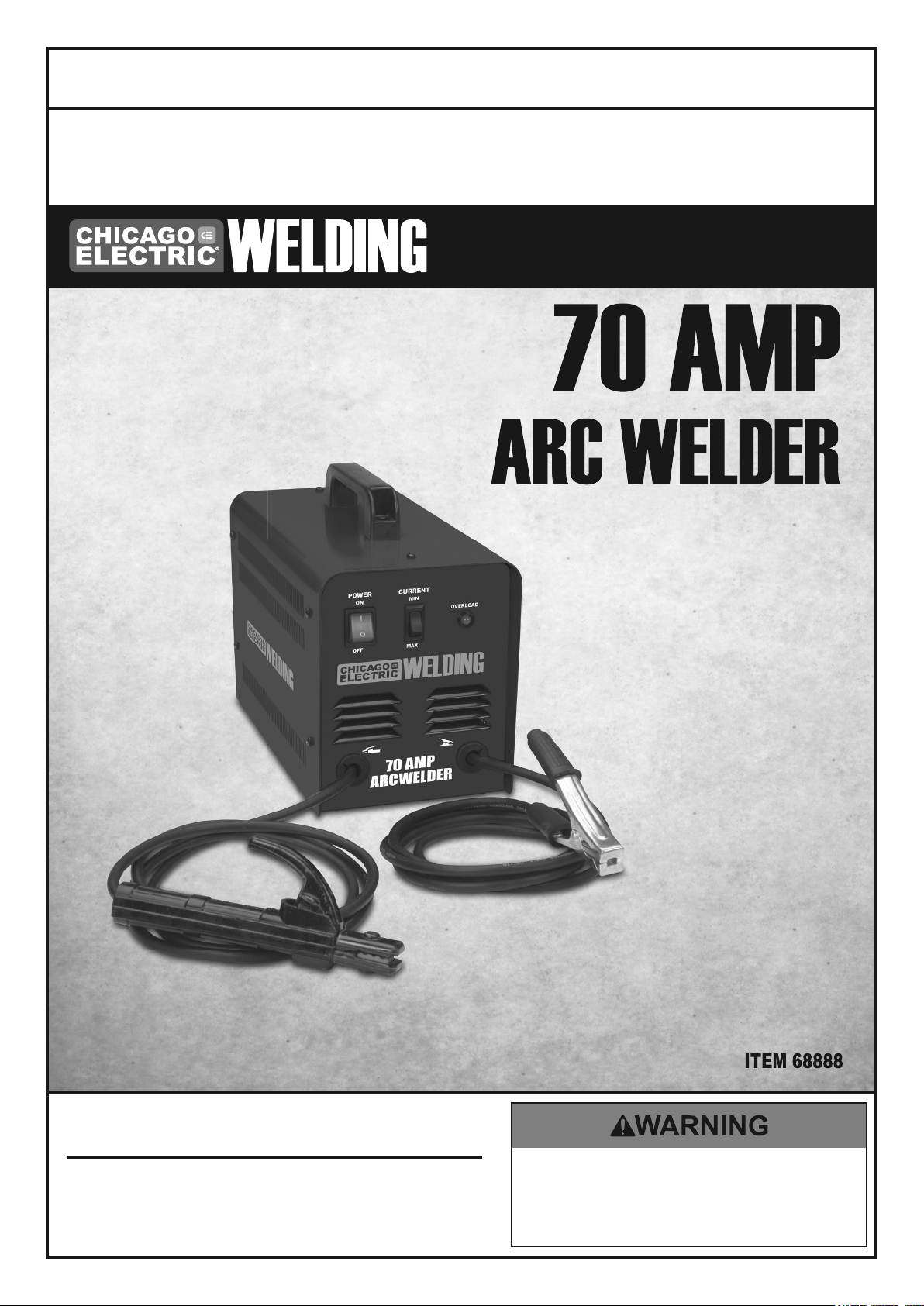

Harbor Freight Tools 68888 Product manual

Owner’s Manual & Safety Instructions

Owner’s Manual & Safety Instructions

Owner’s Manual & Safety Instructions

Owner’s Manual & Safety Instructions

Owner’s Manual & Safety Instructions

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference.

