Page 1

Page 2

Specications

Torque Range 50-300 ft-lb

Drive 3/4"

Length 33-1/2"

Accuracy ±4%

Important Safety Information

WARNING Read all safety warnings and instructions.

Failure to follow the warnings and instructions may result in injury.

Save all warnings and instructions for future reference.

1. The warnings, cautions, and instructions

discussed in this instruction manual cannot

cover all possible conditions and situations

that may occur. It must be understood by the

operator that common sense and caution

are factors which cannot be built into this

product, but must be supplied by the operator.

2. Wear ANSI-approved safety goggles and

heavy-duty work gloves during use.

3. Use only within rated torque range.

Do not use for loosening.

4. Use as intended only. Do not use as

hammer or pry bar. Do not use handle

extension to increase force. Do not drop.

5. Inspect before every use; do not use

if damaged or if parts are loose.

6. Keep away from children.

7. For your safety, service, calibration,

and maintenance should be performed

regularly by a qualied technician.

8. Use only sockets with the correct

drive and rated to at least the

torque that will be applied to it.

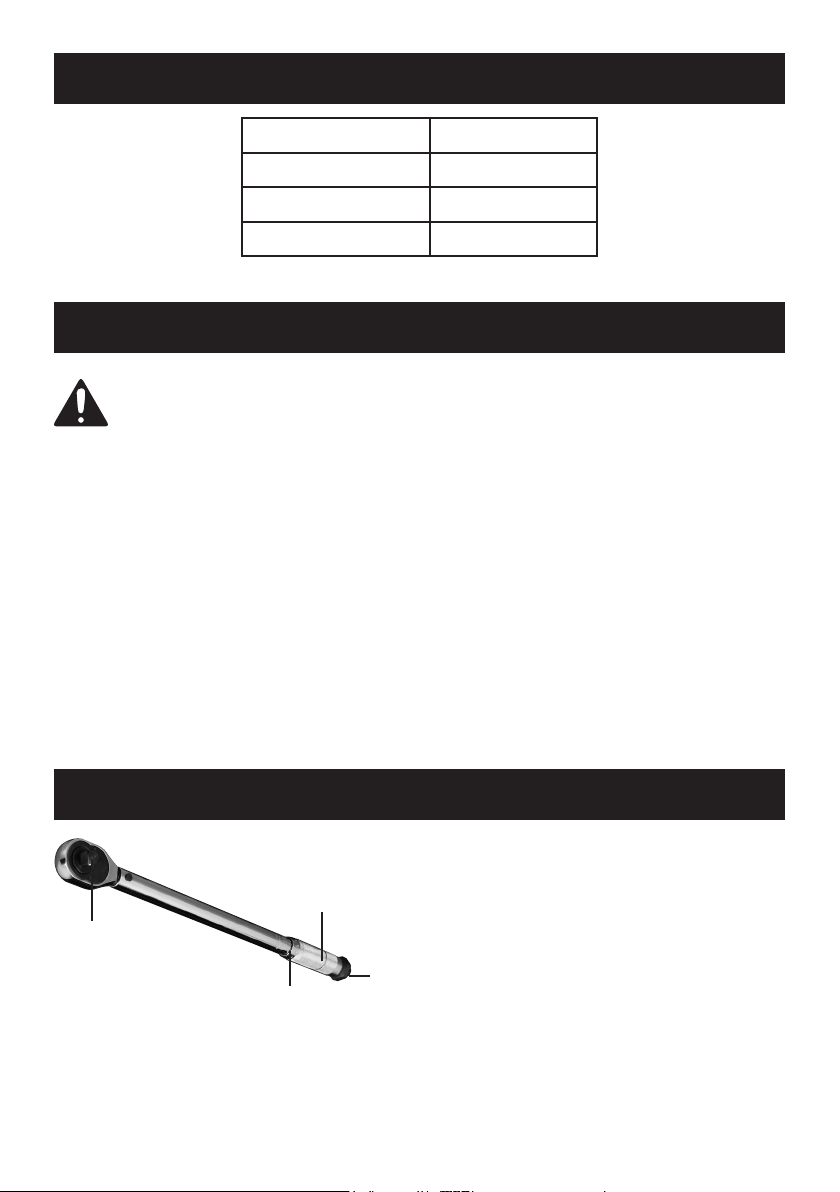

Operating Instructions

2. Clean and/or repair the threads that will be

tightened. Damaged or dirty threads will

Knurled Handle

Drive Anvil

Lock

Torque Settings

1.

Wear ANSI-approved safety goggles

and heavy-duty work gloves.

Page 2 For technical questions, please call 1-800-444-3353. Item 00808

Knob

result in a misleading torque reading.

3. Select the desired socket and verify it ts

properly on the nut or bolt being tightened.

Page 3

4. Press the socket rmly onto the drive anvil.

5. Turn the Lock Knob at bottom of the

Handle counterclockwise until it stops.

6. Turn the handle to set the torque.

To set to 55, for example:

634

5

80

60

70

50

7

(B)

The 50 line is shown in grey because

it will likely be hidden at this point.

b.

Continue turning the knurled handle about

a half turn clockwise until the “5” graduation

mark lines up with the centerline. It is now

set for 55. See illustration (B), above.

189

0

80

60

70

50

2

(A)

a.

Turn the knurled handle (CW or CCW) until

the “0” graduation on the bevel edge lines

up with 50. See illustration (A), above.

7. Retighten the Lock Knob by turning

it all the way clockwise.

Direction

Switch

8.

Set the Direction Switch for clockwise

or counterclockwise operation.

The Switch shown above is in

position for clockwise operation.

9. Place socket onto the nut or bolt and pull

the handle gradually in the desired direction

until a click is heard or felt. Do not pull

