Page 1

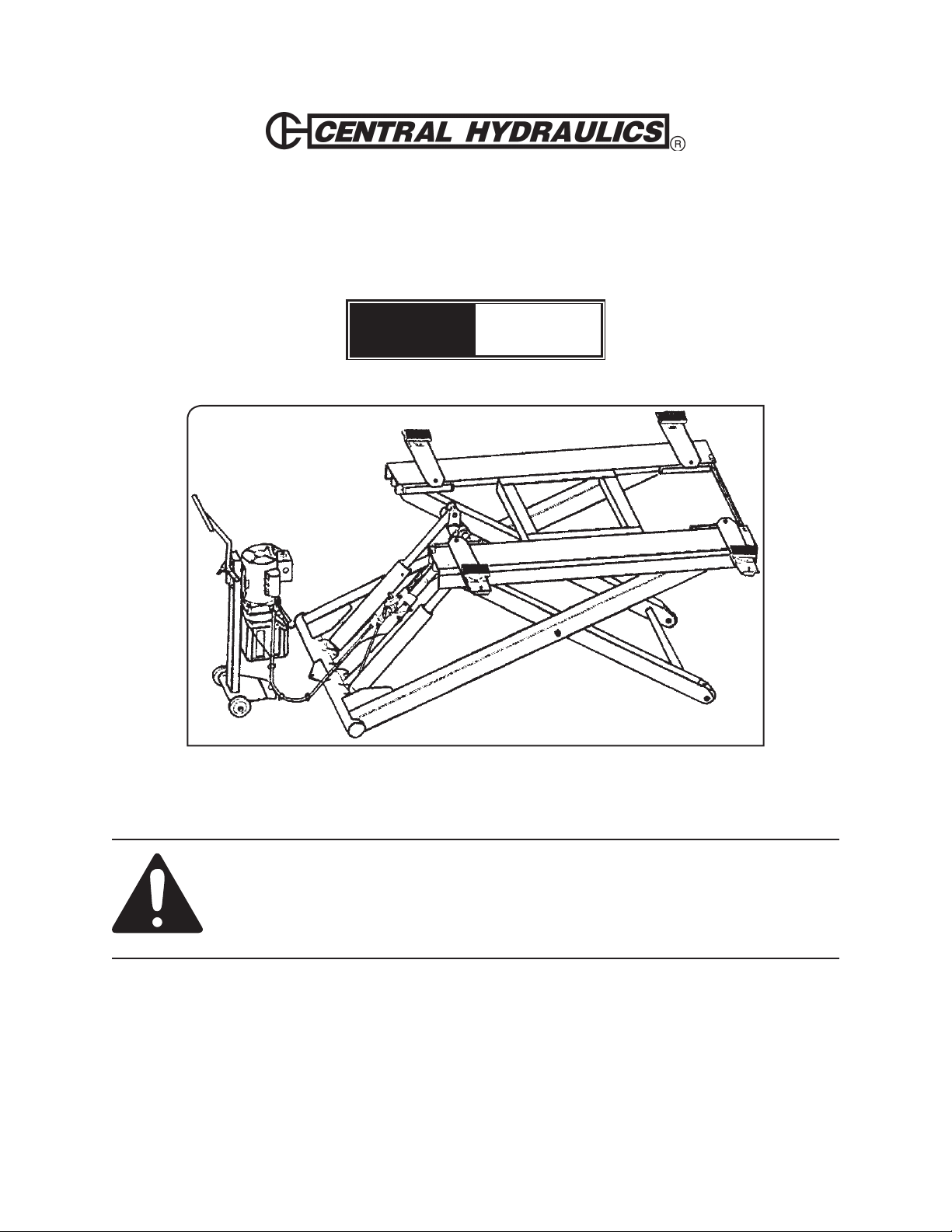

SCISSOR LIFT

6,000 LBS. CAPACITY - 48” HEIGHT

Model

91315

SET UP AND OPERATING INSTRUCTIONS

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2004 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Revised Manual 10j

