Page 1

LATHE DUPLICATOR ATTACHMENT

®

(FOR USE WITH LATHE MODEL 90265)

MODEL 90692

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http//www.harborfreight.com

Copyright 2003 by Harbor Freight Tools. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions, please call 1-800-444-3353.

Page 2

PRODUCT SPECIFICATIONS

Item Description

Product Compatibility For use with Lathe Model 90265

Maximum Turning Length 38”

Maximum Bowl Diameter 8”

Overall Length 40”

Overall Height 7-1/2”

Overall Width 4-5/16”

Scale Inches/Metric – 1/16” & 1MM Segments

Cutting Tool Dimensions 0.195” x 0.512” x 7.875”

Accessories 3MM Hex Wrench

4MM Hex Wrench

6MM Hex Wrench

10MM/12MM Combo Open End Wrench

Weight 22.20 Pounds

SAVE THIS MANU AL

You will need this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures, parts list and assembly diagram. Keep your invoice with this manual. Write the invoice number

on the inside of the front cover. Keep this manual and invoice in a safe and dry

place for future reference.

UNPACKING

When unpacking, check to make sure all the parts shown in the Parts List on page 13 are

included. If an y parts are missing or broken, please call Harbor Freight Tools at the number shown on the cover of this manual as soon as possible.

GENERAL SAFETY WARNINGS AND PRECAUTIONS

1. Keep work area clean and dry. Cluttered, damp, or wet work areas invite

injuries.

2. Keep children away from work area. Do not allow children to handle this

product.

SKU 90692 PAGE 2

Page 3

3. Store idle equipment. When not in use, tools and equipment should be stored

in a dry location to inhibit rust. Always lock up tools and equipment, and keep out

of reach of children.

4. Do not use this product if under the influence of alcohol or drugs. Read

warning labels on prescriptions to determine if your judgement or reflexes are

impaired while taking drugs. If there is any doubt, do not attempt to use this

product.

5. Maintain labels and nameplates on this product. These carry important

information. If unreadable or missing, contact Harbor Freight Tools for a replacement.

6. Dress safely. Do not wear loose clothing or jewelry, as they can become caught

in moving parts. Wear a protective hair covering to prevent long hair from becoming caught in moving parts.

7. Do not overreach. Keep proper footing and balance at all times to prevent

tripping, falling, back injury, etcetera.

8. Industrial applications must follow OSHA requirements.

9. Stay alert. Watch what you are doing at all times. Use common sense. Do not

use this product when you are tired or distracted from the job at hand.

10. Check for damaged parts. Before using this product, carefully check that it will

operate properly and perform its intended function. Check for damaged parts

and any other conditions that may affect the operation of this product. Replace

or repair damaged or worn parts immediately.

11. Replacement parts and accessories: When servicing, use only

identical replacement parts. Only use accessories intended for use with this

product. Approved accessories are available from Harbor Freight Tools.

12. Maintain this product with care. Keep this product clean and dry during storage for better and safer performance. For your safety, service and maintenance

should be performed regularly by a qualified technician.

13. Use the right equipment for the job. Do not attempt to force small equipment

to do the work of a larger industrial tool. There are certain applications for which

this equipment was designed. It will do the job better and more safely at the rate

for which it was intended. Do not modify this equipment, and do not use this

equipment for a purpose for which it was not intended.

14. WARNING! The warnings, precautions, and instructions discussed in this manual

SKU 90692 PAGE 3

Page 4

cannot cover all possible conditions and situations that may occur. The operator

must understand that common sense and caution are factors, which cannot be

built into this product, but must be supplied by the operator.

SPECIFIC PRODUCT WARNINGS AND PRECAUTIONS

1. This Lathe Duplicator Attachment is designed for use ONLY with the Lathe

Model 90265 (available from Harbor Freight Tools). Make sure to read and

understand all instructions and safety precautions as outlined in the manufacturer’s manual for the Model 90265 Lathe with which the Lathe Duplicator

Attachment will be used.

2. Maintain a safe working environment. Keep the work area well lit. Make sure

there is adequate surrounding workspace. Always keep the work area free of

obstructions, oil, grease, trash, and other debris.

3. Keep all safety guards in place, in proper adjustment, and in proper align-

ment.

4. Prior to starting the Lathe and Lathe Duplicator Attachment, make sure all

adjusting keys and wrenches are removed from the equipment.

5. Never adjust the Lathe Duplicator Attachment while it is running. Turn off

and unplug the Lathe from its electrical outlet. Wait until the Lathe comes to a

complete stop before performing any adjustments .

6. Protect hands and fingers from possible injury. Keep hands and fingers

away from the chuck, centers, and other moving parts.

