Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference.

GAL

30

gas powered two-stage

air compressor

REV 15e

Using a generator indoors CAN

KILL YOU IN MINUTES.

Generator exhaust contains

carbon monoxide. This is a poison

you cannot see or smell.

NEVER use inside

a home or garage,

EVEN IF doors and

windows are open.

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

Copyright© 2012 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

Only use OUTSIDE

and far away from

windows, doors,

and vents.

Visit our website at: http://www.harborfreight.com

Email our technical support at: productsupport@harborfreight.com

ITEM 69784

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Table of Contents

Safety ......................................................... 2

Specifications ............................................. 5

Setup .......................................................... 6

SAFETY SETUP OPERATION MAINTENANCE

Operation .................................................... 9

Maintenance .............................................. 13

Parts Lists and Diagrams .......................... 16

Warranty .................................................... 20

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

Symbol Property or Statement

RPM

HP

Revolutions Per Minute

Horsepower

WARNING marking concerning Risk

of Eye Injury. Wear ANSI-approved

safety goggles with side shields.

Symbol Property or Statement

WARNING marking concerning

Risk of Respiratory Injury.

Operate engine OUTSIDE and far away

from windows, doors, and vents.

WARNING marking concerning

Risk of Explosion.

IMPORTANT SAFETY INFORMATION

General Safety Warnings

WARNING Read all safety warnings and instructions.

Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The warnings, precautions, and instructions discussed in this instruction manual cannot cover all possible

conditions and situations that may occur. It must be understood by the operator that common sense

and caution are factors which cannot be built into this product, but must be supplied by the operator.

Set up Precautions

1. Gasoline fuel and fumes are flammable, and

potentially explosive. Use proper fuel storage

and handling procedures. Do not store fuel

or other flammable materials nearby.

2. Have multiple ABC class fire extinguishers nearby.

3. Operation of this equipment may create sparks

that can start fires around dry vegetation. A spark

arrestor may be required. The operator should

contact local fire agencies for laws or regulations

relating to fire prevention requirements.

Page 2 For technical questions, please call 1-888-866-5797. ITEM 69784

4. Set up and use only on a flat, level,

well-ventilated surface.

5. Use only lubricants and fuel recommended

in the engine manual or in the

Specifications chart of this manual.

6. Wear ANSI-approved safety goggles, heavy-duty

work gloves, and dust mask/respirator during set up.

Engine Precautions

Follow engine precautions and instructions in the included engine instruction manual.

Operating Precautions

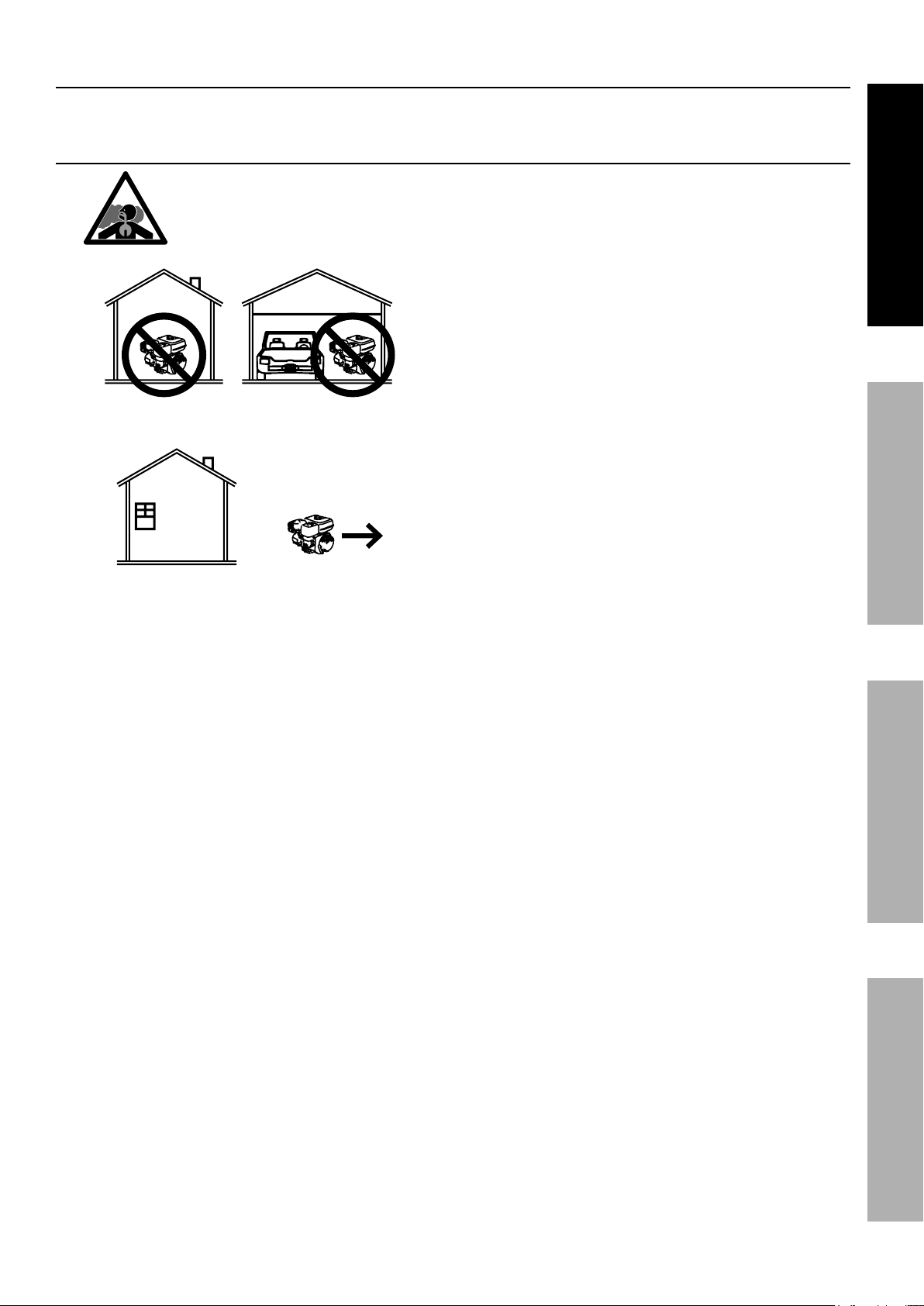

1. CARBON MONOXIDE HAZARD

Using an engine indoors CAN KILL

YOU IN MINUTES.