Page 2

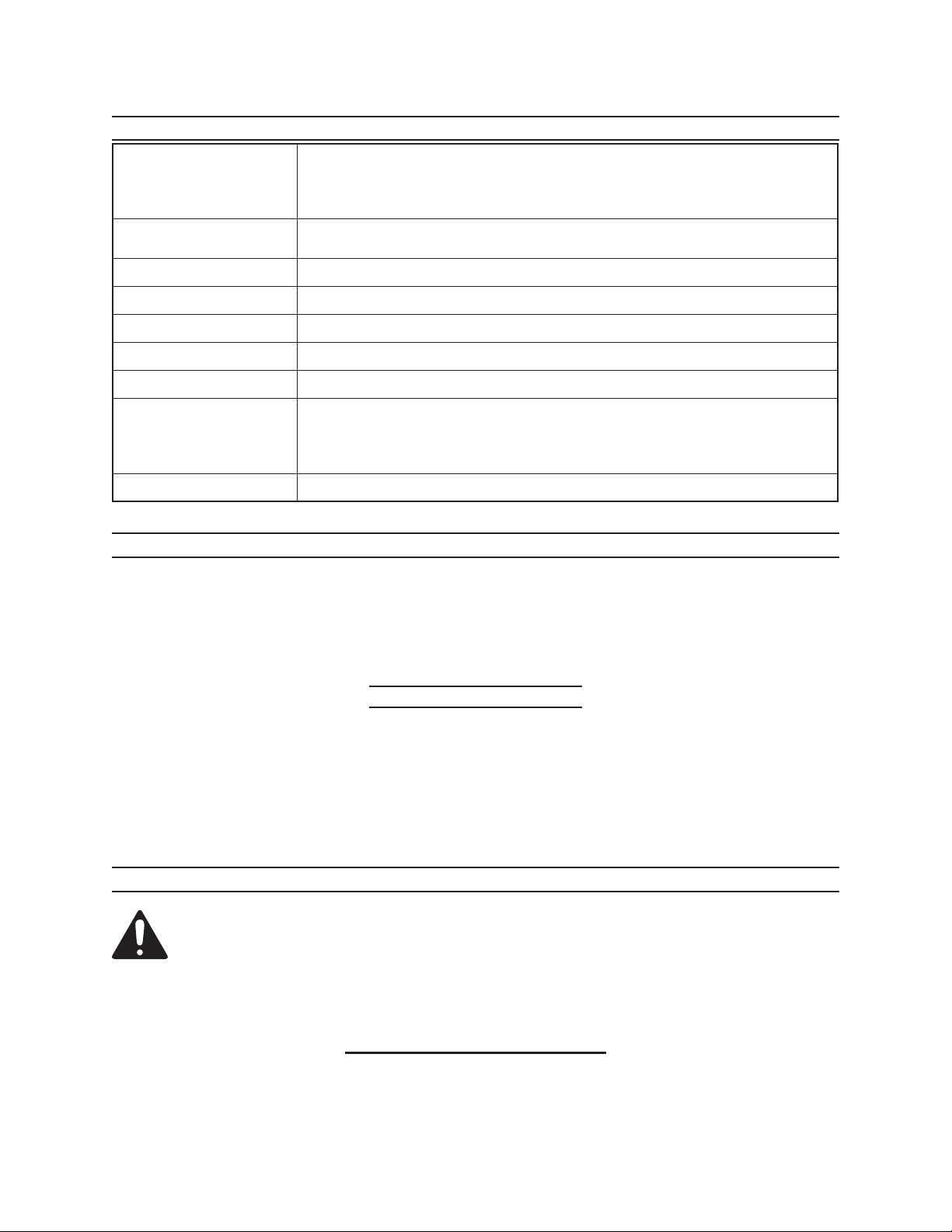

SPECIFICATIONS

220V / 50-60 Hz, 12 FLA / Duty Cycle: 5 min,

Electrical Requirements

Maximum Lifting

Capacity

Minimum Lift Height 7” At Pads

Maximum Lift Height 41/2’ At Pads

Overall Dimensions 993/4” L x 391/2” W x 7” H (Fully Lowered)

Piston Rod Travel 201/2”

Pump Type Hydraulic/Electro w/Steel Dolly

Pump Hydraulic Oil

Capacity/Type

Weight 849 Pounds

2 HP / Single Phase, Dedicated 20A circuit required

Requires a single phase, 3-prong 250V/20A (NEMA L6-20P) power plug (not

included).

6000 Pounds (48” Mid-Rise Scissor Lift)

6.5 Quarts

ISO VG 32 Hydraulic Oil

(Extreme temperature conditions may require an oil with a different

viscosity – consult a qualied technician.)

UNPACKING

When unpacking, check to make sure all the parts shown on the Parts Lists

on pages 17, 18, and 19 are included. If any parts are missing or broken, please

call Harbor Freight Tools at the number shown on the cover of this manual as soon as

possible.

