Harbor Freight Tools 69675, 69676 Owner's Manual

Table of Contents

Safety ......................................................... 2

Setup .......................................................... 6

Specications ............................................. 6

SAFETY OPERATION MAINTENANCESETUP

Operation .................................................... 8

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Maintenance .............................................. 14

Parts List and Diagram .............................. 19

Warranty .................................................... 23

WARNING SYMBOLS AND DEFINITIONS

Obey all safety messages that follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

IMPORTANT SAFETY INSTRUCTIONS

INSTRUCTIONS PERTAINING TO A RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO PERSONS

WARNING – When using tools, basic precautions should always be followed, including the following:

Set up Precautions

1. Gasoline fuel and fumes are ammable,

and potentially explosive. Use proper fuel

storage and handling procedures. Do not store

fuel or other ammable materials nearby.

2. Have multiple ABC class re

extinguishers nearby.

3. Operation of this equipment may create sparks

that can start res around dry vegetation. A

spark arrestor may be required. The operator

should contact local re agencies for laws or

regulations relating to re prevention requirements.

4. Set up and use only on a at, level,

well-ventilated surface.

5. All connections and conduits from the

Generator to the load must only be installed

by trained and licensed electricians, and

in compliance with all relevant local, state,

and federal electrical codes and standards,

and other regulations where applicable.

6. Connections for standby power to a building

electrical system must be made by a qualied

electrician. The connection must isolate the

generator power from utility power, and must comply

with all applicable laws and electrical codes.

7. Wear ANSI-approved safety goggles,

heavy-duty work gloves, and dust

mask/respirator during set up.

Page 2

For Pump technical questions, please call 1-800-444-3353.

For Engine technical questions, please call 1-800-520-0882.

Item 69675 / 69676

Set up Precautions (cont.)

8. Use only lubricants and fuel

recommended in this manual.

9. Improper connections to a building electrical

system can allow electrical current from the

generator to backfeed into the utility lines. Such

backfeed may electrocute utility company workers

or others who contact the lines during a power

outage, and the generator may explode, burn, or

cause res when utility power is restored. Consult

the utility company and a qualied electrician if

intending to use the generator for back up power.