Engine exhaust contains carbon

monoxide. This is a poison you cannot see or smell.

NEVER use inside a home or garage, EVEN IF

doors and windows are open.

Only use OUTSIDE and far away from windows,

doors, and vents.

2. Keep children away from the equipment,

especially while it is operating.

3. Fire Hazard! Do not fill gas tank while

Compressor engine is running. Do not

operate if gasoline has been spilled. Clean

spilled gasoline before starting engine. Do

not operate near pilot light or open flame.

4. Do not touch Compressor engine during

use. Let engine cool down after use.

5. Never store fuel or other flammable

materials near the Compressor engine.

6. Only use a suitable means of transport and

lifting devices with sufficient weight bearing

capacity when transporting the Compressor.

7. Secure the Compressor on transport vehicles to

prevent the tool from rolling, slipping, and tilting.

8. Industrial applications must follow

OSHA requirements.

9. Do not leave the equipment unattended when it is

running. Turn off the equipment (and remove safety

keys, if available) before leaving the work area.

10. Wear ANSI-approved safety glasses, hearing

protection, and NIOSH-approved dust mask/

respirator under a full face shield along

with steel-toed work boots during use.

11. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields

in close proximity to a heart pacemaker could

cause pacemaker interference or pacemaker

failure. Caution is necessary when near

the engine’s magneto or recoil starter.

12. Use only accessories that are recommended

by Harbor Freight Tools for your model.

Accessories that may be suitable for one

piece of equipment may become hazardous

when used on another piece of equipment.

13. Do not operate in explosive atmospheres,

such as in the presence of flammable

liquids, gases, or dust. Gasoline-powered

engines may ignite the dust or fumes.

14. Stay alert, watch what you are doing and

use common sense when operating this

piece of equipment. Do not use this piece

of equipment while tired or under the

influence of drugs, alcohol or medication.

15. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the equipment in unexpected situations.

16. Dress properly. Do not wear loose clothing or

jewelry. Keep hair, clothing and gloves away

from moving parts. Loose clothes, jewelry or

long hair can be caught in moving parts.

17. Parts, especially exhaust system components,

get very hot during use. Stay clear of hot parts.

18. Do not cover the engine or

equipment during operation.

19. Keep the equipment, engine, and

surrounding area clean at all times.

20. Use the equipment, accessories, etc., in

accordance with these instructions and in the

manner intended for the particular type of

equipment, taking into account the working

conditions and the work to be performed. Use of

the equipment for operations different from those

intended could result in a hazardous situation.

21. Do not operate the equipment with known

leaks in the engine’s fuel system.

22. WARNING: This product contains or, when

used, produces a chemical known to the State

of California to cause cancer and birth defects

or other reproductive harm. (California Health

& Safety Code § 25249.5, et seq.)

SAFETYSETUPOPERATIONMAINTENANCE

Page 3For technical questions, please call 1-888-866-5797.ITEM 69784

23. WARNING: The brass components of this product

contain lead, a chemical known to the State

of California to cause cancer and birth defects

or other reproductive harm. (California Health

& Safety Code § 25249.5, et seq.)

SAFETY SETUP OPERATION MAINTENANCE

24. When spills of fuel or oil occur, they must be

cleaned up immediately. Dispose of fluids and

cleaning materials as per any local, state, or

federal codes and regulations. Store oil rags in

a bottom-ventilated, covered, metal container.

Service Precautions

25. Keep hands and feet away from moving parts. Do

not reach over or across equipment while operating.

26. Before use, check for misalignment or binding

of moving parts, breakage of parts, and any

other condition that may affect the equipment’s

operation. If damaged, have the equipment

serviced before using. Many accidents are

caused by poorly maintained equipment.

27. Use the correct equipment for the application.

Do not modify the equipment and do not use the

equipment for a purpose for which it is not intended.

1. Before service, maintenance, or cleaning:

a. Turn the engine switch to its “OFF” position.

b. Allow the engine to completely cool.

c. Then, remove the spark plug

cap from the spark plug.

2. Keep all safety guards in place and in

proper working order. Safety guards include

muffler, air cleaner, mechanical guards,

and heat shields, among other guards.

3. Do not alter or adjust any part of the

equipment or its engine that is sealed by the

manufacturer or distributor. Only a qualified

service technician may adjust parts that may

increase or decrease governed engine speed.

Air Compressor Safety Warnings

1. Risk of fire or explosion - Do not spray flammable

liquid in a confined area or towards a hot surface.

Spray area must be well-ventilated. Do not

smoke while spraying or spray where spark or

flame is present. Arcing parts - Keep compressor

at least 20 feet away from explosive vapors,

such as when spraying with a spray gun.

2. Risk of bursting - Do not adjust regulator higher

than maximum stated pressure of attachment.

3. Risk of injury - Do not direct air

stream at people or animals.

4. Do not use to supply breathing air.

5. Do not use the air hose to move the compressor.

6. Drain Tank daily and after use. Internal

rust causes tank failure and explosion.

4. Wear ANSI-approved safety goggles,

heavy-duty work gloves, and dust

mask/respirator during service.

5. Maintain labels and nameplates on

the equipment. These carry important

information. If unreadable or missing, contact

Harbor Freight Tools for a replacement.

6. Have the equipment serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the equipment

is maintained. Do not attempt any service or

maintenance procedures not explained in this

manual or any procedures that you are uncertain

about your ability to perform safely or correctly.

7. Store equipment out of the reach of children.

8. Follow scheduled engine and

equipment maintenance.

7. Add correct amount of compressor oil before

first use and every use. Operating with the

incorrect amount of oil causes permanent

damage and voids warranty. To prevent

damage, do not use with overfilled or low oil.

8. Compressor head gets hot during operation.

Do not touch it or allow children nearby

during or immediately following operation.

9. Release the pressure in the storage

tank before moving.

10. The use of accessories or attachments not

recommended by the manufacturer may

result in a risk of injury to persons.

11. All air line components, including hoses, pipe,

connectors, filters, etc., must be rated for a minimum

working pressure of 125 PSI, or 150% of the

maximum system pressure, whichever is greater.

SAVE THESE INSTRUCTIONS.