7. Wear eye, face, and hearing protection. Always wear an ANSI approved full

face safety shield and ANSI approved hearing protectors when using the Lathe

Duplicator Attachment. Wear ANSI approved dust masks or a respirator if the

work performed creates excessive dust.

8. Never leave the Lathe Duplicator Attachment unattended while it is running.

Turn off the electrical power to the Lathe, and do not leave the Lathe Duplicator

Attachment until the Lathe comes to a complete stop.

9. Never stand on the Lathe Duplicator Attachment. Serious injury could occur if

the equipment is tipped or if the sharp centers are accidentally contacted.

10. Keep the Cutting Tool sharp and dry for better and safer performance.

SKU 90692 PAGE 4

Page 5

11. Keep the Lathe Duplicator Attachment dry and its moving parts properly

oiled for better and safer performance.

12. WARNING! Some dust created by power sanding, sawing, grinding, drilling,

lathe operations, and other construction activities, contain chemicals known (to

the State of California) to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are: lead from lead-based paints, crystalline

silica from bricks and cement or other masonry products, arsenic and chromium

from chemically treated lumber. Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

(California Health & Safety Code 25249.5, et seq.)

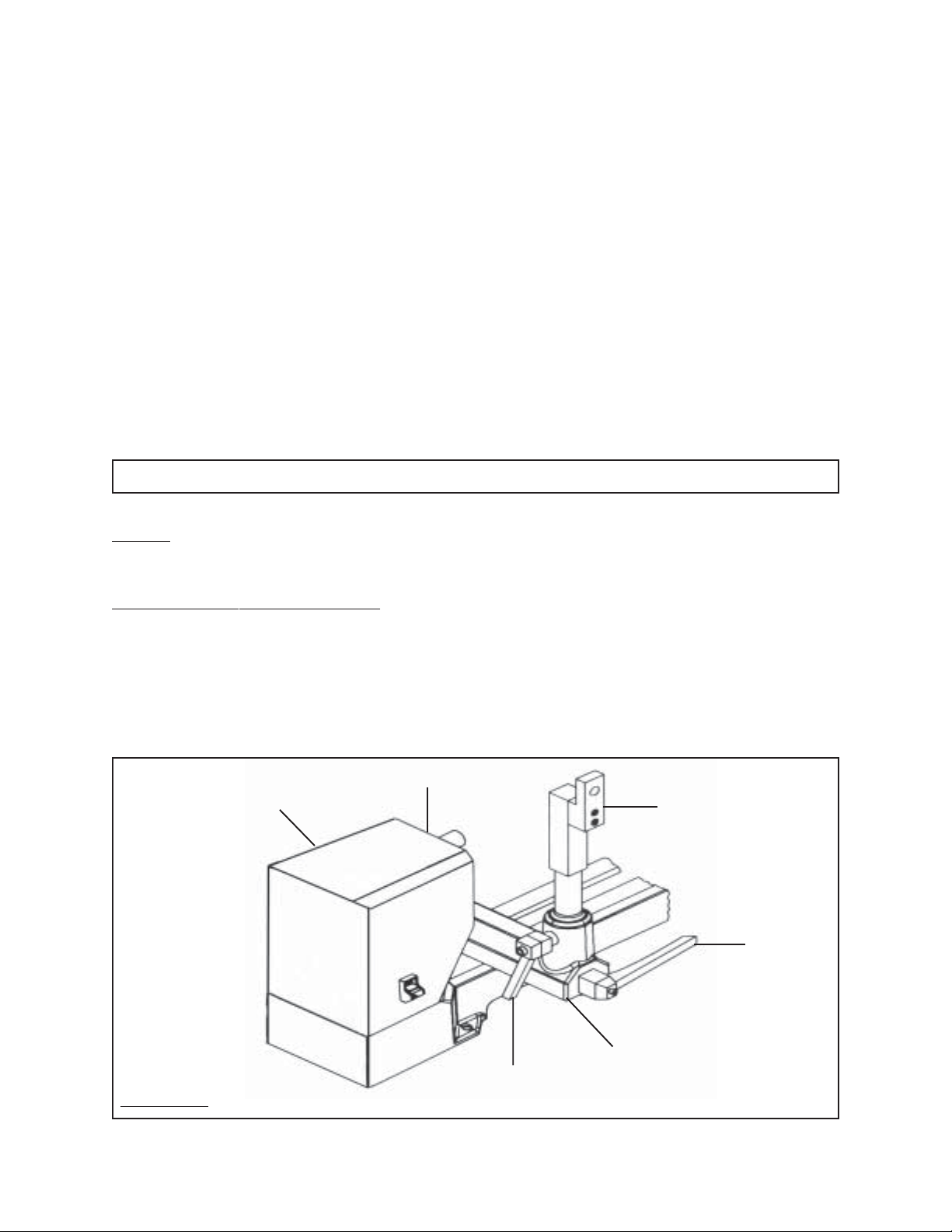

ASSEMBLY INSTRUCTIONS

NOTE: For additional references to the parts listed in the following pages, refer to the

Assembly Diagram on page 14.