Operating Precautions

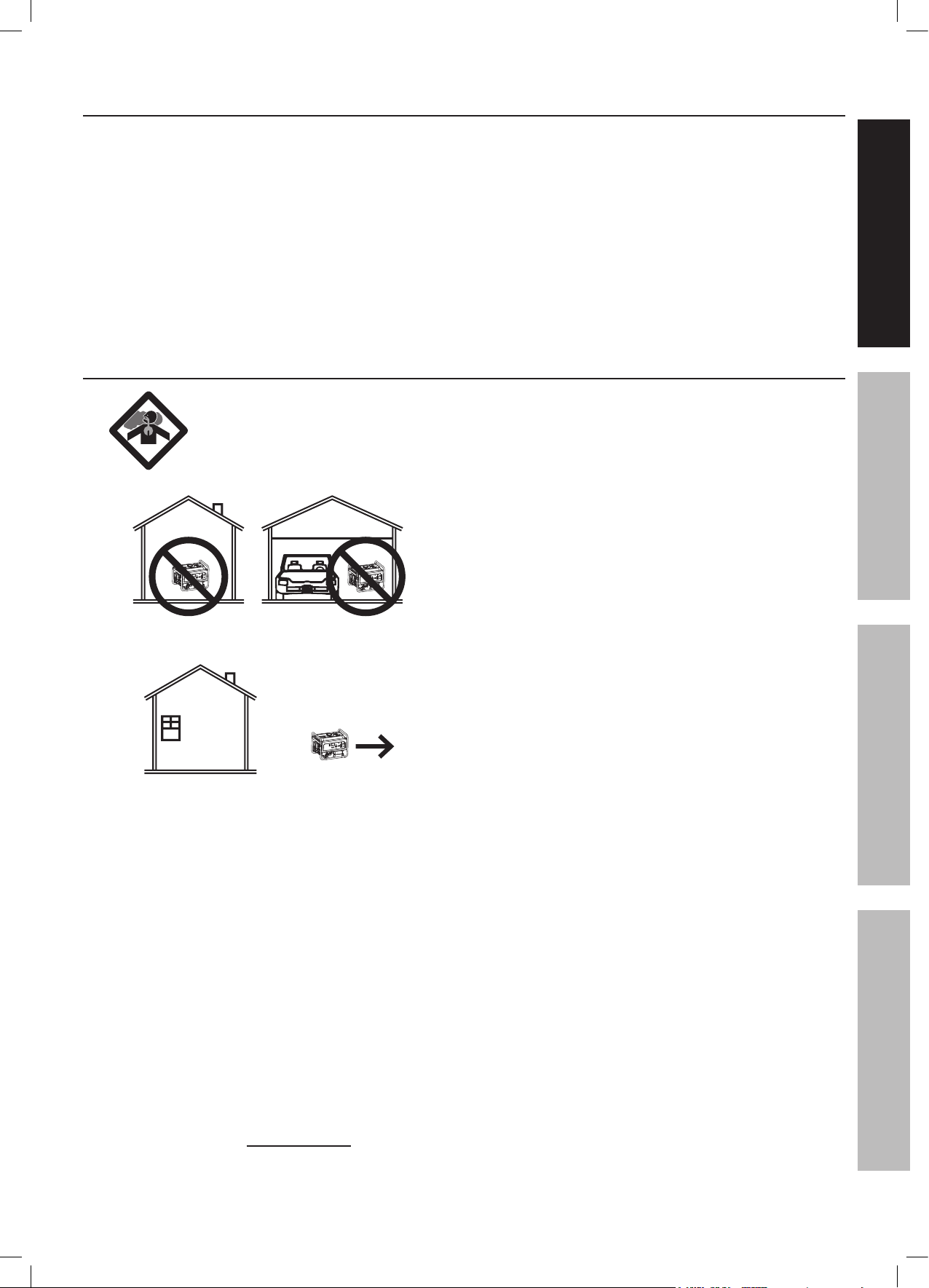

1. CARBON MONOXIDE HAZARD

Using a generator indoors CAN KILL

YOU IN MINUTES.

Generator exhaust contains carbon

monoxide. This is a poison you cannot

see or smell.

10. Do not operate the Generator before grounding.

The Generator must be earth-grounded

in accordance with all relevant electrical

codes and standards before operation.

SAFETYOPERATIONMAINTENANCE SETUP

7. Fire Hazard! Do not ll gas tank while engine

is running. Do not operate if gasoline has been

spilled. Clean spilled gasoline before starting engine.

Do not operate near pilot light or open ame.

8. Do not touch engine during use. Let engine

cool down before service or storage.

9. Never store fuel or other ammable

materials near the engine.

NEVER use inside a home or garage, EVEN IF doors

and windows are open.

Only use OUTSIDE and far away from windows,

doors, and vents.

2. Never use a generator indoors, including in

garages, basements, crawl spaces and sheds.

Opening doors and windows or using fans will NOT

prevent carbon monoxide build up in the home.

3. When using generators, keep them outdoors

and far away from open doors, windows,

and vents to avoid toxic levels of carbon

monoxide from building up indoors.

4. If you start to feel sick, dizzy, or weak while

using a generator, get to fresh air right away.

The carbon monoxide from generators can

quickly lead to full incapacitation and death.

5. Keep children away from the equipment,

especially while it is operating.

6. Keep all spectators at least six feet

from the Engine during operation.

10. If the plugged in product operates abnormally

or unusually slow, immediately stop using the

generator as a power source. Always read and

adhere to the instruction manual of the product

to be powered, to make sure that it can be safely

and efciently powered by a portable generator.

11. Before connecting an appliance or power

cord to the generator: Make sure that it is in

good working order. Faulty appliances or power

cords can create a potential for electrical shock.

12. Do not exceed the maximum power rating of

the generator. Make sure that the total electrical

rating of the all of the tools or appliances plugged

into the generator at the same time does not

exceed that of the generator. Check that the startup

surge will not be beyond the limit of the Generator.