Page 4 For technical questions, please call 1-888-866-5797. ITEM 69784

Specifications

Pump Two stage

Air Outlet Size 1/2″- NPT female

Air Pressure

Auto Shut-Off @ 180 PSI

Restart @ 140 PSI

Air Tank Capacity 30 Gallons

Air Flow Capacity

18 CFM @ 90 PSI

19.5 CFM @ 40 PSI

Oil Capacity 49 oz. (1.45L)

SAE 30W non-detergent

Oil Type

Air Compressor Oil

(Item 95048, sold separately)

Required Rotation

viewed from PTO

(power takeoff - the output shaft)

Required Engine

Idle Speed

Counterclockwise

2100 RPM ± 100 RPM

Note: Engine specifications are found in the engine manual supplied with this equipment.

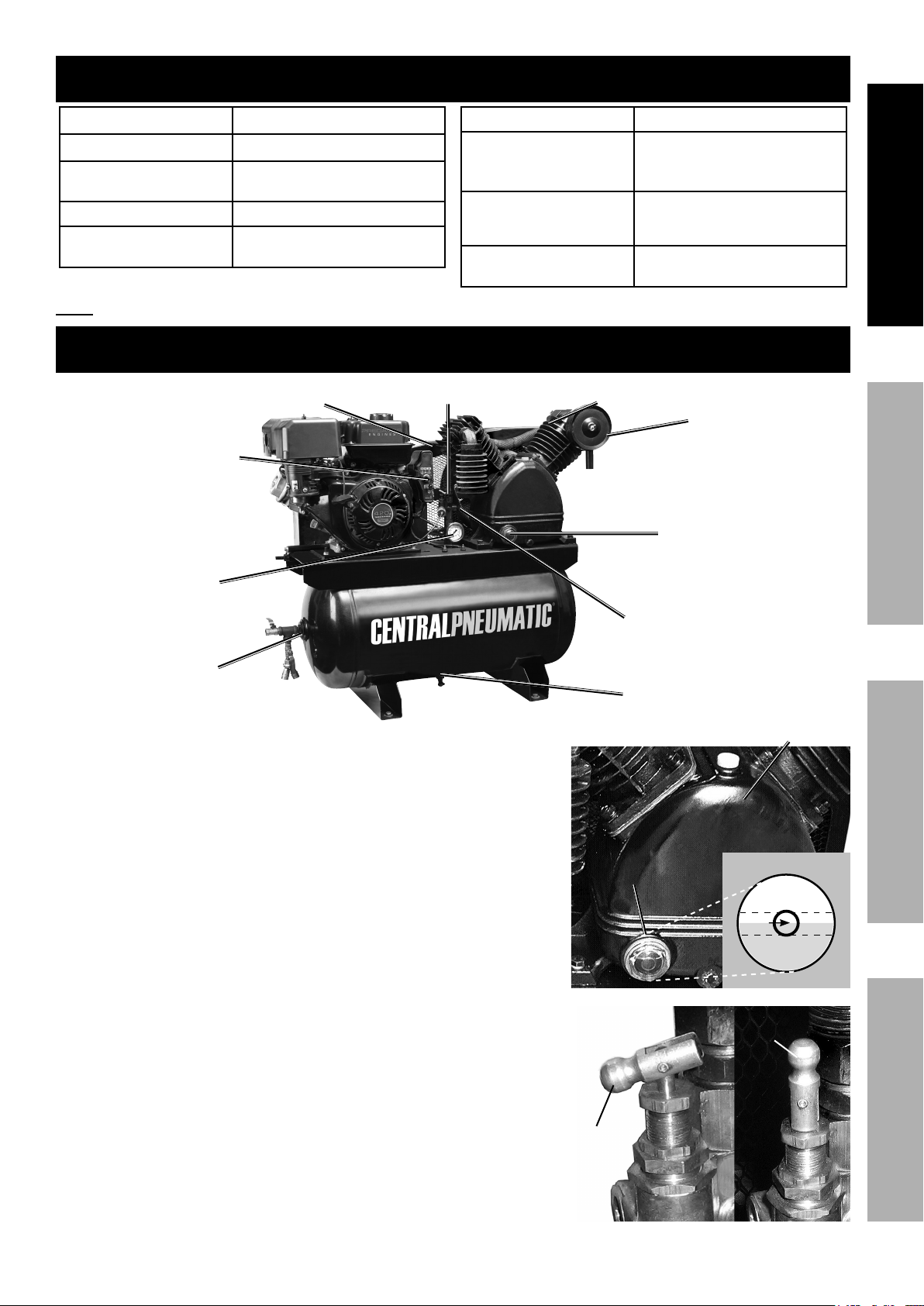

Engine Controls

Belt Guard Frame (122) &

Belt Guard Cover (130)

ON/OFF

Switch

Tank

Pressure

Gauge (97)

Pilot Valve

Pump Safety Valve (91)

SAFETYSETUPOPERATIONMAINTENANCE

Air Filter

Assembly

(84)

Oil Sight

Glass (19)

Air Outlet (106)

1. Belt Guard - The Belt Guard encloses the pulleys and drive belts.

It protects the user from the moving parts and allows the

large pulley to direct cooling air to the Air Pump.

