Page 1

TOUCH-UP GUN

Model

00086

SET UP AND OPERATING INSTRUCTIONS

Diagrams within this manual may not be drawn proportionally.

Due to continuing improvements, actual product may differ slightly from the product described herein.

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 1997 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

SAVE THIS MANUAL

You will need this manual for the safety instructions,

assembly and operating instructions and parts list. Put it in

a safe, dry place for future reference. Keep your invoice

with this manual. Write the invoice number on the

inside front cover.

READ ALL INSTRUCTIONS

BEFORE OPERATING THE

TOUCH-UP GUN

SPECIFICATIONS

Characteristic Value

Minimum Operating Air Pressure 33 PSI

Maximum Operating Air Pressure 50 PSI

Cup Paint Volume 7 oz.

Hose Size 3/8”

Material Output 2.8 CFM @ 30 PSI - 4.0 CFM @ 50 PSI

Air Inlet 1/4” NPS

SAFETY WARNINGS & CAUTIONS

1. KEEP WORK AREA CLEAN. Cluttered areas invite injuries.

2. KEEP CHILDREN AWAY. All children should be kept away from the work area. Don't let

them handle tool.

3. DO NOT OPERATE THE TOUCH-UP GUN IF UNDER THE INFLUENCE OF ALCOHOL

OR DRUGS. Read warning labels on prescriptions to determine if your judgment or

reexes are impaired while taking drugs. If there is any doubt, do not attempt to operate.

4. DO NOT SPRAY NEAR OPEN FLAMES, PILOT LIGHTS IN STOVES OR HEATERS,

OR ANY OTHER HEAT SOURCE. Most solvents and coatings are highly ammable,

particularly when sprayed. Always make sure there is adequate ventilation. Extinguish

all cigarettes when painting or cleaning. Industrial applications must follow OSHA

requirements.

5. READ ALL INFORMATION CONCERNING COATING PRODUCTS AND CLEANING

SOLVENTS. Chlorinated solvents, e.g. 1-1-1 Trichloroethane and Methylene Chloride

(also known as methyl chloride) can chemically react with aluminum and may explode.

Many paint sprayers contain aluminum. If you are in any doubt what-so-ever, contact

the solvent or coating manufacturer.

6. MATERIALS USED WHEN PAINTING AND CLEANING MAY BE HARMFUL OR FATAL

IF INHALED AND/OR SWALLOWED. Once again, when spraying, always make sure

there is adequate ventilation. Use a mask or respirator when painting.

7. CHECK ALL SEALS BEFORE CONNECTING TO AIR SUPPLY. Make sure lid is fully

attached to cup, retaining ring is screwed past the rst thread, air pressure plug is

tightened fully, and air supply tube is rmly attached. Never release the lid while the cup

is pressurized.

8. USE EYE PROTECTION. Coatings will cause eye irritation. Wear ANSI approved

chemical splash safety goggles. Goggles are available from Harbor Freight Tools.

When cleaning, be especially careful as solvents can be forcibly ejected from uid and

air passages.

REV 09d

Page 2SKU 00086 For technical questions, please call 1-800-444-3353.

Page 3

9. DRESS SAFELY. Protective gloves and non-skid footwear or safety shoes are

recommended when working with and operating the Touch-Up Gun. Don't wear loose

clothing or jewelry. They can get caught in moving parts. Also, wear a protective hair

covering to prevent long hair from getting caught in the Touch-Up Gun.

10. DON'T OVERREACH. Keep proper footing and balance at all times.

11. STAY ALERT. Watch what you are doing. Use common sense. Do not operate any tool

when you are tired.

12. CHECK DAMAGED PARTS. Before using any tool, any part that is damaged should

be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, breakage of parts, and other conditions

that may affect its operation.

13. REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only identical

replacement parts. Only use accessories intended for use with this Touch-Up Gun.

Approved accessories are available from Harbor Freight Tools.

14. STORE IDLE EQUIPMENT. When not in use, Touch-Up Gun should be cleaned and

stored, fully assembled, in a dry location to reduce rust. For safety, keep out of reach of

children.

