.

If this is not practical, use

a more powerful Cutter.

PROBLEM PERSISTS AT

MAXIMUM SETTING

Air pressure too low.

Check the Air Pressure setting

on the regulator’s gauge.

AIR PRESSURE

TOO LOW

a. Verify that the compressor

is delivering at least

3.5 CFM @ 80 PSI.

b. Set Regulator on the

unit to at least 60 PSI.

TORCH IN GOOD

CONDITION

Cut at a slower pace, the arc

may not have enough time to

cut through the workpiece.

If the steps above do not solve the problem or if the repairs involved are too complex,

contact a qualied technician.

Page 16 For technical questions, please call 1-800-444-3353. SKU 95136

Replace any damaged or

missing components and

reassemble carefully, following

the directions on pages 6-11.

DAMAGED

COMPONENTS FOUND

Page 17

Troubleshooting (cont.)

IMPORTANT!

Be CERTAIN to shut off the Plasma Cutter, and disconnect it from power and air before adjusting, cleaning, or

repairing the unit. A technician should discharge all capacitors before performing any internal procedures.

FAST NOZZLE WEAR

OR

EXCESSIVE SLAG FORMATION

These two problems have similar causes

and will often appear simultaneously.

The same diagnostic procedures

and remedies apply to both.

Amperage setting too high; cut at lowest

setting possible for the metal being cut.

SAFETYSERVICE OPERATIONTECHNIQUES SETUP

PROBLEMS

REDUCED

Take into account the thickness

and type of metal to be cut before

starting. Thinner materials

require lower amp settings.

TORCH IN GOOD

CONDITION

Air supply pressure may be inadequate:

a. Verify that the compressor is

delivering at least 3.5 CFM @ 80 PSI.

b. Set Regulator on the unit

to at least 60 PSI.

PROBLEMS PERSIST AT

LOWEST PRACTICAL SETTING

Disconnect the Torch Cables.

Disassemble the torch assembly

and inspect all internal components,

as explained on page 11.

DAMAGED

COMPONENTS FOUND

Replace any damaged or

missing components and

reassemble carefully, following

the directions on pages 6-11.

If the steps above do not solve the problem or if the repairs involved are too complex,

contact a qualied technician.

Page 17For technical questions, please call 1-800-444-3353.SKU 95136

Page 18

Parts List and Diagrams

PLEASE READ THE FOLLOWING CAREFULLY

SAFETY SERVICEOPERATION TECHNIQUESSETUP

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS MANUAL

AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY

REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO

MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS

OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES

THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND

LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Parts List

Part Description Qty

1 Handle 1

2 Main body cover 1

3 Air supply solenoid 1

4 Control transformer 1

5 Transfer arc circuit board 1

6 Control circuit board 1

7 Chassis 1

8 Splitter 1

9 Current check coil 1

10 Reactor 1

11 Main transformer 1

12 Digital amp meter 1

13 Indicator 3

14 Air switch 1

15 Power supply controller 1

16 Lower cover 1

17 Torch cable connector 1

18 Ground cable connector 1

19 Air pressure relief valve 1

20 Internal & external tooth bent joints 1

21 Solenoid holder 1

22 Timing control PCB 1

23 Drive circuit board 1

Part Description Qty

24 Fast recover diode 1

25 Reactor 1

26 Metal resistor 2

27 Thermostat 1

28 Cement resistor 2

29 Radiator 1

30 Power switch 1

31 Breaker holder 1

32 Regulator 1

33 Pressure gauge 1

34 Fitting 1

35 Gas inlet connector 1

36 Power supply circuit board 1

37 Rectier bridge 1

38 Radiator 1

39 Radiator 1

40 Radiator 1

41 Inverter circuit board 1

42 Fan 1

43 Fan grill 3

44 Power cable connector 1

45 Insulated foot 4

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and

are not available individually as replacement parts.