Power levels between rated and maximum

may be used for no more than 30 minutes.

13. Avoid substantially overloading which will

trip the circuit breaker. Exceeding the time

limit for maximum power operation or slightly

overloading the generator may not switch the

circuit breaker or circuit protector OFF, but will

shorten the service life of the generator.

14. Do not attempt to connect or disconnect

load connections while standing in

water, or on wet or soggy ground.

15. Do not touch electrically energized parts of

the Generator and interconnecting cables

or conductors with any part of the body, or

with any non-insulated conductive object.

Item 69675 / 69676

For Pump technical questions, please call 1-800-444-3353.

For Engine technical questions, please call 1-800-520-0882.

Page 3

Operating Precautions (cont.)

16. Connect the Generator only to a load or

electrical system (120 volt or 240 volt) that is

compatible with the electrical characteristics

SAFETY OPERATION MAINTENANCESETUP

and rated capacities of the Generator.

17. Insulate all connections and disconnected wires.

18. Guard against electric shock. Prevent

body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerators.

19. Only use a suitable means of transport and

lifting devices with sufcient weight bearing

capacity when transporting the generator.

20. Secure the Generator on transport vehicles to

prevent the tool from rolling, slipping, and tilting.

21. Industrial applications must

follow OSHA requirements.

22. Do not leave the Generator unattended when it is

running. Turn off the Generator (and remove safety

keys, if available) before leaving the work area.

23. The Generator engine can produce high

noise levels. Prolonged exposure to noise levels

above 85 dBA is hazardous to hearing. Always

wear ear protection when operating or working

around the gas engine while it is operating.

29. Stay alert, watch what you are doing

and use common sense when operating

this piece of equipment. Do not use this

piece of equipment while tired or under the

inuence of drugs, alcohol or medication.

30. Dress properly. Do not wear loose clothing or

jewelry. Keep hair, clothing and gloves away

from moving parts. Loose clothes, jewelry or

long hair can be caught in moving parts.

31. Parts, especially exhaust system components,

get very hot during use. Stay clear of hot parts.

32. Do not cover the generator or its

engine during operation.

33. Keep the generator, its engine, and

surrounding area clean at all times.

34. Use the generator, accessories, etc., in

accordance with these instructions and in

the manner intended for the particular type of

equipment, taking into account the working

conditions and the work to be performed. Use

of the equipment for operations different from those

intended could result in a hazardous situation.

35. Do not operate the generator with known

leaks in the engine’s fuel system.

24. Wear ANSI-approved safety glasses and

hearing protection during use.

25. People with pacemakers should consult their

physician(s) before use. Electromagnetic

elds in close proximity to a heart pacemaker

could cause pacemaker interference or

pacemaker failure. Caution is necessary when

near the engine’s magneto or recoil starter.

26. Use only accessories that are recommended

by Harbor Freight Tools for your model.

Accessories that may be suitable for one

piece of equipment may become hazardous

when used on another piece of equipment.

27. Do not operate in explosive atmospheres,

such as in the presence of ammable

liquids, gases, or dust. Gasoline-powered

engines may ignite the dust or fumes.

28. Keep grounded conductive objects, such as

tools, away from exposed, live electrical parts

and connections to avoid sparking or arcing.

These events could ignite fumes or vapors.

36. This product contains or, when used,

produces a chemical known to the State of

California to cause cancer and birth defects

or other reproductive harm. (California

Health & Safety Code § 25249.5, et seq.)

37. When spills of fuel or oil occur, they must

be cleaned up immediately. Dispose of uids

and cleaning materials as per any local, state, or

federal codes and regulations. Store oil rags in

a bottom-ventilated, covered, metal container.

38. Keep hands and feet away from moving parts. Do

not reach over or across generator while operating.

39. Before use, check for misalignment or binding

of moving parts, breakage of parts, and any

other condition that may affect the generator’s

operation. If damaged, have the generator

serviced before using. Many accidents are

caused by poorly maintained equipment.

40. Use the correct generator for the

application. Do not modify the generator or

its engine, and do not use the generator for

a purpose for which it is not intended.