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures, parts list and assembly

diagram. Keep your invoice with this manual. Write the invoice number on the inside

of the front cover. Keep this manual and invoice in a safe and dry place for future

reference.

GENERAL SAFETY RULES

WARNING! Read all instructions

Failure to follow all instructions listed below may result in electric shock,

re, and/or serious injury. The term “power tool” in all of the warnings listed

below refers to your line-operated (corded) power tool or battery-operated

(cordless) power tool.

SAVE THESE INSTRUCTIONS

REV 05l, 06k, 07j

SKU 91315 For technical questions, please call 1-800-444-3353. Page 2

Page 3

WORK AREA

1. Keep your work area clean and well lit. Cluttered benches and dark areas

invite accidents.

2. Do not operate power equipment in explosive atmospheres, such as in the

presence of ammable liquids, gases, or dust. Power equipment can create

sparks which may ignite ammables.

3. Keep bystanders, children, and visitors away while operating power

equipment. Distractions can cause you to lose control.

PERSONAL SAFETY

1. Stay alert. Watch what you are doing, and use common sense when

operating power equipment. Do not use power equipment while tired or

under the inuence of drugs, alcohol, or medication. A moment of inattention

while operating power equipment may result in serious personal injury.

2. RISK OF ENTANGLEMENT! Dress properly. Do not wear loose

clothing or jewelry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes, jewelry, or

long hair can be caught in moving parts.

3. Avoid accidental starting. Be sure the Power Switch is off before plugging

in. Plugging in power equipment with the Power Switch on invites accidents.

4. Remove adjusting keys or wrenches before turning on power equipment.

A wrench or a key that is left attached to a moving part of power equipment may

result in personal injury.

5. Do not overreach. Keep proper footing and balance at all times. Proper

footing and balance enables better control of the power equipment in unexpected

situations.

6. Use safety equipment. Always wear ANSI approved safety impact eye

goggles underneath a full face shield.

TOOL USE AND CARE

1. Use clamps (not included) or other practical ways to secure and support

the workpiece to a stable platform. Holding the work by hand or against your

body is unstable and may lead to loss of control.

2. Do not force power equipment. Use the correct equipment for your

application. The correct equipment will do the job better and safer at the rate for

which it is designed.

SKU 91315 For technical questions, please call 1-800-444-3353. Page 3

Page 4

3. Do not use power equipment if the Power Switch does not turn it on or off.

Any equipment that cannot be controlled with the Power Switch is dangerous and

must be repaired or replaced.

4. Disconnect the Power Cord Plug from the power source before making

any adjustments, changing accessories, or storing the power equipment.

Such preventive safety measures reduce the risk of starting the equipment

accidentally.

5. Store idle equipment out of reach of children and other untrained persons.

Power equipment is dangerous in the hands of untrained users.

6. Maintain power equipment with care. Properly maintained equipment are less

likely to fail and are easier to control. Do not use damaged power equipment.

Tag damaged power equipment “Do not use” until repaired.

7. Check for misalignment or binding of moving parts, breakage of parts, and

any other condition that may affect the power equipment’s operation. If

damaged, have the equipment serviced before using. Many accidents are

caused by poorly maintained power equipment.

8. Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one power equipment may become

hazardous when used on another power equipment.

SERVICE

1. Tool service must be performed only by qualied repair personnel. Service

or maintenance performed by unqualied personnel could result in a risk of injury.

2. When servicing a tool, use only identical replacement parts. Follow

instructions in the “Inspection, Maintenance, And Cleaning” section of this

manual. Use of unauthorized parts or failure to follow maintenance instructions

may create a risk of electric shock or injury.

ELECTRICAL SAFETY

1. Grounded tools must be plugged into an outlet properly installed and

grounded in accordance with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way. Do not use any adapter

plugs. Check with a qualied electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools should electrically malfunction or

break down, grounding provides a low resistance path to carry electricity away

from the user.

2. Double insulated tools are equipped with a polarized plug (one blade is

wider than the other). This plug will t in a polarized outlet only one way.

SKU 91315 For technical questions, please call 1-800-444-3353. Page 4

Page 5

If the plug does not t fully in the outlet, reverse the plug. If it still does

not t, contact a qualied electrician to install a polarized outlet. Do not

change the plug in any way. Double insulation eliminates the need for the

three wire grounded power cord and grounded power supply system.