15. MAINTAIN TOOLS WITH CARE. Keep tools clean for better and safer performance.

Follow instructions for lubricating, cleaning and changing accessories. Keep handles

dry, clean and free from oil and grease.

16. OUTDOOR EXTENSION CORDS. When air compressor is used outdoors, use only

rounded jacket extensions cords intended for outside use. See manufacturer’s manual

for the AWG required for the compressor’s amperage draw.

17. BE AWARE OF AIR HOSES AND THEIR CONNECTIONS. Don’t trip over hoses. Make

sure all connections are tight. Keep an eye out for any leaks which should be repaired

immediately.

18. BE AWARE OF OTHER PEOPLE. Never spray directly at people or animals.

UNPACKING

The Touch-Up Gun needs minor assembly. If any parts are missing or broken, please call

Harbor Freight Tools at the number on the cover of this manual.

Item # Description Qty

A Spray Unit 1

B Canister Unit 1

C Repair Kit 1

Page 3SKU 00086 For technical questions, please call 1-800-444-3353.

Page 4

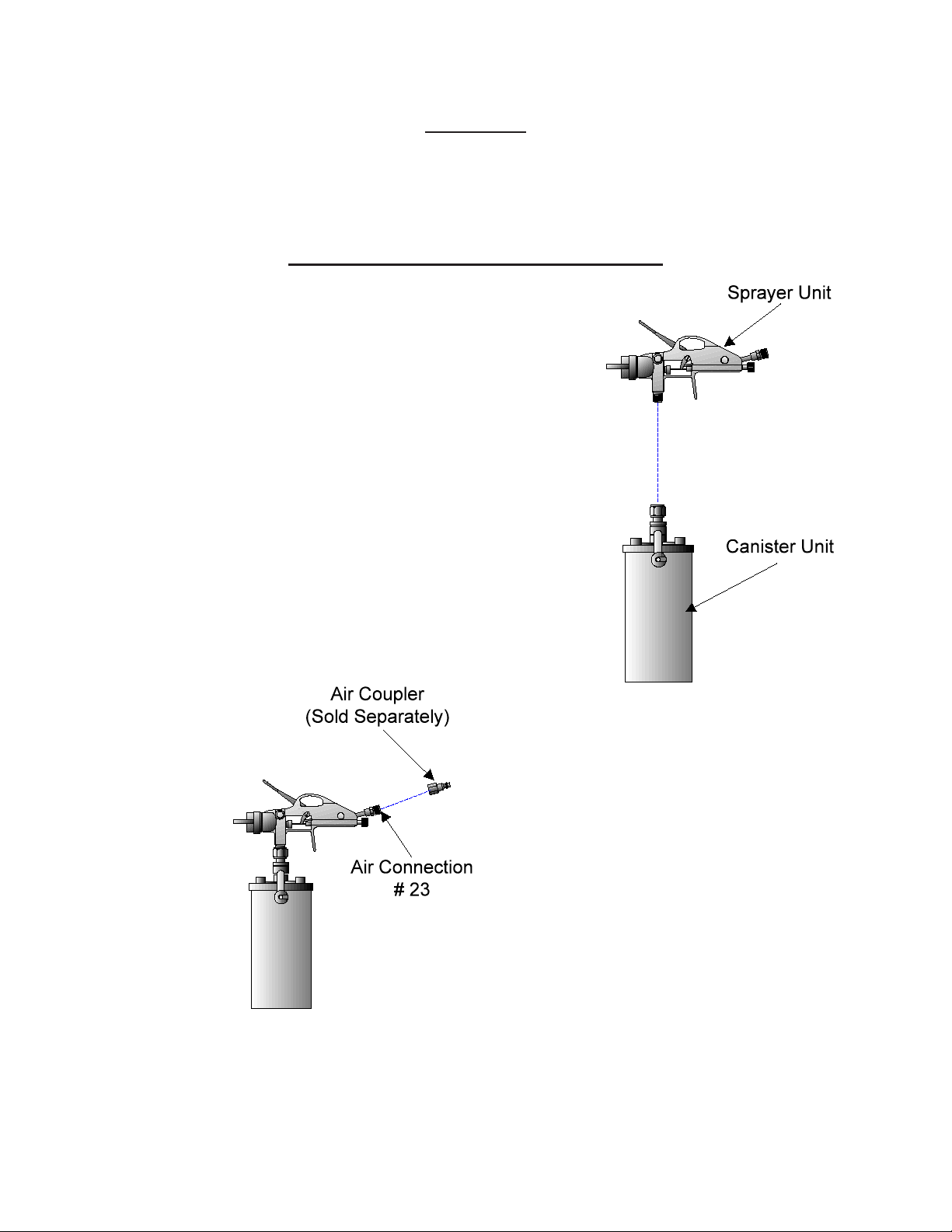

ASSEMBLY

Connect the Spray Unit to the Canister Unit as shown in Figure 1.

BEFORE YOU USE YOUR TOUCH-UP GUN

A coupler is required to connect the Touch-Up Gun to an air

compressor. Select the coupler, e.g. ¼” “M” style NPT, etc. that

mates with the end of the air hose you are using, and screw

it onto the AIR CONNECTION (#23) located at the end of the

Touch-Up Gun’s handle (see Figure 2).

Figure 2 -- Attaching Air Coupler

Figure 1 -- Connecting the

Spray Unit and Canister

Page 4SKU 00086 For technical questions, please call 1-800-444-3353.

Page 5

OPERATION

Setup

Refer to Figure 3 for the location of parts called out in this section.

Figure 3 -- Operation Diagram

Step 1. Move the LEVER (#29) counterclockwise until the YOKE (#30) is free from the CUP

LOCKS (#35).

Step 2. Lift and remove the Paint Gun from the CUP (#34).

Step 3. Prepare the paint or coating per the manufacturer’s instructions for air spray guns.