Page 4

For Pump technical questions, please call 1-800-444-3353.

For Engine technical questions, please call 1-800-520-0882.

Item 69675 / 69676

Service Precautions

1. Before service, maintenance, or cleaning:

a. Unplug all devices from the generator.

b. Turn the engine switch to its “OFF” position.

c. Allow the engine to completely cool.

d. Then, remove the spark plug

cap from the spark plug.

2. Keep all safety guards in place and in

proper working order. Safety guards include

mufer, air cleaner, mechanical guards,

and heat shields, among other guards.

3. Keep all electrical equipment clean and

dry. Replace any wiring where the insulation is

cracked, cut, abraded, or otherwise degraded.

Replace terminals that are worn, discolored, or

corroded. Keep terminals clean and tight.

4. Do not alter or adjust any part of the

equipment or its engine that is sealed by the

manufacturer or distributor. Only a qualied

service technician may adjust parts that may

increase or decrease governed engine speed.

5. Wear ANSI-approved safety goggles,

heavy-duty work gloves, and dust

mask/respirator during service.

7. Have the equipment serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the

equipment is maintained. Do not attempt any service

or maintenance procedures not explained in this

manual or any procedures that you are uncertain

about your ability to perform safely or correctly.

8. Store equipment out of the reach of children.

9. Follow scheduled engine and

equipment maintenance.

Refueling:

1. Do not smoke, or allow sparks, ames,

or other sources of ignition around the

equipment, especially when refuelling.

2. Do not rell the fuel tank while the

engine is running or hot.

3. TO PREVENT FUEL LEAKAGE AND FIRE

HAZARD, Do not overll with fuel. Fill with

fuel according to the Fuel Level information

below the Specication chart for your model.

4. Do not ll fuel tank to the top. Leave a little

room for the fuel to expand as needed.

SAFETYOPERATIONMAINTENANCE SETUP

6. Maintain labels and nameplates on

the equipment. These carry important

information. If unreadable or missing, contact

Harbor Freight Tools for a replacement.

5. Refuel in a well-ventilated area only.

6. Wipe up any spilled fuel and allow excess

to evaporate before starting engine. To

prevent FIRE, do not start the engine

while the smell of fuel hangs in the air.

SAVE THESE

INSTRUCTIONS.

Item 69675 / 69676

For Pump technical questions, please call 1-800-444-3353.

For Engine technical questions, please call 1-800-520-0882.