3. Avoid body contact with grounded surfaces such as pipes, radiators,

ranges, and refrigerators. There is an increased risk of electric shock if your

body is grounded.

4. Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

5. Do not abuse the Power Cord. Never use the Power Cord to carry the

tools or pull the Plug from an outlet. Keep the Power Cord away from

heat, oil, sharp edges, or moving parts. Replace damaged Power Cords

immediately. Damaged Power Cords increase the risk of electric shock.

6. When operating a power tool outside, use an outdoor extension cord

marked “W-A” or “W”. These extension cords are rated for outdoor use, and

reduce the risk of electric shock.

WARNING!

IMPORTANT! A 220V / 50-60 Hz, 12 FLA / Duty Cycle: 5 min, 2 HP /

Single Phase, Dedicated 20A circuit is required. It also requires a

single phase, 3-prong 250V/20A (NEMA L6-20P) power plug (not

included).

THIS WIRING PROCEDURE MUST ONLY BE DONE BY A QUALIFIED,

CERTIFIED ELECTRICIAN!

Symbology

Double Insulated

Canadian Standards Association

Underwriters Laboratories, Inc.

V~

A

n0 xxxx/min.

Volts Alternating Current

Amperes

No Load Revolutions per Minute

(RPM)

SPECIFIC SAFETY RULES

1. DANGER! Make sure you know the weight of the vehicle you are

going to lift before using the Scissor Lift. Do not exceed the maximum lift

capacity (6,000 pounds at 48” elevation) for the Scissor Lift. Overloading the

Scissor Lift could cause personal injury and/or property damage. Be aware of

REV 07j

SKU 91315 For technical questions, please call 1-800-444-3353. Page 5

Page 6

dynamic loading! If a weight suddenly falls onto the Scissor Lift, it may create for

a brief instant an excess load which may result in personal injury and/or damage

to the vehicle and Scissor Lift.

2. Use the Scissor Lift only in well ventilated areas. Carbon monoxide

exhausted from running vehicle engines is a colorless, odorless fume that, if

inhaled, can cause serious personal injury or death.

3. Maintain labels and nameplates on the Scissor Lift. These carry important

information. If unreadable or missing, contact Harbor Freight Tools for a

replacement. There is a WARNING label attached to the Scissor Lift. Read and

fully understand the contents of the WARNING label. Do not remove the warning

label from the Scissor Lift.

4. Make sure to read and understand all instructions and safety precautions

as outlined in the manufacturer’s manual for the vehicle you are lifting. All

four Rubber Saddles (39B) of the Scissor Lift must be used when lifting a vehicle.

Always use the manufacturer’s recommended lifting points.

5. Do not use the Scissor Lift on any asphalt surface. Make sure the Scissor

Lift is used on a dry, oil/grease free, at, level, CONCRETE surface capable

of supporting the weight of the Scissor Lift, the vehicle being lifted, and any

additional tools and equipment. The concrete oor surface should have a

minimum thickness of 5”. The concrete must have a minimum strength of 4,000

PSI, and should be aged at least 30 days prior to use. Do not use the Scissor

Lift on concrete expansion seams or on cracked, defective concrete.

6. Always examine the Scissor Lift for structural cracks, bends, damage to

the hydraulic hoses and electrical wiring, and any other condition that may

affect the safe operation of the Lift. Do not use the Scissor Lift even if minor

damage is detected.

7. IMPORTANT! Operation (raising or lowering) of the Scissor Lift can be

immediately stopped at any time by releasing pressure on the Power

Switch located on the Motor (1A).

8. Make sure the Oil Tank (13A) is completely lled (approx. 6.5 quarts) with a

premium quality hydraulic oil prior to operating the Scissor Lift.

9. Always allow at least two seconds after the Motor (1A) starts to raise or

lower the Scissor Lift. Failure to do so may cause the Motor to burn out.

10. Prior to beginning a job, make sure the Safety Lock Assembly (36B) and its

Safety Catches are in the proper position. NEVER work underneath a vehicle

without using additional safety support devices (i.e., jack stands) to support the

vehicle.

SKU 91315 For technical questions, please call 1-800-444-3353. Page 6

Page 7

11. Always keep hands, ngers, and feet away from the moving parts of the

Scissor Lift when applying or releasing a load. Remain clear of the Scissor

Lift when raising or lowering a vehicle.

12. Use extreme caution when applying or releasing a load. Never allow the load

to suddenly release. Slowly and carefully apply and release the load.