Keep this manual and the receipt in a safe and dry place for future reference.

Keep this manual and the receipt in a safe and dry place for future reference.

Keep this manual and the receipt in a safe and dry place for future reference.

Keep this manual and the receipt in a safe and dry place for future reference.

Keep this manual and the receipt in a safe and dry place for future reference.

REV 15d

Visit our website at: http://www.harborfreight.com

When unpacking, make sure that the product is intact

When unpacking, make sure that the product is intact

When unpacking, make sure that the product is intact

When unpacking, make sure that the product is intact

When unpacking, make sure that the product is intact

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

and undamaged. If any parts are missing or broken,

and undamaged. If any parts are missing or broken,

and undamaged. If any parts are missing or broken,

and undamaged. If any parts are missing or broken,

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

please call 1-888-866-5797 as soon as possible.

please call 1-888-866-5797 as soon as possible.

please call 1-888-866-5797 as soon as possible.

please call 1-888-866-5797 as soon as possible.

please call 1-888-866-5797 as soon as possible.

Copyright© 2011 by Harbor Freight Tools®. All rights reserved.

Copyright© 2011 by Harbor Freight Tools®. All rights reserved.

Copyright© 2011 by Harbor Freight Tools®. All rights reserved.

Copyright© 2011 by Harbor Freight Tools®. All rights reserved.

Copyright© 2011 by Harbor Freight Tools®. All rights reserved.

Copyright© 2011 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

No portion of this manual or any artwork contained herein may be reproduced in

No portion of this manual or any artwork contained herein may be reproduced in

No portion of this manual or any artwork contained herein may be reproduced in

No portion of this manual or any artwork contained herein may be reproduced in

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

any shape or form without the express written consent of Harbor Freight Tools.

any shape or form without the express written consent of Harbor Freight Tools.

any shape or form without the express written consent of Harbor Freight Tools.

any shape or form without the express written consent of Harbor Freight Tools.

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

Diagrams within this manual may not be drawn proportionally. Due to continuing

Diagrams within this manual may not be drawn proportionally. Due to continuing

Diagrams within this manual may not be drawn proportionally. Due to continuing

Diagrams within this manual may not be drawn proportionally. Due to continuing

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

improvements, actual product may differ slightly from the product described herein.

improvements, actual product may differ slightly from the product described herein.

improvements, actual product may differ slightly from the product described herein.

improvements, actual product may differ slightly from the product described herein.

improvements, actual product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

Tools required for assembly and service may not be included.

Tools required for assembly and service may not be included.

Tools required for assembly and service may not be included.

Tools required for assembly and service may not be included.

Tools required for assembly and service may not be included.

Email our technical support at: productsupport@harborfreight.com

Read this material before using this product.

Read this material before using this product.

Read this material before using this product.

Read this material before using this product.

Read this material before using this product.

Read this material before using this product.

Failure to do so can result in serious injury.

Failure to do so can result in serious injury.

Failure to do so can result in serious injury.

Failure to do so can result in serious injury.

Failure to do so can result in serious injury.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

SAVE THIS MANUAL.

SAVE THIS MANUAL.

SAVE THIS MANUAL.

SAVE THIS MANUAL.

SAVE THIS MANUAL.

Table of Contents

Safety ......................................................... 2

Setup .......................................................... 7

Specifications ............................................. 7

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

Basic Welding ............................................. 8

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

IMPORTANT SAFETY INFORMATION

Welding Tips ............................................... 9

Maintenance .............................................. 13

Parts List and Diagram .............................. 14

Warranty .................................................... 16

WARNING SYMBOLS AND DEFINITIONS

Obey all safety messages that follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

Read all safety warnings and instructions.

Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

General Safety

PROTECT yourself and others. Read and understand this information.