Page 5

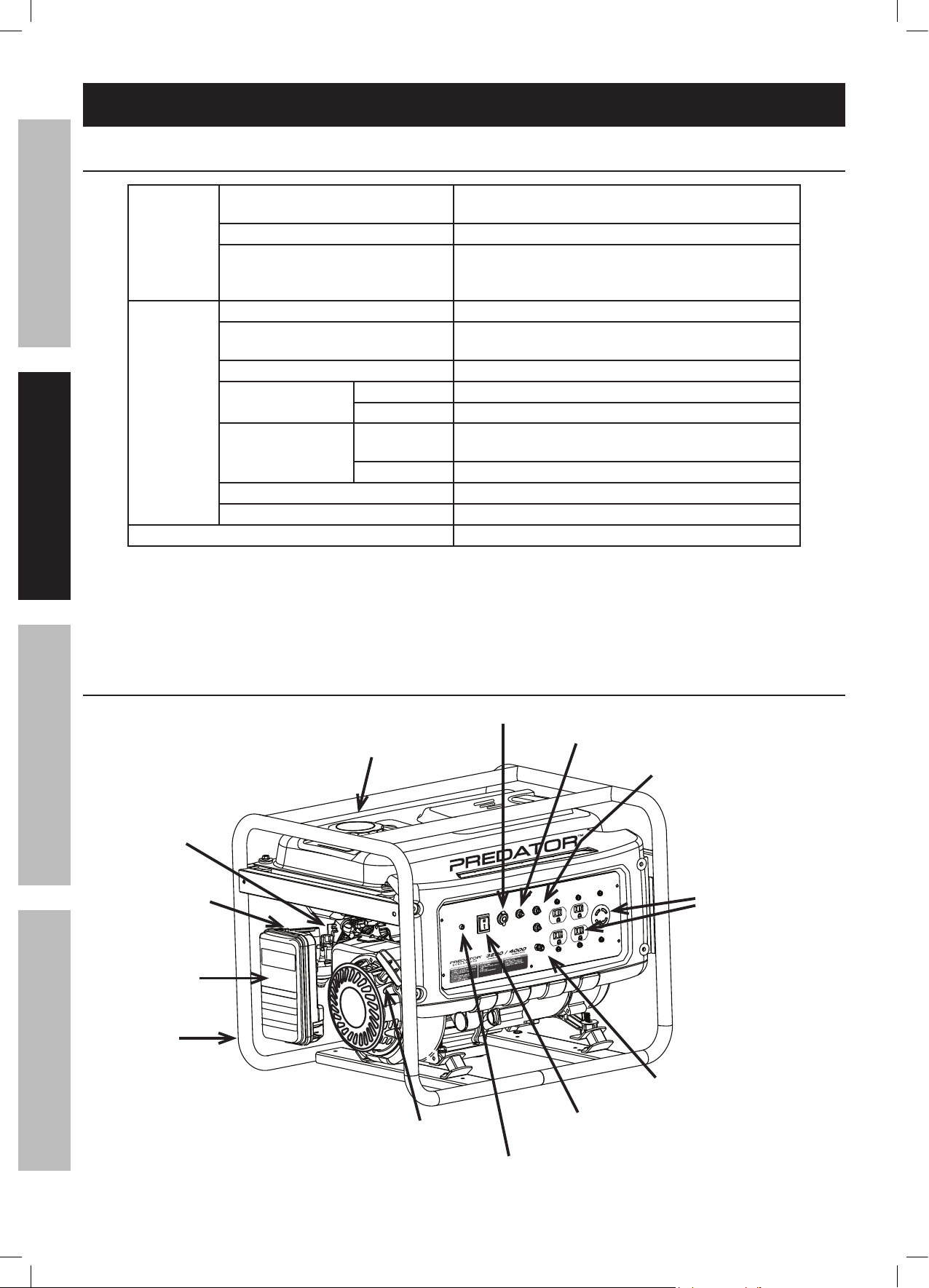

Functional Description

Specications

SAFETY OPERATION MAINTENANCESETUP

Rated Output

Generator

Engine

Item 69675 - The emission control system for this Generator’s Engine is warranted for standards set by the U.S.

Environmental Protection Agency and by the California Air Resources Board (also known as CARB). For warranty

information, refer to the last pages of this manual.

Item 69676 - The emission control system for this Generator’s Engine is warranted for standards set by the U.S.

Environmental Protection Agency. For warranty information, refer to the last pages of this manual.

Phase Single

Electrical Receptacle

Displacement 212cc

Engine Type

Cooling System Forced air cooled

Fuel

Engine Oil

Run Time @ 50% load 10 hr.

Operational Volume 72 dB

Available accessories Wheel kit (sold separately)

Type 87+ octane unleaded gasoline

Capacity 4 Gallons (15L)

Type SAE

Capacity .6 Quart (.6L)

120/240V~, 60Hz

3,200 Watts (4,000 max)

Two 3-Prong, duplex NEMA #5-20 120V

One 4-Prong, NEMA #L14-30 twistlock 120V/240V

One DC Outlet 12VDC

Horizontal Single Cylinder 4 stroke OHV

EPA phase III compliant

10W-30 above 32° F

5W-30 at 32° F or below

Components and Controls

Fuel Cap

Fuel Valve

Choke

Air Filter

Frame

DC Receptacle

DC Circuit Breaker

AC Circuit Breaker

AC Receptacles

Ground Terminal

Page 6

Starter

Handle

Low Oil Indicator

For Pump technical questions, please call 1-800-444-3353.

For Engine technical questions, please call 1-800-520-0882.