13. Never leave the Scissor Lift unattended when the Lift is under a load.

Whenever the Scissor Lift is under a load there is a very large amount of force

that has been stored in the Outside/Inside Scissors (24B, 25B) which must be

controlled until the load is relaxed.

14. Before driving a vehicle onto the Scissor Lift make sure the Lift is fully

lowered. Before driving a vehicle onto the Scissor Lift, position the Plates (42B)

and Rubber Saddles (39B) inward. Do not hit or run over the Plates and Rubber

Saddles, as this could damage the vehicle. Make sure the Scissor Lift is fully

lowered before driving the vehicle off.

15. Should any weight component be removed from, or added to the vehicle,

use a jack stand (not included) to support the over balanced end during the

maintenance procedure. Do not operate the Scissor Lift if the vehicle load tilts

or binds during the up or down movement. Always position the vehicle with the

center of gravity midway between the Rubber Saddles (39B). Avoid excessive

rocking of the vehicle while it is in its raised position.

16. Never lift a vehicle with anyone inside it. Do not allow others in the lift area

while operating the Scissor Lift. Do not allow anyone to ride on the Scissor Lift

while it is being raised or lowered.

17. When lifting a vehicle raise the Rubber Saddles (39B) slowly until the

Rubber Saddles securely contact the vehicle manufacturer’s recommended

lifting points. Then, lift the vehicle to the desired working height. ALWAYS lift

the vehicle high enough for the Safety Lock Assembly (36B) to operate properly.

18. Do not use the Scissor Lift as a permanent stand for a vehicle. Use the

Scissor Lift only while making repairs. Then, immediately remove the vehicle

from the Scissor Lift.

19. Before lowering the Scissor Lift, make sure tool trays, stands, and all other

tools and equipment are removed from under the vehicle.

20. Make sure to squeeze and hold in on the Brake Lever (13B) before

attempting to lower the vehicle. Do not release pressure on the Brake Lever

until the Scissor Lift is completely lowered.

21. Before removing a vehicle from the Scissor Lift make sure the Plates (42B)

and Rubber Saddles (39B) are moved inward to provide an unobstructed

exit.

SKU 91315 For technical questions, please call 1-800-444-3353. Page 7

Page 8

22. People with pacemakers should consult their physician(s) before use.

Electromagnetic elds in close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.

23. This product contains or produces a chemical known to the State of California to

cause cancer and birth defects (or other reproductive harm). (California Health &

Safety Code § 25249.5, et seq.)

24. The warnings, precautions, and instructions discussed in this manual cannot

cover all possible conditions and situations that may occur. The operator must

understand that common sense and caution are factors which cannot be built into

this product, but must be supplied by the operator.

ASSEMBLY INSTRUCTIONS

Note: For additional references to the parts listed in the following pages, refer to the

Assembly Diagrams on pages 17, 18, and 19.

Determine The Proper Scissor Lift Location:

1. Do not use the Scissor Lift on any asphalt surface. Make sure the Scissor

Lift is used on a dry, oil/grease free, at, level, CONCRETE surface capable

of supporting the weight of the Scissor Lift, the vehicle being lifted, and any

additional tools and equipment. The concrete oor surface should have a

minimum thickness of 5”. The concrete must have a minimum strength of 4,000

PSI, and should be aged at least 30 days prior to use. Do not use the Scissor

Lift on concrete expansion seams or on cracked, defective concrete.

2. Make sure to check the desired location for possible obstructions such as a low

ceiling, overhead lines, adequate working area, access ways, exits, etcetera.

3. Make sure to allow a minimum space of 14 feet in front and behind the Scissor

Lift to accommodate all vehicles. Certain allowances should be made for special

vehicle requirements or unusual oor plans.

SKU 91315 For technical questions, please call 1-800-444-3353. Page 8

Page 9

To Attach The Hydraulic Pump To The Scissor Lift:

HYDRAULIC PUMP - SIDE VIEW

POWER

SWITCH

POWER CORD

HYDRAULIC OIL DELIVERY PORT

PRESSURE RELIEF

VALVE HANDLE

(3A)

OIL TANK FILL CAP

OIL TANK

(13A)

MOTOR

(1A)

DOLLY ARM

HANDLE

(11B)

BOLT (14B)

BRAKE LEVER ASS’Y.

