Harbor Freight Tools 69888 Owner's Manual

Table of Contents

Safety ......................................................... 2

Specifications ............................................. 3

Functions .................................................... 4

SAFETY OPERATION MAINTENANCESPECIFICATIONS

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Operation .................................................... 5

Maintenance ............................................... 7

Warranty ..................................................... 7

WARNING SYMBOLS AND DEFINITIONS

Obey all safety messages that follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

IMPORTANT SAFETY INSTRUCTIONS

INSTRUCTIONS PERTAINING TO A

RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS

WARNING – When using tools, basic precautions

should always be followed, including the following:

1. Wear ANSI-approved safety goggles during

set up and use of the Battery Tester.

2. Test in a well ventilated area.

Explosive gases may be produced during testing.

Do not smoke, cause sparks, or strike

matches near the battery when testing.

3. Refer to the user manual of the Battery being

tested for testing instructions and precautions

prior to using the Battery Tester.

4. Do not connect in reverse polarity.

7. Use this product in accordance with these

instructions, taking into account the working

conditions and the work to be performed.

Use of this product for operations different from those

intended could result in a hazardous situation.

8. This product is not a toy.

Keep it out of reach of children.

9. Maintain labels and nameplates on the unit.

These carry important safety information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

10. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields in

close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.

Caution is necessary when near coil, spark

plug cables, or distributor of running engine.

Engine should be off during distributor adjustment.

5. Do not expose this product to rain or wet conditions.

6. Maintain this product. Check for breakage

of parts and any other condition that may

affect this product’s operation. If damaged,

have the unit repaired before use.

Page 2 For technical questions, please call 1-800-444-3353. Item 69888

11. Undercharged lead-acid batteries

will freeze during cold weather.

Do not test or charge a frozen battery.

12. When connecting the Battery Cables to the

battery, avoid creating sparks; especially when

the battery is being charged. Explosive gases

are created during charging. Sparking could

also damage the vehicle electrical system.

13. Do not touch the cooling vents on the Battery

Tester during or immediately after testing

the battery. They become very hot.

14. When placing the Battery Tester in the vehicle’s

engine compartment, take special care that

the metal housing of the Tester does not

come in contact with either terminal of the

battery or other electrical connections.

15. Be certain of the test battery polarity before

connecting the test Cable Clamps. The red Cable

Clamp goes to the positive terminal of the battery.

The black Cable Clamp goes to the negative terminal

of the battery. Reversing Battery Tester Cable

Clamps on the battery will damage the tester.

SAVE THESE INSTRUCTIONS.

16. Do not drop the Battery Tester as it

may affect proper operation.

17. Do not smoke or have open flames near the battery.

18. Do not connect the Battery Tester to

the battery while the engine is running.

Turn the engine off before connecting.

19. The warnings and precautions discussed in this

manual cannot cover all possible conditions and

situations that may occur. It must be understood

by the operator that common sense and caution

are factors which cannot be built into this

product, but must be supplied by the operator.

SAFETYOPERATIONMAINTENANCE SPECIFICATIONS

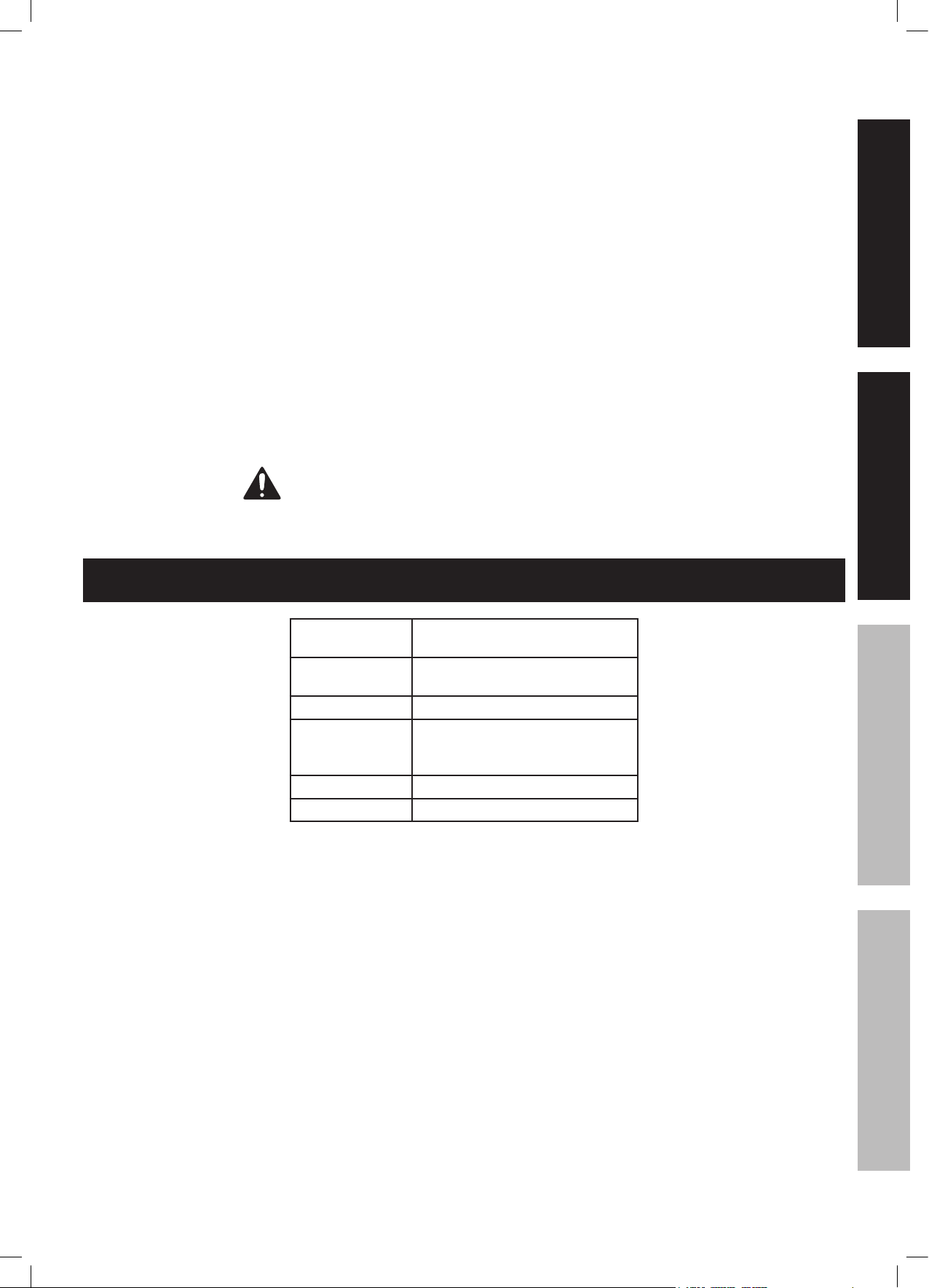

Specifications

Testing

Capability

Load Test

Capacity

Display Meters Analog, 0 ~ 16 VDC (max.)

Test Cycle

Battery Cable 16-3/4 IN. long including clamps

Clamps Copper plated clamps

6 and 12 VDC battery tester

100 amps;

500 ~ 1000 cold cranking amps

10 seconds per test with

1 minute cool down;

3 tests in 5 minutes

Page 3For technical questions, please call 1-800-444-3353.Item 69888

Loading...

Loading...