Power Switch

Item 69675 / 69676

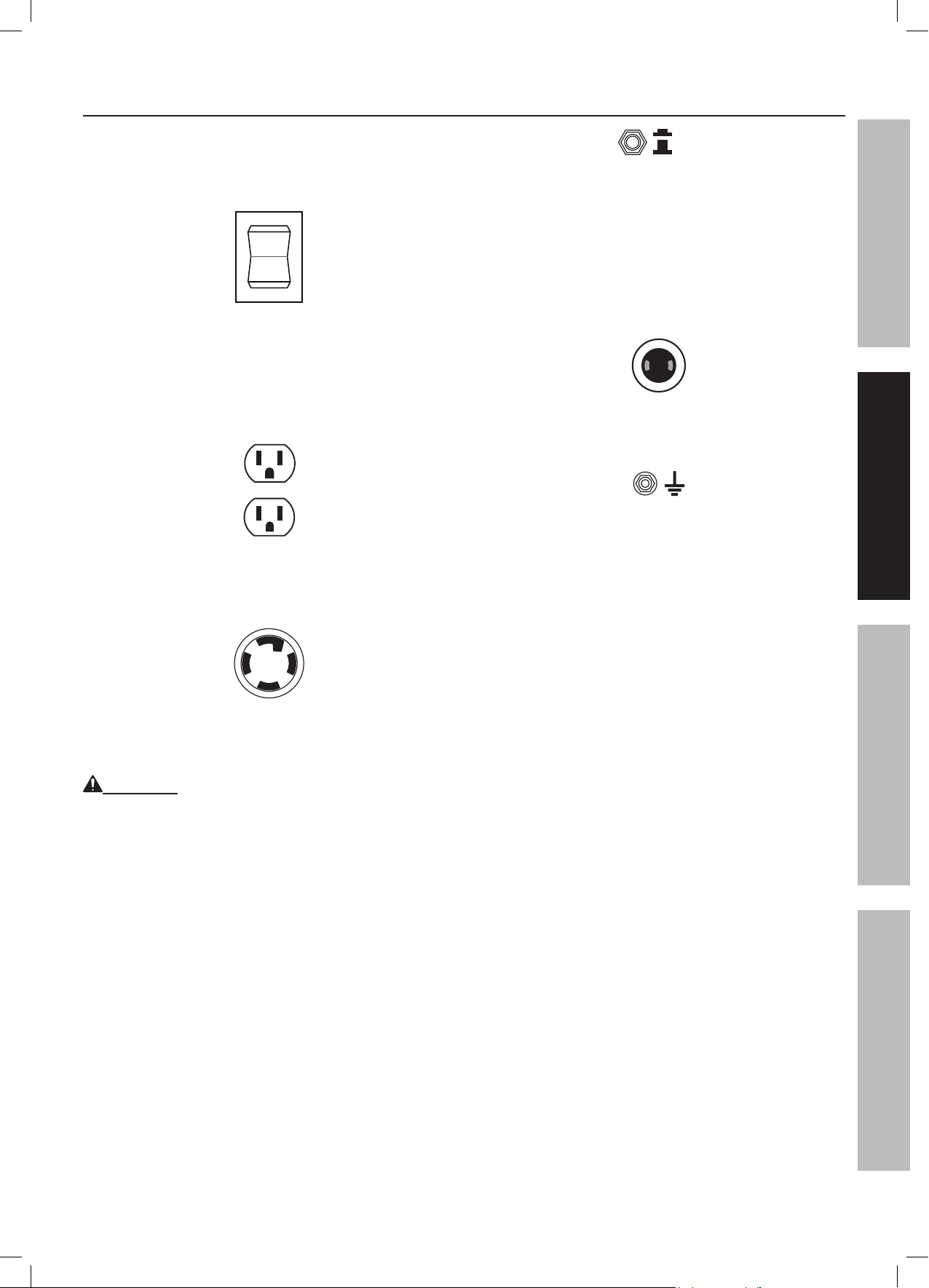

Components and Controls (cont.)

The following are descriptions of the controls

on the power panel. Your generator has

sockets to power your products with circuit

breakers to protect the voltage ow.

I

O

1.

Engine Switch: Used to enable/disable Generator

operation.

