Harbor Freight Tools 69705 Product manual

Owner’s Manual & Safety Instructions

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

Save This Manual Keep this manual for the safety warnings and precautions, assembly, operating,

operating, inspection, maintenance and cleaning procedures� Write the product’s serial number in the

inspection, maintenance and cleaning procedures� Write the product’s serial number in the back of the manual

back of the manual near the assembly diagram (or month and year of purchase if product has no number)�

near the assembly diagram (or month and year of purchase if product has no number)�

Keep this manual and the receipt in a safe and dry place for future reference�

Keep this manual and the receipt in a safe and dry place for future reference�

REV 15c

NOTICE

CLEAN IMMEDIATELY

Clean the Spray Gun

IMMEDIATELY after use.

Delayed or inadequate cleaning will

permanently clog the Spray Gun.

Visit our website at: http://www.harborfreight.com

When unpacking, make sure that the product is intact

When unpacking, make sure that the product is intact

and undamaged� If any parts are missing or broken,

and undamaged� If any parts are missing or broken,

please call 1‑888‑866‑5797 as soon as possible�

please call 1‑888‑866‑5797 as soon as possible�

Copyright© 2012 by Harbor Freight Tools®� All rights reserved�

Copyright© 2012 by Harbor Freight Tools®� All rights reserved�

No portion of this manual or any artwork contained herein may be reproduced in

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools�

any shape or form without the express written consent of Harbor Freight Tools�

Diagrams within this manual may not be drawn proportionally� Due to continuing

Diagrams within this manual may not be drawn proportionally� Due to continuing

improvements, actual product may differ slightly from the product described herein�

improvements, actual product may differ slightly from the product

Tools required for assembly and service may not be included�

described herein� Tools required for assembly and service may not be included�

Email our technical support at: productsupport@harborfreight.com

Read this material before using this product.

Read this material before using this product.

Failure to do so can result in serious injury.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

SAVE THIS MANUAL.

Clean the Spray Gun IMMEDIATELY after EVERY use.

NOTICE

Delayed or inadequate cleaning will permanently clog the Spray Gun.

Latex paint hardens quickly and permanently inside Spray Gun.

SAFETY OPERATION MAINTENANCESETUP

Safety �������������������������������������������������2

Specifications �������������������������������������5

Setup ��������������������������������������������������6

Operation ��������������������������������������������9

Table of Contents

Maintenance ��������������������������������������13

Parts List and Diagram ����������������������18

Warranty ��������������������������������������������20

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol� It is used to alert you to

potential personal injury hazards� Obey all safety messages

that follow this symbol to avoid possible injury or death�

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury�

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury�

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury�

Addresses practices not related to personal injury�

IMPORTANT SAFETY INSTRUCTIONS

INSTRUCTIONS PERTAINING TO A RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO PERSONS

The warnings and precautions discussed in this manual cannot cover all possible conditions

and situations that may occur� It must be understood by the operator that common sense and

caution are factors which cannot be built into this product, but must be supplied by the operator�

WARNING – When using tools, basic precautions should always be followed, including the following:

Work Area

a� Keep the work area clean and well lighted.

Cluttered benches and dark areas

increase the risks of electric shock,

fire, and injury to persons�

Page 2 For technical questions, please call 1-888-866-5797. Item 69705

b� Keep bystanders, children, and

visitors away while operating the tool.

Distractions are able to result in

the loss of control of the tool�

Personal Safety

Clean the Spray Gun IMMEDIATELY after EVERY use.

NOTICE

Delayed or inadequate cleaning will permanently clog the Spray Gun.

Latex paint hardens quickly and permanently inside Spray Gun.

a� Stay alert. Watch what you are

doing and use common sense when

operating the tool. Do not use the

tool while tired or under the influence

of drugs, alcohol, or medication.

