Harbor Freight Tools 91012 Product manual

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference.

Visit our website at: http://www.harborfreight.com

Email our technical support at: productsupport@harborfreight.com

REV 14i

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

Copyright© 2009 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Specifications

Up to 12 Gauge Sheet Metal at 18″

Bending Capacity

(Gauge x Width)

Bend Angles 0 to 120°

Max. Box Depth 3″

Max. Beam Lift 7/8″

Up to 16 Gauge Sheet Metal at 36″

Up to 16 Gauge Mild Steel at 18″

Up to 20 Gauge Mild Steel at 36″

Up to 22 Gauge Stainless Steel

IMPORTANT SAFETY INFORMATION

1. Do not exceed the maximum bending capacities

of 18” wide stock (for 12 gauge steel) or

36” wide stock (for 16 gauge steel.)

2. Wear ANSI-approved safety goggles and

heavy-duty work gloves during assembly.

3. Keep fingers clear of Press Plate (14) and

Press Plate Assembly (17) during use.

4. Assemble only according to these instructions.

Improper assembly can create hazards.

5. Place only on a flat, stable surface able

to support weight of Metal Brake, item

being bent, and the bending force.

6. Verify that installation surface has no hidden

utility lines before drilling the holes.

Assembly and Installation Instructions

WARNING! The weight of the Brake and Stand requires

that two people assist in the assembly and installation.

1. Place the Metal Brake (back side) on the floor

with the mounting feet facing forward.

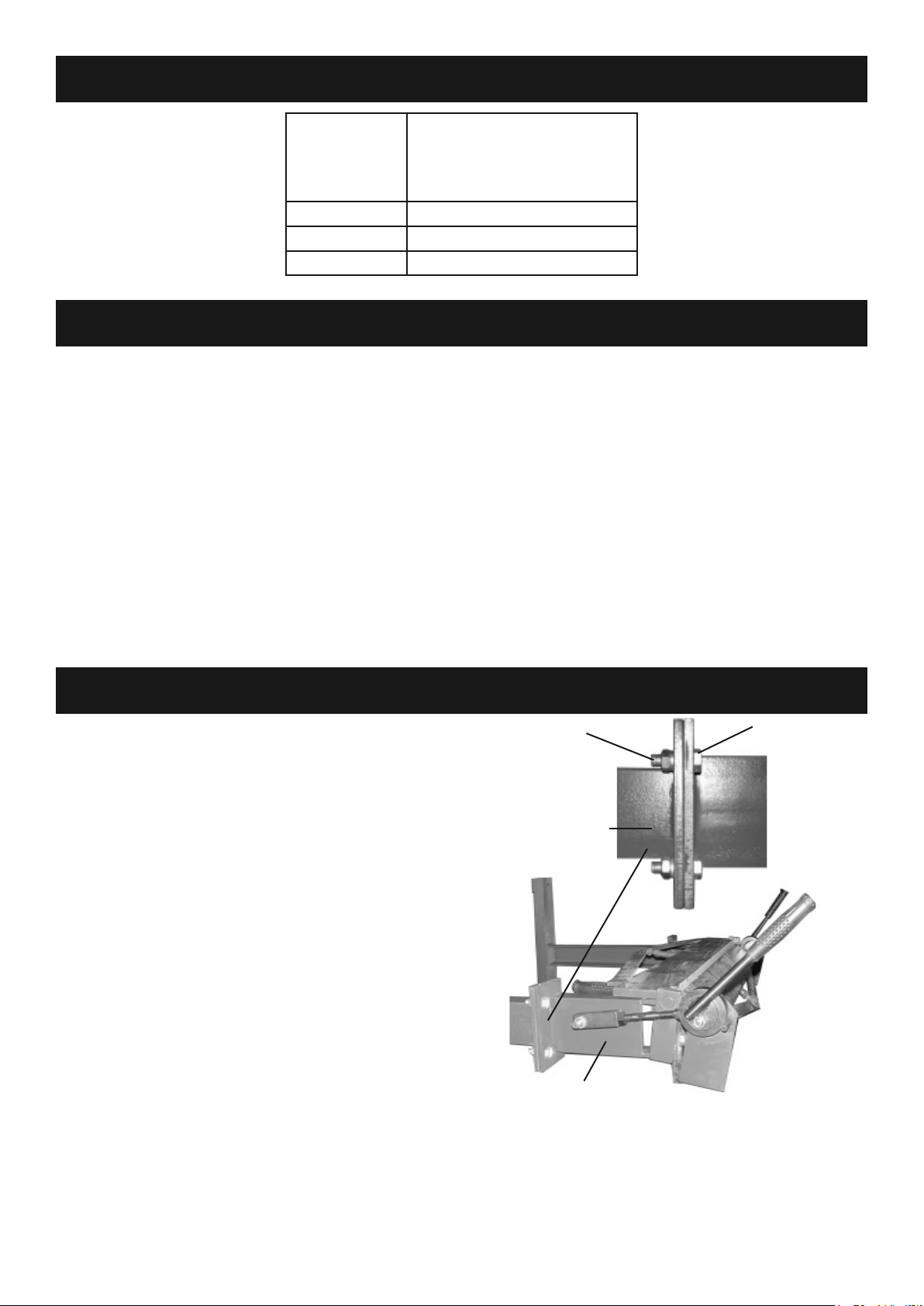

2. Place the Left Brake Stand (20) mounting pad

against the left mounting foot of the Brake.

3. Assemble with Bolt (12), Washer (11), and Nut (10)

as shown in Figure A. Securely tighten.

7. Keep assembly and work area clean and well lit.

8. Keep bystanders out of the area

during assembly and use.

9. Do not assemble when tired or when under the

influence of drugs, alcohol or medication.

10. This product is not a toy. Do not allow

children to play with or near this item.

11. Use as intended only.

12. Inspect before every use; do not use

if parts are loose or damaged.

13. Maintain product labels and nameplates. These carry

important safety information. If unreadable or missing,

contact Harbor Freight Tools for a replacement.

Nut (10)

Bolt (12)

and Washer

(11)

Left and Right

Brake Stands

(19, 20)

4. Mount the Right Brake Stand (19)

as described in Step 2.

5. Using two people, carefully lift the

Brake and Stand it upright.

6. Place the Brake and Stand in the location where it will

be mounted to the floor, then mark through the 1/2 inch

holes in the Left and Right Brake Stands (20 and 19).

CAUTION! Before drilling the mounting holes, verify that you

will not be drilling through any utility lines or water pipes.

7. Drill four mounting holes into the floor

and secure the Brake with four bolts*,

lock washers, and nuts (not supplied).

*Use expansion anchor bolts for concrete floors.

For wooden floors, use lag bolts.

Page 2 For technical questions, please call 1-888-866-5797. Item 91012

Body (18)

Figure A

Loading...

Loading...