(13B)

OIL PIPE CONNECTOR

(17B)

BRAKE STEEL CABLE

(10B)

GENERAL INLET PIPE

(18B)

FIGURE D

1.

Locate the Hydraulic Pump unit (1A through 15A) in an area where it will be out

of the way, is safe from damage and weather, and where it can be easily reached

to operate. (See Figure D.)

2. One end of the General Inlet Pipe (18B) has been pre-attached to the Scissor

Lift by the manufacturer. To attach the remaining end of the General Inlet Pipe to

the Hydraulic Pump wrap the male threads of the Oil Pipe Connector (17B) with

about 4” of pipe thread seal tape (not included). Remove the Oil Filler Nut Cap

(4A) from the threaded Hydraulic Oil Delivery Port. Then, wrench tighten the Oil

Pipe Connector into the Hydraulic Oil Delivery Port. (See Figure D.)

3. One end of the Brake Steel Cable (10B) has been pre-attached to the Scissor

Lift by the manufacturer. The Brake Lever Assembly (13B) is located on the

remaining end of the Brake Steel Cable, and must be attached to the Handle

(11B) of the Dolly. To do so, slide the Brake Lever Assembly onto the Handle.

Then, secure the Brake Lever Assembly to the Handle by tightening the Bolt

(14B). (See Figure D.)

SKU 91315 For technical questions, please call 1-800-444-3353. Page 9

Page 10

To Fill The Oil Tank With Hydraulic Oil:

The hydraulic Oil Tank (13A) has a holding capacity of 6.5 quarts. To ll the Oil

Tank, squeeze and hold the Brake Lever (13B) to release any load on the Scissor

Lift. Remove the Oil Tank Fill Cap on the Oil Tank. Add a premium quality

hydraulic oil until the level of the oil is even with the Oil Tank’s ll hole. Then,

replace the Oil Tank Fill Cap. (See Figure D.) Before the rst use and before

all subsequent uses, check the hydraulic oil tank to make sure the Oil Tank is

properly lled.

OPERATING INSTRUCTIONS

Check The Safety Lock Assembly:

PLATE

(42B)

RUBBER SADDLE

(39B)

SAFETY LOCK ASSEMBLY

(1C THROUGH 11C)

GENERAL INLET PIPE

(18B)

BRAKE STEEL CABLE

(10B)

FIGURE E

1.

WARNING! Never operate the Scissor Lift if the Safety Lock Assembly

(1C through 11C) is not working properly. (See Figure E.)

2. Insert the Power Plug (not included) of the Lift into a properly grounded, 3-hole,

220 volt electrical receptacle, and allow several seconds for the Motor (1A) to

warm up. (See Figure D.)

3. Squeeze and release the Brake Lever (13B) several times and, while doing so,

observe that the Safety Lock Assembly (1C through 11C) operates properly in

REV 07j

SKU 91315 For technical questions, please call 1-800-444-3353. Page 10

Page 11

response to the Brake Lever. Then, release pressure on the Brake Lever.

(See Figures D and E.)

4. Press on the Power Switch and hold, and observe that the Safety Lock Assembly

(1C through 11C) “clicks” into place as the Scissor Lift rises. NOTE: There are

safety catches on the Safety Lock Assembly as the Scissor Lift rises. Once the

Safety Lock Assembly locks into each of these safety catches, you must squeeze

and hold in on the Brake Lever (13B) to lower the Scissor Lift.

(See Figures D and E.)

5. Once the Scissor Lift is fully elevated, release pressure on the Power Switch.

(See Figure D.)

6. Without squeezing the Brake Lever (13B), press in on the Pressure Relief Valve

Handle (3A) and hold. Observe that the Scissor Lift will not lower, as the Safety

Lock Assembly (1C through 11C) is engaged. CAUTION! If the Safety Lock

Assembly does not engage, fully lower the Scissor Lift and have a qualied

service technician immediately repair the Safety Lock Assembly.

(See Figures D and E.)

7. Should the Safety Lock Assembly (1C through 11C) not operate as described

in Step #6, raise the Scissor Lift slightly to take pressure off the safety catches.

Then, while squeezing the Brake Lever (13B) lower the Scissor Lift fully to the

oor.

Note: When working properly, you must BOTH squeeze in and hold the Brake Lever

and press in and hold the Pressure Relief Valve Handle (3A) to lower the Scissor

Lift. (See Figure D.)