A moment of inattention while operating the

tool increases the risk of injury to persons�

b� Dress properly. Do not wear

loose clothing or jewelry. Contain

long hair. Keep hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long hair

increases the risk of injury to persons as

a result of being caught in moving parts�

Tool Use and Care

a� Do not force the tool. Use the correct

tool for the application� The correct tool

will do the job better and safer at the

rate for which the tool is designed�

b� Disconnect the tool from the air source

before making any adjustments,

changing accessories, or storing the tool.

Such preventive safety measures reduce

the risk of starting the tool unintentionally�

Turn off and detach the air supply, safely

discharge any residual air pressure, and

release the throttle and/or turn the switch to

its off position before leaving the work area�

c� Store the tool when it is idle out of reach

of children and other untrained persons.

A tool is dangerous in the hands

of untrained users�

c� Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enables better

control of the tool in unexpected situations�

d� Use safety equipment.

Wear heavy‑duty work gloves and

a NIOSH‑approved respirator

during use� Non‑skid safety shoes

and a hard hat must be used for the

applicable conditions�

e� Always wear eye protection.

Wear ANSI‑approved

safety goggles�

d� Check for misalignment or binding

of moving parts, breakage of parts,

and any other condition that affects

the tool’s operation. If damaged,

have the tool serviced before using�

Many accidents are caused by poorly

maintained tools� There is a risk of

bursting if the tool is damaged�

e� Use only accessories that are identified

by the manufacturer for the specific

tool model. Use of an accessory not

intended for use with the specific tool model,

increases the risk of injury to persons�

SAFETYOPERATIONMAINTENANCE SETUP

Service

a� Tool service must be performed only

by qualified repair personnel.

b� When servicing a tool, use only

identical replacement parts.

Use only authorized parts.

c� Use only lubricants supplied with the

tool or specified by the manufacturer.

Page 3For technical questions, please call 1-888-866-5797.Item 69705

Clean the Spray Gun IMMEDIATELY after EVERY use.

Delayed or inadequate cleaning will permanently clog the Spray Gun.

Latex paint hardens quickly and permanently inside Spray Gun.

Air Source

SAFETY OPERATION MAINTENANCESETUP

a� Never connect to an air source

serious injury to persons� Use only clean, dry,

regulated compressed air at the rated

pressure or within the rated pressure range as

marked on the tool� Always verify prior to

using the tool that the air source has been

adjusted to the rated air pressure or within the

rated air‑pressure range�

that is capable of exceeding

200 psi. Over pressurizing the

tool may cause bursting, abnormal

operation, breakage of the tool or

SAVE THESE INSTRUCTIONS.