To Attach The Tool Rest Base:

1. Loosen the Tool Rest Handle of the

lathe

to as near the Headstock of the

lathe

, and slide the Tool Rest Base of the

lathe

as possible. (See Figure A.)

2. Loosen the Support Bar Handle of the Model 90265

Rest Base of the

MODEL 90265 LATHE

NOT INCLUDED.

lathe

. (See Figure A.)

HEADSTOCK

lathe

, and remove the Tool

LOWER VERTICAL

SUPPORT BAR

(46)

TOOL REST

HANDLE

SUPPORT BAR HANDLE

FIGURE A

SKU 90692 PAGE 5

TOOL REST BASE

Page 6

3. Install one Lower Vertical Support Bar (46) onto the Tool Rest Base of the

and secure it by tightening the Support Bar Handle of the lathe. (See Figure A.)

lathe

4. Loosen the Tailstock Handle of the

of the

lathe

. (See Figure B.)

LOWER VERTICAL

SUPPORT BAR

(46)

, and remove the Tailstock from the Bed

TAILSTOCK

TAILSTOCK

HANDLE

lathe

,

TOOL REST BASE

(44)

SUPPORT BAR

HANDLE

(45)

SUPPORT BAR INSERT (53)

HEX NUT (17)

BED OF LATHE

TOOL REST HANDLE

(55)

FIGURE B

5. Loosen the Hex Nut (17) from the bottom of the Tool Rest Base (44) and Support

Bar Insert (53), and slide the Tool Rest Base assembly onto the Bed of the

lathe

. Then, re-tighten the Hex Nut. (See Figure B.)

6. Replace the Tailstock of the

tightening the Tailstock Handle of the

lathe

onto the Bed of the

lathe

. (See Figure B.)

lathe,

and secure it by

To Install The U-Bracket Assembly:

1. Screw one Pattern Bolt (42) into the side of one Pattern Support Bar (41) and

secure the Pattern Bolt with a Hex Nut (39). Then, slide the Pattern Support Bar

into one U-Bracket (38). (See Figure C, next page.)

2. Screw one Handle (3) into the U-Bracket (38). (See Figure C.)

3. Insert the U-Bracket (38) onto the Lower Vertical Support Bar (46), and secure

the U-Bracket by tightening the Handle (3). (See Figure C.)

4. Repeat Steps #1, #2, #3 for the remaining U-Bracket Assembly.

(See Figure C.)

SKU 90692 PAGE 6

Page 7

PATTERN SUPPORT BAR (41)

PATTERN BOLT (42)

U-BRACKET (38)

HANDLE (3)

LOWER VERTICAL

SUPPORT BAR

(46)

LOWER VERTICAL

SUPPORT BAR

(46)

U-BRACKET

ASSEMBLY

U-BRACKET

ASSEMBLY

FIGURE C

To Attach The Support Bar:

1. Remove the End Cap (12) from each end of the Support Bar (54).

(See Assy. Diagram.)

2. Remove the two Square Nuts (47) from the Handles (48), and insert the Square

Nuts into the T-Slot of the Support Bar (54).

(See Figure D, next page.)

3. Insert the threaded, bolt portion of the Handles (48) through the Lockwashers

(34), Flat Washers (40), and holes in the Lower Vertical Support Bars (46). Then,

screw the threaded, bolt portion of the Handles into the two Square Nuts (47) on

the Support Bar (54).

(See Figure D.)

4. Replace the End Cap (12) on each end of the Support Bar (54).

(See Assy. Diagram.)

SKU 90692 PAGE 7

Page 8

SUPPORT BAR (54)

SQUARE NUT (47)

SQUARE

NUT

(47)

LOCKWASHER

(34)

FLAT WASHER (40)

LOCKWASHER (34)

HANDLE (48)

FLAT WASHER

(40)

HANDLE

(48)

FIGURE D

To Assemble The Tool Holder:

1. Loosen the two Set Screws (20) on the Tool Holder (24), and extend the Cutting

Tool (31) out about 4 inches. Then re-tighten the two Set Screws to secure the

Cutting Tool in place. (See Figure E.)