2. AC Receptacles: The Generator contains several

AC Receptacles to power tools and equipment.

a.

3-Prong, duplex

120 volt AC Receptacle

(NEMA #5-20)

ON

OFF

Circuit Breakers: The circuit breaker protects the

3.

Generator from overloading. The rating of the breaker

and the load it protects are marked near the breaker.

Should any of the Circuit Breakers trip, the Generator

will stop the electricity output. If this happens, unplug

all loads from the Generator. Allow the Generator to

cool down. Then, press the tripped Circuit Breaker,

restart the Engine, and re-attach loads.

DC Outlet Receptacle: 12 VDC outlet receptacle set

4.

provides a power source for 12 volt DC items.

5.

Grounding Terminal: Prior to each use, set

up the ground wire (not included) connection

to the Grounding Terminal to properly ground

the Generator. See Set up instructions

to properly ground the Generator.

SAFETYOPERATIONMAINTENANCE SETUP

4-Prong, twistlock

b.

120/240 volt AC Receptacle

(NEMA #L14-30)

WARNING! Connect tools and equipment

only to the AC Receptacle that is compatible with

the electrical characteristics and rated capacities

of the tools and equipment being used.

Item 69675 / 69676

For Pump technical questions, please call 1-800-444-3353.

For Engine technical questions, please call 1-800-520-0882.

Page 7

Initial Tool Set Up/Assembly

Read the ENTIRE IMPORTANT

SAFETY INFORMATION section at the

SAFETY OPERATION MAINTENANCESETUP

TO PREVENT SERIOUS INJURY:

Operate only with proper spark arrestor installed.

Operation of this equipment may create sparks that

can start res around dry vegetation.

A spark arrestor may be required.

The operator should contact local re

agencies for laws or regulations relating

to re prevention requirements.

Note: For additional information regarding the parts listed in the following pages,

refer to the Assembly Diagram near the end of this manual.

Note: Wheel Kit, item # 68531 (sold separately) can be used with this generator.

beginning of this manual including

all text under subheadings therein

before set up or use of this product.

At high altitudes, the engine’s carburetor, governor,

and any other parts that control the fuel-air ratio will

need to be adjusted by a qualied mechanic to allow

efcient high-altitude use and to prevent damage to the

engine and any other devices used with this product.

CAUTION: This generator is not intended to power

sensitive electronic equipment without the addition of an

appropriate line conditioner and surge protector (both not

included). Sensitive electronic equipment includes,

but is not limited to, audio/video equipment, some

television sets, computers, and printers. Sensitive

electronic equipment should be operated on approved

inverter type generators or pure sine wave generators.

Grounding

The Generator must be properly grounded before

use. Have the unit grounded by a qualied

electrician if you are not qualied to do so.

Operating Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this

manual including all text under subheadings therein before set up or use of this product.

Inspect tool before use, looking for damaged, loose, and missing parts.

If any problems are found, do not use tool until repaired.

Generator Pre-Start Checks

Inspect engine and equipment, looking for

damaged, loose, and missing parts before set

up and starting. If any problems are found,

do not use equipment until xed properly.