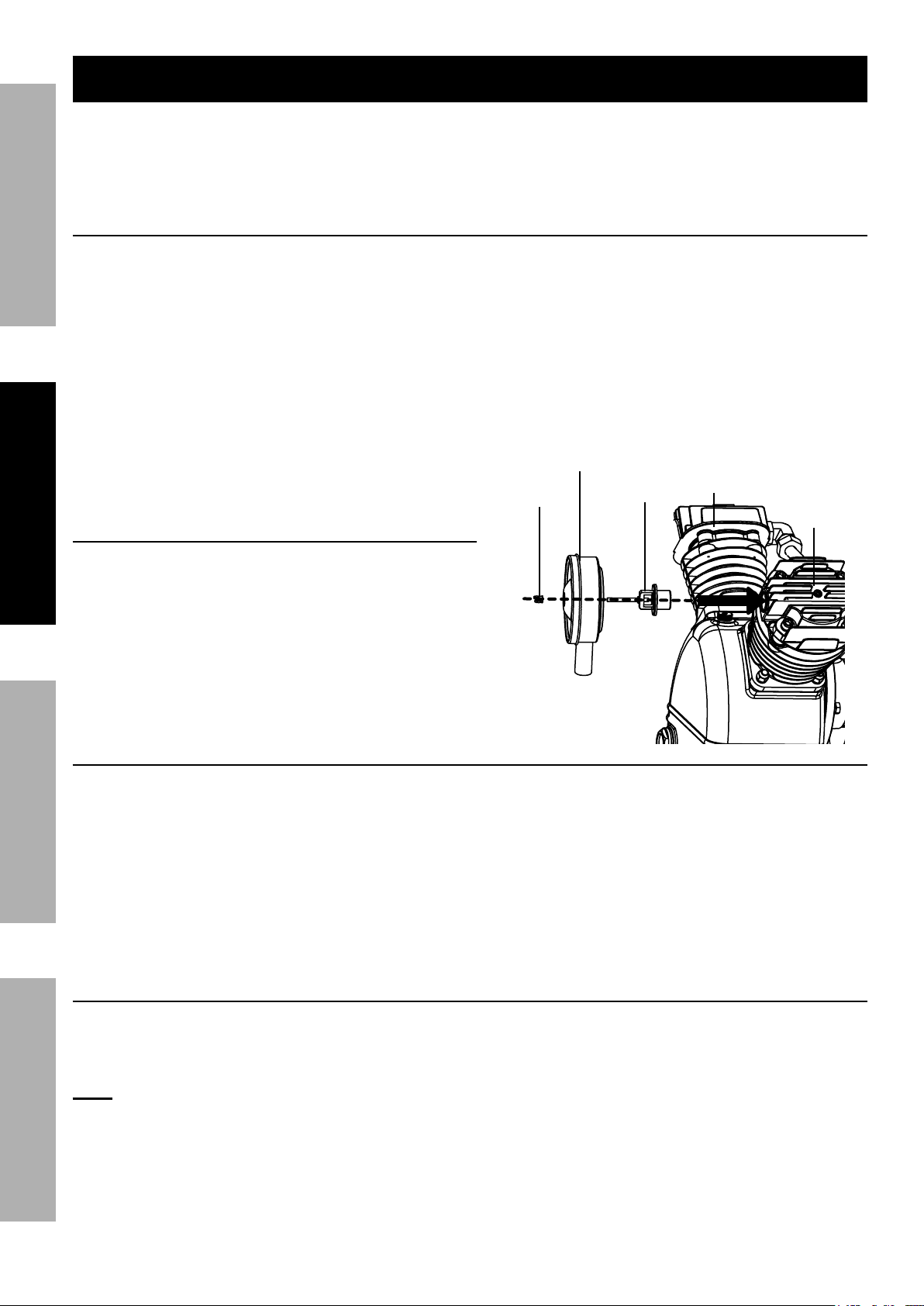

2. Oil Sight Glass - The oil sight glass shows proper level of

the oil. Oil level should be at center of Sight Glass.

3. Tank Drain Valve - The Air Tank Drain Valve allows moisture

to be removed from the tank to prevent corrosion.

4. Safety Valve - The Safety Valve automatically releases

air if the Air Tank pressure exceeds the preset maximum.

In an emergency, the ring can be pulled to relieve tank air pressure.

There is one safety valve on the pump and one on the tank.

5. Air Outlet - An air hose attaches to this valve.

Air pressure required by tools is set by an air pressure regulator.

6. Air Storage Tank - The Air Tank is where air

pressurized by the Air Pump is stored for use.

7. Tank Pressure Gauge - The Air Tank Pressure

Gauge displays the air pressure in the tank.

8. Pilot Valve - Open the Pilot Valve before starting the engine.

It relieves resistance on the engine to make starting possible.

Rotate the pin so it is vertical to open it. Once the engine is running,

close the Pilot Valve so the Compressor can build up pressure.

Tank Safety Valve (98)

Drain Valve (137)

Oil Sight Glass (19)

Closed

Pilot Valve

Crankcase (16)

OIL LEVEL

OVERFILL

FULL

LOW

Opened

Pilot Valve

Page 5For technical questions, please call 1-888-866-5797.ITEM 69784

Setup

The emission control system for this Compressor’s Engine is warranted for standards set by the U.S. Environmental

Protection Agency and by the California Air Resources Board (also known as CARB). For warranty information,

refer to the engine manual.

SAFETY SETUP OPERATION MAINTENANCE

Mounting to a Truck bed

1. Before mounting, if needed, reinforce the area with plywood or steel plating.

2. With assistance, move the compressor to the truck bed location and mark the floor of the truck

bed through the holes in the compressor’s feet. Check for any hidden wiring or cables and

adjust the location for the holes as needed. Then, temporarily set the compressor aside.

3. Drill the four 1/2″ diameter holes through the truck bed and any reinforcing materials.

4. Set the compressor back in place, and align the foot holes with the pre-drilled holes. Use four 1/2″

diameter, bolts, washers and lock washers (all not included) to secure the compressor in place.

Air Filter

Assembly (84)

Wing Nut Connector

Assembly

To install the Air Filter Assembly (84), fit the Connector

into the Air Filter Assembly and slide the assembly into

the hole on the side of the First Stage Cylinder Head (61).

Secure in place with the Wing Nut.

Break-In Compressor

Break in the new Air Compressor as follows:

a. Make sure the engine is off. Open the air outlet valve on the left side of the tank.

b. Check all fluid levels in the engine and pump.

c. Start the engine following the General Operating Instructions.

d. Let the unit run for 30 minutes. Air will expel freely through the Coupler.

e. Turn OFF the engine.

f. Remove the male coupler.

Second Stage

Cylinder Head

(21)

First Stage

Cylinder Head

(61)