2. Slide the Pattern Follower Assembly into the T-Slot located at the bottom of the

Tool Holder (24). (See Figure E.)

SET SCREW (20)

T-SLOT

TOOL HOLDER (24)

PATTERN FOLLOWER

.

.

ASSEMBLY

CUTTING TOOL (31)

FIGURE E

SKU 90692 PAGE 8

Page 9

To Attach The Tool Holder Assembly:

1. Slide the Cutting Tool (31) of the Tool Holder (24) into the Slot located on the

Side Plate (50). (See Figures E and F.)

2. Attach the Spring (19) over the Pointer (14) on the Side Plate (50).

(See Figure F.)

3. Adjust the Spring (19) so that there is enough tension to keep the Tool Holder

(24) firmly against the Support Bar (54). (See Figure F.)

SUPPORT BAR (54)

POINTER (14)

SLIDE PLATE

(50)

TOOL

HOLDER

(24)

SPRING

(19)

FIGURE F

To Attach The Safety Shield:

1. Attach the Safety Shield Bracket (10) to the Safety Shield (8), using the Pan

Head Screw (9), Flat Washer (21), and Hex Nut (7).

(See Figure G, next page.)

2. Unscrew and remove the Handle (51) from the Bolt located on the Support Bar

(54). Place the Safety Shield Plate (43) on the Bolt. Then, re-tighten the

Handle onto the Bolt.

(See Figure G.)

3. Attach the Safety Shield Bracket (10) to the Safety Shield Plate (43), using a Hex

Head Bolt (11), Flat Washer (40), and Hex Nut (39).

(See Figure G.)

SKU 90692 PAGE 9

Page 10

SAFETY SHIELD (8)

PAN HEAD SCREW (9)

FLAT WASHER (21)

HANDLE (51)

SAFETY SHIELD PLATE (43)

BOLT

SUPPORT BAR (54)

HEX HEAD BOLT (11)

FLAT WASHER (40)

HEX NUT (7)

HEX NUT (39)

FIGURE G

OPERATING INSTRUCTIONS

To Adjust The Cutting Tool:

1. Prior to use, the Cutting Tool (31) must be set approximately 1/8” above the

Spindle of the

lathe. (See Figure H.)

lathe

. Make sure to check at the Headstock and Tailstock of the

2. The Cutting Tool (31) can be adjusted

vertically

Handles (45) which secure the Lower Vertical Support Bars (46) in place.

(See Figure B.)

SET SCREW (20)

SOCKET HEAD BOLT

(25)

SKU 90692 PAGE 10

by loosening the Support Bar

CUTTING

TOOL

(31)

FIGURE H

Page 11

3. The Cutting Tool (31) also can be adjusted

Head Bolt (25) which secures the Tool Holder (24) in place. Once adjusted,

make sure to re-tighten the Socket Head Bolt. (See Figure H.)

vertically

by loosening the Socket

4. The Cutting Tool (31) can be adjusted

across the Bed of the lathe, towards or away from the Spindle of the lathe.

(See Figure A.)

5. The Cutting Tool (31) also can be adjusted horizontally by loosening the two Set

Screws (20), moving the Cutting Tool in or out, and then re-tightening the Set

Screws. (See Figure H.)

horizontally

by moving the Tool Rest Base

To Perform Duplicate Turning:

1. Mount the

The Tool Rest Bases (44) will need to be adjusted along the Bed of the lathe to

the required length. (See Figures A, and C.)

2. Mount the new piece of woodstock in the lathe. When starting with a square

piece of woodstock that will be cut to a cylinder, detach the Spring (19) on the

Tool Holder (24) from the Support Bar (54). Manually feed the Cutting Tool into

the woodstock with a light depth of cut until the cylinder has been formed. Do

not start cutting on the end of the woodstock, as the Cutting Tool may

become caught and damage the woodstock. (See Figure F.)

original woodstock that is to be duplicated

in the Pattern Bolts (42).

3. Turn the woodstock to a cylinder slightly larger than final size. Then, reattach the

Spring from the Tool Holder (24) to the Support Bar (54) and adjust the Pattern

Follower assembly against the original woodstock. (See Figures E, and F.)

4. Continue gliding the Tool Holder (24) along the Support Bar (54) until the new

piece of woodstock fully duplicates the original piece of woodstock.

(See Figure F.)

5. Always make sure to turn off the lathe and unplug it from its electrical outlet when

finished with duplicate turning. Wait until the lathe and Lathe Duplicator Attachment stop completely before attempting to remove the pieces of woodstock.