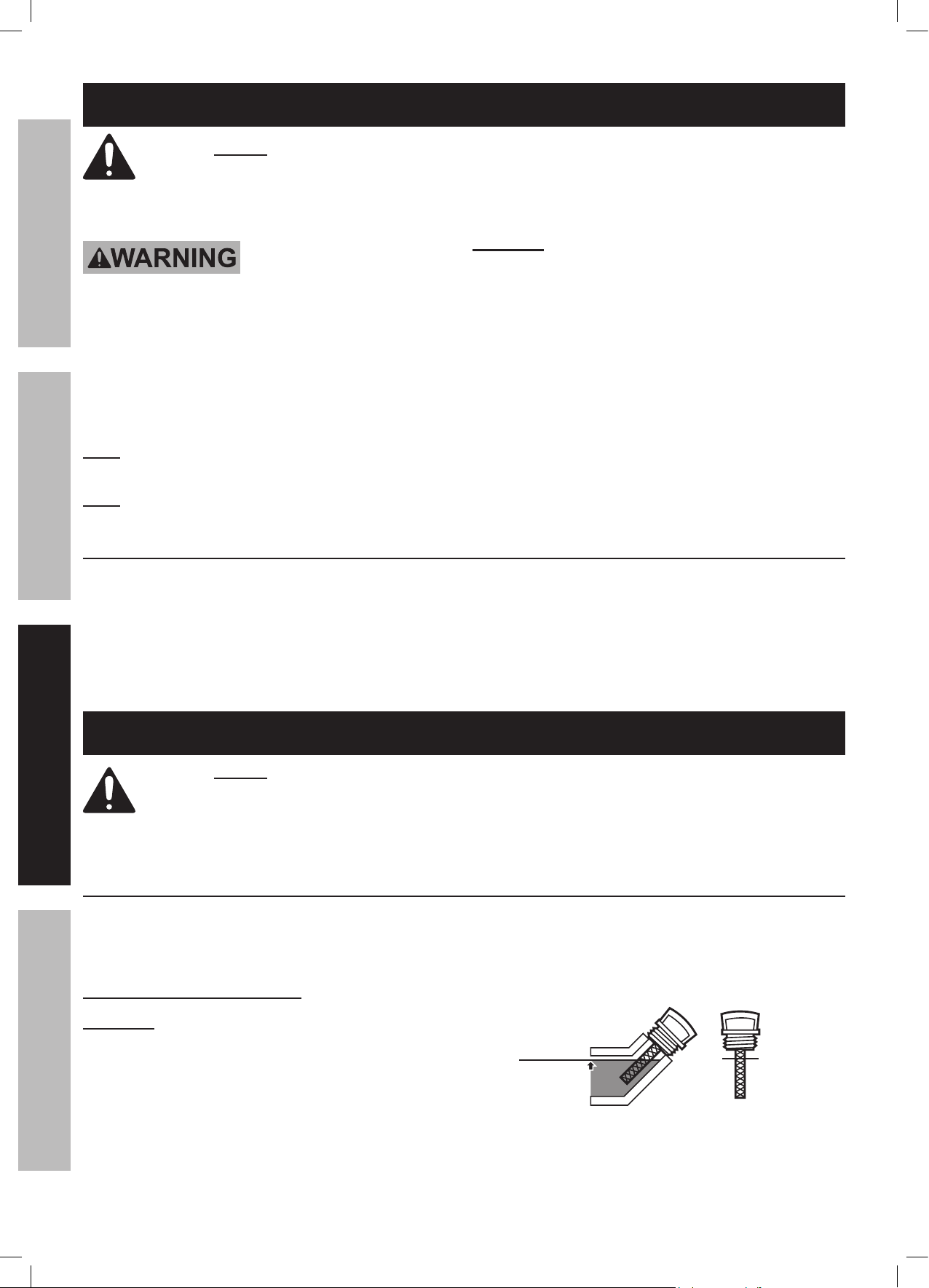

Checking and Filling Engine Oil

To ground the Generator, connect a #6 AWG

grounding wire (not included) from the Grounding

Terminal on the Control Panel to a grounding rod

(not included) that has been driven at least 24

inches deep into the earth. The grounding rod must

be an earth-driven copper or brass rod (electrode)

which can adequately ground the Generator.

2. Close the Fuel Valve.

3. Clean the top of the Dipstick and the area around it.

Remove the Dipstick by threading it counterclockwise,

and wipe it off with a clean lint free rag.

CAUTION! Your Warranty is VOID if the engine’s

crankcase is not properly lled with oil before each

use.

Before each use, check the oil level. Do not run the

engine with low or no engine oil.

Running the engine with no or low engine oil

WILL permanently damage the engine.

1. Make sure the engine is stopped and is level.

For Pump technical questions, please call 1-800-444-3353.

Page 8

For Engine technical questions, please call 1-800-520-0882.

Full level

4.

Reinsert the Dipstick without threading it in and

remove it to check the oil level. The oil level

should be up to the full level as shown above.

Item 69675 / 69676

Full level

Loading...

Loading...