1. Before use, read and understand

manufacturer′s instructions,

Material Safety Data Sheets (MSDSs),

employer′s safety practices, and ANSI Z49.1.

2. Keep out of reach of children.

Keep children and bystanders away while operating.

3. Place the welder on a stable location before use.

If it falls while plugged in, severe injury,

electric shock, or fire may result.

4. Do not overreach.

Keep proper footing and balance at all times.

5. Stay alert, watch what you are doing and use

common sense when operating a welder.

Do not use a welder while you are tired or under

the influence of drugs, alcohol or medication.

A moment of inattention while operating welders

may result in serious personal injury.

6. Avoid unintentional starting. Make sure you are

prepared to begin work before turning on the Welder.

7. Never leave the Welder unattended while

energized. Turn power off if you have to leave.

8. The warnings, precautions, and instructions

discussed in this instruction manual cannot

cover all possible conditions and situations

that may occur. It must be understood by the

operator that common sense and caution are

factors which cannot be built into this product,

but must be supplied by the operator.

9. WARNING: This product, when used for welding,

plasma cutting, soldering, or similar applications,

produces chemicals known to the State of

California to cause cancer and birth defects

or other reproductive harm. (California Health

& Safety Code § 25249.5, et seq.)

10. WARNING: The cord of this product contains

lead and/or di (2-ethylhexyl) phthalate (DEHP),

chemicals known to the State of California

to cause cancer, and birth defects or other

reproductive harm. Wash hands after handling.

(California Health & Safety Code § 25249.5, et seq.)

11. WARNING: This product contains di (2-ethylhexyl)

phthalate (DEHP), a chemical known to the State

of California to cause cancer and birth defects

or other reproductive harm. (California Health

& Safety Code § 25249.5, et seq.)

Page 2 For technical questions, please call 1-888-866-5797. Item 68888

Fume and Gas Safety

FUMES AND GASES can be hazardous to your health.

1. Exposure to welding or cutting

exhaust fumes can increase the risk

of developing certain cancers, such as

cancer of the larynx and lung cancer.

Also, some diseases that may be linked to exposure

to welding or cutting exhaust fumes are:

• Early onset of Parkinson’s Disease

• Heart disease • Ulcers

• Damage to the reproductive organs

• Inflammation of the small intestine

or stomach • Kidney damage

• Respiratory diseases such as

emphysema, bronchitis, or pneumonia

2. Do not use near degreasing or

painting operations.

3. Keep head out of fumes.

Do not breathe exhaust fumes.

Arc Ray Safety

ARC RAYS can injure eyes and burn skin.

4. Use enough ventilation, exhaust at arc, or

both, to keep fumes and gases from breathing

zone and general area. If engineering controls

are not feasible, use an approved respirator.

5. Work in a confined area only if it

is well-ventilated, or while wearing

an air-supplied respirator.

6. Have a recognized specialist in

Industrial Hygiene or Environmental Services

check the operation and air quality

and make recommendations

for the specific welding situation.

Follow OSHA guidelines for

Permissible Exposure Limits (PEL’s) and

the American Conference of Governmental

Industrial Hygienists recommendations for

Threshold Limit Values (TLV’s) for fumes and gases.

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

1. Wear ANSI-approved welding eye protection

featuring at least a number 10 shade lens rating.

2. Wear leather leggings, fire resistant shoes

or boots during use. Do not wear pants with

cuffs, shirts with open pockets, or any clothing

that can catch and hold molten metal or sparks.

3. Keep clothing free of grease, oil,

solvents, or any flammable substances.

Wear dry, insulating gloves and protective clothing.

Electrical Safety

ELECTRIC SHOCK can KILL.

1. Turn off, disconnect power, and

discharge electrode to ground before setting

down torch/electrode holder and before service.

2. Do not touch energized electrical parts.

Wear dry, insulating gloves. Do not touch electrode

holder, electrode, welding torch, or welding wire with

bare hand. Do not wear wet or damaged gloves.

3. Connect to grounded, GFCI-protected

power supply only.