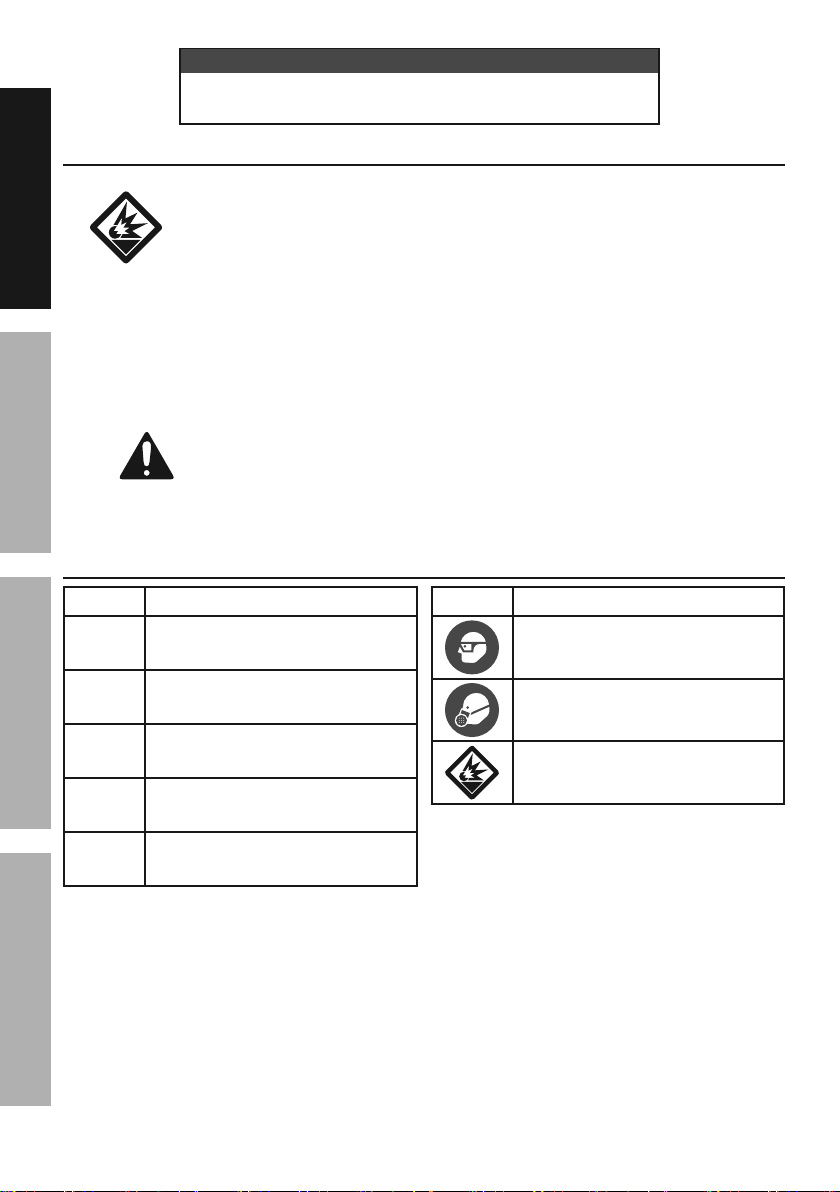

Symbol Definitions

NOTICE

b� Never use oxygen, carbon dioxide,

combustible gases or any bottled

gas as an air source for the tool.

Such gases are capable of explosion

and serious injury to persons�

Symbol Property or Statement

PSI

CFM

SCFM

NPT

NPS

Page 4 For technical questions, please call 1-888-866-5797. Item 69705

Pounds per square inch of pressure

Cubic Feet per Minute flow

Cubic Feet per Minute flow

at standard conditions

National pipe thread, tapered

National pipe thread, straight

Symbol Property or Statement

WARNING marking concerning

Risk of Eye Injury� Wear

ANSI‑approved eye protection�

WARNING marking concerning

Risk of Respiratory Injury�

Wear NIOSH‑approved respirator�

WARNING marking concerning

Risk of Explosion�

Clean the Spray Gun IMMEDIATELY after EVERY use.

Delayed or inadequate cleaning will permanently clog the Spray Gun.

Latex paint hardens quickly and permanently inside Spray Gun.

Specific Safety Instructions

NOTICE

1� Do not direct spray at people or animals�

2� Do not exceed maximum air pressure�

3� Do not spray near open flames, pilot lights,

stoves, heaters, the air compressor, or

any other heat source� Most solvents and

coatings are highly flammable, particularly

when sprayed� Maintain a distance of at least

25 feet from the air compressor� If possible,

locate the air compressor in a separate room�

4� Read all of the information concerning

coating products and cleaning solvents�

Do not use chlorinated solvents

(e.g. 1-1-1 trichloroethylene and

dichloromethane, also known as

methylene chloride) to clean spray guns.