To Position, Lift, And Lower A Vehicle On The Scissor Lift:

1. Before driving a vehicle onto the Scissor Lift make sure that the Lift is fully

lowered, and position the Plates (42B) and Rubber Saddles (39B) inward.

(See Figure E.)

SKU 91315 For technical questions, please call 1-800-444-3353. Page 11

Page 12

DRIVE-ON

DIRECTION

OF VEHICLE

UNDERNEATH

VEHICLE

DIMENSIONAL

CENTER OF

VEHICLE

CENTER

OF

GRAVITY

VEHICLE

ENGINE

FIGURE F

2.

Drive the vehicle over the Scissor Lift while keeping the vehicle parallel with

the Lift and aligning the center of gravity of the vehicle with the center of the

Lift. NOTE: The “Center of Gravity” (COG) of the vehicle is the balance point at

which there is equal weight in front of and behind the COG, and equal weight on

both sides of the COG. The COG is not necessarily the dimensional center of

the vehicle, but is often slightly toward the engine from the dimensional center of

the vehicle. (See Figure F.)

3. Turn off the vehicle’s engine and engage the parking brake of the vehicle.

4. Read the vehicle owner’s manual to identify the recommended vehicle lifting

points.

5. Move the Plates (42B) outward, and position the Rubber Saddles (39B) to

contact the vehicle lifting points. (See Figures E and F.)

6. WARNING! Do not lift the vehicle if you cannot establish secure and level

lifting points. Do not use substandard shims or other devices in place of

approved and recommended Rubber Saddle (39B) adapters. Never use the

Scissor Lift without the Rubber Saddles in place on each Plate (42B) and in

contact with the lifting points of the vehicle. (See Figure E.)

7. Once the Rubber Saddles (39B) have been positioned under the vehicle lifting

points, operate the Power Switch to lift the vehicle slightly, and test to make sure

the vehicle is well balanced and the contact between the Rubber Saddles and

vehicle lifting points are secure. Then, proceed to lift the vehicle to the desired

height. (See Figure E.)

8. NOTE: When the vehicle has been lifted to the desired height, and the Safety

Lock Assembly (1C through 11C) has locked in place, make sure to install proper

safety jack stands (not included), under the vehicle once it is lifted to the desired

height, as an additional safety measure.

SKU 91315 For technical questions, please call 1-800-444-3353. Page 12

Page 13

9. Once the repair work to the vehicle is completed make sure to remove all tools,

safety jack stands, and materials from under the vehicle and Scissor Lift. Also,

make sure the work area is clear and it is safe to lower the vehicle.

10. To lower the Scissor Lift, use the Power Switch and raise the vehicle slightly

to take weight off the Safety Lock Assembly (1C through 11C). Then, release

pressure on the Power Switch. (See Figure D.)

11. Stand well away from the Scissor Lift and vehicle. Then squeeze and hold in the

Brake Lever (13B) while at the same time pushing in and holding the Pressure

Release Valve Handle (3A) to slowly lower the Scissor Lift all the way down to

the oor. (See Figure D.)

12. Move the Rubber Saddles (39B) and Plates (42B) inward, out of the path of the

vehicle. (See Figure E.)

13. Disengage the vehicle parking brake. Start the vehicle’s engine, and drive the

vehicle off the Scissor Lift slowly and carefully.

INSPECTION, MAINTENANCE, AND CLEANING

WARNING! Always unplug the Power Cord from its electrical outlet before

performing any inspection, adjustments, maintenance, or cleaning.

1. Before each use, inspect the general condition of the Scissor Lift. Check for

loose screws, misalignment or binding of moving parts, cracked or broken parts,

damaged electrical wiring and hoses, and any other condition that may affect its

safe operation. If abnormal noise or vibration occurs, have the problem corrected

before further use.

Do not use damaged equipment.

2. Daily: With compressed air or a vacuum, remove all dirt and debris from the

Scissor Lift. Also, use a detergent or mild solvent to remove oil and grease from

the unit. Then, use a premium quality, machine oil to lubricate all moving parts.

3. Daily: Check the level of hydraulic oil in the Oil Tank. The Oil Tank (13A) has a

holding capacity of 6.5 quarts. To ll the Oil Tank, squeeze and hold the Brake

Lever (13B) to release any load on the Scissor Lift. Remove the Oil Tank Fill Cap

on the Oil Tank. Add a premium quality hydraulic oil until the level of oil is even

with the Oil Tank’s ll hole. Then, replace the Oil Tank Fill Cap. (See Figure D.)