Connection

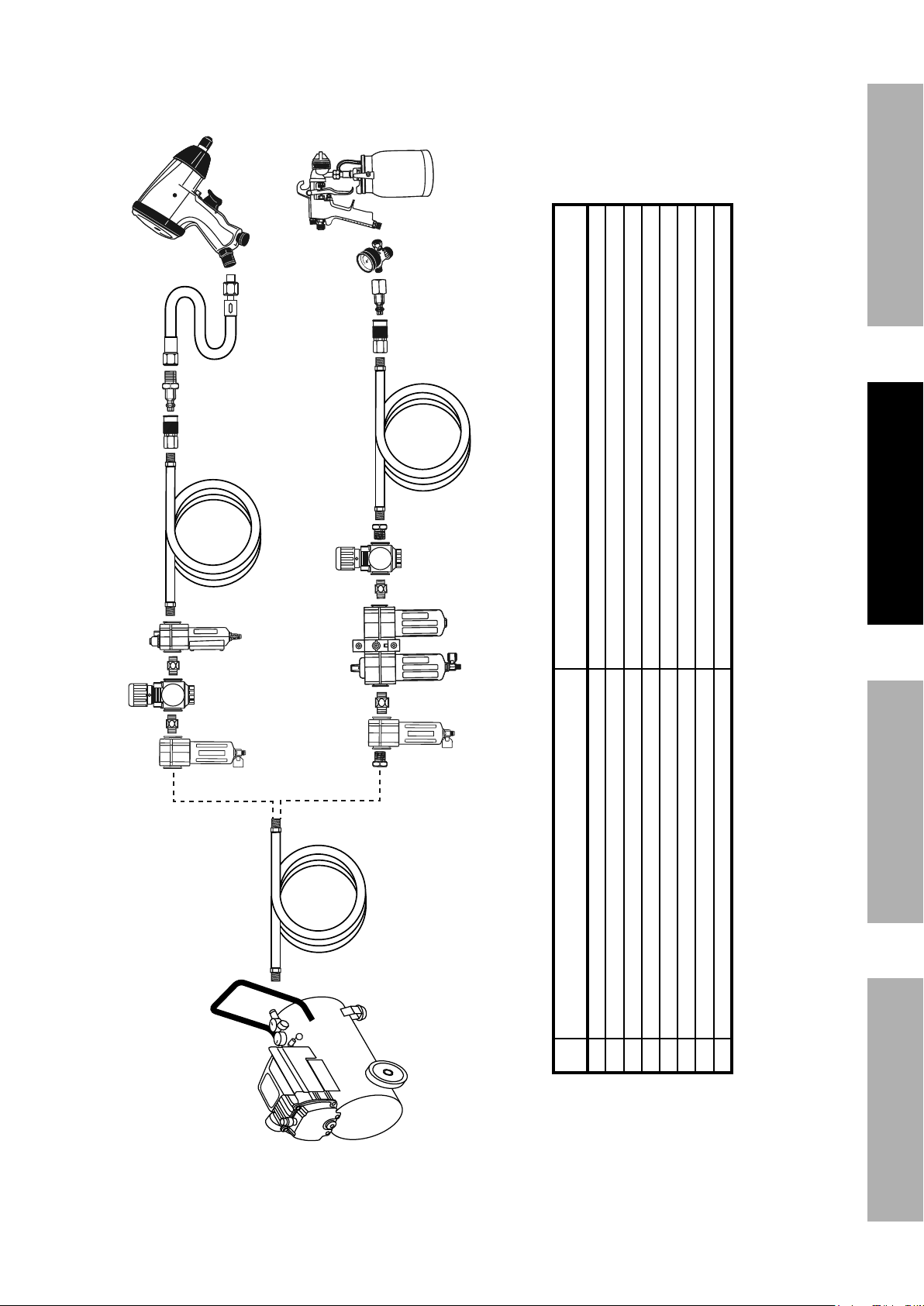

1. Connect a regulator valve, an in-line shut off valve and a 1/2″ NPT air hose

(all sold separately) to the Quick Coupler. The air hose must be long enough to reach

the work area with enough extra length to allow free movement while working.

Note: An in-line shutoff ball valve is an important safety device because it controls the air supply even

if the air hose is ruptured. The shutoff valve should be a ball valve because it can be closed quickly.

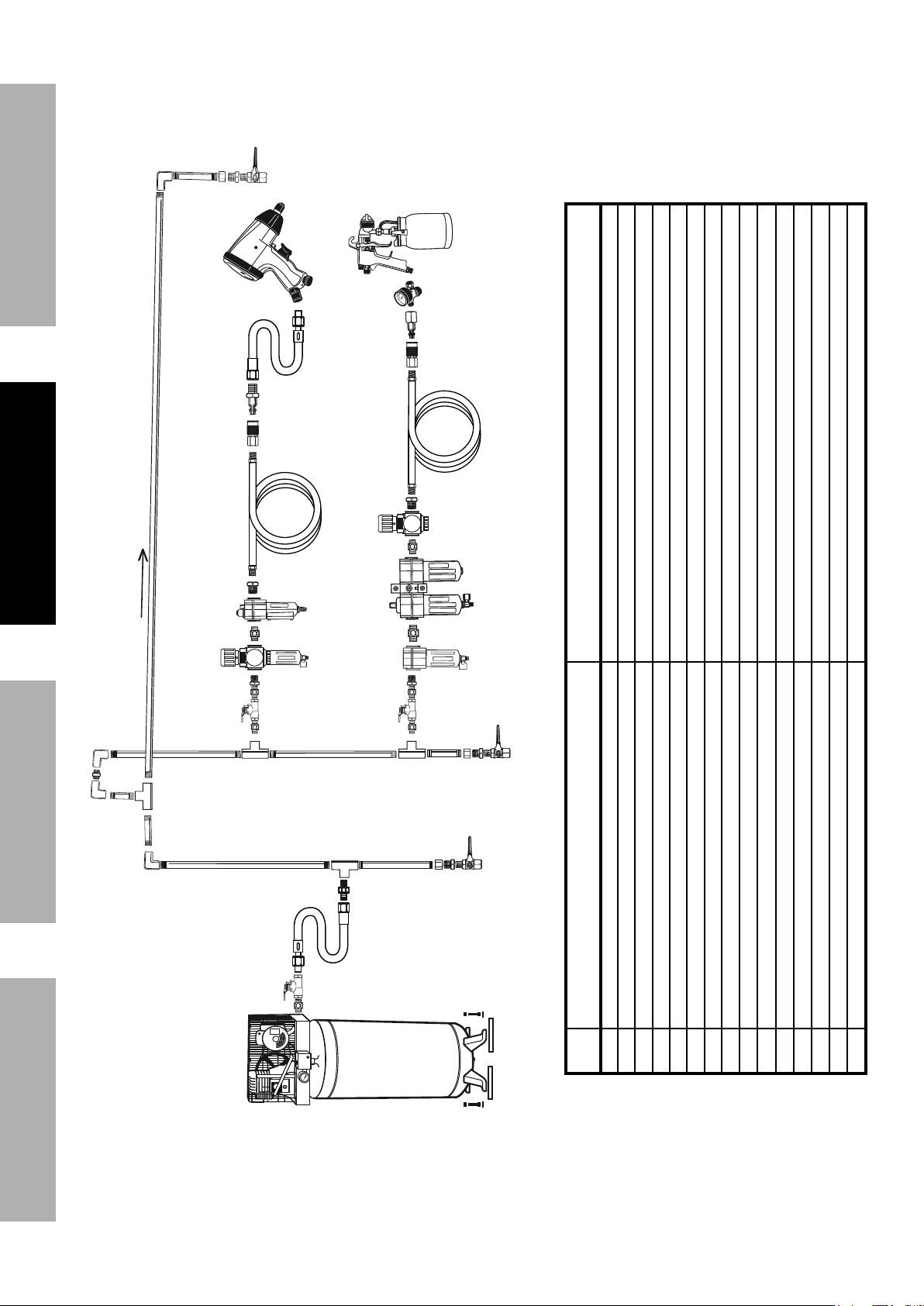

2. Depending on the tool which you will be using with this compressor, you may need to incorporate additional

components, such as an in-line oiler, a filter, or a dryer (all sold separately). Consult your air tool’s manual

for needed accessories. See Typical Air Line Setup charts on the following pages.