INSPECTION, MAINTENANCE, AND CLEANING

1. Before each use, inspect the general condition of the Lathe Duplicator Attachment. Check for broken, cracked, or bent parts, loose or missing parts, and any

condition that may affect the proper operation of the product. If a problem

SKU 90692 PAGE 11

Page 12

occurs, have the problem corrected before further use.

p

,

g

Do not use damaged equipment.

2. For better and safer performance, always keep the Cutting Tool (31) clean and

sharp.

3. Daily, with a clean cloth, brush, or vacuum remove all debris fromthe Lathe Duplicator Attachment. Then, use a lightweight machine oil to lubricate all moving

parts.

TROUBLESHOOTING GUIDE

Symptom Possible Cause(s) Corrective Action

Machine slows down

while operating.

Tool “chatters” during

turning operation.

1. Applying too much

pressure to workpiece.

1. Workpiece is too

far out of round.

2. Workpiece has too

much wobble.

3. Operator using

improper technique.

4. Cutting motion is against

the grain of the workpiece.

5. Work

and is deflected by tool

pressure.

iece is too long and thin

1. Ease up on pressure.

1. True up the roundness

of the workpiece before

turning operation.

2. Establish new center

marks on ends to reduce

wobble.

3. Read instructions, and

take lighter cuts to

minimize chatter.

4. Use cutting motion that is

with the grain.

5. Install a steady rest in the

middle, behind the

workpiece.

Workpiece splits or

breaks up during

turning operation.

Workpiece finish poor. 1. Prototype or template loose.

1. Workpiece contained defects

before mounting.

2. Loose tool holder.

3. Pattern follower not

contacting original.

1. Select or assemble a

workpiece that is free

of defects.

1. Secure prototype or

template.

2. Ti

3. Adjust pattern follower

firmly against original.

hten tension of spring.

SKU 90692 PAGE 12

Page 13

PLEASE READ THE FOLLOWING CAREFULLY

#

#

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST

AND ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION

OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO

MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO

REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTUER AND/OR

DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS,

AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF

REPLACEMENT PARTS THERETO.

PARTS LIST

Part

1 Socket Head Bolt (5/16”-18*1”)4 28 Rod 1

2 Upper Vertical Support Bar 2 29 Flat Washer (1/4”) 1

3 Handle 2 30 Hex Nut (1/4”-20) 1

4 Dowel Pin (3*12MM) 4 31 Cutting Tool 1

5 Spring Pin (3*10MM) 1 32 Dowel Pin Base 1

6 Square Nut (1/4”-20) 1 33 Dowel Pin (3*18.7MM) 4

7 Hex Nut (#10-24) 2 34 Lock Washer (5/16”) 8

8 Safety Shield 1 35 Socket Head Bolt 4

9 Pan Head Screw (#10-24*1/2”) 2 36 Socket Head Bolt 2

10 Bracket 1 37 Hex Head Bolt 1

11 Hex Head Bolt (5/16”x18*3/4”) 1 38 U-Bracket 2

12 Cap (Set of 2) 1 39 Hex Nut (5/16”-18) 3

13 Flat Head Screw (#10-24*3/8”) 1 40 Flat Washer (5/16”) 3

14 Pointer 1 41 Pattern Support Bar 2

15 Flat Head Screw (#10-24*1/4”) 1 42 Pattern Bolt 2

16 Scale 1 43 Plate 1

17 Hex Nut 2 44 Tool Rest Base 1

18 Slide Plate Base 1 45 Handle 1

19 Spring 1 46 Lower Vert. Support Bar2

20 Set Screw (1/4-20*1/4”) 2 47 Square Nut (5/16”-18) 2

21 Flat Washer (#10) 3 48 Handle 2

22 Lock Washer (#10) 3 49 Pan Washer Head Screw2

23 Wing Nut (#10-24) 1 50 Slide Plate 1

24 Tool Holder 1 51 Handle 1

25 Socket Head Bolt (#10-24*3/8”)1 52 Ball (5/16”) 8

26 Bracket 1 53 Support Bar Insert 1

27 Ball Bearing (R83022) 5 54 Support Bar 1

----------- --------------------------------------------- -------- 55 Tool Rest Handle 1

Description Qty. Part

Description Qty.

SKU 90692 PAGE 13

Page 14

ASSEMBLY DIAGRAM

42

41

32

38

3

39

12

26

6

28

15

14

29

5

27

49

54

31

17

33

32

18

39

53

14

34

34

52

25

35

41

51

43

11

50

40

39

38

37

36

2

42

38

45

2

16

46

19

23

1

22

21

13

30

24

20

25

8

9

21

22

7

10

12

49

3

47

46

1

48

40

55

45

NOTE: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

SKU 90692 PAGE 14

44

Loading...

Loading...