SKU 91315 For technical questions, please call 1-800-444-3353. Page 13

Page 14

PARTS LIST/ASSEMBLY DIAGRAM A

Part Description Qty.

1A Motor 1

2A Nut (M20 x 1.5) 1

3A Pressure Relief Valve Handle 1

4A Oil Fill Cap 1

5A Release Valve Assy. 1

6A Check Valve Assy. 1

7A 9 Gear Bearing Cap 1

8A Safety Valve Nut Cap 1

1A

Part Description Qty.

9A Safety Valve Assy. 1

10A Valve Seat 1

11A Gear Pump 1

12A Bolt 2

13A Oil Tank 1

14A Bolt 4

15A Bumper Assy. 1

2A

3A

4A

6A

5A

10A

11A

13A

7A

8A

9A

15A

12A

14A

NOTE: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

SKU 91315 For technical questions, please call 1-800-444-3353. Page 14

Page 15

PARTS LIST/ASSEMBLY DIAGRAM B

Part #

1B Table 1

2B Retaining Ring (18) 6

3B Locking Nut (M20) 1

4B Oil Pipe Connector (3) 3

5B Branch Inlet Pipe 2

6B Oil Pipe Connector (2) 2

7B Oil Supply Fitting 1

8B Nut (M8) 4

9B Washer (8) 4

10B Brake Steel Cable 1

11B “Down” Handle 1

12B Hex Screw (M8) 4

13B Brake Lever Assy. 1

14B Bolt (M8) 4

15B Dolly 1

16B Rubber Cap 3

17B Oil Pipe Connector (1) 1

18B General Inlet Pipe 1

19B Check Valve 2

20B Safety Locking Pin 1

21B Retaining Ring (20) 6

Description Qty.

Part #

23B Scissor Pin 2

24B Outer Scissor 1

25B Inner Scissor 1

26B Wheel Pin 2

27B Large Wheel 2

28B Small Wheel 2

29B Wheel Pin 2

30B Connecting Pin 2

31B Cylinder Pin 2

32B Safety Lock Pin 1

35B Cylinder Assy. 2

36B Safety Lock Assy. 1

37B Retaining Ring (24) 2

38B Saddle Holder 4

39B Rubber Saddle 4

40B Locking Nut 4

41B Washer (20) 4

42B Plate 4

43B Bolt (M8 x 20) 4

44B Ring (15) 2

45B Wheel 2

46B Nut 2

Description Qty.

NOTE: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

REV 07a, 10j

SKU 91315 For technical questions, please call 1-800-444-3353. Page 15

Page 16

PARTS LIST/ ASSEMBLY DIAGRAM C

Part # Description Qty.

1C Pin 1

2C Spring 1

3C Lock Block 1

4C Lock Pole 3

5C Lock Wheel 1

6C Nut M (8) 1

7C Bolt (M8) 1

8C Steel Wire Cable 1

9C Lock Sheath 1

10C Washer (12) 1

11C Bolt (M12) 1

12C Check Valve 1

11C

10C

12C

1C

2C

4C

9C

8C

7C

6C

3C

5C

NOTE: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND

ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE

MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF

ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE

PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT.

IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL

REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND

LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK

AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR

REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF

REPLACEMENT PARTS THERETO.

SKU 91315 For technical questions, please call 1-800-444-3353. Page 16

Page 17

90 Day Warranty

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality

and durability standards, and warrants to the original purchaser that this product is free

from defects in materials and workmanship for the period of 90 days from the date of

purchase. This warranty does not apply to damage due directly or indirectly, to misuse,

abuse, negligence or accidents, repairs or alterations outside our facilities, criminal

activity, improper installation, normal wear and tear, or to lack of maintenance. We

shall in no event be liable for death, injuries to persons or property, or for incidental,

contingent, special or consequential damages arising from the use of our product.

Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation of exclusion may not apply to you. THIS WARRANTY

IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the

complaint must accompany the merchandise. If our inspection veries the defect, we

will either repair or replace the product at our election or we may elect to refund the

purchase price if we cannot readily and quickly provide you with a replacement. We will

return repaired products at our expense, but if we determine there is no defect, or that

the defect resulted from causes not within the scope of our warranty, then you must

bear the cost of returning the product.

This warranty gives you specic legal rights and you may also have other rights which

vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

REV 07j

SKU 91315 For technical questions, please call 1-800-444-3353. Page 17

Loading...

Loading...