This is a truckbed compressor, so use the portable setup as a model.

Page 6 For technical questions, please call 1-888-866-5797. ITEM 69784

F

A

C

E

A

D

SAFETYSETUPOPERATIONMAINTENANCE

E H

C

G

Figure A: Portable Air Supply Setup

B

Lubricated

Tools

A

B

Non-lubricated

Tools

Description Function

A Air Hose Connects air to tool

B Filter Prevents dirt and condensation from damaging tool or work piece

C Regulator Adjusts air pressure to tool

F Leader Hose (optional) Increases coupler life

E Coupler and Plug Provides quick connection and release

D Lubricator (optional) For air tool lubrication

H Air Adjusting Valve (optional) For fine tuning airflow at tool

G Air Cleaner / Dryer (optional) Prevents water vapor from damaging work piece

Page 7For technical questions, please call 1-888-866-5797.ITEM 69784

SAFETY SETUP OPERATION MAINTENANCE

Tools

F

Slope

M

L

H

K

J

C

Lubricated

Tools

L O

H

J

N

I

I

C

Non-lubricated

Figure B: Stationary Air Supply Setup

G

E

D

C

F

B B

A

F

Description Function

I Filter Prevents dirt and condensation from damaging tool or work piece

A Vibration Pads For noise and vibration reduction

B Anchor Bolts Secures air compressor in place

C Ball Valve Isolates sections of system for maintenance

F Ball Valve To drain moisture from system

E Main Air Line - 3/4″ minimum recommended Distributes air to branch lines

D Isolation Hose For vibration reduction

G Branch Air Line -1/2″ minimum recommended Brings air to point of use

J Regulator Adjusts air pressure to tool

H Air Hose Connects air to tool

L Coupler and Plug Provides quick connection and release

K Lubricator (optional) For air tool lubrication

N Air Cleaner / Dryer (optional) Prevents water vapor from damaging work piece

O Air Adjusting Valve (optional) For fine tuning airflow at tool

M Leader Hose (optional) Increases coupler life

Page 8 For technical questions, please call 1-888-866-5797. ITEM 69784

Operation

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this

manual including all text under subheadings therein before set up or use of this product.

Using the Compressor

Inspect Compressor, engine, pump and equipment looking for damaged, loose, and missing parts

before set up and starting. If any problems are found, do not use equipment until fixed properly.

Note: At the beginning of the day’s first use of the Air Compressor, check for air leaks by applying soapy water to

connections while the Air Compressor is pumping and after pressure cut-out. Look for air bubbles. If air bubbles

are present at connections, tighten connections. Do not use the air compressor unless all connections are air tight.

The extra air leaking out will cause the compressor to operate too often, increasing wear on the compressor.

Before starting the Compressor:

a. Follow the Set Up Instructions in the equipment manual to prepare the equipment.

b. Follow the Set Up Instructions in the Engine manual to prepare the engine.

c. Inspect all components of the setup. Make sure all nuts and bolts are tight.

d. Fill the Engine with the proper amount and type of both fuel and oil.

e. Fill the Compressor Pump with compressor oil following

the Maintenance Instructions in this manual.