Many spray guns contain aluminum,

which reacts strongly to chlorinated

solvents. Contact the solvent or coating

manufacturer as needed regarding

potential chemical reactions�

5� Industrial applications must

follow OSHA requirements�

6� Spraying hazardous materials may

result in serious injury or death�

Do not spray pesticide, acid, corrosive

material, fertilizer, or toxic chemicals�

7� Paints and solvents may be harmful or fatal if

swallowed or inhaled� Avoid prolonged skin

contact with solvents or paints as they will

irritate skin� After any contact, immediately

wash off exposed area with hot, soapy water�

8� Attach all accessories properly to the

tool before connecting the air supply�

A loose accessory may detach

or break during operation�

9� Install an in‑line shutoff valve

to allow immediate control over

the air supply in an emergency,

even if a hose is ruptured�

10� Air hose fittings may get hot during use�

Allow fittings to cool before disconnecting�

11� WARNING: Some dust created by power

sanding, sawing, grinding, drilling, and

other construction activities, contains

chemicals known to the State of California

to cause cancer and birth defects or other

reproductive harm� Some examples of these

chemicals are:

• Lead from lead‑based paints

• Crystalline silica from bricks and cement or

other masonry products

• Arsenic and chromium from chemically

treated lumber

Your risk from these exposures varies,

depending on how often you do this type

of work� To reduce your exposure to

these chemicals: work in a well ventilated

area, and work with approved safety

equipment, such as those dust masks

that are specially designed to filter out

microscopic particles� (California Health

& Safety Code § 25249�5, et seq.)

12� WARNING: The brass components of

this product contain lead, a chemical

known to the State of California to

cause cancer and birth defects or other

reproductive harm� (California Health

& Safety Code § 25249�5, et seq.)

SAFETYOPERATIONMAINTENANCE SETUP

Specifications

Air Pressure Range 15 – 45 PSI

Maximum Air Pressure 45 PSI

Air Inlet 1/4 IN� – 18 NPS

Air Consumption 12 CFM @ 45 PSI

Cup Capacity 20 FL� OZ�

Page 5For technical questions, please call 1-888-866-5797.Item 69705

Clean the Spray Gun IMMEDIATELY after EVERY use.

NOTICE

Delayed or inadequate cleaning will permanently clog the Spray Gun.

Latex paint hardens quickly and permanently inside Spray Gun.

SAFETY OPERATION MAINTENANCESETUP

Initial Set Up

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this

manual including all text under subheadings therein before set up or use of

this product.

Note: For additional information regarding the parts listed in the following

pages, refer to the Assembly Diagram near the end of this manual�

Before Setup

1� This air tool may be shipped with a

protective plug covering the air inlet�

Remove this plug before set up�

Air Supply Setup

TO PREVENT SERIOUS INJURY FROM EXPLOSION:

Use only clean, dry, regulated, compressed air to power this tool. Do not use

oxygen, carbon dioxide, combustible gases, or any other bottled gas as a power

source for this tool.

1� Incorporate a filter, regulator with pressure

gauge, in‑line shutoff valve, and quick coupler

for best service, as shown on Figure A on

page 7 and Figure B on page 8�

An in-line shutoff ball valve is an important

safety device because it controls the air

supply even if the air hose is ruptured.

The shutoff valve should be a ball valve

because it can be closed quickly.

Note: Do not use an automatic oiler system or

add oil to airline� The oil will contaminate the

material being propelled, ruining the final result�

2� Attach an air hose to the

compressor’s air outlet� Connect the

air hose to the air inlet of the tool�

Other components, such as a coupler plug

and quick coupler, will make operation

more efficient, but are not required�

2� Before first use, clean the Spray Gun using

a solvent-based thinner. If not removed,

the material used for testing and corrosion

prevention will contaminate paint�

WARNING! TO PREVENT SERIOUS

INJURY FROM ACCIDENTAL OPERATION:

Do not install a female quick coupler

on the tool. Such a coupler contains

an air valve that will allow the air tool to

retain pressure and operate accidentally

after the air supply is disconnected�

Note: Air flow, and therefore tool

performance, can be hindered by

undersized air supply components�

3� The air hose must be long enough to reach

the work area with enough extra length

to allow free movement while working�

4� Close the in‑line shutoff valve between

the compressor and the tool�

5� Turn on the air compressor according to

the manufacturer’s directions and allow it

to build up pressure until it cycles off�

Page 6 For technical questions, please call 1-888-866-5797. Item 69705

Loading...

Loading...