Step 4. Fill the cup up to the ¾-full mark shown in Figure 4. DO NOT OVERFILL!

Step 5. Lower and replace the Paint

Gun onto the CUP.

Step 6. Align the YOKE with the CUP

LOCKS and move the LEVER

clockwise until tight. DO NOT

FORCE THE LEVER!

Step 7. Set the compressor’s pressure

regulator to the lowest setting

recommended by the paint or coating manufacturer.

Figure 4--

CAUTION:When the

CUP contains uid,

always keep the Touch-

Up Gun upright. This

will keep paint from

contaminating portions of

the gun in which it is not

intended to go.

Filling the Paint Gun

Step 8. Connect the TOUCH-UP GUN’s coupler to the air

compressor’s hose. If leaking is detected, disconnect the air hose and repair before

use.

PATTERN CONTROL

The Touch-Up Gun is capable of spraying in different fan sizes and different shapes. Never

touch the trigger or point the gun at the face or body when adjusting the fan size or jet

shape.

Adjusting Fan Size

Page 5SKU 00086 For technical questions, please call 1-800-444-3353.

Page 6

The fan size is adjusted by turning the FAN ADJUSTING SCREW (#28) clockwise for a narrow

spray and counterclockwise for a wider spray.

Adjusting Jet Shape

The Jet Shape is adjusted by turning the AIR CAP (#1). It should be perpendicular to the

ground to create a horizontal jet and parallel to the ground to create a vertical jet.

Adjusting Paint Output

The Volume Output is adjusted by turning the VOLUME ADJUSTMENT SCREW (#12)

clockwise to reduce the output and counterclockwise to increase the output.

Page 6SKU 00086 For technical questions, please call 1-800-444-3353.

Page 7

SPRAYING TECHNIQUES

Your Touch-Up Gun is designed for light touch-up work, stenciling, and small job duties. For

heavy or medium production work, we suggest our H.V.L.P. and professional model spray guns.

For most uses, e.g. painting walls, benches, vehicles, etc., the best results are obtained by

spraying thin, even coats of paint. Let the layers dry in between coats.