To Start and Use the Compressor

SAFETYSETUPOPERATIONMAINTENANCE

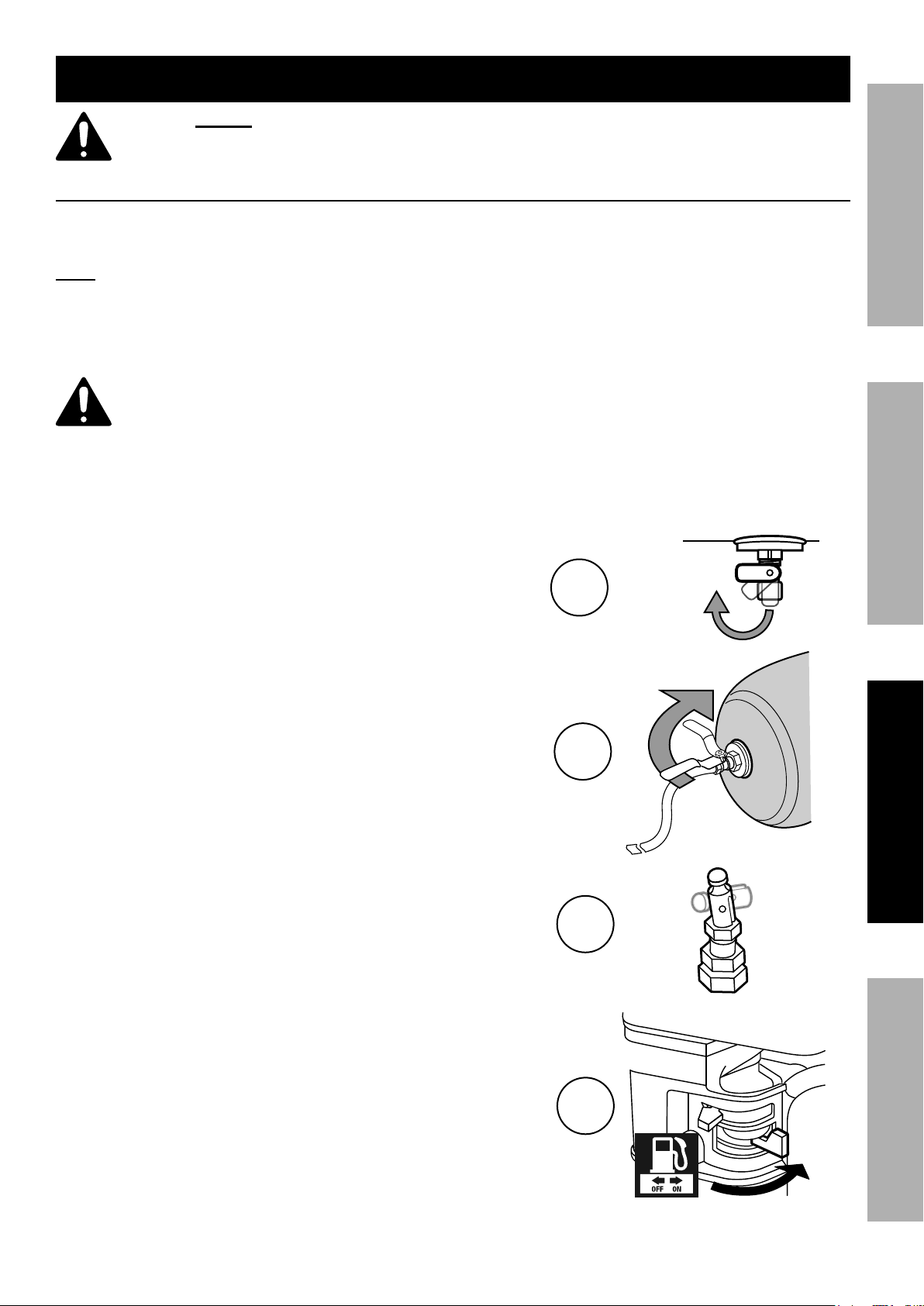

1. Close the Drain Valve (137) by turning the lever

up so that it is perpendicular to the valve.

2. Close the in-line Shutoff Valve between

the compressor and the air hose.

3. Open the Pilot Valve by rotating it to a vertical position.

1

2

3

4. Open the Fuel Valve.

4

Page 9For technical questions, please call 1-888-866-5797.ITEM 69784

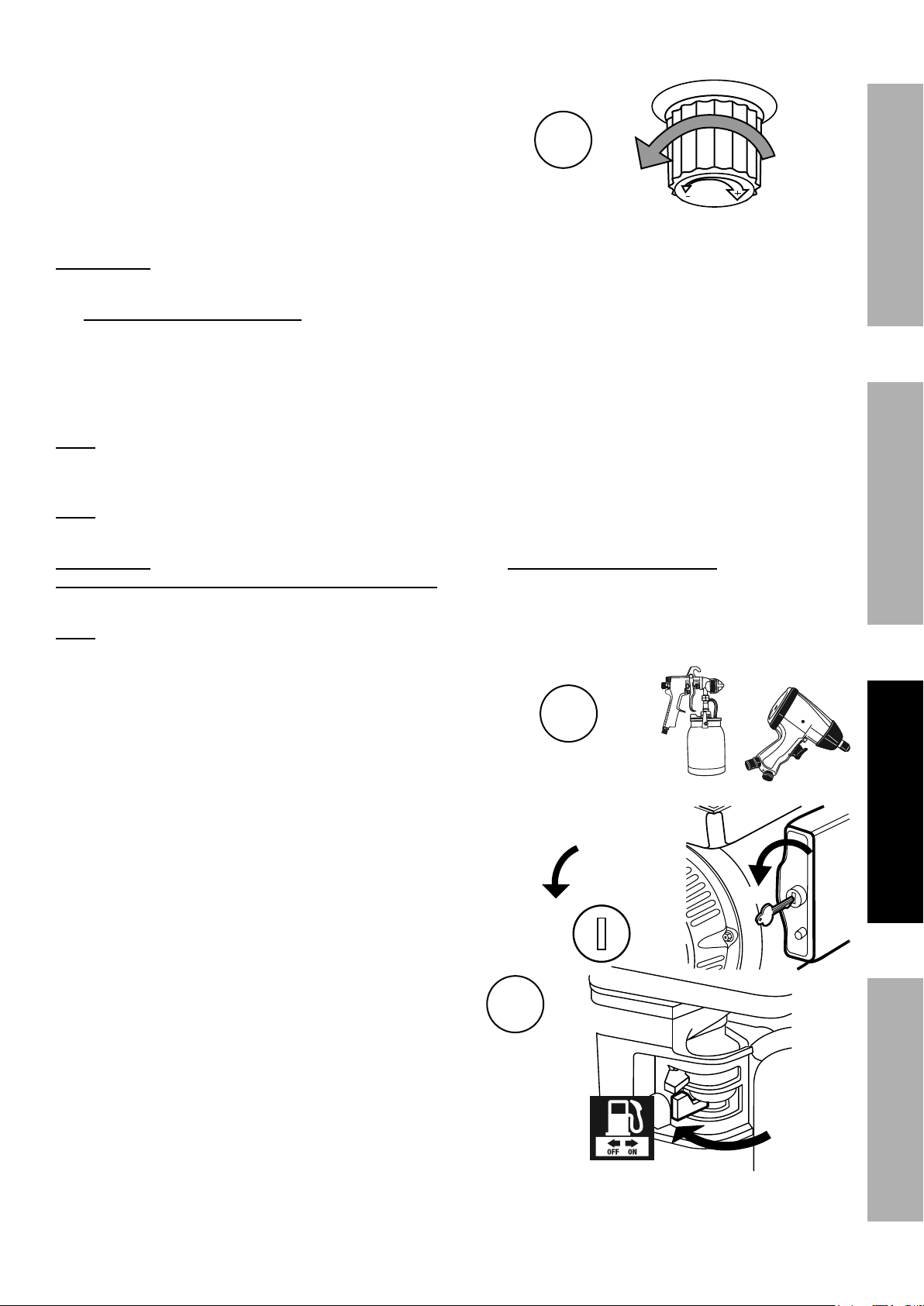

5. To start a cold engine, move the Choke to the CHOKE

(start/closed) position.

To restart a warm engine, leave the

Choke in the RUN position.

SAFETY SETUP OPERATION MAINTENANCE

5

6. For MANUAL START

a. Turn the Engine Switch to ON.

ON

OFF START

b. Grip the Starter Handle of the Engine loosely and

pull it slowly several times to allow the gasoline

to flow into the Engine’s carburetor. Then pull

the Starter Handle gently until resistance is felt.

Allow Cable to retract fully and then pull it quickly.

Repeat until the engine starts. Note: Do not let

the Starter Handle snap back against the engine.

Hold it as it recoils so it doesn't hit the engine.

ON

For ELECTRIC START

Turn the Engine Switch to START.

Note: To prolong starter life, use short starting

cycles (5 seconds maximum). Then wait one

minute before attempting to start again.

ON

OFF START

START

7. Allow the Engine to run for several seconds.

Then, if the Choke lever is in the CHOKE position,

move the Choke Lever very slowly to its RUN position.

Note: Moving the Choke Lever too fast could kill the engine.