beyond that point; the click indicates that

the torque setting has been reached.

10. Stop pulling and the Torque Wrench

will automatically reset.

11. When nished, loosen the lock knob and set

the Torque to the lowest torque setting (not

lower than the lowest setting) before storing

inside case indoors out of reach of children.

Page 3For technical questions, please call 1-800-444-3353.Item 00808

Page 4

Maintenance and Servicing

Procedures not specically explained in this manual

must be performed only by a qualied technician.

TO PREVENT INJURY FROM TOOL FAILURE:

Do not use damaged equipment. If abnormal noise or vibration occurs,

have the problem corrected before further use.

1. BEFORE EACH USE, inspect the general

condition of the tool. Check for loose

hardware, misalignment or binding of moving

parts, cracked or broken parts, and any other

condition that may affect its safe operation.

2. If the Torque Wrench has not been used

for some time, turn the knurled handle

(clockwise and counterclockwise) several

3. Wipe Torque Wrench with a cloth to clean.

Do not immerse in any cleaning solution.

This would damage the internal lubrication.

4. Every 6 months, have the Wrench calibrated

and serviced by a qualied technician.

Note: Replacement parts are not

available for this item.

times to re-lubricate the internal workings.

Then, operate at a low torque setting

several times. This ensures proper operation.

Do not turn knurled handle below

the lowest torque setting.

Limited 90 Day Warranty

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability

standards, and warrants to the original purchaser that this product is free from defects in materials

and workmanship for the period of 90 days from the date of purchase. This warranty does not apply to

damage due directly or indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside

our facilities, criminal activity, improper installation, normal wear and tear, or to lack of maintenance.

We shall in no event be liable for death, injuries to persons or property, or for incidental, contingent,

special or consequential damages arising from the use of our product. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation of exclusion

may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with transportation charges

prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise.

If our inspection verifies the defect, we will either repair or replace the product at our election or we may

elect to refund the purchase price if we cannot readily and quickly provide you with a replacement. We will

return repaired products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Loading...

Loading...