4. Wear an approved head covering to protect

the head and neck. Use aprons, cape, sleeves,

shoulder covers, and bibs designed and

approved for welding and cutting procedures.

5. When welding/cutting overhead or in confined

spaces, wear flame resistant ear plugs or

ear muffs to keep sparks out of ears.

6. Do not expose welders to rain or wet conditions.

Water entering a welder will increase

the risk of electric shock.

7. Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

welder. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

8. Do not use outdoors.

4. Do not use near water or damp objects.

5. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields

in close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.

9. Insulate yourself from the workpiece and ground.

Use nonflammable, dry insulating material if possible,

or use dry rubber mats, dry wood or plywood, or

other dry insulating material large enough to cover

your full area of contact with the work or ground.

Page 3For technical questions, please call 1-888-866-5797.Item 68888

Fire Safety

ARC AND HOT SLAG can cause fire.

1. Clear away or protect flammable objects.

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

Remove or make safe all combustible materials for a

radius of 35 feet (10 meters) around the work area.

Use a fire resistant material to cover or block all open

doorways, windows, cracks, and other openings.

2. Keep ABC-type fire extinguisher near

work area and know how to use it.

3. Maintain a safe working environment.

Keep the work area well lit.

Make sure there is adequate surrounding workspace.

Keep the work area free of obstructions,

grease, oil, trash, and other debris.

4. Do not operate welders in atmospheres

containing dangerously reactive or

flammable liquids, gases, vapors, or dust.

Provide adequate ventilation in work areas

to prevent accumulation of such substances.

Welders create sparks which may ignite flammable

substances or make reactive fumes toxic.

5. If working on a metal wall, ceiling, etc.,

prevent ignition of combustibles on the

other side by moving the combustibles to a

safe location. If relocation of combustibles is

not possible, designate someone to serve as

a fire watch, equipped with a fire extinguisher,

during the cutting process and for at least one

half hour after the cutting is completed.

6. Do not weld or cut on materials having

a combustible coating or combustible

internal structure, as in walls or ceilings, without

an approved method for eliminating the hazard.

7. Do not dispose of hot slag in containers

holding combustible materials.

8. After welding, make a thorough examination

for evidence of fire. Be aware that easily

visible smoke or flame may not be present

for some time after the fire has started.

9. Do not apply heat to a container that has held

an unknown substance or a combustible

material whose contents, when heated,

can produce flammable or explosive vapors.

Clean and purge containers before applying heat.

Vent closed containers, including castings,

before preheating, welding, or cutting.

Welder Use and Care

1. Do not use the welder if the switch does not turn

it on and off. Any welder that cannot be controlled

with the switch is dangerous and must be repaired.

2. Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing welders.

Such preventive safety measures reduce the

risk of starting the welder accidentally.

3. Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source or moving the welder. Carrying or energizing

welders that have the switch on invites accidents.

4. Store idle welders out of the reach of children and

do not allow persons unfamiliar with the welder or

these instructions to operate the welder. Welders

are dangerous in the hands of untrained users.

5. Use the welder and accessories in accordance

with these instructions, taking into account the

working conditions and the work to be performed.

Use of the welder for operations different from those

intended could result in a hazardous situation.

Page 4 For technical questions, please call 1-888-866-5797. Item 68888

Maintenance

1. Maintain welders. Check for misalignment or

binding of moving parts, breakage of parts

and any other condition that may affect the

welder’s operation. If damaged, have the

welder repaired before use. Many accidents

are caused by poorly maintained welders.

2. Have your welder serviced by a qualified

repair person using only identical

replacement parts. This will ensure that

the safety of the welder is maintained.

SAVE THESE INSTRUCTIONS.

3. Maintain labels and nameplates on the Welder.

These carry important information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

4. Unplug before maintenance. Unplug the Welder

from its electrical outlet before any inspection,

maintenance, or cleaning procedures.

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

Page 5For technical questions, please call 1-888-866-5797.Item 68888

Loading...

Loading...