As with any manual process, practice leads to perfection. The following are a few general rules

that may be of help in perfecting your process:

Use the lowest pressure setting •

recommended by the paint manufacturer.

Keep the gun perpendicular to the ground.•

Maintain a distance of about 8” from the work •

as shown in Figure 5.

Make smooth, thin and even strokes across the •

work.

Overlap each stroke by about 50%. (See Figure •

6)

Let each coat dry before re-coating.•

When painting with metallic, pearls, etc., always •

cross coat the paint.

CAUTION:Always keep the LID (#32)

tight when connected to the air source.

Figure 5 -- Distance from wall

Figure 6 -- Overlapping strokes

Page 7SKU 00086 For technical questions, please call 1-800-444-3353.

Page 8

MAINTENANCE

General Maintenance

Checking & Replacing the Needle

Needle wear is expexcted and inspection during Cleaning will ensure the continued topperformance of your Touch-Up Gun. If needle tip wear is noted:

Step 1. Unscrew the FAN ADJUSTING

SCREW (#28) and remove the

SPRING (#27).

Step 2. Using a pair of pliers or other

suitable device, carefully pull and

twist the NEEDLE ASSEMBLY

(#24”S”) until it has been removed.

Step 3. Purchase an identical replacement NEEDLE ASSEMBLY from Harbor Freight

Tools.

Step 4. By hand, carefully insert the needle into the GUN HOUSING (#5) and push until

the tip has exited the hole in the AIR CAP (#1).

Step 5. Place the SPRING over the NEEDLE ASSEMBLY and insert it into the

SPRAYER HOUSING.

Step 6. Replace the ADJUSTING SCREW and readjust its setting to the position it was in

before removed (refer to Step 1).

NOTE (Step 1)Before unscrewing the

ADJUSTMENT SCREW, place a mark on the

ADJUSTMENT SCREW where it meets the

GUN HOUSING (#13). This will make re-

adjusting the gun, after maintenance, easier.

Page 8SKU 00086 For technical questions, please call 1-800-444-3353.

Page 9

Cleaning:

WARNING:Always dispose of paints, coating and other chemicals in a proper way. If you have

questions regarding the proper disposal of any chemical, contact the chemical manufacturer for

instructions.

Step 1. Depressurize the cup and disconnect the air hose.

Step 2. Remove the Paint Gun from the CUP as described in OPERATION.

Step 3. Empty the paint or coating from the CUP. Dispose of properly.

Step 4. Pour a small amount of clean solvent (as specied by the paint manufacturer) in the

CUP. See Safety Warnings and Cautions.

Step 5. Place the Paint Gun into the CUP and tighten the LEVER until the assembly is sealed.

Step 6. Reconnect the air hose and pressurize the cup.

Step 7. Clean the Touch-Up Gun by shaking it vigorously and spraying the solvent through the

gun.

Step 8. Repeat steps 1 through 7 until the

sprayed solvent appears clean and

clear.

Step 9. Disconnect the gun from the air supply.

Step 10. Remove the Paint Gun Assembly from

the Cup Assembly and dispose of the

surplus solvent.

Step 11. Wipe the Cup clean with a dry, lint-free

cloth.

CAUTION:For thorough cleaning, the CUP

may be fully immersed in solvent. DO NOT

LEAVE CUP IN SOLVENT FOR MORE

THAN 24 HOURS as damage may occur.

NEVER IMMERSE THE TOUCH-UP GUN

IN SOLVENT. When cleaning, brush solvent

onto exterior parts only.

Page 9SKU 00086 For technical questions, please call 1-800-444-3353.

Page 10

Lubrication:

Before and after each use of the TOUCH-UP GUN, perform the following lubrication process,

using a non-silicon, spray gun lubricant:

Step 1. Put two or three drops of lubricant on the NEEDLE (#24), in front of the TRIGGER

(#14). Tip the gun backward and allow the lubricant to drip into the front of the GUN

HOUSING (#13).