8. Close the Pilot Valve by rotating

it to a horizontal position.

7

8

Page 10 For technical questions, please call 1-888-866-5797. ITEM 69784

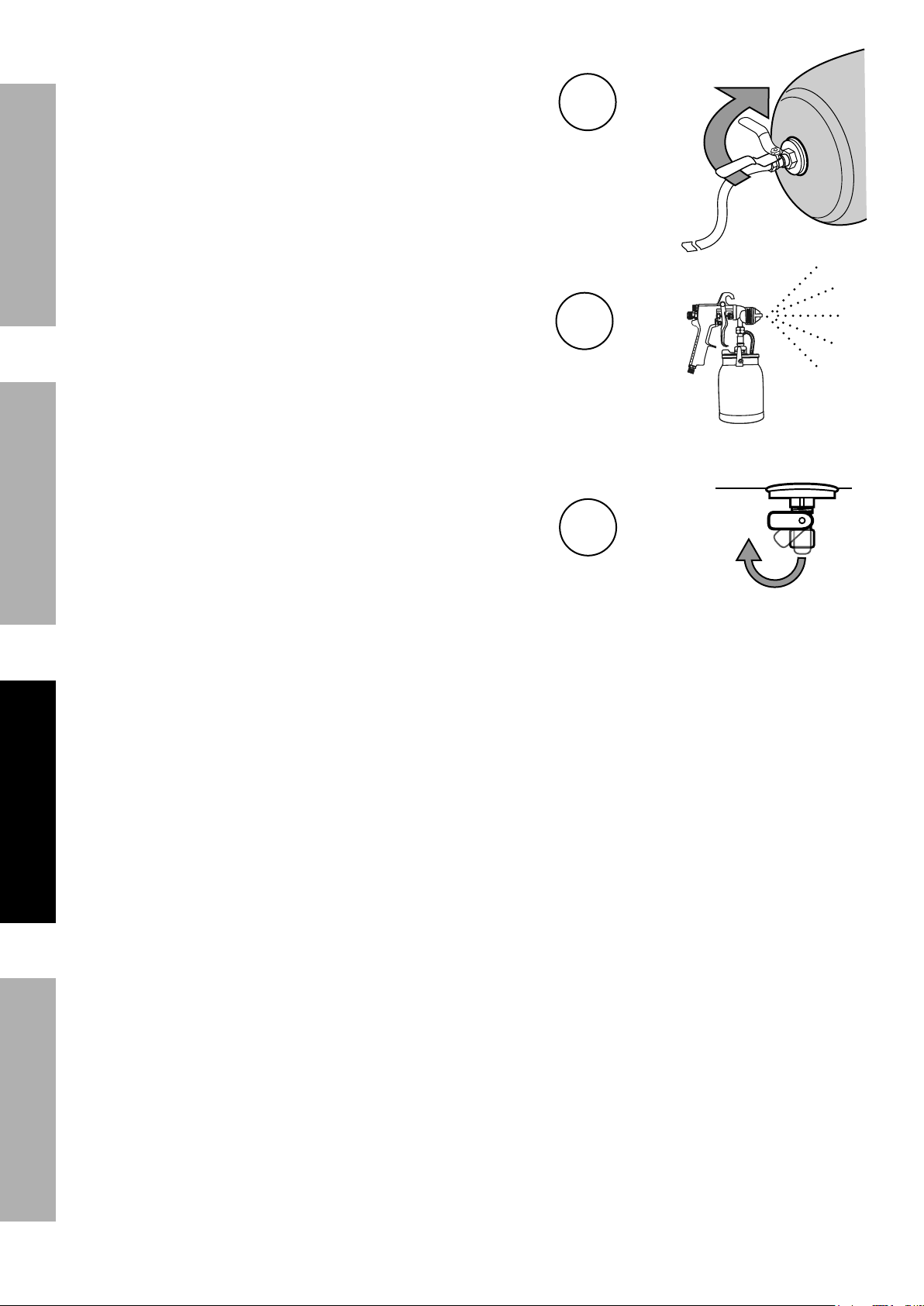

9. When the Gas Engine is started and running, the

compressor Pump starts compressing air into the Air

Tank. Open the in-line Shutoff Valve and adjust the

Pressure Regulator (sold separately) so that the air

output is enough to properly power the tool, but the

output will not exceed the tool’s maximum air pressure

at any time. Turn the knob clockwise to increase the

pressure and counterclockwise to decrease pressure.

Adjust the pressure gradually, while checking

the air output gauge to set the pressure.

IMPORTANT: Allow the engine to run for five minutes with no load

after each start-up so that the engine can stabilize.

Maintenance Break-in Period:

Breaking-in the engine will help to ensure proper equipment and engine operation.

The maintenance break-in period will last about 20 hours of use. After this period, change the engine oil.

Under normal operating conditions, subsequent maintenance follows the schedule

explained in the MAINTENANCE AND SERVICING section.

Note: When maximum tank pressure is reached, the compressor automatically disengages, and the engine

RPM drops down to idle speed. The engine remains at idle until Air Tank pressure falls to a preset level.

The Gas Engine will then accelerate and air pressure once again begins to build up in the Air Tank.

Note: As long as the engine is running, the operation of the Air Compressor

is automatic, controlled by an internal pressure switch.

9

SAFETYSETUPOPERATIONMAINTENANCE

IMPORTANT: The internal pressure switch is not user adjustable; do not make changes to the

air pressure settings of the internal pressure switch. Any change to the automatic pressure

levels may cause excess pressure to accumulate, causing a hazardous situation.

Note: Depressurization - If it is necessary to quickly depressurize the Compressor, turn OFF the engine.

Then, pull on the ring on the tank Safety Valve to release stored air pressure.

10. Use the air tool as needed.

11. After the job is complete, turn OFF the engine.

To stop the engine in an emergency,

turn the Engine Switch off.

Under normal conditions, use the following procedure:

a. Turn the Engine Switch off.

b. Close the Fuel Valve.

10

ON

OFF START

OFF

11

Page 11For technical questions, please call 1-888-866-5797.ITEM 69784

12. Close the in-line Shutoff Valve.

SAFETY SETUP OPERATION MAINTENANCE

12

13. Bleed air from the tool then disconnect the tool.

14. Open the Drain Valve at the bottom of the Tank,

to release any built-up moisture

and the internal tank pressure.

15. Clean, then store the Air Compressor indoors.

13

14

Page 12 For technical questions, please call 1-888-866-5797. ITEM 69784

Loading...

Loading...