Page 18 For technical questions, please call 1-800-444-3353. SKU 95136

Page 19

Assembly Diagram

SAFETYSERVICE OPERATIONTECHNIQUES SETUP

Page 19For technical questions, please call 1-800-444-3353.SKU 95136

Page 20

Wiring Diagram

ZT1

C4

103/3KV

C3

103/ 3KV

C5

103/3KV

ZK1

1 2

FL1

50A/75MV

400R/60W

LGK-40-cpu

L1

φ10×20

1KV/20D

10R/50W

10R/50W

1KV/20D

2*102/2KV

2*102/2KV

R1

400R/60W

1KV/20D

DA2F75P12SA

+

_

L=2mH

S2

AC

11

IN

+5VDC

GND

IN

PCB6

FHP06110508

AC

11

IN

+5VDC

GND

IN

+5VDC

GND

IN

PCB7

LED

+5VDC

GND

IN

R2

L2

L3

SAFETY SERVICEOPERATION TECHNIQUESSETUP

BD1

MDQ100-16

240VAC INPUT

P1

32A/500V

FAN1

104/280V

S1

32A/500V

104/ 630V

100k/3w

S1

CN4-3

CN4-4

CN4-5

FHP06320608-3

CN8-2

CN8-3

CN8-1

11 30

14

FHP06060506-3

S4

S2

CN4-1

CN1-3

CN1-1

CN9-1

DF1

CN9-2

24V/DC

CN5-1

5K /2W

CN5-4

CN6-2

CN6-3

CN7-3

CN2-1

22V

CN2-2

BK1

S4

CN2-1

CN2-6

CN2-3CN7-2

CN2-5

15V

CN1CN2

FHP06070509

CN4-1

CN4-2

CN3-1

CN3-2

FHP06930703-2

CN1-1

CN1-2

22V

CN3

CN4

CN5 -2

CN5 -1

FHP06640604-1

36

36

DC+

DC+

DC-

DC-

36

36

11

20

28

27

27

28

10

10

11

11

11

11

12

12

112220

241125

112220

241125

CN3

CN3

37

38

37

38

37

38

37

38

1131321130

1131321130

CN4

CN4

39

39

4043423941

4043423941

FHP06650604-1

1131323011

1131323011

FHP06060506-3

11

28

11

28

414043

42

414043

42

52

52

Iout1122v

Iout1122v

CT1

51

51

19

19

11

11

17

17

16

16

15

15

14

14

13

13

34

35

34

35

QA17050HA2BL/230V

BK1

22V

TH1

t

LED1 YL/D5

TH2

LED2 RED/D5

t

LED3 RED/D5

Page 20 For technical questions, please call 1-800-444-3353. SKU 95136

Page 21

ZT1

C4

103/3KV

C3

103/ 3KV

C5

103/3KV

ZK1

1 2

FL1

50A/75MV

400R/60W

LGK-40-cpu

L1

φ10×20

1KV/20D

10R/50W

10R/50W

1KV/20D

2*102/2KV

2*102/2KV

R1

400R/60W

1KV/20D

DA2F75P12SA

+

_

L=2mH

S2

AC

11

IN

+5VDC

GND

IN

PCB6

FHP06110508

AC

11

IN

+5VDC

GND

IN

+5VDC

GND

IN

PCB7

LED

+5VDC

GND

IN

R2

L2

L3

Wiring Diagram (cont.)

L2

ZT1

SAFETYSERVICE OPERATIONTECHNIQUES SETUP

L1

φ10×20

L3

R2

10R/50W

2*102/2KV

1KV/20D

DA2F75P12SA

1KV/20D

ZK1

10R/50W

400R/60W

C3

2*102/2KV

1KV/20D

R1

400R/60W

1 2

50A/75MV

FL1

C4

103/3KV

103/ 3KV

C5

103/3KV

L=2mH

S2

_

+

AC

AC

11

11

IN

IN

PCB6

FHP06110508

+5VDC

+5VDC

GND

GND

IN

IN

+5VDC

+5VDC

GND

GND

IN

IN

PCB7

LED

LGK-40-cpu

Page 21For technical questions, please call 1-800-444-3353.SKU 95136

Page 22

90 Day Warranty

Harbor Freight Tools Co. makes every effort to assure

that its products meet high quality and durability

SAFETY SERVICEOPERATION TECHNIQUESSETUP

standards, and warrants to the original purchaser

that this product is free from defects in materials and

workmanship for the period of 90 days from the date

of purchase. This warranty does not apply to damage

due directly or indirectly, to misuse, abuse, negligence

or accidents, repairs or alterations outside our facilities,

criminal activity, improper installation, normal wear and

tear, or to lack of maintenance. We shall in no event

be liable for death, injuries to persons or property, or

for incidental, contingent, special or consequential

damages arising from the use of our product. Some

states do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation of

exclusion may not apply to you. THIS WARRANTY IS

EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part

must be returned to us with transportation charges

prepaid. Proof of purchase date and an explanation

of the complaint must accompany the merchandise. If

our inspection veries the defect, we will either repair

or replace the product at our election or we may elect

to refund the purchase price if we cannot readily and

quickly provide you with a replacement. We will return

repaired products at our expense, but if we determine

there is no defect, or that the defect resulted from

causes not within the scope of our warranty, then

you must bear the cost of returning the product.

This warranty gives you specic legal rights and you may

also have other rights which vary from state to state.

Page 22 For technical questions, please call 1-800-444-3353. SKU 95136

Page 23

Page 23For technical questions, please call 1-800-444-3353.SKU 95136

Page 24

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Loading...

Loading...