Step 2. Put two or three drops of lubricant on the VOLUME ADJUSTING SCREW (#12). Tip

the gun sideways and allow the lubricant to drip into the SPRAYER HOUSING.

Step 3. Put two or three drops of lubricant on the FAN ADJUSTING SCREW (#28). Tip the gun

forward and allow the lubricant to drip into the back of the HOUSING (#13).

Step 4. Put one drop of lubricant on the inside of the TRIGGER SCREW (#15). Work the

TRIGGER (#14) to allow the lubricant to coat the parts.

Figure 6 -- Lubricating the Touch-Up Gun

Page 10SKU 00086 For technical questions, please call 1-800-444-3353.

Page 11

Preventative Maintenance

Periodically check the following:

Needle Wear:

Visually inspect NEEDLE (#24) tip for wear. NEEDLE wear will cause the paint pattern to be

uneven. If NEEDLE wear is noted, replace the NEEDLE per GENERAL MAINTENANCE,

CHECKING AND REPLACING THE NEEDLE.

Cup Gasket Wear:

Step 1. Remove the Paint Gun from the CUP as described in OPERATION.

Step 2. Visually inspect the Canister gasket for uneven depressions, scratches, cracks and

general appearance. The gasket is not replaceable. If wear is noted, replace the

Canister Lid in accordance with the following steps.

Step 3. Remove the Lid Nut. Retain the Nut for reassembly.

Step 4. Remove and replace the Lid with identical part.

Step 5. Replace the LID NUT and tighten.

Check & Clean Air Cap / Retainer Ring Holes:

Step 1. Remove the AIR CAP (#1) by unscrewing the RETAINER RING (#3).

Step 2. Verify the four holes around the NEEDLE (#19) hole are not blocked or restricted

by paint and coatings. If necessary, clean the holes by soaking the AIR CAP in

solvent and blowing clear with pressurized air.

Step 3. Replace the AIR CAP and tighten the RETAINER RING.

Page 11SKU 00086 For technical questions, please call 1-800-444-3353.

Page 12

PARTS LIST

PART # DESCRIPTION QTY PART # DESCRIPTION QTY

1 Air Cap 1 23 Union 1

2 Inner Ring 1 24 Needle 1

3 Retainer Ring 1 25 Lock Nut 1

4 Fluid Nozzle 1 26 Rear Nut 1

9 Ring 1 27 Spring 1

10 Packing 1 28 Fan Adjusting Screw 1

11 Vol. Adj. Screw Receiver 1 29 Lever 1

12 Volume Adjusting Screw 1 30 Yoke 1

13 Gun Housing 1 31 Fluid Stem 1

14 Trigger 1 32 Lid 1

15 Trigger Screw 1 33 Lid Nut 1

16 Packing 1 34 Cup 1

17 Nut 1 35 Cup Locks 2

19 Packing 1 1”S” Nozzle Assembly 1

20 Valve Nut 1 9”S” Volume Adjustment Assy. 1

21 Stem Assembly 1 24”S” Needle Assembly 1

22 Spring 1

Page 12SKU 00086 For technical questions, please call 1-800-444-3353.

Page 13

LIMITED 1 YEAR WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that this product

is free from defects in materials and workmanship for the period of one year from the

date of purchase (90 days if used by a professional contractor or if used as rental equipment). This warranty does not apply to damage due directly or indirectly, to misuse,

abuse, negligence or accidents, repairs or alterations outside our facilities, normal wear

and tear, or to lack of maintenance. We shall in no event be liable for death, injuries

to persons or property, or for incidental, contingent, special or consequential damages

arising from the use of our product. Some states do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitation of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY

AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection veries the defect, we will either repair or replace the product at our election or we may elect to refund the purchase

price if we cannot readily and quickly provide you with a replacement. We will return repaired products at our expense, but if we determine there is no defect, or that the defect

resulted from causes not within the scope of our warranty, then you must bear the cost

of returning the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not avail-

able individually as replacement parts.

REV 09d

Page 13SKU 00086 For technical questions, please call 1-800-444-3353.

Loading...

Loading...